A New Approach to Assess the Retained Value of Functionalized and Stabilized Wood Products through Aging

Abstract

:1. Introduction

Proposed Method

- LOV%: Loss of value for having a selected defect

- $(without defect): Value of a wood product without a selected defect

- $(with defect): Value of the same product downgraded due to the selected defect

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Ethics Statements

References

- Architecture 2030. Why the Building Sector? Available online: https://architecture2030.org/WHY-THE-BUILDING-SECTOR/ (accessed on 14 February 2022).

- United Nations. UN Department of Economic and Social Affairs: 2018 Revision of World Urbanization Prospects. Available online: https://www.un.org/development/desa/publications/2018-revision-of-world-urbanization-prospects.html (accessed on 14 February 2022).

- Gu, H.; Nepal, P.; Arvanitis, M.; Alderman, D. Carbon impacts of engineered wood products in construction. In Engineered Wood Products for Construction; IntechOpen: London, UK, 2021. [Google Scholar]

- Guinee, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future; ACS Publications: Washington, DC, USA, 2011. [Google Scholar]

- Swedish Wood. Surface Treatment of Exterior Wood. Available online: www.swedishwood.com/building-with-wood/construction/surface-treatment (accessed on 14 February 2022).

- MBIE. Acceptable Solutions and Verification Methods for New Zealand Building Code Clause: B2 Durability. 2019. Available online: https://www.building.govt.nz/building-code-compliance/b-stability/b2-durability/#jumpto-standards (accessed on 31 March 2022).

- Militz, H. Wood modification research in Europe. Holzforschung 2020, 74, 333. [Google Scholar] [CrossRef] [Green Version]

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Homan, W.J.; Jorissen, A.J. Wood modification developments. Heron 2004, 49, 360–369. [Google Scholar]

- Taghiyari, H.R.; Tajvidi, M.; Taghiyari, R.; Mantanis, G.I.; Esmailpour, A.; Hosseinpourpia, R. Nanotechnology for wood quality improvement and protection. In Nanomaterials for Agriculture and Forestry Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 469–489. [Google Scholar]

- Papadopoulos, A.N.; Bikiaris, D.N.; Mitropoulos, A.C.; Kyzas, G.Z. Nanomaterials and chemical modifications for enhanced key wood properties: A review. Nanomaterials 2019, 9, 607. [Google Scholar] [CrossRef] [Green Version]

- Schultz, T.P.; Nicholas, D.D.; Preston, A.F. A brief review of the past, present and future of wood preservation. Pest Manag. Sci. Former. Pestic. Sci. 2007, 63, 784–788. [Google Scholar] [CrossRef]

- Scheffer, T.C.; Morrell, J.J. Natural Durability of Wood: A Worldwide Checklist of Species; Oregon State University: Corvallis, OR, USA, 1998. [Google Scholar]

- Stirling, R.; Alfredsen, G.; Brischke, C.; De Windt, I.; Francis, L.P.; Frühwald Hansson, E.; Humar, M.; Jermer, J.; Klamer, M.; Kutnik, M. Global survey on durability variation–on the effect of the reference species. In Proceedings of the 47th Annual Meeting of the International Research Group on Wood Protection (IRG47), Lisbon, Portugal, 15–19 May 2016. [Google Scholar]

- Lebow, S.; Woodward, B.; Kirker, G.; Lebow, P. Long-term durability of pressure-treated wood in a severe test site. Adv. Civ. Eng. Mater. 2013, 2, 178–188. [Google Scholar] [CrossRef]

- Brischke, C.; Alfredsen, G.; Humar, M.; Conti, E.; Cookson, L.; Emmerich, L.; Flæte, P.O.; Fortino, S.; Francis, L.; Hundhausen, U. Modelling the material resistance of wood—Part 3: Relative resistance in above and in ground situations—Results of a global survey. Forests 2021, 12, 590. [Google Scholar] [CrossRef]

- Feist, W.C. Outdoor Wood Weathering and Protection. In Archaeological Wood: Properties, Chemistry, and Preservation, Proceedings of the 196th Meeting of the American Chemical Society, Los Angeles, WA, USA, 25–28 September 1988; Rowell, R.M., Barbour, R.J., Eds.; Advances in Chemistry Series 225; American Chemical Society: Washington, DC, USA, 1990; pp. 263–298. [Google Scholar]

- Kránitz, K.; Sonderegger, W.; Bues, C.-T.; Niemz, P. Effects of aging on wood: A literature review. Wood Sci. Technol. 2016, 50, 7–22. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. Wood degradation under UV irradiation: A lignin characterization. J. Photochem. Photobiol. B: Biol. 2016, 158, 184–191. [Google Scholar] [CrossRef]

- Evans, P.D.; Haase, J.G.; Seman, A.S.; Kiguchi, M. The search for durable exterior clear coatings for wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef] [Green Version]

