Abstract

Wood is an excellent building material or component that has been used all over the world. The rise in energy consumption worldwide, particularly in the building sector, has led to the development of diverse methods to overcome this problem. Embedding phase change material, PCM, into the wood has been researched as one of the most effective alternatives of controlling the thermal loads of wood, as it can store and release latent heat energy at a specific temperature range. Due to increasing interest, this article reviews the PCM in wood, including some research on the recent efforts that has been made by other researchers regarding this topic. This article also provides insight into problems associated with the wood and wood-based products incorporated with PCM. From the three groups of PCM, namely organic, inorganic, and eutectic mixture, the organic and eutectic mixture were most commonly chosen and successfully impregnated into wood structure. Carbonization and delignification can help to increase the stabilization of the PCM in wood. Adding PCM to wood sometimes decreases its strength, thus balancing between the thermal regulative performance and other industrial requirements needed to fabricate a fully functional thermal-regulative wood.

1. Introduction

Energy is a primary essential element needed in social development and the economic sector. Recently, the rise in energy consumption worldwide is gaining concern due to its adverse effects on the environment and human health, which lead to climate change. Building sectors are responsible for 40% of the total global energy consumption [1,2], which is expected to rise to 50% by 2050 [3]. The energy types used in buildings include electricity, pipeline gas, natural gas, gasoline, liquefied petroleum gas (LPG), coal, solar energy, biogas, and biomass. Meanwhile, the primary purposes of this energy consumption are for space heating and cooling, lighting, cooking, hygiene/cleanliness/cleansing, and entertainment [4,5]. High energy consumption in the building sector is problematic as it will lead to high gas emissions, such as greenhouse gasses, including the carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and other airborne pollutants, e.g., sulfur dioxide (SO2), carbon monoxide (CO), nitrogen oxide (NOx), etc. Solar, biogas, and natural gas are considered clean energy due to the few emissions produced but support only a tiny portion of energy demand [5].

Reducing energy consumption in a building is a matter of most significant importance worldwide. Energy consumption reduction can be performed in many ways, such as using renewable energy; clean energy systems; improving energy efficiency in the buildings, including individual energy using devices; improving the building shape; and optimizing the building envelopes. Generally, a large amount of energy can be reduced by using renewable and clean energy systems for heating, cooling, and lighting systems rather than using more efficient home devices, such as lamps and fans [6]. However, renewable energy sources, such as solar and wind, cannot always be relied upon. For example, there is no sunlight during the night and the wind may not always blow. Therefore, thermal energy storage systems that are more cost-effective and capable of storing large scale energy amounts are needed. Several ways to store and regulate energy are available, including using phase-change material (PCM) [7]. These materials can effectively store thermal energy from various sources, including renewable sources.

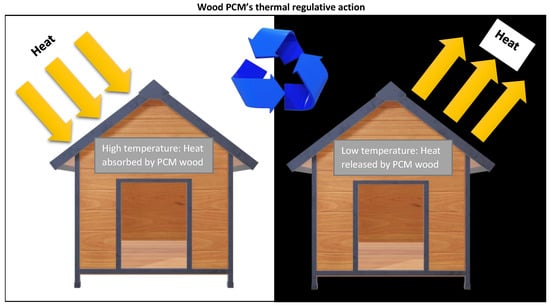

Phase change materials can be embedded into building envelopes to do their job. Improving building envelopes was a great way to reduce energy (50%–75% savings) [8] by lessening the need for heating and cooling devices without neglecting the comfort and quality of life. Phase change material is incorporated in wood to give a new thermal regulative property to the wood as a sustainable building material. The theory of the thermal-regulating effect of PCM-impregnated wood is shown in Figure 1.

Figure 1.

The theory of the thermal-regulating effect of PCM-impregnated wood.

Wood is one of the oldest and most reliable building materials used all over the world. The excellent physical and mechanical properties of wood ensure the stability of the built structure in any construction. During ancient times, wood was frequently used in the form of lumber. Over the years/in the past few decades, an increased variety of wood products has been developed to fulfil the high demand for wood in construction areas. Three classifications of wood products that have frequently been used are panel products (i.e., veneer, wafer board, strand board, particleboard, fibreboard), glulam, and structural composite lumber (laminated veneer and oriented strand) [9].

Wood has some disadvantages, for instance, it undergoes dimensional changes during applications when exposed to moisture, causing anisotropic swelling or shrinkage [10,11,12]. Others are biodegradation and photodegradation, which deteriorate its physical properties [13]. Although most of the construction industry these days are diverting their favour to the other building materials, such as concrete, steel, and aluminium, wood still has advantages that prevail over them. Most wood properties are highly dependable on the structure itself. The basic components of wood cell walls are primarily composed of cellulose (50%–60%), which is cemented together by lignin (20%–35%), with the rest occupied by ash-forming materials (5%–10%) [14]. The interactions between these materials produce a long and tough structure called fibrils. This structure gives a high tensile strength to the wood, making it a lightweight building material with a high breaking length (self-support length).

Natural wood advantages including low-cost, renewability, and biocompatible substrate, besides the ability to insulate heat transition [15]. Wood has the advantage of having electrical and heat resistance properties that provide stability and safety implications for fire events in a finished building [16]. Using wood as the main material in a wood–plastic composite can overcome the deficiencies of existing lightweight steel–wood–plastic composite buildings [17]. In terms of appearance, wood can offer diverse attractive appeal due to the various wood species available. In fact, wood with similar species can still provide a different appearance due to the different arrangement of wood’s internal structure. Wood has the remarkable ability to minimize echoing by reducing noise, as wood does not reflect or amplify the sound but absorbs it. Wood is a renewable building material, as wood can be grown and regrown. This advantage must be combined with good practice in selecting, harvesting, and replanting to ensure the sustainability of the wood supply [18]. Unlike steel and plastic, wood can provide a higher insulation rate due to its natural cellular structure, thus enhancing energy efficiency in building. This implies that a building built from wood is able to maintain heating and cooling with minimal energy requirements [9]. Apart from these advantages, the material of wood could be improved by giving it new thermal regulative feature to be used in energy efficient buildings. The porous structure of wood make it possible to be successfully impregnated with other materials [19]. Wood has high compatibility with impregnating materials due to its natural multidimensional channel structure and excellent mechanical stability, which is beneficial as a self-supporting material [20].

2. Phase Change Material (PCM)

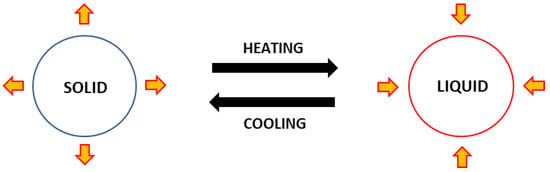

Phase change material (PCM) is described as a material that is able to store and release heat energy (known as latent heat energy) through its physical phase change from solid to liquid and vice versa [21]. The heat energy of a substance is considered latent because it is stored between molecules until it changes from one phase to another. The matter comprises molecules, which are held together by chemical bonds. Those chemical bonds are used as heat stores and releases. Physical changes in matter can occur when the matter goes through phase changes. The phase changes of material happen due to the changes in its temperature when it is heated or cooled within its specific temperature range. A PCM works by storing (absorbing) heat energy as it is heated, breaking down the bonding responsible for the solid structure and changing it to a liquid state [22].

Meanwhile, energy is released as the PCM cools down and changes from liquid to solid. A PCM’s functioning process is illustrated as in Figure 2. The action of releasing and absorbing energy happens only with latent heat energy, without changing the temperature of the PCM.

Figure 2.

Illustration concept of phase change material.

