1. Introduction

In the specific conditions of forestry in the Slovak Republic (terrain, economic, social conditions, and qualification preconditions), 85% of forest harvesting is carried out by a hand-held chainsaw [

1,

2]. In terms of safety and health at work, working with a hand-held chainsaw in forest harvesting is one of the riskiest tasks in forestry [

1,

3,

4,

5]. Most accidents at work, including fatal ones, are affected by the working methods used and the poor technological discipline of workers rather than work equipment and tools [

6].

From the first half of the 20th century, the working tool of the hand-held chainsaw has undergone dynamic development to become today’s ergonomically, economically, and technologically advanced form. However, the main shortcomings of the impact on human health were also not addressed in terms of the technological nature of the facility. The chainsaw still emits a high sound pressure level at the operator’s ear (above 100 dB) and a relatively high level of vibration on the front and rear handles (up to 6 m/s

2). These negative factors, when exposed to the human body over a long period of time, cause various types of occupational diseases [

7,

8]. The generation of vibrations is mainly related to the reciprocating movement of the chainsaw motor piston, and other components of the saw have a statistically negligible effect on the magnitude of vibrations [

9]. The level of vibration is also fundamentally affected by the sharpness of the chain and its correct tension [

10]. Thus, in the ergonomic dimensioning of the operating parts of chainsaws, the designers focus primarily on user comfort (e.g., heated handles) and the application of damping elements to reduce the negative effect of vibrations [

11,

12].

When developing the technological elements of the chainsaw, the designer must take into account various influencing factors, especially ergonomics. Knowledge of user requirements and preferences is required to create a specific product [

13]. The development of ergonomic elements must be adapted to the specific group of users and their physical dimensions. Work in the forestry sector, especially in forest harvesting, is usually associated with risky conditions, the need for physical fitness and is characterized by great physical effort. Therefore, work with hand-held chainsaws in forest harvesting is almost exclusively performed by men [

14,

15]. Thus, the physical preferences of the male population are taken into account when dimensioning the ergonomic elements of hand-held chainsaws.

Dynamic changes in the human population in the social and technological fields are closely correlated and have resulted in regulations in the field of hand tool design [

1,

16,

17]. The anthropometric dimensions of the adult population are changing in the long run. With the development of human society and rising living standards, they are generally growing. We call this trend of long-term changes in the anthropometric dimensions of the population a secular trend. It is mainly influenced by population feeding, morbidity, and socioeconomic status in the development of the population [

18,

19,

20,

21,

22].

The application of the secular trend in the anthropometric dimensions of the adult population should play a key role in applying the ergonomic principles of new work equipment design. The technical standards for designing the parameters of hand-held chainsaws are limited to the sound pressure and vibration levels at which protective equipment must be used (as they cannot be eliminated below the permissible level). The Geneva-based International Labor Office has published a handbook on “Safe design and use of chainsaws” [

23]. This manual has become the basic rule for the design parameters of hand-held chainsaws. The aim of this work is the analysis of selected anthropometric dimensions of the upper limbs of the adult male population and their comparison with parameters and approaches in the design of controls for manual chainsaws.

