Abstract

The utilization of wood as a construction material offers inherent advantages, including its renewability, good process property, wide availability, and carbon sequestration. However, its susceptibility to combustion and limited mechanical properties also constrain its applications. In this work, calcium phosphate was in situ deposited in dignified Chinese fir wood, followed by hot-pressed densification. Thermogravimetric analysis (TG) reveals that mineralization and densification alleviate the thermal decomposition and combustion behavior of wood, which greatly promotes the formation of the dense char layer during wood combustion. Therefore, the maximum heat release rate (HRR), total heat release rate (THR), and total smoke production rate (TSP) of the as-prepared mineralized dense wood were significantly reduced by 37%, 32%, and 56% compared with the control one. Further, the mineralized dense wood showed a remarkable enhancement in flexural strength and flexural modulus of elasticity, 203% and 220% higher than the natural wood, respectively. This study demonstrated a straightforward and eco-friendly approach to fabricating structural wood possessing exceptional flame retardancy and mechanical characterization, which holds immense potential for application in energy-efficient green buildings.

1. Introduction

With the continuous advancement of science and technology, a large number of novel building materials have emerged. Despite the exceptional properties exhibited by iron, plastics, and inorganic polymers, their production and utilization contribute significantly to carbon emissions [1]. Wood has been utilized as a structure material since ancient times due to its high strength-to-weight ratio, wide availability, good process properties, and thermo-hygrometric properties [2,3]. Since the global consensus to reduce carbon emissions has come into being, wood has shown new application prospects due to its carbon sequestration capacity. However, its ignition propensity and limited mechanical strength impose limitations on its applicability [4,5,6]. Therefore, it is imperative to explore strategies for improving the fire retardant and mechanical properties of wood while preserving its inherent advantages [7].

The densification of wood represents a highly effective approach to enhance the mechanical properties of low-density wood [8], which could also restrict the infiltration of oxygen and facilitate the formation of carbon, thus improving the flame retardant property of wood. The methods employed for wood densification encompass mechanical compression [9], impregnation [10], and a combination thereof. The mechanical hot compression method offers the advantage of easy operation and has been widely employed. To avoid the brittle failure of wood during the hot compression process, a pretreatment to soften wood is needed. The pretreatment methods mainly include boiling, high-temperature steam, microwave heating, and chemical delignification, etc. The first three involve an increase in heat and moisture, which enables the hemicellulose and lignin to enter a viscous flow state, thus improving the plasticity of wood. The last one partially or completely removes the lignin and hemicellulose, so that the chemical bond between the three main compositions is reduced, resulting in the softening of wood. Because a large number of active sites could be exposed after the removal of lignin and hemicellulose, this method facilitates better interaction between fillers impregnation and wood.

Resins such as phenolic resin are commonly used to impregnate wood, which can greatly enhance the mechanical properties and flame retardance. However, most of the resins come from fossil fuels and show a poor biodegradability, which inevitably impacts the environment. Compared with the impregnation of resins, mineralization is more environmentally friendly. Inorganic salt solutions have been impregnated into the cellular structure of wood and then deposited in situ after drying or chemical reaction. The as-introduced minerals could greatly improve the fire resistance of wood through methods including endothermic degradation, the release of non-combustion gas, and the promotion of wood into carbon [11,12,13].

The primary techniques employed for wood mineralization include direct impregnation, the two-agent diffusion method, layer-by-layer self-assembly, and sol−gel synthesis. The most conventional method employed for wood mineralization is the direct impregnation of minerals, such as silicon dioxide and carbonates. However, due to biomass recalcitrance, mineral particles with submicron sizes are difficult to invade. Further, suffering from a lack of interaction with wood, the as-introduced minerals are easily lost [14]. The sol−gel method involves the impregnation of the mineral precursor and the following gelation and drying, which avoids the blockage of wood holes to a large extent. However, only certain minerals can be loaded in wood, even though this method takes both the reaction mechanism and economic issues into consideration [15]. Layer-by-layer self-assembly (LBL) involves immersing wood alternately in polyelectrolyte solutions with opposite charges, thereby harnessing the principle of electrostatic adsorption to facilitate the formation of a self-assembled film layer composed of polyelectrolytes through multiple immersion cycles [16,17]. In the sol−gel method for wood modification, silanol initially undergoes a reaction with water molecules to generate siloxanes. Subsequently, the condensation of siloxane molecules occurs until they attain a specific molecular weight and precipitate as an insoluble phase, thereby facilitating the preparation of a wood−inorganic composite material [18,19,20]. Vacuum impregnation is widely employed in wood mineralization owing to its operational simplicity [21,22]. For example, Garskaite’s team used this method and successfully obtained in situ phosphate mineral brushite in wood, which effectively improved the flame retardancy of wood. However, sole mineralization has a limited effect to improve the physical and mechanical properties [23]. If the mineralization and hot pressing modification were integrated, it could be inferred that both the flame retardancy and mechanical properties of wood could be improved [8]. Liu’s [24] team employed in situ mineralization of MAP (magnesium ammonium phosphate) minerals within the wood, followed by a combination technique of cold and hot pressing to fabricate compressed wood mineralized dense wood. As a result, the tensile strength and compressive strength of the wood were enhanced by 2.2 times and 1.6 times, respectively. Furthermore, the flame-retardant performance of the wood was significantly improved due to MAP’s inherent fire resistance properties and its catalytic role in forming a carbon layer. This work provides inspiration for further designing and optimizing minerals, mineralization methods, and hot-pressing processes to improve both the flame retardancy and mechanical properties of wood.

