Abstract

The IML PD series Resi is an instrument designed to measure the drilling resistance of wood. Use of the IML PD series Resi instrument is rapidly becoming a routine method among Australian forest plantation growers for wood quality assessments. The major driver in the commercial uptake of the IML Resi is that it is fast, cheap, and sufficiently precise for commercial use, particularly when the data are processed through a user-friendly, web-based processor. This study examined whether the accuracy of wood density predictions was impacted by the use of different Resi tools and different operators, which has never been examined before. Seven Resi instruments were evaluated across six sites with two operators on plantation-grown Southern Pine (Pinus caribaea var. hondurensis (Sénéclauze) or hybrids between Pinus elliottii var. elliottii (Engelm) × P. caribaea var. hondurensis) trees. Two types of Resi instruments were used (IML Resi PD-400 and IML Resi PD-500), and all had been recently serviced or were new. The instruments were operated by experienced operators. Constant sampling conditions of feed speed 200 cm/min and 3500 RPM were used. The order of instrument use, and hence the order of operator assessment at each site, was randomized. The variance between Resi instruments was small. The measured mean basic density of 50 mm outerwood cores across all plots was 542 kg/m3, while Resi-predicted basic density varied among instruments between 535 and 547 kg/m3. One Resi instrument underpredicted basic density by 9 kg/m3 and another overpredicted by 5 kg/m3. The operator had no effect on the basic density prediction. Resi PD400 or PD500 instruments gave similar basic density predictions.

1. Introduction

Mobile resistance drilling, using thin needles to inspect trees, timber, and structures, has been in development since 1987 [1,2,3,4]. The drilling resistance method using the IML PD series Resi instrument is now commonly used in Australian forestry for standing tree wood quality assessment, driven by its speed, cost-effectiveness, and precision, particularly when complemented by web-based trace processing platforms, offering affordable field applications and high-resolution data [5,6]. The Resi works by driving a 3 mm wide triangular spade-type bit on a 1.5 mm needle-like shaft through a tree at a constant forward feed speed (cm/min) and rotation rate/revolutions per minute (rpm). The Resi measures resistance to the turning of the spade bit at 0.1 mm intervals at a scale from 0 to 100% [7,8].

The drilling resistance method has been used extensively in scientific studies for wood density assessment, primarily in tree breeding [9,10,11,12,13,14], but also to evaluate wood property variation within trees [15,16], to quantify the effects of silviculture and environment on wood properties [17,18], and to assess tree growth rate [19]. Drilling resistance is strongly correlated with mean stand density data obtained through SilviScan analyses, increment cores, and at the individual sample level [2,6,15,16,20,21,22].

As the drilling resistance method becomes common within the forestry sector, it is important to consider the potential inconsistencies in predicted basic density measurements that could arise when different instruments are used. Many forest growers and processors are using multiple Resi instruments with different operators for wood quality assessment at different sites or to complete measurements more rapidly. However, it remains uncertain as to whether variations in operator, instrument type (PD400 vs. PD500), or the specific Resi tool used might influence the accuracy of wood quality measurements obtained through this technique.

The specific questions this study addresses are as follows:

- Do recently serviced Resi instruments have statistically different slopes in the relationship between Resi values and basic density?

- Is there an effect of operator and instrument type on Resi-predicted basic density?

2. Materials and Methods

2.1. Resi Instruments

Seven Resi instruments were evaluated across six different sites with two operators on plantation-grown Southern Pine (Pinus caribaea var. hondurensis (Sénéclauze)(PCH) or hybrids between Pinus elliottii var. elliottii (Engelm) × PCH) trees. There were two types of Resi instruments used (IML Resi PD-400 and IML Resi PD-500 (IML System GmbH, Wiesloch, Germany) (Table 1)). All instruments were recently serviced or new. The instruments were operated by experienced operators. All Resi instruments were fitted with new 3.14 (±0.01) mm diameter needles. Constant sampling conditions of feed speed 200 cm/min and 3500 RPM were used. The order of instrument use, and hence the order of operator assessment at each site, was randomized. Instruments 1 to 5 were tested in April, but instrument 6 was only available in June, and instrument 7 and the newly serviced Resi instrument 1 were tested in November.

Table 1.

The Resi instruments, types, and measurement times.

2.2. Site Selection

The sites were selected to represent a wide range of Resi amplitude values in trees at or near final harvest age across HQPlantations’ (https://www.hqplantations.com.au/, accessed on 10 December 2023) Toolara estate in Southeast Queensland, Australia. The plots sampled three Southern Pine taxa and varied from 27 to 33.9 years of age at the time of testing (Table 2).

Table 2.

Sites selection and description where the different instruments were tested.

2.3. Tree Selection and Sampling Positions and Coring

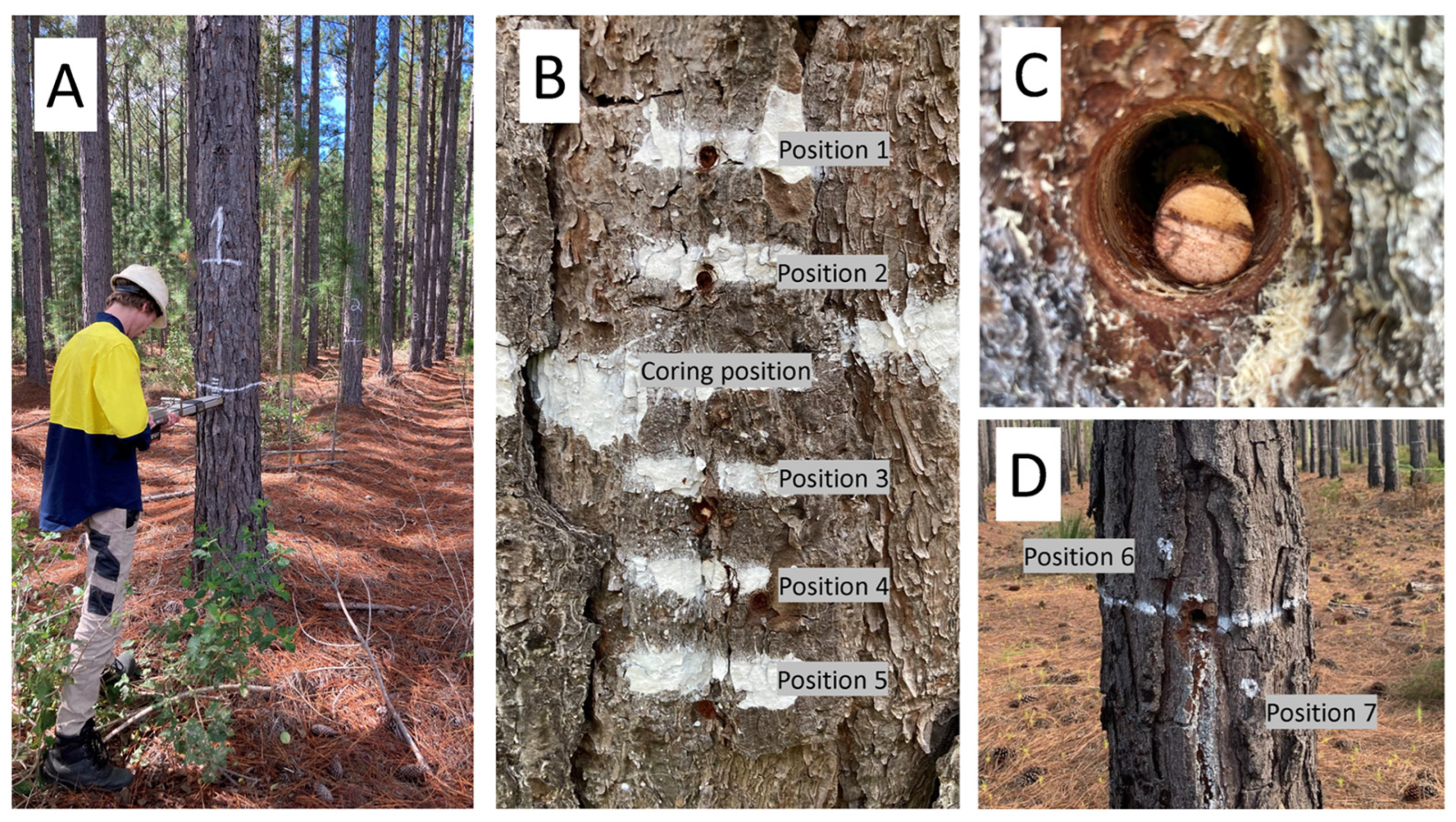

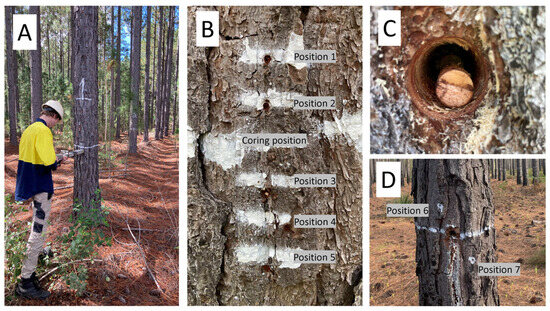

Thirty trees were selected per site, in three rows of ten trees each, rejecting trees with obvious defects at or around breast height that could impact Resi predictions (Figure 1A). Where possible, trees exceeding 400 mm in bark diameter were avoided to maximize the number of full-diameter traces possible from the study.

