Modeling and Optimization Sustainable Forest Supply Chain Considering Discount in Transportation System and Supplier Selection under Uncertainty

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable Forest Supply Chain

2.2. Forest Supply Chain Planning and Decision-Making

2.3. Research Gap, Goals and Assumptions

- Developing a mathematical model for a sustainable forest supply chain to deal with multiple products;

- Improving the adverse impacts of transportation costs;

- Making more deliberate and realistic strategic, tactical, and operational decisions;

- Investigating the impact of uncertainty on forest supply chain models.

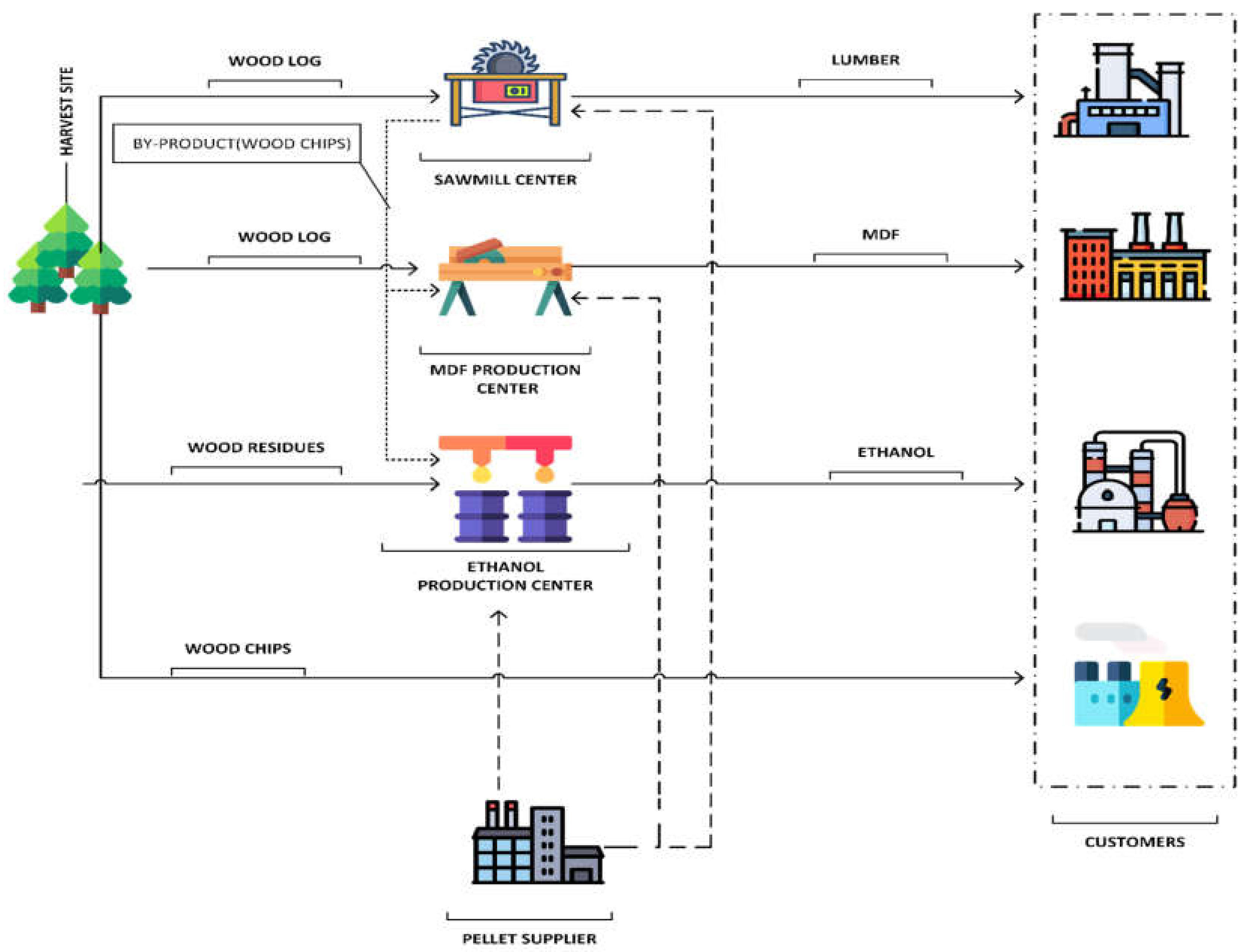

- Designing a sustainable forest supply chain considering log, MDF, and ethanol production facilities;

- Presenting a multi-period multi-product MINLP model, including four objective functions to minimize the profit, improve social aspects, reduce environmental pollution, and minimize lost demands;

- Considering discount in vehicle leasing costs;

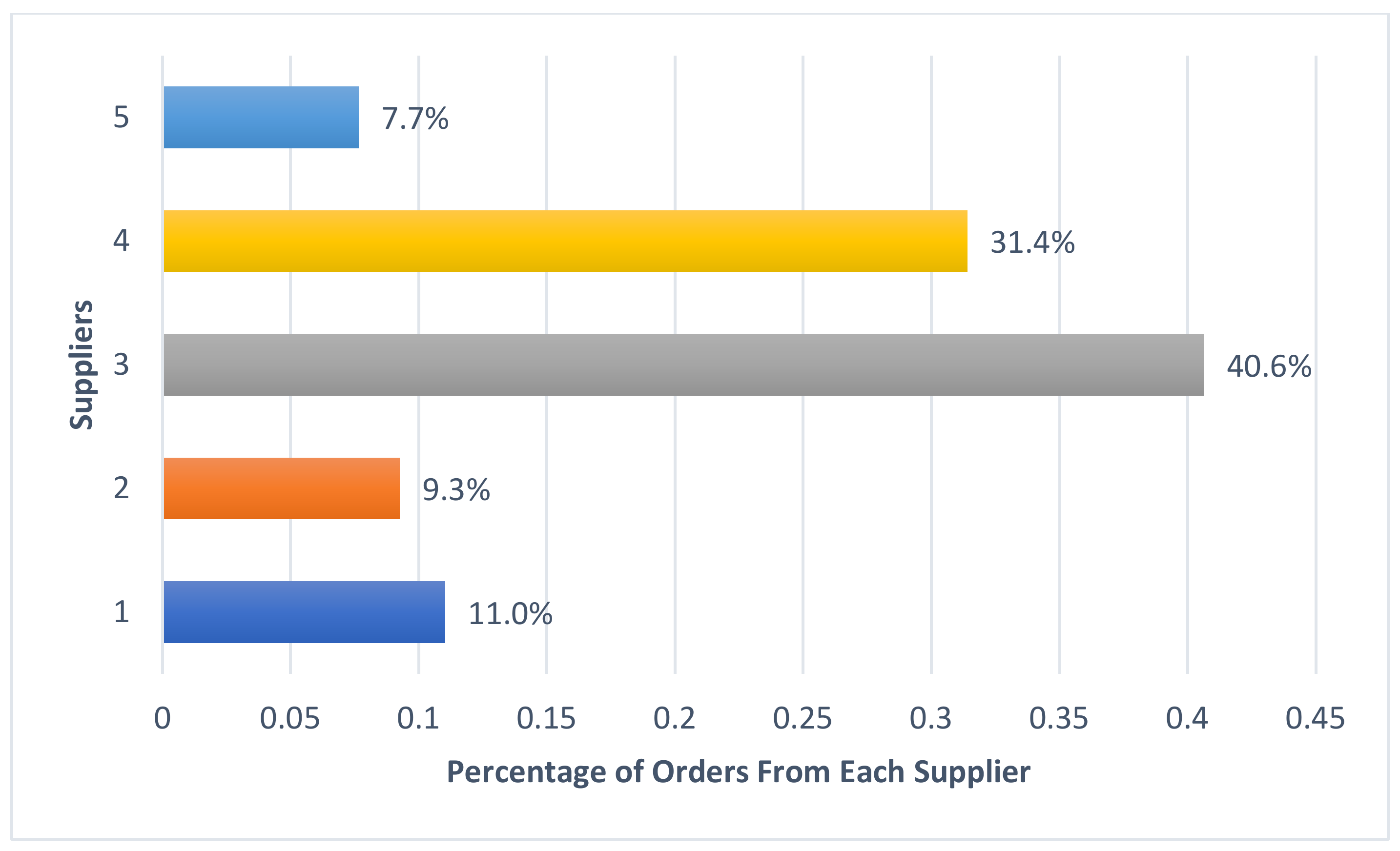

- Selecting pellet suppliers based on two elements, order quantity discount and improving social dimensions;

- Considering uncertainty for important parameters that cannot be assumed certain due to their nature.

