Leachability of Fast-Growing Wood Impregnated with Low Concentrations of Furfuryl Alcohol

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Leaching Procedure

2.2.2. Analysis of Leachates

2.2.3. Morphology and Microstructure

2.2.4. Statistical Analysis

3. Results and Discussion

3.1. Analysis of the WPG and BC of Furfurylated Wood

3.2. Analysis of Leachate

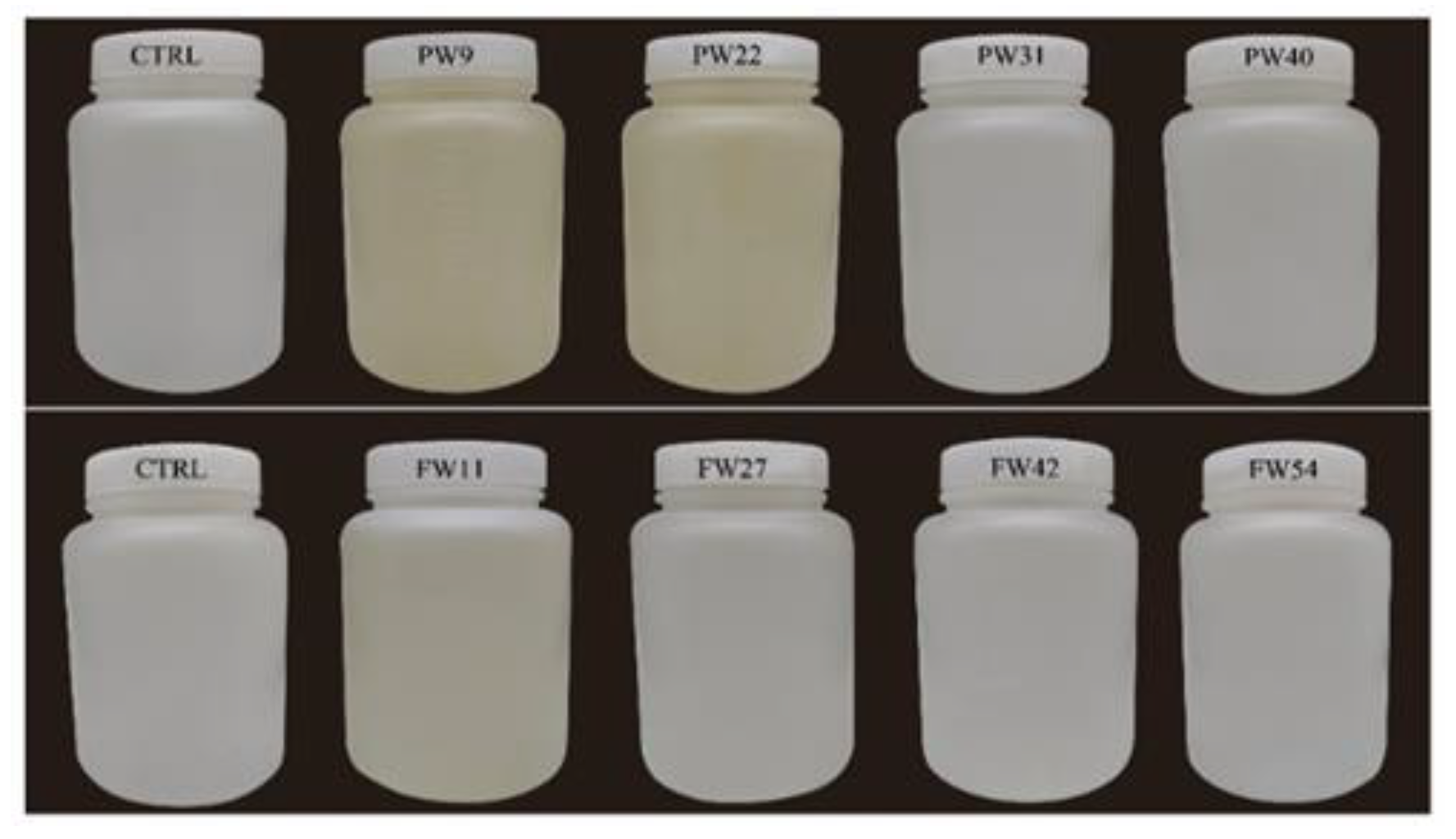

3.3. Analysis of Leached Water from Furfurylated Wood

3.4. Morphology and Microstructure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, X.; Wang, J.; Wang, Z.; Hua, F.; He, S.; Lu, B.; Wang, X.; Zhang, X.; Leng, W. Microstructural and thermo-mechanical characterization of furfurylated douglas fir. Polymers 2022, 14, 4641. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Li, W.; Guo, F.; Wang, H.; Zhang, X.; Yu, Y. Dimensionally stable and highly durable bamboo material prepared through a simple surface furfurylation. Constr. Build. Mater. 2021, 276, 122156. [Google Scholar] [CrossRef]

