Preliminary Tests of a Hybrid Cable Splice (Synthetic–Metal) to Innovate Timber Harvesting in the Mediterranean Forestry Sector

Abstract

1. Introduction

- Similar resistance as steel cables, depending on the diameter and composition (EIPS or Swaged), and a much lower weight, about eight or nine times less [25].

- -

- Develop and test a new solution to merge synthetic and wire cables thus creating a “hybrid splice” featuring the benefits of the steel cable in the last few meters (resistance to abrasion) and those of synthetic cable in the remaining portion (lightweight);

- -

- Test in the laboratory the strength of the hybrid splice and, in case of several viable solutions, identify the most suitable for forest hauling;

- -

- Deploy the chosen hybrid cable in commercial forest operations to prove the reliability of the concept and guide its further developments.

2. Materials and Methods

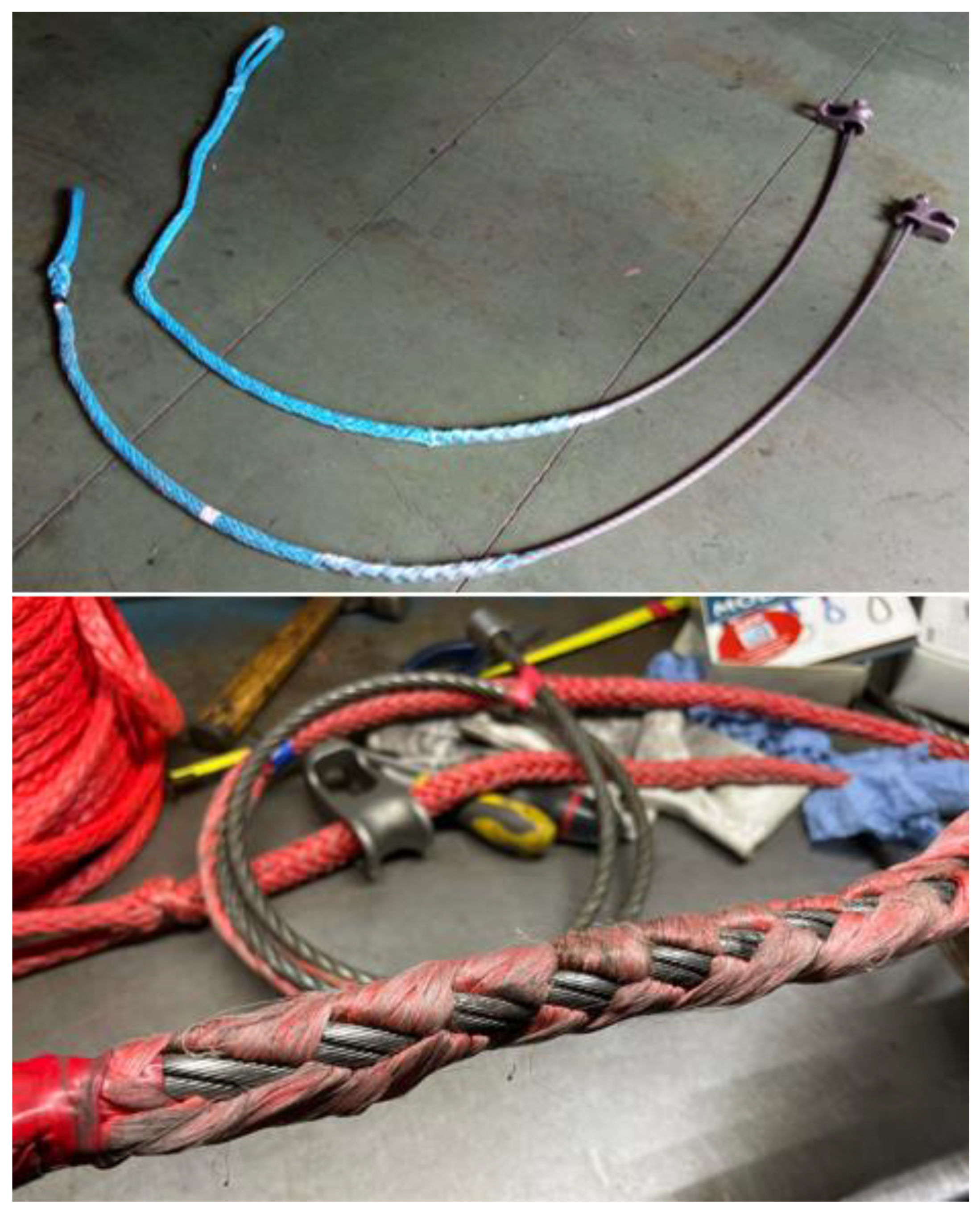

2.1. Hybrid Splice Fabrication

- (1)

- A conic steel core was made by cutting the six strands of the cable at an increasing length (multiples of 10 cm) and following a rotatory order (Figure 2). As a result, moving clockwise, the first strand was cut at 10 cm, and the last one at 60 cm, creating a conic shape with a total length of 60 cm (Figure 3). This was inserted for 90 cm into the synthetic rope and constituted its conic steel core. This last operation can be facilitated by the use of a special needle (Figure 3a).

- (2)

- Braiding of the synthetic and the wire cables was carried out. The first thirty centimeters of synthetic rope was unbraided up to the base of the conic steel core. This area was fixed with a loop of tape to avoid the accidental unbraiding of the synthetic rope (Figure 3b). The loose synthetic strands were joined in three bunches, each with the same number of strands, and braided, intercalated, under two consecutives steel strands (Figure 3c) until each bunch of synthetic strands was completely used (Figure 3d). This was the most complex and time-consuming step of the hybrid splicing. At the end of the process, the hybrid splice featured the conical steel core on one side, the steel cable inside the synthetic rope in the center and the braided part on the other side.

- (3)

- A protective synthetic cover along the entire length of the splice was installed, braiding the cover on one splice side, within the strands of the steel cable and on the other side, with the strands of the synthetic rope. In order to properly adhere to the splice, the highest tension possible was applied on the cover.