3. Materials and Methods

3.1. Mathematical Model

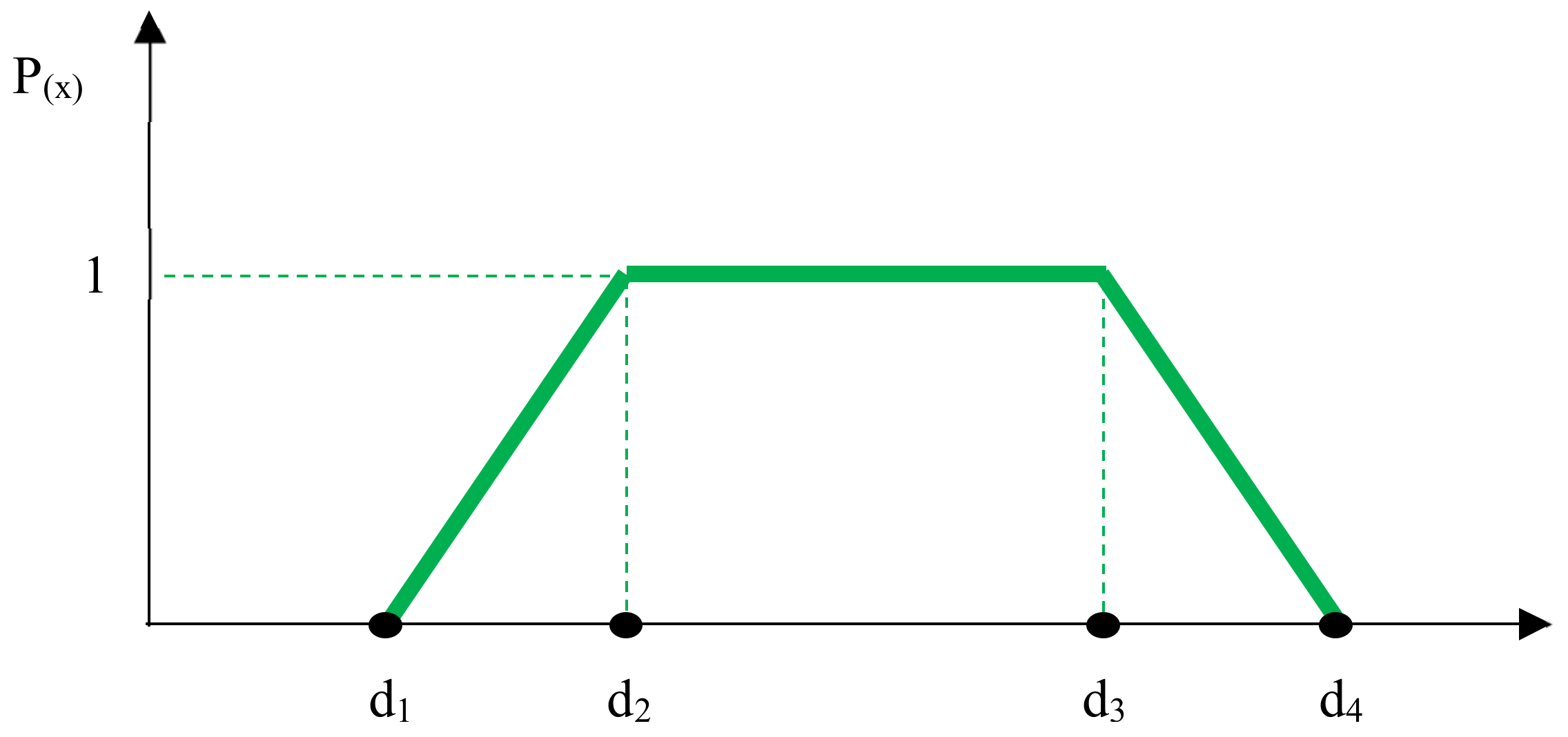

3.2. Hybrid Robust Possibilistic Programming (HRPP-II)

3.3. Solution Method

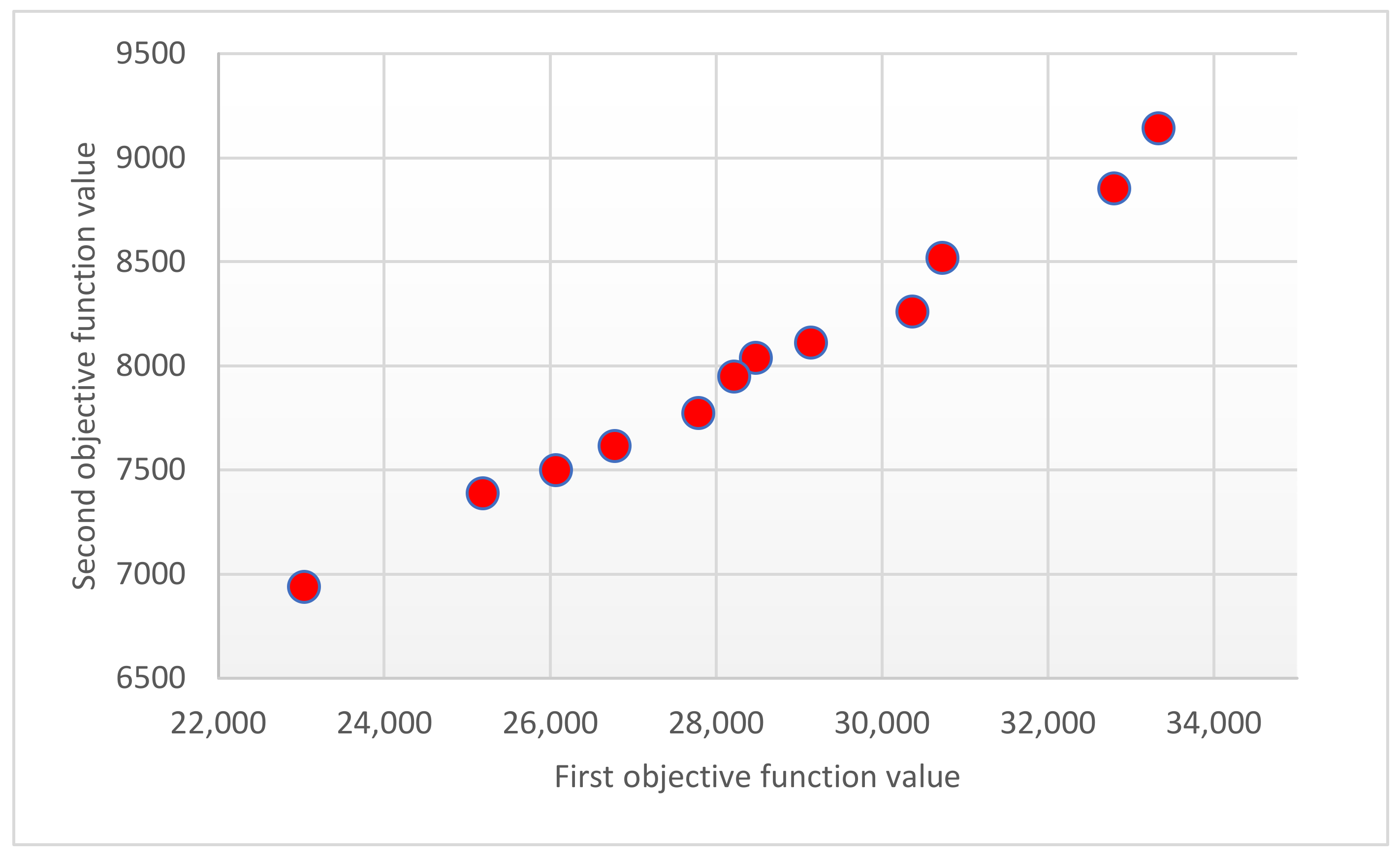

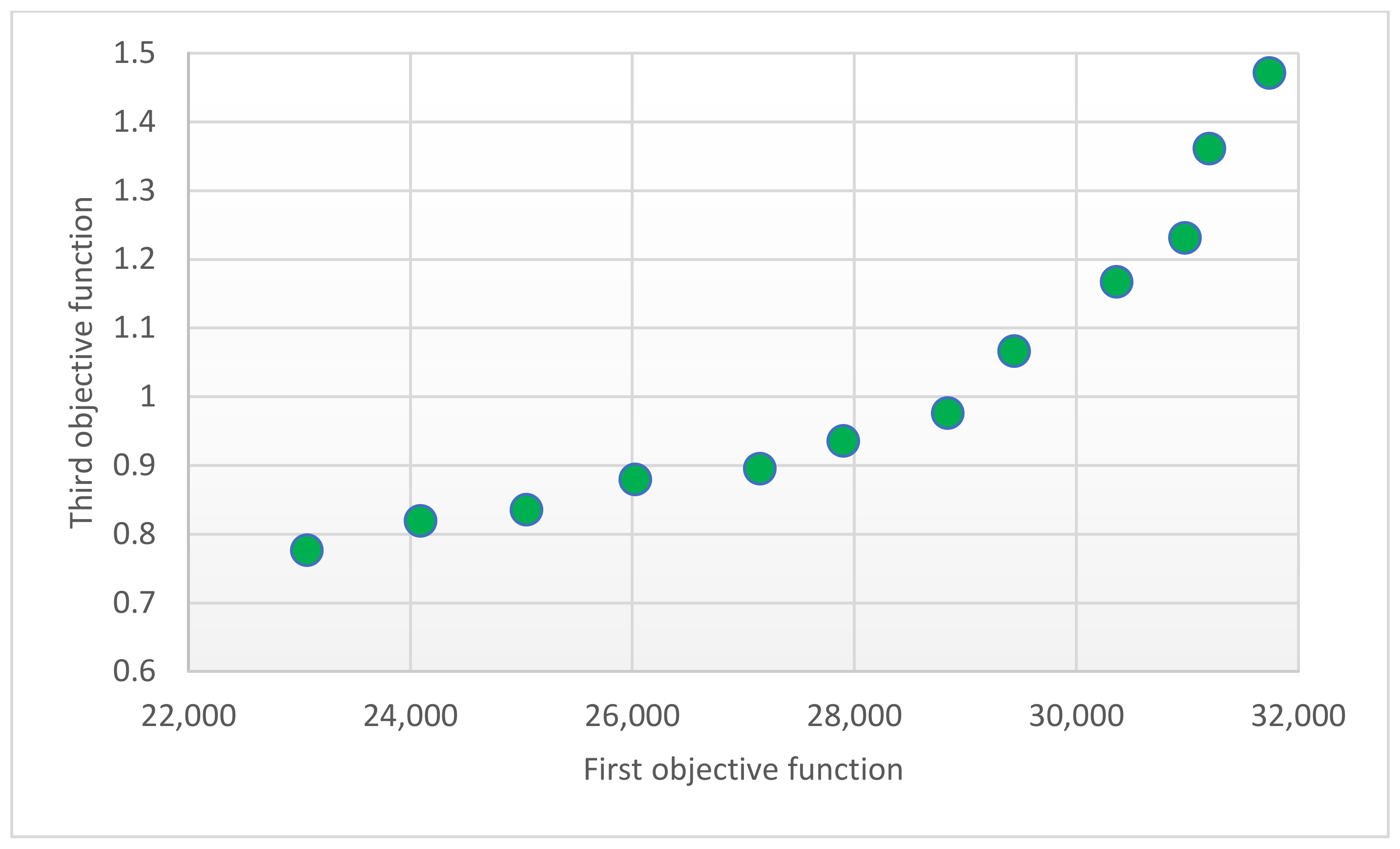

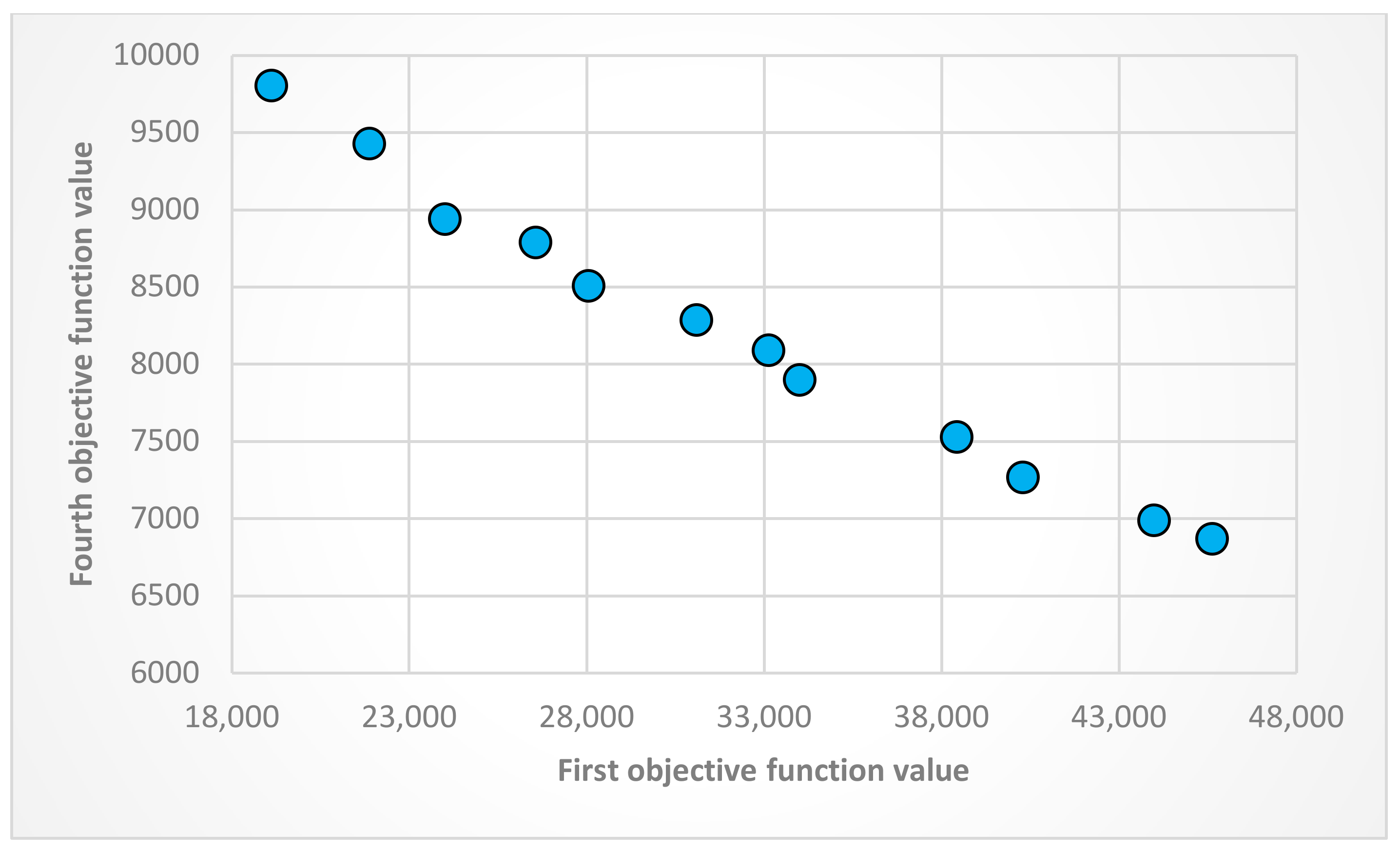

3.3.1. Method of Epsilon Constraint

