Some Properties of Briquettes and Pellets Obtained from the Biomass of Energetic Willow (Salix viminalis L.) in Comparison with Those from Oak (Quercus robur)

Abstract

1. Introduction

2. Materials and Methods

2.1. Ecological Aspects

- —

- Determining the weight of the green biomass cutting from the part above the ground, using the following relationship for the group of twigs:

- —

- The addition of the woody part corresponding to the root, which corresponds to about 10% of the area above the ground, respectively, the total value of the woody part will be:

- —

- Determination of the absolute dry mass of the woody mass resulting from a stump group, taking into account that 72.5% is dry mass and 27.5% is water in different forms (liquid, vapor, and chemically dissociated), that is, this will be:

- —

- —

- Determination of the sequestered carbon dioxide content in the woody part of the biomass. It is taken into account that CO2 has one carbon molecule and two other oxygen molecules, the atomic mass of carbon is 12, and that of oxygen is 16. Consequently, the mass of CO2 will be a ratio between the atomic mass of all CO2 and the atomic mass of carbon, respectively, 44/12 = 3.67. Therefore, to determine the mass of carbon dioxide sequestered in trees, the previous mass of carbon M4 will be multiplied by 3.67, which will be:

- —

- For an energetic willow crop, the amount of sequestered carbon dioxide per surface unit is calculated with the following relationship:

