Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum camphora)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composition Analysis

2.3. The Process of Manufacturing BFIB

2.4. Microstructure Study

2.5. Characterization of the Crystallinity

2.6. Compaction Rate

2.7. Bonding Strength Test

2.8. Moisture Resistance

2.9. The Thermal Insulation Properties

2.10. Fire Behavior

2.11. Data Analysis

3. Results and Discussion

3.1. Lignocellulosic Analysis

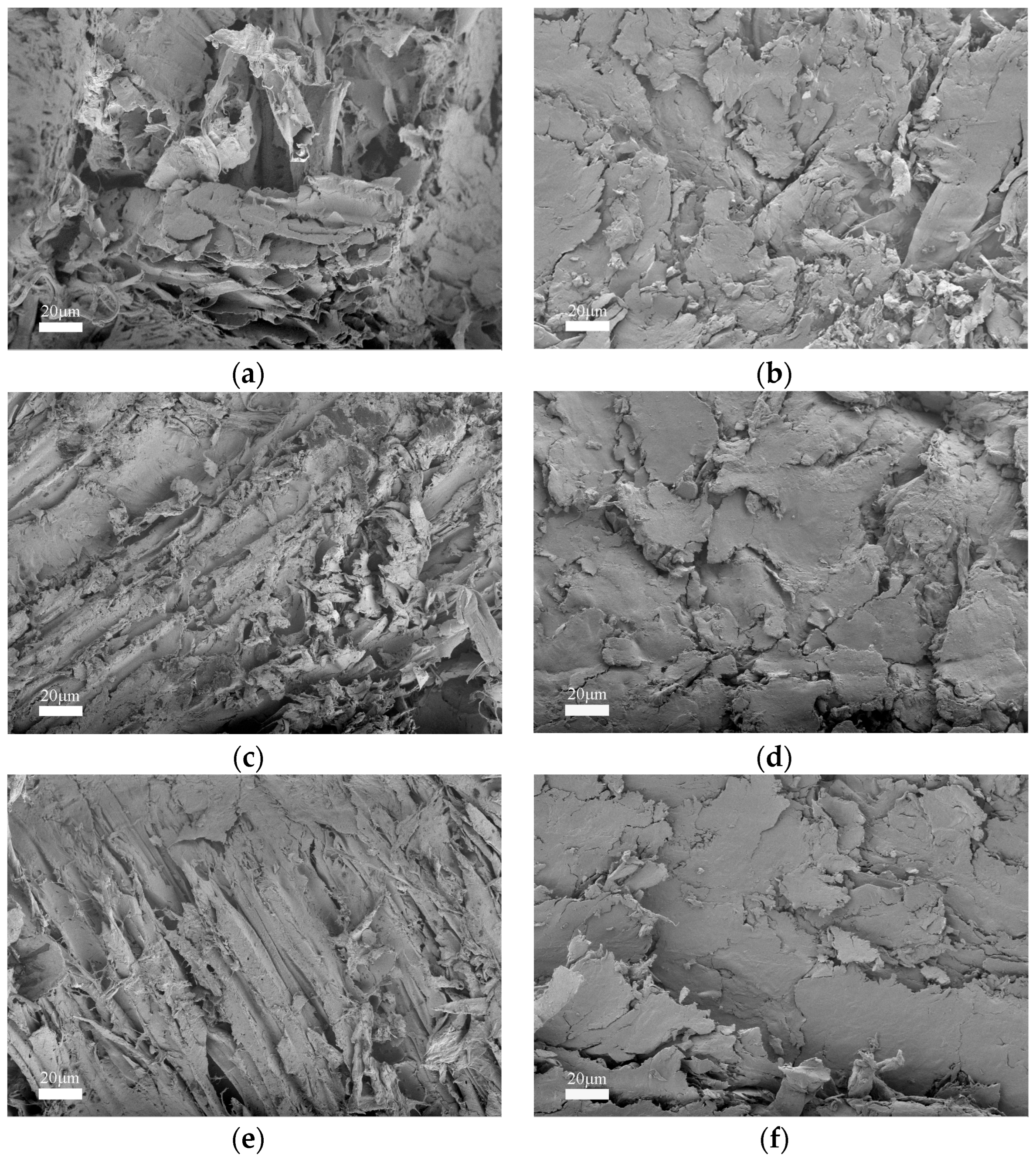

3.2. SEM Imaging

3.3. Wide-Angle X-ray Diffraction (WAXD) Analysis

