Temperature-Dependent Creep Behavior and Quasi-Static Mechanical Properties of Heat-Treated Wood

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Heat Treatment

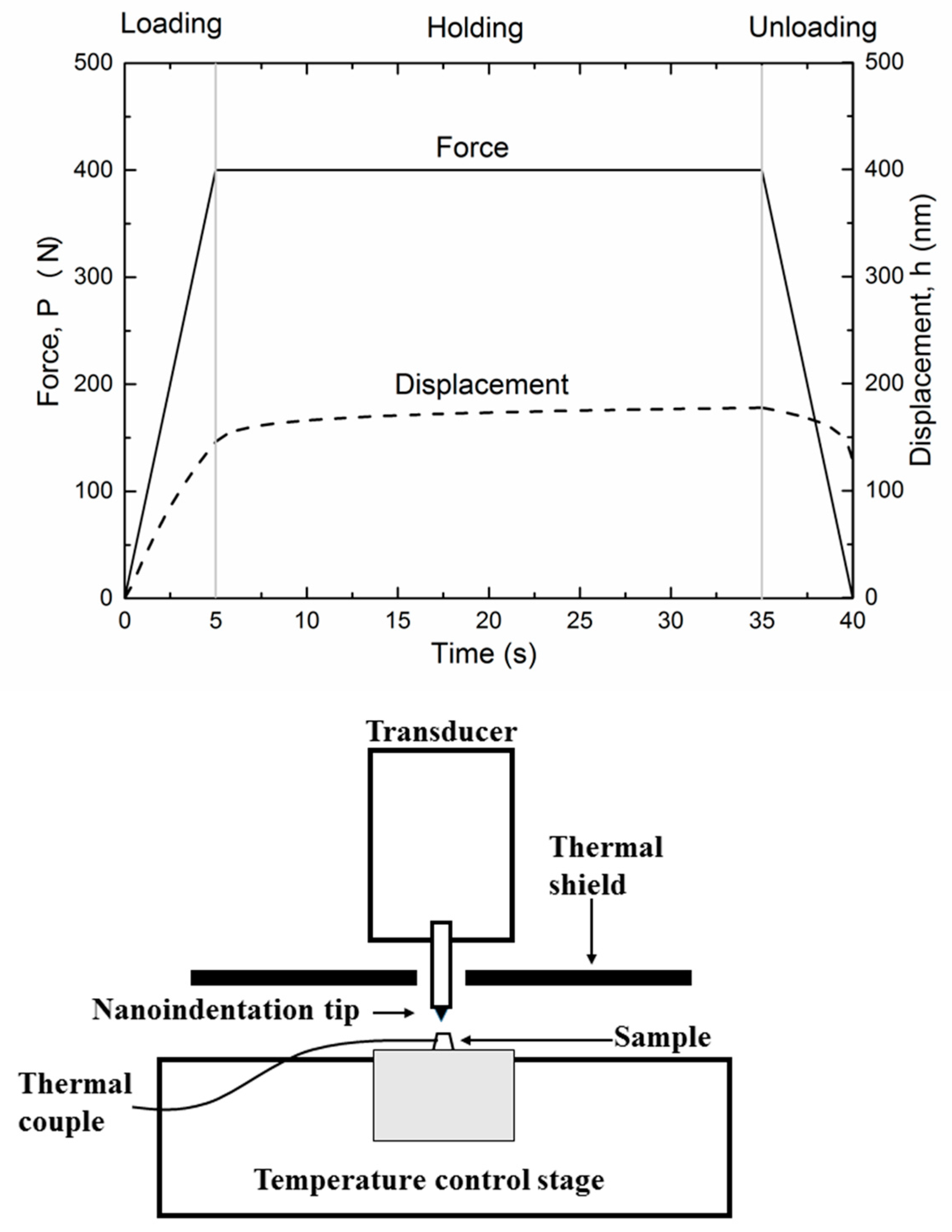

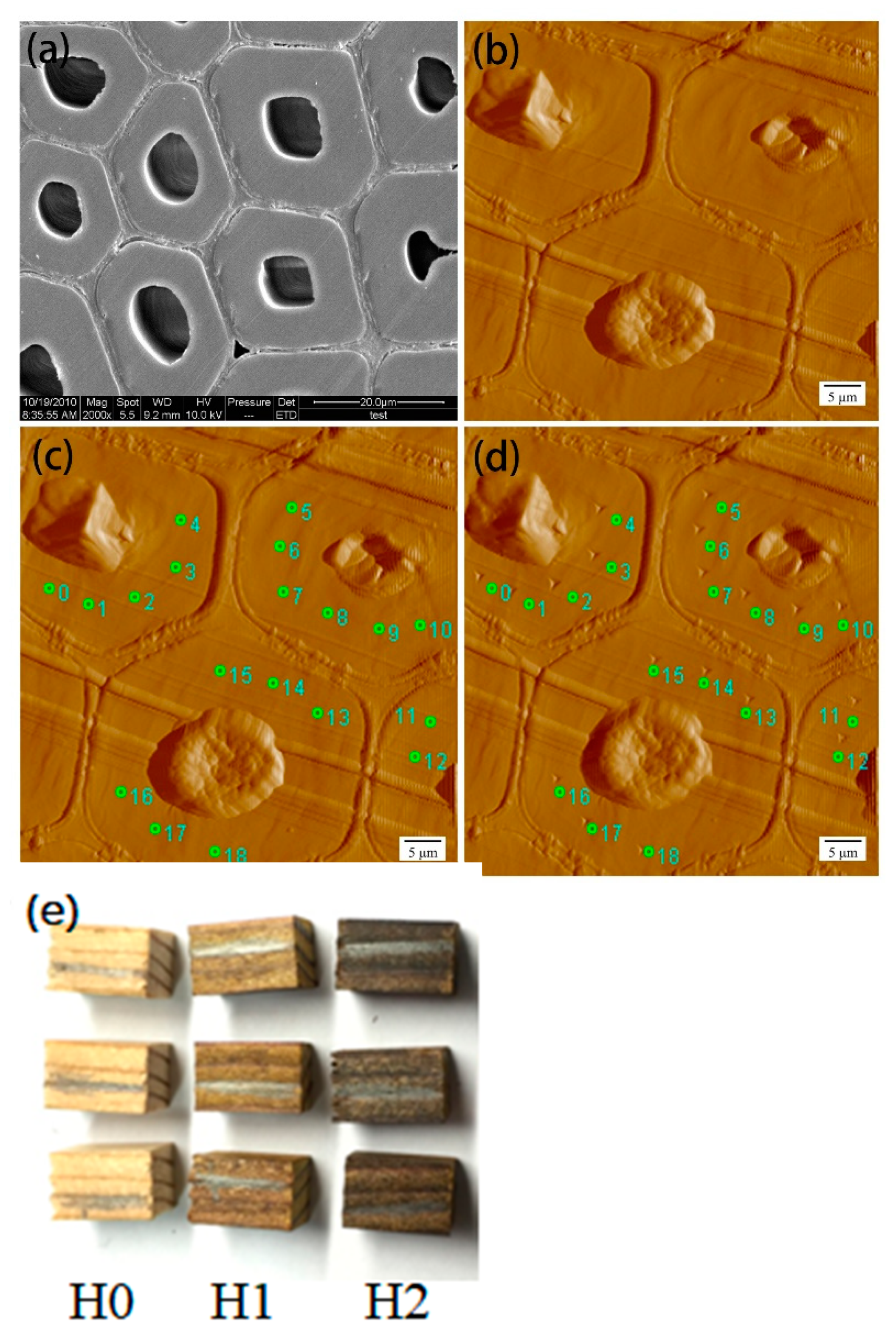

2.3. Viscoelastic Properties-Creep Behavior Nanoindentation Test

3. Results and Discussion