- Liu, M.; Lyu, S.; Peng, L.; Fan, Z.; Cai, L.; Huang, Z.; Lyu, J. Study on properties of radiata pine wood treated with furfuryl alcohol as fretboard materials for string instruments. Eur. J. Wood Wood Prod. 2022, 80, 1185–1200. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, C.; Huang, Y.; Ou, R.; Hu, C.; Wang, X.; Zhou, Q.; Tu, D. Developing a unilaterally surface-densified wood composite with excellent performance through surface impregnation of furfuryl alcohol resin. ACS Appl. Polym. Mater. 2022, 4, 5308–5318. [Google Scholar] [CrossRef]

- Shen, X.; Yang, S.; Li, G.; Liu, S.; Chu, F. The contribution mechanism of furfuryl alcohol treatment on the dimensional stability of plantation wood. Ind. Crop Prod. 2022, 186, 115143. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Mulyosari, D.; Herliyana, E.N.; Pari, G.; Arsyad, W.O.M.; Abdillah, I.B.; Gérardin, P. Furfurylation of wood from fast-growing tropical species to enhance their resistance to subterranean termite. Eur. J. Wood Wood Prod. 2021, 79, 1007–1015. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Chen, J.; Cao, J. Dimensional stability and decay resistance of clay treated, furfurylated, and clay-reinforced furfurylated poplar wood. Chem. Phys. Technol. Wood 2022, 76, 256–267. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Herliyana, E.N.; Mulyosari, D.; Abdillah, I.B.; Pari, R.; Hiziroglu, S. Termite resistance of furfuryl alcohol and imidacloprid treated fast-growing tropical wood species as function of field test. Appl. Sci. 2020, 10, 6101. [Google Scholar] [CrossRef]

- Skrede, I.; Solbakken, M.H.; Hess, J.; Fossdal, C.G.; Hegnar, O.; Alfredsen, G.; Master, E.R. Wood modification by furfuryl alcohol resulted in a delayed decomposition response in rhodonia (postia) placenta. Appl. Environ. Microbio. 2019, 85, e00338-19. [Google Scholar] [CrossRef]

- Xu, J.; Hu, D.; Zheng, Q.; Meng, Q.; Li, N. The distribution and polymerization mechanism of polyfurfuryl alcohol (pfa) with lignin in furfurylated wood. Polymers 2022, 14, 1071. [Google Scholar] [CrossRef]

- Shen, X.; Guo, D.; Jiang, P.; Li, G.; Yang, S.; Chu, F. Reaction mechanisms of furfuryl alcohol polymer with wood cell wall components. Holzforschung 2021, 75, 1150–1158. [Google Scholar] [CrossRef]

- Mantanis, G.I. Chemical modification of wood by acetylation or furfurylation: A review of the present scaled-up technologies. Bioresources 2017, 12, 4478–4489. [Google Scholar] [CrossRef]

- Esteves, B.; Nunes, L.; Pereira, H. Properties of furfurylated wood (Pinus pinaster). Eur. J. Wood Wood Prod. 2011, 69, 521–525. [Google Scholar] [CrossRef]

- Buchelt, B.; Dietrich, T.; Wagenführ, A. Testing of set recovery of unmodified and furfurylated densified wood by means of water storage and alternating climate tests. Hfsg 2014, 68, 23–28. [Google Scholar] [CrossRef]

- Lande, S.; Westin, M.; Schneider, M. Properties of furfurylated wood. Scand. J. For. Res. 2011, 19, 22–30. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Ren, D.; Yu, Y.; Yu, Y. Wood modification with furfuryl alcohol catalysed by a new composite acidic catalyst. Wood Sci. Technol. 2015, 49, 845–856. [Google Scholar] [CrossRef]

- Thygesen, L.G.; Barsberg, S.; Venås, T.M. The fluorescence characteristics of furfurylated wood studied by fluorescence spectroscopy and confocal laser scanning microscopy. Wood Sci. Technol. 2010, 44, 51–65. [Google Scholar] [CrossRef]

- Liu, M.; Guo, F.; Wang, H.; Ren, W.; Cao, M.; Yu, Y. Highly stable wood material with low resin consumption via vapor phase furfurylation in cell walls. Acs Sustain. Chem. Eng. 2020, 8, 13924–13933. [Google Scholar] [CrossRef]

