Kiln-Furnace System: Validation of a Technology for Producing Charcoal with Less Environmental Impact in Brazil

Abstract

1. Introduction

2. Background of the Previous Studies

3. Materials and Methods

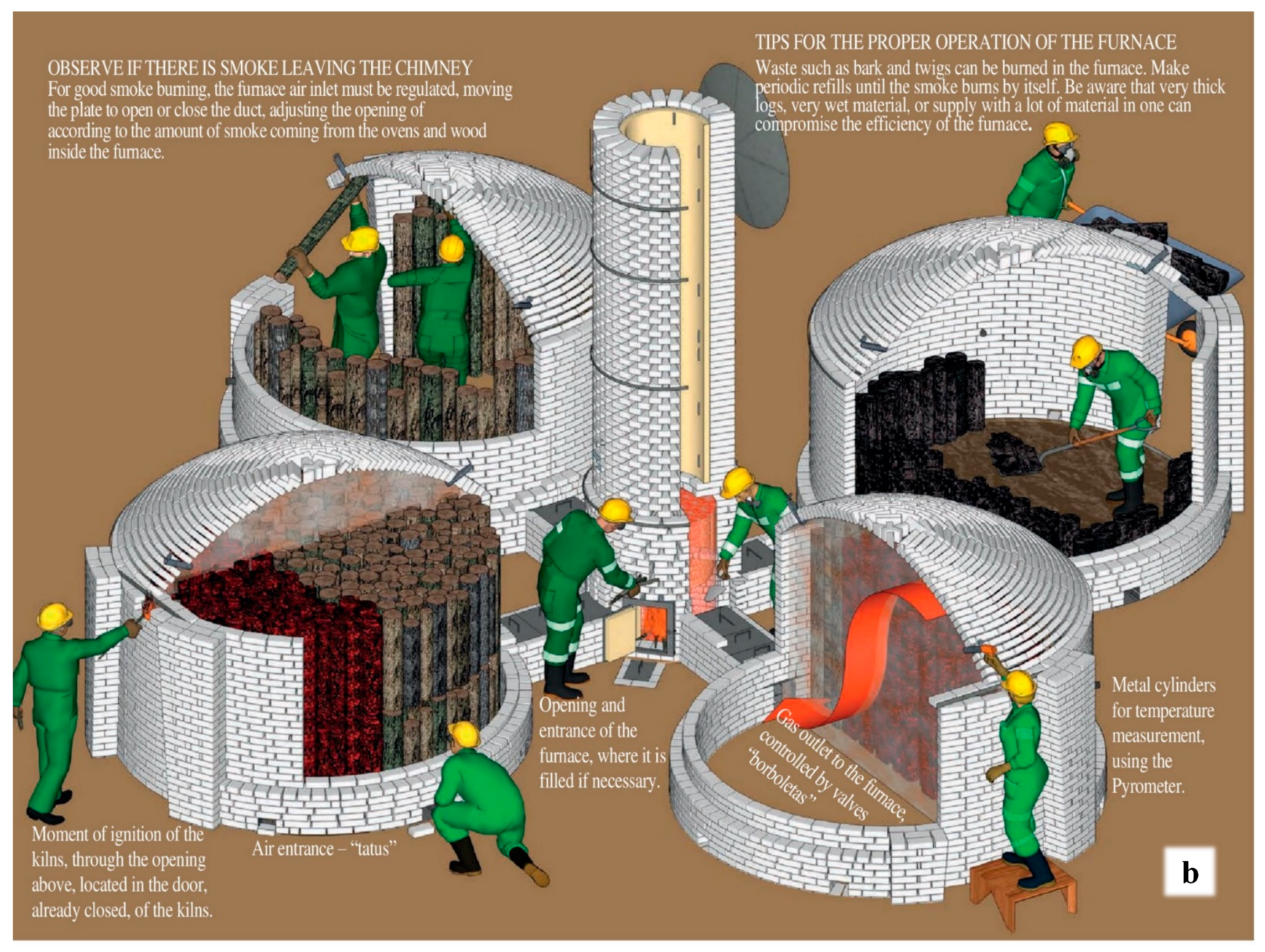

3.1. Study Area, Description of the Kiln-Furnace System, and Wood Carbonization Process

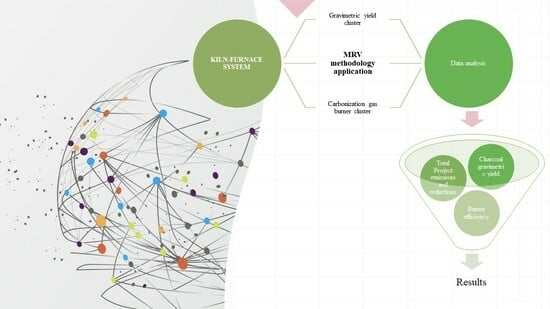

3.2. Application of the MRV Methodology for the Assessment of the Kiln-Furnace System

3.3. MRV Cluster—Gravimetric Yield of Charcoal

3.4. MRV Cluster—Carbonization Gas Burners

4. Results

4.1. Characterization of the Wood and Charcoal Obtained from Carbonization

4.2. MRV Cluster—Gravimetric Yield of Charcoal—Reviews

4.3. MRV Cluster—Gas Burning System

5. Discussion

Limitations, Prospects, and Political Implications of This Study

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Relatório especial do Painel Intergovernamental sobre Mudanças Climáticas. Brasil, 2019. 28p. 2020. Available online: https://www.ipcc.ch/site/assets/uploads/2019/07/SPM-Portuguese-version.pdf (accessed on 12 October 2020).

- Flores-Granobles, M.; Saeys, M. Minimizing CO2 emissions with renewable energy: A comparative study of emerging technologies in the steel industry. Energy Environ. Sci. 2020, 13, 1923–1932. [Google Scholar] [CrossRef]

- Carvalho, P.S.L.; Mesquita, P.P.D.; Araújo, E.D.G. Sustentabilidade da Siderurgia Brasileira: Eficiência Energética, Emissões e Competitividade; BNDES Setorial: Rio de Janeiro, Brazil, 2015; 56p. [Google Scholar]