Latent heat is the energy required to change a given substance from one physical state to another at a given temperature [23]. Because of the tremendous amount of energy needed to move from one physical state to another, PCM is considered an efficient source of latent heat energy storage. Therefore, PCM is gaining attention regarding its application in the building sector as an effective way to improve the building envelopes, which can resolve the contradiction between the energy demand and supply efficiently and reduce energy consumption effectively. Generally, all materials are phase change materials since they experience phase transformation at a certain temperature range. Yet not all materials are fit for storing latent heat energy. Several characteristics are required for a material to be used in thermal energy storage. High thermal conductivity, high latent heat of melting, low vapour pressure, high density, chemical inertia and stability, nontoxicity, non-flammability, non-corrosivity, cost efficiency, congruent melting and cooling, minimal subcooling, and a phase transition that occurs in the practical range of operation are the requirements for the material to be used as a thermal regulator component [24]. In selecting a PCM for any application, the heating and cooling operating temperature should match the PCM’s phase transition temperature. Most of the PCMs used do not satisfy the required criteria for thermal energy storage. Meanwhile, PCM criteria, such as melting temperature, cost, toxicity, flammability, and stability, were taken into account in the building sector. The main disadvantages of pure PCM are leakage and low thermal conductivity, which limits their practical energy storage efficiency [25]. Materials such as wood powder and porous cellulose nanofibril hybrid supporting materials could increase their thermal conductivity [26].

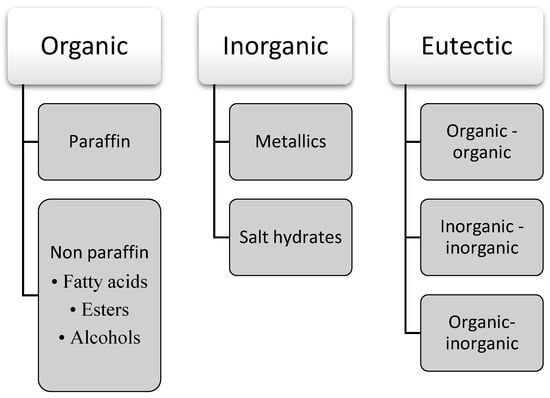

3. Classification of Phase Change Materials

PCMs are categorized into three classes, which are organic, non-organic, and eutectic [27,28]. A detailed classification of PCM is depicted in Figure 3.

Figure 3.

Detailed classification of PCM.

The organic PCM mainly consists of paraffin, and non-paraffin material comprises fatty acids, esters, and alcohols. Natural paraffin primarily contains a mixture of pure alkanes with a wide range of phase change temperatures. Of these, paraffin wax is an organic PCM mainly used commercially. Paraffin wax is insoluble in water and does not react with most common chemical reagents. Meanwhile, researchers use non-paraffin as the most favourable PCM due to its availability in an extensive range of temperatures and a high fusion heat. Fatty acids are the most common inorganic PCM used. The confirmation of its continuous supply due to its sources that come from common vegetables and animal oil is one of the factors that make fatty acids the most favourable PCM under the non-paraffin group.

Salt hydrate and metallic are included in the inorganic PCM group. Metal is the most minor preferred type of PCM due to its low latent heat and weight penalties. However, metal still can give some advantages, especially in applications where compactness is the main goal due to its high heat of fusion per unit volume. Aluminium, zinc, magnesium, and their alloys are fit to be used in an application with high temperatures. Meanwhile, indium, cesium, bismuth, gallium, and tin are types of metals that can be used in applications with low temperatures. Additionally, metal has high thermal conductivity as well as high physical and chemical stability. Salt hydrates are an ionic compound with a three-dimensional structure. The salt hydrate ions can attract several water molecules and enclose them inside their crystal lattice. Despite several advantages offered by salt hydrates over the organic PCM, the chemical instability of salt hydrates limits its broad utilization. They possess a high tendency of phase separation due to their primary components comprising salt and water. Water is lost after every heating cycle, while hydrated salts tend to settle out during the melting process. However, this issue can be fixed to a certain extent using thickened or gelled mixtures. The other significant drawback of salt hydrates is supercooling. A high degree of supercooling prevents salt hydrates from crystallizing at the specified freezing point. Using suitable nucleating agents that can trigger the crystal growth in the storage medium can help with supercooling issues.

Lastly, the mixture of two or more organic, inorganic, or both compounds are classified as a eutectic group. The advantage carried out by eutectic PCM is the preferable selective combination of excellent performances between these two compounds. They have a higher density than organic PCM and form a crystal during crystallization. Eutectic mixtures freeze and melt as a single compound to an intimate mixture of crystals simultaneously, without undergoing phase separation. Countless eutectics can be produced for any preferred melting point. It can be seen that most eutectics for PCMs are developed from the mixture of salt hydrates and fatty acids, respectively. However, recent research has turned to producing eutectics from organic groups due to salt hydrates’ phase separation and supercooling issues [29]. Still, eutectic PCM’s thermal and physical properties data are still inadequate due to their recent introduction. The advantages and disadvantages of the organic, inorganic, and eutectic groups are displayed in Table 1.

Table 1.

Advantages and disadvantages of three broad types of PCM with examples [29,30,31].

4. Impregnation and Evaluation of Phase Change Material in Wood

Leaking and low thermal conductivity are common issues encountered as PCM is used directly in the application. Thus, a porous shape stabilizer or supporting materials are required to hold the PCM so that PCM can serve as energy storage efficiently. Porous supporting materials can adsorb and keep the PCM through several mechanisms, including capillary force, surface tension, and other connections between PCM and supporting materials. However, the inherent nanoconfinement effect of supporting materials and the melting and freezing enthalpies of the composite PCMs are usually lower than that of bulk PCMs.

Another drawback of pure PCM is its inherent low thermal conductivity, resulting in a hysteretic thermal response. Assembling PCM with thermally conductive materials is a common way to improve thermal conductivity. Metallic substances, metal foams, carbon nanotubes, and graphene are some of the materials combined with the PCM to make a more thermally conductive composite. However, the thermally conductive additive also tends to fall off the composite during the thermal cycle due to changes in interfacial contact. Moreover, the thermal conductivity additives and energy storage density have an opposite relationship, where increasing the additive content will lower the energy storage density [48]. The problem of producing the composite in large scale is also not cost effective, thus limiting its application.

Biomass is a promising material as a replacement for the mentioned materials. Biomass, mainly wood, is a renewable, abundant, and highly cost-effective resource. Wood has a pore structure ranging from millimetres to nanometers, which can be used as supporting material for PCM. The hydrogen bonding between the porous structure and PCM provides good interaction to prevent the PCM from leaching out during thermal cycles. The wood can be carbonized to increase its pore structure further, increasing its thermal conductivity. Shape-stabilized PCM using carbonized biomass has recently been extensively researched [49,50].

Besides carbonization, delignification can also improve the PCM holding capacity of the wood. Delignified wood has a bigger pore size and porosity, which makes the impregnation process easier. Whiter bleached wood also can be fabricated into another functional wood composite. Transparent and thermal regulative wood composite has been manufactured using epoxy resin, polyethylene glycol, and delignified wood [51]. Another transparent and thermal regulative wood composite with thermochromic properties has been fabricated by Yang et al. [52]. The composite showed good enthalpy at about 100 J/g and survived 100 heating and cooling cycles without any leakage. It proves that wood exhibits good thermal energy management ability. The increment in PCM immersion depth also increases the interface resistance between phase change materials and wood cells, as been researched by [53]. Good mechanical properties, excellent heat management ability, and suitable phase change temperature are some characteristics of wood-stabilized PCM for outdoor building energy conservation and management [54].

The unique characteristics of wood have brought back an interest in utilizing wood as construction materials during the last decades. To achieve the primary goal of reducing energy consumption, the application of great thermal energy storage systems, PCM particularly, into the wood, is still growing in interest. The anisotropic microstructure and porous structure with various pore diameters (micropores, mesopores, and macropores) make wood a suitable shape stabilizer or supporting material for PCMs. The micropores can induce the adsorption of PCM through physical forces, such as surface tension and capillary forces. The transport channel mechanism happens inside the mesopores and macropores, especially for the melted PCM [25]. Virgin wood possesses a natural pipe and ordered pore structure that is better for mass and energy transmission, especially in an environment that requires anisotropic heat conduction. They have good compatibility with PCM, inherent low thermal conductivity and can serve as better shape stability and security to the PCM. The other advantage of using wood as a support material for PCM lies in its availability and cost-effectiveness. Furthermore, their mechanical, electrical and thermal properties, such as photoelectric conversion, flame retardancy, and magnetic conductivity, can be easily regulated based on their pores’ nature [55].