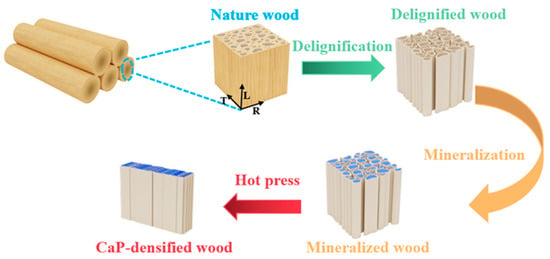

Herein, this work proposes a simple method to fabricate modified wood with an enhanced flame retardancy and mechanical performance, as shown in Figure 1. First, natural wood is partially delignified, which not only enhances the hot-pressing efficiency as mentioned above, but also enlarges the specific surface area for better mineralization. The flame-retardant mineral was then deposited in situ through a calcium phosphate precursor, followed by the hot compress process. The microstructure, chemical components, flammability, and mechanical properties of the as obtained CaP-densified wood were systemically examined. The implementation of this environmentally friendly and viable approach could greatly enhance the fire retardant and mechanical properties of wood, while preserving its inherent advantages, thereby expanding the application potential of wood in green building materials.

Figure 1.

Flow chart for the preparation of modified wood.

2. Materials and Methods

2.1. Materials

The Chinese fir (Cunninghamia lanceolata (Lamb.) Hook.) used in this study was sourced from Quzhou City in Zhejiang Province in China, which had a growth period of 15 years. Only the sapwood portion was utilized in this work, which was processed into several sizes, as detailed in Section 2.5. Sodium hydroxide (NaOH, ≥97%), ammonia (NH3·H2O, 25%), anhydrous calcium chloride (CaCl2, ≥96%), and dipotassium hydrogen phosphate (K2HPO4, ≥99%) were purchased from China Aladdin Co., Ltd. (Shanghai, China).

2.2. Preparation of Partially Delignified Wood (dW)

The natural wood (NW) blocks were immersed in 5% NaOH solution and heated at 80 °C for 5 h for the partial removal of lignin. Then, they were washed with deionized water several times and boiled in water to remove residual reagents. Finally, the samples were step-dried to prevent cracking. In detail, the samples were first dried at 60 °C for 3 h, then kept at 80 °C for another 3 h, and finally kept at 103 °C for 6 h.

2.3. Preparation of Mineralized Wood (CaP-dW)

CaP-dW was fabricated by the in situ deposition of CaP through the step impregnation of precursors, which utilized the “breathing method”. First, dW was immersed in a CaCl2 solution (1.5 mol/L) under vacuum (1 kPa) for 8 h. Afterwards, the sample surface was rinsed with deionized water and dried in an oven at 50 °C for 4 h. Then, the samples were immersed in a K2HPO4 solution (0.9 mol/L) under pressure (0.6 MPa) for 8 h. After mineralization, they were transferred to ammonia water with a pH of 11 to stabilize calcium phosphate precipitation, followed by step drying, as described in Section 2.2, to obtain CaP-dW.

2.4. Preparation of Dense Mineralized Wood (CaP-DdW)

CaP-dW was placed in a constant temperature and humidity box at 20 °C and 65% relative humidity to reach an equilibrium moisture content (EMC) of 14%. A vulcanizing machine (Zhejiang Huzhou Oriental Machinery Co., Ltd., Huzhou, China) was used for hot pressing, with the final thickness and compression rate determined using a 5 mm gauge. After hot pressing at 100 °C for 6 h, the heating was interrupted and the pressure was maintained for 6 h to obtain CaP-DdW. Dense wood (DdW) was prepared using the same method, except for the mineralization process.

2.5. Measurements and Characterization

The morphology and structure of the samples were characterized using scanning electron microscopy (SEM, TM3030, Hitachi, Tokyo, Japan). Before testing, the sample was dried in an oven at 103 °C until its weight remained constant. Then, the sample was sliced into 1 mm thin sections using a blade. The wood’s absolute dry weight was measured using a balance with an accuracy of 0.01 g after drying at 103 °C until its weight remained constant. The height, length, and width were measured using a vernier caliper, and their volumes were calculated. The density of the sample was determined by dividing the mass by the volume. Each sample was measured for five groups, and the results were averaged. The FTIR spectrum was measured using a spectrometer (FTIR, iN10, Thermo Scientific, Waltham, MA, USA) with a wavenumber range of 400–4000 cm−1. Then, 5 mg powder was collected from different parts of wood and dried at 103 °C for 24 h. The samples were tested using the KBr pellet method, and each sample was tested three times. The sample powder was dried thoroughly and subjected to analysis using an X-ray diffractometer (XRD, D2 Phaser, Bruker, Shanghai, China). A copper target was employed as the test ray source, with measurements of 5° to 45° (2θ), and a scanning speed of 5° per minute. The contact angle of water on the sample surface was measured using a video-optical contact angle tester (WCA, OCA50AF, Dataphysics, Beijing, China) with a 5 μL droplet. At least three distinct regions on each sample surface were tested. Thermogravimetric analysis was conducted using a gravimetric analyzer (TG, TG 209 F3 Tarsus, Netzsch, Weimar, Germany). Wood powder was collected from different parts of wood and dried at 103 °C for 24 h. Subsequently, about 10 mg of powder was placed into the alumina crucible and heated from 30 to 800 °C under a nitrogen atmosphere at a heating rate of 10 °C per minute. The limiting oxygen index of the samples was determined using an ultimate oxygen index meter (LOI, JF-3, JueFeng, Shanghai, China) by ISO 4589-2:2017 [25]. Before testing, each group of 10 specimens measuring 100 mm × 10 mm × 5 mm were prepared. The combustion level was determined using a vertical combustion meter (UL94,5402, Vouch, Suzhou, China) according to ISO 9773:1998 [26]. The sample size was 125 mm × 13 mm × 5 mm, and the test included the ignition of each sample twice for 10 s each time with a flame height of 20 mm. The duration of the combustion after each ignition was recorded separately and each group of samples were tested five times. The cone tests were conducted using a cone calorimeter (CONE, 6810, Vouch, China) according to the ISO5660 [27] standard at a heat flux of 35 kW/m2. The specimens were cut into 100 mm × 100 mm × 10 mm, and each set of samples was tested three times to obtain combustion parameters, including the heat release rate (HRR), total heat release (THR), smoke release rate (SPR), and total smoke release (TSP). The mechanical properties were evaluated using a universal mechanical testing machine (5967S2080, INSTRON, Norwood, MA, USA) with the ISO 13061-3:2014 [28] standard. The loading rate for the elasticity tests was set at 1.0 mm/min, and each group consisted of 10 samples, of which the average value was considered as the final result.