2. Materials and Methods

2.1. Anthropometric Analysis

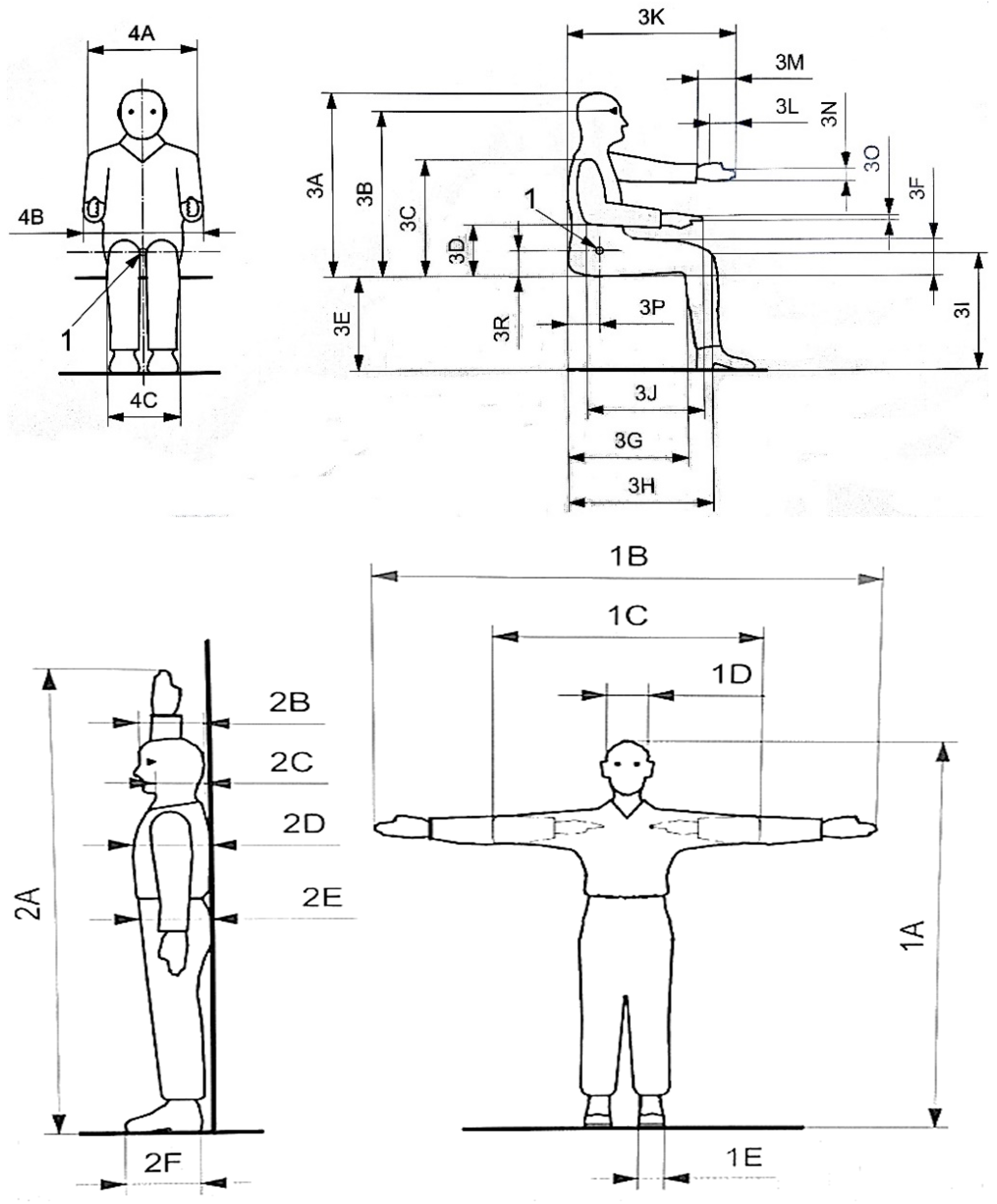

For anthropometric analysis, the body dimensions of the adult male population were measured during the period 2001 to 2021. The range of the group was 1629 men aged 18 to 25. The reason for choosing the adult population is, in particular, the fact that, except for educational purposes, a hand-held chainsaw can only be professionally operated by an adult with the appropriate authorization. The measurements took place at the Technical University in Zvolen (Slovakia). This age group is important in terms of the perspective of working in forestry and determining the development trend for the design of ergonomic parameters. A total of 6 upper limb body dimensions of the adult population were selected in accordance with EN ISO 3411 [

24]. The following dimensions were measured: standing height (1A), upper arm height during flexion in the elbow (3C-3D), forearm fingertip length (3J), anterior arm reach (3K), hand width (3L), and hand length (3M) (

Figure 1). The measurements were performed with a certified anthropometer and a caliper.

