Forestry Ergonomics Publications in the Last Decade: A Review

Abstract

1. Introduction

2. Materials and Methods

3. Results

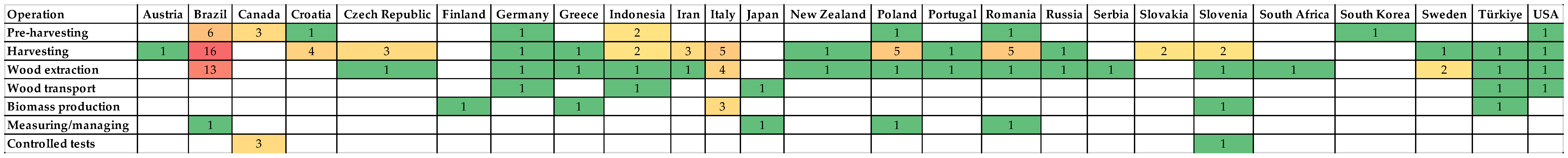

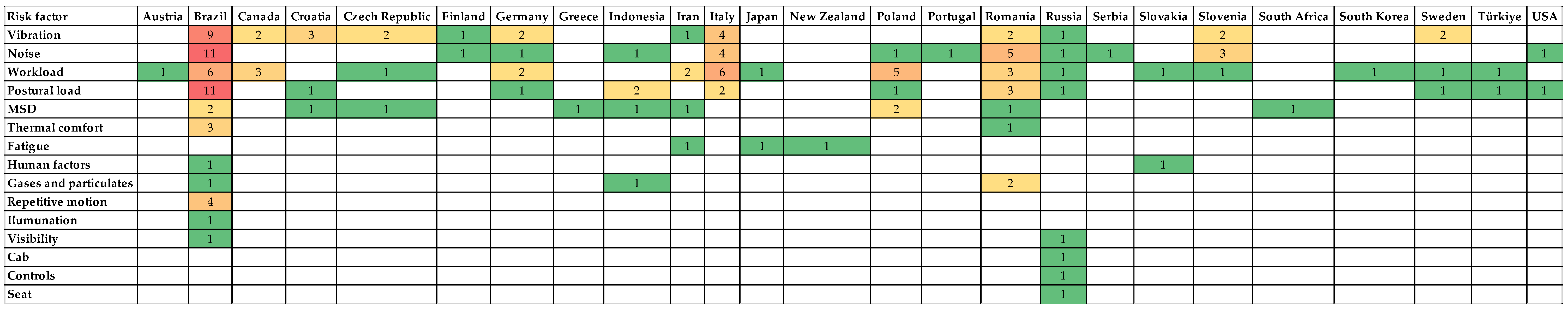

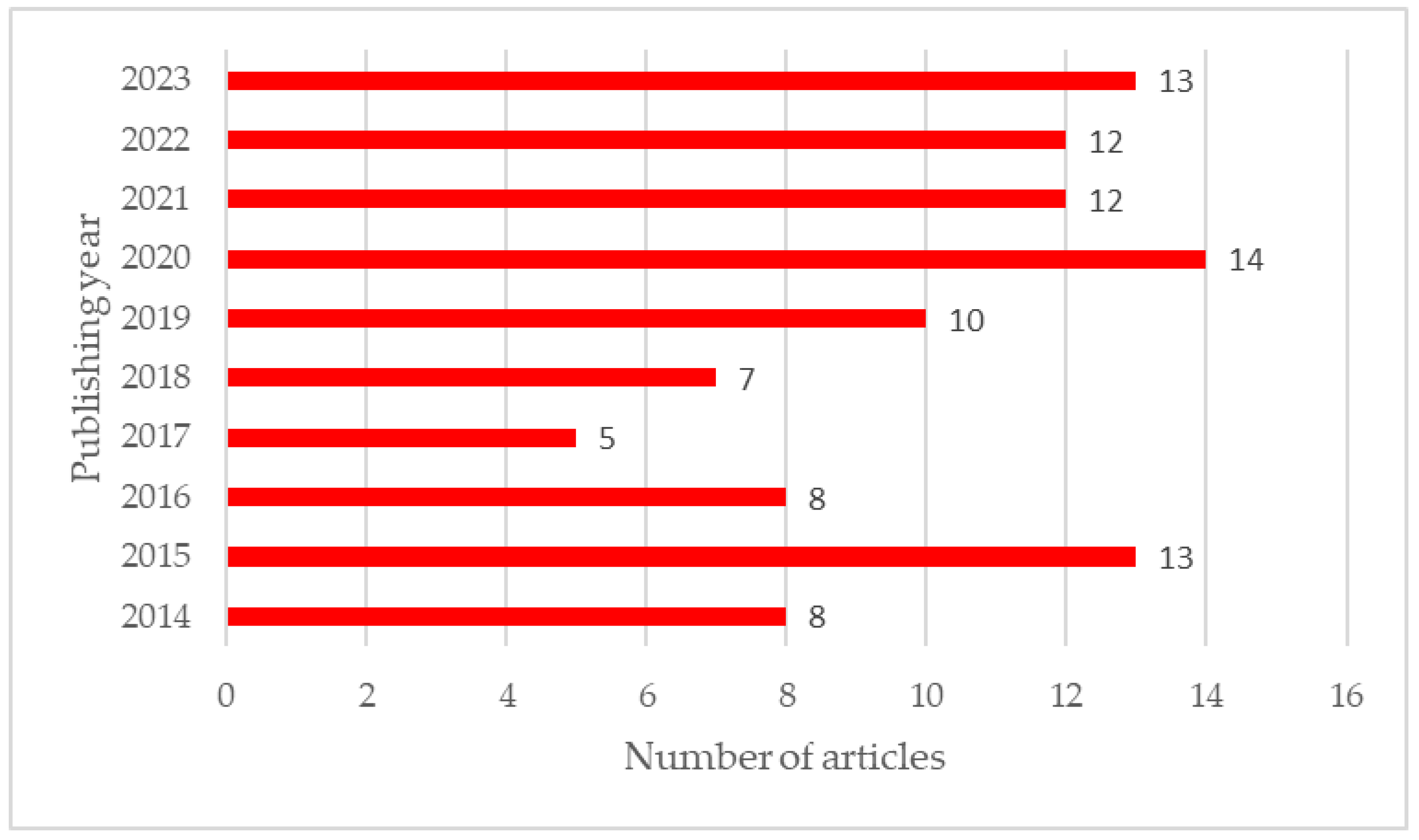

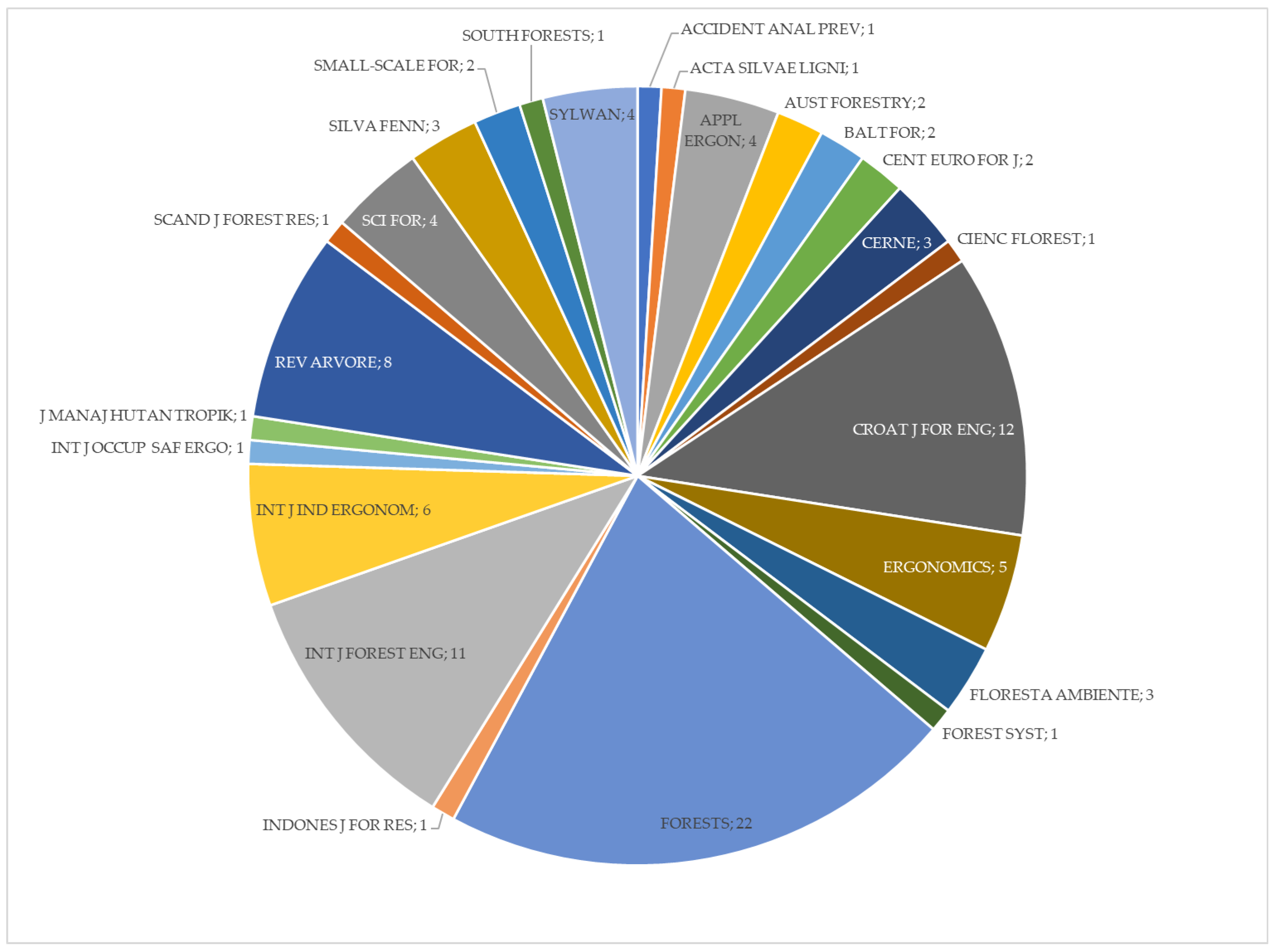