- Lande, S.; Westin, M.; Schneider, M.H. Eco-efficient wood protection. Manag. Environ. Qual. Int. J. 2004, 15, 529–540. [Google Scholar] [CrossRef]

- Vetter, L.; Pilgård, A.; Treu, A.; Westin, M.; Acker, J. Combined evaluation of durability and ecotoxicity: A case study on furfurylated wood. Wood Mater. Sci. Eng. 2009, 4, 30–36. [Google Scholar] [CrossRef]

- Lande, S.; Eikenes, M.; Westin, M. Chemistry and ecotoxicology of furfurylated wood. Scand. J. For. Res. 2004, 19, 14–21. [Google Scholar] [CrossRef]

- Lin, C.; Kim, I.; Mantanis, G.I.; Karlsson, O.; Jones, D.; Sandberg, D. Leach-resistant fire-retardant treated furfurylated wood by incorporating guanyl-urea phosphate. Wood Mater. Sci. Eng. 2021, 16, 429–431. [Google Scholar] [CrossRef]

- Lin, C.; Karlsson, O.; Kim, I.; Myronycheva, O.; Mensah, R.A.; Försth, M.; Das, O.; Mantanis, G.I.; Jones, D.; Sandberg, D. Fire retardancy and leaching resistance of furfurylated pine wood (Pinus sylvestris L.) Treated with guanyl-urea phosphate. Polymers 2022, 14, 1829. [Google Scholar] [CrossRef] [PubMed]

- Rahayu, I.S.; Wahyuningtyas, I.; Zaini, L.H.; Darmawan, W.; Maddu, A.; Prihatini, E. Physical properties of impregnated ganitri wood by furfuryl alcohol and nano-SiO2. Iop Conf. Ser. Earth Environ. Sci. 2021, 891, 012012. [Google Scholar] [CrossRef]

- Baysal, E.; Ozaki, S.K.; Yalinkilic, M.K. Dimensional stabilization of wood treated with furfuryl alcohol catalysed by borates. Wood Sci. Technol. 2004, 38, 405–415. [Google Scholar] [CrossRef]

- Kong, L.; Guan, H.; Wang, X. In situ polymerization of furfuryl alcohol with ammonium dihydrogen phosphate in poplar wood for improved dimensional stability and flame retardancy. ACS Sustain. Chem. Eng. 2018, 6, 3349–3357. [Google Scholar] [CrossRef]

- Pu, H.; Chen, T.; Li, Y. Influences of furfurylation modification on the wood properties of rubberwood. J. For. Eng. 2014, 4, 50–53. [Google Scholar]

- CEN 2020: SS-EN 84:2020; Wood Preservatives—Accelerated Ageing of Treated Wood Prior to Biological Testing—Leaching Procedure. CEN: Brussels, Belgium, 2020.

- Beck, G. Leachability and decay resistance of wood polyesterified with sorbitol and citric acid. Forests 2020, 11, 650. [Google Scholar] [CrossRef]

- Miyauchi, T.; Mori, M.; Imamura, Y. Leaching characteristics of homologues of benzalkonium chloride from wood treated with ammoniacal copper quaternary wood preservative. J. Wood Sci. 2008, 54, 225–232. [Google Scholar] [CrossRef]

- Ehmcke, G.; Koch, G.; Richter, K.; Pilgård, A. Topochemical and light microscopic investigations of non-enzymatic oxidative changes at the initial decay stage of furfuryl alcohol-modified radiata pine (Pinus radiata) degraded by the brown rot fungus Rhodonia placenta. Int. Biodeterior. Biodegrad. 2020, 154, 105020. [Google Scholar] [CrossRef]

- Xie, W.; Chen, Q.; Wang, H.; Zhang, J. Rapid determination of furfural and furfuryl alcohol contents through UV spectra. China Pulp Pap. Ind. 2018, 39, 11–14. [Google Scholar]

- Boneka, A.S.; Uyup, M.K.A.; Hua, L.S.; Siam, N.A.; Salim, S.; Ashaari, Z. Sorption isotherm and physico-mechanical properties of kedondong (Canarium spp.) Wood treated with phenolic resin. Constr. Build. Mater. 2021, 288, 123060. [Google Scholar] [CrossRef]

- Mulyosari, D.; Hadi, Y.S.; Herliyana, E.N.; Pari, G.; Pari, R.; Abdillah, I.B. Physical properties of furfurylated mangium (Acacia mangium willd.) And pine (Pinus merkusii jungh et de vriese) woods. Iop Conf. Ser. Mater. Sci. Eng. 2020, 935, 12009. [Google Scholar] [CrossRef]