The anthropometric data were compared with the recommended design dimensions of the hand-held chainsaw controls set out in the professional manual [

23]. The recommended minimum dimensions for chainsaw designers and their characteristics are shown in

Figure 2 and

Table 1. These dimensions are recommended for chainsaw design and are intended to improve the user comfort of the saw operators, especially in good handling of the saw controls. When assessing anthropometric dimensions, it is also necessary to take into account the fact that the operator uses the chainsaw with gloves of a certain thickness.

2.2. Statistical Analysis

The measured anthropometric data for the whole period were analyzed by simple descriptive statistics to verify the timeliness of the currently recommended dimensions for dimensioning the held controls of chainsaws.

The number of measured subjects was very variable during individual years and varied from 19 measured subjects in 2008 to 340 measured subjects in 2018. The measured results represent only a certain characteristic part of the population at the national level and cannot be generalized in the context of world developments.

Standard statistical parameters were evaluated: arithmetic means, mode, minimum, maximum, variance, standard deviation, and standard error. Statistical data were evaluated and values were calculated using standard procedures mentioned in the literature [

25,

26,

27,

28]. The software Microsoft Excel and STATISTICA 12.0 were used for calculating and visualizing the results.

The proposed parameters of the saw handle from the manual [

23] were compared with the measured anthropometric dimensions. The comparison was evaluated statistically and graphically. The results should provide information on the need to take into account the secular trend in the design of hand tools and especially hand-held chainsaws, which are professionally used in forestry and agriculture.