The incorporation of PCM can be performed on different forms of wood, including solid wood, wood-based composites, and transparent wood. Various tests on PCM-impregnated wood were carried out to determine its characteristics in terms of its heat energy storage capacity, heat stability, heat conductivity, thermal/heat cycling stability, physical (hygroscopic, morphological, leaking) properties, mechanical properties, and chemical and crystalline structure.

Fourier transform infrared spectroscopy (FTIR) tests revealed the PCM-impregnated wood’s chemical components. The type of interaction between the PCM material and wood can be displayed in this result. The interaction is said to occur physically if no new peak appears, indicating that no new chemical component has developed and vice versa if the interactions happen chemically. The PCM material is embedded inside the wood’s porous channels, preventing it from leaking out either in its solid or liquid phase [25].

Differential scanning calorimetry (DSC) is used to identify PCM-based wood’s thermal characteristics. The phase change enthalpy is the most reliable indicator for estimating the thermal performance in PCM-based wood. The enthalpy value of PCM-based wood can be improved by subjecting the wood to the delignification process. This fact can be proven by observing the increment of melting enthalpy and solidification enthalpy through the DSC test.

Thermal stability is vital in evaluating PCM-based wood’s practical application value. This can be carried out through a thermogravimetric test by analysing the PCM-based wood’s TG and DTG thermograms. The weight loss rate and residual amount can be used as thermal stability indicators. In this case, a slow weight loss rate with a low amount of residue is favourable. Another method to evaluate the thermal stability of PCM-based wood is by running leakage testing through the melting–impregnation method. The PCM-based wood is heated up to the melting point of PCM. The PCM-based wood is said to own thermal stability if the wood can maintain its shape while effectively trapping or confining the melting PCM inside its pores without leakage. The PCM is trapped inside the porous structure of the wood through capillary action and hydrogen bonding force.

Other than thermal stability, thermal conductivity is another significant indicator of PCM-based wood. As is well-known, the thermal conduction of non-metallic materials is primarily dominated by the thermal vibration of the crystal lattice, namely, phonons [50]. The highly conjugated π–π bond in the carbon materials is advantageous in boosting its thermal vibration, thus enhancing the PCM-based wood’s thermal conductivity. Adding materials with electronic structure characteristics may help improve the thermal conductivity of PCM-based wood. This is because this material can facilitate carbon materials’ thermal vibration.

5. Insight into Previous Works on Phase Change Materials Embedded in Wood

Previous works on PCM-impregnated wood are shown in Table 2. Temiz, Gökhan, Gaye, Ahmet and Mohd. Hazim [3] conducted a study to find a potential use of Scots pine (Pinus sylvestris L.) sapwood incorporated with eutectic PCM as a building material that can provide energy efficiency consumption in a building. In their study, a mixture of capric acid (CA) and stearic acid (SA) with a weight percentage (wt%) ratio of 83:17 was used. They investigated the morphological, physical, mechanical, thermal properties, thermal stability, thermal cycling, and thermo-regulative performance of produced CA-SA wood, with non-impregnated wood as a control sample. They found that the CA-SA was successfully impregnated into the wood through a physical reaction. Additionally, the CA-SA wood possesses excellent physical and mechanical properties along with outstanding thermal characteristics. Therefore, the effectiveness of CA-SA wood as a building material is verified, as the CA-SA wood showed excellent capabilities in regulating the environment temperature without lessening the physical and mechanical properties vital in the building sector.

Table 2.

List of wood-based PCM applications by previous researchers.

The novel study on transmittance energy storage wood (TESW) was conducted by Xia, Zhang, Yang, Zhao, Liu, and Guo [51]. The combination of transparent wood from Balsa wood species with polyethylene glycol (PEG) as PCM is used to produce TESW in this study. Transparent wood has various excellent properties as a building material. Outstanding insulation properties, low thermal conductivity, high light transmittance, and higher mechanical strength than natural wood can be conducive to reducing energy consumption without neglecting the strength/structural properties of the building. Adding PCM into the transparent wood further enhanced the function of PCM, thus giving another high added value product with great potential to be used, particularly in the energy efficiency of building.

A recent study on the incorporation of polyethylene glycol (PEG) as PCM into the wood-based composite (particleboard) was performed by Chen, Guo, Lin, Fan, and Sun [54]. They expanded their work by impregnating litmus into the PCM-based wood composite as a pH indicator to monitor the acid rain. The novelty in this work is when they used delignified Poplar wood particles to fabricate the particleboard before being steeped with both PEG and litmus. A comparison was made between the delignified particleboard impregnated with both PEG and litmus (LPB), delignified particleboard impregnated with only PEG (PB), non-impregnated delignified particleboard (WB) and pure particleboard without delignified particles, PEG, and litmus (wood). In this study, it was found that the delignification process of wood particles gave more internal spaces to accommodate both PEG and litmus by opening up more pores. The litmus performed its job very well as a pH indicator without disturbing or masking the effect of PEG as a thermal regulator.

The drawback is that the mechanical properties of delignified particleboard were lower than the pure particleboard, which is presumably due to the lignin removal. However, adding PEG and litmus increased the tensile properties of the particleboard. In conclusion, the addition of pH indicator along with PCM is possible. However, further research in finding a more effective method or the other species of particles needs to be carried out to ensure the products are able to perform all of their functions without decreasing the other essential properties.

Meanwhile, Said and Tohir [56] have studied the capability of ultraviolet (UV) curable coating to retain the PCM in wood. Additionally, they added a flame-retardant additive to study its ability to reduce the flammability of PCM-impregnated wood. Paraffin wax RT21 and propyl ester (80% stearic + 20% palmitate) were used as PCM to vacuum-impregnate the pine wood. The coating study was run by applying the epoxy acrylate lacquer. Meanwhile, the coating and the fire properties were studied by mixing the epoxy acrylate with ammonium polyphosphate (APP). The finding in this study revealed that the UV curable coating is capable of reducing the mass loss that occurs at room and 50 °C temperatures. This is clearly seen on the pine wood impregnated with paraffin wax RT21 that was left at room temperature.

Furthermore, samples coated with epoxy acrylate-mixed APP showed better retention properties than those non-coated and coated with epoxy acrylate alone. Additionally, samples coated with epoxy acrylate-mixed APP showed better fire properties by taking a longer time to ignite and having a lower peak heat release rate (PHRR) than samples coated with epoxy acrylate. However, the smoke production rate and total smoke production increased, which is undesirable. Adding coating and flame-retardant additives is an excellent way to elevate and reduce PCM-filled wood’s good and bad properties. However, selecting the appropriate elements must be carried out correctly to gain only favourable properties without flaws.

The pre-treatment of wood through the delignification process has been known to increase the wood’s specific surface area and improve the PCM’s loading rate into the wood. However, this process leads to the weakening of the wood’s strength as well. Therefore, Li, Huang, Lv, Wang, Jiang, and Wang [25] ran a study on using cellulase enzyme on a delignified basswood to create a vast porous structure to the wood without deteriorating its mechanical strength. The findings in this study revealed that cellulase has the ability to hydrolyze cellulose molecules selectively. This resulted in a rougher inner cell wall of wood due to plenty of shallow nanopores, which is not seen in delignified wood without enzymolysis treatment.

Yang, Chao, Di, Yang, Yang, Yu, Liu, Li, Li, and Wang [62] researched the addition of magnetic property to add another function to the PCM-based wood. Fe3O4 nanoparticles were added to the delignified Balsa wood impregnated with 1-tetradecanol as PCM. The resulting magnetic PCM-based wood was revealed to have excellent latent heat (179 J/g), excellent thermal stability after 100 cycles of heating and cooling, and excellent shape stability. The magnetic PCM-based wood demonstrates multifunctional properties by improving both solar-to-thermal and magnetic-to-thermal conversion efficiency that significantly reduce energy consumption.