3.3.2. Lagrangian Relaxation

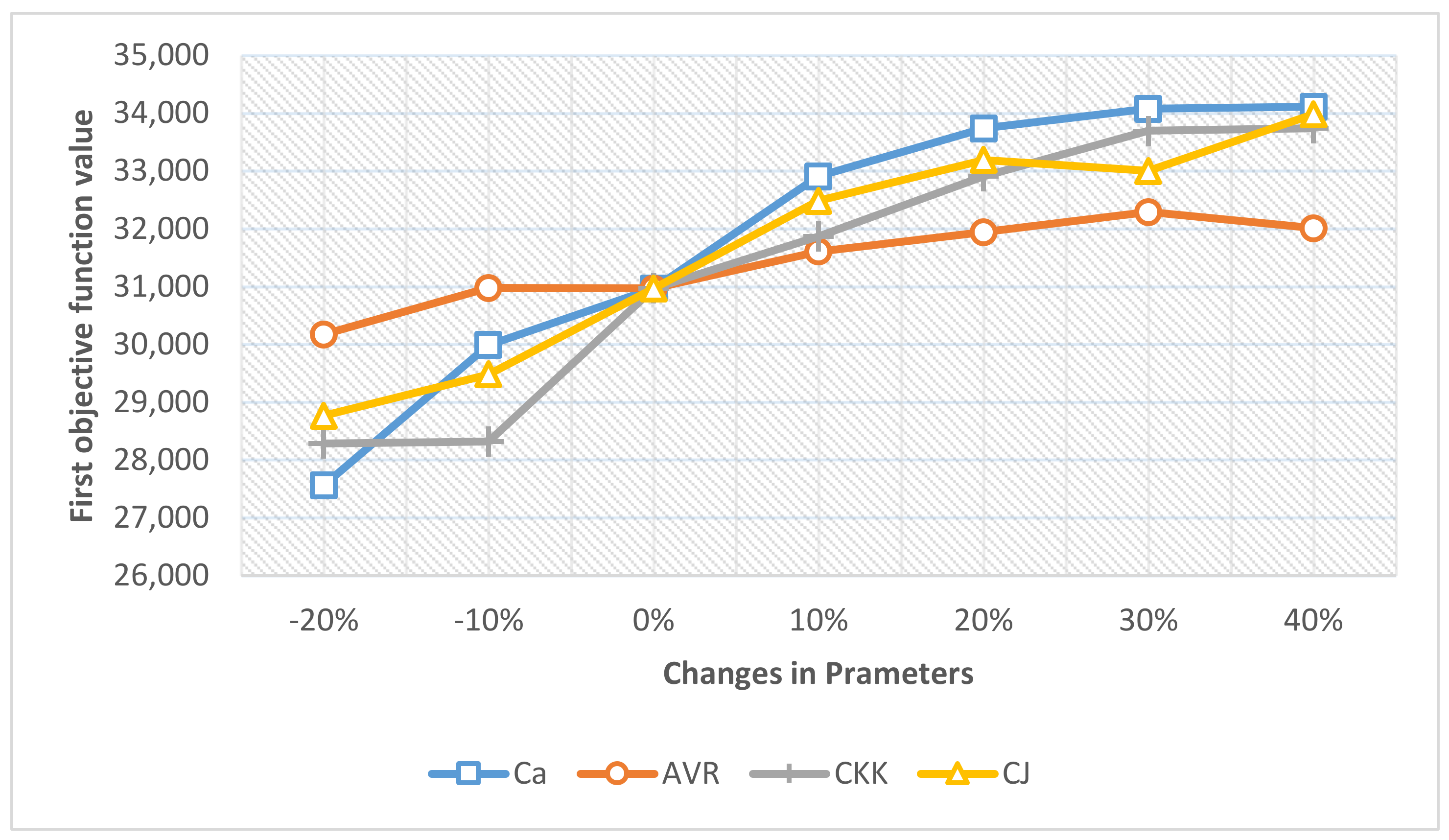

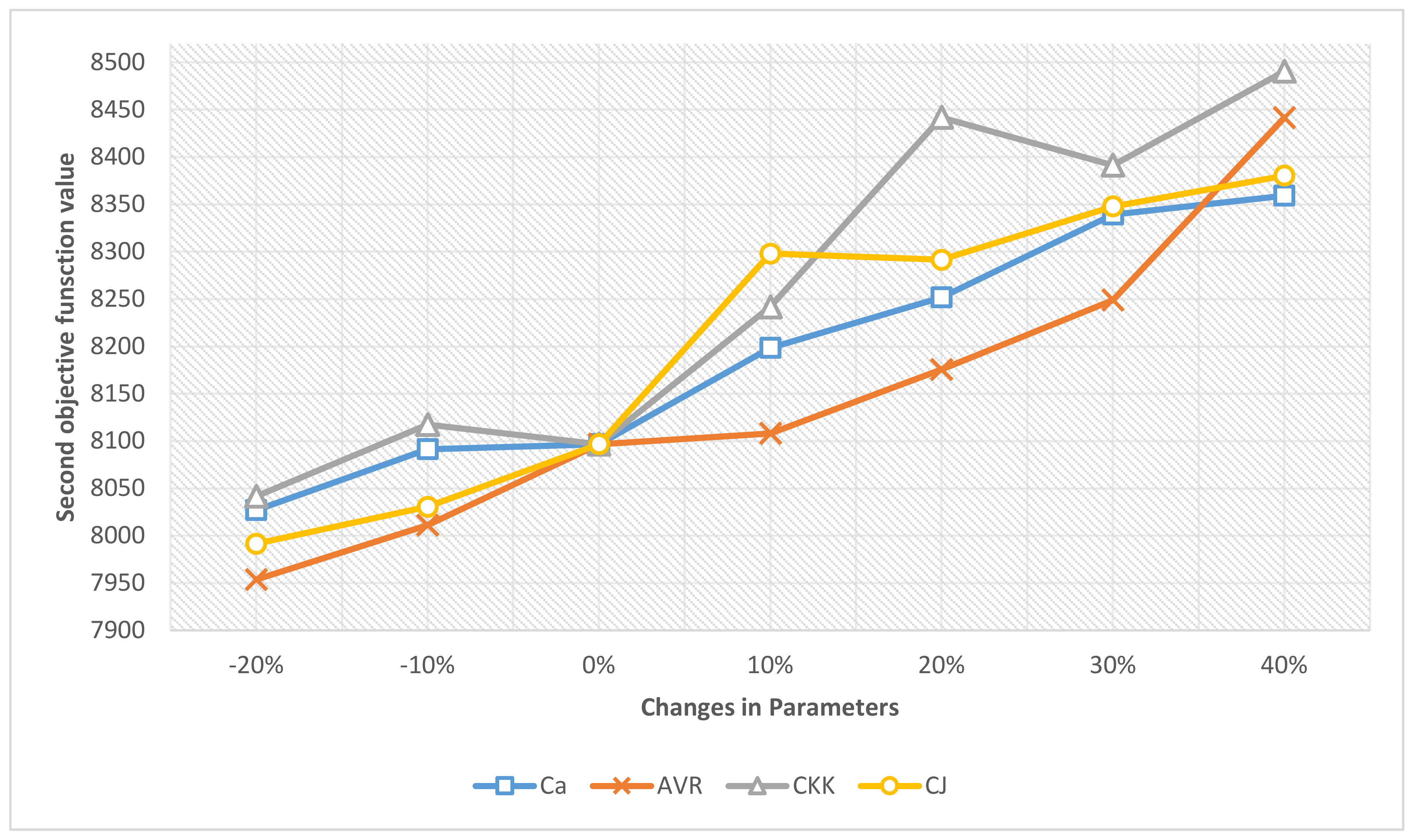

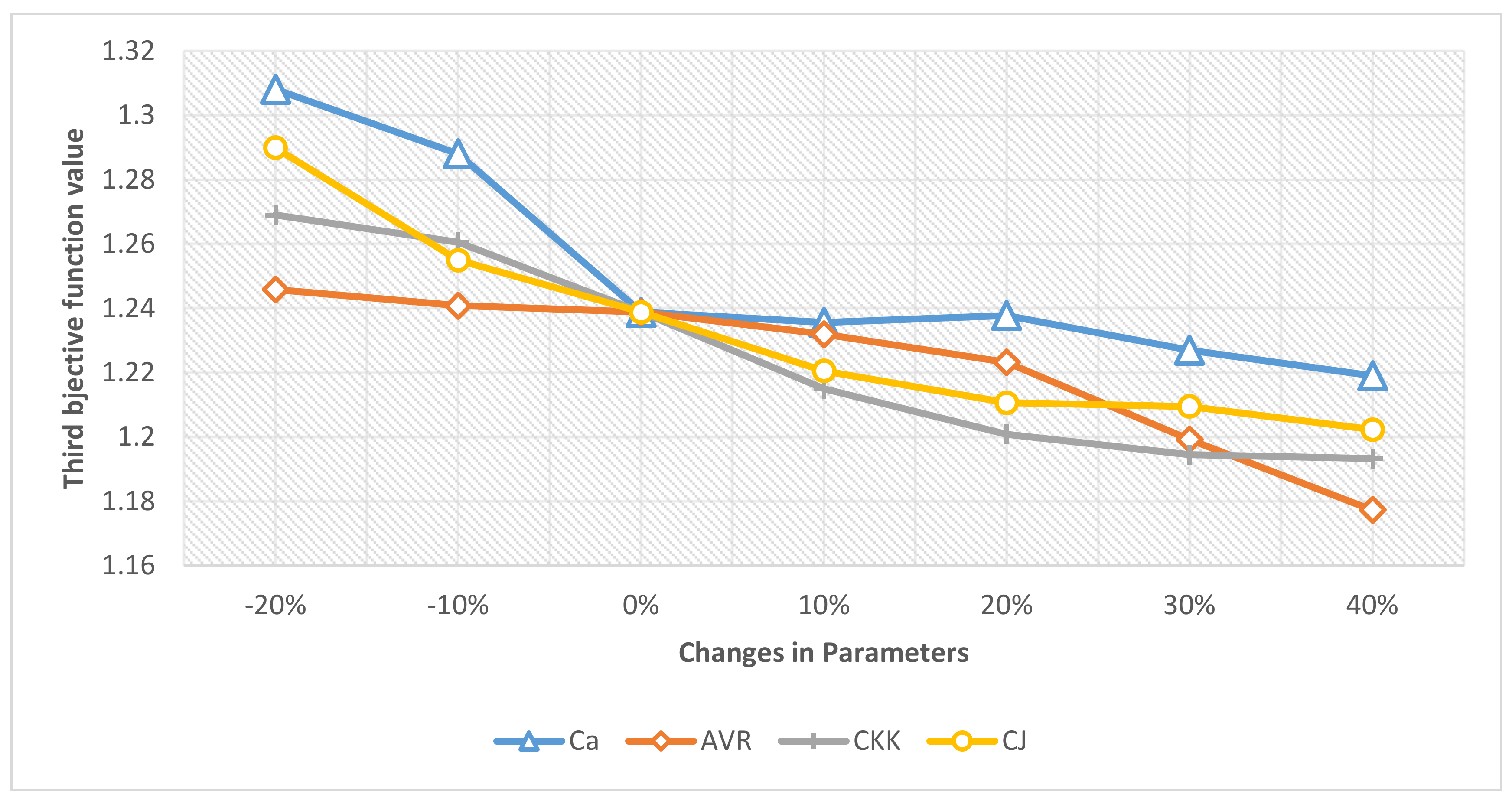

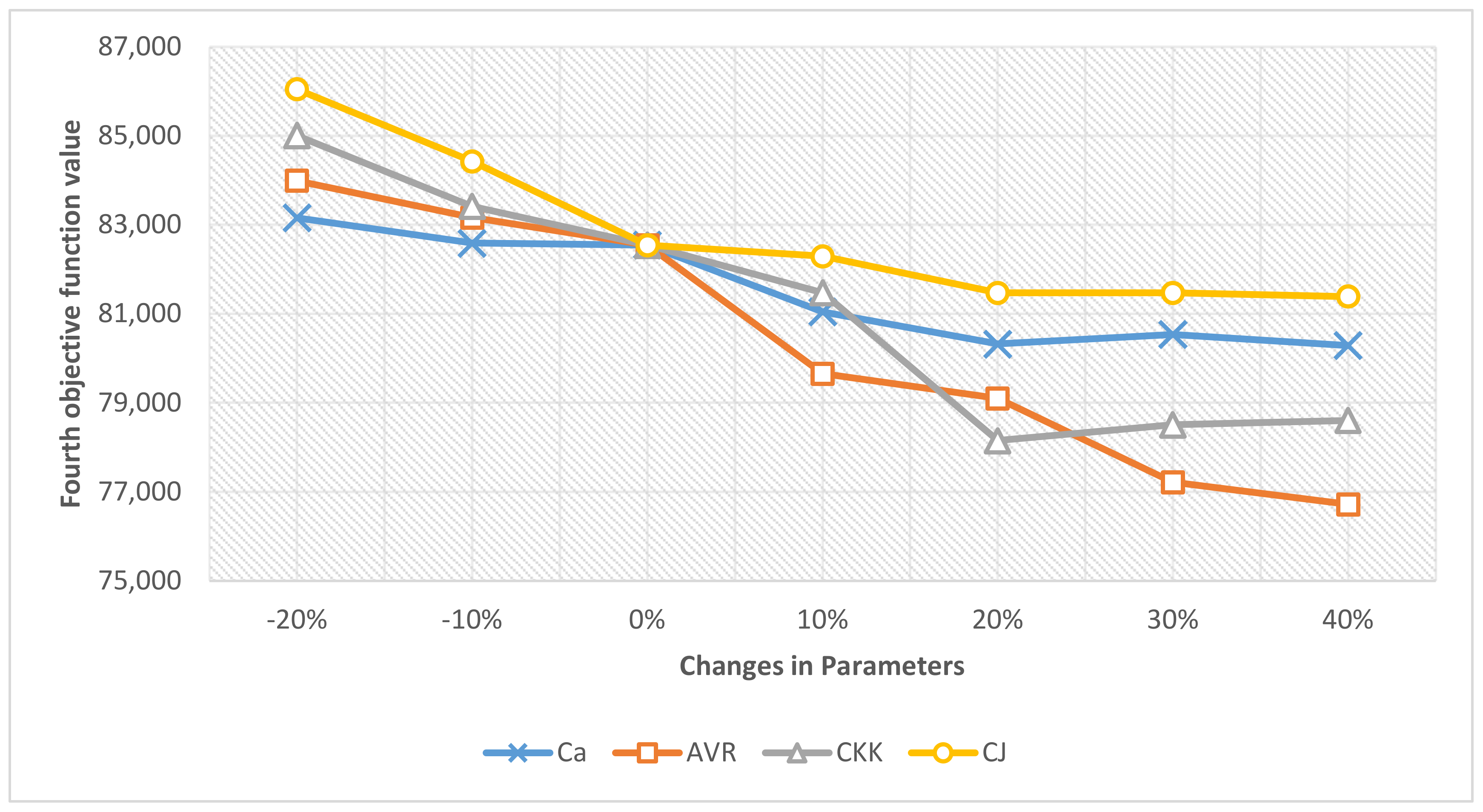

3.4. Sensitivity Analysis

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Broz, D.; Rossit, D.; Rossit, D.; Cavallín, A. The argentinian forest sector: Opportunities and challenges in supply chain management. Uncertain Supply Chain. Manag. 2018, 6, 375–392. [Google Scholar] [CrossRef]

- Meyer, R.; Campanella, S.; Corsano, G.; Montagna, J.M. Optimal design of a forest supply chain in Argentina considering economic and social aspects. J. Clean. Prod. 2019, 231, 224–239. [Google Scholar] [CrossRef]

