Abstract

The application of various graphic analytical software solutions in the research aimed at designing and determining the ergonomic and biomechanical harmony between forestry workers’ anthropometric measures and their working positions and movements is still scientifically incomplete and largely unexplored in forestry, especially regarding motor manual work with chainsaws. Accordingly, the aim of this research is to numerically represent the general kinematic model of forestry workers’ upper body while starting a chainsaw. The same is determined by using a state-of-the-art motion capture suit with inertial measurement units (IMUs). An additional research aim is to investigate numerical values of the forestry worker kinematic model against the three potentially applicable methods of starting a chainsaw and work experience with a chainsaw. Field data collection was carried out during the spring and summer of 2022 and 2023, and a total of 51 chainsaw workers were sampled in different relief areas. The results of the subject research show that none of the observed methods of starting a chainsaw are entirely safe for the worker, concerning the aspect of MSD development, if the body movements within the working element are performed in an incorrect way. From safety and kinematic aspects, regarding forestry workers’ upper body values, the most neutral work posture (N-pose) is when a worker is using the “between the knees” method. The method “from the ground” can be used as secondary option if the workers are educated in taking the correct position of the upper body, i.e., to practice the rule of hip hinge. With the aim of extending the working ability and working life of forestry workers, interdisciplinary cooperation between occupational medicine, kinesiologists, and forestry experts is needed to create a guide of statodynamic efforts and correct postural movement habits during motor manual work in logging operations.

1. Introduction

Regardless of the significant developments achieved in forestry mechanization in the last three decades, together with the wide range of available Industry 4.0 and 5.0 solutions, logging operations in countries of southeastern Europe, but also beyond, are still primarily performed motor manually by using chainsaws. This greatly contributes to designating everyday forestry work as one of the most physically demanding and dangerous occupations in the world [1,2,3,4]. Consequently, today’s forestry sector is constantly faced with the challenge of obtaining a qualified and sustainable workforce, while the shortage of skilled forestry workers is becoming an increasingly frequent problem in European and global forestry [5,6,7,8]. Thereat, continuous development of forest sector technologies and know-how can potentially ensure workforce retention as processes like job demands and skill requirements change.

Everyday motor manual harvesting activities expose forestry workers to a wide range of risk factors, such as lifting heavy loads, repetitive movements, prolonged adoption of awkward postures, lack of breaks, etc. These can, in addition to frequent work accidents and numerous professional diseases, cause significant musculoskeletal disorders (MSDs) [4,9,10]. Röjgren and Widell [10] pointed out that there is a strong correlation between MSDs and factors of the working environment where exposure to vibrations, a substantial part of manual work, and exposure to extreme temperatures [11,12] stand out as proactive factors in the development of MSDs in workers. Accordingly, lower back pain is one of the most common reasons for work absenteeism and is often a recurring ailment [10], where the WHO [13] cites that 568 million people worldwide suffer from the ailment. In the forestry sector, MSDs have been frequently reported by chainsaw workers regarding different body areas like hands, elbows, shoulders, neck [4,14,15], with constantly occurring pain in the lower back being experienced by 38% [15] to almost 71% [4] of workers.

In biomechanical research, the human body is viewed as a set of connected rigid segments. Within the framework of kinematic research, worker safety is observed from the viewpoint of postural movement habits at working technique that chainsaw workers apply in real-time field conditions, and in connection to natural forms of movement (N-pose). Improper postural and movement habits can lead to the appearance and progression of structural and/or functional changes in a worker’s locomotor system, and thus to the occurrence of acute and/or cumulative trauma. The application of innovative wearable technology, like a motion capture suit, is increasingly being used in ergonomic research [16,17] and in sports for the investigation of kinematic differences in the technical performance of a certain elements [18,19]. The application of similar technologies for ergonomic research in the forestry sector is more recent, and is mainly related to body posture analysis using the Zephry Bioharness measurement system [20], Center of Mass (CoM) assessments using a motion capture suit [21], and designing a work aid for a chainsaw workers aligned with the solutions of Industry 5.0 [10].

The application of various graphic analytical software solutions in the research aimed at designing and determining the ergonomic and biomechanical harmony between forestry workers’ anthropometric measures and their working positions and movements is still scientifically incomplete and largely unexplored in forestry, especially regarding motor manual work with chainsaws. According to Masci et al. [18] occupational research in the field of forestry requires innovative methodologies to assess anatomical and cardiovascular parameters, especially under challenging environmental work conditions. Attention to body mechanics is considered fundamental for work design interventions directed at reducing the physiological effort and potential injuries in professional chainsaw workers. Accordingly, the aim of this research is to numerically represent the general kinematic model of the forestry workers’ upper body while starting a chainsaw. The same is determined by using a state-of-the-art motion capture suit with inertial measurement units (IMUs). An additional research aim is to investigate numerical values of the forestry worker kinematic model against the three potentially applicable methods of starting a chainsaw and work experience with a chainsaw.