- Emaminasab, M.; Tarmian, A.; Oladi, R.; Pourtahmasi, K.; Avramidis, S. Fluid permeability in poplar tension and normal wood in relation to ray and vessel properties. Wood Sci. Technol. 2017, 51, 261–272. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, Y.; Fu, Z.; Gao, X.; Zhou, F.; Fu, F. Effects of microwave treatment on microstructure of Chinese fir. Forests 2020, 11, 772. [Google Scholar] [CrossRef]

- Beck, G.; Hill, C.; Cocher, P.M.; Alfredsen, G. Accessibility of hydroxyl groups in furfurylated wood at different weight percent gains and during rhodonia placenta decay. Eur. J. Wood Wood Prod. 2019, 77, 953–955. [Google Scholar] [CrossRef]

- Thygesen, L.G.; Engelund, E.T.; Hoffmeyer, P. Water sorption in wood and modified wood at high values of relative humidity. Part i: Results for untreated, acetylated, and furfurylated norway spruce. Holzforschung 2010, 64, 315–323. [Google Scholar] [CrossRef]

- Chen, T.; Luo, P.; Xu, Z.; Luo, X.; Hu, Z. Effects of furfuryl alcohol impregnation on physical and mechanical properties of densified poplar wood. J. For. Eng 2016, 1, 21–25. [Google Scholar]

- Pilgård, A.; Treu, A.; Albert, N.; Zeeland, V.; Richard, J.; Westin, M. Toxic hazard and chemical analysis of leachates from furfurylated wood. Environ. Toxicol. Chem. 2010, 29, 1918–1924. [Google Scholar] [CrossRef]

- Svensson, H.; Marques, M.; Kaczala, F.; Hogland, W. Leaching patterns from wood of different tree species and environmental implications related to wood storage areas. Water Environ. J. 2014, 28, 227–284. [Google Scholar] [CrossRef]

- Martha, R.; Mubarok, M.; Batubara, I.; Rahayu, I.S.; Setiono, L.; Darmawan, W.; Akong, F.O.; George, B.; Gérardin, C.; Gérardin, P. Effect of furfurylation treatment on technological properties of short rotation teak wood. J. Mater. Res. Technol. 2021, 12, 1689–1699. [Google Scholar] [CrossRef]

| Sample | FA Concentration | 0% | 5% | 10% | 15% | 20% |

|---|---|---|---|---|---|---|

| Chinese fir | abbreviation | CTRL | FW11 | FW27 | FW42 | FW54 |

| WPG | −0.15 e (0.08) | 11.69 d (0.01) | 27.96 c (0.02) | 42.38 b (0.05) | 54.15 a (0.04) | |

| BC | −0.20 e (0.14) | 5.47 d (0.01) | 8.00 c (0.02) | 9.51 b (0.02) | 11.61 a (0.03) | |

| poplar | abbreviation | CTRL | PW9 | PW22 | PW31 | PW40 |

| WPG | −0.37 e (0.01) | 9.41 d (0.01) | 22.07 c (0.02) | 31.40 b (0.04) | 40.98 a (0.05) | |

| BC | −0.46 d (0.06) | 3.80 c (0.01) | 6.48 b (0.01) | 8.52 a (0.01) | 9.07 a (0.01) |

| FA Concentration | 0% | 5% | 10% | 15% | 20% | |

|---|---|---|---|---|---|---|

| Chinese fir | MC | 294.10 a (0.24) | 225.07 b (0.13) | 150.86 b (0.20) | 105.53 d (0.13) | 85.20 e (0.13) |

| V | 15.30 a (0.03) | 11.24 b (0.02) | 8.41 b (0.02) | 6.93 d (0.02) | 6.04 d (0.02) | |

| poplar | MC | 196.81 a (0.24) | 167.65 b (0.11) | 141.53 b (0.10) | 115.68 d (0.10) | 100.16 e (0.09) |

| V | 14.82 a (0.02) | 9.20 b (0.02) | 7.65 b (0.01) | 6.44 d (0.01) | 6.09 d (0.01) | |

| FA Concentration | 0% | 5% | 10% | 15% | 20% | |

|---|---|---|---|---|---|---|

| Chinese fir | MCWA | 243.96 a (0.34) | 201.38 b (0.14) | 179.00 c (0.11) | 164.36 b (0.12) | 138.09 e (0.08) |

| VWA | 15.55 a (0.03) | 11.15 b (0.02) | 7.76 c (0.03) | 6.90 cd (0.01) | 5.89 d (0.01) | |