- (a)

- Simple steel core (SSC): in this splice, the conic steel core was replaced by the simple core of the original steel cable. All strands were cut at 55 cm, leaving 5 cm between the braided part and the conic steel shape to ensure that the braid would not slip out of place.

- (b)

- Decreased-length conic core (DLCC): the conic steel core was made with the same technique used for the standard core, but the strands were cut every 5 cm instead than every 10 cm. Therefore, the resulting length of the conic steel core was 30 cm instead of 60 cm as for the standard core.

2.2. Laboratory Tests

2.3. Field Study

- -

- Group 1: three crews with a double-drum skidder (pulling force of 140–180 kN for each one), hooking the timber directly with the cable.

- -

- Group 2: seven crews using a farm tractor equipped with a 60–100 kN winch, using chains as the hooking system and, therefore, with choker slides.

- -

- Group 3: two crews using a farm tractor equipped with a 60 kN winch, hooking the timber directly with the cable.

- -

- Group 1: all skidder crews received a new 16 mm diameter synthetic cable featuring a hybrid splice with 10–15 m of 14 mm steel cable. In case of breakage, the crew would continue working with the remaining 16 mm synthetic cable without the splice (no steel component). The second drum of the skidders was left with the common steel cable and was not involved in the study.

- -

- Group 2: four crews received a new synthetic cable of 14 mm diameter featuring a hybrid splice with 5 m of 12 mm steel cable, and the remaining three crews deployed, since the beginning, a synthetic cable without the splice.

- -

- Group 3: one crew used a hybrid splice, while the other worked with the purely synthetic cable.

- -

- Tons extracted by the drum; the data were reported on a daily basis as a cumulative figure (in the case of machines with a double drum, the data were requested for both drums);

- -

- Number of hauling cycles per day (rope pulls);

- -

- Average winching distance (general in the specific work site or on a daily basis);

- -

- Main winching direction (uphill, downhill or both directions);

- -

- Cable damage (meters lost and number of breaks);

- -

- Splice damage (if any);

- -

- Forest stand description (species, slope, type of terrain, silvicultural treatment);

- -

- Distributed presence of stones that might damage the cables (stoniness);

- -

- Further observations.