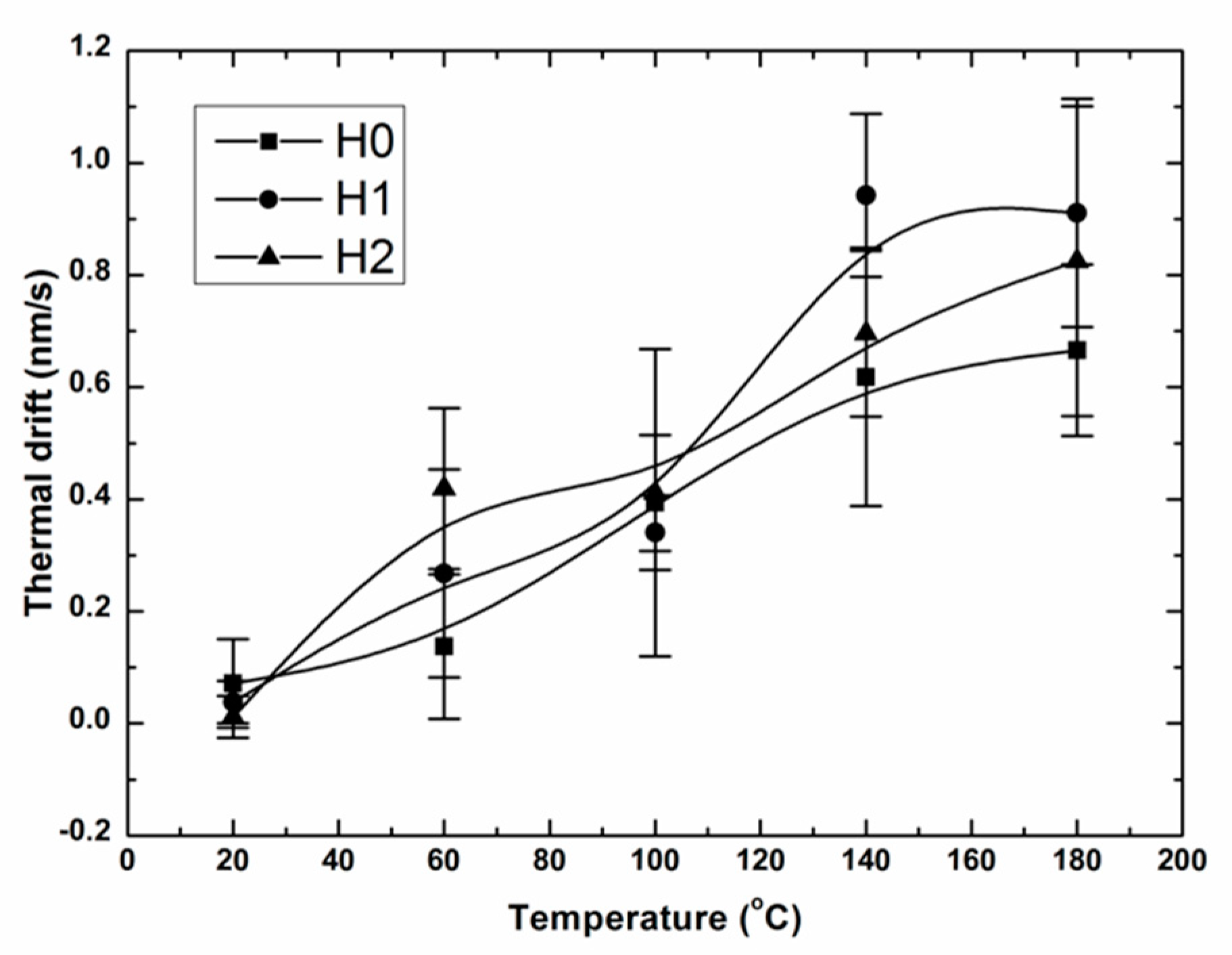

3.1. Thermal Drift

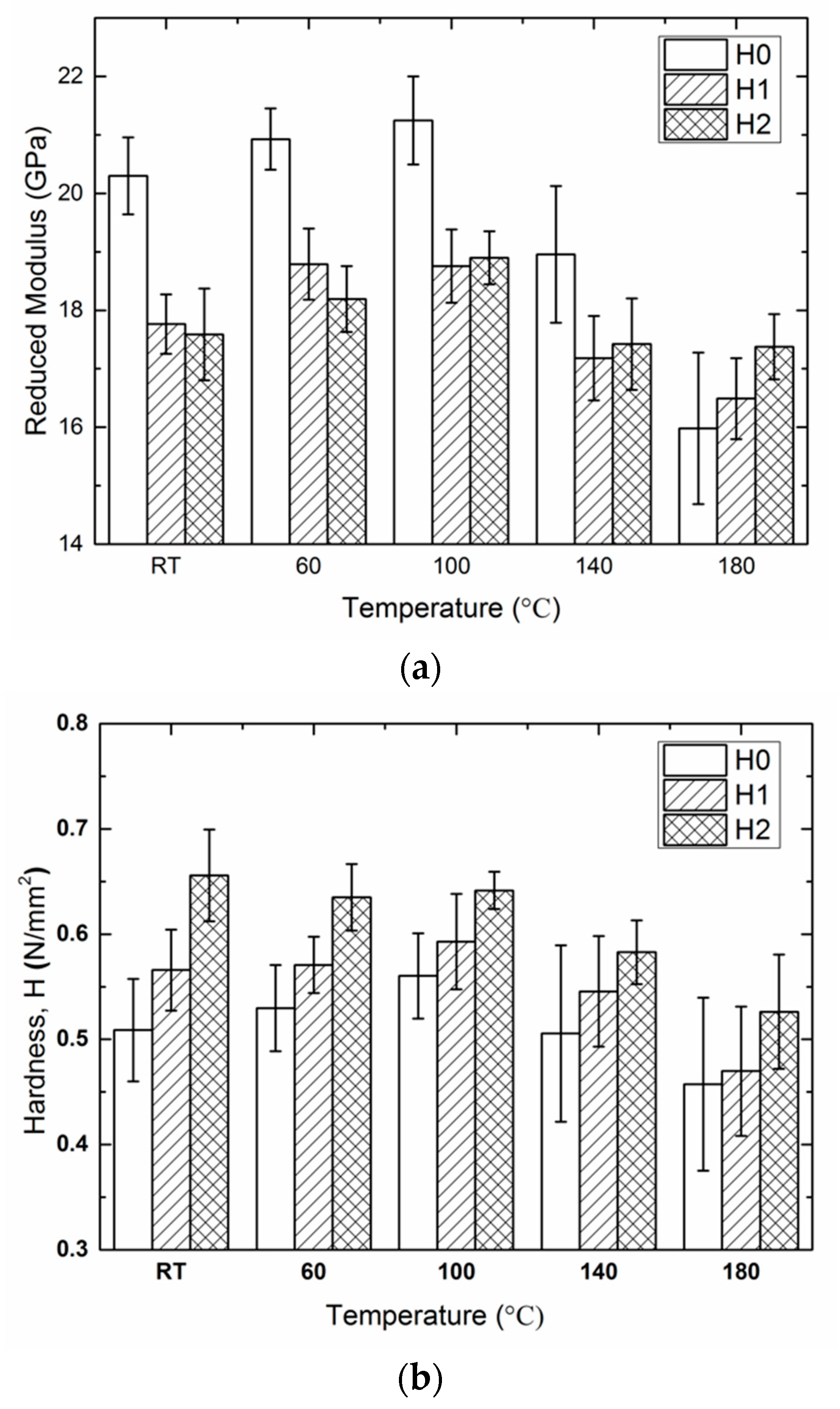

3.2. Temperature on Quasi-Static Mechanical Properties

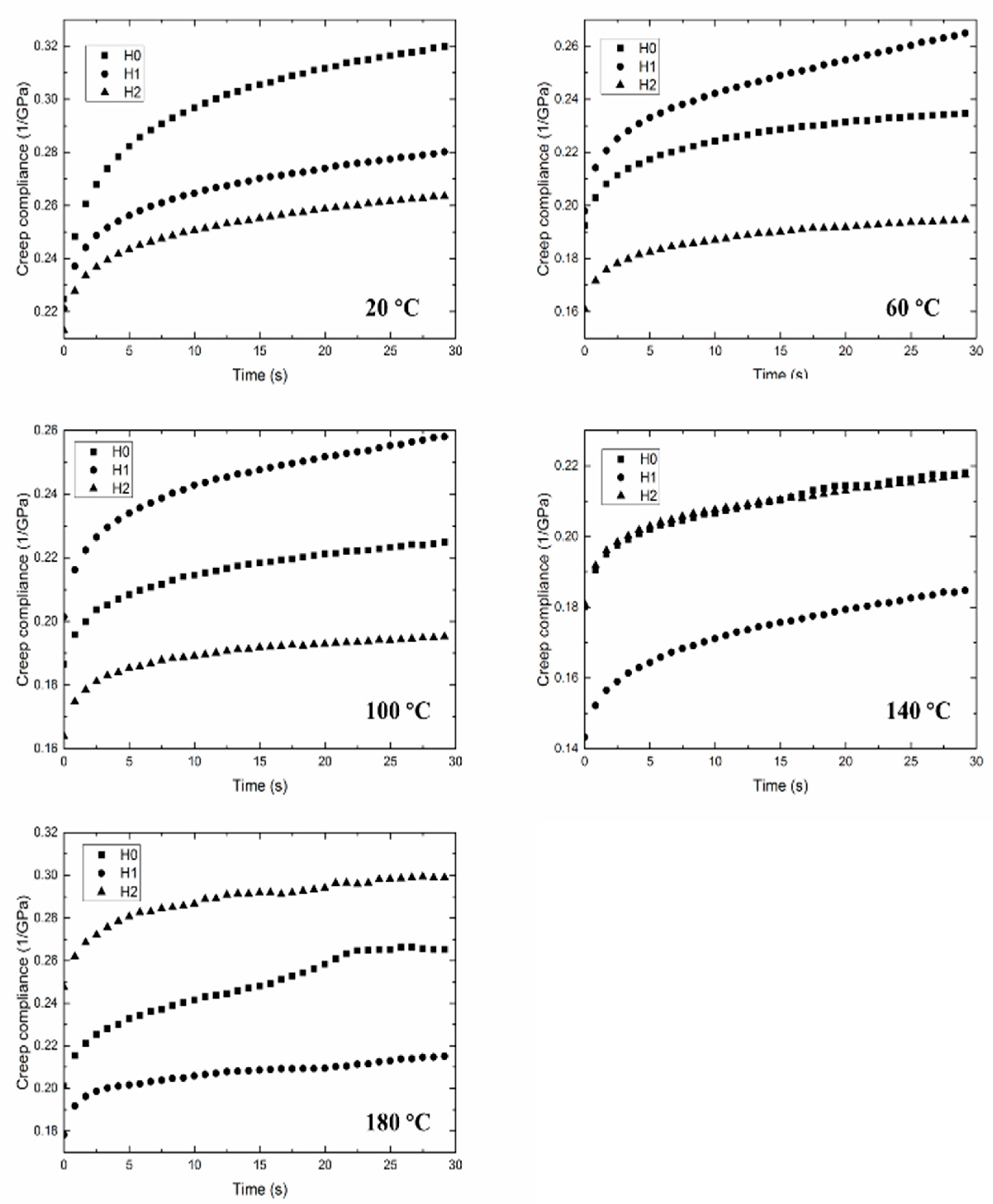

3.3. Temperature on Creep Behaviors

3.4. Heat Treatment on Creep Behaviors

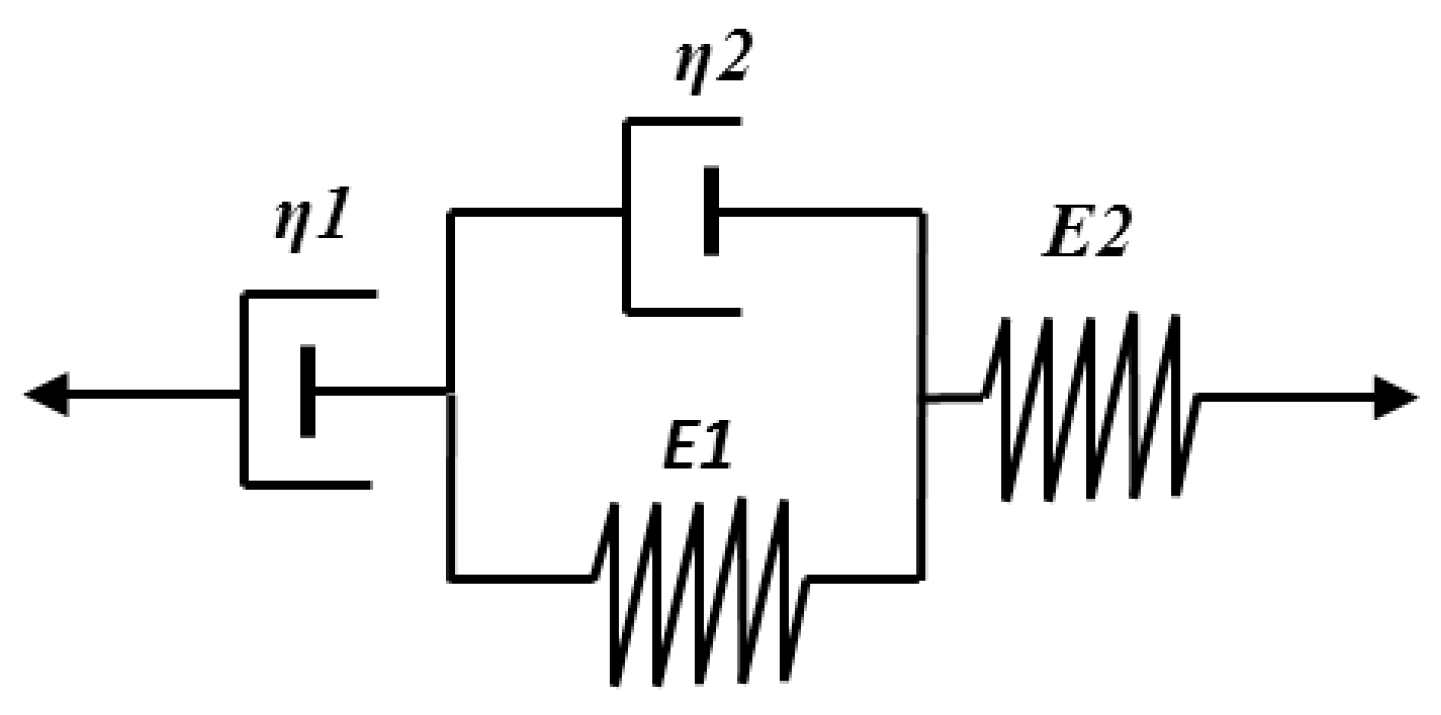

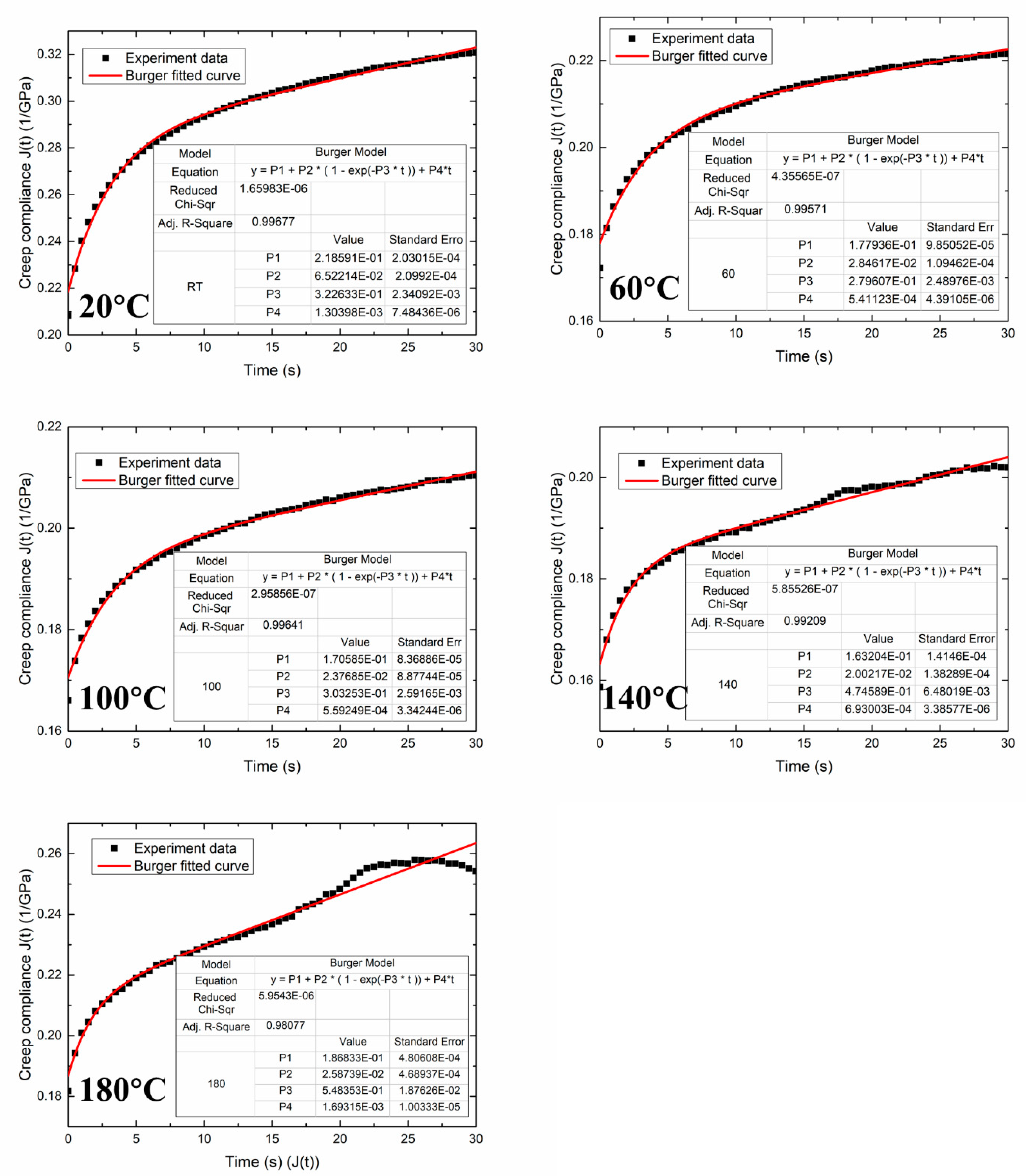