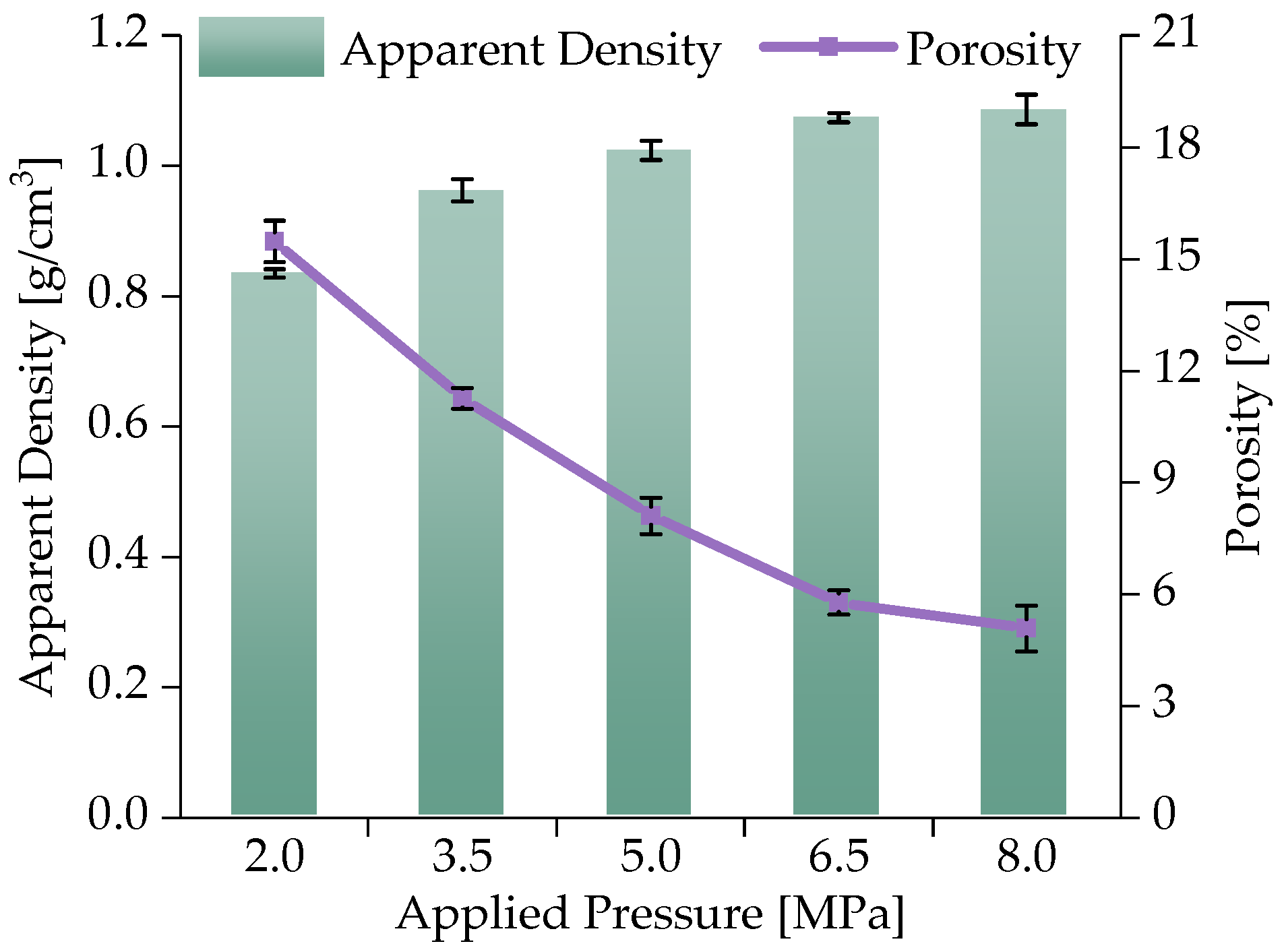

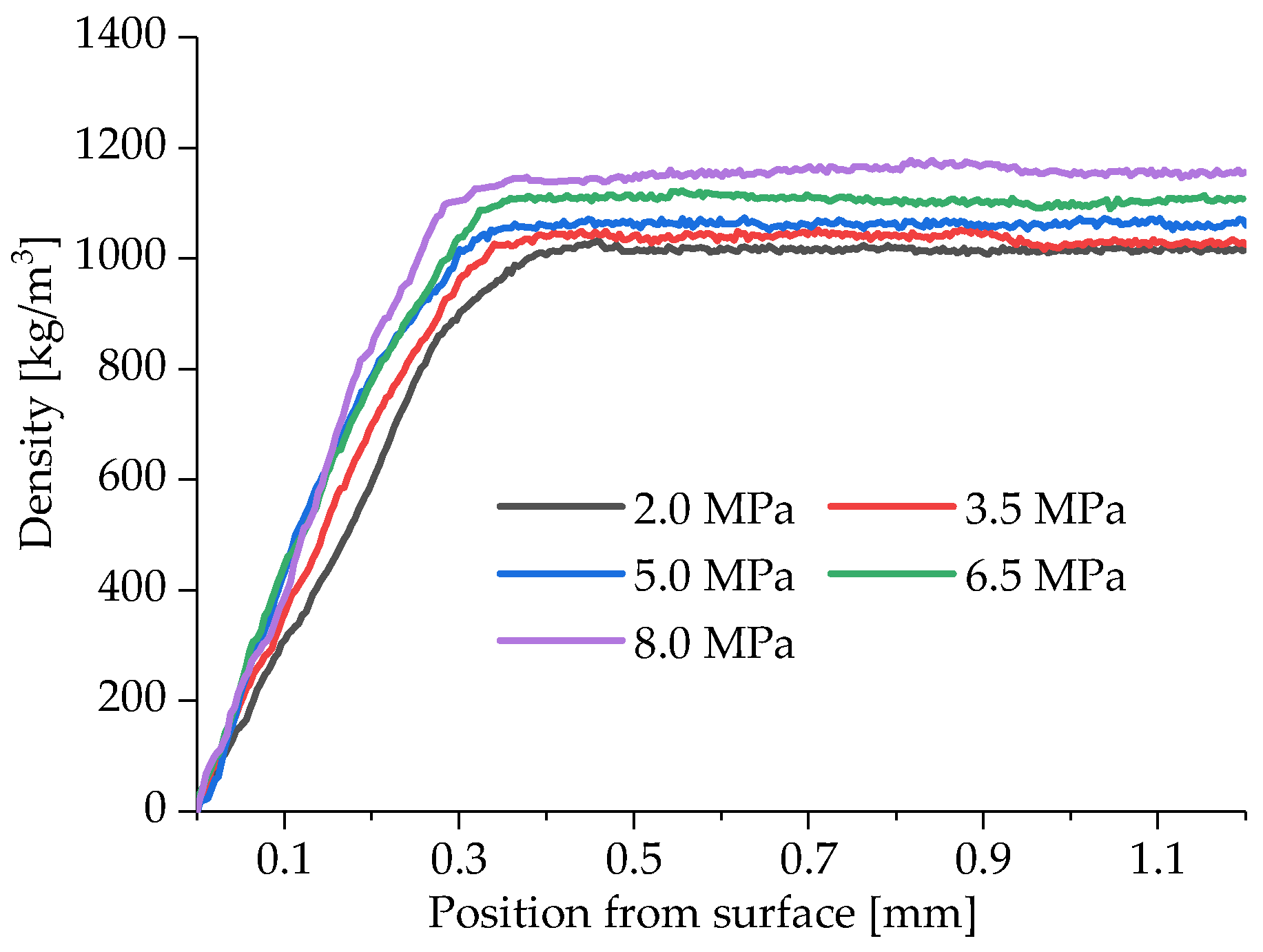

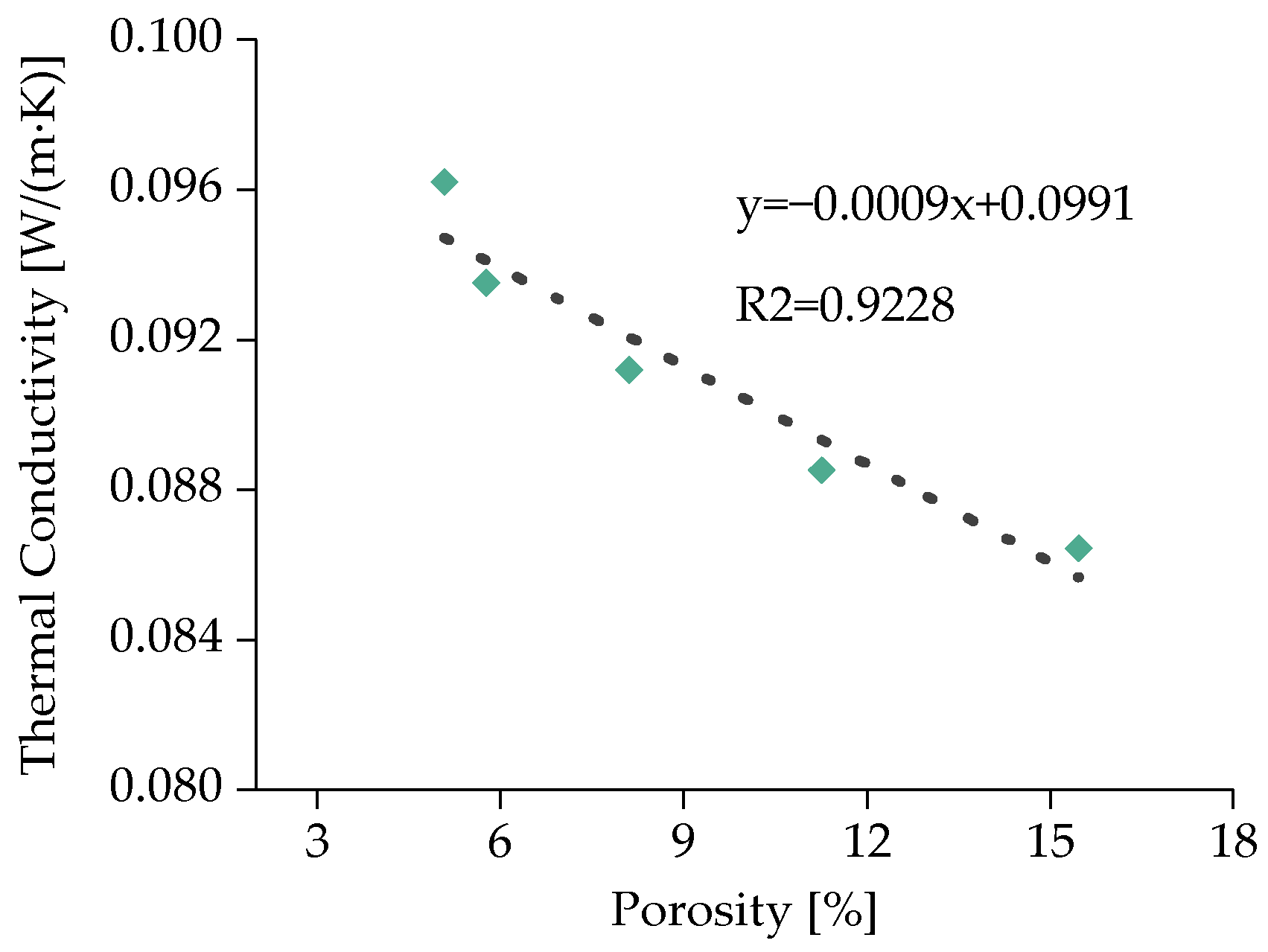

3.4. Porosity Measurement

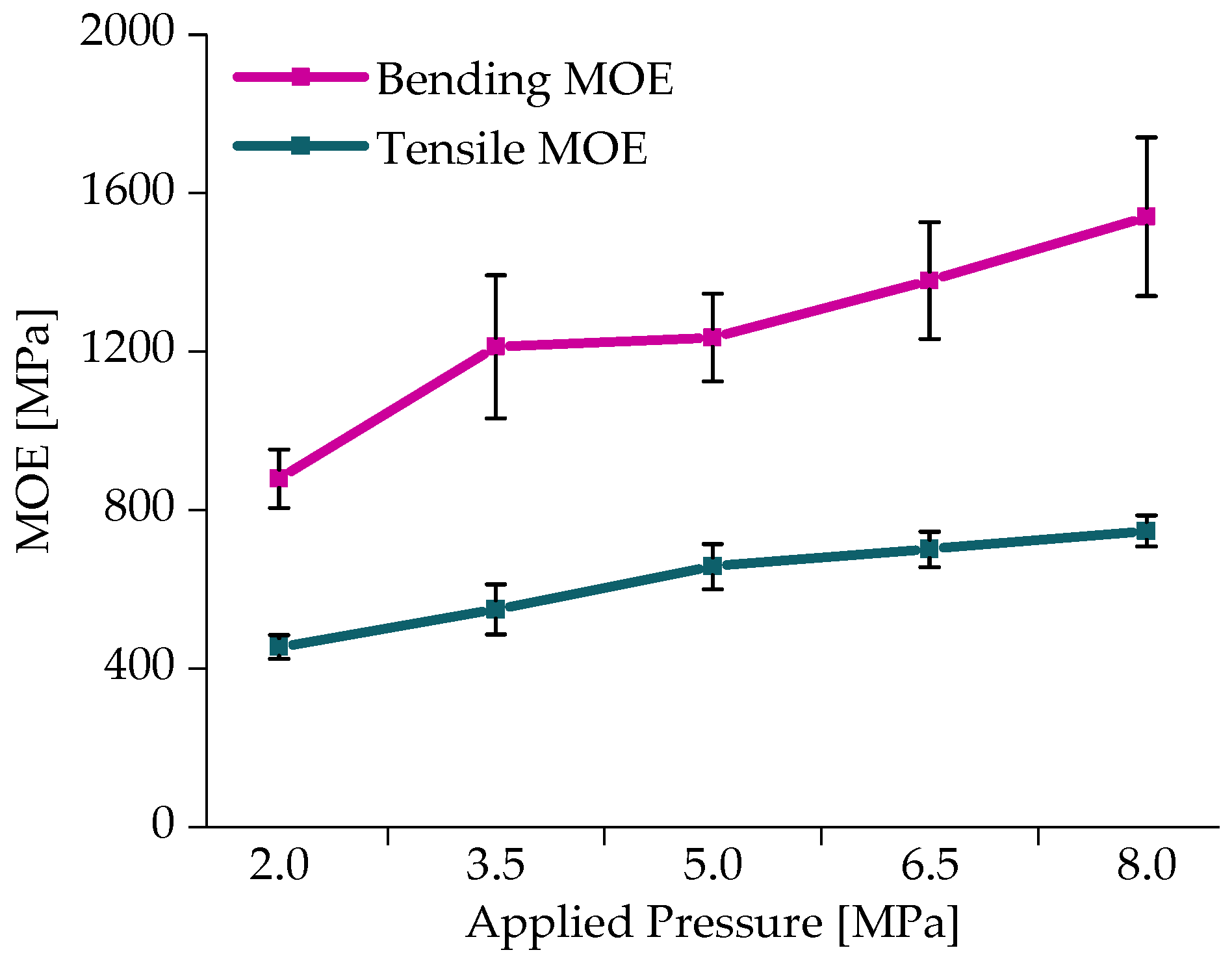

3.5. Mechanical Properties