| poplar | MCWA | 203.12 a (0.21) | 177.15 b (0.16) | 154.59 c (0.13) | 125.95 d (0.10) | 113.77 e (0.12) |

| VWA | 14.82 a (0.02) | 10.00 b (0.02) | 7.66 c (0.01) | 6.57 d (0.01) | 6.35 d (0.01) | |

| FA Concentration | 0% | 5% | 10% | 15% | 20% | |

|---|---|---|---|---|---|---|

| Chinese fir | ML | 0.77 e (0.02) | 31.28 a (0.05) | 12.99 b (0.11) | 8.00 c (0.11) | 4.98 d (0.05) |

| VL | 2.28 c (0.01) | 4.50 a (0.02) | 3.88 b (0.02) | 3.80 ab (0.01) | 3.52 b (0.01) | |

| poplar | ML | 1.52 ab (0.01) | 37.67 a (0.05) | 16.88 b (0.02) | 12.71 c (0.02) | 8.04 d (0.01) |

| VL | 2.95 ab (0.02) | 1.68 c (0.01) | 2.41 bc (0.01) | 2.02 a (0.02) | 2.40 b (0.01) | |

| Sample | Chinese Fir | Poplar | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CTRL | FW11 | FW27 | FW42 | FW54 | CTRL | PW9 | PW22 | PW31 | PW40 | |

| Water saturation | 0.05 | 3.426 | 0.800 | 0.608 | 0.514 | 0.240 | 2.080 | 1.277 | 0.773 | 0.486 |

| 12 h | 0.305 | 4.554 | 1.434 | 1.060 | 0.801 | 0.261 | 5.652 | 2.519 | 1.706 | 1.218 |

| 24 h | 0.156 | 2.393 | 0.724 | 0.671 | 0.510 | 0.181 | 2.514 | 1.673 | 1.359 | 0.713 |

| 48 h | 0.199 | 2.381 | 1.295 | 1.039 | 0.870 | 0.061 | 1.807 | 0.503 | 0.923 | 0.679 |

| 72 h | 0.124 | 1.801 | 1.104 | 0.939 | 0.808 | 0.073 | 1.370 | 0.676 | 0.540 | 0.513 |

| 96 h | 0.121 | 1.485 | 0.889 | 0.667 | 0.693 | 0.056 | 1.452 | 1.016 | 1.005 | 0.771 |

| 120 h | 0.068 | 1.220 | 0.760 | 0.516 | 0.419 | 0.031 | 0.964 | 0.651 | 0.574 | 0.269 |

| 168 h | 0.085 | 1.322 | 1.016 | 0.707 | 0.521 | 0.063 | 1.248 | 1.029 | 0.909 | 0.636 |

| 216 h | 0.062 | 0.915 | 0.708 | 0.456 | 0.348 | 0.011 | 1.653 | 0.887 | 0.673 | 0.651 |

| 264 h | 0.050 | 0.807 | 0.642 | 0.468 | 0.315 | 0.028 | 0.906 | 0.748 | 0.989 | 0.736 |

| 312 h | 0.071 | 0.628 | 0.522 | 0.498 | 0.395 | 0.053 | 0.989 | 0.716 | 0.757 | 0.595 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Gong, Y.; Yan, Y.; Fu, C.; Zhan, K.; Dong, C.; Xie, L.; Chen, T. Leachability of Fast-Growing Wood Impregnated with Low Concentrations of Furfuryl Alcohol. Forests 2023, 14, 1901. https://doi.org/10.3390/f14091901

Sun H, Gong Y, Yan Y, Fu C, Zhan K, Dong C, Xie L, Chen T. Leachability of Fast-Growing Wood Impregnated with Low Concentrations of Furfuryl Alcohol. Forests. 2023; 14(9):1901. https://doi.org/10.3390/f14091901

Chicago/Turabian StyleSun, He, Yizhi Gong, Yuntian Yan, Changqing Fu, Ke Zhan, Chunlei Dong, Linkun Xie, and Taian Chen. 2023. "Leachability of Fast-Growing Wood Impregnated with Low Concentrations of Furfuryl Alcohol" Forests 14, no. 9: 1901. https://doi.org/10.3390/f14091901

APA StyleSun, H., Gong, Y., Yan, Y., Fu, C., Zhan, K., Dong, C., Xie, L., & Chen, T. (2023). Leachability of Fast-Growing Wood Impregnated with Low Concentrations of Furfuryl Alcohol. Forests, 14(9), 1901. https://doi.org/10.3390/f14091901