Figure 1.

(A) Sampling trees at DBH 1.3 m with Resi in the plot. (B) Allocated sampling and coring positions on the tree with visible Resi holes. (C) Drilled 12 mm diameter and 50 mm length core in the outerwood in the tree. (D) Additional Resi sampling positions added after the core has been taken.

On each tree, 6 paint rectangles were marked, with each spot vertically separated by 20 mm. The third rectangle from the top was at the 1.3 m line on the tree and used for taking a 50 mm outerwood cores to allow calibration of the Resi tools against outerwood basic density (Figure 1B). For instrument 6, the sampling positions were randomly located either 20 mm above position 1 or 20 mm below position 5. For instrument 7, and for repeated measurement of instrument 1, sampling positions were randomly selected as position 6 or 7 (Figure 1D), located 50 mm above and 40 mm to the side of previous positions, to avoid the potential effects of resin bleed resulting from the earlier samplings. The position of the Resi sampling on the tree was randomized and a restricted randomization was used to ensure that operator effects could be tested.

To compare Resi values with basic density, outerwood cores were collected for each tested tree across the sites. A 12 mm diameter, a 50 mm long core free from bark, knot, and damage was taken using a Hilti 36-volt power drill (Hilti, Schaan, Liechtenstein) with a custom designed core during May 2022 (Figure 1C). All cores were labelled, sealed inside Ziploc bags, placed in a chilled icebox until returned to the laboratory, then stored in a −20 °C freezer until they could be processed.

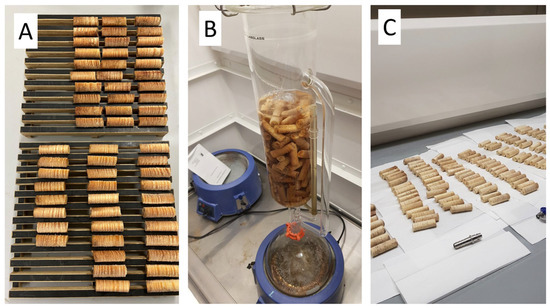

2.4. Core Extractives Removal and Basic Density Measurements

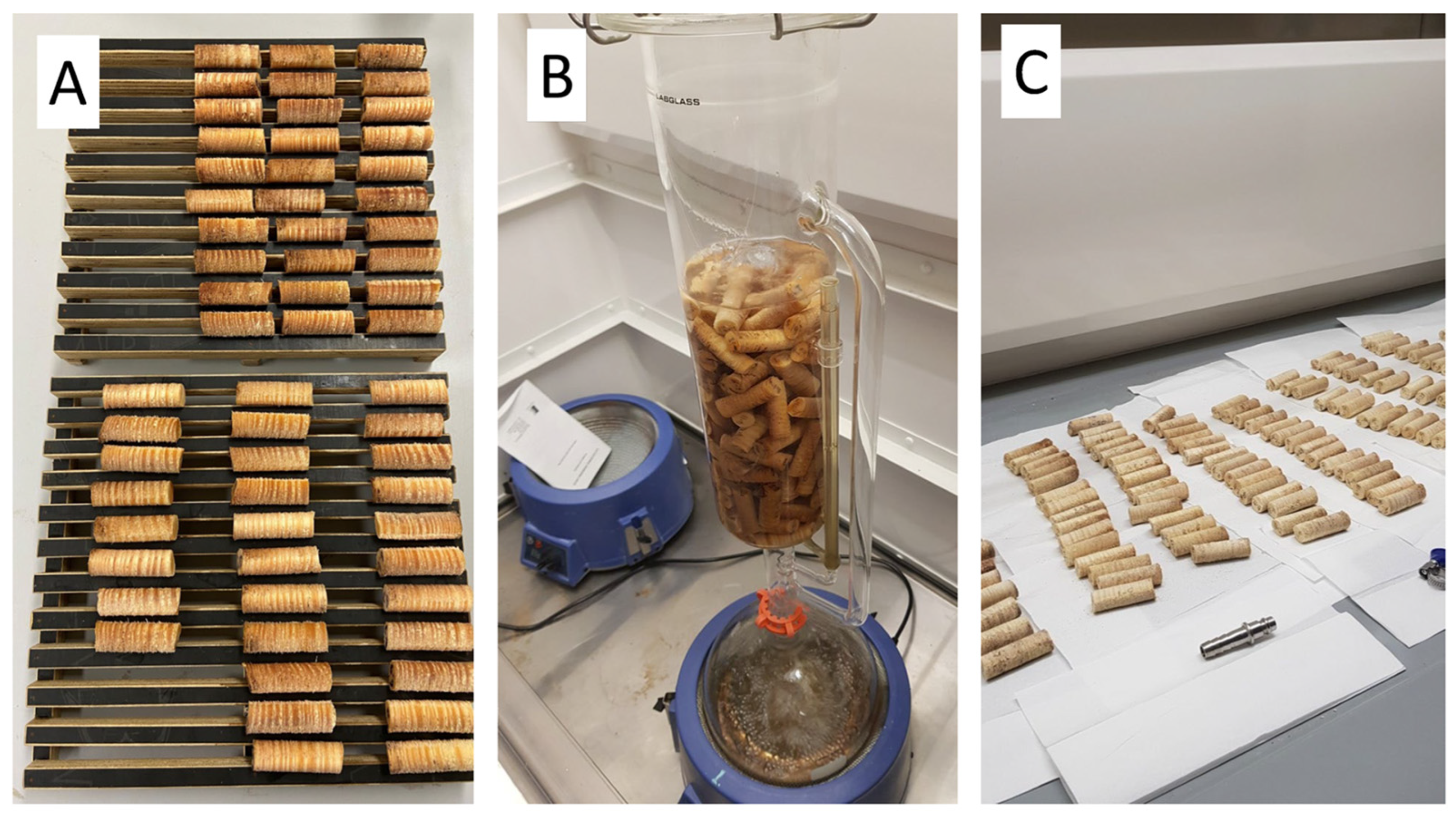

Cores were defrosted and green volume measured in the laboratory using the water displacement method [23]. Removal of extractives in the cores was carried out in a soxhlet extraction apparatus as described by Browning [24] (Figure 2), using a solution of acetone, toluene, and ethanol, mixed in a 4:1:1 ratio. The cores were refluxed for 48 h. After extraction, core basic density was determined using the test method described in AS/NZS 1080.3:2000 [25]. Oven-dry mass was measured after drying at 103 ± 2 °C until the cores reached constant mass. The basic density of the cores was calculated as the ratio of oven dry mass (kg) to green volume (m3).

Figure 2.

(A) Green 50 mm length and 12 mm diameter cores before extraction. (B) Removing extractives using a soxhlet extraction apparatus set up in a fume hood. (C) Cores after extractives have been removed.

2.5. Data Analysis

Six cores were eliminated from the data as outliers based on green volume or density metrics. This resulted in 48 Resi traces (6 × 8 Resi traces) from the associated trees being discarded from the analysis. Resi traces were manually checked for correct positioning of entry and exit cambia, pith position, and uniformity of the trace by the automated processing platform. The data were processed using a web-based platform similar to (https://forestquality.shinyapps.io/FQ_ResiProcessor/, accessed on 10 December 2023) [6,26] but customized for the HQPlantations Southern Pine resource.

In the following analyses, site mean values based on Resi data were the unweighted average of the 30 individual trees sampled. All analyses and reporting were prepared in R [27] using RMarkdown [28] within the RStudio environment [29].

Differences between operators, instrument type, and instrument number were examined using a linear mixed-effects models using the “lmer” function in the lme4 package [30] by fitting the following models:

- (1)

- Y = µ + Operator + Resi instrument number + Plot:Tree + error;

- (2)

- Y = µ + Instrument type + Resi instrument number + Plot:Tree + error;

- (3)

- Y = µ + Resi instrument number + Plot:Tree + error.