3.6. Water Vapor Permeability

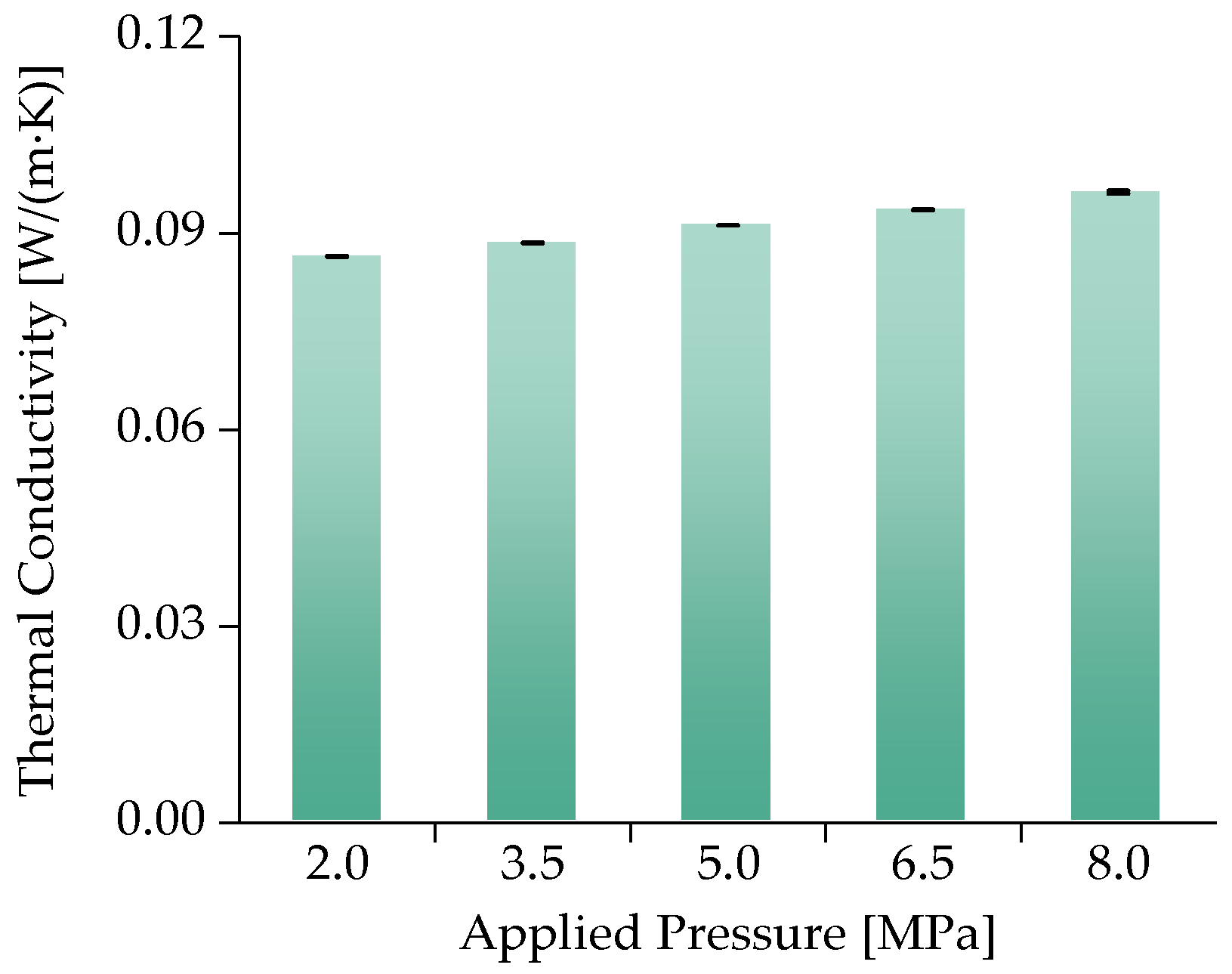

3.7. Thermal Conductivity Measurement

3.8. Limiting Oxygen Index (LOI)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Public Information and Research Project on Electricity Supply and Demand Measures in 2018. Available online: https://www.meti.go.jp/meti_lib/report/H30FY/000385.pdf (accessed on 18 October 2023).