Most PCM and wood are materials that carry both the hygroscopic and hydrophilic character. This character can lead to crack formation between the interfaces of the wood and PCM. These cracks cause a decline in thermal energy storage capacity, particularly in wet and humid environments. Therefore, Yang, Wang, Wang, Chao, Wang, Ding, Liu, Yu, Yang, Yang, Li, Wang, and Li [64] studied the utilization of superhydrophobic coating on the surface of PCM-based wood. Delignified basswood and 1-tetradecnol were used as supporting material and PCM, respectively. Before impregnating 1-tetradecnol into delignified basswood, the pre-coat process was carried out by spraying the surface of PCM-based wood with epoxy resin/acetone solution. This was followed by depositing the modified Sio2 as a superhydrophobic coating. The resulting PCM-based wood possessed a high water contact angle, better wear resistance, and a superhydrophobic stability at 20–100 °C and pH 3–12. It also showed excellent thermal stability and had a large energy storage capacity. Hence, the PCM-based wood with a superhydrophobic character is ideal for outdoor applications, particularly in wet or humid environments.

Wood flour is an inevitable by-product of wood processing, such as sawing and planning. Wood flour is a low-priced, value-added product typically used as a fuel or a building material like wood–plastic and density boards. Cheng and Feng [33] studied the impregnation of PCM into wood flour. They utilized myristyl alcohol as PCM and Poplar wood flour as supporting materials. The wood flour was first subjected to delignification before impregnation with myristyl alcohol. The resulting PCM-based wood flour was then fabricated into a board with urea-formaldehyde resin as the binder. The produced board was later tested to evaluate its morphological, mechanical properties, and thermal stability. The results in this study showed that PCM-based wood flour board has a potential to be used as building material and broad its application in energy reduction.

Pyrolysed wood and biomass materials in the form of carbon are also a promising shape stabilizing agent for PCM. The carbon generated from these materials has certain advantages, such as being renewable and cost-effective, having considerable thermal transfer ability, and containing diverse microstructures [82]. An example of pyrolyzed materials are the carbonized maize straw [75] and waste sugar beet pulp [81] impregnated with PCM to create composite phase change material with more versatile application potential.

6. Challenges of PCM-Impregnated Wood in Real World Application

Using PCM in wood as a building heat regulator seems to be a good idea theoretically. However, several challenges should be considered before real application. This subchapter will address some of the discovered challenges in the making and using of a PCM-impregnated wood.

Choosing the right PCM for the correct application is a must. The temperature where the PCM-impregnated wood will be used is important to ensure its functionality. There is no single PCM that can be used in all places. Every PCM has its own range of temperatures where heat exchange can happen. A properly chosen PCM should absorb heat when their surrounding temperatures are high and release it when the temperature drops. Besides hot and cold regions, the seasons of the year (winter vs. hot season) also showed different heat exchange effects by the PCM [83]. A study was carried out by Soleiman Dehkordi and Afrand [84], who found that if the PCM is not selected properly, it can have a negative effect by increasing the building’s energy demand. Thicker PCM-based building envelopes intensify the positive or negative effects of PCM.

Cost is an important factor in determining the PCM choice for large scale, industrial application. The inorganic PCMs are generally lower in cost compared to organic PCM. For example, organic PCMs, such as paraffin waxes, cost around 1.88 to 2.00 USD/kg; fatty acid organic PCMs, such as stearic acid, cost 1.43 to 1.56 USD/kg; palmitic acid costs in the range of 1.61 to 1.72 USD/kg; and oleic acid costs around 1.67 to 1.76 USD/kg, which are all relatively high [85]. Despite the lower price, other limitations of inorganic PCMs should be considered before making a decision.

The economic feasibility of employing a PCM latent heat storage material in a system depends on the long term stability of the storage material. A good PCM should not have its melting temperature and latent heat altered after repeating thermal cycles. Some PCMs also tend to degrade after prolonged heating–cooling cycles. Thermal cycling tests are commonly performed to estimate the thermal stability of a PCM. Research has been conducted on the thermal cycling stability of several organic and inorganic PCM types. Heating and cooling cycles of 200 g PCMs were carried out using a heating oven, and the PCMs were analyzed using a differential scanning calorimeter, DSC, to detect changes in the latent heat capacity after a certain interval up to 600 thermal cycles. The paraffin wax with different melting temperatures, and Erythritol (C4H6OH4) represents the organic PCM, while Sodium hydroxide (NaOH), Di-sodium borate (Na2B4O7·10H2O), Ferric nitrate (Fe(NO3)3·6H2O), and Barium hydroxide (Ba(OH)2·10H2O) represent the inorganic PCM. Analysis has shown that inorganic PCMs are unsuitable to be used as latent heat storage due to gradual change in melting temperatures and the latent heat of fusion after undergoing multiple thermal cycles, despite their lower cost of production. Paraffin wax has the most stable thermal recycling ability, while erythritol has a very high energy density [86]. However, due to higher costs, careful decisions should be made when choosing between organic and inorganic PCMs. It is almost impossible to re-impregnate PCM into wood after the treated wood has been in service; therefore, thermal storage stability is also an important characteristic of PCMs for wood.

Inorganic PCMs also have compatibility issues, where it causes corrosion to metals [87,88]. Many wood fasteners are made using metal; therefore, the presence of inorganic PCM impregnated into wood cells will corrode the nails and screws used to join the wood structure together. This is dangerous in long term as the deterioration of the fasteners will lead to the disintegration of the joint structures. Meanwhile, organic PCMs, for example paraffin, are consistent, safe, understood, and generally noncorrosive [89].

Thermal conductivity is another thing to be considered, as many organic and inorganic PCMs possess low thermal conductivity [90,91,92]. To improve PCM thermal conductivity, several techniques can be utilized, including the addition of graphite fibres to salt [93], the incorporation of aluminum thermal conductivity promoters [94], the insertion of PCMs into a metal matrix, microencapsulation, and PCM impregnation into porous materials [95,96]. However, these techniques add to the cost of production of the final wood products.

The leaking of PCM in its liquid phase commonly happens, mainly in organic PCMs [97]. Repeated thermal cycling leads to PCM mass loss after long period, which is a waste of material [98]. Shape stabilization by impregnating with sawdust [78], porous materials (biochar) [99], polymers [100], and microencapsulation [101] can help to maintain PCMs within the wood structure and to reduce PCM wastage but increase production cost is inevitable.

7. Opportunities for Future PCM-Based Wood Products

With the increasing energy demand and increasing electricity bill prices, the passive and active thermal regulative application of wood-impregnated PCM has promising potential. The passive system includes the replacement of the building materials with PCM-impregnated materials to naturally carry out the thermal regulative process while the active system involves positioning the PCM-impregnated wood together with building’s air ventilation system to increase thermal exchange [102].

There are various attempts to include PCM in building materials, such as brick and concrete walls [103,104], wall plasterboards [105,106], floors [107,108], ceilings [109,110], and roofs [111,112]. Most applications involve the microencapsulation of the PCM materials into polymer shells. A simpler process could be utilized by using wood sawdust as the PCM shape stabilizer. The wood-based PCM application can be carried out through the direct usage of PCM-impregnated solid wood or the inclusion of shape stabilized wood-PCM into the polymer or as a composite filler.

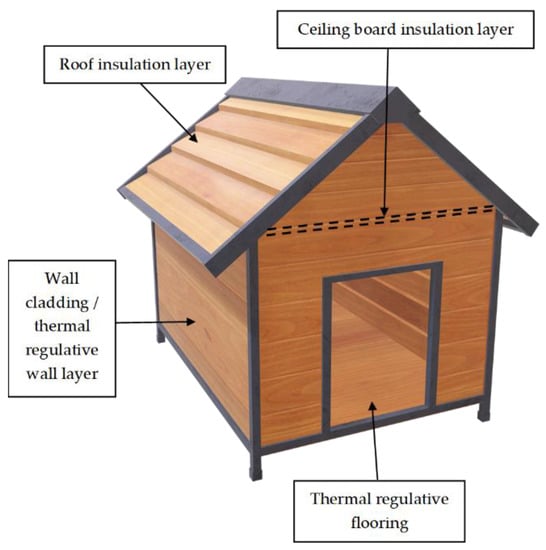

Figure 4 simplifies the potential applications of PCM-impregnated wood in building. PCM-impregnated wood particles could be blended with polymers to create an insulation layer for the roof to absorb direct heat from the sun’s rays. A PCM-impregnated wood polymer composite layer could also be built into the wall of a building to cool and heat the internal part of the house, according to the current ambient temperature. The PCM-impregnated wood could be blend with gypsum to produce the thermal regulative ceiling board. For solid wood-based PCM, a possible utilization is for wall cladding in order to create a thermal envelope around the building. Solid wood-based PCM also has the potential to be used as thermal regulative flooring, also known as parquet. Using PCM-based wood building material as much as possible should increase electricity power efficiency by reducing dependency on air conditioning devices.