It should be noted that there are solutions to almost completely eliminate the chainsaw starting procedure, i.e., to mitigate human input in that process. By using electric or cordless (battery-powered) chainsaws there is no need for a chainsaw starting procedure because the chain is instantly driven by simply pressing a switch. However, the plausibility of the application of battery-powered chainsaws in felling and processing operations is still questionable [22]. Another solution is using an external power source (portable drill) and quick-start extension of the crankshaft to crank the two-stroke engine of the chainsaw [23] (patent number 10087905). A limiting factor is of course the need to have a portable drill onsite during every chainsaw starting.

2. Materials and Methods

Field surveys and data collection were carried out during the spring and summer of 2022 and 2023, encompassing the entire territory of the Republic of Croatia. A total of 51 chainsaw workers were sampled in different relief areas, from lowland to mountainous regions. Sampling of forestry workers was in accordance with the territorial distribution of the regional forest administrations within the state forestry company Hrvatske šume Ltd. (Zagreb, Croatia), which manages 76% of forests and forest land in Croatia [24]. The Stihl brand of chainsaw was used by all sampled workers, but the model of the chainsaw differed from worker to worker (MS 500i in 17%, MS 461 in 18%, MS 661 in 24%, and MS 462 in 41% of cases).

The methodology of worker sampling included an intentional (quota) sample based on the personal judgment of the researcher due to health reasons and technical limitations of the used measuring equipment. The underlying health problem was related to possible transmission of COVID-19 or hepatitis virus, so to this end, during one day of measurement, only one worker could wear an available Lycra suit. The second limitation was related to the size of the suit, i.e., workers’ anthropometric measures, especially the upper torso, and also their personal consent to wear the motion capture suit with sensors on almost naked body under their working suit. Regardless of the stated limitations and high time costs when using Xsens technologies, motion capture with camera and image analysis solutions were not used in this case study because the main goal was to collect and analyze joint angle values for the working element of starting a chainsaw against three methods used in practice. Methods using cameras, illuminating light, and markers cannot measure and process target-defined data (joint angle values), nor can they provide uniform values that are scientifically acceptable for further processing. During the two-year sampling of the forest workers, the researchers considered representativeness according to age group and work experience.

This study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by the Ethical Committee of the Faculty of Forestry and Wood Technology of Zagreb University (protocol code 251-72-06-20-1, 22 January 2020), and the same was accepted by the Management board of the Croatian Science Foundation. All sampled workers at forest sites, one week before field measurements, received information about the purpose of the research and provided their informed consent for inclusion before they participated in this study.

2.1. Field Measurement with the Xsens Motion Capture Suit

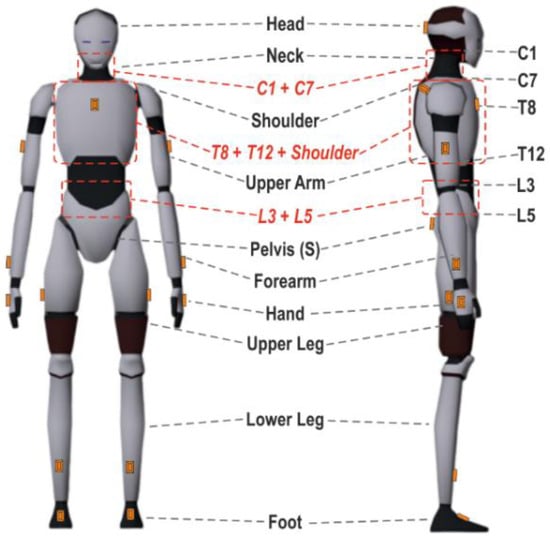

Descriptive values obtained by the kinematic analysis of the forestry workers’ upper body during a chainsaw starting activity were measured with Xsens MVN Link motion capture suit and analyzed with MVN BIOMECH software® (Xsens, MVN Analyzer Pro, Version 2021.2.0, Enschede, The Netherlands). The Xsens MVN motion capture suit (Figure 1) is an easy-to-use system for full-body human motion capture that consists of 17 miniature inertial 3DOF Orientation Trackers (MTx sensors). The MTx is an inertial and magnetic measurement unit and comprises 3D gyroscopes, 3D accelerometers, and 3D magnetometers that are chained together to the Xbus Masters. The Xbus Masters synchronize all sensor sampling, provide sensors with power, and handle wireless communication with the PC or laptop [25]. The sampling rate was set at 240 HZ for the optoelectronic system.

Figure 1.

Visualization of sensor positioning on the Xsens motion capture suit.

All values of the kinematic indicators, which are expressed through joint angle values, as part of the obtained and analyzed chainsaw worker model, are shown in degrees. According to literary sources [26,27], back extension values are up to 25° while flexion is up to 90°. Lateral bending (flexion) for the back is up to 25° left or right. For the neck area, extension is up to 60° and flexion up to 50°. Shoulder extension is up to 50°, and flexion up to 150°. Additionally, shoulder abduction is up to 150° and adduction is up to 30°. For the elbow (forearm) and wrist, pronation or supination is up to 80° left or right. Regarding the wrist, flexion or extension is up to 60°.