3. Result Analysis

3.1. Microstructures

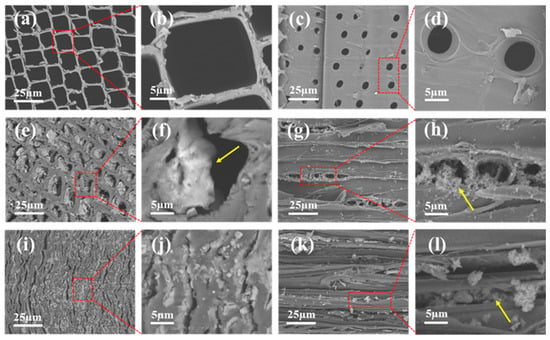

The microscopic morphology of NW, CaP-dW, and CaP-DdW in the cross-section and radial section is depicted in Figure 2. As can be seen, NW is a porous material composed of cell walls and cavities, similar to a honeycomb (Figure 2a,b). To enhance the permeability and softness of wood, a partial delignification treatment was conducted, which did not change the honeycomb-like structure of the cell wall, only resulting in a slight decrease in the thickness of the wall.

Figure 2.

Microstructure of wood specimens. (a,e,i)—SEM images of NW, CaP-dW, and CaP-DdW obtained in the cross-section. (c,g,k)—SEM images of NW, CaP-dW, and CaP-DdW acquired in the radial section. (b,d,f,h,j,l)—enlarged images in the corresponding red rectangles.

After in situ mineralization, the cross-section of CaP-dW is illustrated in Figure 2e,f, where a substantial number of deposits can be observed within the cell lumen. From the radial sections (Figure 2g,h), it can also be seen that the smooth cell wall is attached with minerals, suggesting successful mineral deposition. Further, CaP-dW was subjected to hot pressing, and the thickness was reduced to one-third of the original. It was observed that the wood channels within CaP-DdW were completely collapsed and almost all of the cavity spaces were eliminated (Figure 2i,j), the cellulose fibers in the radial section (Figure 2k,l) exhibited a densely arranged structure along their growth direction, which played a crucial role in enhancing the properties of the modified wood [29].

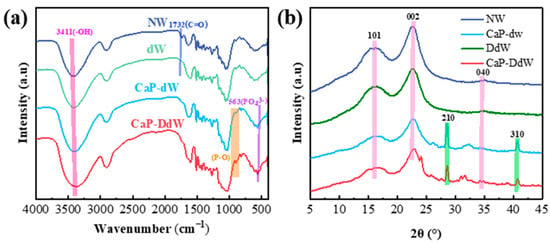

3.2. Chemical Composition Analysis

To reveal the chemical change, the wood samples were further investigated using Fourier-transform infrared (FTIR) spectroscopy. As can be observed in Figure 3a, a strong absorption peak appeared around 3411 cm−1 for all of the samples, which could be ascribed to the stretching vibration of the hydroxyl group [30]. A slight red-shift could be observed in CaP-DdW, indicating the formation of hydrogen bonds after the hot-pressing treatment. The peak located at approximately 1732 cm−1 belonged to the vibrational stretching of C=O in acetyl (CH3C=O) group of xylan, which became undetectable after alkaline treatment, demonstrating the partial removal of hemicellulose [31]. After mineralization, the wood was supposed to exhibit absorption peaks in the range of 850–1000 cm−1, primarily attributed to the P–O stretching vibrations of the HPO4 group [23,32,33]. The inconspicuous phosphate ion absorption peak located at approximately 563 cm−1 was also expected to be observed [34]. However, due to the presence of absorption peaks in the wood at 1150–950 cm−1, which were attributed to the various vibrations of polysaccharides, the characteristic peaks corresponding to mineral groups were not clearly discernible. So, X-ray diffractometer tests were also conducted to further explore the formation of minerals.

Figure 3.

The chemical composition of wood samples showcasing the FTIR spectra (a) and XRD spectra (b).