3. Results

3.1. Laboratory Results

3.2. Forest Work Results

4. Discussion

4.1. Hybrid Splice Fabrication

4.2. Performance in Timber Extraction

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hisano, M.; Searle, E.B.; Chen, H.Y.H. Biodiversity as a Solution to Mitigate Climate Change Impacts on the Functioning of Forest Ecosystems. Biol. Rev. 2018, 93, 439–456. [Google Scholar] [CrossRef] [PubMed]

- Barañano, L.; Unamunzaga, O.; Garbisu, N.; Briers, S.; Orfanidou, T.; Schmid, B.; de Arano, I.M.; Araujo, A.; Garbisu, C. Assessment of the Development of Forest-Based Bioeconomy in European Regions. Sustainability 2022, 14, 4747. [Google Scholar] [CrossRef]

- Bauer, N.; Hilaire, J.; Brecha, R.J.; Edmonds, J.; Jiang, K.; Kriegler, E.; Rogner, H.H.; Sferra, F. Assessing Global Fossil Fuel Availability in a Scenario Framework. Energy 2016, 111, 580–592. [Google Scholar] [CrossRef]

- Tumala, M.M.; Salisu, A.; Nmadu, Y.B. Climate Change and Fossil Fuel Prices: A GARCH-MIDAS Analysis. Energy Econ. 2023, 124, 106792. [Google Scholar] [CrossRef]

- Verkerk, P.J.; Martinez de Arano, I.; Palahí, M. The Bio-Economy as an Opportunity to Tackle Wildfires in Mediterranean Forest Ecosystems. For. Policy Econ. 2018, 86, 1–3. [Google Scholar] [CrossRef]

- Geng, A.; Yang, H.; Chen, J.; Hong, Y. Review of Carbon Storage Function of Harvested Wood Products and the Potential of Wood Substitution in Greenhouse Gas Mitigation. For. Policy Econ. 2017, 85, 192–200. [Google Scholar] [CrossRef]

- Bottalico, F.; Pesola, L.; Vizzarri, M.; Antonello, L.; Barbati, A.; Chirici, G.; Corona, P.; Cullotta, S.; Garfì, V.; Giannico, V.; et al. Modeling the Influence of Alternative Forest Management Scenarios on Wood Production and Carbon Storage: A Case Study in the Mediterranean Region. Environ. Res. 2016, 144, 72–87. [Google Scholar] [CrossRef]

- Imbrenda, V.; Coluzzi, R.; Mariani, F.; Nosova, B.; Cudlinova, E.; Salvia, R.; Quaranta, G.; Salvati, L.; Lanfredi, M. Working in (Slow) Progress: Socio-Environmental and Economic Dynamics in the Forestry Sector and the Contribution to Sustainable Development in Europe. Sustainability 2023, 15, 10271. [Google Scholar] [CrossRef]

- Verkerk, P.J.; Levers, C.; Kuemmerle, T.; Lindner, M.; Valbuena, R.; Verburg, P.H.; Zudin, S. Mapping Wood Production in European Forests. For. Ecol. Manag. 2015, 357, 228–238. [Google Scholar] [CrossRef]

- Moreno, M.; Simioni, G.; Cailleret, M.; Ruffault, J.; Badel, E.; Carrière, S.; Davi, H.; Gavinet, J.; Huc, R.; Limousin, J.M.; et al. Consistently Lower Sap Velocity and Growth over Nine Years of Rainfall Exclusion in a Mediterranean Mixed Pine-Oak Forest. Agric. For. Meteorol. 2021, 308–309, 108472. [Google Scholar] [CrossRef]

- Raddi, A. An Approach to Forest Products Price Series Analysis in Catalonia: The Example of the Scots Pine Trend. Quad. Agrar. 2023, 54–55, 29–45. [Google Scholar] [CrossRef]