- Zhou, X.Y.; Zheng, F. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and ther future mal building insulation materials and solutions–Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Khedari, J.; Nankongnab, N. New low-cost insulation particleboards from mixture of durian peel and coconut coir. Build. Environ. 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Khedari, J.; Charoenvai, S. New insulating particleboards from durian peel and coconut coir. Build. Environ. 2003, 38, 435–441. [Google Scholar] [CrossRef]

- Binici, H.; Eken, M.; Kara, M. An environment-friendly thermal insulation material from sunflower stalk, textile waste and stubble fibers. In Proceedings of the International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20 October 2013. [Google Scholar]

- Paiva, A.; Pereira, S. A contribution to the thermal insulation performance characterization of corn cob particleboards. Energy Build. 2012, 45, 274–279. [Google Scholar] [CrossRef]

- Thomson, A.; Walker, P. Durability characteristics of straw bales in building envelopes. Constr. Build. Mater. 2014, 68, 135–141. [Google Scholar] [CrossRef]

- Shea, A.; Wall, K. Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build Serv. Eng. Res. Technol. 2013, 34, 369–380. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C. Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol-JMRT 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D. Alternative lignocellulosic raw materials in particleboard production: A review. Ind. Crop. Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Ferreira, G.; Thiex, N. Symposium review: Fiber and in vitro methods, analytical variation, and contributions to feed analysis. J. Dairy Sci. 2023, 106, 4464–4469. [Google Scholar] [CrossRef] [PubMed]

- Miranda, M.T.; Arranz, J.I. Energetic characterization of densified residues from Pyrenean oak forest. Fuel 2009, 88, 2106–2112. [Google Scholar] [CrossRef]

- El Oudiani, A.; Chaabouni, Y. Crystal transition from cellulose I to cellulose II in NaOH treated Agave americana L. fibre. Carbohydr. Polym. 2011, 86, 1221–1229. [Google Scholar] [CrossRef]

- Segal, L.G.J.M.A.; Creely, J.J. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- JIS A. 5905; Japanese Industrial Standards. Fiberboards: Tokyo, Japan, 2014.

- McCurdy, C.; Dixion, D. A Comparison of the Sealing, Forming and Moisture Vapour Transmission Properties of Polylactic Acid (PLA), Polyethene (PE) and Polyethylene Terephthalate (PET) Coated Boards for Packaging Applications. J. Packag. Technol. Res. 2022, 6, 91–100. [Google Scholar] [CrossRef]

- JIS Z. 0208; Japanese Industrial Standards, Testing Methods for Determination of the Water Vapour Transmission Rate of Moisture−Proof Packaging Materials (Dish Method). Fiberboards: Tokyo, Japan, 1976.

- ISO 22007-6; Comparative Method for Low Thermal Conductivities Using a Temperature-Modulation Technique. International Organization for Standardization: Geneva, Switzerland, 2014.

- JIS K 7201-2; Japanese Industrial Standards, Plastics−Determination of Burning Behaviour by Oxygen Index−Part 2: Ambient-Temperature Test. Fiberboards: Tokyo, Japan, 2007.

- Field, A.P. Discovering Statistics Using SPSS: (and Sex, Drugs and Rock’N’Roll). No Title 2005, xxxiv. Available online: https://cir.nii.ac.jp/crid/1370848662539321089 (accessed on 18 October 2023).

- Song, X.; Wang, X. Effects of heating temperature on the properties of bio-board manufactured by using soybean straw. Materials 2020, 13, 662. [Google Scholar] [CrossRef]

- Nasir, M.; Khali, D.P. Recent development in binderless fiber-board fabrication from agricultural residues: A review. Constr. Build. Mater. 2019, 211, 502–516. [Google Scholar] [CrossRef]

- Shi, J.; Zhong, T. Eco-friendly and special-shaped bamboo binderless fiberboards fabricated by self-bonding technology: Effect of bamboo fibers with different sizes. Ind. Crop. Prod. 2023, 194, 116300. [Google Scholar] [CrossRef]

- Yin, J.; Yuan, T. Effect of compression combined with steam treatment on the porosity, chemical compositon and cellulose crystalline structure of wood cell walls. Carbohydr. Polym. 2017, 155, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.P.; Guo, M.H. Influence of ammonium lignosulfonate on the mechanical and dimensional properties of wood fiber biocomposites reinforced with polylactic acid. Ind. Crop. Prod. 2015, 78, 48–57. [Google Scholar] [CrossRef]