Figure 4.

Potential use of PCM-impregnated wood in buildings.

8. Conclusions

Excellent energy consumption efficiency is significant for economic, social, and industrial development. One of the alternatives to develop energy efficiency in the building sector is by incorporating phase change material into building materials. Wood is the only renewable building material that can provide excellent properties as a building material. On the other hand, the naturally porous structure of wood makes it suitable to be used as a supporting material to hold PCMs. However, like all other materials, wood still has some drawbacks. Therefore, producing a wood-stabilized PCMs with all advantages but without the disadvantages is a great challenge. It is vital to study every part or process in order to produce wood-stabilized PCM, starting from selecting and treating the materials, impregnating the PCM, and retaining the durability and stability of both the PCM and wood.

The addition of co-additives is a great way to provide multifunctional properties in the wood-stabilized PCM, as well as thermal energy efficiency. Additionally, any flaws that exist in the wood-stabilized PCM can be concealed by the addition of additives. To conclude, the production of wood-stabilized PCM must be carried out precisely so that it can serve as an excellent energy storage method efficiently without neglecting the requirements of actual industrial applications. Features of wood, especially in terms of mechanical properties, should be maintained to be used as structural materials in the building sector.

Author Contributions

Investigation, N.S.S.; resources, M.H.M.A.; writing—original draft preparation, N.S.S.; writing—review and editing, M.H.M.A.; supervision, M.H.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This APC was funded by Fundamental Research Grant Scheme (FRGS 2020-1) from the Ministry of Higher Education Malaysia, grant number FRGS/1/2020/TK0/UMK/02/2.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the Ministry of Higher Education Malaysia, for the Fundamental Research Grant Scheme (FRGS/1/2020/TK0/UMK/02/2) for Mohd Hazim Mohamad Amini, and Universiti Malaysia Kelantan for Postdoctoral Scheme for Nurul Syuhada Sulaiman.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Han, Y.; Lou, X.; Feng, M.; Geng, Z.; Chen, L.; Ping, W.; Lu, G. Energy consumption analysis and saving of buildings based on static and dynamic input-output models. Energy 2022, 239, 122240. [Google Scholar] [CrossRef]

- Hassan, J.; Mohamad zin, R.; Abd Majid, M.Z.; Balubaid, S.; Hainin, M.R. Building Energy Consumption in Malaysia: An Overview. J. Teknol. 2014, 707, 2180–3722. [Google Scholar] [CrossRef]

- Temiz, A.; Gökhan, H.; Gaye, K.D.; Ahmet, S.; Mohd Hazim, M.A. Phase Change Material Impregnated Wood for Passive Thermal Management of Timber Buildings. Int. J. Energy Res. 2020, 44, 10495–10505. [Google Scholar] [CrossRef]

- Wróblewski, P.; Niekurzak, M. Assessment of the Possibility of Using Various Types of Renewable Energy Sources Installations in Single-Family Buildings as Part of Saving Final Energy Consumption in Polish Conditions. Energies 2022, 15, 1329. [Google Scholar] [CrossRef]

- Zhao, C.-S.; Niu, S.-W.; Zhang, X. Effects of Household Energy Consumption on Environment and its Influence Factors in Rural and Urban Areas. Energy Procedia 2012, 14, 805–811. [Google Scholar]

- Dincer, I.; Acar, C. A review on clean energy solutions for better sustainability. Int. J. Energy Res. 2015, 39, 585–606. [Google Scholar] [CrossRef]

- Aftab, W.; Usman, A.; Shi, J.; Yuan, K.; Qin, M.; Zou, R. Phase change material-integrated latent heat storage systems for sustainable energy solutions. Energy Environ. Sci. 2021, 14, 4268–4291. [Google Scholar] [CrossRef]

- Harvey, D. Reducing Energy Use in the Buildings Sector: Measures, Costs, and Examples. Energy Effic. 2009, 2, 139–163. [Google Scholar] [CrossRef]

- James, P.W. Use of Wood in Buildings and Bridges. In Wood Handbook—Wood as an Engineering Material, Centennial Edition ed.; Robert, J.R., Ed.; Forest Products Laboratory (FPL): Madison, WI, USA, 2010; 508p. [Google Scholar]

- Bak, M.; Molnár, F.; Rákosa, R.; Németh, Z.; Németh, R. Dimensional stabilization of wood by microporous silica aerogel using in-situ polymerization. Wood Sci. Technol. 2022, 56. [Google Scholar] [CrossRef]

- Jiang, J.; Li, H.; Pang, J.; Mei, C. Heat treatment induces chemical changes and silica sol penetration in wood for properties improvement: Hydrophobicity, thermal stability, and surface hardness. J. Wood Chem. Technol. 2022, 42, 104–113. [Google Scholar] [CrossRef]

- Jiang, J.; Zhou, Y.; Mei, C.; Cao, J. Polyethylene glycol and silica sol penetration improves hydrophobicity and dimensional stability of wood after a short-time treatment. Eur. J. Wood Wood Prod. 2021, 79, 1395–1404. [Google Scholar] [CrossRef]

- Shen, H.; Cao, J.; Jiang, J.; Xu, J. Antiweathering properties of a thermally treated wood surface by two-step treatment with titanium dioxide nanoparticle growth and polydimethylsiloxane coating. Prog. Org. Coat. 2018, 125, 1–7. [Google Scholar] [CrossRef]

- Michael, C.W. Characteristics and Availability of Commercially Important Woods. In Wood Handbook—Wood as an Engineering Material, Centennial Edition ed.; Robert, J.R., Ed.; Forest Products Laboratory (FPL): Madison, WI, USA, 2010; 508p. [Google Scholar]

- Zou, Y.; Yang, P.; Yang, L.; Li, N.; Duan, G.; Liu, X.; Li, Y. Boosting solar steam generation by photothermal enhanced polydopamine/wood composites. Polymer 2021, 217, 123464. [Google Scholar] [CrossRef]

- Tsoumis, G. Science and Technology of Wood: Structure, Properties, Utilization; Van Nostrand Reinhold: New York, NY, USA, 1991; Volume 115. [Google Scholar]

- Zhang, L.; Chen, Z.; Dong, H.; Fu, S.; Ma, L.; Yang, X. Wood plastic composites based wood wall’s structure and thermal insulation performance. J. Bioresour. Bioprod. 2021, 6, 65–74. [Google Scholar] [CrossRef]

- Robert, H.F. Wood as a Sustainable Building Material. In Wood Handbook—Wood as an Engineering Material, Centennial Edition ed.; Robert, J.R., Ed.; Forest Products Laboratory (FPL): Madison, WI, USA, 2010; Volume 1, 508p. [Google Scholar]

- Huang, C.; Chui, Y.; Gong, M.; Chana, F. Mechanical behaviour of wood compressed in radial direction: Part II. Influence of temperature and moisture content. J. Bioresour. Bioprod. 2020, 5, 266–275. [Google Scholar] [CrossRef]

- Ma, X.; Xiong, Y.; Liu, Y.; Han, J.; Duan, G.; Chen, Y.; He, S.; Mei, C.; Jiang, S.; Zhang, K. When MOFs meet wood: From opportunities toward applications. Chem 2022, 8, 2342–2361. [Google Scholar] [CrossRef]

- Demirbas, M.F. Thermal Energy Storage and Phase Change Materials: An Overview. Energy Sour. Part B Econ. Plan. Policy 2006, 1, 85–95. [Google Scholar] [CrossRef]

- Eanest Jebasingh, B.; Valan Arasu, A. A comprehensive review on latent heat and thermal conductivity of nanoparticle dispersed phase change material for low-temperature applications. Energy Storage Mater. 2020, 24, 52–74. [Google Scholar] [CrossRef]

- Cárdenas, B.; León, N. High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques. Renew. Sustain. Energy Rev. 2013, 27, 724–737. [Google Scholar] [CrossRef]