3.1. Publishing Year, Country, Journal, and Field Overview

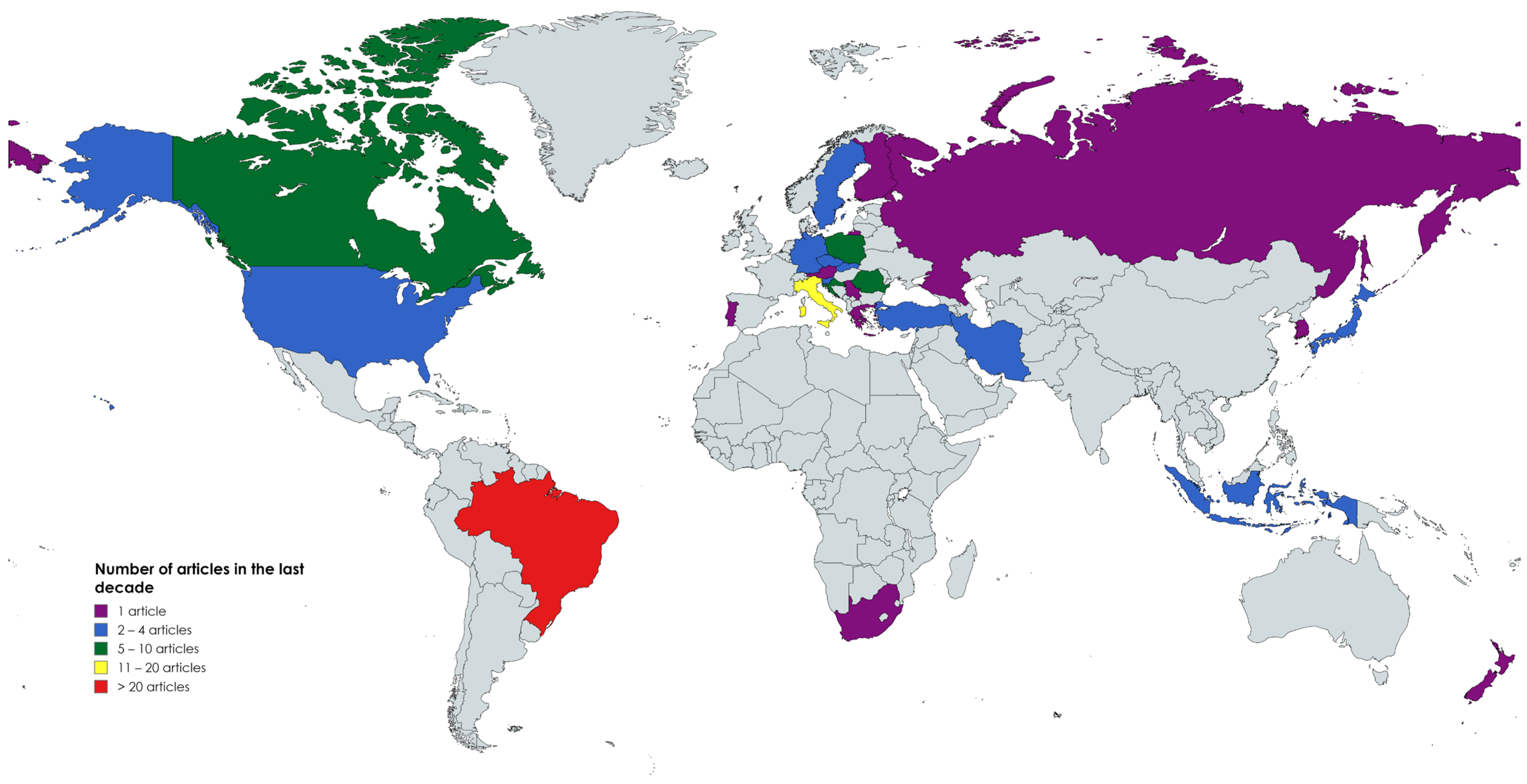

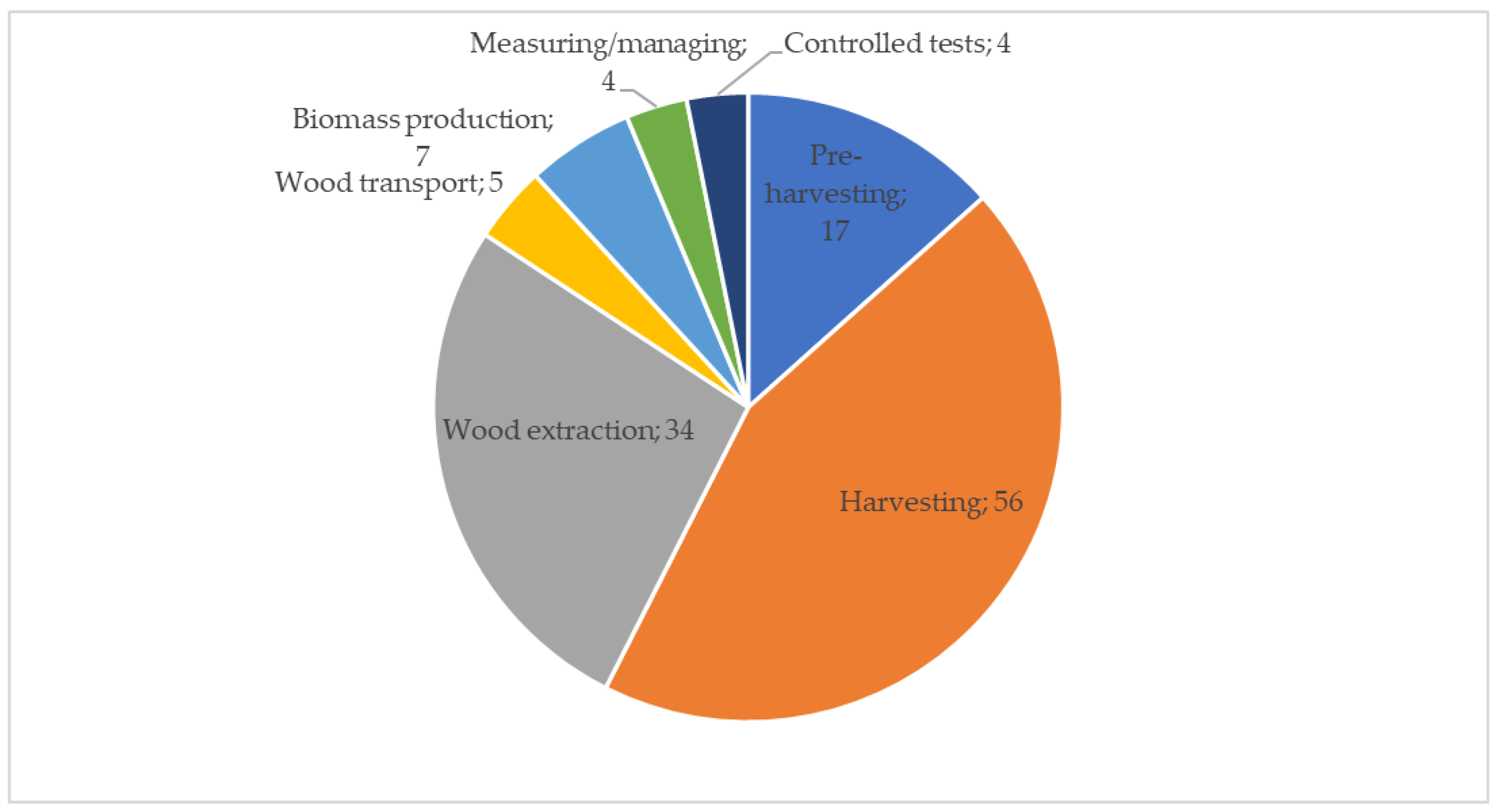

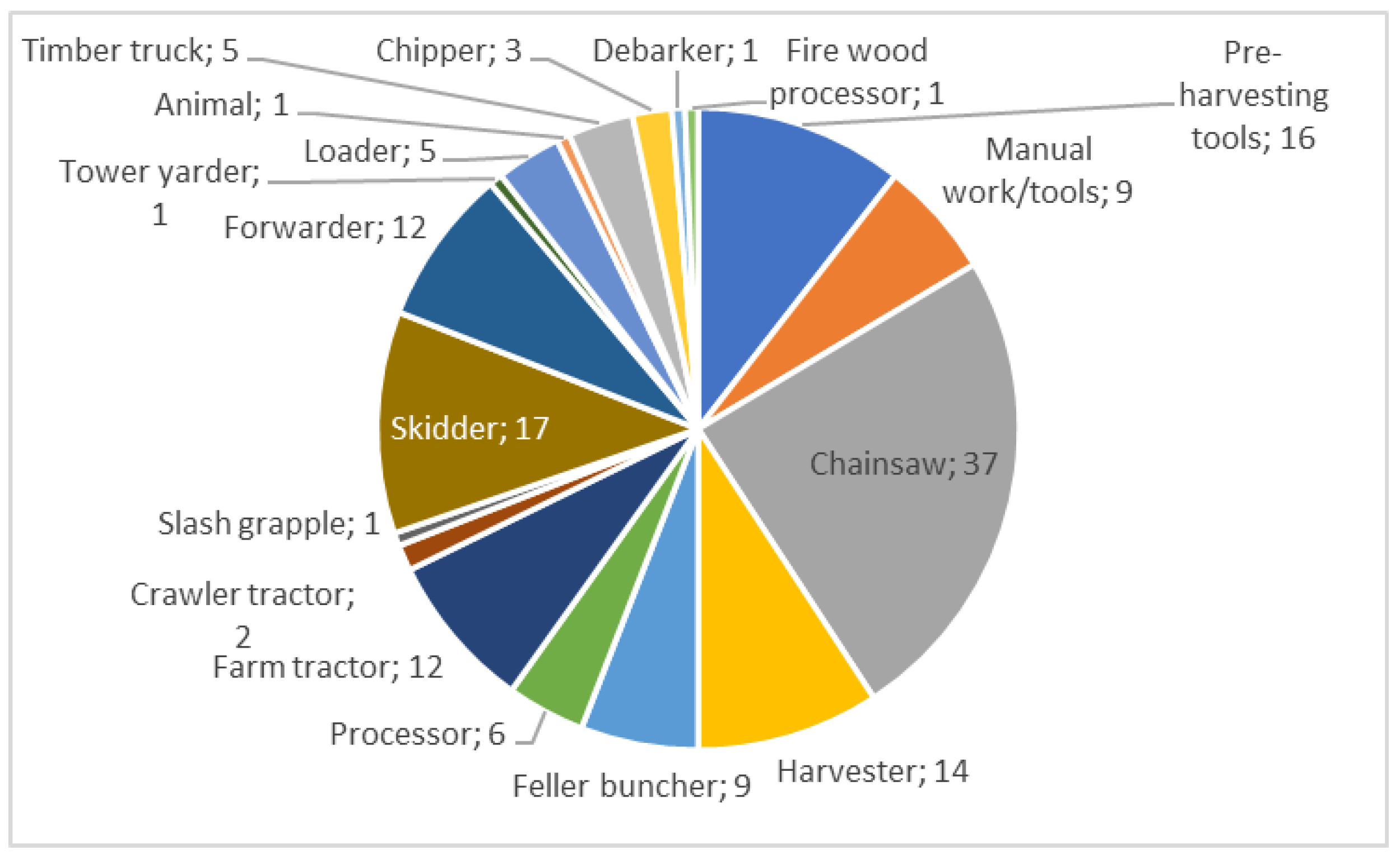

3.2. Article Classification

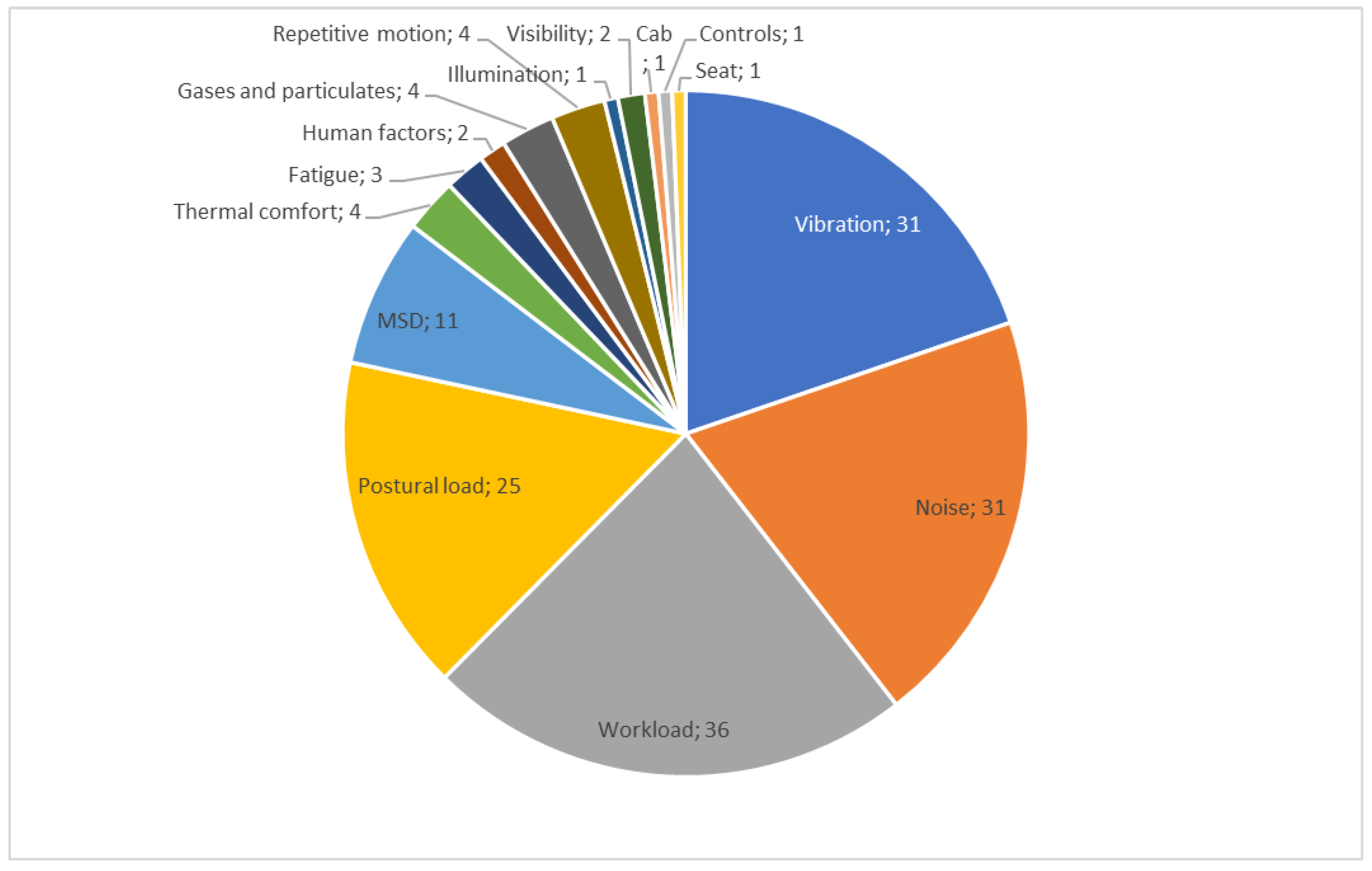

3.3. Recent Study Results per Risk Factors Overview

3.3.1. Noise and Vibration

3.3.2. Workload

3.3.3. Postural Load

3.3.4. MSDs (Musculoskeletal Disorders)

- The work environment and performance of work contribute significantly to the condition;

- The condition is made worse or persists longer due to work conditions.