3. Results

3.1. Anthropometric Analysis

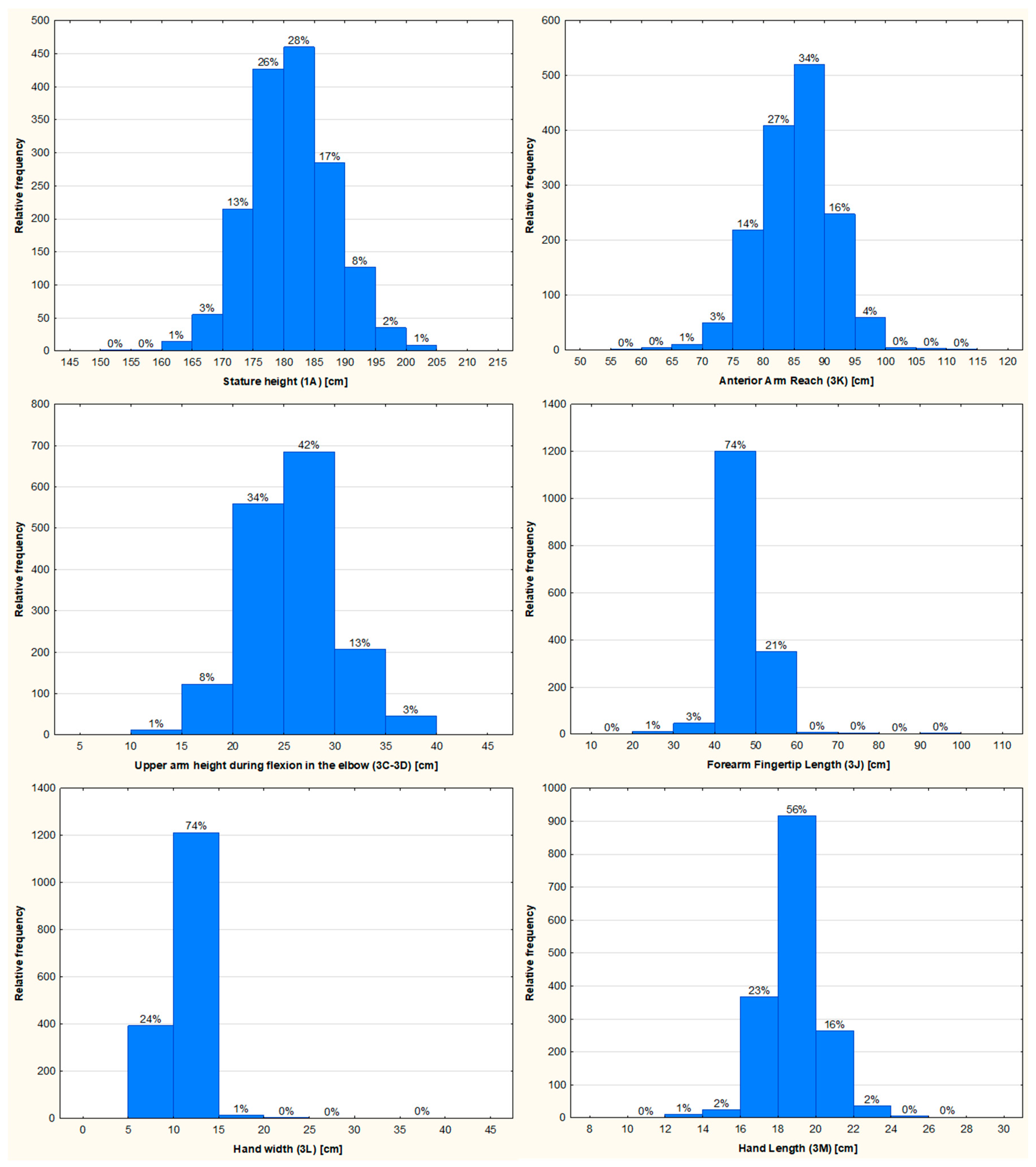

Figure 3 shows histograms of the relative frequency of analyzed anthropometric dimensions and their intervals. The dimension of body height is not directly related to the design of the chainsaw controls, but other body dimensions, which relate to the upper limbs, generally derive from this dimension. Body height in the analyzed population sample varied from 152 cm to 205 cm. The most common value (mode) was for a body height of 180 cm. More than half of the measured individuals ranged from 175 cm to 185 cm. Upper arm height during flexion in the elbow (3C-3D) was in the range of 25–30 cm in more than 40% of the analyzed group. The Anterior arm reaches (3K), most often ranging from 85 to 90 cm.

Forearm–fingertip length was in the range of 40–50 cm in more than 70% of the analyzed group. This body parameter is especially important for the implementation of several branching methods, in combination with the Upper arm height during flexion in the elbow (3C-3D) there is a change in dimensions from folded arms to outstretched, which can affect especially dimension C in the sense of

Table 1.

The dimensions (3L) and (3M) are mainly connected with the controls on the rear handle and the control of the “gas” button. The width of the hand was most often in the range between 10 and 15 cm and the length of the hand in more than half of the analyzed group in the interval between 18 and 20 cm. These dimensions also partially predict the development of the required dimensions of the hand-held chainsaw handles in the coming decades. Simple methods of descriptive statistics were used to adequately evaluate the development of anthropometric dimensions over time. The results can be compared with the recommended values for sizing the controls of hand-held chainsaws in accordance with

Table 1.

3.2. Analysis of Recommended Chainsaw Parameters

Table 2 shows the results of the basic descriptive statistical parameters for the values of anthropometric dimensions in accordance with the EN ISO 3411 standard, which were measured on a selected sample of the male population. The most suitable parameter for assessing the proposed dimensions of chainsaws seems to be the mode that best takes into account the latest trends in the design of their manual controls. It provides an overview of the most common frequency of a given dimension in the analyzed sample. However, it is also necessary to take into account changes over time and the overall development of the characteristic.

The dimensions of the parameters of the rear handle of the chainsaw F, G, E, D are mainly influenced by the dimensions of the length and width of the hand (3L and 3M). The mode of values for hand width (3L) represented the level of 11 cm and values for hand length (3M) represented 20 cm. If we calculate the dimensions of the hand width clearance (F), the finger clearance at the released throttle control trigger (D) and the projected thickness of the rear handle (G) we obtain a minimum dimension of 11 cm. When we compare this dimension with the value of the hand length mode (20 cm), we find that the minimum values for these hand controls are sufficient even with the planned reserve. However, when we compare them with the absolute minimum value of the hand length, it is clear that this limit exactly matches. It can, thus, be stated that the proposed parameters for the rear handle of the hand-held chainsaw are still current and satisfactory.