- Mohsen, M. (Ed.) Introductory Chapter: Phase Change Material. In Phase Change Materials and Their Applications; IntechOpen: London, UK, 2018; 174p. [Google Scholar]

- Li, Y.; Huang, X.; Lv, J.; Wang, F.; Jiang, S.; Wang, G. Enzymolysis-treated wood-derived hierarchical porous carbon for fluorescence-functionalized phase change materials. Compos. Part B Eng. 2022, 234, 109735. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Huang, X.; Jiang, S.; Wang, G. Anisotropy-functionalized cellulose-based phase change materials with reinforced solar-thermal energy conversion and storage capacity. Chem. Eng. J. 2021, 415, 129086. [Google Scholar] [CrossRef]

- Kumar, N.; Gupta, S.K.; Sharma, V.K. Application of phase change material for thermal energy storage: An overview of recent advances. Mater. Today Proc. 2021, 44, 368–375. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Zeynali Famileh, I.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Rathod, M.K. Thermal Stability of Phase Change Material. In Phase Change Materials and Their Applications; Mhadhbi, M., Ed.; IntechOpen: London, UK, 2018; 174p. [Google Scholar]

- Zari, N.; Raji, M.; El Mghari, H.; Bouhfid, R.; Qaiss, A.E.K. Chapter 3—Nanoclay and polymer-based nanocomposites: Materials for energy efficiency. In Polymer-Based Nanocomposites for Energy and Environmental Applications; Jawaid, M., Khan, M.M., Eds.; Woodhead Publishing: Southen, UK, 2018; pp. 75–103. [Google Scholar]

- Bruno, F.; Belusko, M.; Liu, M.; Tay, N.H.S. Chapter 9—Solid-liquid phase change materials for thermal energy storage. In Advances in Thermal Energy Storage Systems, 2nd ed.; Cabeza, L.F., Ed.; Woodhead Publishing: Southen, UK, 2021; pp. 221–268. [Google Scholar]

- Almousa, N.H.; Alotaibi, M.R.; Alsohybani, M.; Radziszewski, D.; AlNoman, S.M.; Alotaibi, B.M.; Khayyat, M.M. Paraffin Wax [As a Phase Changing Material (PCM)] Based Composites Containing Multi-Walled Carbon Nanotubes for Thermal Energy Storage (TES) Development. Crystals 2021, 11, 951. [Google Scholar] [CrossRef]

- Vijayrakesh, K.; Muthuvel, S.; Gopinath, G.R.; Qarnain, S.S.; Bathrinath, S. Experimental investigation of the performance of paraffin wax-packed floor on a solar dryer. J. Energy Storage 2021, 43, 103163. [Google Scholar] [CrossRef]

- Gonzalez-Nino, D.; Boteler, L.M.; Ibitayo, D.; Jankowski, N.R.; Urciuoli, D.; Kierzewski, I.M.; Quintero, P.O. Experimental evaluation of metallic phase change materials for thermal transient mitigation. Int. J. Heat Mass Transf. 2018, 116, 512–519. [Google Scholar] [CrossRef]

- Sari, A.; Kaygusuz, K. Thermal performance of a eutectic mixture of lauric and stearic acids as PCM encapsulated in the annulus of two concentric pipes. Sol. Energy 2002, 72, 493–504. [Google Scholar] [CrossRef]

- Majó, M.; Sánchez, R.; Barcelona, P.; García, J.; Fernández, A.I.; Barreneche, C. Degradation of Fatty Acid Phase-Change Materials (PCM): New Approach for Its Characterization. Molecules 2021, 26, 982. [Google Scholar] [CrossRef]

- Li, Y.; Kumar, N.; Hirschey, J.; Akamo, D.O.; Li, K.; Tugba, T.; Goswami, M.; Orlando, R.; LaClair, T.J.; Graham, S.; et al. Stable salt hydrate-based thermal energy storage materials. Compos. Part B Eng. 2022, 233, 109621. [Google Scholar] [CrossRef]

- Dhivya, S.; Hussain, S.I.; Jeya Sheela, S.; Kalaiselvam, S. Experimental study on microcapsules of Ag doped ZnO nanomaterials enhanced Oleic-Myristic acid eutectic PCM for thermal energy storage. Thermochim. Acta 2019, 671, 70–82. [Google Scholar] [CrossRef]

- Kateshia, J.; Lakhera, V. A comparative study of various fatty acids as phase change material to enhance the freshwater productivity of solar still. J. Energy Storage 2022, 48, 103947. [Google Scholar] [CrossRef]

- Zheng, M.; Peng, X.; Liu, J.; Zhang, S.; Zhang, X. Preparation and characterization of composite hydrate salt PCM of industrial grade disodium hydrogen phosphate with sodium carbonate. Int. J. Energy Res. 2021, 45, 7129–7144. [Google Scholar] [CrossRef]

- Saeed, R.M.; Schlegel, J.P.; Castano, C.; Sawafta, R.; Kuturu, V. Preparation and thermal performance of methyl palmitate and lauric acid eutectic mixture as phase change material (PCM). J. Energy Storage 2017, 13, 418–424. [Google Scholar] [CrossRef]

- Prasannaa, P.; Ramkumar, R.; Sunilkumar, K.; Rajasekar, R. Experimental study on a binary mixture ratio of fatty acid-based PCM integrated to PV panel for thermal regulation on a hot and cold month. Int. J. Sustain. Energy 2021, 40, 218–234. [Google Scholar] [CrossRef]

- Singh, V.K.; Kumar, D. Thermal characteristics of hydrated salt blended with Tio2 for thermal energy storage. Heat Transf. 2022, 51, 5368–5385. [Google Scholar] [CrossRef]

- Chinnasamy, V.; Appukuttan, S. Preparation and thermal properties of lauric acid/myristyl alcohol as a novel binary eutectic phase change material for indoor thermal comfort. Energy Storage 2019, 1, e80. [Google Scholar] [CrossRef]

- Lizcano-González, V.A.; Kafarov, V.V.; Mahkamov, K. Production of Fatty Esters from F Palm Oil By-Products for use as Phase Change Materials. Chem. Eng. Trans. 2022, 94, 331–336. [Google Scholar]

- Agrawal, R.; Singh, K.D.P.; Sharma, R.K. Experimental investigations on the phase change and thermal properties of nano enhanced binary eutectic phase change material of palmitic acid-stearic acid/CuO nanoparticles for thermal energy storage. Int. J. Energy Res. 2022, 46, 6562–6576. [Google Scholar] [CrossRef]

- Chinnasamy, V.; Cho, H. Investigation on thermal properties enhancement of lauryl alcohol with multi-walled carbon nanotubes as phase change material for thermal energy storage. Case Stud. Therm. Eng. 2022, 31, 101826. [Google Scholar] [CrossRef]

- Shahil, K.M.F.; Balandin, A.A. Graphene–Multilayer Graphene Nanocomposites as Highly Efficient Thermal Interface Materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef]

- Zhao, P.-P.; Deng, C.; Zhao, Z.-Y.; Lu, P.; He, S.; Wang, Y.-Z. Hypophosphite tailored graphitized hierarchical porous biochar toward highly efficient solar thermal energy harvesting and stable Storage/Release. Chem. Eng. J. 2021, 420, 129942. [Google Scholar] [CrossRef]

- Huang, X.; Chen, X.; Li, A.; Atinafu, D.; Gao, H.; Dong, W.; Wang, G. Shape-stabilized phase change materials based on porous supports for thermal energy storage applications. Chem. Eng. J. 2019, 356, 641–661. [Google Scholar] [CrossRef]

- Xia, R.; Zhang, W.; Yang, Y.; Zhao, J.; Liu, Y.; Guo, H. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation. J. Clean. Prod. 2021, 296, 126598. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Y.; Yu, Q.; Cao, G.; Yang, R.; Ke, J.; Di, X.; Liu, F.; Zhang, W.; Wang, C. Composite phase change materials with good reversible thermochromic ability in delignified wood substrate for thermal energy storage. Appl. Energy 2018, 212, 455–464. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Q.; Li, L. Delignified wood/capric acid-palmitic acid mixture stable-form phase change material for thermal storage. Sol. Energy Mater. Sol. Cells 2019, 194, 215–221. [Google Scholar] [CrossRef]