To further explore the formation of minerals, X-ray diffractometer tests were also conducted. The X-ray diffraction pattern of wood is depicted in Figure 3b. It is obvious that three distinct diffraction peaks appeared around 15.9°, 22.8°, and 34.7° for all of the wood samples, which corresponded to the (101), (002), and (040) planes of the cellulose crystal, respectively [31,35,36,37]. After the alkaline treatment, the intensities of the diffraction peaks were reduced, while no significant alteration was observed in the peak positions. This phenomenon could be attributed to the swelling of the crystalline cellulose region by the NaOH solution [38]. After mineralization, CaP-dW and CaP-DdW exhibited additional diffraction peaks at approximately 28.5° and 40.7°, respectively. These two peaks corresponded to the (210) and (310) plane of the hydroxyapatite crystals, respectively. In addition, the peaks at around 31.5° could be ascribed to the mixed peaks of hydroxyapatite crystals [23,39,40,41]. It can be inferred that calcium phosphate mineral precipitate was in situ formed inside the wood through impregnation using the “breathing method” [23,34].

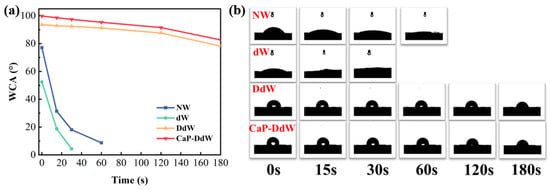

3.3. Wettability Properties Analysis

The inherent hydrophilicity of wood renders it susceptible to decay in humid environments and compromises its mechanical stability, thereby impeding its practical applications. The water contact angle of the material was measured to investigate the alteration in its wettability before and after modification, and the results are recorded in Figure 4. As could be seen, the water contact angle (WCA) of NW was 77° at 0 s, indicating it as being inherently hydrophilic. As it is known, wood is mainly formed through the multistage assembly of cellulose hemicellulose and lignin, the former two of which contains abundant polar hydroxyl groups, while lignin contains a non-polar benzene ring. When lignin is partially removed, more hydrophilic groups are exposed. Consequently, in comparison with NW, dW exhibits an enhanced hydrophilicity with a contact angle of 52°. While the WCA of NW remained at 10° after one minute, almost the whole water droplets penetrated dW within 30 s. As for DdW, the initial WCA was 93°, which diminished slowly to 87° after 2 min. This could be attributed to the heat degradation of hydroxyl groups on the wood surface, as well as densification, which reduced the micro-porous structure of the wood [9]. The contact angle of the wood was further enhanced by the co-treatment of in situ mineralization and hot press modification. At 0 s, the contact angle of the wood surface was 99°, which decreased to 91° after 2 min. This value represented a high level that was superior to DdW. The primary factor lay in the obstruction of wood pores by the generated calcium phosphate minerals. The reinforcing the hydrophobic characteristics of wood facilitated its broader utilization in moist environments.

Figure 4.

The results of the water contact angle test on wood samples: the curve of water contact angle change (a) and a picture illustrating the change in contact angle (b).

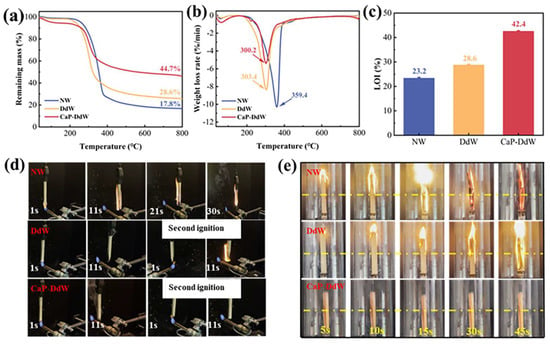

3.4. Thermal Stability Analysis

The thermal stability of the modified wood was evaluated using a thermogravimetric analyzer. The TG (Figure 5a) and DTG (Figure 5b) curves of NW, DdW, and CaP-DdW were obtained. The initial stage, occurring below 150 °C, involved weight loss attributed to the evaporation of water and volatile compounds. Subsequently, the main volatilization stage occurred within a temperature range of 200–500 °C, which could be attributed to the thermal decomposition of cellulose, hemicellulose, and certain lignin components [42]. The DTG curves exhibited prominent peaks at 359.4 °C, 303.4, °C and 300.2 °C for NW, DdW, and CaP-DdW, respectively, implying that both hot pressing and mineralization exhibited a decelerating effect on the extent and velocity of thermal wood degradation. After the third pyrolysis stage to a temperature of 800 °C, the final residue masses of the NW, DdW, and CaP-DdW were determined to be 17.8%, 28.6%, and 44.7%, respectively. The residue mass predominantly comprised the residual carbon generated during lignin pyrolysis [43]. The 60.67% higher residue mass of DdW than NW could be ascribed to the obstruction of mass transfer because of the denser structure. As the entry of air and the release of combustible micromolecular were all impeded, more incomplete combustion was generated [44]. Further combining the mineralization, CaP-DdW exhibited another 90.45% higher residue mass than NW. This could be attributed to both the flame-retarding effect of calcium phosphate and the higher ash content after the third pyrolysis stage.

Figure 5.

The results of thermal stability, vertical burning rating, and limiting oxygen index tests conducted on wood samples: TG (a), DTG (b), UL−94 (c), LOI (d), and burning pictures at a 30% oxygen concentration (e).