The clearance between finger on throttle trigger and center line on front handle (C) and the projected thickness of the front handle (B) are closely related to dimension 3J and 3C-3D. The minimum dimension of the forearm fingertip length (3J) was measured at the level of 20 cm in the sample. The prescribed minimum dimension distance (C) is at the level of 18 cm. When we add to this dimension the minimum dimension of the projected handle thickness (B) 1.1 cm, we obtain the value 19.1 cm. The mode of size 3J was at the level of 48 cm. From this point of view, it would be appropriate to adjust the minimum value of dimension (C) in the rules for designing the parameters of saws by 1 cm upwards. This is also due to the expected further long-term development of the dimensions of the adult population. Although the upper arm height during flexion in the elbow (3C-3D) is not a standard dimension in the sense of EN ISO 3411, together with the forearm fingertip length (3J), it is an important dimension for assessing the sum of the dimensions in the C + F design parameters, which should correspond to these dimensions (minimum 25.6 cm). Based on the minimum measured parameters of dimensions (3C-3D) + (3J), the minimum values of this dimension were 22 cm. At mode values, this dimension was a total of 73 cm. From this point of view, the minimum value of the parameters can be considered sufficient, even if it would not be satisfactory at the minimum measured dimensions. From the point of view of the reality and complexity of performing work with a hand-held chainsaw, it cannot be assumed that people who are not physically mature enough will perform this work. From this point of view, the proposed parameters of dimensions C and F concerning dimensions (3C-3D) and (3J) can be considered sufficient.

The sum of the design parameters of the C + F dimensions is also closely related to the parameter of the anterior arm reach (3K), whose minimum value was at the level of 58 cm and the mode value at the level of 90 cm. From this point of view, the design parameters are in order and it is recommended to increase their minimum values. However, it is always necessary to consider these dimensions concerning the stature height (1A), as this affects the working and technological procedures carried out with a hand-held chainsaw.

4. Discussion

The results of the assessment of the anthropometric parameters of the adult male population showed that only dimensions C and F in the design parameters of hand-held chainsaws would need to be adjusted, as they are too undersized.

Kaljun and Dolšak [

13] propose an angle between the front and rear handles of approximately 25°, which should provide sufficient comfort for the operator’s wrist in all working positions. For dimension F, they propose a minimum level of 11 cm, which is 3.4 cm more than the current minimum value. Given our results, this proposal can be considered justified. In other proposals, these authors focused more on the ergonomic parameters of the handle in terms of materials used and the thickness of the vibration damping grip.

Raghav et al. [

17] evaluated the ergonomic parameters of hand-held chainsaws in terms of the effect of the vibrations. They also identified the angle between the front and rear handles of the hand-held chainsaw as the biggest problem in terms of vibration transmission to both hands, suggesting a minimum angle in the range of 30° to 45°.

There are relatively few works involved in evaluating the ergonomic parameters of the control elements of hand-held chainsaws. Rather, existing work has focused on assessing the effect of these controls on the transmission of vibrations from the saw to the operator’s hands. Rottensteiner and Stampfer [

29] found that higher levels of vibration generally affect the operator at the rear handle of the saw, whereas at the front handle the vibrations are lower. They also found that the use of a safety bar did not have a significant effect on the level of vibration. Thus, the negative effects of vibration can be influenced by personal protective equipment or redesign of the controls, but they cannot be completely prevented [

9].

In addition to the ergonomic design, the use of electronic battery hand-held chainsaws appears to reduce noise and vibration. The results suggest, in part, that battery chainsaws can reduce daily vibration exposure by more than 45% and noise exposure by approximately 78.4% compared with internal combustion engine chainsaws [

30]. Landekic et al. [

31] analyzed the vibrations of several types of chainsaws and found that their levels did not affect the age of use of the chainsaw in operation. They identified the performance and type of chainsaw as having a major impact, recommending the use of lighter and smaller chainsaws whenever possible. Due to this recommendation, following our results, it would be possible to reduce some parameters, in particular, the front handle of the hand-held chainsaw, using smaller power parameters. Lighter chainsaws have their benefits in physical workload and postural load. However, a smaller mass of the chainsaw can induce greater vibration levels [

32].