- Albizu-Urionabarrenetxea, P.M.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and Health in Forest Harvesting Operations. Diagnosis and Preventive Actions. A Review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Tsioras, P.A. Perspectives of the Forest Workers in Greece. IForest 2010, 3, 118–123. [Google Scholar] [CrossRef]

- Axelsson, S. The Mechanization of Logging Operations in Sweden and Its Effect on Occupational Safety and Health. Int. J. For. Eng. 1998, 9, 25–31. [Google Scholar] [CrossRef]

- Spinelli, R.; Lombardini, C.; Magagnotti, N. The Effect of Mechanization Level and Harvesting System on the Thinning Cost of Mediterranean Softwood Plantations. Silva Fenn. 2014, 48, 1003. [Google Scholar] [CrossRef]

- Magagnotti, N.; Spinelli, R.; Güldner, O.; Erler, J. Site Impact after Motor-Manual and Mechanised Thinning in Mediterranean Pine Plantations. Biosyst. Eng. 2012, 113, 140–147. [Google Scholar] [CrossRef]

- Pucher, C.; Erber, G.; Hasenauer, H. Europe’s Potential Wood Supply by Harvesting System. Forests 2023, 14, 398. [Google Scholar] [CrossRef]

- Vilkriste, L. Necessity and Feasibility to Increase Supply of Timber from the Private Forest Sector in Lativa. In Proceedings of the IUFRO Small-Scale Forestry Conference Synergies and Conflicts in Social, Ecological and Economic Interactions, Freiburg, Germany, 24–28 July 2011. [Google Scholar]

- Poje, A.; Pezdevšek Malovrh, Š.; Krč, J. Factors Affecting Harvesting Intensity in Small-Scale Private Forests in Slovenia. Small-Scale For. 2016, 15, 73–91. [Google Scholar] [CrossRef]

- Spinelli, R.; Aalmo, G.O.; Magagnotti, N. The Effect of a Slack-Pulling Device in Reducing Operator Physiological Workload during Log Winching Operations. Ergonomics 2015, 58, 781–790. [Google Scholar] [CrossRef]

- Magagnotti, N.; Aalmo, G.O.; Brown, M.; Spinelli, R. A New Device for Reducing Winching Cost and Worker Effort in Steep Terrain Operations. Scand. J. For. Res. 2016, 31, 602–610. [Google Scholar] [CrossRef]

- Bont, L.G.; Fraefel, M.; Frutig, F.; Holm, S.; Ginzler, C.; Fischer, C. Improving Forest Management by Implementing Best Suitable Timber Harvesting Methods. J. Environ. Manag. 2022, 302, 114099. [Google Scholar] [CrossRef]

- Labelle, E.R.; Lemmer, K.J. Selected Environmental Impacts of Forest Harvesting Operations with Varying Degree of Mechanization. Croat. J. For. Eng. 2019, 40, 239–257. [Google Scholar] [CrossRef]

- Hartter, J.; Leonard, J.; Garland, J.; Pilkerton, S. Research on Synthetic Rope and Its Future in Timber Harvesting. N. Z. J. For. 2006, 51, 23–30. [Google Scholar]

- Pilkerton, S.J.; Garland, J.J.; Hatter, J. Comparison of Ergonomic Performance for a Skidder Operator Using Steel Wire and Synthetic rope Winch Line. In Proceedings of the Council on Forest Engineering (COFE) Conference Proceeding: “Machines and People, The Interface”, Hot Springs, AK, USA, 27–30 April 2004. [Google Scholar]

- Magagnotti, N.; Spinelli, R. Replacing Steel Cable with Synthetic Rope to Reduce Operator Workload during Log Winching Operations. Small-Scale For. 2012, 11, 223–236. [Google Scholar] [CrossRef]

- Hartter, J. Synthetic Rope End Connections for Use in Timber Harvesting. Int. J. For. Eng. 2006, 17, 39–51. [Google Scholar] [CrossRef]