- Fu, R.; Qiang, Q.; Ke, K.; Huang, Z. Closed-loop supply chain network with interaction of forward and reverse logistics. Sustain. Prod. Consum. 2021, 27, 737–752. [Google Scholar] [CrossRef]

- Carlsson, D.; Rönnqvist, M. Supply chain management in forestry—Case studies at Södra Cell AB. Eur. J. Oper. Res. 2005, 163, 589–616. [Google Scholar] [CrossRef]

- Rönnqvist, M.; D’Amours, S.; Weintraub, A.; Jofre, A.; Gunn, E.; Haight, R.G.; Martell, D.; Murray, A.T.; Romero, C. Operations Research challenges in forestry: 33 open problems. Ann. Oper. Res. 2015, 232, 11–40. [Google Scholar] [CrossRef]

- Campanella, S.; Corsano, G.; Montagna, J.M. A modeling framework for the optimal forest supply chain design considering residues reuse. Sustain. Prod. Consum. 2018, 16, 13–24. [Google Scholar] [CrossRef]

- Long, X.; Ge, J.; Shu, T.; Liu, C. Production Decision and Coordination Mechanism of Socially Responsible Closed-Loop Supply Chain. Complexity 2020, 2020, 9095215. [Google Scholar] [CrossRef]

- Tan, M.; Tu, M.; Wang, B.; Zou, T.; Cheng, H. A Two-Echelon Agricultural Product Supply Chain with Freshness and Greenness Concerns: A Cost-Sharing Contract Perspective. Complexity 2020, 2020, 8560102. [Google Scholar] [CrossRef]

- Weintraub, A.; Epstein, R.; Morales, R.; Serón, J.; Traverso, P. A Truck Scheduling System Improves Efficiency in the Forest Industries. Interfaces 1996, 26, 1–12. [Google Scholar] [CrossRef]

- Broz, D.R. Técnicas de Simulación y Optimización Aplicadas a la Planificación Forestal; EdiUNS: Bahía Blanca, Argentina, 2015. [Google Scholar]

- Lin, P.; Contreras, M.A.; Dai, R.; Zhang, J. A multilevel ACO approach for solving forest transportation planning problems with environmental constraints. Swarm Evol. Comput. 2016, 28, 78–87. [Google Scholar] [CrossRef]

- Troncoso, J.J.; Garrido, R.A. Forestry production and logistics planning: An analysis using mixed-integer programming. For. Policy Econ. 2005, 7, 625–633. [Google Scholar] [CrossRef]

- François, J.; Moad, K.; Bourrières, J.-P.; Lebel, L. A tactical planning model for collaborative timber transport. IFAC-PapersOnLine 2017, 50, 11713–11718. [Google Scholar] [CrossRef]

- Ganeshan, R. Managing supply chain inventories: A multiple retailer, one warehouse, multiple supplier model. Int. J. Prod. Econ. 1999, 59, 341–354. [Google Scholar] [CrossRef]

- Žic, J.; Žic, S. Multi-criteria decision making in supply chain management based on inventory levels, environmental impact and costs. Adv. Prod. Eng. Manag. 2020, 15, 151–163. [Google Scholar] [CrossRef]

- Zimon, D.; Tyan, J.; Sroufe, R. Implementing Sustainable Supply Chain Management: Reactive, Cooperative, and Dynamic Models. Sustainability 2019, 11, 7227. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M. A Relationship Between Supply Chain Practices, Environmental Sustainability and Financial Performance: Evidence from Manufacturing Companies in Jordan. Sustainability 2021, 13, 2152. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable supply chain network design: An optimization-oriented review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Palmeros Parada, M.; Osseweijer, P.; Posada Duque, J.A. Sustainable biorefineries, an analysis of practices for incorporating sustainability in biorefinery design. Ind. Crops Prod. 2017, 106, 105–123. [Google Scholar] [CrossRef]

- Tang, C.S. Socially responsible supply chains in emerging markets: Some research opportunities. J. Oper. Manag. 2018, 57, 1–10. [Google Scholar] [CrossRef]

- Santos, A.; Carvalho, A.; Barbosa-Póvoa, A.P.; Marques, A.; Amorim, P. Assessment and optimization of sustainable forest wood supply chains—A systematic literature review. For. Policy Econ. 2019, 105, 112–135. [Google Scholar] [CrossRef]

- Miret, C.; Chazara, P.; Montastruc, L.; Negny, S.; Domenech, S. Design of bioethanol green supply chain: Comparison between first and second generation biomass concerning economic, environmental and social criteria. Comput. Chem. Eng. 2016, 85, 16–35. [Google Scholar] [CrossRef]

- You, F.; Wang, B. Life cycle optimization of biomass-to-liquid supply chains with distributed-centralized processing networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input-output analysis. AIChE J. 2012, 58, 1157–1180. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; González-Campos, J.B.; Ponce-Ortega, J.M.; Serna-González, M.; El-Halwagi, M.M. Optimal planning of a biomass conversion system considering economic and environmental aspects. Ind. Eng. Chem. Res. 2011, 50, 8558–8570. [Google Scholar] [CrossRef]

- Sacchelli, S.; Bernetti, I.; De Meo, I.; Fiori, L.; Paletto, A.; Zambelli, P.; Ciolli, M. Matching socio-economic and environmental efficiency of wood-residues energy chain: A partial equilibrium model for a case study in Alpine area. J. Clean. Prod. 2014, 66, 431–442. [Google Scholar] [CrossRef]

- Čuček, L.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Total footprints-based multi-criteria optimisation of regional biomass energy supply chains. Energy 2012, 44, 135–145. [Google Scholar] [CrossRef]

- Pérez-Fortes, M.; Laínez-Aguirre, J.M.; Bojarski, A.D.; Puigjaner, L. Optimization of pre-treatment selection for the use of woody waste in co-combustion plants. Chem. Eng. Res. Des. 2014, 92, 1539–1562. [Google Scholar] [CrossRef]

- Chompu-Inwai, R.; Jaimjit, B.; Premsuriyanunt, P. A combination of Material Flow Cost Accounting and design of experiments techniques in an SME: The case of a wood products manufacturing company in northern Thailand. J. Clean. Prod. 2015, 108, 1352–1364. [Google Scholar] [CrossRef]

- Banerjee, O.; Alavalapati, J.R.R.; Lima, E. A framework for ex-ante analysis of public investment in forest-based development: An application to the Brazilian Amazon. For. Policy Econ. 2016, 73, 204–214. [Google Scholar] [CrossRef]

- Hsueh, S.L. Assessing the effectiveness of community-promoted environmental protection policy by using a Delphi-fuzzy method: A case study on solar power and plain afforestation in Taiwan. Renew. Sustain. Energy Rev. 2015, 49, 1286–1295. [Google Scholar] [CrossRef]

- Machani, M.; Nourelfath, M.; D’Amours, S. A scenario-based modelling approach to identify robust transformation strategies for pulp and paper companies. Int. J. Prod. Econ. 2015, 168, 41–63. [Google Scholar] [CrossRef]

- Galatsidas, S.; Petridis, K.; Arabatzis, G.; Kondos, K. Forest Production Management and Harvesting Scheduling Using Dynamic Linear Programming (LP) Models. Procedia Technol. 2013, 8, 349–354. [Google Scholar] [CrossRef][Green Version]

- Santibañez-Aguilar, J.E.; Rivera-Toledo, M.; Flores-Tlacuahuac, A.; Ponce-Ortega, J.M. A mixed-integer dynamic optimization approach for the optimal planning of distributed biorefineries. Comput. Chem. Eng. 2015, 80, 37–62. [Google Scholar] [CrossRef]

- Mobini, M.; Sowlati, T.; Sokhansanj, S. Forest biomass supply logistics for a power plant using the discrete-event simulation approach. Appl. Energy 2011, 88, 1241–1250. [Google Scholar] [CrossRef]

- Handler, R.M.; Shonnard, D.R.; Lautala, P.; Abbas, D.; Srivastava, A. Environmental impacts of roundwood supply chain options in Michigan: Life-cycle assessment of harvest and transport stages. J. Clean. Prod. 2014, 76, 64–73. [Google Scholar] [CrossRef]

- Boukherroub, T.; Ruiz, A.; Guinet, A.; Fondrevelle, J. An integrated approach for sustainable supply chain planning. Comput. Oper. Res. 2015, 54, 180–194. [Google Scholar] [CrossRef]

- Tonini, D.; Vadenbo, C.; Astrup, T.F. Priority of domestic biomass resources for energy: Importance of national environmental targets in a climate perspective. Energy 2017, 124, 295–309. [Google Scholar] [CrossRef]

- Chazara, P.; Negny, S.; Montastruc, L. Quantitative method to assess the number of jobs created by production systems: Application to multi-criteria decision analysis for sustainable biomass supply chain. Sustain. Prod. Consum. 2017, 12, 134–154. [Google Scholar] [CrossRef]

- Leong, H.; Leong, H.; Foo, D.C.Y.; Ng, L.Y.; Andiappan, V. Hybrid approach for carbon-constrained planning of bioenergy supply chain network. Sustain. Prod. Consum. 2019, 18, 250–267. [Google Scholar] [CrossRef]

- She, J.; Chung, W.; Vergara, H. Multiobjective record-to-record travel metaheuristic method for solving forest supply chain management problems with economic and environmental objectives. Nat. Resour. Model. 2020, 34, e12256. [Google Scholar] [CrossRef]

- Alayet, C.; Lehoux, N.; Lebel, L. Logistics approaches assessment to better coordinate a forest products supply chain. J. For. Econ. 2018, 30, 13–24. [Google Scholar] [CrossRef]

- She, J.; Chung, W.; Han, H. Economic and Environmental Optimization of the Forest Supply Chain for Timber and Bioenergy Production from Beetle-Killed Forests in Northern Colorado. Forests 2019, 10, 689. [Google Scholar] [CrossRef]