In addition to ergonomic parameters, the risk of accidents and occupational diseases when working with a hand-held chainsaw is mainly influenced by the choice of a suitable type for specific working conditions [

33]. However, this risk is fundamentally influenced in particular by the work organization system and compliance with technological and working methods [

1].

Research at work [

34] has confirmed a higher frequency of wrist injuries among hand-held chainsaw operators, which has even risen among young workers. This indicates that modern trends in handle ergonomic design do not take into account current anthropometric trends in the adult male population. In the design of controls, chainsaw manufacturers should thus return to the proven dimensions and grips, especially the front handles. However, the most suitable solution seems to be the design of several size classes of front handles, which could be easily exchanged to better suit a particular employee.

5. Conclusions

Working with a hand-held chainsaw is one of the most demanding and also riskiest tasks in forestry. Not only the physical fitness, professional competence, and adult age of the operator are required, but also strict adherence to work and technological discipline. Even if all conditions are met, a risk factor for human health and life cannot be completely ruled out. From a long-term perspective, operators are exposed to excessive noise and vibration. They should use personal protective equipment against their side effects. In addition to this protection, hand-held chainsaw designers should pay particular attention to user comfort and minimize unnecessary operator movements when working with the chainsaw. For the winter conditions, there are heated chainsaw handles and new trends are moving towards smaller and lighter chainsaws or battery chainsaws.

However, in addition to emphasizing the development of these new technological solutions, designers should also focus on the ergonomic parameters of the controls and handles concerning the dimensions of the adult population. The results of our work have shown that the recommended minimum dimensions of hand-held chainsaws, which were defined in the 1970s, are still largely satisfactory when considered in correlation with the population average. However, the secular trend and growth of some adult dimensions in the long term is to be taken into account when designing chainsaw controls. In the results section, we have proposed adjustments to the minimum values of some chainsaw controls to take this trend into account as best we can. Most of the dimensioned elements of the front and rear handles are satisfactory in terms of the recommended dimensions. However, to increase the user comfort of the operators, we propose increasing some of the minimum recommended values of handles dimensions.

Author Contributions

Conceptualization, M.G.; methodology, M.G. and M.H.; software, M.G.; validation, M.G. and M.H.; formal analysis, M.G.; data curation, M.H. and R.K.; writing—original draft preparation, M.G.; writing—review and editing, M.G. and M.H.; funding acquisition, R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Slovak Research and Development Agency (grant number APVV-20-0004 The effect of an increase in the anthropometric measurements of the Slovak population on the functional properties of furniture and the business processes). Operational Programme Integrated Infrastructure (OPII) funded by the ERDF (grant numbers: ITMS: 313011T720 Progressive research of performance properties of wood-based materials and products (LignoPro); ITMS: 313011T678 Comprehensive research of mitigation and adaptation measures to diminish the negative impacts of climate changes on forest ecosystems in Slovakia (FORRES)).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gejdoš, M.; Vlčková, M.; Allmanová, Z.; Balážová, Ž. Trends in Workplace Injuries in Slovak Forest Enterprises. Int. J. Environ. Res. Public Health 2019, 16, 141. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ministry of Agriculture and Rural Development of the Slovak Republic. Green Report 2021. Available online: https://www.mpsr.sk/?navID=123 (accessed on 14 March 2022).