3.3.5. Thermal Comfort, Gases and Particulates, Repetitive Motion, Fatigue, Human Factors, and Visibility

3.3.6. Illumination, Cab, Controls, and Seat

4. Discussion

5. Conclusions

- The number of articles is ever-increasing with the last four years having an above average number of articles (12). An increase is also observed cumulatively compared to a previous study [26], from 76 to 102 articles.

- Countries from Europe and South America (Brazil) have the most publications at 57 and 27, respectively.

- Most of the journals are ranked in the top 50%, while Brazil—a country with the highest number of articles—was mostly (19 out of 27) publishing in domestic journals.

- Harvesting (44%), wood extraction (27%), and pre-harvesting (13%) operations have the highest percentage of records.

- Chainsaw, skidder, and pre-harvesting tools are the most observed means of work with 24%, 11%, and 11% of records, respectively.

- The risk factors with the highest percentage of records are workload (23%), noise (20%), vibration (20%), postural load (16%), and MSD occurrence (7%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Authors and Reference Numbers in Chronological Order (Left to Right) | |||

|---|---|---|---|

| Nuutinen et al., 2014 [91] | Leszczyński and Stańczykiewicz 2014 [102] | Gerasimov and Sokolov 2014 [23] | Sasaki et al., 2014 [103] |

| Britto et al., 2014 [104] | Oliveira et al., 2014 [71] | Barbosa et al., 2014 [105] | Silva et al., 2014 [89] |

| Leszczyński and Stańczykiewicz 2015 [106] | Spinelli et al., 2015 [79] | Almeida et al., 2015 [88] | Yovi and Prajawati 2015 [107] |

| Dubé et al., 2015 [98] | Ji et al., 2015 [96] | Fonseca et al., 2015 [108] | Poje et al., 2015 [92] |

| Souza et al., 2015 [109] | Minette et al., 2015 [110] | Huber and Stampfer 2015 [111] | Grzywiński 2015 [112] |

| Britto et al., 2015 [66] | Poje et al., 2016 [80] | Magagnotti et al., 2016 [113] | Grzywinski et al., 2016 [56] |

| Dubé et al., 2016 [114] | Ottaviani Aalmo et al., 2016 [76] | Häggström et al., 2016 [29] | Phairah et al., 2016 [60] |

| Schettino et al., 2016 [59] | Marzano et al., 2017 [115] | Spinelli et al., 2017 [116] | Ji et al., 2017 [97] |

| Schettino et al., 2017 [82] | Brokmeier 2017 [94] | Poje et al., 2018 [93] | Spinelli et al., 2018 [117] |

| Granzow et al., 2018 [118] | Cheţa et al., 2018 [119] | Tomczak et al., 2018 [18] | Neri et al., 2018 [120] |

| Poje et al., 2018 [121] | Billo et al., 2019 [31] | Yovi and Yamada 2019 [19] | Enez and Nalbantoğlu 2019 [95] |

| Bowen et al., 2019 [64] | Borz et al., 2019 [32] | Poje et al., 2019 [34] | Lopes et al., 2019 [52] |

| Bligård and Häggström 2019 [122] | Paini et al., 2019 [53] | Grzywinski et al., 2019 [90] | Oliveira et al., 2020 [24] |

| Santos et al., 2020 [63] | Stenlund et al., 2020 [54] | Spinelli et al., 2020 [46] | Martins et al., 2020 [8] |

| Szewczyk et al., 2020 [47] | Arab et al., 2020 [72] | Dimou et al., 2020 [81] | Iftime et al., 2020 [62] |

| Berendt et al., 2020 [123] | Naskrent et al., 2020 [3] | Landekić et al., 2020 [37] | Paini et al., 2020 [124] |

| Martins et al., 2020 [125] | McLain et al., 2021 [87] | Oliveira-Nascimento et al., 2021 [42] | Schönauer et al., 2021 [44] |

| Veiga et al., 2021 [33] | Arman et al., 2021 [43] | Zurita Vintimilla et al., 2021 [126] | Szewczyk et al., 2021 [127] |

| Camargo et al., 2021 [4] | Yovi et al., 2021 [128] | Çağlar 2021 [129] | Borz et al., 2021 [15] |

| Huber et al., 2021 [35] | Iftime et al., 2022 [61] | Pajek et al., 2022 [49] | Camargo et al., 2022 [5] |

| Arman et al., 2022 [48] | Lee et al., 2022 [45] | Staněk and Mergl 2022 [130] | Gejdoš et al., 2022 [131] |

| Camargo et al., 2022 [6] | Hnilica et al., 2022 [132] | Camargo et al., 2022 [7] | Papandrea et al., 2022 [38] |

| Borz et al., 2022 [16] | Landekić et al., 2023 [17] | Landekić et al., 2023 [57] | Staněk et al., 2023 [9] |

| Bačić et al., 2023 [10] | Feyzi et al., 2023 [11] | Ottaviani Aalmo et al., 2023 [12] | Neri et al., 2023 [36] |

| Bačić et al., 2023 [133] | Okuda et al., 2023 [13] | Sláma et al., 2023 [14] | Lima et al., 2023 [134] |

| Staněk et al., 2023 [58] | Nakata et al., 2023 [65] | ||

References

- Apud, E.; Meyer, F.; Espinoza, J.; Oñate, E.; Freire, J.; Maureira, F. Ergonomics and Labour in Forestry. In Tropical Forestry Handbook; Pancel, L., Köhl, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 3211–3310. [Google Scholar] [CrossRef]

- Heinimann, H.R. Forest Operations Engineering and Management—The Ways behind and Ahead of a Scientific Discipline. Croat. J. For. Eng. 2007, 28, 107–121. [Google Scholar]

- Naskrent, B.; Grzywiński, W.; Łukowski, A.; Polowy, K. Influence of Cutting Attachment on Noise Level Emitted by Brush Cutter during Tending of Young Forests. Croat. J. For. Eng. 2020, 41, 129–135. [Google Scholar] [CrossRef]

- Camargo, D.A.; Munis, R.A.; Simões, D. Investigation of Exposure to Occupational Noise among Forestry Machine Operators: A Case Study in Brazil. Forests 2021, 12, 299. [Google Scholar] [CrossRef]

- Camargo, D.A.; Munis, R.A.; Batistela, G.C.; Simões, D. Exposure to Occupational Noise: Machine Operators of Full Tree System in Brazil. Croat. J. For. Eng. 2022, 43, 391–402. [Google Scholar] [CrossRef]

- Camargo, D.A.; Munis, R.A.; Rocha, Q.S.; Simões, D. Evaluation of Occupational Noise Exposure among Forest Machine Operators: A Study on the Harvest of Pinus taeda Trees. Aust. For. 2022, 85, 89–94. [Google Scholar] [CrossRef]

- Camargo, D.A.; Munis, R.A.; Miyajima, R.H.; Lima, R.C.A.; Simões, D. Mechanized Wood Extraction: Impacts on Operators’ Hearing Health. Forests 2022, 13, 1553. [Google Scholar] [CrossRef]

- Martins, A.B.; Lopes, E.d.S.; Fiedler, N.C.; de Oliveira, F.M.; Pagnussat, M.B. The Whole-Body Vibration in Operation of Wheeled and Tracked Harvester IN PINUS Thinning. Int. J. Ind. Ergon. 2020, 80, 103006. [Google Scholar] [CrossRef]

- Stanëk, L.; Neruda, J.; Mergl, V.; Kotek, T. Difference in the Magnitude of Power Saw Vibrations Affecting the Operator during Forest Felling. Cent. Eur. For. J. 2023, 69, 59–67. [Google Scholar] [CrossRef]

- Bačić, M.; Landekić, M.; Šušnjar, M.; Šporčić, M.; Pandur, Z. Vibration Levels and Daily Vibration Exposure While Using Different Tools in a Forest Cleaning. Cent. Eur. For. J. 2023, 69, 49–58. [Google Scholar] [CrossRef]

- Feyzi, M.; Jafari, A.; Ahmadi, H. The Effect of Wood Species on Chainsaw Vibrations during Bucking Operations. Int. J. For. Eng. 2023, 34, 417–425. [Google Scholar] [CrossRef]

- Ottaviani Aalmo, G.; Spinelli, R.; Magagnotti, N.; Visser, R. Quantitative and Qualitative Workload Assessment in Steep Terrain Forest Operations: Fostering a Safer Work Environment through Yarder Automation. Ergonomics 2023, 66, 717–729. [Google Scholar] [CrossRef] [PubMed]