In the two-year period, a total of 51 chainsaw workers (Table 1) were sampled and measured using the Xsens MVN Link motion capture suit and parallelly recorded using a GoPro Hero 8 video camera. The basic anthropometric parameters of each worker were recorded before the field measurements, and the calibration of the sensors on the motion capture suit was performed using N-pose [28].

Table 1.

Anthropometric values of sampled chainsaw workers (n = 51).

2.2. Data Processing and Statistical Analysis

MVN BIOMECH software® (Xsens, MVN Analyzer Pro, Version 2021.2.0, Enschede, The Netherlands) was used for offline data processing. The sampling rate was set at 240 HZ, which resulted in 81,214 recorded frames (1 frame represents 14 milliseconds of data recording) for further statistical analysis. Systematization and filtration of the primary data were performed in the software package Microsoft Excel® (Version 2311), and further descriptive processing of data and testing of differences were performed using the statistical software package Statistica® (TIBCO Software Inc., version 14, Palo Alto, CA, USA) and SPSS® (IBM-SPSS Inc., version 28, Armonk, NY, USA).

Calculation and display of basic characteristics of sampled workers was performed using descriptive statistical analysis. Two variables were used to examine the differences within the kinematic values of the forestry workers’ upper body: (a) method of starting the chainsaw and (b) work experience with a chainsaw. The methods of starting the chainsaw were divided into three groups (group 1—“from the ground”; 2—“between the knees”; 3—“drop starting”). From the total number of sampled workers, 13 used the “from the ground” method, 17 used the “between the knees” method, and 21 used the “drop start” method. The second variable, concerning chainsaw work experience in the logging industry, was also divided into three groups (group 1 = 5 years or less; group 2 = from 6 to 15 years; group 3 = 16 years or more). The Shapiro–Wilk and Levine tests were used to test distribution normality and homogeneity of variance for each variable, and based on the obtained results, the following data processing was performed: the Kruskal–Wallis rank-based nonparametric test was used to test the differences between the groups with the two previously mentioned variables and the Mann–Whitney U test was performed with the aim of finding out which groups made the difference.

3. Results

Table 2 shows the general information regarding chainsaw workers who participated in the kinematic study. Obtained values regarding work experience with a chainsaw and age correspond well with the distribution of the general worker population while body mass and body mass index are lower due to the aforementioned limitation related to wearing the full-body human motion capture suit and its size.

Table 2.

Descriptive values of sampled chainsaw workers (N = 51).

In Table 3, the descriptive kinematic values of the forestry workers’ upper body summarized for all three methods of starting the chainsaw are shown. Descriptive data show higher mean values of flexion in the area of the spine, especially between the pelvic and lumbar spine segment (L5S1) and between the thoracic and cervical segments of the spine (C7T1). Due to the different methods of starting the chainsaw, negative minimum values were also achieved, which represent the extension of the worker’s spine (Table 3). No significant values were measured in the case of lateral flexion of the spine (Table 3). High mean and maximum flexion values were also measured at the right shoulder and right elbow, compared to the values measured on the left side of the chainsaw worker’s body. Regarding the wrist, higher negative values were achieved on the left side of the body, which represents a more pronounced extension of the left hand compared to the right hand (Table 3).

Table 3.

Kinematic values of the forestry workers’ upper body while starting a chainsaw (N = 51).

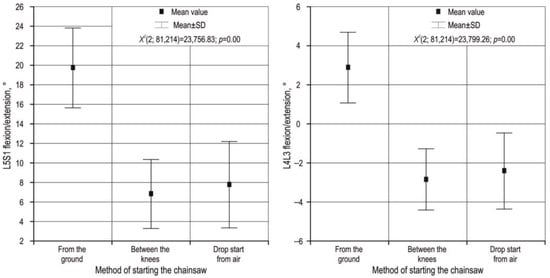

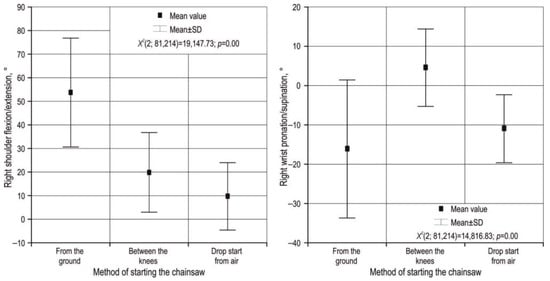

Table 4 shows the results of the Kruskal–Wallis H test regarding the three methods of starting the chainsaw in analyzed kinematic variables of forestry workers’ upper body. All variables showed that there is a statistically significant difference in upper body posture between the three chainsaw starting methods (Table 4). In the area of the spine (C1-C7-T1-T12-L1-L5-S1) the measured kinematic values of lateral bending are statistically different between the three methods, but the difference in question is not nearly the same as in flexion/extension of the subject area (Table 4, Figure 2). Statistically significant and perceptible differences in the measured kinematic values, compared to the three methods of starting a chainsaw, were also obtained in the flexion and extension of the right and left shoulder (Table 4, Figure 3). Regarding pronation/supination values, statistical differences were obtained for the right and left wrist (Table 4, Figure 3).