In the analysis, Y represents the observed response for Resi amplitude. The fixed terms included in the model are Operator, Instrument type, and Resi instrument number. The random terms, indicated in italics, were Resi instrument number and Plot:Tree, with the tree nested within the plot. Statistical significance of the main effects was evaluated using an F-test with Satterthwaite’s method [31]. To discern differences between operators, instrument types, and instrument numbers, Tukey’s multiple comparison test was applied at the 0.05 significance level using the “emmeans” R package (Version 1.5.0; R Foundation for Statistical Computing, Vienna, Austria) [32].

3. Results

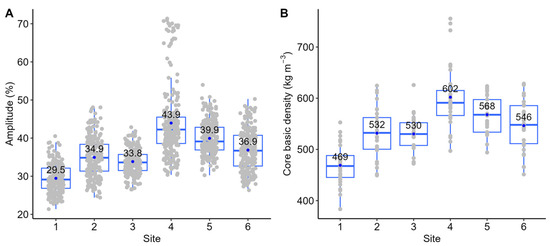

3.1. Sites

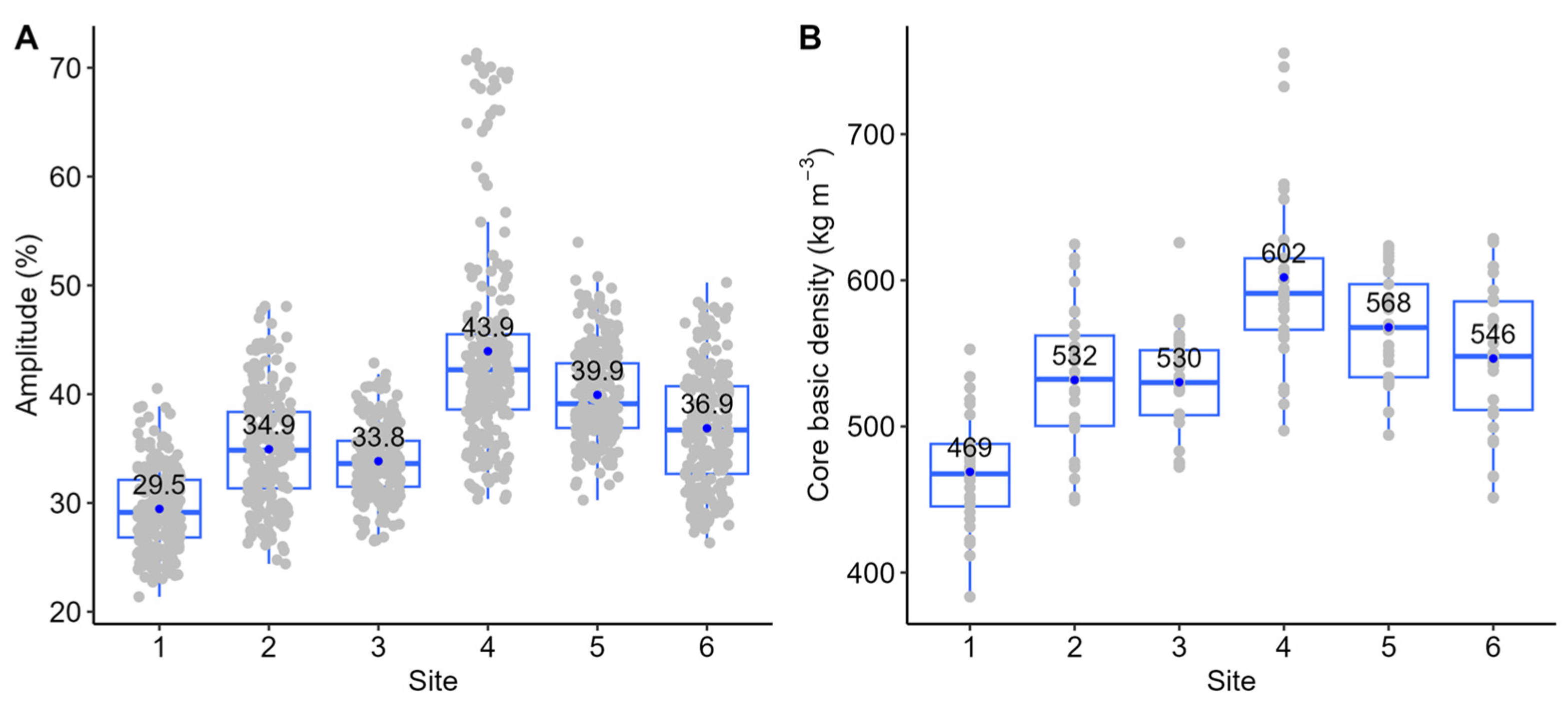

Across the six sites, the mean Resi amplitude in the outerwood (50 mm from the bark) ranged from 29.5% to 43.9%, with the lowest amplitude recorded at site 1 and the highest at site 4 (Figure 3). The sampled outerwood core densities ranged from 469 to 602 kg/m3, with the lowest density observed at site 1 and the highest at site 4. Notably, some trees at site 4 exhibited exceptionally high amplitudes. Cores from these trees also had extremely high densities, exceeding 700 kg/m3, of which Resi amplitudes were approximately 70%. Overall Resi outerwood amplitudes were observed to correspond well with the 50 mm outerwood cores, ranking the sites similarly (Figure 3).

Figure 3.

(A) Box plot of Resi outerwood amplitude for each site using all seven IML Resi tools. (B) Corresponding 50 mm outerwood core-extracted basic density for each site. Mean values are represented by blue dots.