- Okuda, M.; Kawamoto, Y.; Tado, H.; Fujita, Y.; Inomata, Y. Energy Expenditure Estimation for Forestry Workers Moving on Flat and Inclined Ground. Forests 2023, 14, 1038. [Google Scholar] [CrossRef]

- Sláma, D.; Mergl, V.; Pavlíková, E.A. Analysis of the Heart Rate of Operators of Forwarding Machines during Work Activities. Forests 2023, 14, 1348. [Google Scholar] [CrossRef]

- Borz, S.A.; Iordache, E.; Marcu, M.V. Enhancing Working Posture Comparability in Forest Operations by the Use of Similarity Metrics. Forests 2021, 12, 926. [Google Scholar] [CrossRef]

- Borz, S.A.; Papandrea, S.F.; Marcu, M.V.; Bacenetti, J.; Proto, A.R. Postural Assessment of Three Wood Measurement Options by the OWAS Method: Digital Solutions Seem to Be Better. Forests 2022, 13, 2007. [Google Scholar] [CrossRef]

- Landekić, M.; Bačić, M.; Bakarić, M.; Šporčić, M.; Pandur, Z. Working Posture and the Center of Mass Assessment While Starting a Chainsaw: A Case Study among Forestry Workers in Croatia. Forests 2023, 14, 395. [Google Scholar] [CrossRef]

- Tomczak, A.; Grzywiński, W.; Jelonek, T. Capabilities of Manhandling Small Logs in Commercial Thinning in Pine, Spruce, Beech, and Birch Stands. Sylwan 2018, 162, 531–538. [Google Scholar]

- Yovi, E.Y.; Yamada, Y. Addressing Occupational Ergonomics Issues in Indonesian Forestry: Laborers, Operators, or Equivalent Workers. Croat. J. For. Eng. 2019, 40, 351–363. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting Working Postures in Industry: A Practical Method for Analysis. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef]

- Kuorinka, I.; Jonsson, B.; Kilbom, A.; Vinterberg, H.; Biering-Sørensen, F.; Andersson, G.; Jørgensen, K. Standardised Nordic Questionnaires for the Analysis of Musculoskeletal Symptoms. Appl. Ergon. 1987, 18, 233–237. [Google Scholar] [CrossRef] [PubMed]

- Gerasimov, Y.; Sokolov, A. Ergonomic Evaluation and Comparison of Wood Harvesting Systems in Northwest Russia. Appl. Ergon. 2014, 45, 318–338. [Google Scholar] [CrossRef]

- de Oliveira, F.M.; Lopes, E.d.S.; Fiedler, N.C.; Koehler, H.S. Indicator for Urgency Assessment in Ergonomic Intervention of Wood Harvesting Machines. Rev. Árvore 2020, 44, e4428. [Google Scholar] [CrossRef]

- Gellerstedt, S. European Ergonomic and Safety Guidelines for Forest Machines 2006; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2006; pp. 1–100. [Google Scholar]

- Potočnik, I.; Poje, A. Forestry Ergonomics and Occupational Safety in High Ranking Scientific Journals from 2005–2016. Croat. J. For. Eng. 2017, 38, 291–310. [Google Scholar]

- Workplace Noise: More than Just “All Ears”. Available online: https://blogs.cdc.gov/niosh-science-blog/2018/06/28/noise-effects/ (accessed on 21 March 2024).

- Hand Arm Vibration in Forestry and Arboriculture. Available online: https://www.hse.gov.uk/treework/health/hand-arm-vibration.htm (accessed on 21 March 2024).

- Häggström, C.; Öhman, M.; Burström, L.; Nordfjell, T.; Lindroos, O. Vibration Exposure in Forwarder Work: Effects of Work Element and Grapple Type. Croat. J. For. Eng. 2016, 37, 107–118. [Google Scholar]

- Rehn, B.; Nilsson, T.; Lundström, R.; Hagberg, M.; Burström, L. Neck Pain Combined with Arm Pain among Professional Drivers of Forest Machines and the Association with Whole-Body Vibration Exposure. Ergonomics 2009, 52, 1240–1247. [Google Scholar] [CrossRef]

- Billo, D.; Mendes, L.; Nascimento, G.; Fiedler, N.; Berude, L. Analysis of Noise Transmitted to Workers in Motor-Manual Forest Harvesting in Minas Gerais State. Floresta Ambiente 2019, 26, e20180395. [Google Scholar] [CrossRef]

- Borz, S.A.; Talagai, N.; Cheţa, M.; Chiriloiu, D.; Gavilanes Montoya, A.V.; Castillo Vizuete, D.D.; Marcu, M.V. Physical Strain, Exposure to Noise and Postural Assessment in Motor-Manual Felling of Willow Short Rotation Coppice: Results of a Preliminary Study. Croat. J. For. Eng. 2019, 40, 377–388. [Google Scholar] [CrossRef]

- Veiga, R.K.; Gontijo, L.A.; Masiero, F.C.; Venturi, J. Analysis of Spatial Distribution of Noise Near Agricultural and Forestry Machinery. Ciênc. Florest. 2021, 31, 43–65. [Google Scholar] [CrossRef]

- Poje, A.; Grigolato, S.; Potočnik, I. Operator Exposure to Noise and Whole-Body Vibration in a Fully Mechanised CTL Forest Harvesting System in Karst Terrain. Croat. J. For. Eng. 2019, 40, 139–150. [Google Scholar]

- Huber, M.; Hoffmann, S.; Brieger, F.; Hartsch, F.; Jaeger, D.; Sauter, U.H. Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests 2021, 12, 1120. [Google Scholar] [CrossRef]

- Neri, F.; Laschi, A.; Bertuzzi, L.; Galipò, G.; Frassinelli, N.; Fabiano, F.; Marchi, E.; Foderi, C.; Marra, E. A Comparison between the Latest Models of Li-Ion Batteries and Petrol Chainsaws Assessing Noise and Vibration Exposure in Cross-Cutting. Forests 2023, 14, 898. [Google Scholar] [CrossRef]

- Landekić, M.; Bačić, M.; Pandur, Z.; Šušnjar, M. Vibration Levels of Used Chainsaws. Forests 2020, 11, 249. [Google Scholar] [CrossRef]

- Papandrea, S.F.; Cataldo, M.F.; Zimbalatti, G.; Grigolato, S.; Proto, A.R. What Is the Current Ergonomic Condition of Chainsaws in Non-Professional Use? A Case Study to Determine Vibrations and Noises in Small-Scale Agroforestry Farms. Forests 2022, 13, 1876. [Google Scholar] [CrossRef]

- Kinoshita, H. Effects of Different Loads and Carrying Systems on Selected Biomechanical Parameters Describing Walking Gait. Ergonomics 1985, 28, 1347–1362. [Google Scholar] [CrossRef] [PubMed]

- Brookhuis, K.A.; de Waard, D. The Use of Psychophysiology to Assess Driver Status. Ergonomics 1993, 36, 1099–1110. [Google Scholar] [CrossRef] [PubMed]

- Brookhuis, K.A.; de Waard, D. Assessment of Drivers’ Workload: Performance and Subjective and Physiological Indexes. In Stress, Workload, and Fatigue, 1st ed.; Hancock, P.A., Desmond, P.A., Eds.; CRC Press: Boca Raton, FL, USA, 2000; pp. 1–13. [Google Scholar] [CrossRef]

- Oliveira, N.K.A.; Niro, H.; DeArmond, D.; Gonçalves, R.R.C.; Eduardo, A.J.; Fidalgo, C.J.P. Environmental Thermal Conditions Related to Performance, Dynamics and Safety of Logging in the Brazilian Amazon. Croat. J. For. Eng. 2021, 42, 419–435. [Google Scholar] [CrossRef]

- Arman, Z.; Nikooy, M.; Tsioras, P.A.; Heidari, M.; Majnounian, B. Physiological Workload Evaluation by Means of Heart Rate Monitoring during Motor-Manual Clearcutting Operations. Int. J. For. Eng. 2021, 32, 91–102. [Google Scholar] [CrossRef]

- Schönauer, M.; Hoffmann, S.; Nolte, M.; Jaeger, D. Evaluation of a New Pruning and Tending System for Young Stands of Douglas Fir. Silva Fenn. 2021, 55, 10447. [Google Scholar] [CrossRef]

- Lee, E.; Baek, K.; Lee, S.; Cho, M.-J.; Choi, Y.-S.; Cho, K.-H. The Impact of Season on Heart Rate Variability and Workload of Workers in Young Tree Tending Operations of a Larix Kaempferi (Lamb.) Carr. Stand: A Preliminary Study. Int. J. For. Eng. 2022, 33, 139–145. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Labelle, E.R. The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators. Croat. J. For. Eng. 2020, 41, 177–190. [Google Scholar] [CrossRef]