Table 4.

Kruskal–Wallis H test results for three methods of starting a chainsaw.

Figure 2.

Flexion and extension of the lower spine area versus the three methods of starting a chainsaw.

Figure 3.

Visual display of workers’ spine flexion regarding three methods of starting a chainsaw (A) from the ground, (B) between the knees, (C) “drop starting”.

The Mann–Whitney U post-hoc test was used to determine the difference between groups for certain variables from Table 4. Significantly greater flexion of the spine in the L5S1 zone (Figure 2 and Figure 3) is visible within the “from the ground” method (M = 19.74; Md = 20.70) compared to the “between the knees” method (M = 6.83; Md = 7.35) (Z = 137.01; p = 0.00) and compared to the “drop start” method (M = 7.78; Md = 7.01) (Z = 134.73; p = 0.00). For the L4L3 spine area (Figure 2 and Figure 3) a significant difference was found between the “from the ground” method (M = 2.93; Md = 3.36) and “between the knees” method (M = −2.81; Md = −2.57) (Z = 137.06; p = 0.00) and also compared to the “drop start” method (M = −2.38; Md = −2.71) (Z = 134.88; p = 0.00). A statistically significant difference between the “from the ground” method and the remaining two methods was also found in flexion/extension values of the T1C7 spine area (Z = −67.03; p = 0.00) and in the C1 and head area (Z = −105.66; p = 0.00)

Higher positive values and significant differences for right shoulder flexion (Figure 4) were recorded for the “from the ground” method (M = 54.18; Md = 62.54) compared to the “between the knees” method (M = 20.32; Md = 20.79) (Z = 103.89; p = 0.00) and also compared to the “drop start” method (M = 10.16; Md = 11.57) (Z = 122.59; p = 0.00). The significant difference for right shoulder flexion was also recorded between the “between the knees” method (M = 20.32; Md = 20.79) and the “drop start” method (M = 10.16; Md = 11.57) (Z = 63.78; p = 0.00). Recorded values for left shoulder flexion were also significantly different for the “from the ground” method (M = 58.81; Md = 62.79) compared to the “between the knees” method (M = 26.78; Md = 28.56) (Z = 123.09; p = 0.00) and also compared to the “drop start” method (M = 9.16; Md = 6.34) (Z = 139.82; p = 0.00).

Figure 4.

Deviation of right shoulder and wrist kinematic values in relation to the three methods of starting a chainsaw.

In the flexion or extension of the right wrist, a significant difference in the measured values was found between the “drop start” method (M = 1.78; Md = 0.96) and the “from the ground” method (M = −5.88; Md = −6.28) (Z = −42.82; p = 0.00) and also the “between the knees” method (M = −6.38; Md = −6.20) (Z = −44.57 ; p = 0.00). For the left wrist flexion or extension values, a significant difference was found between the “from the ground” method (M = −20.00; Md = −22.67) and the “between the knees” method (M = −11.09; Md = −11.17) (Z = −63.49; p = 0.00) and also the “drop start” method (M = −11.23; Md = −11.50) (Z = −66.57; p = 0.00). Regarding the pronation or supination values of the right joint (Figure 4), positive values close to the N-pose were obtained with the “between the knees” method (M = 4.56; Md = 2.07). The values obtained within this starting method were statistically different from the “from the ground” method (M = −15.87; Md = −16.23) (Z = −117.61; p = 0.00) and the “drop start” method (M = −10.72; Md = −11.25) (Z = 107.02; p = 0.00).

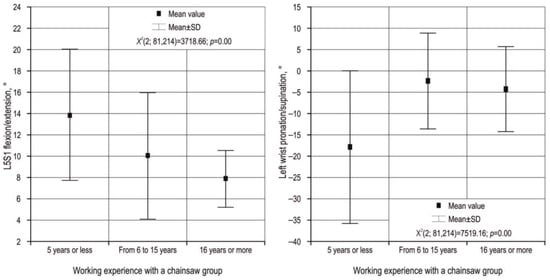

According to the clustered groups related to work experience with a chainsaw, the Kruskal–Wallis H test results in Table 5 are shown only for variables that displayed a noticeably significant difference in Table 4. All analyzed variables show that there is a statistically significant difference in upper body posture between the three groups regarding work experience with a chainsaw (Table 5). In all areas of the forestry workers’ upper body, the measured flexion or extension kinematic values differ statistically regarding work experience with a chainsaw (Table 5).

Table 5.

Kruskal–Wallis H test results for work experience with a chainsaw groups.