- EPE. Empresa de Pesquisa Energética. Balanço Energético Nacional 2020: Ano Base 2019. Rio de Janeiro. 2020; 264p. Available online: https://www.epe.gov.br (accessed on 12 October 2020).

- SINDIFER. Sindicato Da Indústria Do Ferro Gusa No Estado De Minas Gerais. 2020. In Anuário Estatístico 2020; SINDIFER: Belo Horizonte, Brazil, 2020; 50p. [Google Scholar]

- IBA. Instituto Brasileiro de Árvores. Relatório Anual 2020: Ano base 2019. São Paulo. 2020. 66p. Available online: https://iba.org/datafiles/publicacoes/relatorios/relatorio-iba-2020.pdf (accessed on 12 October 2020).

- Pereira, E.G.; Martins, M.A.; Pecenka, R.; Angélica de Cássia, O.C. Pyrolysis gases burners: Sustainability for integrated production of charcoal, heat and electricity. Renew. Sustain. Energy Rev. 2017, 75, 592–600. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Umeki, K.; Mousa, E.; Hedayati, A.; Romar, H.; Kemppainen, A.; Wang, C.; Phounglamcheik, A.; Tuomikoski, S.; Norberg, N.; et al. Use of biomass in integrated steelmaking–Status quo, future needs and comparison to other low-CO2 steel production technologies. Appl. Energy 2018, 213, 384–407. [Google Scholar] [CrossRef]

- FAO. Food and Agriculture Organization of the United Nations, FAO. The Charcoal Transition—Greening the Charcoal Value Chain to Mitigate Climate Change and Improve Local Livelihoods. Rome, 184p. 2017. Available online: http://www.fao.org/publications/card/en/c/a19084da-53ca-4ec8-a0dc-0200d8390d65 (accessed on 12 October 2020).