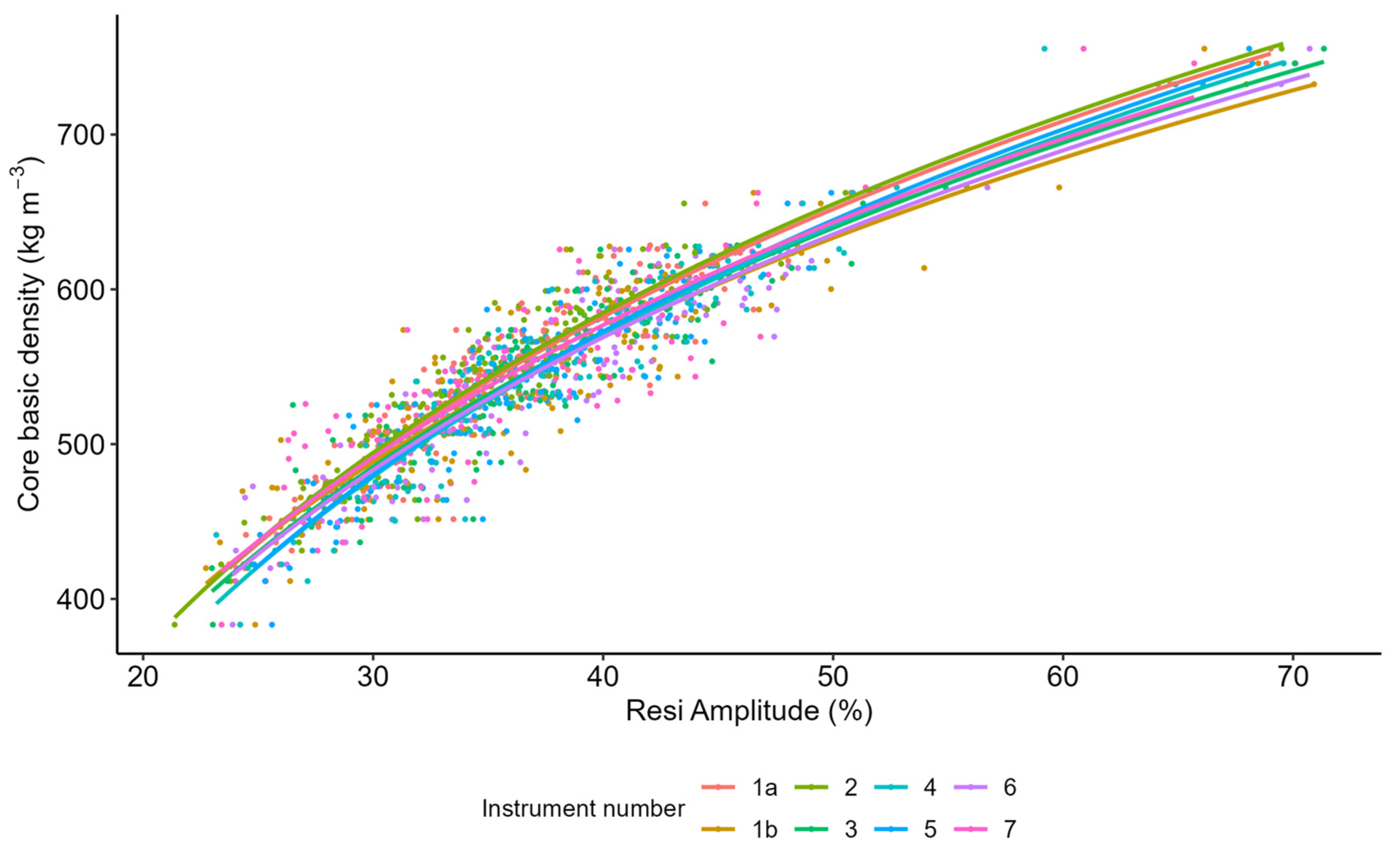

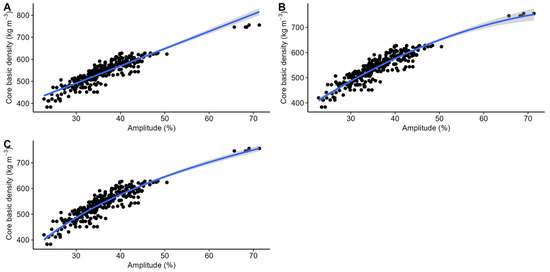

3.2. Relationship between Basic Density and Amplitude

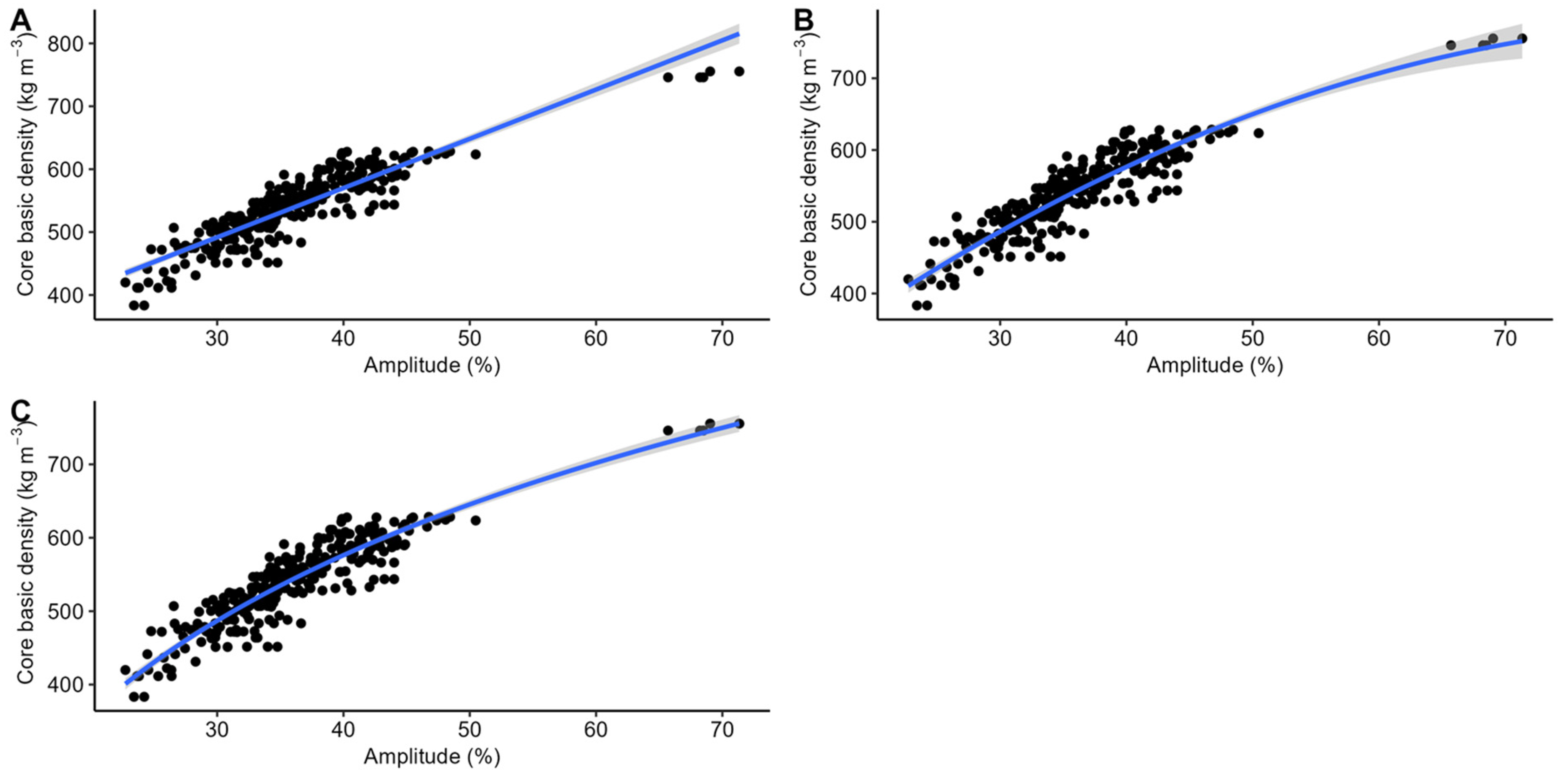

Amplitudes from the seven Resi tools ranged from 21.4% to 71.3%, while the basic density of core samples ranged from 383.4 to 755.5 kg/m3. Interestingly, the outerwood core density did not show a linear relationship with Resi amplitude.

To analyse the data, we randomly split all Resi instrument data into training and test sets, using an 80–20 split. Models were fitted to the training set and then applied to predict the test set, as detailed in Table 3. The best-performing model was the natural log model, as it exhibited the highest adjusted R2 and the lowest root mean square error (RMSE). The modeled test data are shown in Figure 4.

Table 3.

Models tested examining the relationship between outerwood basic density and outerwood average amplitude from a cross validation study. BD is basic density, AMP is Resi amplitude, and RMSE root mean square error.

Figure 4.

Modeled test data from a randomized 80/20 split of the data from the seven Resi tools: (A) linear model; (B) power model; (C) natural log model.

The natural log model still emerged as the best fit, while the linear model performed the poorest for this dataset. Notably, the linear model tended to overpredict very high basic densities and to underpredict values below 450 kg/m3.