Related to work experience with a chainsaw, higher measured and statistically different L5S1 flexion values for the spine area (Figure 5) are visible within the group with 5 years or less work experience (M = 13.92; Md = 15.58) compared to the 6 to 15 years of work experience group (M = 9.84; Md = 8.11) (Z = 47.87 ; p = 0.00) and also compared to the 16 years or more of work experience group (M = 7.52; Md = 8.27) (Z = 57.82; p = 0.00). For the left wrist example (Figure 5), there is a graphically visible and statistically proven difference in the measured values of pronation and supination between the 5 years or less work experience group (M = −17.95; Md = −18.27) compared to the 6 to 15 years of work experience group (M = −2.40; Md = −5.30) (Z = −82.63; p = 0.00) and also compared to the 16 years or more of work experience group (M = −4.30; Md = −1.04) (Z = −59.09; p = 0.00).

Figure 5.

Example of differences in kinematic values for work experience with chainsaw groups.

4. Discussion

According to some estimates, around 13.7 million workers are formally (legally) employed in forestry in the world today [29], and annual felling is estimated at 3.5 billion m3 of wood [30]. Forestry work, especially logging, is a high-risk, physically very intensive, and professionally highly demanding activity. The basic characteristic of motor manual work in logging i.e., when performing most of the elements of the working technique (e.g., starting the chainsaw, performing undercut, performing final cut, etc.) in felling and processing of trees is constantly leaning forward while holding the chainsaw in front of the trunk. If the forward lean of the trunk is performed improperly, the aforementioned entails other compensatory movements, and thus the potential accumulation of micro-traumas in the form of musculoskeletal disorders (MSDs) or even immediate injuries. According to EU-OSHA [31], physical and biomechanical risk factors for the occurrence of MSDs are load handling, especially when bending and turning. The basic consensus of recent studies [4,14,15] is that manual work with a chainsaw correlates with a significant risk of developing MSDs in the lumbar spine of chainsaw workers. The lumbar spine serves several functions, including supporting the upper body and distributing body weight, allowing for body movement, and creating a protective shell for the spinal cord [32]. The lumbar spine also allows for movement in several directions: flexion (bending forwards), extension (bending backwards), rotation, and lateral bending. In kinesiology, it is generally known that the lumbar part of the spine most often lacks stability, not mobility [33]. According to Röjgren and Widell [10], the lower back is mainly affected by body posture and the physical load when performing work tasks with a chainsaw, frequently executed with a forward-leaning posture and standing with bent legs. The tasks with the highest risk of postural strain are felling and limbing, where the working posture in combination with duration is classified as high ergonomic risk [10]. Anderson, Otun, and London [34] found that workers who perform manual handling with spine flexion have significantly greater problems with intervertebral discs compared to those who perform it with a neutral spine. This regards spina shear forces and intervertebral compression. Wilke et al. [35] showed that the pressure in the intervertebral disc (L4–L5) is 35% higher when the person performs manual handling of 20 kg loads with spine flexion (2.3 MPa) than with neutral spine (1.7 MPa). Also, McGill [36] stated that the margin of safety is much larger in compressive mode than in shear mode since the spine can safely tolerate well over 10 kN in compression, but 1000 N of shear causes injury with cyclic loading.

The objective of this research was to numerically represent the general kinematic model of forestry workers’ upper body while starting a chainsaw utilizing a state-of-the-art motion capture suit. The aim was also to investigate the numerical values of the forestry workers’ kinematic model against the three potentially applicable methods of starting the chainsaw.

Regarding the results of this study, significantly greater flexion of the spine in the L5S1 zone was recorded in the “from the ground” method. The above indicates the greatest deviation in worker posture from the mostly neutral work posture (N-pose), which in everyday and frequent execution can lead to the development of MSDs. Excessive lumbar spine flexion can be named as an injury mechanism, and neutral pelvic and spine position in different working tasks can be named as an injury prevention mechanism. McGill [36] showed the reduction in shear forces of lumbar spine from 1900 N to 200 N when a person changed from flexed posture to neutral spine posture. The obtained results of flexion of the lower part of the spine are in accordance with the obtained values of Center of Mass vertical deviation [21] and with other findings on postural strain in the spine area [10,20,32,37]. To reduce the risk of musculoskeletal disorders, chainsaw workers should be educated in taking the correct position of the upper body, i.e., the rule of hip hinge [38]. For the L3L4 spine area, kinematic data showed flexion of the vertebrae in the “from the ground” method, which deviates to a lesser extent from the N-pose. For the remaining two starting methods, a slight extension of the L3L4 spine area was determined. In the area of the C1 vertebra and head, the mostly neutral work posture (N-pose) was assumed with the “drop start” method, while the greatest extension of the head was recorded with the “from the ground” method. In the shoulder area (right and left), the highest flexion values were also recorded in the “from the ground” method. For the left wrist, the highest extension values (farthest from N-position) were recorded with the “from the ground” method, and for the right wrist flexion values closest to the N-position they were recorded for the “drop start” method. Kinematic data for the right and left wrist show supination values close to the N-pose during the “between the knees” method, and high pronation values in the remaining two methods. When starting a chainsaw, it is recommended that the forearm and hand are in a semi-supinated position [38], not in pronation (palm towards the ground). This is especially important when starting a chainsaw, where the right shoulder must be in internal rotation to avoid contact between the supraspinatus tendon and the acromion [39] to avoid irritation and the development of shoulder impingement syndrome.