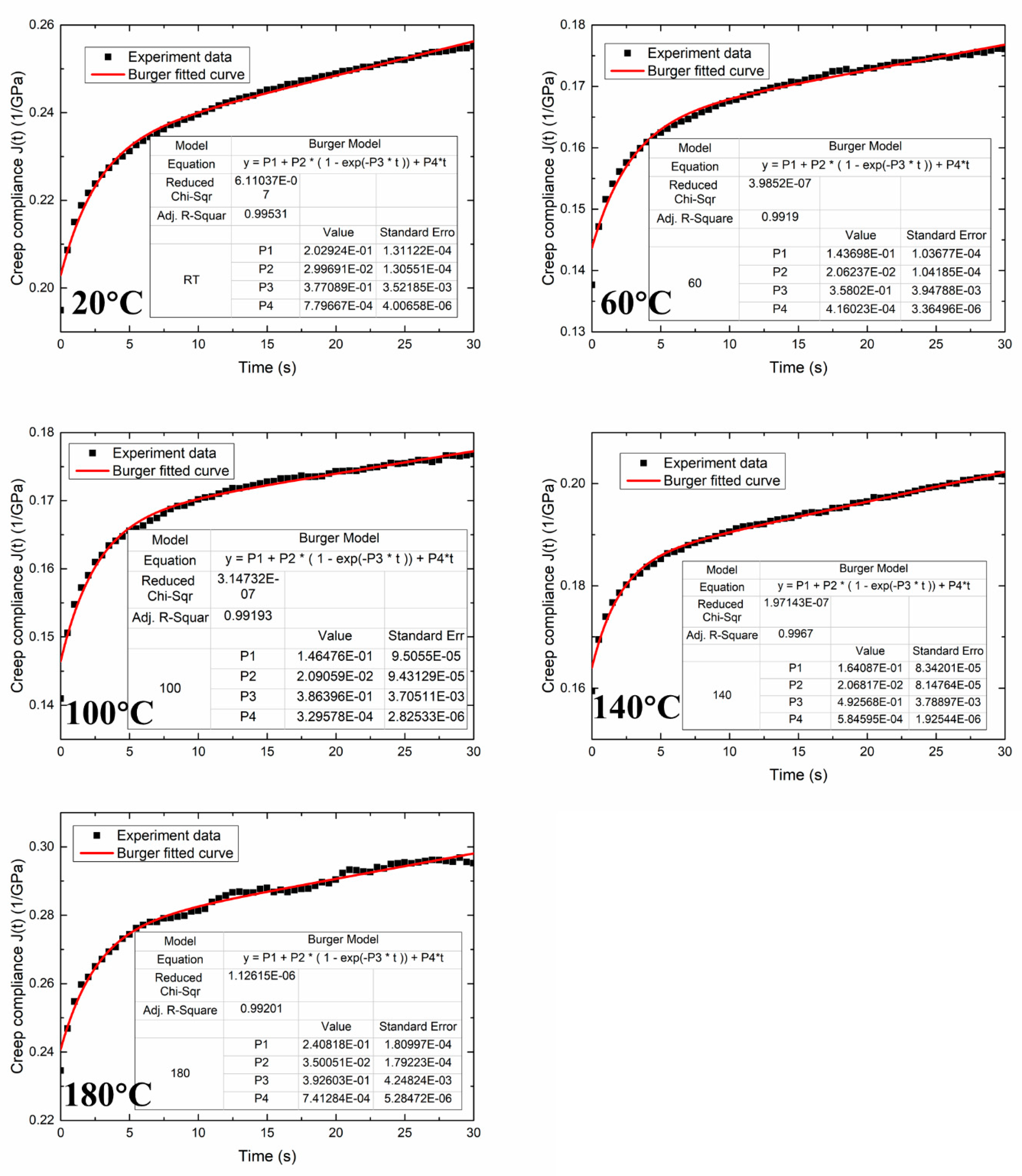

3.5. Burgers Model

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, D.; Lin, L.; Fu, F. The difference of creep compliance for wood cell wall CML and secondary S2 layer by nanoindentation. Mech. Time-Depend. Mater. 2019, 9, 1–12. [Google Scholar] [CrossRef]