- Juran, J.; Godfrey, A.B. Quality Handbook; McGraw-Hill: New York, NY, USA, 1999; Volume 173. [Google Scholar]

- Garvin, D.A. What Dose Product Quality Really Means? Sloan Manag. Rev. 1984, 10, 25–43. [Google Scholar]

- Hansen, E.; Bush, R. Consumer perceptions of softwood lumber quality. For. Prod. J. 1996, 46, 29. [Google Scholar]

- Johansson, G.; Kliger, R.; Perstorper, M. Quality of structural timber-product specification system required by end-users. Holz Als Roh-Und Werkst. 1994, 52, 42–48. [Google Scholar] [CrossRef]

- Bayne, K.; Roper, J.; Harding, V.; Van Wyk, L. Customer Perceptions of Distortion in Structure lumber; New Zealand Forest Research Institute Limited: Rotorua, New Zealand, 1998. [Google Scholar]

- Standards New Zealand. New Zealand Timber Grading Rules. Available online: https://www.standards.govt.nz/shop/nzs-36311988/ (accessed on 1 February 2022).

- Mitchell, H.L. A Concept of Intrinsic Wood Quality, and Nondestructive Methods for Determining Quality in Standing Timber; Forest Products Laboratory, Forest Service U.S. Department of Agriculture: Madison, WI, USA, 1961.

- Zhang, S. Wood quality: Its definition, impact, and implications for value-added timber management and end uses. In Proceedings of the Timber Management Toward Wood Quality and End-Product Value, CTIA/IUFRO International Wood Quality Workshop, Quebec City, QC, Canada, 18–22 August 1997; pp. 22–28. [Google Scholar]

- Hao, B.; Avramidis, S. Annual ring orientation effect and slope of grain in hemlock timber drying. For. Prod. J. 2004, 54, 41. [Google Scholar]

- Cown, D.; Haslett, A.; Kimberley, M.; McConchie, D. The influence of wood quality on lumber drying distortion. Ann. For. Sci. 1996, 53, 1177–1188. [Google Scholar] [CrossRef] [Green Version]

- Johansson, M.; Ormarsson, S. Influence of growth stresses and material properties on distortion of sawn timber–numerical investigation. Ann. For. Sci. 2009, 66, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Jozsa, L.; Middleton, G. A Discussion of Wood Quality Attributes and Their Practical Implications; Forintek Canada Corp.: Vancouver, BC, Canada, 1994. [Google Scholar]

- Macdonald, E.; Hubert, J. A review of the effects of silviculture on timber quality of Sitka spruce. Forestry 2002, 75, 107–138. [Google Scholar] [CrossRef] [Green Version]

- Ridley-Ellis, D.; Stapel, P.; Baño, V. Strength grading of sawn timber in Europe: An explanation for engineers and researchers. Eur. J. Wood Wood Prod. 2016, 74, 291–306. [Google Scholar] [CrossRef]

| Appearance | Structural | Cuttings | Other | |

|---|---|---|---|---|

| Native Softwood | (1) Clears (2) Premium (3) Dressing | (1) Building | (1) No. 1 Cuttings (2) No. 2 Cuttings | (1) Box |

| Hardwood | (1) Clears (2) Premium (3) Dressing | (1) Engineering (2) Building | (1) No. 1 Cuttings (2) No. 2 Cuttings | (1) Box |

| Exotic Softwood | (1) Clears (2) Select A (3) Select B (4) Dressing (5) Merchantable | (1) Engineering (2) No.1 Framing (3) No.2 Framing | (1) No. 1 Cuttings (2) No. 2 Cuttings | (1) Box |