For the clustered groups related to work experience with a chainsaw, all variables resulted in a statistically significant difference in upper body posture. Higher flexion values were recorded for the L5S1 spine area for the 5 years or less of work experience group. This is in line with the research results of Landekić et al. [21], where younger chainsaw workers with less work experience had lower values of the CoM vertical deviation, i.e., the workers CoM position is more forward bent (or in flexion) on the x-axis.

Certain limitations should be considered when interpreting the results of this research. The obtained numerical values of the kinematic model for the working element of starting a chainsaw largely depend on the implementation of the first calibration measurement, which refers to the measured workers taking the correct N-pose, as well as providing detailed instructions to the worker and active observation of the entire calibration process by the researcher. Secondly, the presence of researchers may have influenced the workers in the selection of chainsaw starting method in contrast to everyday practice. Thirdly, although the results show a difference in the measured kinematic values for work experience with chainsaw groups, future inspection of the differences should be carried out against chainsaw starting methods within defined groups of work experience. In this research, it was not possible to investigate the above due to too small a sample within certain groups.

5. Conclusions

The forestry sector in Europe and worldwide is increasingly faced with a noticeable lack of productive forestry workers due to (a) demographic trends (population ageing, migrations, declining birth rates, rural depopulation), (b) a significant share of informal employment in forestry, (c) a pronounced lack of interest in 3D “black collar” jobs, and (d) high-risk and physically demanding work activities with numerous injuries and occupational diseases. If we want to practice sustainable forest management in the future, it is also necessary to systematically develop a safety culture where the lifelong professional training of forestry workers through correct work techniques combined with the recertification process is the key starting point in improving the current situation.

The main objective of this case study was to numerically represent, through joint angels, the general kinematic model of forestry workers’ upper body while starting a chainsaw and to compare the obtained values against three potentially applicable methods of starting a chainsaw and work experience with a chainsaw. The results of the subject research show that none of the observed methods of starting a chainsaw are entirely safe for the worker, concerning the aspect of MSD development, if the body movements within the working element are performed in an incorrect way. From safety and kinematic aspects, regarding forestry workers’ upper body values, the most neutral work posture (N-pose) is when a worker is using the “between the knees” method. The second method regarding starting the chainsaw, “from the ground”, can be used as a secondary option from an ergonomic point of view if the workers are educated in taking the correct upper body position, i.e., the rule of hip hinge. The hip hinge represents the ability to move the hips while not allowing the lumbar spine (low back) to flex along with it, i.e., to preserve the neutral position of the spine (straight back). Additional knowledge when starting a chainsaw is particularly related to flexion and rotation of the right shoulder and taking the position of semi-supination of the right forearm and wrist when pulling the starter rope to avoid irritation and the development of shoulder impingement syndrome. Future directions of the current study should be the development of ergonomic guidelines for chainsaw worker training programs related to the use of correct postural movement habits when performing a particular work element (such as processing of root buttress, performing undercut, preforming final cut, etc.) in felling and tree processing operations. However, before making the above, it is necessary to make additional analyses related to measuring/mapping the areas of worker hands, shoulders, and spine movements within the working area defined by the structural elements of a chainsaw for all three methods. With the aim of extending the working ability and working life of forestry workers, interdisciplinary cooperation between occupational medicine, kinesiologists, and forestry safety experts is needed to create a guide and implement practical education of statodynamic efforts and correct postural movement habits during motor manual work in logging operations.

Author Contributions

Conceptualization, M.L. and J.N.; methodology, M.L. and M.Š.; validation, Z.P., M.B. (Marin Bačić) and J.N.; formal analysis, M.L.; data curation, M.L. and M.B. (Matija Bakarić); writing—original draft preparation, M.L., M.Š. and M.B. (Marin Bačić); writing—review and editing, J.N. and Z.P.; visualization, M.B. (Matija Bakarić). All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the Croatian Science Foundation within the Project “Increasing the Competitiveness of Forestry Sector Through Development of Safety Culture (ForSaf2024)”, project number IP-2020-02-7637. The APC was also funded by the Croatian Science Foundation and the Faculty of Forestry and Wood Technology of Zagreb University.

Institutional Review Board Statement

All subjects provided their informed consent for inclusion before participating in this study. This study was conducted according to the guidelines of the Declaration of Helsinki and the protocol was approved by the Ethics Committee of Faculty of Forestry and Wood Technology of Zagreb University (protocol code 251-72-06-20-1, 22 January 2020).

Informed Consent Statement

Not applicable.

Data Availability Statement

Data supporting this study may be provided upon reasonable request to the authors.