- Passard, J.; Perré, P. Viscoelastic behaviour of green wood across the grain. Part II. A temperature dependent constitutive model defined by inverse method. Ann. For. Sci. 2005, 62, 823–830. [Google Scholar] [CrossRef]

- Zhang, T.; Bai, S.L.; Zhang, Y.F.; Thibaut, B. Viscoelastic properties of wood materials characterized by nanoindentation experiments. Wood Sci. Technol. 2012, 46, 1003–1016. [Google Scholar] [CrossRef][Green Version]

- Báder, M.; Németh, R.; Konnerth, J. Micromechanical properties of longitudinally compressed wood. Eur. J. Wood Wood Prod. 2019, 77, 341–351. [Google Scholar] [CrossRef]

- Meng, Y.; Xia, Y.; Young, T.M.; Cai, Z.; Wang, S. Viscoelasticity of wood cell walls with different moisture content as measured by nanoindentation. RSC Adv. 2015, 5, 47538–47547. [Google Scholar] [CrossRef]

- Kaufman, J.D.; Miller, G.J.; Morgan, E.F.; Klapperich, C.M. Time-dependent mechanical characterization of poly(2-hydroxyethyl methacrylate) hydrogels using nanoindentation and unconfined compression. J. Mater. Res. 2008, 23, 1472–1481. [Google Scholar] [CrossRef][Green Version]