- Mousa, E.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass applications in iron and steel industry: An overview of challenges and opportunities. Renew. Sustain. Energy Rev. 2016, 65, 1247–1266. [Google Scholar] [CrossRef]

- Rodrigues, T.; Junior, A.B. Charcoal: A discussion on carbonization kilns. J. Anal. Appl. Pyrolysis 2019, 143, 104670. [Google Scholar] [CrossRef]

- Rodrigues, T.; Junior, A.B. Technological prospecting in the production of charcoal: A patent study. Renew. Sustain. Energy Rev. 2019, 111, 170–183. [Google Scholar] [CrossRef]

- PNUD. Programa Das Nações Unidas Brasil. Projeto Siderurgia Sustentável. Available online: https://www.br.undp.org/content/brazil/pt/home/projects/SiderurgiaSustentvel.html (accessed on 12 October 2020).

- Mitchell, A.L.; Rosenqvist, A.; Mora, B. Current remote sensing approaches to monitoring forest degradation in support of countries measurement, reporting and verification (MRV) systems for REDD+. Carbon Balance Manag. 2017, 12, 9. [Google Scholar] [CrossRef]

- Mucci, M. Measurement, Reporting and Verification: A Note on the Concept with an Annotated Bibliography; The International Institute for Sustainable Development: Winnipeg, MB, Canada, 2012; 19p. [Google Scholar]

- FGVCES. Requerimentos para um Sistema Nacional de Monitoramento, Relato e Verificação de Emissões de Gases de Efeito Estufa; Centro de Estudos em Sustentabilidade da Escola de Administração de Empresas de São Paulo da Fundação Getulio Vargas: São Paulo, Brazil, 2013; 304p. [Google Scholar]

- Amellina, A. Enhancing the Joint Crediting Mechanism MRV to Contribute to Sustainable Development. In Evaluating Climate Change Action for Sustainable Development; Springer: Cham, Switzerland, 2017; pp. 111–127. [Google Scholar]

- Goes, G.V.; Gonçalves, D.N.S.; Márcio de Almeida, D.A.; La Rovere, E.L.; de Mello Bandeira, R.A. MRV framework and prospective scenarios to monitor and ratchet up Brazilian transport mitigation targets. Clim. Change 2020, 162, 2197–2217. [Google Scholar] [CrossRef]

- Zahar, A.; Zhang, H. Monitoring, reporting, and verification of greenhouse gas emissions in China: A legal analysis. In Climate Change Law in China in Global Context; Routledge: London, UK, 2020; pp. 118–148. [Google Scholar]

- García-Quezada, J.; Musule-Lagunes, R.; Wehenkel, C.; Prieto-Ruíz, J.A.; Núñez-Retana, V.; Carrillo-Parra, A. Effect of Firewood Moisture Content on Quality, Yield, and Economic Gain during Charcoal Production in a Modified Half-Orange Kiln. Fuels 2023, 5, 1–16. [Google Scholar] [CrossRef]

- Okeke, C.E.; Egarievwe, S.U.; Animalu, A.O.E. Effects of coal and charcoal on solar-still performance. Energy 1990, 15, 1071–1073. [Google Scholar] [CrossRef]

- Nyarko, I.; Nwaogu, C.; Miroslav, H.; Peseu, P.O. Socio-economic analysis of wood charcoal production as a significant output of forest bioeconomy in Africa. Forests 2021, 12, 568. [Google Scholar] [CrossRef]

- Brasil. Ministério do Meio Ambiente. Produção Sustentável de Carvão Vegetal: Manual de Construção de Sistema Fornos-Fornalha/Ministério do Meio Ambiente… [et al.]; MMA: Brasília, Brazil, 2019; 60p. [Google Scholar]

- Brasil. Ministério do Meio Ambiente. Produção Sustentável de Carvão Vegetal: Manual de Operação de Sistema Fornos-Fornalha/Ministério do Meio Ambiente… [et al.]; MMA: Brasília, Brazil, 2019; 64p. [Google Scholar]

- Rocha, M.T. Produto 3: Metodologia de Mensuração, Relato e Verificação (MRV) Para o Setor de Ferro Gusa, aço e Ferro Ligas; PNUD: Minas Gerais, Brazil, 2018; 63p. [Google Scholar]

- Mendes, M. Aplicação da Metodologia MRV para Quantificação das Emissões do Sistema Forno-Fornalha no Contexto do Projeto Siderurgia Sustentável; Trabalho de conclusão de curso (Engenharia Florestal); Universidade Federal de Viçosa: Viçosa, Brazil, 2018; 57p. [Google Scholar]

- ACM0021. ACM0021: Reduction of Emissions from Charcoal Production by Improved Kiln Design and/or Abatement of Methane—Version 1.0.0. Available online: https://cdm.unfccc.int/methodologies/DB/AA1T5PNLA4SMCJA2OQK9XRTC08BA6J (accessed on 12 December 2020).