- Woo, H.; Han, H.; Cho, S.; Jung, G.; Kim, B.; Ryu, J.; Won, H.K.; Park, J. Investigating the optimal location of potential forest industry clusters to enhance domestic timber utilization in South Korea. Forests 2020, 11, 936. [Google Scholar] [CrossRef]

- Newton, P.; Agrawal, A.; Wollenberg, L. Enhancing the sustainability of commodity supply chains in tropical forest and agricultural landscapes. Glob. Environ. Chang. 2013, 23, 1761–1772. [Google Scholar] [CrossRef]

- Midgley, S.J.; Stevens, P.R.; Arnold, R.J. Hidden assets: Asia’s smallholder wood resources and their contribution to supply chains of commercial wood. Aust. For. 2017, 80, 10–25. [Google Scholar] [CrossRef]

- Leyder, C.; Klippel, M.; Bartlomé, O.; Heeren, N.; Kissling, S.; Goto, Y.; Frangi, A. Investigations on the Sustainable Resource Use of Swiss Timber. Sustainability 2021, 13, 1237. [Google Scholar] [CrossRef]

- D’amours, S.; Rönnqvist, M.; Weintraub, A. Using Operational Research for supply chain planning in the forest products industry. INFOR Inf. Syst. Oper. Res. 2008, 46, 265–281. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives—A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2018, 268, 399–431. [Google Scholar] [CrossRef]

- Gunnarsson, H.; Rönnqvist, M.; Carlsson, D. Integrated production and distribution planning for Södra Cell AB. J. Math. Model. Algorithms 2007, 6, 25–45. [Google Scholar] [CrossRef]

- Beaudoin, D.; LeBel, L.; Frayret, J.M. Tactical supply chain planning in the forest products industry through optimization and scenario-based analysis. Can. J. For. Res. 2007, 37, 128–140. [Google Scholar] [CrossRef]

- Lòpez, R.C.; Carrero, G.O.E.; Jerez, M.; Quintero, M.M.A.; Stock, J. Modelo preliminar para la planificación del aprovechamiento en plantaciones forestales industriales en Venezuela. Interciencia 2008, 33, 802–809. [Google Scholar]

- Chauhan, S.S.; Frayret, J.M.; LeBel, L. Multi-commodity supply network planning in the forest supply chain. Eur. J. Oper. Res. 2009, 196, 688–696. [Google Scholar] [CrossRef]

- Kanzian, C.; Holzleitner, F.; Stampfer, K.; Ashton, S. Regional energy wood logistics—Optimizing local fuel supply. Silva Fenn. 2009, 43, 113–128. [Google Scholar] [CrossRef]

- Rix, G.; Rousseau, L.-M.; Pesant, G. A Transportation-Driven Approach to Annual Harvest Planning; CIRRELT: Montréal, QC, Canada, 2014. [Google Scholar]

- Akhtari, S.; Sowlati, T.; Day, K. Optimal flow of regional forest biomass to a district heating system. Int. J. Energy Res. 2014, 38, 954–964. [Google Scholar] [CrossRef]

- Gautam, S.; Le Bel, L.; Beaudoin, D.; Simard, M. Modelling hierarchical planning process using a simulation-optimization system to anticipate the long-term impact of operational level silvicultural flexibility. IFAC-PapersOnLine 2015, 28, 616–621. [Google Scholar] [CrossRef]

- Sosa, A.; Sosa, A.; Acuna, M.; McDonnell, K.; Devlin, G. Managing the moisture content of wood biomass for the optimisation of Ireland’s transport supply strategy to bioenergy markets and competing industries. Energy 2015, 86, 354–368. [Google Scholar] [CrossRef]

- Oliveira, O.; Gamboa, D.; Fernandes, P. An Information System for the Furniture Industry to Optimize the Cutting Process and the Waste Generated. Procedia Comput. Sci. 2016, 100, 711–716. [Google Scholar] [CrossRef]

- Palander, T. The environmental emission efficiency of larger and heavier vehicles—A case study of road transportation in Finnish forest industry. J. Clean. Prod. 2017, 155, 57–62. [Google Scholar] [CrossRef]

- Woo, Y.B.; Cho, S.; Kim, J.; Kim, B.S. Optimization-based approach for strategic design and operation of a biomass-to-hydrogen supply chain. Int. J. Hydrogen Energy 2016, 41, 5405–5418. [Google Scholar] [CrossRef]

- Mansoornejad, B.; Pistikopoulos, E.N.; Stuart, P. Metrics for evaluating the forest biorefinery supply chain performance. Comput. Chem. Eng. 2013, 54, 125–139. [Google Scholar] [CrossRef]

- Kim, M.; Kim, J. Optimization model for the design and analysis of an integrated renewable hydrogen supply (IRHS) system: Application to Korea’s hydrogen economy. Int. J. Hydrogen Energy 2016, 41, 16613–16626. [Google Scholar] [CrossRef]

- Whitman, M.G.; Barker, K.; Johansson, J.; Darayi, M. Component importance for multi-commodity networks: Application in the Swedish railway. Comput. Ind. Eng. 2017, 112, 274–288. [Google Scholar] [CrossRef]

- Zahiri, B.; Pishvaee, M.S. Blood supply chain network design considering blood group compatibility under uncertainty. Int. J. Prod. Res. 2017, 55, 2013–2033. [Google Scholar] [CrossRef]

- Jonkman, J.; Kanellopoulos, A.; Bloemhof, J.M. Designing an eco-efficient biomass-based supply chain using a multi-actor optimisation model. J. Clean. Prod. 2019, 210, 1065–1075. [Google Scholar] [CrossRef]

- Jonkman, J.; Barbosa-Póvoa, A.P.; Bloemhof, J.M. Integrating harvesting decisions in the design of agro-food supply chains. Eur. J. Oper. Res. 2019, 276, 247–258. [Google Scholar] [CrossRef]

- Fernandez-Lacruz, R.; Eriksson, A.; Bergström, D. Simulation-based cost analysis of industrial supply of chips from logging residues and small-diameter trees. Forests 2020, 11, 1. [Google Scholar] [CrossRef]

- Acuna, M.; Sessions, J.; Zamora, R.; Boston, K.; Brown, M.; Ghaffariyan, M.R. Methods to Manage and Optimize Forest Biomass Supply Chains: A Review. Curr. For. Rep. 2019, 5, 124–141. [Google Scholar] [CrossRef]

- Strandgard, M.; Turner, P.; Mirowski, L.; Acuna, M. Potential application of overseas forest biomass supply chain experience to reduce costs in emerging Australian forest biomass supply chains—A literature review. Aust. For. 2019, 82, 9–17. [Google Scholar] [CrossRef]

- Akhtari, S.; Sowlati, T.; Siller-Benitez, D.G.; Roeser, D. Impact of inventory management on demand fulfilment, cost and emission of forest-based biomass supply chains using simulation modelling. Biosyst. Eng. 2019, 178, 184–199. [Google Scholar] [CrossRef]

- Soares, R.; Marques, A.; Amorim, P.; Rasinmäki, J. Multiple vehicle synchronisation in a full truck-load pickup and delivery problem: A case-study in the biomass supply chain. Eur. J. Oper. Res. 2019, 277, 174–194. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K. A multi-stage stochastic program for the sustainable design of biofuel supply chain networks under biomass supply uncertainty and disruption risk: A real-life case study. Transp. Res. Part E Logist. Transp. Rev. 2018, 118, 534–567. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, X. Approximation based fuzzy multi-objective models with expected objectives and chance constraints: Application to earth-rock work allocation. Inf. Sci. 2013, 238, 75–95. [Google Scholar] [CrossRef]

- Mousazadeh, M.; Torabi, S.A.; Pishvaee, M.S.; Abolhassani, F. Health service network design: A robust possibilistic approach. Int. Trans. Oper. Res. 2018, 25, 337–373. [Google Scholar] [CrossRef]

- Haimes, Y.Y. Integrated System Identification and Optimization. Control Dyn. Syst. 1973, 10, 435–518. [Google Scholar]

- Mavrotas, G. Effective implementation of the ε-constraint method in Multi-Objective Mathematical Programming problems. Appl. Math. Comput. 2009, 213, 455–465. [Google Scholar] [CrossRef]

- Fisher, M.L. The Lagrangian Relaxation Method for Solving Integer Programming Problems. Manag. Sci. 1981, 27, 1–18. [Google Scholar] [CrossRef]

- Croom, S.; Romano, P.; Giannakis, M. Supply chain management: An analytical framework for critical literature review. Eur. J. Purch. Supply Manag. 2000, 6, 67–83. [Google Scholar] [CrossRef]

- Zimon, D.; Woźniak, J.; Domingues, P.; Ikram, M.; Kuś, H. Proposition of Improving Selected Logistics Processes of Pellet Production. Int. J. Qual. Res. 2021, 15, 387–402. [Google Scholar] [CrossRef]

- Domingues, P.; Sampaio, P.; Arezes, P.M. Integrated management systems assessment: A maturity model proposal. J. Clean. Prod. 2016, 124, 164–174. [Google Scholar] [CrossRef]

- Khan, A.S.; Salah, B.; Zimon, D.; Ikram, M.; Khan, R.; Pruncu, C.I. A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach. Energies 2020, 13, 6612. [Google Scholar] [CrossRef]

- Zimon, D. ISO 14001 and the creation of SSCM in the textile industry. Int. J. Qual. Res. 2020, 14, 739–748. [Google Scholar] [CrossRef]

- Chkanikova, O.; Sroufe, R. Third-party sustainability certifications in food retailing: Certification design from a sustainable supply chain management perspective. J. Clean. Prod. 2021, 282, 124344. [Google Scholar] [CrossRef]

- Budzik, G.; Woźniak, J.; Paszkiewicz, A.; Przeszłowski, Ł.; Dziubek, T.; Dębski, M. Methodology for the Quality Control Process of Additive Manufacturing Products Made of Polymer Materials. Materials 2021, 14, 2202. [Google Scholar] [CrossRef] [PubMed]