- Esteves, B.; Cruz-Lopes, L.S.; Figueirinha, A.; Lemons, L.T.; Ferreira, J.; Pereira, H.; Domingos, I. Heat-treated wood as chromium adsorption material. Eur. J. Wood Wood Prod. 2017, 75, 903–909. [Google Scholar] [CrossRef]

- Kufre, E.O.; Fengcai, L.; Yandan, C.; Biao, H. Effect of silicone oil heat treatment on the chemical composition, cellulose crystalline structure and contact angle of Chinese parasol wood. Carbohydr. Polym. 2017, 164, 179–185. [Google Scholar]

- Nguyen, T.T.; Nguyen, T.H.V.; Ji, X.D.; Yuan, B.N.; Trinh, H.M.; Do, K.T.L.; Guo, M.H. Prediction of the color change of heat-treated wood during artificial weathering by artificial neural network. Eur. J. Wood Wood Prod. 2019, 77, 1107–1116. [Google Scholar] [CrossRef]

- Chang, C.W.; Kuo, W.L.; Lu, K.T. On the Effect of Heat Treatments on the Adhesion, Finishing and Decay Resistance of Japanese cedar (Cryptomeria japonica D. Don) and Formosa acacia (Acacia confuse Merr. (Leguminosae)). Forests 2019, 10, 586. [Google Scholar] [CrossRef]

- Yuan, H.; Tang, S.; Luo, Q.; Xiao, T.; Wu, Y. Micro-FTIR spectroscopy and partial least-squares regression for rapid determination of moisture content of nanogram-scaled heat-treated wood. J. Wood Sci. 2020, 66, 1–7. [Google Scholar] [CrossRef]

- Delucis, R.; Beltrame, R.; Gatto, D.A. Discolouration of heat-treated fast-growing eucalyptus wood exposed to natural weathering. Cell Chem. Technol. 2019, 53, 635–641. [Google Scholar] [CrossRef]

- Rindler, A.; Hansmann, C.; Konnerth, J. The effect of moisture on the mechanical response of wood, adhesive and their interphase by means of nanoindentation. Wood Sci. Technol. 2019, 53, 729–746. [Google Scholar] [CrossRef]

- Liang, R.; Zhu, Y.H.; Yang, X.; Gao, J.S.; Cai, L.P. Study on the ultrastructure and properties of gelatinous layer in poplar. J. Mater. Sci. 2021, 56, 415–427. [Google Scholar] [CrossRef]

- Lucca, D.A.; Herrmann, K.; Klopfstein, M.J. Nanoindentation: Measuring methods and applications. CIRP Ann. 2010, 59, 803–819. [Google Scholar] [CrossRef]

- Li, Y.; Huang, C.; Wang, L.; Wang, S.; Wang, X. The effects of thermal treatment on the nanomechanical behavior of bamboo (Phyllostachys pubescens Mazel ex H. De Lehaie) cell walls observed by nanoindentation, XRD, and wet chemistry. Holzforschung 2016, 71, 129–135. [Google Scholar] [CrossRef]

- Xing, D.; Li, J.; Wang, S. Comparison of the chemical and micromechanical properties of Larix spp. after eco-friendly heat treatments measured by in situ nanoindentation. Sci. Rep. 2020, 10, 4358. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhao, L.; Deng, Y.; Li, Y.; Wang, S. Effect of the penetration of isocyanates (pMDI) on the nanomechanics of wood cell wall evaluated by AFM-IR and nanoindentation (NI). Holzforschung 2017, 72, 301–309. [Google Scholar] [CrossRef]

- Chen, Y.P.; Guo, J.P.; Cai, Y.Y. An anisotropic distribution dislocation loop model for simulation of nanoindentation of single crystals. Mech. Mater. 2017, 108, 1–10. [Google Scholar] [CrossRef]

- Han, R.; Wang, X.; Zhu, G.; Han, N.; Xing, F. Investigation on viscoelastic properties of urea-formaldehyde microcapsules by using nanoindentation. Polym. Test. 2019, 80, 106146. [Google Scholar] [CrossRef]

- Shepherd, T.N.; Zhang, J.; Ovaert, T.C.; Roeder, R.K.; Niebur, G.L. Direct comparison of nanoindentation and macroscopic measurements of bone viscoelasticity. J. Mech. Behav. Biomed. 2011, 4, 2055–2062. [Google Scholar] [CrossRef] [PubMed]

- Hadjab, I.; Farlay, D.; Crozier, P.; Douillard, T.; Follet, H. Intrinsic Properties of Osteomalacia Bone evaluated by Nanoindentation and FTIRM Analysis. J. Biomech. 2021, 117, 110247. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.N.; Tian, Z.Q.; Yuan, Z.Q.; Li, J.J.; Wu, W.P.; Xia, R. Temperature and loading sensitivity investigation of nanoindentation short-term creep behavior in Nafion (R). Mater. Res. Express 2019, 6, 055304. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Bubach, B. Application of nanoindentation to characterize creep behavior of oil shales. J. Pet. Sci. Eng. 2018, 167, 729–736. [Google Scholar] [CrossRef]

- Gibson, L.J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 2012, 9, 2749–2766. [Google Scholar] [CrossRef]