- AM0041. AM0041: Mitigation of Methane Emissions in the Wood Carbonization Activity for Charcoal Production—Version 1.0. Available online: https://cdm.unfccc.int/methodologies/DB/B2SCH5WZLQYHTVSHQ4BIADMCBQ1P9U (accessed on 12 December 2020).

- ACM0001. ACM0001: Flaring or Use of Landfill Gas—Version 19.0. Available online: https://cdm.unfccc.int/methodologies/DB/JPYB4DYQUXQPZLBDVPHA87479EMY9M (accessed on 12 December 2020).

- CDM. CDM Methodologies Booklet—Twelfth edition—Information up to EB 108—December 2020. Available online: https://cdm.unfccc.int/methodologies/documentation/index.html (accessed on 12 December 2020).

- Ribeiro, G.B.D.D.; Carneiro, A.D.C.O.; Lana, A.Q.; Valverde, S.R. Economic viability of four charcoal productive systems from Minas Gerais state. Rev. Árvore 2020, 44, e440101. [Google Scholar] [CrossRef]

- Andrade, F.W.C.; Tomazello Filho, M.; Moutinho, V.H.P. Influence of Wood Physical Properties on Charcoal from Eucalyptus spp. Floresta Ambiente 2018, 25, e20150176. [Google Scholar] [CrossRef]

- Silva, F.T.M.; Ataíde, C.H. Valorization of Eucalyptus urograndis wood via carbonization: Product yields and characterization. Energy 2019, 172, 509–516. [Google Scholar] [CrossRef]

- Canal, W.D.; Carvalho, A.M.M.; Figueiró, C.G.; Carneiro, A.C.O.; Fialho, L.F.; Donato, D.B. Impacto f wood moisture in charcoal production na quality. Floresta e Ambiente 2020, 27, e20170999. [Google Scholar] [CrossRef]

- COPAM—Conselho Estadual de Política Ambiental—MG. Deliberação Normativa COPAM n° 227, de 29 de Agosto de 2018. Available online: http://www.meioambiente.mg.gov.br/images/stories/2019/REGULARIZACAO/TRs/Termo_de_Refer%C3%AAncia_para_cumprimento_da_DN_COPAM_N_227_2018_quanto_%C3%A0_performance_da_produ%C3%A7%C3%A3o_de_carv%C3%A3o_vegetal_proveniente_de_floresta_plantada.docx (accessed on 25 May 2021).

- Weber, K.; Heuer, S.; Quicker, P.; Li, T.; Løvås, T.; Scherer, V. An alternative approach for the estimation of biochar yields. Energy Fuels 2018, 32, 9506–9512. [Google Scholar] [CrossRef]

- de Jesus, M.S.; Carneiro, A.D.C.O.; Martinez, C.L.M.; Vital, B.R.; Carneiro, A.P.S.; de Assis, M.R. Thermal decomposition fundamentals in large-diameter wooden logs during slow pyrolysis. Wood Sci. Technol. 2019, 53, 1353–1372. [Google Scholar] [CrossRef]

- Damasio, R.A.P.; Oliveira, A.C.; Carneiro, A.C.O.; Barcelos, D.C.; Pereira, B.L.C.; Magalhães, M.A.; Silva, C.M.S. Perfil térmico e controle da carbonização em forno circular por meio da temperatura interna. Ciência Da Madeira Braz. J. Wood Sci. 2015, 6, 11–22. [Google Scholar] [CrossRef]