3.5. Flame Retardant Property Analysis

3.5.1. LOI and UL−94 Analysis

The flame retardancy of NW, DdW, and CaP-DdW were evaluated using LOI and UL−94. Figure 5d illustrates the results obtained from the LOI test, while Figure 5e describes the flame images of wood samples at various stages of a 30% concentration in combustion oxygen index tests. The UL−94 test outcomes are presented in Figure 5c and Table 1. In an environment with a 30% oxygen concentration, NW exhibited a burning length of more than 5 cm within 10 s, and the LOI was only 23.2%. According to the UL−94 test, NW was classified as no grade due to its tendency for complete combustion following the initial ignition. After delignification and densification, the wood sample was extinguished once the initial 10 s of ignition was terminated. However, after the 10 s ignition period, DdW sustained combustion for over 30 s, resulting in a burning length of 5 cm, indicating an absence of UL−94 rating for DdW. CaP-DdW could not be ignited after two 10 s ignitions at an oxygen concentration of 30%, indicating that CaP-DdW reached a V-0 level according to UL−94 standards. The LOI of CaP-DdW was 42.4%, approximately 19% higher than that of NW. The significant increase in LOI was attributed to the highly dense interlayer structure after compaction and in situ mineralization, which impeded the touchtone between the wood interior and combustible gases [45]. Moreover, the CaP minerals could also enhance the char formation of wood compounds [46].

Table 1.

Vertical burning rating test results of wood samples.

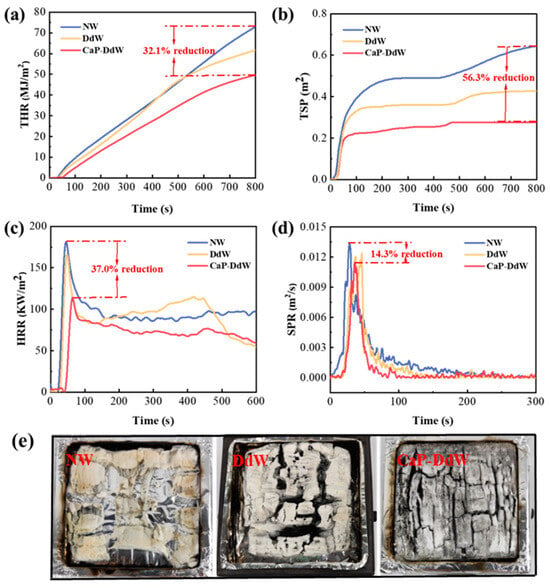

3.5.2. Cone Calorimeter Analysis

The burning behavior of wood samples in a fire was characterized by a cone calorimeter. As shown in Table 2, the time to ignition (TTI) of NW was 17 s, whereas DdW and CaP-DdW exhibited TTI values of 31 s and 48 s, respectively. The longer TTI illustrated that thermocompression and mineralization resulted in wood being more difficult to ignite. Further, the peaks of the first heat release rate (HRRpk1) of DdW and CaP-DdW were 7.9% and 37.1% lower than that of DW (Figure 6c), respectively. During the combustion phase, a protective layer was rapidly formed by DdW and CaP-DdW through the surface carbonization (Figure 6e). This layer effectively impeded the rapid release of combustible gases during thermal decomposition, thereby mitigating the heat release rate (HRR) [47]. After compressing the wood cells, the porosity and interstitial spaces within the dense wood layer were significantly reduced. Calcium phosphate salts catalyzed CaP-DdW pyrolysis to form a stable char layer.

Table 2.

Cone calorimetry results of the wood samples.

Figure 6.

Cone calorimetry curves of wood samples: THR (a), TSP (b), HHR (c), and THR (d). The residual structures of NW, DdW, and CaP-DdW after CONE testing (e).

During combustion, minerals were embedded within this char layer, thereby augmenting its flame-retardant properties. This charcoal layer not only provided exceptional thermal insulation, but also effectively impeded the ingress of the external oxygen, thereby preventing further pyrolysis and reducing the rate of heat release from the mineralized wood [12]. The THR curves of DdW and CaP-DdW (Figure 6a) exhibited similar trends to NW but with lower values, measuring 61.4 MJ/m2 for DdW and 49.5 MJ/m2 for CaP-DdW, respectively. These values were found to be lower 15.7% and 32% than that observed for NW at 72.8 MJ/m2, indicating a synergistic effect between densification and mineral enhancement for improving the flame-retardant properties [48].

Smoke release behavior plays a crucial role in wood safety. NW exhibited rapid gas emission during combustion, with the smoke release (Figure 6d) occurring early on (1–100 s), with an NW smoke release rate (SPRpk) of 0.0133 m2/s. Then, the smoke released gradually diminished, resulting in a final cumulative smoke generation (Figure 6b) of 0.64 m2. Compared with NW, both DdW and CaP-DdW exhibited a decrease in the peak smoke release rate (SPRpk) of 0.0123 m2/s and 0.0114 m2/s, representing reductions of 7.5% and 14.3%, respectively. The smoke generations were measured to be 0.42 m2 for DdW and 0.28 m2 for CaP-DdW, indicating a reduction of 34.4% and 56.2%, respectively. The findings suggested that both dense and mineralized modifications exhibited exceptional smoke suppression properties due to their lower rate of mass loss during combustion compared with NW. This resulted in a reduced intensity of combustion, with decreased production of combustible and non-combustible volatiles and an increased amount of residual char produced [16].

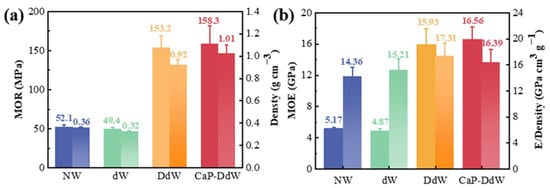

3.6. Mechanical Performance Analysis

To investigate the effects of the densification and mineralization modifications on wood, a comparative analysis of the mechanical properties of wood specimens was conducted. The variations in adiabatic density, modulus of elasticity (MOE), and modulus of rupture (MOR) for cedar wood under different treatment conditions are illustrated in Figure 7. The density of NW was initially 0.36 g cm−3, which decreased to 0.32 g cm−3 after the delignification treatment and it subsequently increased to 0.92 g cm−3 due to the compression. Through in situ mineralization and subsequent hot pressing, the density further increased to 1.01 g cm−3, indicating successful mineral generation within the wood pores and a remarkable density increase compared with NW.