| Appearance Grades | Relative $ |

|---|---|

| Clears | 1.00 |

| Select A | 0.67 |

| Select B | 0.60 |

| Dressing | 0.55 |

| Merchantable | 0.62 |

| No.1 cuttings | 0.67 |

| No.2 cuttings | 0.55 |

| Box | 0.39 |

| Defect | Principal Parameter | Secondary Parameter |

|---|---|---|

| Bow | Gap | |

| Crook | Gap | |

| Cup | Gap | |

| Twist | Gap | |

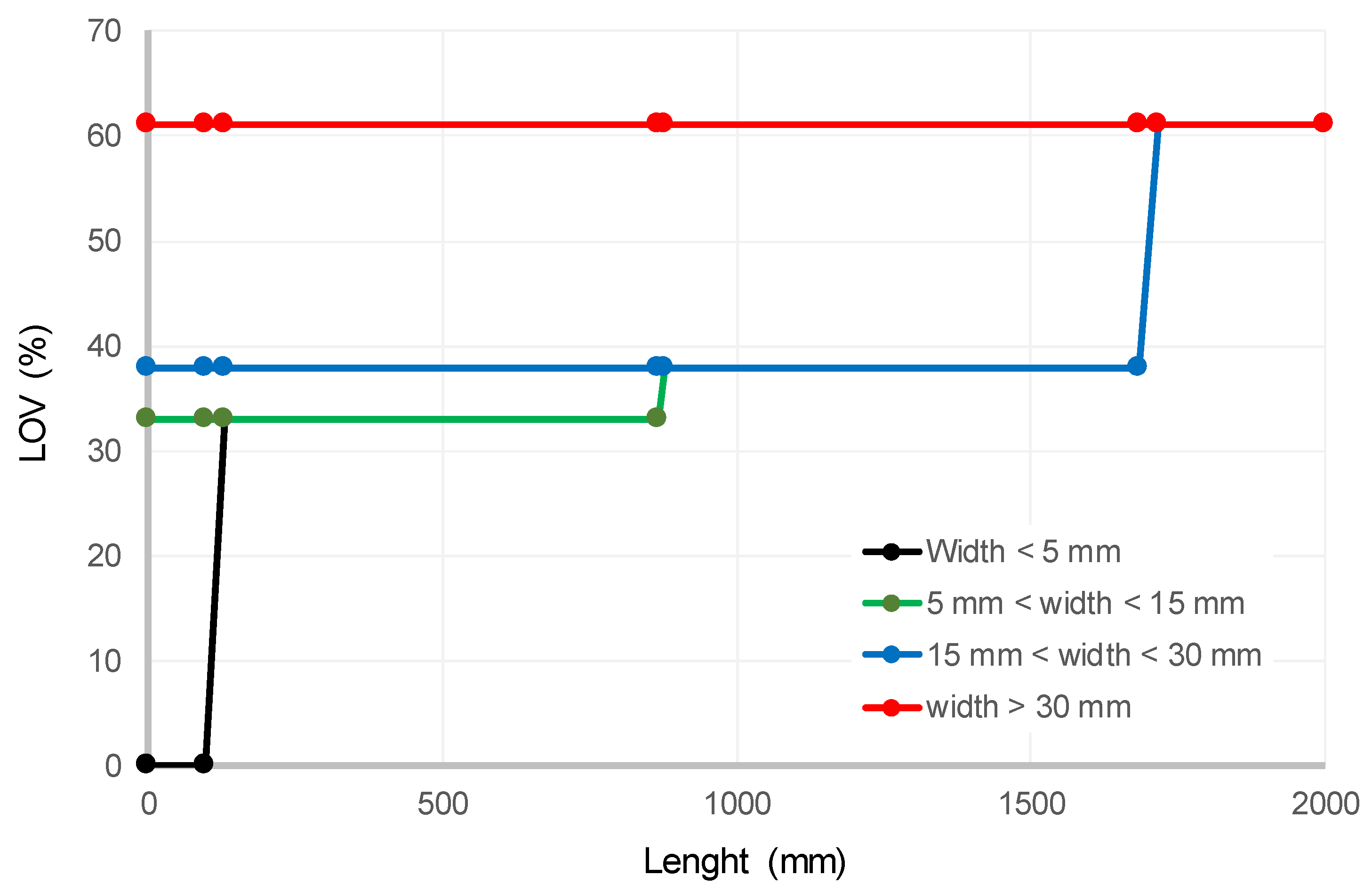

| Surface checks | Length | Width |

| Checks in knots | Width | |

| Collapse | Yes/No | |

| Shakes | Length | Slope |

| Splits | Length | |

| Stain | Yes/No | |

| Resin streaks | Length | Width |

| Defect | Appearance Grades | |

|---|---|---|

| X | 0 < X < θ | X > θ |

| Bow | 33% | 61% |

| Crook | 33% | 61% |

| Cup | 0 | 61% |

| Twist | 33% | 61% |

| Checks in knots | 38% | 38% |

| Shakes | 38% | 61% |

| Splits | 61% | 61% |

| Collapse | 33% | 38% |

| Stain | 33% | 61% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elustondo, D.; Gaunt, D. A New Approach to Assess the Retained Value of Functionalized and Stabilized Wood Products through Aging. Forests 2022, 13, 643. https://doi.org/10.3390/f13050643

Elustondo D, Gaunt D. A New Approach to Assess the Retained Value of Functionalized and Stabilized Wood Products through Aging. Forests. 2022; 13(5):643. https://doi.org/10.3390/f13050643

Chicago/Turabian StyleElustondo, Diego, and Douglas Gaunt. 2022. "A New Approach to Assess the Retained Value of Functionalized and Stabilized Wood Products through Aging" Forests 13, no. 5: 643. https://doi.org/10.3390/f13050643

APA StyleElustondo, D., & Gaunt, D. (2022). A New Approach to Assess the Retained Value of Functionalized and Stabilized Wood Products through Aging. Forests, 13(5), 643. https://doi.org/10.3390/f13050643