2.2. Granulometry of the Energetic Willow and Oak Crushed Material

2.3. Obtaining Briquettes and Pellets

2.4. Unit Density of Briquettes and Pellets

2.5. The Pellet Torrefaction Treatment

2.6. Color Determination of Native and Torrefied Pellets with CIELab Colorimetric Space

2.7. Calorific Value and Energetic Density of Briquettes and Pellets

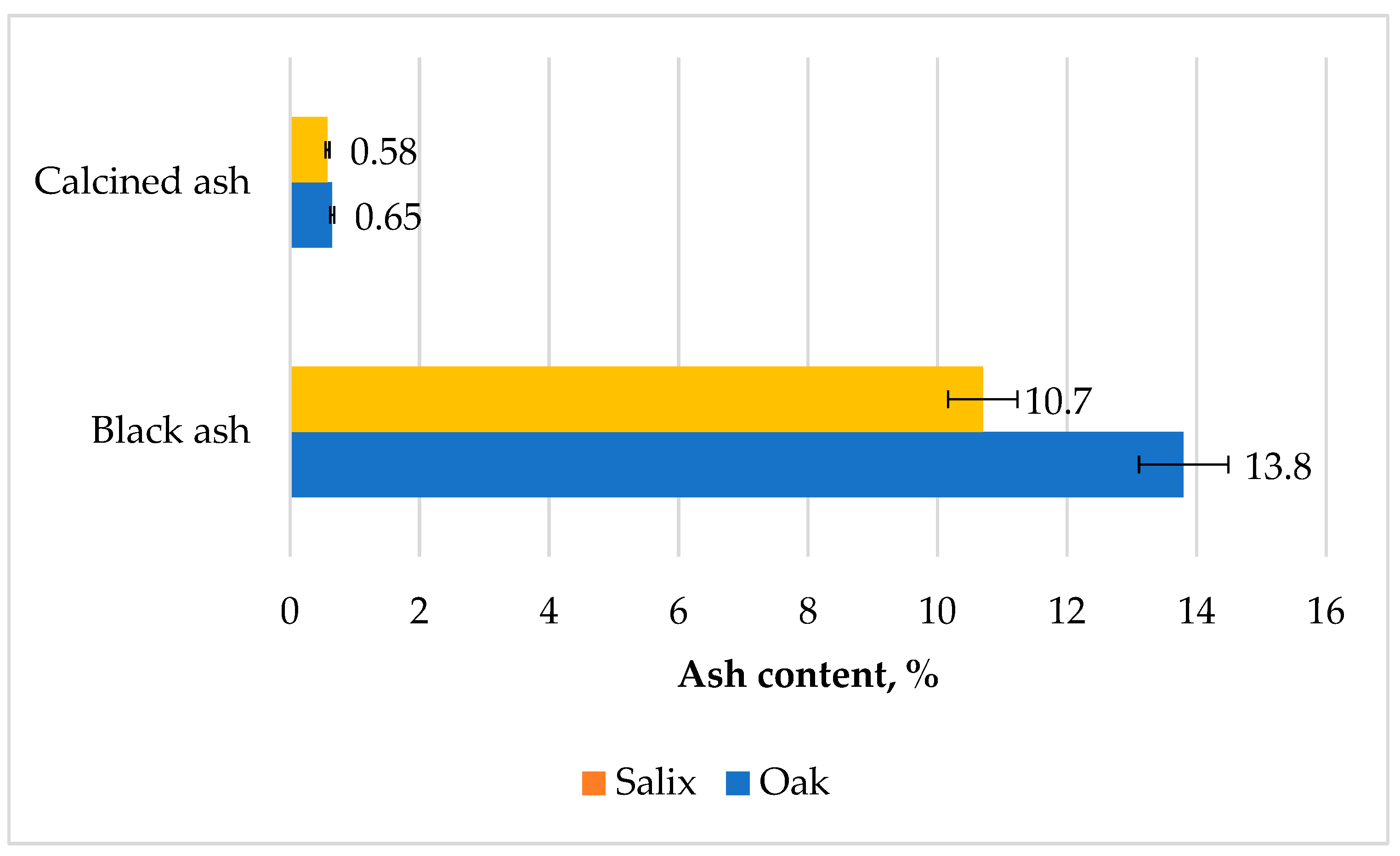

2.8. Ash Content

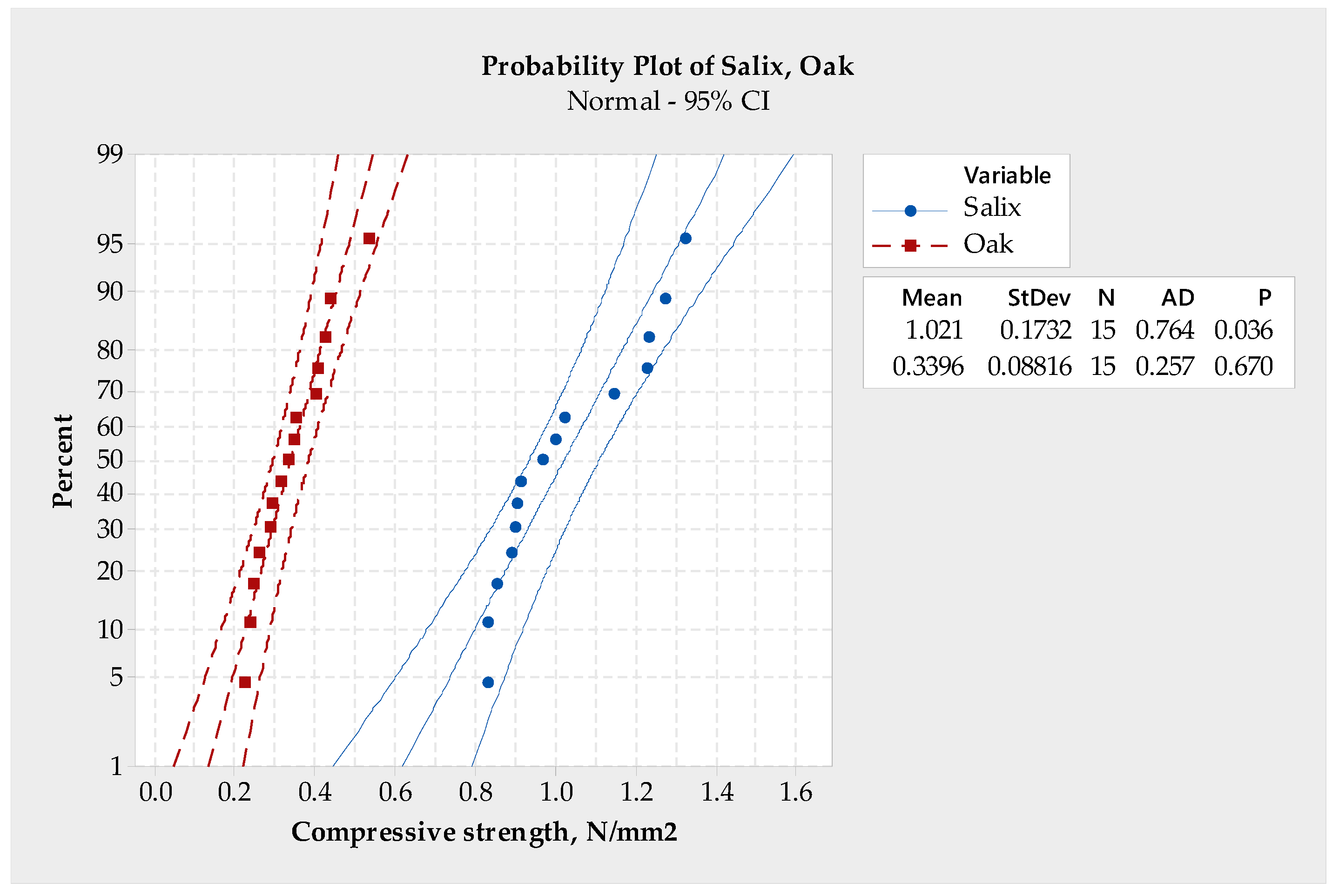

2.9. The Compressive Strength of Briquettes

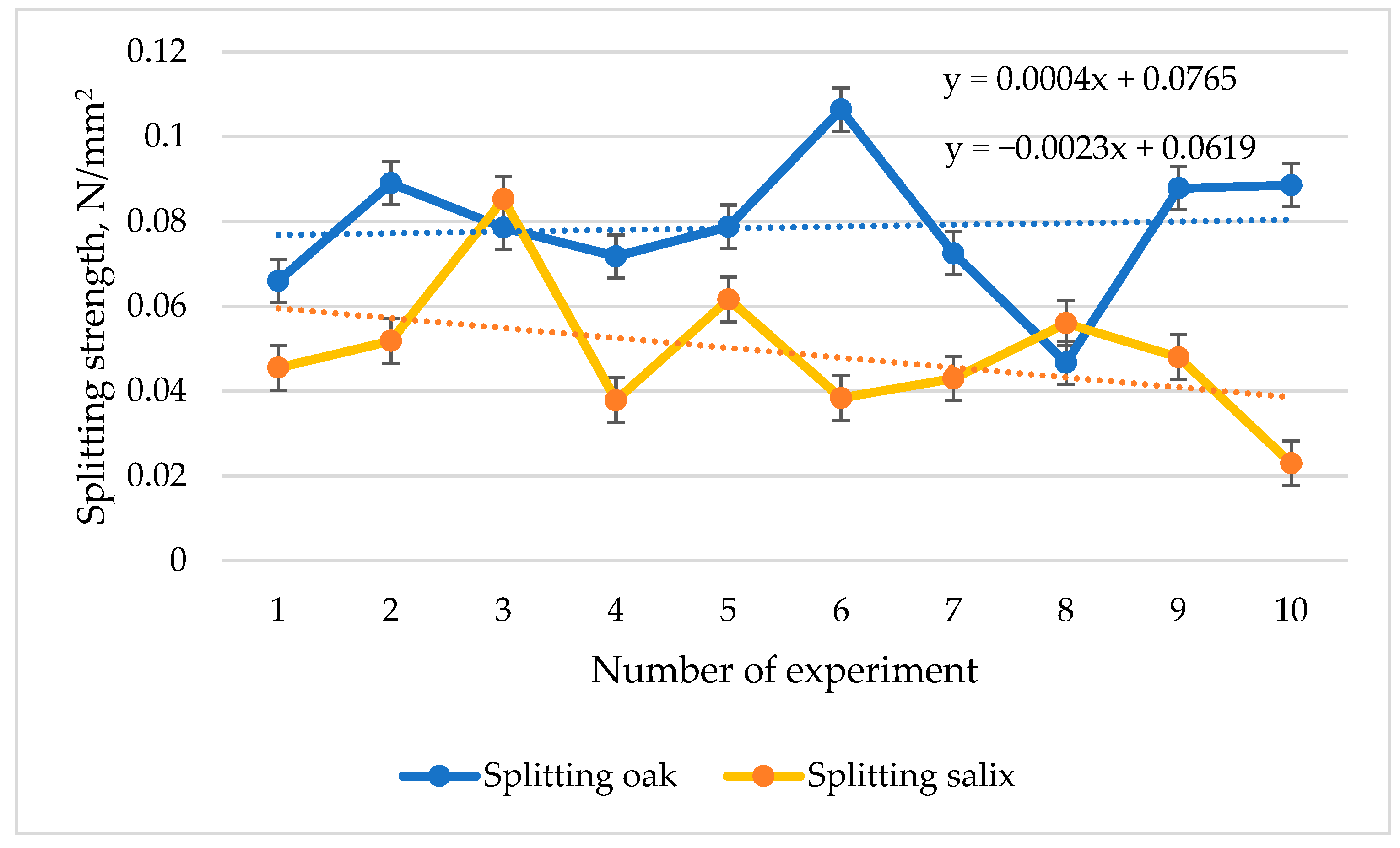

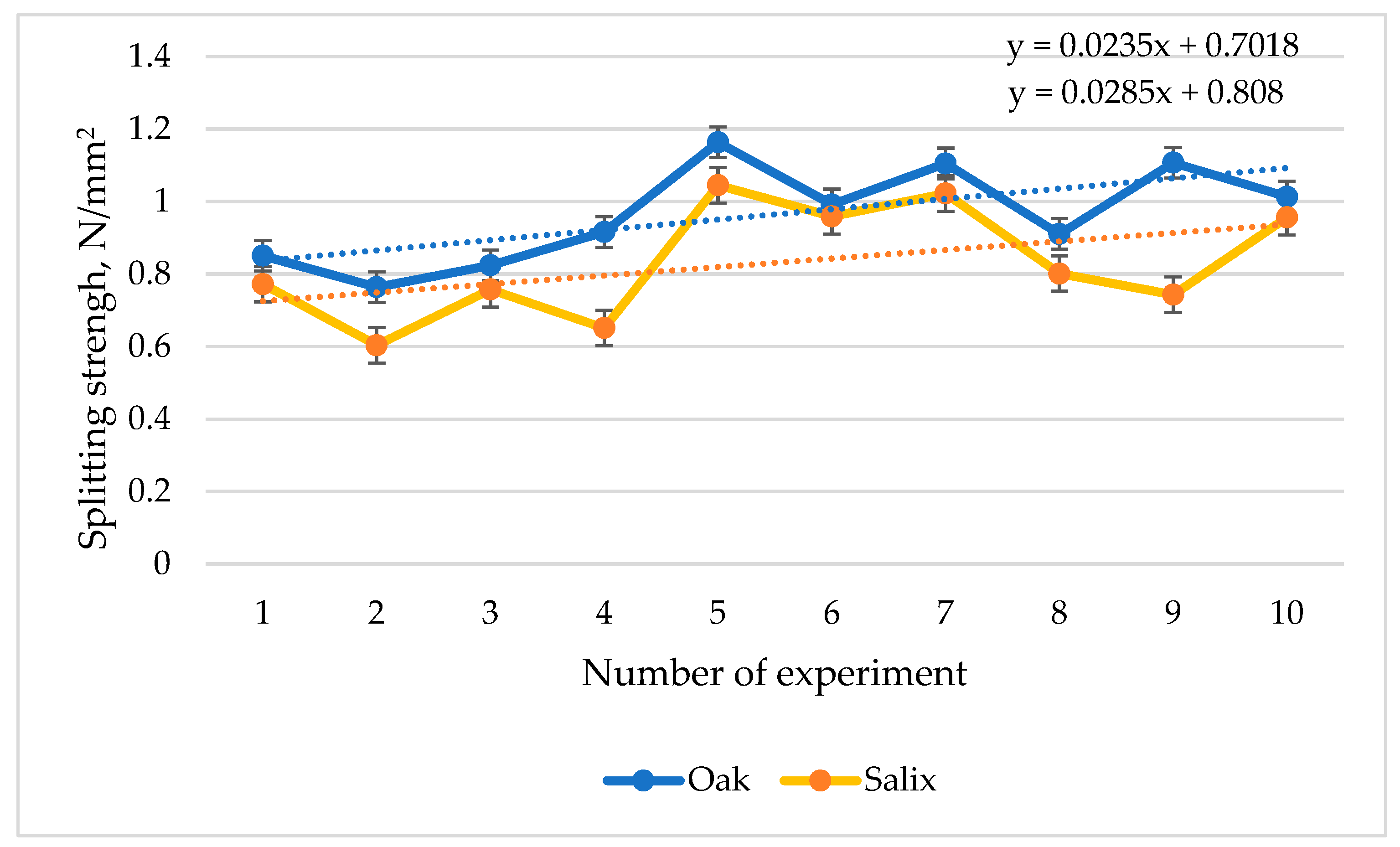

2.10. Splitting Resistance of Briquettes (Perpendicular and Parallel to the Length)

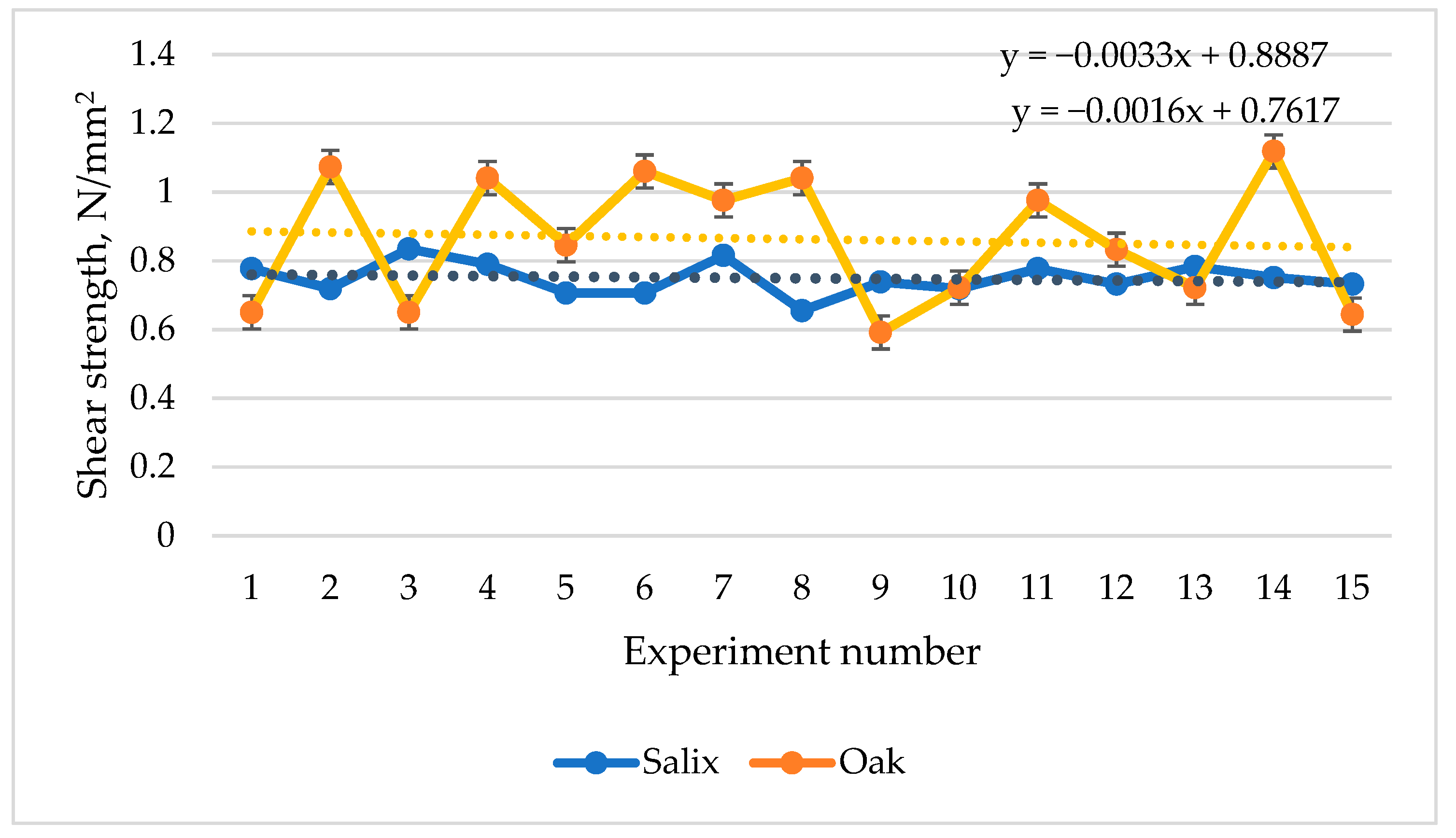

2.11. The Pellet Shearing Strength

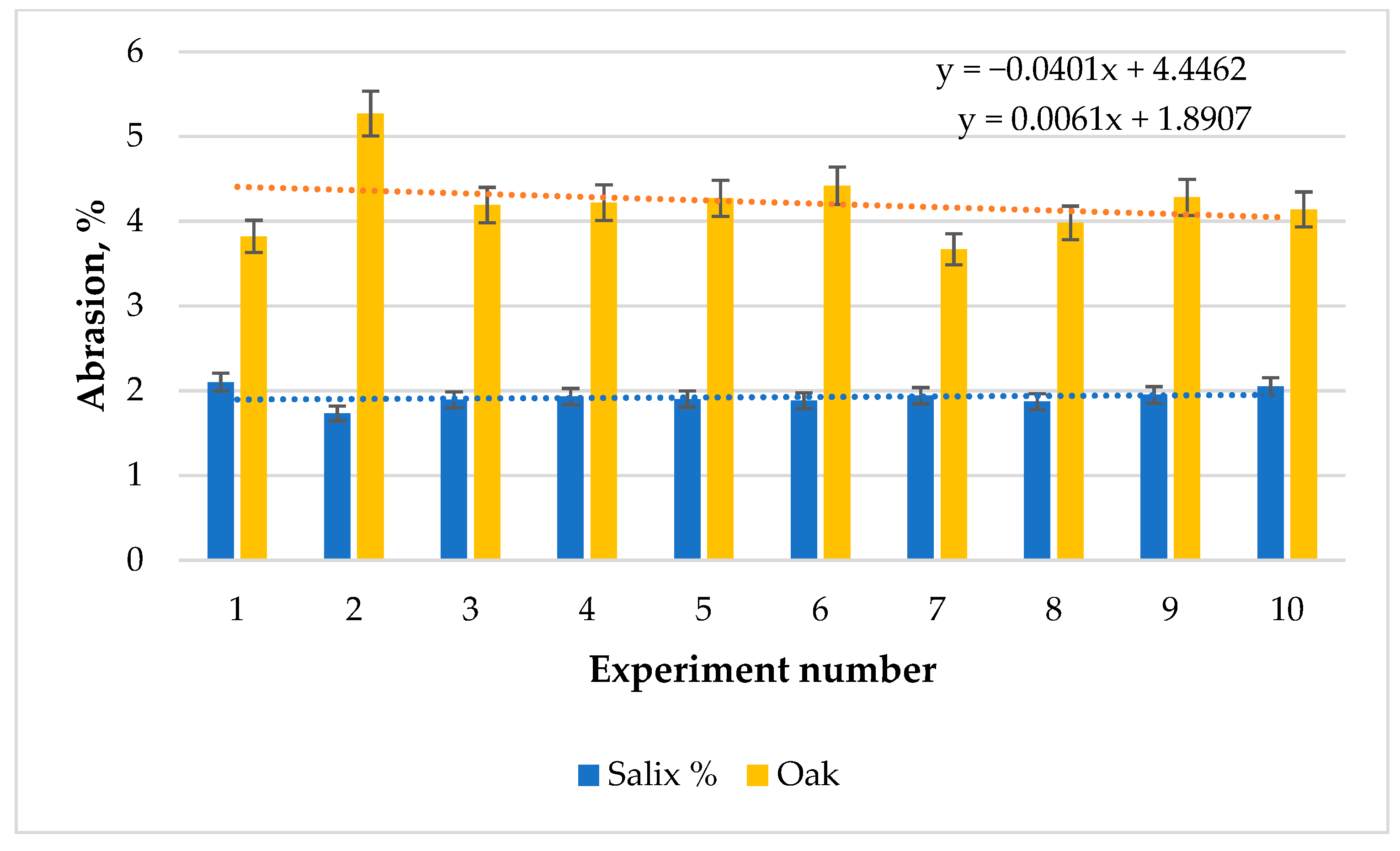

2.12. The Briquettes Abrasion

2.13. Statistical Analysis

3. Results

3.1. Ecological Aspects of the Willow/Oak Plantation

3.2. Bulk Density of the Sawdust of the Two Types of Biomasses

3.3. Granulometry of Wood Particles

3.4. Dimensions of Briquettes and Pellets

3.5. Unit Density of Briquettes and Pellets

3.6. Pellet Torrefaction

3.7. Calorific Value and Energetic Density

3.8. The Pellets Color after the Torrefaction Process

3.9. Compressive Strength of Briquettes

3.10. The Splitting Strength of Briquettes

3.11. Shear Strength of Pellets

3.12. The Briquette Abrasion