- Nemestóthy, N. Synthetic Fibre Ropes for Forestry Use—Further Developments in Finding Criteria for the Replacement State of Fibre Ropes. In Proceedings of the FORMEC 2011, 44th International Symposium on Forestry Mechanisation, Graz, Austria, 9–13 October 2011; p. 7. [Google Scholar]

- Kirth, R.; Schiemer, S.; Nemestothy, N.; Sperrer, S. Further Developments of Synthetic Ropes for Logging. In Proceedings of the Austro2007/FORMEC’07: Meeting the Needs of Tomorrows’ Forests—New Developments in Forest Engineering, Vienna and Heiligenkreuz, Austria, 7–11 October 2007; p. 13. [Google Scholar]

- Smeets, P. The Use of High Performance Synthetic Fibers in Ropes for Logging Applications. In Proceedings of the Formec, Vienna, Austria, 8–9 October 2007; pp. 1–11. [Google Scholar]

- de Camargo, F.V.; Guilherme, C.E.M.; Fragassa, C.; Pavlovic, A. Cyclic Stress Analysis of Polyester, Aramid, Polyethylene and Liquid Crystal Polymer Yarns. Acta Polytech. 2016, 56, 402–408. [Google Scholar] [CrossRef]

- Slugeň, J.; Matúška, R. Proposal of Application of Synthetic Ropes in Forestry. Acta Univ. Agric. Silvic. Mendel. Brun. 2014, 62, 581–591. [Google Scholar] [CrossRef]

- Ottaviani, G.; Talbot, B.; Nitteberg, M.; Stampfer, K. Workload Benefits of Using a Synthetic Rope Strawline in Cable Yarder Rigging in Norway. Croat. J. For. Eng. 2011, 32, 561–569. [Google Scholar]

- Canga, E.; Fanjul, A.; Sanchez-Garcia, S.; Alonso-Graña, M.; Majada, J. Replacement of Steel Cable with Synthetic Rope in Mountain Logging Operations in Castanea Sativa Mill. Coppice Stands. For. Syst. 2014, 23, 461–469. [Google Scholar] [CrossRef]

- Nemestóthy, N. Synthetic Fibre Ropes for Forestry Use—Criteria for the Replacement of Fibre Ropes. In Proceedings of the FORMEC 2010, 43th International Symposium on Forest Mechanization, Padova, Italy, 11–14 July 2010; p. 7. [Google Scholar]

- Tusell, J.M.; Rovira, J. Catalunya Forestal 129. Silvicultura i Biodiversitat. Catalunya For. 2016, 128, 1–36, ISSN 2014-0681. [Google Scholar]

- Pilkerton, S.; Garland, J.; Leonard, J.; Sessions, J. Synthetic Rope Use in Logging Winching Applications. In Proceedings of the 2003 Annual Council on Forest Engineering Conference (COFE), Bar Harbor, ME, USA, 7–10 September 2003; p. 6. [Google Scholar]

- Garland, J.J.; Sessions, J.; Pilkerton, M.S.; Stringham, M.B. Using Synthetic Rope to Reduce Workloads in Logging; Oregon State University: Corvallis, OR, USA, 2002. [Google Scholar]

- Pilkerton, S.; Garland, J.J. Rigging and Operations Guide: Use of Synthetic Ropes as Alternatives to Steel Wire Ropes in Logging Applications; Oregon State University: Corvallis, OR, USA, 2004. [Google Scholar]

- Polman, J.-W. Splicing Modern Ropes: A Practical Handbook; Bloomsbury: London, UK, 2016; ISBN 9781472924919. [Google Scholar]

- Harttner, J. Investigation of Synthetic Rope End Connections and Terminations in Timber Harvesting Applications; Oregon State University: Corvallis, OR, USA, 2004. [Google Scholar]