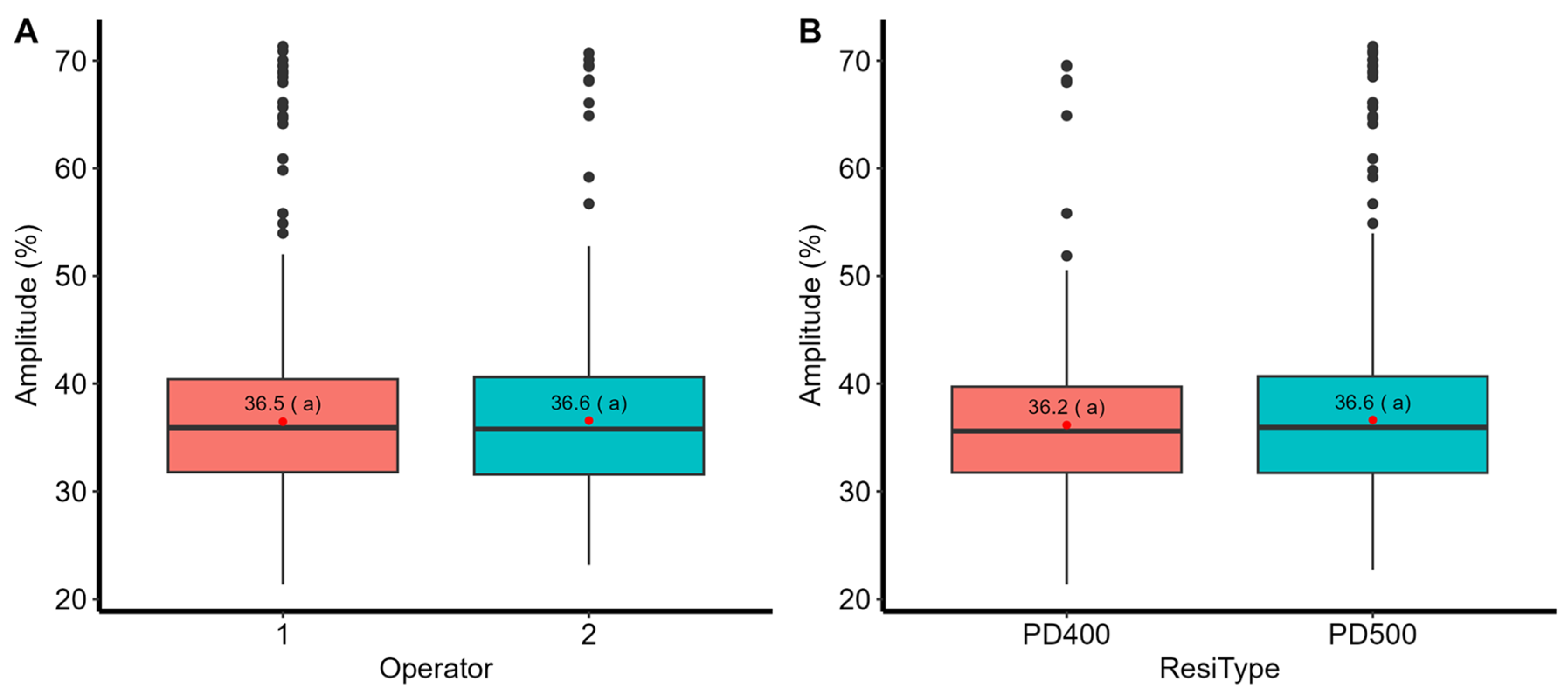

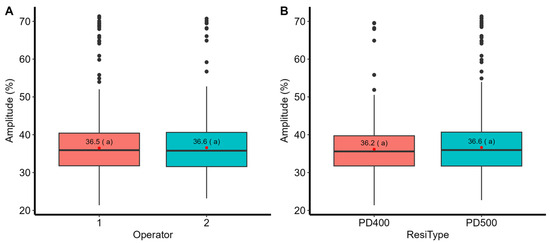

3.3. Operator, Machine Type

The operator did not have any detectable effect on the Resi data collected (Figure 5A). Furthermore, there was no significant difference observed between the PD400 and PD500 Resi tools (Figure 5B).

Figure 5.

Variation in Resi amplitudes detected for seven IML Resi tools. (A) Resi amplitude between two operators. (B) Resi amplitudes detected for the two types of Resi tools (PD400 and PD500) used in the study. Means with a common letter are not significantly different.

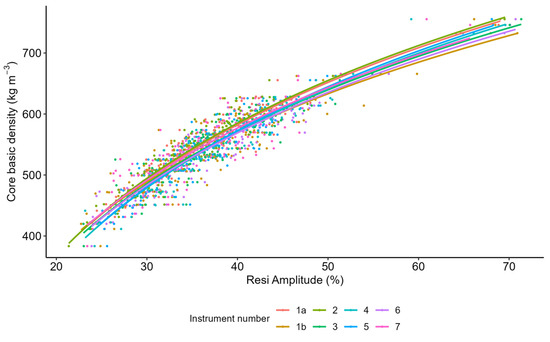

3.4. Regression between Density and Amplitude for Each Instrument

The fitted natural log (Ln) regression lines for the different Resi tools exhibit slight variations (Table 4), with an R2 range of 0.82 to 0.91 (Figure 6). The standard errors also vary slightly, ranging from 18.6 to 25.9 kg/m3, with an average of 21.5 kg/m3. Notably, instruments 7 and 1b, which were tested six months after the bulk of the measurements and furthest from the core sampling position in both the vertical and circumferential directions, displayed lower R2 values and higher RMSE values. In general, the range of variation between instruments from the mean RMSE is in the order of 3–4 kg/m3 (Table 4).

Table 4.

Table of regression parameters for each Resi tool relating amplitude to outerwood basic density for Figure 6.

Figure 6.

Resi amplitudes detected for seven IML Resi tools used in the study. Instrument 1a and 1b are the same Resi tool used as new and post-servicing by IML.

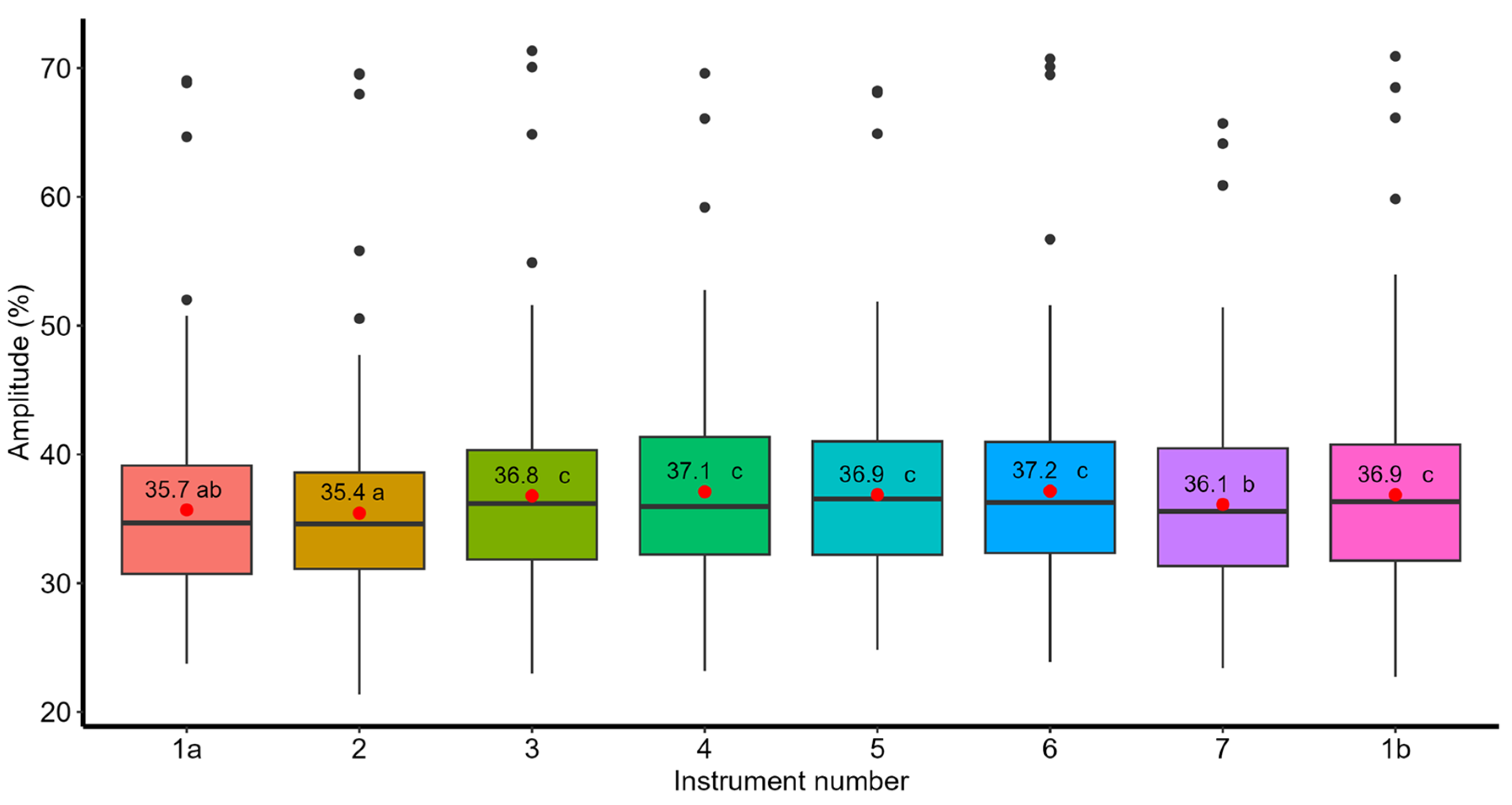

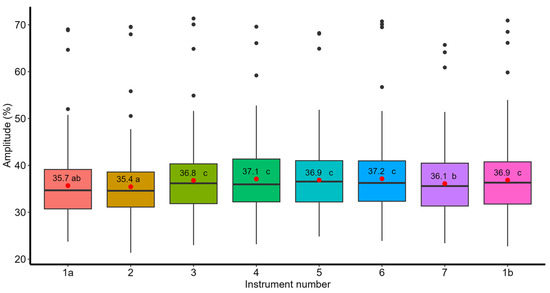

3.5. Amplitude Variation among Instruments

The mean Resi amplitude across the instruments ranged from 35.4% to 37.2% (Figure 7). Notably, instruments 1a and 2 consistently generated lower amplitudes compared to instruments 3, 4, 5, and 6. The largest difference in amplitude was observed between the lowest amplitude generated by Resi 2 and the highest amplitude generated by Resi 6, with a gap of 1.8%. Furthermore, there was a 1.2% difference between instrument 1a (new) and 1b (after servicing), where 1b was positioned furthest away from the core sampling location and tested six months later (Figure 7).