- Barthelat, F.; Zhen, Y.; Buehler, M.J. Structure and mechanics of interfaces in biological materials. Nat. Rev. Mater. 2016, 1, 16007. [Google Scholar] [CrossRef]

- Grishkewich, N.; Mohammed, N.; Tang, J.; Tam, K.C. Recent advances in the application of cellulose nanocrystals. Curr. Opin. Colloid 2017, 29, 32–45. [Google Scholar] [CrossRef]

- Xing, D.; Li, J.; Wang, X.; Wang, S.Q. In situ measurement of heat-treated wood cell wall at elevated temperature by nanoindentation. Ind. Crop. Prod. 2016, 87, 142–149. [Google Scholar] [CrossRef]

- Ben, D.B.; James, F.S. High-temperature nanoindentation testing of fused silica and other materials. Philos. Mag. A 2002, 82, 2179–2186. [Google Scholar]

- Stanzl-Tschegg, S.; Beikircher, W.; Loidl, D. Comparison of mechanical properties of thermally modified wood at growth ring and cell wall level by means of instrumented indentation tests. Holzforschung 2009, 63, 443–448. [Google Scholar] [CrossRef]

- Marcio, R.S.; José, O.B.; José, S.G.; Gilmara, O.M.; Carlito, C.J.; André, L.C.; Francisco, A.R.L. Chemical and Mechanical Properties Changes in Corymbia Citriodora Wood Submitted to Heat Treatment. Int. J. Mater. Eng. 2015, 5, 98–104. [Google Scholar]

- Zickler, G.A.; Schöberl, T.; Paris, O. Mechanical properties of pyrolysed wood: A nanoindentation study. Philos. Mag. 2006, 86, 1373–1386. [Google Scholar] [CrossRef]

- Xu, F.; Long, Z.L.; Deng, X.H.; Zhang, P. Loading rate sensitivity of nanoindentation creep behavior in a Fe-based bulk metallic glass. Trans. Nonferrous Met. Soc. China 2013, 23, 1646–1651. [Google Scholar] [CrossRef]

- Chen, Y.H.; Huang, J.C.; Wang, L.; Nieh, T.G. Effect of residual stresses on nanoindentation creep behavior of Zr-based bulk metallic glasses. Intermetallics 2013, 41, 58–62. [Google Scholar] [CrossRef]

- Mukudai, J.; Yata, S. Modeling and simulation of viscoelastic behavior (tensile strain) of wood under moisture change. Wood Sci. Technol. 1986, 20, 335–348. [Google Scholar] [CrossRef]

| Temp (°C) | No. | E1 (GPa) | E2 (GPa) | η1 (GPa·S) | η2 (GPa·S) | τ0 (S) | R2 |

|---|---|---|---|---|---|---|---|

| 20 | H0 | 4.57 | 15.33 | 769.23 | 47.52 | 3.10 | 0.997 |

| H1 | 4.71 | 27.99 | 1086.19 | 74.20 | 2.65 | 0.996 | |

| H2 | 4.93 | 33.37 | 1282.60 | 88.48 | 2.65 | 0.995 | |

| 60 | H0 | 5.62 | 35.14 | 1848.01 | 125.66 | 3.58 | 0.996 |

| H1 | 5.42 | 31.40 | 719.42 | 67.52 | 2.15 | 0.998 | |

| H2 | 6.96 | 48.50 | 2403.71 | 135.46 | 2.79 | 0.992 | |

| 100 | H0 | 5.86 | 42.07 | 1788.11 | 138.73 | 3.30 | 0.996 |

| H1 | 5.29 | 29.88 | 1097.24 | 81.92 | 2.74 | 0.997 | |

| H2 | 6.83 | 47.82 | 3034.18 | 123.77 | 2.59 | 0.992 | |

| 140 | H0 | 6.13 | 49.95 | 1443.00 | 105.25 | 2.11 | 0.992 |

| H1 | 8.13 | 49.02 | 1315.31 | 155.38 | 3.17 | 0.998 | |

| H2 | 6.09 | 48.36 | 1710.59 | 98.17 | 2.03 | 0.997 | |

| 180 | H0 | 5.35 | 38.65 | 591.72 | 70.49 | 1.82 | 0.981 |

| H1 | 6.25 | 44.70 | 1736.70 | 55.56 | 1.24 | 0.990 | |

| H2 | 4.15 | 28.56 | 1349.01 | 72.75 | 2.55 | 0.992 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, D.; Wang, X.; Wang, S. Temperature-Dependent Creep Behavior and Quasi-Static Mechanical Properties of Heat-Treated Wood. Forests 2021, 12, 968. https://doi.org/10.3390/f12080968

Xing D, Wang X, Wang S. Temperature-Dependent Creep Behavior and Quasi-Static Mechanical Properties of Heat-Treated Wood. Forests. 2021; 12(8):968. https://doi.org/10.3390/f12080968

Chicago/Turabian StyleXing, Dong, Xinzhou Wang, and Siqun Wang. 2021. "Temperature-Dependent Creep Behavior and Quasi-Static Mechanical Properties of Heat-Treated Wood" Forests 12, no. 8: 968. https://doi.org/10.3390/f12080968

APA StyleXing, D., Wang, X., & Wang, S. (2021). Temperature-Dependent Creep Behavior and Quasi-Static Mechanical Properties of Heat-Treated Wood. Forests, 12(8), 968. https://doi.org/10.3390/f12080968