- Chen, X.; Guo, X.; Lin, X.; Fan, M.; Sun, W. pH-responsive wood-based phase change material for thermal energy storage building material application. J. Mater. Sci. 2022, 57, 13515–13526. [Google Scholar] [CrossRef]

- Chen, H.; Xuan, J.; Deng, Q.; Gao, Y. Wood/PCM Composite With Enhanced Energy Storage Density And Anisotropic Thermal Conductivity. Prog. Nat. Sci. Mater. Int. 2022, 32, 190–195. [Google Scholar] [CrossRef]

- Said, M.S.M.; Tohir, M.Z.M. The effect of ultraviolet coating on containment and fire hazards of phase change materials impregnated wood structure. J. Energy Storage 2020, 32, 101727. [Google Scholar] [CrossRef]

- Barreneche, C.; Vecstaudza, J.; Bajare, D.; Fernandez, A.I. PCM/wood composite to store thermal energy in passive building envelopes. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012111. [Google Scholar] [CrossRef]

- Lin, X.; Jia, S.; Liu, J.; Wang, W.; Cao, H.; Guo, X.; Sun, W. Fabrication of thermal energy storage wood based on graphene aerogel encapsulated polyethylene glycol as phase change material. Mater. Res. Express 2020, 7, 095503. [Google Scholar] [CrossRef]

- Wang, W.; Cao, H.; Liu, J.; Jia, S.; Ma, L.; Guo, X.; Sun, W. A thermal energy storage composite by incorporating microencapsulated phase change material into wood. RSC Adv. 2020, 10, 8097–8103. [Google Scholar] [CrossRef] [PubMed]

- Chung, M.; Park, J. An Experimental Study on the Thermal Performance of Phase-Change Material and Wood-Plastic Composites for Building Roofs. Energies 2017, 10, 195. [Google Scholar] [CrossRef]

- Sarı, A.; Hekimoğlu, G.; Tyagi, V.V. Low cost and eco-friendly wood fiber-based composite phase change material: Development, characterization and lab-scale thermoregulation performance for thermal energy storage. Energy 2020, 195, 116983. [Google Scholar] [CrossRef]

- Yang, H.; Chao, W.; Di, X.; Yang, Z.; Yang, T.; Yu, Q.; Liu, F.; Li, J.; Li, G.; Wang, C. Multifunctional wood based composite phase change materials for magnetic-thermal and solar-thermal energy conversion and storage. Energy Convers. Manag. 2019, 200, 112029. [Google Scholar] [CrossRef]

- Saavedra, H.; García-Herrera, C.; Vasco, D.A.; Salinas-Lira, C. Characterization of mechanical performance of Pinus radiata wood impregnated with octadecane as phase change material. J. Build. Eng. 2021, 34, 101913. [Google Scholar] [CrossRef]

- Yang, H.; Wang, S.; Wang, X.; Chao, W.; Wang, N.; Ding, X.; Liu, F.; Yu, Q.; Yang, T.; Yang, Z.; et al. Wood-based composite phase change materials with self-cleaning superhydrophobic surface for thermal energy storage. Appl. Energy 2020, 261, 114481. [Google Scholar] [CrossRef]

- Liu, S.; Sheng, M.; Wu, H.; Shi, X.; Lu, X.; Qu, J. Biological porous carbon encapsulated polyethylene glycol-based phase change composites for integrated electromagnetic interference shielding and thermal management capabilities. J. Mater. Sci. Technol. 2022, 113, 147–157. [Google Scholar] [CrossRef]

- Xu, J.; Yang, T.; Xu, X.; Guo, X.; Cao, J. Processing solid wood into a composite phase change material for thermal energy storage by introducing silica-stabilized polyethylene glycol. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106098. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, J.; Zhao, Y.; Wang, G.; Gu, W.; Ji, G. Hierarchically porous wood-derived carbon scaffold embedded phase change materials for integrated thermal energy management, electromagnetic interference shielding and multifunctional application. Carbon 2021, 183, 515–524. [Google Scholar] [CrossRef]

- Cheng, L.; Feng, J. Form-stable phase change materials based on delignified wood flour for thermal management of buildings. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105690. [Google Scholar] [CrossRef]

- Shi, X.; Meng, Y.; Bi, R.; Wan, Z.; Zhu, Y.; Rojas, O.J. Enabling unidirectional thermal conduction of wood-supported phase change material for photo-to-thermal energy conversion and heat regulation. Compos. Part B Eng. 2022, 245, 110231. [Google Scholar] [CrossRef]

- Mohamad Amini, M.H.; Temiz, A.; Hekimoğlu, G.; Köse Demirel, G.; Sarı, A. Properties of Scots pine wood impregnated with capric acid for potential energy saving building material. Holzforschung 2022, 76, 744–753. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, H.; Wang, X.; Wang, X.; Cui, E.; Wang, L. Form-stable paraffin/rice straw/polyvinyl alcohol composite phase change material for thermal energy storage. Mater. Lett. 2021, 294, 129790. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, C.; Jin, T.; Dong, H. Water evaporation inspired biomass-based PCM from daisy stem and paraffin for building temperature regulation. Renew. Energy 2022, 194, 211–219. [Google Scholar] [CrossRef]

- Gencel, O.; Sarı, A.; Kaplan, G.; Ustaoglu, A.; Hekimoğlu, G.; Bayraktar, O.Y.; Ozbakkaloglu, T. Properties of eco-friendly foam concrete containing PCM impregnated rice husk ash for thermal management of buildings. J. Build. Eng. 2022, 58, 104961. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, N.; Pan, X.; Zhong, W.; Qiu, B.; Cai, Y.; Yuan, Y. Thermal properties of biomass-based form-stable phase change material for latent heat thermal energy storage. Int. J. Energy Res. 2021, 45, 20372–20383. [Google Scholar] [CrossRef]

- Wen, R.; Liu, Y.; Yang, C.; Zhu, X.; Huang, Z.; Zhang, X.; Gao, W. Enhanced thermal properties of stearic acid/carbonized maize straw composite phase change material for thermal energy storage in buildings. J. Energy Storage 2021, 36, 102420. [Google Scholar] [CrossRef]

- Feng, N.; Kang, Z.; Hu, D. Shape-stabilized and antibacterial composite phase change materials based on wood-based cellulose micro-framework, erythritol-urea or erythritol-thiourea for thermal energy storage. Sol. Energy 2021, 223, 19–32. [Google Scholar] [CrossRef]

- Liu, S.; Wu, H.; Du, Y.; Lu, X.; Qu, J. Shape-stable composite phase change materials encapsulated by bio-based balsa wood for thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 230, 111187. [Google Scholar] [CrossRef]

- Liang, B.; Lu, X.; Li, R.; Tu, W.; Yang, Z.; Yuan, T. Solvent-free preparation of bio-based polyethylene glycol/wood flour composites as novel shape-stabilized phase change materials for solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2019, 200, 110037. [Google Scholar] [CrossRef]

- Fernández, V.; Valderrama-Ulloa, C.; Rouault, F.; Schmitt, C.; del Río, R.; Vasco, D. Thermal and Mechanical Analysis of Plywood Boards Thermally Enhanced with Phase Change Materials. IOP Conf. Ser. Earth Environ. Sci. 2020, 503, 012074. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Y.; Liu, Z.; Liang, D.; Liu, F.; Zhang, W.; Di, X.; Wang, C.; Ho, S.-H.; Chen, W.-H. Enhanced thermal conductivity of waste sawdust-based composite phase change materials with expanded graphite for thermal energy storage. Bioresour. Bioprocess. 2017, 4, 52. [Google Scholar] [CrossRef]

- Sarı, A.; Hekimoğlu, G.; Karabayır, Y.; Sharma, R.K.; Arslanoğlu, H.; Gencel, O.; Tyagi, V.V. Capric-stearic acid mixture impregnated carbonized waste sugar beet pulp as leak-resistive composite phase change material with effective thermal conductivity and thermal energy storage performance. Energy 2022, 247, 123501. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, Y.; Olayiwola, S.; Lau, C.; Fan, M.; Ng, K.; Tan, G. Biomass-derived porous carbons support in phase change materials for building energy efficiency: A review. Mater. Today Energy 2022, 23, 100905. [Google Scholar] [CrossRef]