3.13. Ash Content

3.14. Modeling the Calorific Power Depending on the Content of Chemical Components

4. Discussion

5. Conclusions

- Energetic willow has a calorific value of 20.7 MJ/kg and an energy density of 22.7 × 103 MJ/m3, higher than those of oak of 20.58 MJ/kg and 26.6 × 103 MJ/m3, respectively. So, the energetic willow has very good calorific behavior, its properties being better than those of oak and other wood species used in the energetic field. Moreover, the research demonstrated why willow is considered one of the deciduous species with the highest calorific value.

- The torrefaction treatment at maximum regime led to a better calorific value of 21.43 MJ/kg in the case of energetic willow, compared to only 21.29 MJ/kg in the case of oak.

- The calcined ash content was lower in the case of energetic willow, with a value of 0.59%, compared to 0.65% in the case of oak.

- Ecologically, energetic willow has the same positive effects of sequestering carbon dioxide from the air and releasing oxygen as any other fast-growing woody species used in combustion.

- Future research will be focused on increasing the carbon content of the energetic willow biomass during the torrefaction process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Manzone, M.; Balsari, P. Planters’ performance during a Very Short Rotation Coppice planting. Biomass Bioenergy 2014, 67, 188–192. [Google Scholar] [CrossRef]

- Wilkinson, J.M.; Evans, E.J.; Bilsborrow, P.E.; Wright, C.; Wewison, W.O.; Pilbeam, D.J. Yield of willow cultivars at different planting densities in a commercial short rotation coppice in the north of England. Biomass Bioenergy 2007, 31, 469–474. [Google Scholar] [CrossRef]

- Amichev, B.Z.; Hangs, R.D.; van Ress, K.C.J. A novel approach to simulate the growth of multi-stem willow in bioenergy production systems with a simple process-based model (3PG). Biomass Energy 2011, 35, 473–488. [Google Scholar] [CrossRef]

- Mleczek, M.; Rutowski, P.; Rissman, I.; Kaczmarek, Z.; Golinski, P.; Szentner, K.; Strazynska, K.; Stachowiak, A. Biomass productivity and phytoremediation potential of Salix alba and Salix viminalis. Biomass Bioenergy 2010, 34, 1410–1418. [Google Scholar] [CrossRef]

- Mleczek, M.; Gąseckaa, B.; Waliszewska, Z.; Magdziak, M.; Szostek, P.; Rutkowskid, J.; Kaniuczakc, M.; Zborowskab, S.; Budzyńskaa, P.; Mleczek, P.; et al. Salix viminalis L.—A highly effective plant in phytoextraction of elements. Chemosphere 2018, 212, 67–78. [Google Scholar] [CrossRef]

- Scriba, C.; Lunguleasa, A.; Spirchez, C.; Ciobanu, V. Influence of INGER and TORDIS Energetic Willow Clones Planted on Contaminated Soil on the Survival Rates, Yields and Calorific Value. Forests 2021, 12, 826. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Rebina 2022, Rebina Agrar. Available online: https://balkangreenenergynews.com/energy-willow-salix-viminalis-biomass-where-you-want-it/ (accessed on 2 October 2022).