Figure 7.

Physical and mechanical properties of wood samples: MOR (a) and MOE (b).

The mechanical properties of wood were investigated by examining the modulus of rupture and modulus of elasticity, with a focus on the effects of densification and mineralization. Compared with NW, a slight decrease in mechanical strength was observed after partial delignification. This could be ascribed to the impairing of the synergistic interactions between lignin and hemicellulose, as well as the partial degradation of woody macromolecules after alkali treatment [49]. The flexural strengths of DdW and CaP-DdW were 153.2 MPa and 158.3 MPa, respectively, exhibiting a significant enhancement by factors of 3 and 3.1 compared with that of NW. Figure 7b illustrates the E-values and E/densities for NW (5.17 GPa and 14.36 GPa cm3 g−1), DdW (15.93 GPa and 17.31 GPa cm3 g−1), and CaP-DdW (16.56 GPa and 16.39 GPa cm3 g−1). The slight disparity in the mechanical properties of DdW and CaP-DdW could be attributed to the inherent brittleness of calcium phosphate salt minerals. The compressive strength was influenced not only by their composition, crystallinity, and particle size, but it was also significantly affected by the specific conditions under which the material underwent formation [23]. The formation of a substantial number of repetitive hydrogen bonds between cellulose and cellulose hydroxyl groups during the hot-pressing process is pivotal for augmenting the mechanical properties, thereby playing a crucial role in fortifying the strength and toughness of wood [50]. Furthermore, hot pressing significantly enhanced the wood’s density, effectively mitigating its initial defects and resulting in a substantial enhancement in both the MOR and MOE of the modified wood.

4. Conclusions

In this study, CaP-DdW was prepared through the in situ deposition of calcium phosphate salt minerals in delignified wood, followed by densification via wood hot pressing. Calcium phosphate salt minerals were injected into wood pores primarily physically. The conical calorimetric and flexural tests revealed a remarkable enhancement in both the refractory and mechanical properties of CaP-DdW. The decomposition of calcium phosphate salts catalyzed the formation of a protective charcoal layer in the wood, which effectively hindered heat transfer from the surface to the interior and restricted the release of pyrolytic combustible gases. Consequently, this mechanism safeguarded the internal structure and preserved the excellent mechanical properties of wood under high flame exposure. The material CaP-DdW exhibited significant potential for sustainable and energy-efficient building applications. Because of cost-effective and environmentally conscious manufacturing, it effectively addressed the mechanical strength limitations associated with conventional wood mineralization.

Author Contributions

Conceptualization, Y.P. and Y.Y.; data curation, J.Y. and Y.Q.; formal analysis, J.Y. and Y.Q.; funding acquisition, Y.P. and Y.Y.; methodology, J.Y. and Y.Y.; project administration, Y.Y.; resources, H.C.; supervision, Y.P. and Y.Y.; validation, J.Y. and S.Z.; visualization, J.Y. and S.Z.; writing—original draft, J.Y. and S.Z.; writing—review and editing, H.C. and Y.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was grateful for financial support from the National Natural Science Foundation of China (grant no. 32071684) and the Talent Startup Project of the Scientific Research and Development Foundation of Zhejiang A&F University (no. 2021LFR068).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhu, C.; Tan, H.; Du, C.; Wang, J.; Deng, X.; Zheng, Z.; He, X. Enhancement of ultra-fine slag on compressive strength of solid waste-based cementitious materials: Towards low carbon emissions. J. Build. Eng. 2023, 63, 105475. [Google Scholar] [CrossRef]

- Pramreiter, M.; Nenning, T.; Malzl, L.; Konnerth, J. A plea for the efficient use of wood in construction. Nat. Rev. Mater. 2023, 8, 217–218. [Google Scholar] [CrossRef]

- Fu, Q.; Chen, Y.; Sorieul, M. Wood-based flexible electronics. ACS Nano 2020, 14, 3528–3538. [Google Scholar] [CrossRef]

- Yue, K.; Wu, J.; Xu, L.; Tang, Z.; Chen, Z.; Liu, W.; Wang, L. Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Constr. Build. Mater. 2020, 241, 118101. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Ali, M.R.; Abdullah, U.H.; Ashaari, Z.; Hamid, N.H.; Hua, L.S. Hydrothermal modification of wood: A review. Polymers 2021, 13, 2612. [Google Scholar] [CrossRef]

- Kamperidou, V.; Barboutis, I.; Vasileiou, V. Influence of thermal treatment on mechanical strength of scots pine (Pinus sylvestris L.) wood. Wood Res. 2014, 59, 373–378. [Google Scholar] [CrossRef]

- Fan, C.; Gao, Y.; Li, Y.; Yan, L.; Zhu, D.; Guo, S.; Ou, C.; Wang, Z. A flame-retardant densified wood as robust and fire-safe structural material. Wood Sci. Technol. 2023, 57, 111–134. [Google Scholar] [CrossRef]

- Chen, C.; Tu, D.; Zhou, Q.; Zhou, J.; Wang, X.; Cherdchim, B.; Ou, R. Development and evaluation of a surface-densified wood composite with an asymmetric structure. Constr. Build. Mater. 2020, 242, 118007. [Google Scholar] [CrossRef]