- Oszust, K.; Stecko, J. Theoretical aspects of consumer behaviour together with an analysis of trends in modern consumer behaviour. Mod. Manag. Rev. 2020, 2, 113. [Google Scholar] [CrossRef]

| Indices | Description |

|---|---|

| I | Set for harvest site |

| J | Set for sawmill facility |

| K | Set for MDF production facility |

| M | Set for ethanol production facility |

| N | Set for power station |

| F | Set for harvester machine |

| R | Set for chipper machine |

| P | Set for MDF demand zone |

| D | Set for lumber demand zone |

| B | Set for ethanol demand zone |

| A | Set for pellet supplier |

| C | Set for supplier discount level |

| Q | Set for renting truck discount level |

| T | Set for period time |

| Parameter | Description |

|---|---|

| Minimum working hours of harvester machine F | |

| Normal working hours of harvester machine F | |

| Maximum working hours of harvester machine F | |

| Maximum available logs in the harvest site i () | |

| Available number of harvester machine F | |

| Coefficient of wood residues obtained per unit of harvested log (m2) | |

| Log harvesting coefficient per hour of harvester machine operation | |

| Coefficient of wood waste obtained from each unit of harvested log that can be converted into wood chips | |

| Normal working hours of chipper machine r | |

| Maximum working hours of chipper machine r | |

| Minimum working hours of chipper machine r | |

| Conversion rate of wood waste into wood chips per hour of operation of the chipper machine r | |

| Available number of chipper machine r | |

| Number of gangsaw machines located in production line of sawmill J | |

| Conversion rate of log into lumber by gangsaw machine | |

| Conversion rate of log into lumber by portable bandsaw machine | |

| Number of rentable portable bandsaw machines for sawmill J | |

| Coefficient of lumber obtained per unit of log | |

| The amount of wood chips produced per unit of lumber produced in facility J (kg) | |

| Maximum storage capacity of logs in sawmill j | |

| Conversion rate of log into MDF by MDF production facilities | |

| Coefficient of MDF obtained per unit of log in facility k | |

| Number of production lines in facility k | |

| Maximum logs storage capacity in facility k | |

| Conversion rate of wood residues into ethanol | |

| Production capacity of ethanol in facility m in period t | |

| Maximum wood residues inventory capacity in facility m | |

| Energy required to produce each unit MDF | |

| Conversion rate of wood chips into energy | |

| Conversion rate of pellets into energy | |

| Energy required to produce each unit ethanol(L) | |

| MDF demand in customer zone p in period time t | |

| Lumber demand in customer zone d in period time t | |

| Ethanol demand in customer zone b in period time t | |

| Wood chips demand by power station n in period time t | |

| Sale price per lumber unit (m2) | |

| Sale price per MDF unit (m2) | |

| Sale price per ethanol unit (L) | |

| Sale price per wood chips unit | |

| Cost of extra-hours working of the harvester machine | |

| Cost of regular-hours working of the harvester machine | |

| Cost of renting harvester machine | |

| Cost of renting chipper machine | |

| Cost of extra-hours working of the chipper machine | |

| Cost of regular-hours working of the chipper machine | |

| i | Cost of renting harvest site i |

| Holding cost of logs in sawmill | |

| Holding cost of logs in facility k | |

| Holding cost of logs in facility m | |

| Production cost of each unit lumber(m2) | |

| Production cost of each unit MDF(m2) | |

| Production cost of each unit ethanol (L) | |

| Cost of renting portable bandsaw | |

| Cost of increasing each unit of storage capacity facility J in each period | |

| i | Maximum possible increase in storage capacity of facility J |

| Cost of increasing production capacity in facility m | |

| Purchase price of each pellet unit as fuel from supplier a, with discount level c | |

| Pellet transportation cost between supplier a and facility | |

| Penalty coefficient for lost demand in zone p | |

| Penalty coefficient for lost demand in zone d | |

| Penalty coefficient for lost demand in zone b | |

| Penalty coefficient for lost demand in power station | |

| Transportation cost between facility and | |

| Cost of renting log transport truck | |

| Cost of renting wood residues transport truck | |

| Capacity of lumber transport truck | |

| Capacity of MDF transport truck | |

| Capacity of ethanol transport truck | |

| Capacity of wood chips transport truck | |

| Amount of CO2 emission per hour of harvester machine operation | |

| Amount of CO2 emission per hour of chipper machine operation | |

| Amount of CO2 emission per produced lumber unit | |

| Amount of CO2 emission per produced MDF unit | |

| Amount of CO2 emission per produced ethanol unit | |

| Amount of CO2 emission by transportation between | |

| Coefficient of job opportunity per hour harvester machine operation | |

| Unemployment rate in the area where harvester site i is located | |

| Coefficient of job opportunity per hour chipper machine operation | |

| Regional economic value in supplier a location | |

| Regional economic value in the location of harvest site i | |

| Development coefficient of the area where the supplier a is located | |

| Available number of log transport trucks | |

| Capacity of log transport truck | |

| Capacity of wood residues transport truck | |

| Available number of wood residues transport trucks | |

| Maximum capacity of supplier a | |

| MECj | Maximum expandable storage capacity sawmill J |

| The lower limit of the discount level c for the purchase of pellets, which is set by supplier a in period t | |

| Amount of energy required to reduce log moisture per unit of lumber produced | |

| Upper bound of rentable lumber transport trucks between facility j and customer zone d with discount interval q | |

| Upper bound of rentable wood chips transport trucks between harvest site i and power station n with discount interval q | |

| Upper bound of rentable MDF transport trucks between facility m and customer zone b with discount interval q | |

| Upper bound of rentable ethanol transport trucks between facility k and customer zone p with discount interval q | |

| Rent cost of MDF transport trucks between facility m and customer zone b with discount interval q | |

| Rent cost of lumber transport trucks between facility j and customer zone d with discount interval q | |

| Rent cost of ethanol transport trucks between facility k and customer zone p with discount interval q | |

| Rent cost of wood chips transport trucks between harvest site i and customer zone n with discount interval q |