- Albertsson, J.; Verwijst, T.; Hansson, D.; Bertholdsson, N.-O.; Åhman, I. Effects of competition between short-rotation willow and weeds on performance of different clones and associated weed flora during the first harvesting cycle. Biomass Bioenergy 2014, 70, 364–372. [Google Scholar] [CrossRef]

- Bergante, S.; Manzone, M.; Facciotto, F. Alternative planting method for short rotation coppice with poplar and willow. Biomass Bioenergy 2016, 87, 39–45. [Google Scholar] [CrossRef]

- Dimitrious, I.; Rosenqvist, H.; Berndes, G. Slow expansion and low yields of willow short rotation coppice in Sweden; implications for future strategies. Biomass Bioenergy 2011, 35, 4613–4618. [Google Scholar] [CrossRef]

- Buchholz, T.; Volk, T.A. Improving the profitability of willow crops-identifying opportunities with a crop budget model. Bioenergy Res. 2011, 4, 85–95. [Google Scholar] [CrossRef]

- Balloffet, N.; Deal, R.; Hines, S.; Larry, B.; Smith, N. Ecosystem Services and Climate Change 2012; U.S. Department of Agriculture, Forest Service, Climate Change Resource Center. Available online: www.fs.usda.gov/ccrc/topics/ecosystem-services (accessed on 15 March 2023).