- Szewczyk, G.; Spinelli, R.; Magagnotti, N.; Tylek, P.; Sowa, J.M.; Rudy, P.; Gaj-Gielarowiec, D. The Mental Workload of Harvester Operators Working in Steep Terrain Conditions. Silva Fenn. 2020, 54, 10355. [Google Scholar] [CrossRef]

- Arman, Z.; Nikooy, M.; Tsioras, P.A.; Heidari, M.; Majnounian, B. Mental Workload, Occupational Fatigue and Musculoskeletal Disorders of Forestry Professionals: The Case of a Loblolly Plantation in Northern Iran. Croat. J. For. Eng. 2022, 43, 403–424. [Google Scholar] [CrossRef]

- Pajek, L.; Geršak, G.; Poje, A. Influence of Use of Forestry Personal Protective Equipment on Psychophysical Load. Acta Silvae Ligni 2022, 129, 43–56. [Google Scholar] [CrossRef]

- Sarkar, K.; Dev, S.; Das, T.; Chakrabarty, S.; Gangopadhyay, S. Examination of Postures and Frequency of Musculoskeletal Disorders among Manual Workers in Calcutta, India. Int. J. Occup. Environ. Health 2016, 22, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Risk Factors for Musculoskeletal Disorders—Working Postures—OSHwiki|European Agency for Safety and Health at Work. Available online: https://oshwiki.osha.europa.eu/en/themes/risk-factors-musculoskeletal-disorders-working-postures (accessed on 22 March 2024).

- Lopes, E.d.S.; Britto, P.C.; Rodrigues, C.K. Postural Discomfort in Manual Operations of Forest Planting. Floresta Ambiente 2018, 26, e20170030. [Google Scholar] [CrossRef]

- Paini, A.d.C.; Lopes, E.d.S.; Souza, d.A.P.; Oliveira, d.F.M.; Rodrigues, C.K. Repetitive Motion and Postural Analysis of Machine Operators in Mechanized Wood Harvesting Operations. Cerne 2019, 25, 214–220. [Google Scholar] [CrossRef]

- Stenlund, T.; Lundström, R.; Lindroos, O.; Rehn, B.; Öhberg, F. Seated Postural Loads Caused by Shock-Type Whole-Body Vibration When Driving over Obstacles. Int. J. For. Eng. 2020, 31, 184–191. [Google Scholar] [CrossRef]

- Work-Related Musculoskeletal Disorders & Ergonomics|Workplace Health Strategies by Condition|Workplace Health Promotion|CDC. Available online: https://www.cdc.gov/workplacehealthpromotion/health-strategies/musculoskeletal-disorders/index.html (accessed on 29 February 2024).

- Grzywiński, W.; Wandycz, A.; Tomczak, A.; Jelonek, T. The Prevalence of Self-Reported Musculoskeletal Symptoms among Loggers in Poland. Int. J. Ind. Ergon. 2016, 52, 12–17. [Google Scholar] [CrossRef]

- Landekić, M.; Šporčić, M.; Bačić, M.; Pandur, Z.; Bakarić, M. Workability and Physical Wellbeing Among Chainsaw Operators in Croatia. Croat. J. For. Eng. 2023, 44, 83–94. [Google Scholar] [CrossRef]

- Staněk, L.; Neruda, J.; Nevrkla, P. The Magnitude of Fatigue Recorded in Individual Body Parts of Chainsaw Operators after Work. Forests 2023, 14, 2023. [Google Scholar] [CrossRef]

- Schettino, S.; Minette, L.; Souza, A.; Souza, A. Ergonomic Evaluation of Forest Mensuration Process. Sci. For. 2016, 44, 575–586. [Google Scholar] [CrossRef][Green Version]

- Phairah, K.; Brink, M.; Chirwa, P.; Todd, A. Operator Work-Related Musculoskeletal Disorders during Forwarding Operations in South Africa: An Ergonomic Assessment. South. For. 2016, 78, 1–9. [Google Scholar] [CrossRef]

- Iftime, M.D.; Dumitrascu, A.-E.; Ciobanu, V.D. Chainsaw Operators’ Exposure to Occupational Risk Factors and Incidence of Professional Diseases Specific to the Forestry Field. Int. J. Occup. Saf. Ergon. 2022, 28, 8–19. [Google Scholar] [CrossRef] [PubMed]

- Iftime, M.-D.; Dumitrascu, A.-E.; Dumitrascu, D.-I.; Ciobanu, V.D. An Investigation on Major Physical Hazard Exposures and Health Effects of Forestry Vehicle Operators Performing Wood Logging Processes. Int. J. Ind. Ergon. 2020, 80, 103041. [Google Scholar] [CrossRef]

- Santos, D.W.F.d.N.; Valente, D.S.M.; Fernandes, H.C.; de Souza, A.P.; Minette, L.J. Influence of Pump Pressure and Engine Speed on Ergonomic Parameters of Forwarder Operators. Rev. Árvore 2020, 44, e4425. [Google Scholar] [CrossRef]

- Bowen, J.; Hinze, A.; Griffiths, C. Investigating Real-Time Monitoring of Fatigue Indicators of New Zealand Forestry Workers. Accid. Anal. Prev. 2019, 126, 122–141. [Google Scholar] [CrossRef] [PubMed]

- Nakata, C.; Itaya, A.; Inomata, Y.; Yamaguchi, H.; Yoshida, C.; Nakazawa, M. Working Conditions and Fatigue in Log Truck Drivers within the Japanese Forest Industry. Int. J. For. Eng. 2023, 34, 64–75. [Google Scholar] [CrossRef]

- Britto, P.C.; Lopes, E.d.S.; Drinko, C.H.F.; Gonçalves, S.B. Human Factors and Work Conditions in Forest Maintenance and Planting Operations. Floresta Ambiente 2015, 22, 503–511. [Google Scholar] [CrossRef][Green Version]

- UNECE/FAO. Forest Sector Workforce in the UNECE Region—Overview of the Social and Economic Trends with Impact on the Forest Sector; Geneva Timber and Forest Discussion Paper 76; United Nations: Geneva, Switzerland, 2020; p. 77. [Google Scholar]

- de Rijcke, S.; Wouters, P.F.; Rushforth, A.D.; Franssen, T.P.; Hammarfelt, B. Evaluation Practices and Effects of Indicator Use—A Literature Review. Res. Eval. 2016, 25, 161–169. [Google Scholar] [CrossRef]

- Oosthoek, K.J.; Hölzl, R. Managing Northern Europe’s Forests: Histories from the Age of Improvement to the Age of Ecology, 1st ed.; Berghahn Books: Brooklyn, NY, USA, 2018; pp. 1–420. [Google Scholar] [CrossRef]

- Lundbäck, M.; Häggström, C.; Nordfjell, T. Worldwide Trends in Methods for Harvesting and Extracting Industrial Roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- de Oliveira, F.M.; Lopes, E.d.S.; Rodrigues, C.K. Evaluation of the physical work load and biomechanical of workers at manual and semi-mechanized mowing. Cerne 2014, 20, 419–425. [Google Scholar] [CrossRef]

- Arab, S.; Imbeau, D.; Dubeau, D.; Dubé, P.-A.; Auger, I. Comparison of Nine Heart Rate-Based Models to Predict Work Metabolism of Forest Workers. Ergonomics 2020, 63, 1394–1413. [Google Scholar] [CrossRef] [PubMed]

- Bayne, K.M.; Parker, R.J. The Introduction of Robotics for New Zealand Forestry Operations: Forest Sector Employee Perceptions and Implications. Technol. Soc. 2012, 34, 138–148. [Google Scholar] [CrossRef]

- Magagnotti, N.; Spinelli, R. Integrating Animal and Mechanical Operations in Protected Areas. Croat. J. For. Eng. 2011, 32, 489–499. [Google Scholar]

- Albizu-Urionabarrenetxea, P.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and Health in Forest Harvesting Operations. Diagnosis and Preventive Actions. A Review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Ottaviani Aalmo, G.; Magagnotti, N.; Spinelli, R. Forest Workers and Steep Terrain Winching: The Impact of Environmental and Anthropometric Parameters on Performance. Croat. J. For. Eng. 2016, 37, 97–105. [Google Scholar]

- Forest Research. Small and Medium Harvesting and Extraction Machinery: A Guide to Site Suitability; The Research Agency of the Forestry Commission: Cheshire, UK, 2015; pp. 1–18. [Google Scholar]