- Cividino, S.R.S.; Gubiani, R.; Pergher, G.; Dell’Antonia, D.; Maroncelli, E. Accident investigation related to the use of chainsaw. J. Agric. Eng. 2013, 44, 686–689.e137. [Google Scholar] [CrossRef]

- Tobita, K.; Nitami, T.; Yoshioka, T. Factors associated with injuries related to chainsaw tree felling in Japan. Int. J. For. Eng. 2019, 30, 190–194. [Google Scholar] [CrossRef]

- Lopez-Toro, A.A.; Pardo-Ferreira, M.C.; Marinez-Rojas, M.; Carrillo-Castrillo, J.A.; Rubio-Romero, J.C. Analysis of occupational accidents during the chainsaws use in Andalucia. Saf. Sci. 2021, 143, 105436. [Google Scholar] [CrossRef]

- Lindroos, O.; Burstrom, L. Accident rates and types among self-employed private forest owners. Accid. Anal. Prev. 2010, 42, 1729–1735. [Google Scholar] [CrossRef] [Green Version]

- Suchomel, J.; Belanová, K.; Štollmann, V. Analysis of Occupational Diseases Occurring in Forestry and Wood Processing Industry in Slovakia. Driv. Ind. 2011, 62, 219–228. [Google Scholar] [CrossRef] [Green Version]

- Vlčková, M.; Gejdoš, M.; Němec, M. Occupational diseases from noise and vibration in Slovakian forestry. Akustika 2018, 30, 89–93. [Google Scholar]

- Kováč, J.; Krilek, J.; Dado, M.; Beňo, P. Investigating the influence of Design Factors on Noise and Vibrations in the case of Chainsaws for Forestry Work. FME Trans. 2018, 46, 513–519. [Google Scholar] [CrossRef]

- Rottensteiner, C.; Tsioras, P.; Stampfer, K. Wood Density Impact on Hand-Arm Vibration. Croat. J. For. Eng. 2012, 33, 303–312. [Google Scholar]

- Warguła, Ł.; Krawiec, P.; Kukla, M.; Wieczorek, B.; Kaczmarzyk, P. Innovations in Chainsaws Utilised as Mechanical Rescue Devices. Saf. Fire Technol. 2020, 55, 142–153. [Google Scholar] [CrossRef]

- Rukat, W.; Jakubek, B.; Barczewski, R.; Grochalski, K. Identification of operating mode of a petrol chainsaw based on short-time parametrization and analysis of vibro-acoustic signals. Appl. Acoust. 2022, 192, 108704. [Google Scholar] [CrossRef]

- Kaljun, J.; Dolšak, B. Ergonomic design recommendations based on an actual chainsaw design. S. Afr. J. Ind. Eng. 2012, 23, 215–229. [Google Scholar] [CrossRef] [Green Version]

- Gejdoš, M.; Hitka, M.; Potkány, M.; Balážová, Ž. Analysis of Human Resources and Anthropometric Data Relating to Forestry Machine Operators in Slovakia. In Proceedings of the Innovation Management and Education Excellence through Vision 2020, VOLS I–XI, Milan, Italy, 25–26 April 2018; Soliman, K.S., Ed.; International Business Information Management Assoc-Ibima: Norristown, PA, USA, 2018; pp. 2256–2262. [Google Scholar]

- Alicandro, G.; Grande, E.; Sebastiani, G.; Violante, F.S.; La Vecchia, C.; Frova, L. Mortality from suicide among agricultural, fishery, forestry and hunting workers in Italy and the contribution of work-related factors. Occup. Environ. Med. 2021, 78, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Wongwien, T.; Nanthavanij, S. Multi-objective ergonomic workforce scheduling under complex worker and task constraints. Int. J. Ind. Eng.–Theory 2017, 24, 284–294. [Google Scholar]

- Raghav, G.; Farooq, M.; Khan, A.A.; Muzammil, M. Ergonomic modification and Evaluation of the Chain Saw handle in wood cutting. Can. Acoust. 2011, 39, 90–91. [Google Scholar]

- Zellner, K.; Jaeger, U.; Kromeyer Hauschild, K. Height, weight and BMI of schoolchildren in Jena, Germany—Are the secular changes levelling off? Econ. Hum. Biol. 2004, 2, 281–294. [Google Scholar] [CrossRef] [PubMed]

- Bodenhorn, H. Height, weight and body mass index of mid-19th century New York legislative officers. Econ. Hum. Biol. 2010, 8, 291–293. [Google Scholar] [CrossRef]