- El Kasmioui, O.; Ceulemans, R. Financial analysis of the cultivation of short rotation woody crops for bioenergy in Belgium: Barriers and opportunities. BioEnergy Res. 2013, 6, 336–350. [Google Scholar] [CrossRef]

- Fiala, M.; Bacenetti, J. Economic, energetic and environmental impact in short rotation coppice harvesting operations. Biomass Bioenergy 2012, 42, 107–113. [Google Scholar] [CrossRef]

- Ray, M.; Brereton, N.B.; Shield, I.; Karp, A.; Murphy, R. Variation in cell wall composition and accessibility in relation to biofuel potential of short rotation coppice willows. Bioenergy Res. 2012, 5, 685–698. [Google Scholar] [CrossRef]

- Serapiglia, M.; Cameron, K.; Stipanovic, A.; Abrahamson, L.; Volk, T.; Smart, L. Yield and woody biomass traits of novel shrub willow hybrids at two contrasting sites. Bioenergy Res. 2012, 6, 533–546. [Google Scholar] [CrossRef]

- Volk, T.A.; Abrahamson, L.P.; Cameron, K.D.; Castellano, P.; Corbin, T.; Fabio, E. Yields of willow biomass crops across a range of sites in North America. Asp. Appl. Biol. 2011, 112, 67–74. [Google Scholar]

- Larsen, S.U.; Jørgensen, U.; Lærke, P.E. Willow yield is highly dependent on clone and site. BioEnergy Res. 2014, 7, 1280–1292. [Google Scholar] [CrossRef]

- Mitsui, Y.; Seto, S.; Nishio, M.; Minato, K.; Ishizawa, K.; Satoh, S. Willow clones with high biomass yield in short rotation coppice in the southern region of Tohoku district (Japan). Biomass Bioenergy 2010, 34, 467–473. [Google Scholar] [CrossRef]

- Nissim, W.G.; Laberque, M. Planting micro cuttings: An innovative method for establishing a willow vegetation cover. Ecol. Eng. 2016, 91, 472–476. [Google Scholar] [CrossRef]

- Wang, Z.; MacFarlane, D.W. Evaluating the biomass production of coppiced willow and polar clones in Michingan, USA, over multiple rotations and different growing conditions. Biomass Bioenergy 2012, 46, 380–388. [Google Scholar] [CrossRef]

- Tahvanainena, L.; Rytkönena, V.-M. Biomass production of Salix viminalis in southern Finland and the effect of soil properties and climate conditions on its production and survival. Biomass Bioenergy 1999, 16, 103–117. [Google Scholar] [CrossRef]

- Hallingbäck, H.; Berlin, S.; Nordh, N.-E.; Weih, M.; Rönnberg-Wästljung, A.-C. Genome Wide Associations of Growth, Phenology, and Plasticity Traits in Willow (Salix viminalis (L.)). Front. Plant Sci. 2019, 10, 753. [Google Scholar] [CrossRef]

- Almeida, P.; Proux-Wera, E.; Churcher, A. Genome assembly of the basket willow, Salix viminalis, reveals earliest stages of sex chromosome expansion. BMC Biol. 2020, 18, 78. [Google Scholar] [CrossRef]

- Fromm, J.; Spanswick, R. Characteristics of Action Potentials in Willow (Salix viminalis L.). J. Exp. Bot. 1993, 44, 1119–1125. [Google Scholar] [CrossRef]

- Gao, J.; Jebrane, M.; Terziev, N.; Daniel, G. Evaluation of Wood Quality Traits in Salix viminalis Useful for Biofuels: Characterization and Method Development. Forests 2021, 12, 1048. [Google Scholar] [CrossRef]

- Marreiro, H.; Peruchi, R.; Lopes, R.; Andersen, S.; Eliziário, S.; Rotella Junior, P. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Rönnberg-Wästljung, A.C. Genetic structure of growth and phenological traits in Salix viminalis. Can. J. For. Res. 2001, 31, 276–282. [Google Scholar]

- Munshi, L.A.; Dar, A.R. Genetic Diversity in Salix viminalis in the Kashmir Valley, India. Am. J. Biochem. Mol. Biol. 2011, 1, 178–184. [Google Scholar] [CrossRef]

- Lascoux, M.; Thorsén, J.; Gullberg, U. Population structure of a riparian willow species, Salix viminalis L. Genet. Res. 1996, 68, 45–54. [Google Scholar] [CrossRef]

- European Bioenergy Outlook. 2013. Available online: https://www.pfcyl.es/sites/default/files/biblioteca/documentos/european_bioenergy_outlook_2013.pdf (accessed on 3 June 2020).

- Griu, T.; Lunguleasa, A. Salix viminalis vs. Fagus sylvatica—Fight for renewable energy from woody biomass in Romania. Environ. Eng. Manag. J. 2016, 15, 413–420. [Google Scholar]

- Tumuluru, J.S.; Sokhansanj, S.; Wright, C.; Boardman, R.; Hess, J.R. Review on Biomass Torrefaction Process and Product Properties and Design of Moving Bed Torrefaction System Model Development. In Proceedings of the 2011 ASABE Annual International Meeting, Louisville, KY, USA, 7–10 August 2011. [Google Scholar]

- Chen, W.H.; Cheng, W.Y.; Lu, K.M.; Wuang, Y.P. An Evaluation on Improvement of Pulverized Biomass Property for Solid through Torrefaction. Appl. Energy 2011, 11, 3636–3644. [Google Scholar] [CrossRef]

- Ecomatcher 2022. How to Calculate CO2 Sequestration. Available online: https://www.ecomatcher.com/how-to-calculate-co2-sequestration/ (accessed on 7 September 2022).