- Garland, J.J.; Leader, P.; Pilkerton, S. Field Testing of Synthetic Rope in Logging Applications to Reduce Workloads Prepared By; Oregon State University: Corvallis, OR, USA, 2004. [Google Scholar]

| Cable Material | Diameter (mm) | Failure Force (kN) | Linear Density (g/m) |

|---|---|---|---|

| Synthetic | 12 | 132.4 | 79.2 |

| Synthetic | 14 | 171.6 | 107.8 |

| Synthetic | 16 | 223.6 | 140.8 |

| Steel | 10 | 104.1 | 570 |

| Steel | 12 | 144.2 | 770 |

| Steel | 14 | 188.6 | 1040 |

| Rope Diameter (mm) | Steel Diameter (mm) | Splice Type | Resistance Strength (kN) | Elongation (mm) | Test Duration (s) | Failure Area | Valid |

|---|---|---|---|---|---|---|---|

| 12 | 10 | SHS | 76.6 | 170 | 85.2 | End of conic steel core | Yes |

| 14 | 12 | SHS | 70.1 | 137 | 66.7 | End of conic steel core | Yes |

| 14 | 12 | SHS | 33 | 112.1 | 54 | Eye splice | No |

| 14 | 12 | SSC | 39 | 206.6 | 97.2 | Braided part | Yes |

| 14 | 12 | SSC | 29.5 | 143 | 69 | Braided part | Yes |

| 14 | 12 | DLCC | 54.6 | 100.2 | 88.1 | End of conic steel core | Yes |

| 14 | 12 | DLCC | 42.7 | 140.1 | 71.4 | End of conic steel core | Yes |

| Group | Splice and Steel Length (m) | Machine | Hooking System | Workdays | Avg. tons per Cycle | Avg. Loads per Day | Avg. Winching Distance (m) | Main Hauling Direction | Stoniness | Wear (n. Breaks/1000 t) 1 | Wear (m Cable Lost/1000 t) | Resistance (tons) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Yes (15 m) | Skidder (140 kN winch) | Directly with the cable | 47 | 0.47 | 20.7 | 44.1 | Uphill | yes | - | - | 462 |

| 1 | No (purely synthetic) | Skidder (180 kN winch) | Directly with the cable | 28 | 0.95 | 23.6 | 35.5 | Both directions | no | 6.4 | 25.5 | - |

| 2 | Yes (5 m) | Tractor (100 kN winch) | Choker slides | 22 | 2.06 | 13.3 | 7.6 | Both directions | yes | - | - | >714.5 |

| 2 | No (purely synthetic) | Tractor (60–80 kN winch) | Choker slides | 71.8 1 | 0.72 1 | 27.1 1 | 26.8 1 | Both directions | no | 11.25 1 | 14.3 1 | - |

| 3 | Yes (10 m) | Tractor (60–80 kN winch, pulley adapted) | Directly with the cable | 74 | 0.21 | 40.8 | 29.4 | Downhill | no | - | - | >676 |

| 3 | No (purely synthetic) | Tractor (60 kN winch) | Directly with the cable | 64 | 0.67 | 21.8 | 47.4 | Uphill | no | 8.5 | 31.9 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alcoverro, G.; Raddi, A.; Picchi, G. Preliminary Tests of a Hybrid Cable Splice (Synthetic–Metal) to Innovate Timber Harvesting in the Mediterranean Forestry Sector. Forests 2024, 15, 246. https://doi.org/10.3390/f15020246

Alcoverro G, Raddi A, Picchi G. Preliminary Tests of a Hybrid Cable Splice (Synthetic–Metal) to Innovate Timber Harvesting in the Mediterranean Forestry Sector. Forests. 2024; 15(2):246. https://doi.org/10.3390/f15020246

Chicago/Turabian StyleAlcoverro, Gerard, Adriano Raddi, and Gianni Picchi. 2024. "Preliminary Tests of a Hybrid Cable Splice (Synthetic–Metal) to Innovate Timber Harvesting in the Mediterranean Forestry Sector" Forests 15, no. 2: 246. https://doi.org/10.3390/f15020246

APA StyleAlcoverro, G., Raddi, A., & Picchi, G. (2024). Preliminary Tests of a Hybrid Cable Splice (Synthetic–Metal) to Innovate Timber Harvesting in the Mediterranean Forestry Sector. Forests, 15(2), 246. https://doi.org/10.3390/f15020246