- Widyanti, A.; Susanti, L.; Sutalaksana, Z.; Muslim, K. Ethnic differences in Indonesian anthropometry data: Evidence from three different largest ethnics. Int. J. Ind. Ergon. 2015, 47, 72–78. [Google Scholar] [CrossRef]

- Havari, E.; Peracchi, F. Growing up in wartime: Evidence from the era of two world wars. Econ. Hum. Biol. 2017, 25, 9–32. [Google Scholar] [CrossRef]

- Tanner, J.M. Growth as a measure of the nutritional and hygienic status of a population. Horm. Res. 1995, 38, 106–115. [Google Scholar] [CrossRef]

- International Labour Office. Safe Design and Use of Chain Saws, 1st ed.; Cobulle Imprimeur SA: Bulle, Switzerland, 1978; p. 71. [Google Scholar]

- ISO 3411; Earth-Moving Machinery—Physical Dimensions of Operators and Minimum Operator Space Envelope. International Organization for Standardization: Geneva, Switzerland, 2007.

- Baffoe-Djan, J.B.; Smith, S.A. Descriptive statistics in data analysis. In Routledge Handbook of Research Methods in Applied Linguistics, 1st ed.; McKinley, J., Rose, H., Eds.; Routledge: Oxford, UK, 2020; pp. 398–414. [Google Scholar]

- Patten, M.L.; Newhart, M. Descriptive and inferential statistics. In Understanding Research Methods: An Overview of the Essentials, 10th ed.; Patten, M.L., Newhart, M., Eds.; Routledge: Oxford, UK, 2018; pp. 203–206. [Google Scholar]

- Young, J.; Wessnitzer, J. Descriptive statistics, graphs, and visualisation. In Modern Statistical Methods for HCI, 1st ed.; Robertson, J., Kaptein, M., Eds.; Springer: Dordrecht, The Neherlands, 2016; pp. 37–56. [Google Scholar] [CrossRef]

- Šmelko, Š.; Wolf, J. Štatistické Metódy v Lesníctve [Statistical Methods in Forestry, 1st ed.; Príroda Bratislava: Bratislava, Slovakia, 1977; p. 330. [Google Scholar]

- Rottensteiner, C.; Stampfer, K. Evaluation of operator vibration exposure to chainsaws equipped with a Kesper safety bar. Scand. J. For. Res. 2013, 28, 193–200. [Google Scholar] [CrossRef]

- Huber, M.; Hoffmann, S.; Brieger, F.; Hartsch, F.; Jaeger, D.; Sauter, U.H. Vibration and Noise Exposure during Pre-Commercial Thinning Operations: What Are the Ergonomic Benefits of the Latest Generation Professional-Grade Battery-Powered Chainsaws? Forests 2021, 12, 1120. [Google Scholar] [CrossRef]

- Landekic, M.; Bacic, M.; Pandur, Z.; Susnjar, M. Vibration Levels of Used Chainsaws. Forests 2020, 11, 249. [Google Scholar] [CrossRef] [Green Version]

- Malchaire, J.; Piette, A.; Moens, G.; Boodts, S.; Cornillie, F.; Delaruelle, D.; de Cooman, G.; Timmerman, I.; Carlier, P.; Mathy, F.; et al. Vibrations Mains-Bras: Serie Strategie Sobane—Gestion des Risques Professionnels; SPF Emploi, Travail et Concertation Sociale: Brussels, Belgium, 2004; p. 70. [Google Scholar]

- Dabrowski, A. Analysis and Laboratory Testing of Technical Injury Prevention Measures for Portable Combustion Chainsaws. Forests 2020, 11, 276. [Google Scholar] [CrossRef] [Green Version]

- Masci, F.; Spatari, G.; Giorgianni, C.M.; Pernigotti, E.; Antoangeli, L.M.; Bordoni, V.; Biasina, A.M.; Pietrogrande, L.; Colosio, C. Hand-Wrist Disorders in Chainsaw Operators: A Follow-Up Study in a Group of Italian Loggers. Int. J. Environ. Res. Public Health 2021, 18, 7217. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).