Figure 7.

The mean values of Resi amplitudes (50 mm from Resi entry) for seven instruments across the sites. Instruments 1a, 2, 3, 4, and 5 were tested in April, instrument 6 in June, and instruments 1b (post service of instrument 1) and 7 in November, with sampling positions further from the core location. Means with a common letter are not significantly different.

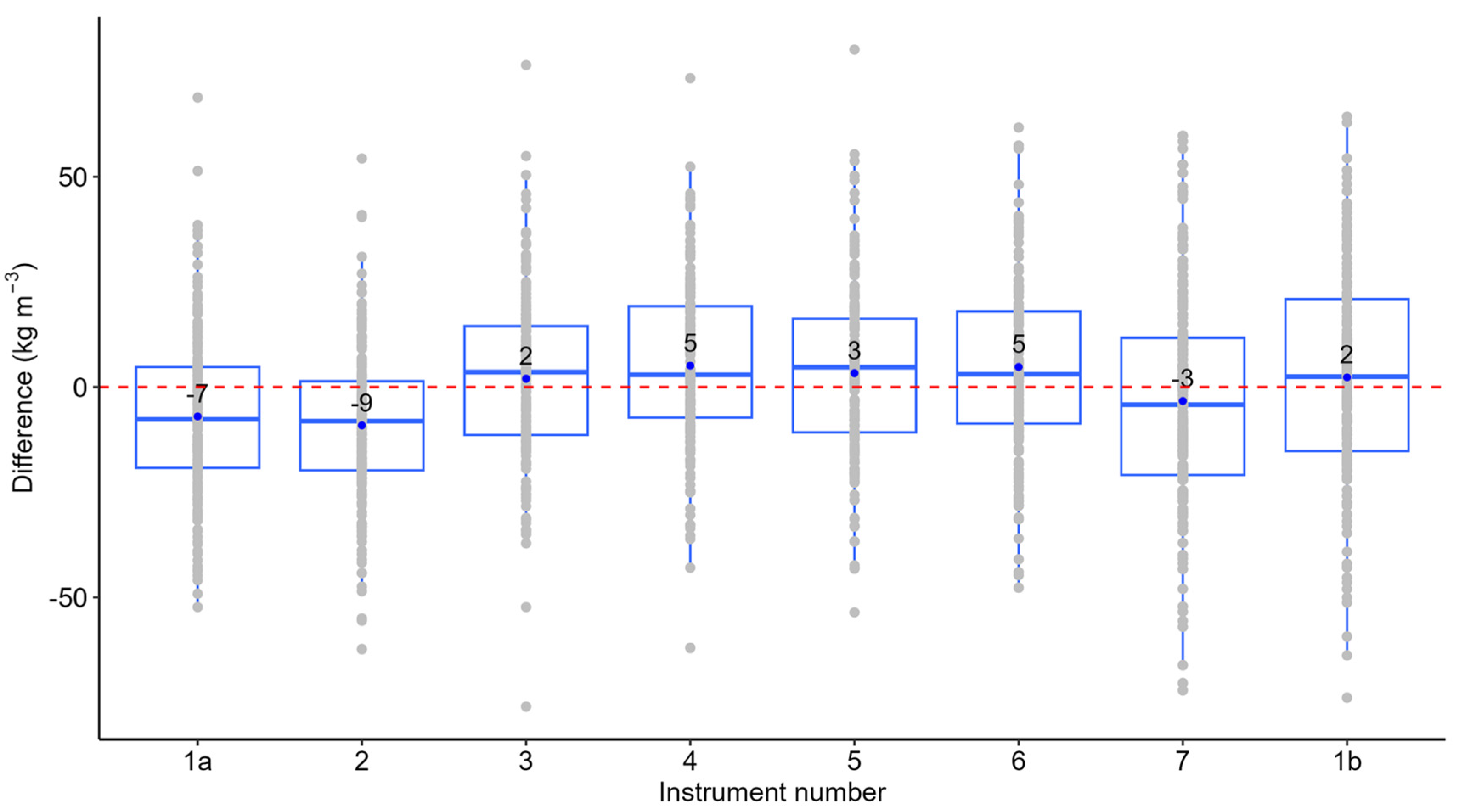

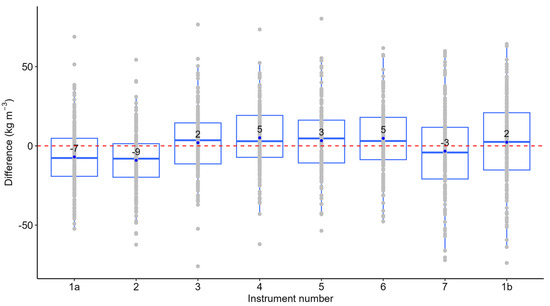

3.6. Resi Basic Density Prediction Using the Same Conversion Parameters

The mean measured basic density of the 50 mm outerwood cores was 542 kg/m3. The predicted mean basic density across the sites for each instrument ranged from 535 to 547 kg/m3. Resi instrument 2 underpredicted basic density by 9 kg/m3, while Resi 1a underpredicted basic density by 7 kg/m3 (Figure 8). The remaining Resi instrument prediction varied very little from −3 to 5 kg/m3 (Figure 8).

Figure 8.

The difference between measured basic density of 50 mm long outerwood cores and the predicted basic density from each Resi instrument using a natural log model from all Resi tools from Table 3. Instruments 1a, 2, 3, 4, and 5 were tested in April, instrument 6 in June, and instruments 1b and 7 were tested in November but positioned further from the core location. The blue dot represents the mean value, and the grey dots represent individual data points. The red dashed line is the reference point of the mean measured basic density.

3.7. Amplitude Effect on Basic Density Predicted by Different Resi Instruments

The most substantial disparities between instruments were predominantly observed at extremely high or very low amplitudes, as Table 5 demonstrates. It is worth noting that the majority of the data in this study fall within the 30%–50% amplitude range. Mid-range amplitudes (30%–40%) demonstrated lower differences (15–16 kg/m3) between instruments compared to a lower amplitude of 10%, which resulted in a difference of up to 51 kg/m3. High amplitudes of 60%–70% resulted in differences of up to 27–32 kg/m3, respectively (Table 5). These very high amplitudes were mostly outliers with respect to the means (Figure 8).

Table 5.

Predicted basic density using a natural logarithmic model for each individual IML Resi instrument and combined model from all instruments.

4. Discussion

The finding that the operator and instrument type had no significant effect suggests that measurements related to wood properties, such as density or stiffness, can be conducted consistently. This consistency can enable greater flexibility in personnel and equipment allocation, potentially resulting in cost savings for forest inventory and research operations. Additionally, the forest industry and researchers can benefit from this knowledge as it allows them to direct resources to other sources of variation that may have a more substantial influence on wood properties predictions. We will suggest testing other species, including the hardwoods, to confirm if it gives the same result. In this study, we compared only two types of Resi instruments. There are various types of drilling resistance instruments used in wood quality research, such as the IML RESI F500-S [33], IML RESI F400-S [34], IML RESI F300-S [35], and Resistograph SC-650 [13]. It is also worth noting that Resi and Resistograph instruments operate differently. In IML’s RESI, the user sets the feed speed and RPM, while in the Resistograph, these settings are automatically configured [36,37]. Therefore, results between these instruments could differ due to these operational variations.

The relationship between amplitude and basic density was not linear, in contrast to previous reports [6,14,15,38]. This is probably attributable to the greater range of basic density sampled in this study compared to previous studies (range 383.4 to 755.5 kg/m3). If using the linear relationship, basic densities above 650 kg/m3 would be overpredicted. This suggests that the Resi requires more power per unit for high-density material than the material actually possesses. Perhaps the presence of resin in these high-density trees—although resin pockets tends to occur close to pith [39]—while we tested close to the outerwood, or potentially compression wood with different wood properties than non-compression wood [40], could be causing this overprediction. Additionally, when drilling higher density material, the resulting higher density frass during drilling might lead to compaction and therefore greater friction on the needle, resulting in higher amplitude values. Another possibility is that in addition to potentially having a mechanical origin, the non-linearity might also result from electronic factors.

Based on the analysis presented here, we have observed that all the Resi tools rank the sites in the same order as their basic density. The average difference between the instruments ranged from −9 to 5 kg/m³. Precision is crucial when comparing small differences between sites or conducting genetic trials [11,12,14,17] or when analyzing tree radial profiles [41]. In cases where precision is required, forest companies or researchers operating multiple Resi instruments might consider calibrating Resi instruments using the individual instrument basic density and amplitude relationship (Figure 6) or adding and subtracting mean basic density values, as in Figure 8.