- Ji, X.; Dong, Y. Environment-friendly wood fibre composite with high bonding strength and water resistance. R. Soc. Open Sci. 2018, 5, 172002. [Google Scholar] [CrossRef] [PubMed]

- Rebolledo, P.; Cloutier, A. Effect of density and fiber size on porosity and thermal conductivity of fiberboard mats. Fibers 2018, 6, 81. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- Boruszewski, P.; Borysiuk, P. The influence of laccase modifications of lignin on the properties of biocomposites from natural-fiber material with lignins as binder. In Proceedings of the International Conference on Environmental Engineering and Applications (ICEEA 2011), San Francisco, CA, USA, 21 October 2011. [Google Scholar]

- Quintana, G.; Velasquez, J. Binderless fiberboard from steam exploded banana bunch. Ind. Crop. Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Ramos, D.; El Mansouri, N.E. All-lignocellulosic fiberboard from steam exploded Arundo donax L. Molecules 2018, 23, 2088. [Google Scholar] [CrossRef]

- Pfundstein, M.; Gellert, R. Statutory instruments and insulating material standards. In Insulating Materials: Principles, Materials, Applications, 1st ed.; Christina, S., Ed.; Birkhäuser: Munich, Germany, 2008; pp. 59–74. [Google Scholar]

- Sonderegger, W.; Niemz, P. Thermal conductivity and water vapour transmission properties of wood-based materials. Eur. J. Wood Wood Prod. 2009, 67, 313–321. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- JIS A. 5908; Japanese Industrial Standards. Particleboards: Tokyo, Japan, 2015.

- Xu, J.; Sugawara, R. Manufacture and properties of low-density binderless particleboard from kenaf core. J. Wood Sci. 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Zou, N.Y. Thermal Insulation Materials for Wall and Roof; Chemical Industry Publish House: Beijing, China, 2008. [Google Scholar]

- Suleiman, B.M.; Larfeldt, J. Thermal conductivity and diffusivity of wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Li, B.; He, J. Investigation of mechanical property, flame retardancy and thermal degradation of LLDPE–wood-fibre composites. Polym. Degrad. Stabil. 2004, 83, 241–246. [Google Scholar] [CrossRef]

- Lau, H.L.; Lamaming, J. Synergistic influence of flame retardant additives and citric acid on the functional properties of rice husk/wood blended particleboards. Maderas-Cienc. Tecnol. 2021, 37, 1–10. [Google Scholar] [CrossRef]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

| Applied Pressure | Heating Temperature | Hot-Press Time |

|---|---|---|

| 2.0 MPa | 110 °C | 2.0 h |

| 3.5 MPa | ||

| 5.0 MPa | ||

| 6.5 MPa | ||

| 8.0 MPa |

| Cellulose (%) | Hemicellulose (%) | Lignin (%) | Reference | |

|---|---|---|---|---|

| Camphor branches | 44.14 ± 1.01 | 20.15 ± 0.43 | 19.18 ± 1.12 | |

| Camphor trunk | 49.87 ± 1.17 | 19.98 ± 0.54 | 18.76 ± 1.03 | |

| Cotton stalk | 39.16 | 13.38 | 25.74 | [3] |

| Soybean straw | 35 | 17 | 21 | [25] |

| LOI Level | Ignitability |

|---|---|

| ≤22 | Combustible |

| 23–27 | Self-extinguishing |

| ≥27 | Fire retardant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Z.; Song, X.; Wang, X.; Guo, T.; Takahashi, H.; Cai, C. Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum camphora). Forests 2024, 15, 156. https://doi.org/10.3390/f15010156

Cai Z, Song X, Wang X, Guo T, Takahashi H, Cai C. Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum camphora). Forests. 2024; 15(1):156. https://doi.org/10.3390/f15010156

Chicago/Turabian StyleCai, Ziyi, Xiaowen Song, Xiulun Wang, Tongxin Guo, Hiroshi Takahashi, and Changqing Cai. 2024. "Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum camphora)" Forests 15, no. 1: 156. https://doi.org/10.3390/f15010156

APA StyleCai, Z., Song, X., Wang, X., Guo, T., Takahashi, H., & Cai, C. (2024). Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum camphora). Forests, 15(1), 156. https://doi.org/10.3390/f15010156