Acknowledgments

The research was funded by the Croatian Science Foundation within the project «Increasing the Competitiveness of the Forestry Sector Through the Development of Safety Culture (ForSaf2024)», project number IP-2020-02-7637.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Blombäck, P. Improving Occupational Safety and Health: The International Labour Organization’s Contribution; FAO: Rome, Italy, 2002. [Google Scholar]

- Gejdoš, M.; Vlčkova, M.; Allmanova, Z.; Blažova, Ž. Trends in Workplace Injuries in Slovak Forest Enterprises. Int. J. Environ. Res. Public Health 2019, 16, 141. [Google Scholar] [CrossRef] [PubMed]

- Garland, J.; Cedergren, J.; Eliasson, L.; van Hensbergen, H.; McEwan, A.; Wästerlund, D. Occupational Safety and Health in Forest Harvesting and Silviculture—A Compendium for Practitioners and Instructors; Forestry Working Paper No. 14; FAO: Rome, Italy, 2020. [Google Scholar]

- Landekić, M.; Šporčić, M.; Bačić, M.; Pandur, Z.; Bakarić, M. Workability and Physical Wellbeing Among Chainsaw Operators in Croatia. Croat. J. For. Eng. 2023, 44, 83–94. [Google Scholar] [CrossRef]

- Salminen, S.; Klein, T.; Ojanen, K. Risk taking and accident frequency among finnish forestry workers. Saf. Sci. 1999, 33, 143–153. [Google Scholar] [CrossRef]

- Perpiñá Castillo, C.; Jacobs-Crisioni, C.; Kavalov, B.; Lavalle, C. Socio-economic and demographic trends in EU rural areas: An indicator-based assessment with LUISA territorial modelling platform. In Proceedings of the 5th International Conference GISTAM, Heraklion, Greek, 3–5 May 2019; pp. 250–258. [Google Scholar]

- Cacot, E.; Grulois, S.; Thivolle-Cazat, A.; Magaud, P. Mechanization of French logging operations: Challenges and prospects in 2020. In Proceedings of the 48th FORMEC Symposioum, Linz, Austria, 4–8 October 2015; pp. 23–30. [Google Scholar]

- UNECE/FAO. Forest Sector Workforce in the UNECE Region—Overview of the Social and Economic Trends with Impact on the Forest Sector; Geneva Timber and Forest Discussion Paper 76; United Nations: Geneva, Switzerland, 2020; p. 77.

- European Agency for Safety and Health at Work—Annual Report 2017; Publications Office of the European: Luxembourg, 2018; ISBN 978-92-9496-815-9. ISSN 1681-0155.

- Röjgren, S.; Widell, A. Development of Exoskeleton for Loggers—User Centred Design of Passive Lower-Back Support for Motor-Manual Tree Felling, in Collaboration with Husqvarna AB. Master’s Thesis, Chalmers University of Technology, Department of Industrial and Materials Science Gothenburg, Göteborg, Sweden, 2022; p. 82. [Google Scholar]

- Nunes, I.; Bush, P. Work-Related Musculoskeletal Disorders Assessment and Prevention; Book Section 1; IntechOpen: Rijeka, Croatia, 2012; pp. 1–26. [Google Scholar]

- Bevan, S. Economic impact of musculoskeletal disorders (MSDs) on work in Europe. Best Pract. Res. Clin. Rheumatol. 2015, 29, 356–373. [Google Scholar] [CrossRef] [PubMed]

- WHO. Musculoskeletal Conditions. Available online: https://www.who.int/news-room/fact-sheets/detail/musculoskeletal-conditions (accessed on 19 September 2023).

- Grzywinski, W.; Wandycz, A.; Tomczak, A.; Jelonek, T. The prevalence of self-reported musculoskeletal symptoms among loggers in Poland. Int. J. Ind. Ergon. 2016, 52, 12–17. [Google Scholar] [CrossRef]

- Lagerstrom, E.; Magzamen, S.; Brazile, W.; Rosecrance, J. Active surveillance of musculoskeletal disorder symptoms in the development of safety interventions for professional loggers. Safety 2019, 5, 23. [Google Scholar] [CrossRef] [PubMed]

- Conforti, I.; Ilaria, M.; Zaccaria, D.P.; Eduardo, P. Measuring Biomechanical Risk in Lifting Load Tasks Machine-Learning Approach. Sensors 2020, 20, 1557. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Kim, W.; Zhang, Y.; Xiong, S. Development and validation of a wearable inertial sensors-based automated system for assessing work-related musculoskeletal disorders in the workspace. Int. J. Environ. Res. Public Health 2020, 17, 6050. [Google Scholar] [CrossRef] [PubMed]

- Cigrovski, V.; Rupčić, T.; Bon, I.; Očić, M.; Krističević, T. How can Xsens kinematic suit add to our understanding of a slalom turn: A case study in laboratory and field conditions. Kinesiology 2020, 52, 187–195. [Google Scholar] [CrossRef]

- Bon, I.; Očić, M.; Cigrovski, V.; Rupčić, T.; Knjaz, D. What Are Kinematic and Kinetic Differences between Short and Parallel Turn in Alpine Skiing? Int. J. Environ. Res. Public Health 2021, 18, 3029. [Google Scholar] [CrossRef]