- Kalbasi, R. Usefulness of PCM in building applications focusing on envelope heat exchange—Energy saving considering two scenarios. Sustain. Energy Technol. Assess. 2022, 50, 101848. [Google Scholar] [CrossRef]

- Soleiman Dehkordi, B.; Afrand, M. Energy-saving owing to using PCM into buildings: Considering of hot and cold climate region. Sustain. Energy Technol. Assess. 2022, 52, 102112. [Google Scholar] [CrossRef]

- Casini, M. (Ed.) 5—Phase-change materials. In Smart Buildings; Woodhead Publishing: Southen, UK, 2016; pp. 179–218. [Google Scholar]

- Shukla, A.; Buddhi, D.; Sawhney, R.L. Thermal cycling test of few selected inorganic and organic phase change materials. Renew. Energy 2008, 33, 2606–2614. [Google Scholar] [CrossRef]

- Tebaldi, M.L.; Belardi, R.M.; Montoro, S.R. Chapter 8—Polymers with Nano-Encapsulated Functional Polymers: Encapsulated Phase Change Materials. In Design and Applications of Nanostructured Polymer Blends and Nanocomposite Systems; Thomas, S., Shanks, R., Chandrasekharakurup, S., Eds.; William Andrew Publishing: Boston, MA, USA, 2016; pp. 155–169. [Google Scholar]

- Shah, K.W.; Huseien, G.F. Chapter 17—Nanostructures encapsulated phase-change materials for sustained thermal energy storage in concrete. In Green Nanomaterials for Industrial Applications; Shanker, U., Hussain, C.M., Rani, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 477–507. [Google Scholar]

- Roy, U.; Pant, H.K. Chapter 9—Current progress in heat exchangers with phase change materials (PCMs): A comprehensive investigation. In Advanced Analytic and Control Techniques for Thermal Systems with Heat Exchangers; Pekař, L., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 219–230. [Google Scholar]

- Safarian, J.; Tangstad, M. Chapter 4—Phase change materials for high-temperature operation. In Ultra-High Temperature Thermal Energy Storage, Transfer and Conversion; Datas, A., Ed.; Woodhead Publishing: Southen, UK, 2021; pp. 85–111. [Google Scholar]

- Kuravi, S.; Trahan, J.; Goswami, D.Y.; Rahman, M.M.; Stefanakos, E.K. Thermal energy storage technologies and systems for concentrating solar power plants. Prog. Energy Combust. Sci. 2013, 39, 285–319. [Google Scholar] [CrossRef]

- Abu-Eishah, S.I. Correlations for the Thermal Conductivity of Metals as a Function of Temperature. Int. J. Thermophys. 2001, 22, 1855–1868. [Google Scholar] [CrossRef]

- Bauer, T.; Tamme, R.; Christ, M.; Öttinger, O. PCM-graphite composites for high temperature thermal energy storage. In Proceedings of the 10th International Conference on Thermal Energy Storage (ECOSTOCK 2006), Galloway, NJ, USA, 31 May–2 June 2006. [Google Scholar]

- Bugaje, I.M. Enhancing the thermal response of latent heat storage systems. Int. J. Energy Res. 1997, 21, 759–766. [Google Scholar] [CrossRef]

- Nomura, T.; Okinaka, N.; Akiyama, T. Impregnation of porous material with phase change material for thermal energy storage. Mater. Chem. Phys. 2009, 115, 846–850. [Google Scholar] [CrossRef]

- Tauseef ur, R.; Ali, H.M.; Janjua, M.M.; Sajjad, U.; Yan, W.-M. A critical review on heat transfer augmentation of phase change materials embedded with porous materials/foams. Int. J. Heat Mass Transf. 2019, 135, 649–673. [Google Scholar] [CrossRef]

- Kong, I. Chapter 7—Polymers with Nano-Encapsulated Functional Polymers. In Design and Applications of Nanostructured Polymer Blends and Nanocomposite Systems; Thomas, S., Shanks, R., Chandrasekharakurup, S., Eds.; William Andrew Publishing: Boston, MA, USA, 2016; pp. 125–154. [Google Scholar]

- Rathore, P.K.S.; Shukla, S.K. Improvement in thermal properties of PCM/Expanded vermiculite/expanded graphite shape stabilized composite PCM for building energy applications. Renew. Energy 2021, 176, 295–304. [Google Scholar] [CrossRef]

- Jeon, J.; Park, J.H.; Wi, S.; Yang, S.; Ok, Y.S.; Kim, S. Characterization of biocomposite using coconut oil impregnated biochar as latent heat storage insulation. Chemosphere 2019, 236, 124269. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.-G.; Lee, J.-H.; Seo, J.; Kim, S. Thermal performance evaluation of Bio-based shape stabilized PCM with boron nitride for energy saving. Int. J. Heat Mass Transf. 2014, 71, 245–250. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Kaushik, S.C.; Tyagi, S.K.; Akiyama, T. Development of phase change materials based microencapsulated technology for buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1373–1391. [Google Scholar] [CrossRef]

- Alam, M.; Zou, P.X.W.; Sanjayan, J.; Ramakrishnan, S. Energy saving performance assessment and lessons learned from the operation of an active phase change materials system in a multi-storey building in Melbourne. Appl. Energy 2019, 238, 1582–1595. [Google Scholar] [CrossRef]

- Hamidi, Y.; Aketouane, Z.; Malha, M.; Bruneau, D.; Bah, A.; Goiffon, R. Integrating PCM into hollow brick walls: Toward energy conservation in Mediterranean regions. Energy Build. 2021, 248, 111214. [Google Scholar] [CrossRef]

- Mahdaoui, M.; Hamdaoui, S.; Ait Msaad, A.; Kousksou, T.; El Rhafiki, T.; Jamil, A.; Ahachad, M. Building bricks with phase change material (PCM): Thermal performances. Constr. Build. Mater. 2021, 269, 121315. [Google Scholar] [CrossRef]

- Paranjothi, G.; Odukomaiya, A.; Cui, S.; Bulk, A. Evaluation of phase change plaster/paste composites for building envelopes. Energy Build. 2021, 253, 111372. [Google Scholar] [CrossRef]

- Hekimoğlu, G.; Nas, M.; Ouikhalfan, M.; Sarı, A.; Tyagi, V.V.; Sharma, R.K.; Kurbetci, Ş.; Saleh, T.A. Silica fume/capric acid-stearic acid PCM included-cementitious composite for thermal controlling of buildings: Thermal energy storage and mechanical properties. Energy 2021, 219, 119588. [Google Scholar] [CrossRef]

- Larwa, B.; Cesari, S.; Bottarelli, M. Study on thermal performance of a PCM enhanced hydronic radiant floor heating system. Energy 2021, 225, 120245. [Google Scholar] [CrossRef]

- Guo, J.; Jiang, Y. A semi-analytical model for evaluating the thermal storage capacity and heat use efficiency of flexible thermal storage heating floor. Appl. Therm. Eng. 2021, 198, 117448. [Google Scholar] [CrossRef]

- Rida, M.; Hoffmann, S. The influence of macro-encapsulated PCM panel’s geometry on heat transfer in a ceiling application. Adv. Build. Energy Res. 2022, 16, 445–465. [Google Scholar] [CrossRef]

- Gallardo, A.; Berardi, U. Evaluation of the energy flexibility potential of radiant ceiling panels with thermal energy storage. Energy 2022, 254, 124447. [Google Scholar] [CrossRef]

- Boobalakrishnan, P.; Manoj Kumar, P.; Balaji, G.; Jenaris, D.S.; Kaarthik, S.; Jaya Prakash Babu, M.; Karthhik, K. Thermal management of metal roof building using phase change material (PCM). Mater. Today Proc. 2021, 47, 5052–5058. [Google Scholar] [CrossRef]

- Meng, E.; Yang, J.; Zhou, B.; Wang, C.; Li, J. Preparation and thermal performance of phase change material (PCM) foamed cement used for the roof. J. Build. Eng. 2022, 53, 104579. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).