- FAO. Environmental Aspects of Natural Resources: Forestry. 2022. Available online: https://www.fao.org/3/ad905e/AD905E02.htm (accessed on 4 April 2022).

- Ens, J.; Farrell, R.; Bélanger, N. Early effects of afforestation with willow (Salix purpurea, “Hotel”) on soil carbon and nutrient availability. Forests 2013, 4, 137–154. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Dąbrowska, M. Influence of the Die Height on the Density of the Briquette Produced from Shredded Logging Residues. Materials 2021, 14, 3698. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Kumar, R.; Pandey, A. Current Developments in Biotechnology and Bioengineering: Waste treatment Processes for Energy Generation; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Francescato, V.; Antonin, E.; Bergomi, L.Z. Wood Fuels Handbook; Print House AIEL—Italian Agri forestry Energy Association: Legnaro, Italy, 2008. [Google Scholar]

- Krajnic, N. Wood Fuel Handbook; Food and Agriculture Organization (FAO) of the United Nations: Pristina, Kosovo, 2015. [Google Scholar]

- Demirbas, A.; Sahin-Demirbas, A. Briquetting Properties of Biomass Waste Materials. Energy Source Part A 2004, 26, 83–91. [Google Scholar] [CrossRef]

- Dhillon, R.S.; von Wuelhlisch, G. Mitigation of Global Warming through Renewable Biomass. Biomass Bioenergy 2013, 48, 75–87. [Google Scholar] [CrossRef]

- Kongsager, R.; Napier, J.; Mertz, O. The carbon sequestration potential of tree crop plantations. Mitig. Adapt. Strateg. Glob. Chang. 2013, 18, 1197–1213. [Google Scholar] [CrossRef]

- Sobczyk, L.W.; Sobczyk, E.J. Economical and ecological effects of cultivation of basket willow Salix viminalis. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012002. [Google Scholar] [CrossRef]

- Wagenführ, R.; Wagenführ, A. Holzatlas; (E-book); Carl Hanser Fachbuchverlag: München, Germany, 2021. [Google Scholar]

- De Neergaard, A.; Porter, J.; Gorissen, A. Distribution of assimilated carbon in plants and rhizosphere soil of basket willow (Salix viminalis L.). Plant Soil 2002, 245, 307–314. [Google Scholar] [CrossRef]

- Dzurenda, L.; Geffertova, J.; Hecl, V. Energy Characteristics of Wood-Chips Produced from Salix viminalis—Clone ULV. Drvna Ind. 2010, 61, 27–31. [Google Scholar]

- Verma, V.K.; Bram, S.; de Ruyck, J. Small Scale Biomass Systems: Standards, Quality Labeling and Market Driving Factors—An EU Outlook. Biomass Bioenergy 2009, 33, 1393–1402. [Google Scholar] [CrossRef]

- Côté, W.A. Chemical Composition of Wood. In Principles of Wood Science and Technology; Springer: Berlin/Heidelberg, Germany, 1968. [Google Scholar] [CrossRef]

- EN 13183-1:2002; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method. European Committee for Standardization: Brussels, Belgium, 2002.

- ASTM E871-82:2019; Standard Test Method for Moisture Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- DIN 51731: 2013; Testing of Solid Fuels—Compressed Untreated Wood—Requirements and Testing. German Institute for Standardisation: Berlin, Germany, 2013.

- EN 15103: 2009; Solid Biofuels—Determination of Bulk Density. European Committee for Standardization: Brussels, Belgium, 2009.

- Mitani, A.; Barboutis, I. Changes Caused by Heat Treatment in Color and Dimensional Stability of Beech (Fagus sylvatica L.) Wood. Drvna Ind. 2014, 65, 225–232. [Google Scholar] [CrossRef]

- ISO 1928: 2020; Coal and Coke—Determination of Gross Calorific Value. International Standardization Organization: Geneva, Switzerland, 2020.

- ASTM E1755-01: 2020; Standard Test Method for Ash in Biomass. ASTM International: West Conshohocken, PA, USA, 2020.

- ISO 2171: 2007; Cereals, Pulses and By-products—Determination of Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2007.

- Balaban, M.; Uçar, G. Extractives and Structural Components in Wood and Bark of Endemic Oak Quercus vulcanica Boiss. Holzforschung 2001, 55, 478–486. [Google Scholar] [CrossRef]

- Maksimuk, Y.; Antonava, Z.; Krouk, V.; Korsakova, A.; Kursevich, V. Prediction of higher heating value (HHV) based on the structural composition for biomass. Fuel 2021, 299, 120860. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. The explained variation by lignin and extractive contents on higher heating value of wood. Biomass Bioenergy 2011, 35, 1663–1667. [Google Scholar] [CrossRef]

- ÖNORM M 7135: 2000; Pellets and Briquettes—Requirements and Test Conditions. Austrian Standards Institute: Vienna, Austria, 2000.

- Gocławski, J.; Korzeniewska, E.; Sekulska-Nalewajko, J.; Kiełbasa, P.; Dróżdż, T. Method of Biomass Discrimination for Fast Assessment of Calorific Value. Energies 2022, 15, 2514. [Google Scholar] [CrossRef]

- Lamlom, H.; Savidge, R.A. A reassessment of carbon content in wood: Variation within and between 41 North American species. Biomass Bioenergy 2003, 25, 381–388. [Google Scholar] [CrossRef]

- Shulga, G.; Betkers, T.; Brovkina, J.; Aniskevicha, O.; Ozolinš, J. Relationship between Composition of the Lignin-based Interpolymer Complex and its Structuring Ability. Environ. Eng. Manag. J. 2008, 7, 397–400. [Google Scholar] [CrossRef]

- Bi, T.; Sokhsansanj, S.; Lim, J. Torrefaction & Densification of Biomass; Biomass and Bioenergy Research Group, Clean Energy Research Centre, University of British Columbia: Vancouver, BC, Canada, 2012. [Google Scholar]