- Nilsson, M. The Farm Tractor in the Forest; Swedish Forest Agency: Jönköping, Sweden, 2017; pp. 1–105. [Google Scholar]

- Spinelli, R.; Aalmo, G.O.; Magagnotti, N. The Effect of a Slack-Pulling Device in Reducing Operator Physiological Workload during Log Winching Operations. Ergonomics 2015, 58, 781–790. [Google Scholar] [CrossRef] [PubMed]

- Poje, A.; Potočnik, I.; Danilović, M.; Antonić, S. A Case Study of the Impact of Skidding Distance on Tractor Operator Exposure to Noise. Balt. For. 2016, 22, 357–364. [Google Scholar]

- Dimou, V.; Malesios, C.; Pispa, S. Monitoring Self-Reported Musculoskeletal Symptoms in Forestry Operations. Int. J. For. Eng. 2020, 31, 106–113. [Google Scholar] [CrossRef]

- Schettino, S.; Campos, J.C.C.; Minette, L.J.; de Souza, A.P. Work Precariousness: Ergonomic Risks to Operators of Machines Adapted for Forest Harvesting. Rev. Árvore 2017, 41, e410109. [Google Scholar] [CrossRef][Green Version]

- Lahrsen, S.; Mologni, O.; Magalhães, J.; Grigolato, S.; Röser, D. Key Factors Influencing Productivity of Whole-Tree Ground-Based Felling Equipment Commonly Used in the Pacific Northwest. Can. J. For. Res. 2022, 52, 450–462. [Google Scholar] [CrossRef]

- Munis, R.A.; Camargo, D.A.; Rocha, Q.S.; Pandolfo, P.T.; da Silva, R.B.G.; Simões, D. Economic Analysis of the Feller Buncher in Brazilian Eucalyptus Plantations: Modeling with Time Series. Int. J. For. Eng. 2023, 1–7. [Google Scholar] [CrossRef]

- Gülci, N.; Yüksel, K.; Gülci, S.; Serin, H.; Bilici, E.; Akay, A.E. Analysis of a Feller-Buncher Productivity: A Case Study of Whole-Tree Harvesting from Marmara Region, Turkey. Ann. For. Res. 2021, 64, 99–110. [Google Scholar] [CrossRef]

- Schweier, J.; Spinelli, R.; Magagnotti, N.; Becker, G. Mechanized Coppice Harvesting with New Small-Scale Feller-Bunchers: Results from Harvesting Trials with Newly Manufactured Felling Heads in Italy. Biomass Bioenergy 2015, 72, 85–94. [Google Scholar] [CrossRef]

- McLain, S.C.; Autenrieth, D.A.; Yang, X.; Brazile, W.J. Noise Exposures and Hearing Protector Use at Small Logging Operations. Small-Scale For. 2021, 20, 1–9. [Google Scholar] [CrossRef]

- Almeida, S.F.; Abrahão, R.F.; Tereso, M.J.A. Evaluation of Occupational Exposure to Whole Body Vibration in Forest Harvesting Machines. Cerne 2015, 21, 1–8. [Google Scholar] [CrossRef][Green Version]

- Silva, E.P.; Minette, L.J.; Sanches, A.L.P.; de Souza, A.P.; Silva, F.L.; Mafra, S.C.T. Prevalence of musculoskeletal symptoms in forest harvesting machine operators. Rev. Árvore 2014, 38, 739–745. [Google Scholar] [CrossRef]

- Grzywiński, W.; Jelonek, T.; Tomczak, A. Physiological workload at forester and deputy forester workstations. Sylwan 2019, 163, 811–819. [Google Scholar]

- Nuutinen, Y.; Laitila, J.; Rytkönen, E. Grinding of Stumps, Logging Residues and Small Diameter Wood Using a CBI 5800 Grinder with a Truck as a Base Machine. Balt. For. 2014, 20, 176–188. [Google Scholar]

- Poje, A.; Spinelli, R.; Magagnotti, N.; Mihelič, M. Exposure to Noise in Wood Chipping Operations under the Conditions of Agro-Forestry. Int. J. Ind. Ergon. 2015, 50, 151–157. [Google Scholar] [CrossRef]

- Poje, A.; Spinelli, R.; Magagnotti, N.; Mihelič, M. The Effect of Feedstock, Knife Wear and Work Station on the Exposure to Noise and Vibrations in Wood Chipping Operations. Silva Fenn. 2018, 52, 1–14. [Google Scholar]

- Brokmeier, H. Central Tire Inflation System for Timber Transport in Germany. Int. J. For. Eng. 2017, 28, 211–225. [Google Scholar] [CrossRef]

- Enez, K.; Nalbantoğlu, S.S. Comparison of Ergonomic Risk Assessment Outputs from OWAS and REBA in Forestry Timber Harvesting. Int. J. Ind. Ergon. 2019, 70, 51–57. [Google Scholar] [CrossRef]

- Ji, X.; Eger, T.R.; Dickey, J.P. Development of a Seat Selection Algorithm to Match Industrial Seats with Specific Forestry Vibration Exposures. Int. J. For. Eng. 2015, 26, 48–59. [Google Scholar] [CrossRef]

- Ji, X.; Eger, T.R.; Dickey, J.P. Evaluation of the Vibration Attenuation Properties of an Air-Inflated Cushion with Two Different Heavy Machinery Seats in Multi-Axis Vibration Environments Including Jolts. Appl. Ergon. 2017, 59, 293–301. [Google Scholar] [CrossRef] [PubMed]

- Dubé, P.-A.; Imbeau, D.; Dubeau, D.; Auger, I.; Leone, M. Prediction of Work Metabolism from Heart Rate Measurements in Forest Work: Some Practical Methodological Issues. Ergonomics 2015, 58, 2040–2056. [Google Scholar] [CrossRef] [PubMed]

- Axelsson, S.-Ă. The Mechanization of Logging Operations in Sweden and Its Effect on Occupational Safety and Health. J. For. Eng. 1998, 9, 25–31. [Google Scholar] [CrossRef]

- Lefort, A.J., Jr.; de Hoop, C.F.; Pine, J.C.; Marx, B.D. Characteristics of Injuries in the Logging Industry of Louisiana, USA: 1986 to 1998. Int. J. For. Eng. 2003, 14, 75–89. [Google Scholar] [CrossRef]

- Potočnik, I.; Pentek, T.; Poje, A. Severity Analysis of Accidents in Forest Operations. Croat. J. For. Eng. 2009, 30, 171–184. [Google Scholar]

- Leszczyński, K.; Stańczykiewicz, A. The Use of Heart Rate Monitor in Assessing the Net Energy Expenditure during Motor-Manual Cutting. Sylwan 2014, 158, 124–131. [Google Scholar]

- Sasaki, R.S.; Furtado Júnior, M.R.; Leite, E.d.S.; Souza, A.P.; Teixeira, M.M.; Fernandes, H.C. Ergonomic evaluation of knapsack sprayers used in forestry. Rev. Árvore 2014, 38, 331–337. [Google Scholar] [CrossRef][Green Version]

- Britto, P.; Lopes, E.; Laat, E.; Fiedler, N. Biomechanical Evaluation in Workers of Different Statures at Planting and Fertilizing Forest Activities. Sci. For. 2014, 42, 191–196. [Google Scholar]

- Barbosa, R.P.; Fiedler, N.C.; do Carmo, F.C.d.A.; Minette, L.J.; Silva, E.N. Analysis of posture in semi-mechanized forest harvesting in steep areas. Rev. Árvore 2014, 38, 733–738. [Google Scholar] [CrossRef]

- Leszczyński, K.; Stańczykiewicz, A. Workload Analysis in Logging Technology Employing a Processor Aggregated with a Farm Tractor. For. Syst. 2015, 24, e024. [Google Scholar] [CrossRef]

- Yovi, E.Y.; Prajawati, W. High Risk Posture on Motor-Manual Short Wood Logging System in Acacia Mangium Plantation. J. Manaj. Hutan Trop. 2015, 21, 11–18. [Google Scholar] [CrossRef][Green Version]

- Fonseca, A.; Aghazadeh, F.; de Hoop, C.; Ikuma, L.; Al-Qaisi, S. Effect of Noise Emitted by Forestry Equipment on Workers’ Hearing Capacity. Int. J. Ind. Ergon. 2015, 46, 105–112. [Google Scholar] [CrossRef]

- de Souza, A.P.; Dutra, R.B.C.; Minette, L.J.; Marzano, F.L.d.C.; Schettino, S. Production Targets for Workers in Forest Harvesting. Rev. Árvore 2015, 39, 713–722. [Google Scholar] [CrossRef][Green Version]