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Wei, S.; Zhu, M.; Fan, X.; Song, J.; Li, K.; Jia, W.; Song, H. Influence of pyrolysis temperature and feedstock on carbon fractions of biochar produced from pyrolysis of rice straw, pine wood, pig manure and sewage sludge. Chemosphere 2019, 218, 624–631. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.J.; Colin, B.; Chen, W.H.; Pétrissans, A.; Rousset, P.; Pétrissans, M. Thermal degradation and compositional changes of wood treated in a semi-industrial scale reactor in vacuum. J. Anal. Appl. Pyrolysis 2018, 130, 8–18. [Google Scholar] [CrossRef]

- Souza, N.D.D.; Amodei, J.B.; Xavier, C.N.; Dias Júnior, A.F.; Carvalho, A.M.D. Estudo de caso de uma planta de carbonização: Avaliação de características e qualidade do carvão vegetal visando uso siderúrgico. Floresta Ambiente 2016, 23, 270–277. [Google Scholar] [CrossRef]

- Miranda Santos, S.D.F.D.O.; Piekarski, C.M.; Ugaya, C.M.L.; Donato, D.B.; Braghini Júnior, A.; De Francisco, A.C.; Carvalho, A.M.M.L. Life cycle analysis of charcoal production in masonry kilns with and without carbonization process generated gas combustion. Sustainability 2017, 9, 1558. [Google Scholar] [CrossRef]

- Amaral, K.G.C.D.; Aisse, M.M.; Possetti, G.R.C. Sustainability assessment of sludge and biogas management in wastewater treatment plants using the LCA technique. Rev. Ambiente Água 2019, 14, e2371. [Google Scholar] [CrossRef]

- Cândido, N.R.; Prauchner, M.J.; de Oliveira Vilela, A.; Pasa, V.M. The use of gases generated from eucalyptus carbonization as activating agent to produce activated carbon: An integrated process. J. Environ. Chem. Eng. 2020, 8, 103925. [Google Scholar] [CrossRef]

- Aganyira, K.; Kabumbuli, R.; Muwanika, V.B.; Nampanzira, D.; Tabuti, J.R.S.; Sheil, D. Learning from failure: Lessons from a forest based carbon and charcoal project. Int. For. Rev. 2019, 21, 1–10. [Google Scholar] [CrossRef]

- Fernández, L.; Ventura, A.C.; Andrade, J.C.; Lumbreras, J.; Cobo-Benita, J.R. The effect of clean development mechanism projects on human resource management practices in Brazil. Int. J. Oper. Prod. Manag. 2017, 37, 1348–1365. [Google Scholar] [CrossRef]

- Lazaro, L.L.B.; Gremaud, A.P. Contribuição para o desenvolvimento sustentável dos projetos de mecanismo de desenvolvimento limpo na América Latina. Organ. Soc. 2017, 24, 53–72. [Google Scholar] [CrossRef][Green Version]

- Fernandes, E.A.; Leite, G.B. Atuação dos projetos de mecanismo de desenvolvimento limpo para o desenvolvimento sustentável no Brasil. Braz. J. Political Econ. 2021, 41, 351–371. [Google Scholar] [CrossRef]

- MMA. Ministério do Meio Ambiente—MMA. Protocolo de Quioto. Available online: https://www.mma.gov.br/ (accessed on 6 October 2020).

- de Souza, J.F.T.; Pacca, S.A. Carbon reduction potential and costs through circular bioeconomy in the Brazilian steel industry. Resour. Conserv. Recycl. 2021, 169, 105517. [Google Scholar] [CrossRef]

- Olugbire, O.O.; Aremu, F.J. Socio-economic characteristics of charcoal marketers in bodija market of Ibadan, Oyo state, Nigeria. Elixir Int. Mark. Manag. 2014, 76, 28422–28425. [Google Scholar]