- Wang, J.; Yao, Y.; Huang, Y.; Ma, Y.; Xi, J.; Wang, X.; Li, H.; Yang, Z. Effects of the combination of compression and impregnation with phenolic resin on the dimensional stability in the multiscale wood structure of Chinese fir. Constr. Build. Mater. 2022, 327, 126960. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Yang, T.; Wang, Z.; Xia, M.; Zhang, M.; Liu, D.; Yuan, G. Mineralizing wood with chitosan–silica to enhance the flame retardant and physical-mechanical properties. J. Sol-Gel Sci. Technol. 2023, 107, 57–69. [Google Scholar] [CrossRef]

- Zhou, H.; Wen, D.; Hao, X.; Chen, C.; Zhao, N.; Ou, R.; Wang, Q. Nanostructured multifunctional wood hybrids fabricated via in situ mineralization of zinc borate in hierarchical wood structures. Chem. Eng. J. 2023, 451, 138308. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Wang, Z.; Zhang, M.; Liu, D.; Yuan, G. Bioinspired mineralized wood hydrogel composites with flame retardant properties. Mater. Today Commun. 2022, 31, 103479. [Google Scholar] [CrossRef]

- Qiu, Z.; Lang, L.Z.; Yu, Z.Y.; Zhu, J.Y.; Ye, Y.H.; Zou, Y.; Xie, Y.J.; Jiang, F. Scalable Production of Robust and Tough Biomimetic Composite by Rapid In-Situ Mineralization. Adv. Funct. Mater. 2023, 34, 2310096. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Wang, Z.H.; Zhang, M.Y.; Liu, D.; Yuan, G.M. Study on properties of gelatin-silica mineralized wood composite. Polym. Compos. 2022, 43, 4371–4381. [Google Scholar] [CrossRef]

- Yang, T.; Xia, M.; Chen, S.; Mu, M.; Yuan, G. Enhancing the thermal stability of silica-mineralized wood via layer-by-layer self-assembly. J. Therm. Anal. Calorim. 2021, 145, 309–318. [Google Scholar] [CrossRef]

- Wan, Y.; Hou, S.; Guo, M.; Fu, Y. Surface properties of spray-assisted layer-by-layer electrostatic self-assembly treated wooden take-off board. Appl. Sci. 2021, 11, 836. [Google Scholar] [CrossRef]

- Dong, X.; Zhuo, X.; Wei, J.; Zhang, G.; Li, Y. Wood-based nanocomposite derived by in situ formation of organic–inorganic hybrid polymer within wood via a sol–gel method. ACS Appl. Mater. Interfaces 2017, 9, 9070–9078. [Google Scholar] [CrossRef] [PubMed]

- Qian, T.; Dang, B.; Chen, Y.; Jin, C.; Qian, J.; Sun, Q. Fabrication of magnetic phase change n-eicosane@ Fe3O4/SiO2 microcapsules on wood surface via sol-gel method. J. Alloys Compd. 2019, 772, 871–876. [Google Scholar] [CrossRef]

- Li, X.; Gao, L.; Wang, M.; Lv, D.; He, P.; Xie, Y.; Zhan, X.; Li, J.; Lin, Z. Recent development and emerging applications of robust biomimetic superhydrophobic wood. J. Mater. Chem. A 2023, 11, 6772–6795. [Google Scholar] [CrossRef]

- Pondelak, A.; Škapin, A.S.; Knez, N.; Knez, F.; Pazlar, T. Improving the flame retardancy of wood using an eco-friendly mineralisation process. Green Chem. 2021, 23, 1130–1135. [Google Scholar] [CrossRef]

- Sun, Z.; Zuo, Y.; Li, P.; Wu, Y.; Wang, Z.; Li, X.; Lyu, J. Hyperbranched organic-inorganic co-modification improves the strength, dimensional stability, and thermal stability of poplar wood. Ind. Crops Prod. 2023, 191, 115923. [Google Scholar] [CrossRef]

- Garskaite, E.; Balciunas, G.; Drienovsky, M.; Sokol, D.; Sandberg, D.; Bastos, A.C.; Salak, A.N. Brushite mineralised Scots pine (Pinus sylvestris L.) sapwood–revealing mineral crystallization within a wood matrix by in situ XRD. RSC Adv. 2023, 13, 5813–5825. [Google Scholar] [CrossRef]

- Liu, X.; Fang, X.; Sun, C.; Zhang, T.; Wang, K.; Dong, Y. Hybrid Wood Composites with Improved Mechanical Strength and Fire Retardance Due to a Delignification–Mineralization–Densification Strategy. Forests 2023, 14, 1567. [Google Scholar] [CrossRef]

- ISO 4589-2:2017; Plastics-Determination of Burning Behaviour by Oxygen Index. Part 2: Ambient-Temperature Test. ISO: Geneva, Switzerland, 2017.

- ISO 9773:1998; Determination of Burning Behaviour of Thin Flexible Vertical Specimens in Contact with a Small-Flame Ignition Source. ISO: Geneva, Switzerland, 1998.

- ISO5660; Heat Release, Smoke Production and Mass Loss Rate. Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). ISO: Geneva, Switzerland, 2015.

- ISO 13061-3-2014; Physical and Mechanical Properties of Wood-Test Methods for Small Clear Wood Specimens. Part 3: DETERMINATION of Ultimate Strength in Static Bending. ISO: Geneva, Switzerland, 2014.