- Minette, L.J.; Schettino, S.; Souza, V.; Duarte, C.L.; Souza, A. Biochemical and Physical Work Load Evaluation of Forest Workers in Mountain Regions. Sci. For. 2015, 43, 541–550. [Google Scholar]

- Huber, C.; Stampfer, K. Efficiency of Topping Trees in Cable Yarding Operations. Croat. J. For. Eng. 2015, 36, 185–194. [Google Scholar]

- Grzywiński, W. Influence of Working Posture during the Felling on Energy Expenditure of a Chainsaw Operator. Sylwan 2015, 159, 824–830. [Google Scholar]

- Magagnotti, N.; Aalmo, G.O.; Brown, M.; Spinelli, R. A New Device for Reducing Winching Cost and Worker Effort in Steep Terrain Operations. Scand. J. For. Res. 2016, 31, 602–610. [Google Scholar] [CrossRef]

- Dubé, P.-A.; Imbeau, D.; Dubeau, D.; Lebel, L.; Kolus, A. Removing the Thermal Component from Heart Rate Provides an Accurate VO2 Estimation in Forest Work. Appl. Ergon. 2016, 54, 148–157. [Google Scholar] [CrossRef] [PubMed]

- Marzano, F.L.d.C.; de Souza, A.P.; Minette, L.J. Proposal for an Ergonomic Conformity Index for Evaluation of Harvesters and Forwarders. Rev. Árvore 2017, 41, e410401. [Google Scholar] [CrossRef]

- Spinelli, R.; Aminti, G.; De Francesco, F. Postural Risk Assessment of Mechanised Firewood Processing. Ergonomics 2017, 60, 375–383. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, R.; Aminti, G.; Magagnotti, N.; De Francesco, F. Postural Risk Assessment of Small-Scale Debarkers for Wooden Post Production. Forests 2018, 9, 111. [Google Scholar] [CrossRef]

- Granzow, R.F.; Schall, M.C.; Smidt, M.F.; Chen, H.; Fethke, N.B.; Huangfu, R. Characterizing Exposure to Physical Risk Factors among Reforestation Hand Planters in the Southeastern United States. Appl. Ergon. 2018, 66, 1–8. [Google Scholar] [CrossRef]

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, Exposure to Noise, and Risk of Musculoskeletal Disorders: A Case Study of Motor-Manual Tree Feeling and Processing in Poplar Clear Cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef]

- Neri, F.; Laschi, A.; Foderi, C.; Fabiano, F.; Bertuzzi, L.; Marchi, E. Determining Noise and Vibration Exposure in Conifer Cross-Cutting Operations by Using Li-Ion Batteries and Electric Chainsaws. Forests 2018, 9, 501. [Google Scholar] [CrossRef]

- Poje, A.; Potočnik, I.; Mihelič, M. Comparison of Electric and Petrol Chainsaws in Terms of Efficiency and Safety When Used in Young Spruce Stands in Small-Scale Private Forests. Small-Scale For. 2018, 17, 411–422. [Google Scholar] [CrossRef]

- Bligård, L.-O.; Häggström, C. CCPE—The Use of an Analytical Method to Evaluate Safety and Ergonomics in Maintenance of Forest Machinery. Aust. For. 2019, 82, 29–34. [Google Scholar] [CrossRef]

- Berendt, F.; Hoffmann, S.; Jaeger, D.; Prettin, S.; Schweier, J. Application of Spiroergometry to Determine Work Metabolism Related Strain in the Course of Cable Work with a Mini Forestry Crawler. Int. J. For. Eng. 2020, 31, 114–125. [Google Scholar] [CrossRef]

- Paini, A.; Lopes, E.; Fiedler, N.; Souza, A.; Rodrigues, C.; Oliveira, F. Postural Analysis and Repetitive Motions of Skidder Operators in Wood Extraction. Sci. For. 2020, 48, e3095. [Google Scholar] [CrossRef]

- Martins, A.; Lopes, E.S.; Pagnussat, M.B.; Fiedler, N.C.; Oliveira, F.M. Upper Limb Posture and Movement during Tracked versus Wheeled Harvester Operation on Pinus Thinning. Int. J. For. Eng. 2020, 31, 263–271. [Google Scholar] [CrossRef]

- Zurita Vintimilla, M.C.; Castro Pérez, S.N.; Borz, S.A. Processing Small-Sized Trees at Landing by a Double-Grip Machine: A Case Study on Productivity, Cardiovascular Workload and Exposure to Noise. Forests 2021, 12, 213. [Google Scholar] [CrossRef]

- Szewczyk, G.; Spinelli, R.; Magagnotti, N.; Mitka, B.; Tylek, P.; Kulak, D.; Adamski, K. Perception of the Harvester Operator’s Working Environment in Windthrow Stands. Forests 2021, 12, 168. [Google Scholar] [CrossRef]

- Yovi, E.Y.; Prasetiana, D.; Nirmalasari, N.A. Work Measurement Study on Motor-Manual Pine Tapping Operation: The Application of the Concept of Lean Manufacturing and Allowances. Indones. J. For. Res. 2021, 8, 111–125. [Google Scholar] [CrossRef]

- Çağlar, S. Work Efficiency and Physical Workload during the Manual Debarking of Scotch Pine Trees. Int. J. For. Eng. 2021, 32, 246–255. [Google Scholar] [CrossRef]

- Staněk, L.; Mergl, V. Whole Body Vibrations during Fully Mechanised Logging. Forests 2022, 13, 630. [Google Scholar] [CrossRef]

- Gejdoš, M.; Hitka, M.; Kampf, R. Anthropometrics Parameters of the Adult Population as Ergonomics Modifier for the Chainsaw Handle. Forests 2022, 13, 645. [Google Scholar] [CrossRef]

- Hnilica, R.; Jankovský, M.; Dado, M. Model Assessment of the Complex Workload of Harvester Operator. Forests 2022, 13, 1196. [Google Scholar] [CrossRef]

- Bačić, M.; Pandur, Z.; Šušnjar, M.; Šporčić, M.; Landekić, M. Daily Vibration Exposure in the Context of State and European Legislature: A Case Study among Chainsaw Operators in Croatia. Forests 2023, 14, 929. [Google Scholar] [CrossRef]

- Lima, R.C.A.; Minette, L.J.; Simões, D.; Rocha, Q.S.; Miyajima, R.H.; Fritz, G.F.; Schettino, S.; Soranso, D.R.; Nascimento, G.S.P.; Vieira, M.P.L.; et al. Measurement Time in the Evaluation of Whole-Body Vibration: The Case of Mechanized Wood Extraction with Grapple Skidder. Forests 2023, 14, 1551. [Google Scholar] [CrossRef]

| Operation | Machine/Tool | Risk Factor |

|---|---|---|

| Pre-harvesting | Pre-harvesting tools | Vibration |

| Harvesting | Manual work/tools | Noise |

| Wood extraction | Chainsaw | Workload 1 |

| Wood transport | Harvester | Postural load |

| Biomass production | Feller buncher | MSD |

| Measuring/managing | Processor | Thermal comfort |

| Controlled tests | Farm tractor | Fatigue |

| Crawler tractor | Human factors | |

| Slash grapple | Gases and particulates | |

| Skidder | Repetitive motion | |

| Forwarder | Illumination | |

| Tower yarder | Visibility | |

| Loader | Cab | |

| Animal | Controls | |

| Timber truck | Seat | |

| Chipper | ||

| Debarker | ||

| Fire wood processor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bačić, M.; Landekić, M.; Pandur, Z.; Šušnjar, M.; Šporčić, M.; Nevečerel, H.; Lepoglavec, K. Forestry Ergonomics Publications in the Last Decade: A Review. Forests 2024, 15, 616. https://doi.org/10.3390/f15040616

Bačić M, Landekić M, Pandur Z, Šušnjar M, Šporčić M, Nevečerel H, Lepoglavec K. Forestry Ergonomics Publications in the Last Decade: A Review. Forests. 2024; 15(4):616. https://doi.org/10.3390/f15040616

Chicago/Turabian StyleBačić, Marin, Matija Landekić, Zdravko Pandur, Marijan Šušnjar, Mario Šporčić, Hrvoje Nevečerel, and Kruno Lepoglavec. 2024. "Forestry Ergonomics Publications in the Last Decade: A Review" Forests 15, no. 4: 616. https://doi.org/10.3390/f15040616

APA StyleBačić, M., Landekić, M., Pandur, Z., Šušnjar, M., Šporčić, M., Nevečerel, H., & Lepoglavec, K. (2024). Forestry Ergonomics Publications in the Last Decade: A Review. Forests, 15(4), 616. https://doi.org/10.3390/f15040616