- Bailis, R.; Rujanavech, C.; Dwivedi, P.; de Oliveira Vilela, A.; Chang, H.; de Miranda, R.C. Innovation in charcoal production: A comparative life-cycle assessment of two kiln technologies in Brazil. Energy Sustain. Dev. 2013, 17, 189–200. [Google Scholar] [CrossRef]

| Carbonization | Wood | Charcoal | Gravimetric Yield Yp,i (%) | Wood Moisture b. s. (%) | Log Diameter (cm) | ||

|---|---|---|---|---|---|---|---|

| Wet Mass (t) | Dry Mass (t) | Wet Mass (t) | Dry Mass (t) | ||||

| 1 | 6.357 | 4.846 | 1.737 | 1.644 | 33.92 | 31.17 | 16.5 |

| 2 | 6.311 | 3.863 | 1.033 | 0.972 | 25.17 | 63.37 | 9.51 |

| 3 | 6.457 | 3.911 | 0.863 | 0.719 | 18.38 | 65.09 | 9.91 |

| Average | 19.125 | 12.621 | 3.633 | 3.335 | - | - | - |

| Parameters | Unit | Project (Kiln Furnace System) |

|---|---|---|

| Sum of Coal Production of All PCUs (Pcharcoal,y) | t | 3.335 |

| Gravimetric Yield (Yp) | % | 18.38 |

| Emission Factor | tCH4/t Charcoal | 0.1188 |

| Total Emission | t CO2e | 8.323 |

| Total Emission Reduction | t CO2e | −2.855 |

| Emissions per Tonne | t CO2e/t Charcoal | 2.495 |

| Emissions Reduction | t CO2e/t Charcoal | −0.855 |

| Parameters | Unit | Project (Kiln-Furnace System) | |

|---|---|---|---|

| Sum of Coal Production of All PCUs | (Pcharcoal,y) | t | 3.338 |

| Gravimetric yield | (YP) | % | 18.38 |

| Emission Factor | tCH4/t Charcoal | 0.1188 | |

| gas burning Efficiency | % | 50.00 | |

| Methane Undestroyed | % | 50.00 | |

| Total Emission | t CO2e | 4.162 | |

| Total Emission Reduction | t CO2e | 1.307 | |

| Emissions per Ton | t CO2e/t Charcoal | 1.247 | |

| Emissions Reduction | t CO2e/t Charcoal | 0.392 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Da Silva, L.F.; Arantes, M.D.C.; Marcelino, R.A.G.; Mendes Castro, A.F.N.; Ataíde, G.D.M.; Castro, R.V.O.; Vieira, R.d.S.; Carneiro, A.d.C.O.; De Siqueira, H.F.; Protásio, T.D.P.; et al. Kiln-Furnace System: Validation of a Technology for Producing Charcoal with Less Environmental Impact in Brazil. Forests 2024, 15, 645. https://doi.org/10.3390/f15040645

Da Silva LF, Arantes MDC, Marcelino RAG, Mendes Castro AFN, Ataíde GDM, Castro RVO, Vieira RdS, Carneiro AdCO, De Siqueira HF, Protásio TDP, et al. Kiln-Furnace System: Validation of a Technology for Producing Charcoal with Less Environmental Impact in Brazil. Forests. 2024; 15(4):645. https://doi.org/10.3390/f15040645

Chicago/Turabian StyleDa Silva, Lívia Ferreira, Marina Donária Chaves Arantes, Reginaldo Arthur Glória Marcelino, Ana Flávia Neves Mendes Castro, Glauciana Da Mata Ataíde, Renato Vinícius Oliveira Castro, Renato da Silva Vieira, Angélica de Cássia Oliveira Carneiro, Humberto Fauller De Siqueira, Thiago De Paula Protásio, and et al. 2024. "Kiln-Furnace System: Validation of a Technology for Producing Charcoal with Less Environmental Impact in Brazil" Forests 15, no. 4: 645. https://doi.org/10.3390/f15040645

APA StyleDa Silva, L. F., Arantes, M. D. C., Marcelino, R. A. G., Mendes Castro, A. F. N., Ataíde, G. D. M., Castro, R. V. O., Vieira, R. d. S., Carneiro, A. d. C. O., De Siqueira, H. F., Protásio, T. D. P., Baraúna, E. E. P., Baldin, T., & Colen, F. (2024). Kiln-Furnace System: Validation of a Technology for Producing Charcoal with Less Environmental Impact in Brazil. Forests, 15(4), 645. https://doi.org/10.3390/f15040645