It should not be forgotten that additional tool-related variance can be caused by needle wear [42], different feed speeds, and RPMs [43]. Also, unwanted variance can be caused by needle friction [6], grain direction [44], and moisture content, albeit only below the fiber saturation point [35,45]. The Resi needle flex curvature while drilling can be minimized by holding the tool perpendicular to the tree [35]. Further research is needed in order to determine the potential effect of Resi needle diameter, Resi needle wear (i.e., how long until the needle needs to be replaced), and Resi battery age and type.

The oldest Resi 2, based on serial number, had the lowest values, while the newest Resi 6 had the highest amplitude values, which suggest that instrument age difference might have a small effect (albeit, at most, 1.2%). Potential effects of changes in instrument electronics and components over time may contribute to the inter-instrument variation.

The disparity between instruments using a common calibration function (amplitude vs. basic density) from all instruments was more pronounced at very low or very high Resi amplitudes. Overall, the most consistent basic density predictions between instruments were observed at a mean Resi amplitude of 20%–50%, and this is the typical amplitude range found when testing Southern Pine. As Southern Pine sampling conditions of feed speed 200 cm/min and 3500 RPM generally have average amplitudes in the range 20%–50%, we can expect basic density variation of up to 15–24 kg/m3 due to instrument differences in the extreme case. For higher density species, it would be better to adjust drilling settings so that the optimal 30%–40% mean amplitude [6] is achieved to avoid the larger differences between instruments due to differences in the calibration curve (amplitude vs. basic density). Targeting the 30%–40% amplitude range also minimizes the risk of overloading the Resi tool [46].

There was a small difference in amplitude observed between the sampling times in April and November. Typically, April is a dry month, while November tends to be wetter, which suggests that the wood may have had varying moisture content during these two periods. However, differences in moisture content above the fiber saturation point were not found to be significant [45]. Therefore, it is unlikely that variations in moisture content between different months would lead to changes in amplitude. Amplitude differences might occur due to the increase in basic density in the tree from April to November due to latewood formation. Also, the observed difference may have occurred due to a slight variation in the sampling orientation, where the November sampling was circumferentially off the aspect from which previous measurements had been taken.

5. Conclusions

This study examined the variability of seven different Resi instruments across six sites with two operators, focusing on the wood quality assessment of Southern Pine trees. The key finding is that Resi instruments consistently and correctly rank sites based on basic density, but with small inter-instrument differences. In contrast to previous work, the relationship between Resi amplitude and basic density was found to be nonlinear. For practical purposes, however, the nonlinearity can be ignored if the amplitude range is restricted and an appropriate linear calibration employed. Overall, this study’s results suggest that operator and instrument type have minimal effects on wood property measurements, providing consistency and flexibility for wood quality assessments in forestry and research applications. Adjusting the drilling settings to target specific amplitude ranges may further enhance measurement consistency.

Author Contributions

Conceptualization, V.G., D.J.L., D.P.K., C.K., G.M.D., M.L. and J.J.H.; methodology, V.G., D.J.L., D.P.K., C.K., G.M.D., M.L. and J.J.H.; software, V.G., D.J.L. and G.M.D.; validation, V.G. and D.J.L.; formal analysis, V.G. and D.J.L.; investigation, V.G., D.J.L., D.P.K., C.K., G.M.D., M.L. and J.J.H.; resources, D.P.K.; data curation, V.G., D.J.L., G.M.D., D.P.K. and C.K.; writing—original draft preparation V.G.; writing—review and editing, V.G., D.J.L., D.P.K., C.K., G.M.D., M.L. and J.J.H.; visualization, V.G.; supervision, D.J.L.; project administration, D.J.L.; funding acquisition, D.J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Forestry and Wood Products Australia project “Assessing and managing mid-rotation wood quality in Australian softwood plantations to produce fit-for-purpose logs”. Project number: PNB548-2021.

Data Availability Statement

Data are available from the corresponding author upon reasonable request.

Acknowledgments

Resi data and core collection were undertaken by Daryl Graham and Aaron Rock of Arbor King. We would like to thank Andrew Hayes (USC), who undertook the wet chemistry processing in the DAF laboratories at the EcoSciences Precinct. Data collection was assisted by Rica Minett at the DAF Salisbury Facility. Thank you to three anonymous reviewers and editors who helped further improve the manuscript.

Conflicts of Interest

Author Dominic P. Kain is employed by the company HQPlantations. Author Geoff M. Downes is employed by the company Forest Quality Pty Ltd. Author Marco Lausberg is employed by the company Wood Quality Consulting. Author Jonathan J. Harrington is employed by the Scion. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The companies HQPlantations, Forest Quality Pty Ltd., Wood Quality Consulting and Scion had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Rinn, F. Basics of micro-resistance drilling for timber inspection. Holztechnologie 2012, 53, 24–29. [Google Scholar]

- Rinn, F.; Schweingruber, F.-H.; Schär, E. Resistograph and X-ray density charts of wood. Comparative evaluation of drill resistance profiles and X-ray density charts of different wood species. Holzforsch. Int. J. Biol. Chem. Phys. Technol. Wood 1996, 50, 303–311. [Google Scholar] [CrossRef]

- Kamm, W.; Voss, S. Process and Device for Determining the Internal Condition of Trees or Wooden Components. US Patent No 4671105, 9 June 1987. [Google Scholar]

- Rinn, F. Device for Material Testing, Especially Wood Inspection by Drill Resistance Measurements. German Patent DE 412 24 94 B4, 11 March 2004. [Google Scholar]

- Schimleck, L.; Dahlen, J.; Apiolaza, L.A.; Downes, G.; Emms, G.; Evans, R.; Moore, J.; Pâques, L.; Van den Bulcke, J.; Wang, X. Non-destructive evaluation techniques and what they tell us about wood property variation. Forests 2019, 10, 728. [Google Scholar] [CrossRef]

- Downes, G.M.; Lausberg, M.; Potts, B.; Pilbeam, D.; Bird, M.; Bradshaw, B. Application of the IML Resistograph to the infield assessment of basic density in plantation eucalypts. Aust. For. 2018, 81, 177–185. [Google Scholar] [CrossRef]

- Gao, S.; Wang, X.; Brashaw, B.K.; Ross, R.J.; Wang, L. Rapid assessment of wood density of standing tree with nondestructive methods—A review. In Proceedings of the 2012 International Conference on Biobase Material Science and Engineering, Changsha, China, 21–23 October 2012. [Google Scholar]

- Downes, G.; Lausberg, M. Evaluation of the RESI software tool for the prediction of HM200 within pine logs sourced from multiple sites across New Zealand and Australia. NZ Solid Wood Innov. 2016, 15, 1. [Google Scholar]

- Walker, T.D.; Isik, F.; McKeand, S.E. Genetic Variation in Acoustic Time of Flight and Drill Resistance of Juvenile Wood in a Large Loblolly Pine Breeding Population. For. Sci. 2019, 65, 469–482. [Google Scholar] [CrossRef]

- Fundova, I.; Funda, T.; Wu, H.X. Non-destructive wood density assessment of Scots pine (Pinus sylvestris L.) using Resistograph and Pilodyn. PLoS ONE 2018, 13, 16. [Google Scholar] [CrossRef]

- Eckard, J.T.; Isik, F.; Bullock, B.; Li, B.; Gumpertz, M. Selection Efficiency for Solid Wood Traits in Pinus taeda using Time-of-Flight Acoustic and Micro-Drill Resistance Methods. For. Sci. 2010, 56, 233–241. [Google Scholar]

- Isik, F.; Li, B. Rapid assessment of wood density of live trees using the Resistograph for selection in tree improvement programs. Can. J. For. Res. 2003, 33, 2426–2435. [Google Scholar] [CrossRef]

- Krajnc, L.; Gričar, J.; Jevšenak, J.; Hafner, P.; Brus, R. Tree rings, wood density and climate–growth relationships of four Douglas-fir provenances in sub-Mediterranean Slovenia. Trees 2023, 37, 449–465. [Google Scholar] [CrossRef]

- Nickolas, H.; Williams, D.; Downes, G.; Harrison, P.; Vaillancourt, R.; Potts, B. Application of resistance drilling to genetic studies of growth, wood basic density and bark thickness in Eucalyptus globulus. Aust. For. 2020, 83, 172–179. [Google Scholar] [CrossRef]