- Masci, F.; Spatari, G.; Bortolotti, S.; Giorgianni, C.M.; Antonangeli, L.M.; Rosecrance, J.; Colosio, C. Assessing the Impact of Work Activities on the Physiological Load in a Sample of Loggers in Sicily (Italy). Int. J. Environ. Res. Public Health 2022, 19, 7695. [Google Scholar] [CrossRef] [PubMed]

- Landekić, M.; Bačić, M.; Bakarić, M.; Šporčić, M.; Pandur, Z. Working Posture and the Center of Mass Assessment while Starting a Chainsaw: A Case Study among Forestry Workers in Croatia. Forests 2023, 14, 395. [Google Scholar] [CrossRef]

- Pandur, Z.; Bačić, M.; Šušnjar, M.; Landekić, M.; Šporčić, M.; Jambreković, B.; Lepoglavec, K. Energy Consumption and Cutting Performance of Battery-Powered Chainsaws. Forests 2023, 14, 1329. [Google Scholar] [CrossRef]

- Budden, D. Patents by Inventor Doyle Budden—Method and Apparatus for Starting a Small Combustion Engine. Patent number 10087905, 2018. Available online: https://patents.justia.com/inventor/doyle-budden (accessed on 19 November 2023).

- Šume, H. 2022: Forest Administrations—Subsidiaries. Available online: https://www.hrsume.hr/o-nama/uprave-suma/ (accessed on 21 September 2023).

- Roetenberg, D.; Luinge, H.; Slycke, P. Xsens MVN: Full 6DOF Human Motion Tracking Using Miniature Inertial Sensors. Xsens Motion Technol. BV Tech. Rep. 2009, 1, 1–7. [Google Scholar]

- Department of Social & Health Services. Department of Social & Health Services. Range of Joint Motion Evaluation Chart. Rev. 03/2014. Available online: https://www.dshs.wa.gov/sites/default/files/forms/pdf/13-585a.pdf (accessed on 20 September 2023).

- Clark, M.A.; Lucett, S.C.; McGill, E.; Montel, I.; Sutton, B.G. NASM Essentials of Personal Fitness Training, 6th ed.; National Academy of Sports Medicine: Gilbert, AZ, USA; Jones & Bartlett Learning: Burlington, MA, USA, 2018; pp. 1–685. [Google Scholar]

- Xsens Technologies. Calibrating Link—Xsens Video Tutorials. Available online: https://tutorial.xsens.com/video/calibratinglink/ (accessed on 3 October 2023).

- International Lauber Organization (ILO). Industries and Sectors—Forestry, Wood, Pulp and Paper. 2021. Available online: https://www.ilo.org/global/industries-and-sectors/forestry-wood-pulp-and-paper/lang--en/index.htm (accessed on 10 October 2023).

- Garland, J.J. Accident Reporting and Analysis in Forestry: Guidance on Increasing the Safety of Forest Work; Forestry Working Paper, No. 2; FAO: Rome, Italy, 2018; p. 77. Available online: https://www.fao.org/3/i9180en/I9180EN.pdf (accessed on 10 October 2023).

- European Agency for Safety and Health at Work (EU-OSHA). Musculoskeletal Disorders. Available online: https://osha.europa.eu/hr/themes/musculoskeletal-disorders (accessed on 10 October 2023).

- Bogduk, N. Clinical Anatomy of the Lumbar Spine and Sacrum. Elsevier/Churchill Livingstone. 2005. Available online: https://books.google.se/books?id=UYC_NpoFfAsC (accessed on 9 October 2023).

- Cook, G. Athletic Body in Balance; Human Kinetics: Champaign, IL, USA, 2003. [Google Scholar]

- Anderson, J.A.D.; Otun, E.O.I.; London, S.E. Occupational hazards and low back pain. Rev. Environ. Health 1987, 7, 121–149. [Google Scholar] [CrossRef] [PubMed]

- Wilke, H.J.; Neef, P.; Caimi, M.; Hoogland, T.; Claes, L.E. New In-vivo measurements of pressures in disc in daily. Spine 1999, 24, 755–762. [Google Scholar] [CrossRef] [PubMed]

- McGill, S. Low Back Disorders—Evidence Based Prevention and Rehabilitation, 3rd ed.; Human Kinetics: Champaign, IL, USA, 2015. [Google Scholar]

- Sassack, B.; Carrier, J. Anatomy, Back, Lumbar Spine; StatPearls Publishing: St. Petersburg, FL, USA, 2021. Available online: https://www.ncbi.nlm.nih.gov/books/NBK557616/ (accessed on 9 October 2023).

- Muscle & Motion App. The Anatomy & Biomechanics of Movement. Mastering the Hip Hinge. Available online: https://www.muscleandmotion.com/mastering-the-hip-hinge/ (accessed on 25 November 2023).

- Anatomy & Biomechanics of Movement. Shoulder Impingement Syndrome—2. Available online: https://app.strength.muscleandmotion.com/theory-video/102 (accessed on 25 November 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).