- Brožek, M.; Nováková, A.; Kolářová, M. Quality evaluation of briquettes made from wood waste. Res. Agric. Eng. 2012, 58, 30–35. [Google Scholar] [CrossRef]

- Hu, W.; Yang, X.; Mi, B.; Liang, F.; Zhang, T.; Fei, B.; Jiang, Z.; Liu, Z. Investigating chemical properties and combustion characteristics of torrefied masson pine. Wood Fiber Sci. 2017, 49, 33–42. [Google Scholar]

- Alizadeh, P.; Tabil, L.G.; Adapa, P.K.; Cree, D.; Mupondwa, E.; Emadi, B. Torrefaction and Densification of Wood Sawdust for Bioenergy Applications. Fuels 2022, 3, 152–175. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguleasa, A.; Antonaru, C. Experiments and modeling of the torrefaction of white wood fuel pellets. BioResources 2017, 12, 8595–8611. [Google Scholar] [CrossRef]

- García-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

| Pellet Specie | Treatment | CIELab | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Salix viminalis | Control | 36.5 | −15.3 | 5.6 |

| 180/3 | 28.7 | −20.1 | 6.5 | |

| 200/3 | 22.8 | −21.5 | 7.1 | |

| 220/3 | 19.4 | −22.7 | 8.4 | |

| Quercus robur | Control | 38.1 | −21.8 | 9.1 |

| 180/3 | 36.2 | −24.5 | 9.7 | |

| 200/3 | 32.5 | −36.9 | 10.1 | |

| 220/3 | 28.5 | −47.5 | 10.9 | |

| Constituents | Extractive | Lignin | Cellulose | Hemicelluloses | Ash | Total | MJ/kg, Equation (18) | |

|---|---|---|---|---|---|---|---|---|

| 34.5 MJ/kg | 24.4 | 18.6 | 16.1 | 0.2 | - | |||

| Salix-native | % | 6.07 | 27.31 | 49.11 | 17.09 | 0.58 | 100 | - |

| KJ/kg | 209.41 | 666.364 | 913.446 | 257.149 | 0.118 | 2046.48 | 20.46 | |

| Salix-torrefied | % | 6.07 | 27.31 | 42.80 | 0 | 0.58 | 77.6 | - |

| %ref. | 7.47 | 33.74 | 54.09 | 3.99 | 0.71 | 100 | - | |

| kJ/kg | 257.025 | 823.256 | 1006.074 | 64.239 | 0.142 | 21150.736 | 21.15 | |

| Oak-native | % | 8.20 | 20.05 | 46.08 | 25.12 | 0.65 | 100 | - |

| kJ/kg | 282.9 | 489.22 | 857.088 | 404.43 | 0.13 | 2033.76 | 20.33 | |

| Oak-torrefied | % | 8.20 | 20.05 | 43.8 | 0 | 0.65 | (−27.4) | - |

| %ref. | 10.44 | 25.54 | 56.42 | 6.87 | 0.82 | 100 | - | |

| kJ/kg | 360.18 | 623.176 | 1047.412 | 110.607 | 0.164 | 2141.539 | 21.41 | |

| No. | Property | Own Values of Research | Other Value | References | |

|---|---|---|---|---|---|

| Willow | Oak | ||||

| 1. | Unit density of briquettes, kg/m3 | 766 | 877 | 620–720 | CRI-R0415 |

| 2. | Unit density of pellets, kg/m3 | 1101 | 1296 | Min 1000 | ONORM M7135 |

| 3. | Mass loss of torrefaction, % | 23 | 27 | 5–22 | Tumuluru et al. [34] |

| 4. | Lightness (L*) of native pellets | 36.5 | 38.1 | 62 (beech) | Mitani and Barboutis [56] |

| 5. | Lightness (L*) of torrefied pellets | 19.4 | 28.5 | 45 (beech) | Mitani and Barboutis [56] |

| 6. | Calorific value for native biomass, MJ/kg | 20.7 | 20.5 | 17.5–19.5 | DIN 51731 |

| 7. | Calorific value after torrefaction, MJ/kg | 21.4 | 21.2 | 22.9 | Bi et al. [67] |

| 8. | Compressive strength, N/mm2 | 1.02 | 0.33 | 0.53 | Brozek et al. [68,69] |

| 9. | Abrasion of briquettes, % | 4.22 | 1.92 | (1.5–3)% | SS 18 17 20 |

| 10. | Ash content, % | 0.58 | 0.62 | Max 6% | ONORM M7135 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dragusanu, V.; Lunguleasa, A.; Spirchez, C.; Scriba, C. Some Properties of Briquettes and Pellets Obtained from the Biomass of Energetic Willow (Salix viminalis L.) in Comparison with Those from Oak (Quercus robur). Forests 2023, 14, 1134. https://doi.org/10.3390/f14061134

Dragusanu V, Lunguleasa A, Spirchez C, Scriba C. Some Properties of Briquettes and Pellets Obtained from the Biomass of Energetic Willow (Salix viminalis L.) in Comparison with Those from Oak (Quercus robur). Forests. 2023; 14(6):1134. https://doi.org/10.3390/f14061134

Chicago/Turabian StyleDragusanu (Japalela), Veronica, Aurel Lunguleasa, Cosmin Spirchez, and Cezar Scriba. 2023. "Some Properties of Briquettes and Pellets Obtained from the Biomass of Energetic Willow (Salix viminalis L.) in Comparison with Those from Oak (Quercus robur)" Forests 14, no. 6: 1134. https://doi.org/10.3390/f14061134

APA StyleDragusanu, V., Lunguleasa, A., Spirchez, C., & Scriba, C. (2023). Some Properties of Briquettes and Pellets Obtained from the Biomass of Energetic Willow (Salix viminalis L.) in Comparison with Those from Oak (Quercus robur). Forests, 14(6), 1134. https://doi.org/10.3390/f14061134