- Singh, K.P.; Siregar, I.Z.; Abad, J.I.M.; Karlinasari, L. Non-destructive modeling using a drilling resistance tool to predict wood basic density of standing trees in a eucalypts plantation in North Sumatra, Indonesia. Biodiversitas 2022, 23, 6218–6226. [Google Scholar] [CrossRef]

- Downes, G.M.; Harrington, J.J.; Drew, D.M.; Lausberg, M.; Muyambo, P.; Watt, D.; Lee, D.J. A Comparison of Radial Wood Property Variation on Pinus radiata between an IML PD-400 ‘Resi’ Instrument and Increment Cores Analysed by SilviScan. Forests 2022, 13, 751. [Google Scholar] [CrossRef]

- Rocha-Sepúlveda, M.F.; Vega, M.; Harrison, P.A.; Joyce, K.; Vaillancourt, R.E.; Potts, B.M. Using ensemble learning to model climate associated variation in wood properties of planted Eucalyptus nitens in north-western Tasmania. New For. 2022, 54, 867–895. [Google Scholar] [CrossRef]

- Vlad, R.; Ispravnic, A.; Dinca, L.; Sidor, C.; Cuciurean, C.; Stefan, G. Influence of Planting Scheme on Some Physical Properties of Norway Spruce (Picea abies (L.) H. Karst) Wood. Forests 2022, 13, 540. [Google Scholar] [CrossRef]

- Orozco-Aguilar, L.; Nitschke, C.R.; Livesley, S.J.; Brack, C.; Johnstone, D. Testing the accuracy of resistance drilling to assess tree growth rate and the relationship to past climatic conditions. Urban For. Urban Green. 2018, 36, 1–12. [Google Scholar] [CrossRef]

- Downes, G.; Drew, D.; Lee, D. Validated Softwood Stiffness Predictions Using IML-Resistograph and eCambium; Forest and Wood Products Australia: Melbourne, Australia, 2020; Available online: https://fwpa.com.au/validated-softwood-stiffness-predictions-using-iml-resistograph-and-ecambium/ (accessed on 1 January 2020).

- Downes, G.M.; Drew, D.; Moore, J.; Lausberg, M.; Harrington, J.; Elms, S.; Watt, D.; Holtorf, S. Evaluating and Modeling Radiata Pine Wood Quality in the Murray Valley Region; FWPA Project PNC325-1314; Forest and Wood Products Australia: Melbourne, Australia, 2016; Available online: https://fwpa.com.au/wp-content/uploads/2021/09/Final_Report__eCambium__PNC325-1314.pdf (accessed on 10 December 2023).

- Downes, G.M.; Lee, D.; Bailleres, H.; Hopewell, G.; Hogg, B. Predicting log quality properties using the IML-Resistograph traces. In FWPA PNC361-1415: Improving Returns from Southern Pine Plantations through Innovative Resource Characterisation; University of the Sunshine Coast: Maroochydore, QLD, Australia, 2018; pp. 1–15. [Google Scholar]

- Heinrichs, J.F.; Lassen, L. Improved technique for determining the volume of irregularly shaped wood blocks. For. Prod. J. 1970, 20, 24. [Google Scholar]

- Browning, B.L. Methods of Wood Chemistry; John Wiley Sons: New York, NY, USA, 1967; Volumes I and II. [Google Scholar]

- AS/NZ 1080.3:2000; Timber—Method of Test—Method 3: Density. Standards Australia: Sydney, Australia. Standards New Zealand: Wellington, New Zealand, 2000.

- Downes, G.M. User Guide to the FWPA ResiProcessor Web Platform; Version 4.3.0; Forest Quality Pty Ltd.: Huonville, TAS, Australia, 2023. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2022. [Google Scholar]

- Allaire, J.; Xie, Y.; Dervieux, C.; McPherson, J.; Luraschi, J.; Ushey, K.; Atkins, A. Rmarkdown: Dynamic Documents for R. 2023. Available online: https://CRAN.R-project.org/package=rmarkdown (accessed on 10 December 2023).

- R Core Team. RStudio: Integrated Development for R; Computer Program; RStudio, PBC: Boston, MA, USA, 2022. [Google Scholar]

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting linear mixed-effects models using lme4. J. Stat. Softw. 2015, 67, 1–48. [Google Scholar] [CrossRef]

- Pinheiro, J.; Bates, D. Mixed-Effects Models in S and S-PLUS; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Russell, L. Emmeans: Estimated Marginal Means, Aka Least-Squares Means, R Package Version 1.5.0. The Comprahensive R Archive Network (CRAN). 2020. Available online: https://CRAN.R-project.org/package=emmeans (accessed on 10 December 2023).

- Pei, G.; Vlad, R.; Sidor, C.G.; Ispravnic, A. Quality assessment of Norway spruce standing trees through non-destructive methods and techniques. Rev. Silvic. Cineg. 2018, 23, 28–33. [Google Scholar]

- Todoroki, C.L.; Lowell, E.C.; Filipescu, C.N. Wood density estimates of standing trees by microdrilling and other non-destructive measures. N. Zealand J. For. Sci. 2021, 51, 1–14. [Google Scholar] [CrossRef]

- Ukrainetz, N.K.; O’Neill, G.A. An analysis of sensitivities contributing measurement error to Resistograph values. Can. J. For. Res. 2010, 40, 806–811. [Google Scholar] [CrossRef]

- Rinntech. Technology and Know-How for Inspecting Trees and Forests, Timber and Structures, Wood and Tree-Rings. RESISTOGRAPH® 6th Generation of Our Portable Resistance Drills since 1986. Available online: http://www.rinntech.de/images/stories/PDF/RINNTECH_RESISTOGRAPH_650_Info.pdf (accessed on 22 September 2023).

- IML—Instrumenta Mechanik Labor System GmbH. Measured Variables of the IML-RESI PowerDrill®Drill Resistance and Feed Force Measurement; IML—Instrumenta Mechanik Labor System GmbH: Wiesloch, Germany, 2022. [Google Scholar]

- Johnstone, D.; Ades, P.; Moore, G.M.; Smith, I.W. Using an IML-Resi drill to assess wood density in Eucalyptus globulus subsp. pseudoglobulus. Aust. For. 2011, 74, 190–196. [Google Scholar] [CrossRef]

- Bailleres, H.; Lee, D.J.; Kumar, C.; Psaltis, S.; Hopewell, G.; Brancheriau, L. Improving Returns from Southern Pine Plantations through Innovative Resource Characterisation; Project Report; Forest & Wood Products Australia: Melbourne, VIC, Australia, 2019; Available online: https://fwpa.com.au/wp-content/uploads/2019/04/Final_Report_Southern_Pines_PNC361-1416.pdf (accessed on 10 December 2023).

- Harris, J.M. Shrinkage and density of radiata pine compression wood in relation to its anatomy and mode of formation. N. Zealand J. For. Sci. 1977, 7, 91–106. [Google Scholar]

- Gendvilas, V.; Neyland, M.; Rocha-Sepúlveda, M.F.; Downes, G.M.; Hunt, M.; Jacobs, A.; Williams, D.; Vega, M.; O’Reilly-Wapstra, J. Effects of thinning on the longitudinal and radial variation in wood properties of Eucalyptus nitens. For. Int. J. For. Res. 2022, 95, 504–517. [Google Scholar] [CrossRef]

- Sharapov, E.; Wang, X.; Smirnova, E.; Wacker, J.P. Wear behavior of drill bits in wood drilling resistance measurements. Wood Fiber Sci. 2018, 50, 154–166. [Google Scholar] [CrossRef]

- Sharapov, E.; Brischke, C.; Militz, H.; Toropov, A. Impact of drill bit feed rate and rotational frequency on the evaluation of wood properties by drilling resistance measurements. Int. Wood Prod. J. 2019, 10, 128–138. [Google Scholar] [CrossRef]

- Sharapov, E.; Brischke, C.; Militz, H. Effect of Grain Direction on Drilling Resistance Measurements in Wood. Int. J. Archit. Herit. 2021, 15, 250–258. [Google Scholar] [CrossRef]

- Sharapov, E.; Brischke, C.; Militz, H.; Smirnova, E. Combined effect of wood moisture content, drill bit rotational speed and feed rate on drilling resistance measurements in Norway spruce (Picea abies (L.) Karst.). Wood Mater. Sci. Eng. 2020, 15, 198–204. [Google Scholar] [CrossRef]

- Gendvilas, V.; Downes, G.M.; Lausberg, M.; Harrington, J.; Lee, D. Predicting wood density using resistance drilling: The effect of varying feed speed and RPM. 2023; Unpublished. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).