- Luan, Y.; Fang, C.-H.; Ma, Y.-F.; Fei, B.-H. Wood mechanical densification: A review on processing. Mater. Manuf. Process. 2022, 37, 359–371. [Google Scholar] [CrossRef]

- Ma, C.-Y.; Wang, H.-M.; Wen, J.-L.; Shi, Q.; Wang, S.-F.; Yuan, T.-Q.; Sun, R.-C. Structural elucidation of lignin macromolecule from abaca during alkaline hydrogen peroxide delignification. Int. J. Biol. Macromol. 2020, 144, 596–602. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Peng, H.; Gu, Q.; Zhang, X.; Liu, X.; Dong, Y.; Cai, Y.; Li, Y.; Li, J. Scalable, large-size, and flexible transparent bamboo. Chem. Eng. J. 2023, 451, 138349. [Google Scholar] [CrossRef]

- Hirsch, A.; Azuri, I.; Addadi, L.; Weiner, S.; Yang, K.; Curtarolo, S.; Kronik, L. Infrared absorption spectrum of brushite from first principles. Chem. Mater. 2014, 26, 2934–2942. [Google Scholar] [CrossRef]

- Mirković, M.M.; Pašti, T.L.; Došen, A.M.; Čebela, M.; Rosić, A.A.; Matović, B.; Babić, B.M. Adsorption of malathion on mesoporous monetite obtained by mechanochemical treatment of brushite. RSC Adv. 2016, 6, 12219–12225. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, Z.; Zhao, Y.; Kong, K.; Pan, H.; Xu, X.; Tang, R.; Liu, Z. A flexible and degradable hybrid mineral as a plastic substitute. Adv. Mater. 2022, 34, 2107523. [Google Scholar] [CrossRef] [PubMed]

- Garvey, C.J.; Parker, I.H.; Simon, G.P. On the interpretation of X-ray diffraction powder patterns in terms of the nanostructure of cellulose I fibres. Macromol. Chem. Phys. 2005, 206, 1568–1575. [Google Scholar] [CrossRef]

- Guan, H.; Cheng, Z.; Wang, X. Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano 2018, 12, 10365–10373. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Q.; Yin, Y.; Pu, J. Fire retardancy of graphene oxide/wood composite (GOW) prepared by a vacuum-pulse dipping technique. Holzforschung 2018, 72, 375–378. [Google Scholar] [CrossRef]

- Ding, D.; Zhou, X.; You, T.; Zhang, X.; Zhang, X.; Xu, F. Exploring the mechanism of high degree of delignification inhibits cellulose conversion efficiency. Carbohydr. Polym. 2018, 181, 931–938. [Google Scholar] [CrossRef]

- Boudemagh, D.; Venturini, P.; Fleutot, S.; Cleymand, F. Elaboration of hydroxyapatite nanoparticles and chitosan/hydroxyapatite composites: A present status. Polym. Bull. 2019, 76, 2621–2653. [Google Scholar] [CrossRef]

- Jin, X.; Chen, X.; Cheng, Y.; Wang, L.; Hu, B.; Tan, J. Effects of hydrothermal temperature and time on hydrothermal synthesis of colloidal hydroxyapatite nanorods in the presence of sodium citrate. J. Colloid Interface Sci. 2015, 450, 151–158. [Google Scholar] [CrossRef]

- Grigoraviciute-Puroniene, I.; Stankeviciute, Z.; Ishikawa, K.; Kareiva, A. Formation of calcium hydroxyapatite with high concentration of homogeneously distributed silver. Microporous Mesoporous Mater. 2020, 293, 109806. [Google Scholar] [CrossRef]

- Torun, S.B.; Cavdar, A.D.; Ozdemir, T. The synergistic effect of intumescent coating containing titanium dioxide and antimony trioxide onto spruce and alder wood species. J. Build. Eng. 2020, 31, 101407. [Google Scholar] [CrossRef]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.-P. The effect of the biomass components lignin, cellulose and hemicellulose on TGA and fixed bed pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Gan, W.; Chen, C.; Wang, Z.; Song, J.; Kuang, Y.; He, S.; Mi, R.; Sunderland, P.B.; Hu, L. Dense, self-formed char layer enables a fire-retardant wood structural material. Adv. Funct. Mater. 2019, 29, 1807444. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H.; Wang, C.; Wang, Z.; Liu, D.; Yang, T.; Deng, Z.; Yuan, G. Performance enhancement of the poplar wood composites biomimetic mineralized by CaCO3. ACS Omega 2022, 7, 29465–29474. [Google Scholar] [CrossRef]

- Franke, T.; Hinterleitner, C.; Maillard, A.; Nedelkoska, E.; Volkmer, T. The impact of moisture on salt treated and 2-step mineralized wood. Holzforschung 2023, 77, 541–553. [Google Scholar] [CrossRef]

- He, L.; Bao, G.; Jin, X.; Zhang, R.; Qin, D. Eco-friendly in-situ mineralization of bamboo for flame retardancy. Ind. Crops Prod. 2023, 197, 116644. [Google Scholar] [CrossRef]

- Meng, D.; Wang, K.; Wang, S.; Qiu, Y.; Gu, X.; Sun, J.; Li, H.; Zhang, S. Preparation of ultra-flame retardant wood materials with mechanical reinforcement and water resistance through biomimetic mineralization of carbonated apatite. Cellulose 2023, 30, 525–537. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.; Huang, Q.; Yang, F.; Wang, Y.; Wang, J. Study on the properties of partially transparent wood under different delignification processes. Polymers 2020, 12, 661. [Google Scholar] [CrossRef]

- Burgert, I.; Cabane, E.; Zollfrank, C.; Berglund, L. Bio-inspired functional wood-based materials–hybrids and replicates. Int. Mater. Rev. 2015, 60, 431–450. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).