| Variable | Description |

|---|---|

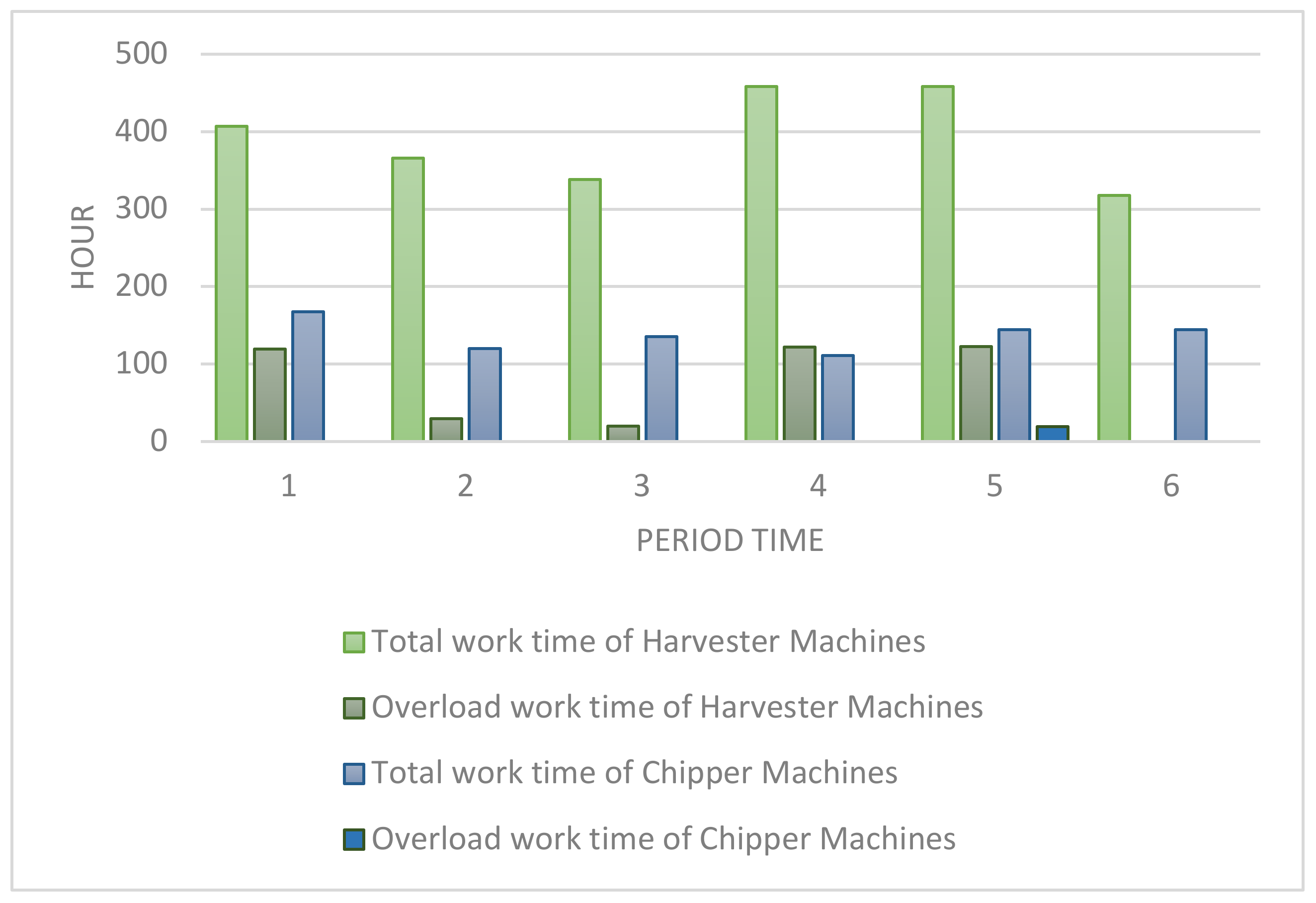

| Total hours used by harvester machine F in harvest site i in period t | |

| Extra hours used by harvester machine F in harvest site i in period t | |

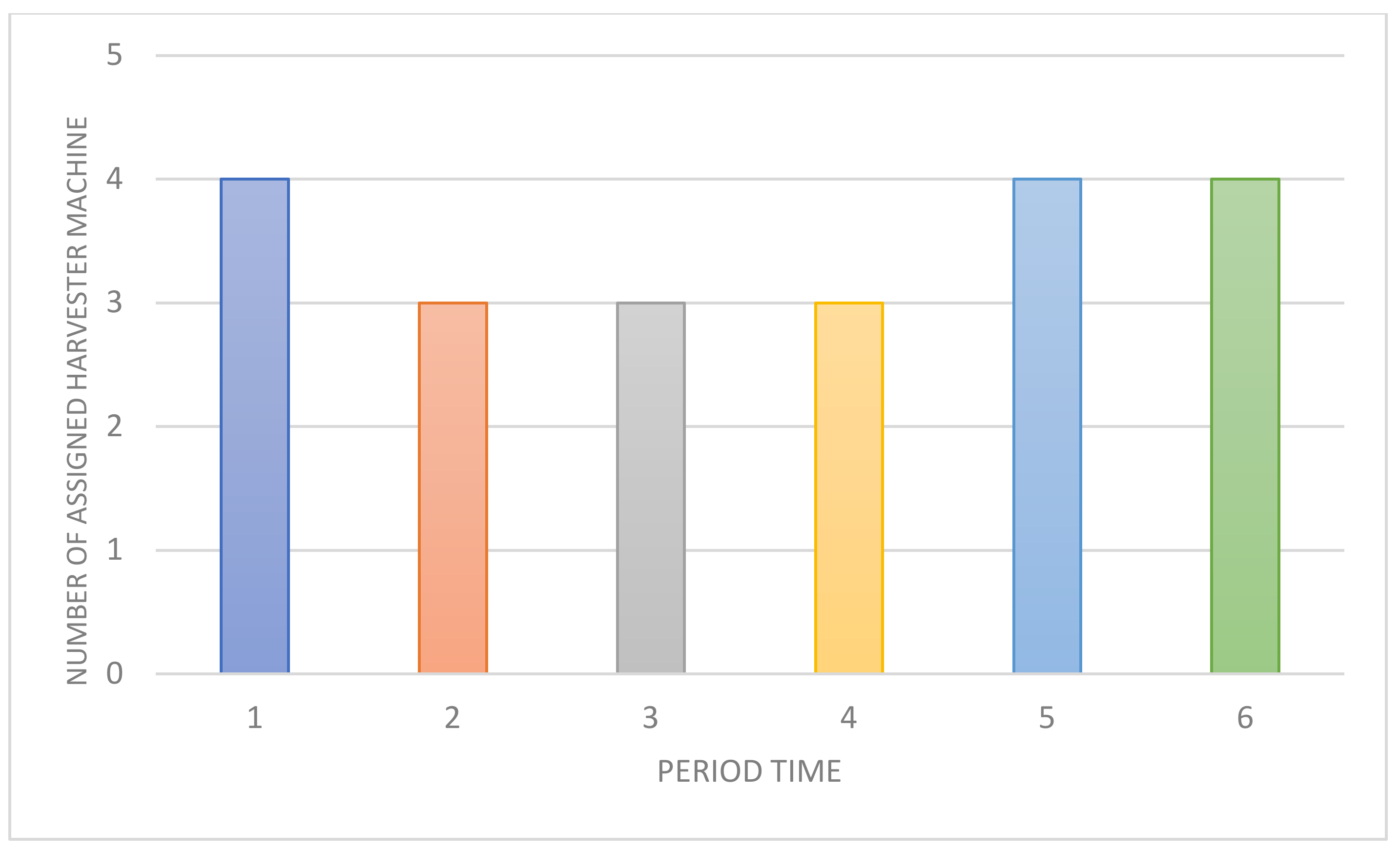

| Number of rented harvester machines in period t | |

| Total hours used by chipper machine r in harvest site i in period t | |

| Extra hours used by chipper machine r in harvest site i in period t | |

| Number of rented chipper machines in period t | |

| Log inventory in facility j in period t (m2) | |

| Number of rented portable bandsaws for facility j in period t | |

| Number of harvested logs in harvest site i (m2) | |

| Number of logs transported from harvest site i to sawmill j in period t | |

| Number of logs transported from harvest site i to MDF production facility k in period t | |

| Amount of wood residues transported from harvest site i to facility m in period t | |

| Amount of wood waste in harvest site i can be converted into wood chips in period t | |

| Amount of lumber transported from sawmill j to demand zone d in period t | |

| Amount of by-product (wood chips) transported from sawmill j to facility k in period t | |

| Amount of by-product (wood chips) transported from sawmill j to facility m in period t | |

| Log inventory in facility k in period t | |

| Amount of MDF transported from facility k to demand zone p in period t | |

| Wood residues inventory in facility m in period t | |

| Amount of produced ethanol transported from facility m to demand zone b in period time t | |

| Increase production capacity in facility m in period time t | |

| Amount of pellets purchased from supplier a to supply energy in facility k in period t (Kg) | |

| Amount of pellets purchased from supplier a to supply energy in facility m in period t (Kg) | |

| Amount of pellets purchased from supplier a to supply energy in facility j in period t (Kg) | |

| Lost demand in customer zone p in period t | |

| Lost demand in customer zone d in period t | |

| Lost demand in customer zone b in period t | |

| Lost demand in power station n in period t | |

| Number of log transport trucks assigned to transportation route between harvest site i and sawmill j | |

| Number of log transport trucks assigned to transportation route between harvest site i and MDF production center k | |

| Number of wood residues transport trucks assigned to transportation route between harvest site i and sawmill j | |

| Number of rented log transport trucks in period time t | |

| Number of rented wood residues transport trucks in period time t | |

| Number of rented lumber transport trucks from facility j to customer zone d in period time t | |

| Number of rented MDF transport trucks from facility k to customer zone p in period time t | |

| Number of rented ethanol transport trucks from facility m to customer zone b in period time t | |

| Number of rented wood chips transport trucks from harvest site i to power station n in period time t | |

| Number of rented wood chips transport trucks from facility j to facility k in period time t | |

| Number of rented wood chips transport trucks from facility j to facility m in period time t | |

| Amount of wood chips transported from harvest site i to power station n in period t | |

| Increased inventory capacity in facility j in period time t | |

| If the harvester machine F is assigned to harvest site i in period t, 1; otherwise, 0 | |

| i | If harvest site i is rented in period t, 1; otherwise, 0 |

| If chipper machine r is assigned to harvest site i in period t, 1; otherwise, 0 | |

| If supplier a is selected in period t, 1; otherwise, 0 | |

| If discount level c is considered for purchase from supplier a in period t,1; otherwise, 0 | |

| 1, if required trucks between facility j and demand zone d are rented at discount level q in period t; otherwise, 0 | |

| 1, if required trucks between facility k and demand zone p are rented at discount level q in period t; otherwise, 0 | |

| 1, if required trucks between facility m and demand zone b are rented at discount level q in period t; otherwise, 0 | |

| 1, if required trucks between harvest site i and power station n are rented at discount level q in period t; otherwise, 0 |

| Equation (12) | ||

| Equation (13) | ||

| Equation (14) | ||

| Equation (15) | ||

| Equation (16) | ||

| Equation (17) | ||

| Equation (18) | ||

| Equation (19) | ||

| Equation (20) | ||

| Equation (21) | ||

| Equation (22) | ||

| Equation (23) | ||

| Equation (24) | ||

| Equation (25) | ||

| Equation (26) | ||

| Equation (27) | ||

| Equation (28) | ||

| Equation (29) | ||

| Equation (30) | ||

| Equation (31) | ||

| Equation (32) | ||

| Equation (33) | ||

| Equation (34) | ||

| Equation (35) | ||

| Equation (36) | ||

| Equation (37) | ||

| Equation (38) | ||

| Equation (39) | ||

| Equation (40) | ||

| Equation (41) | ||

| Equation (42) | ||

| Equation (43) | ||

| Equation (44) | ||

| Equation (45) | ||

| Equation (46) | ||

| Equation (47) | ||

| Equation (48) | ||

| Equation (49) | ||

| Equation (50) | ||

| Equation (51) | ||

| Equation (52) | ||

| Equation (53) | ||

| Equation (54) | ||

| Equation (55) | ||

| Equation (56) | ||

| Equation (57) | ||

| Equation (58) | ||

| Equation (59) | ||

| Equation (60) | ||

| Equation (61) | ||

| Equation (62) | ||

| Equation (63) | ||

| Equation (64) | ||

| Equation (65) | ||

| Equation (66) | ||

| Equation (67) | ||

| Equation (68) | ||

| Equation (69) | ||

| Equation (70) | ||

| Equation (71) | ||

| Equation (72) | ||

| Equation (73) | ||

| Equation (74) | ||

| Equation (75) | ||

| Equation (76) | ||

| Equation (77) |

| Problem Number | Indices | GAMS | LR | Optimality Gap | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | J | K | M | N | F | R | P | D | B | A | T | Run Time | Obj Value | Run Time | Obj Value | ||

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.15 | 421.56 | 0.22 | 421.56 | 0.000000% |

| 2 | 2 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 2 | 0.167 | 592.805 | 0.29 | 592.805 | 0.000000% |

| 3 | 2 | 2 | 2 | 1 | 1 | 2 | 2 | 2 | 3 | 1 | 1 | 2 | 0.291 | 813.11 | 0.394 | 813.11 | 0.000000% |

| 4 | 3 | 2 | 3 | 2 | 1 | 3 | 2 | 2 | 3 | 1 | 2 | 2 | 2.77 | 1346.831 | 0.79 | 1346.831 | 0.000000% |

| 5 | 3 | 2 | 3 | 2 | 2 | 3 | 2 | 2 | 3 | 1 | 2 | 3 | 14.53 | 2496.067 | 5.96 | 2496.067 | 0.000000% |

| 6 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 37.46 | 3062.064 | 11.25 | 3062.064 | 0.000000% |

| 7 | 3 | 3 | 4 | 3 | 2 | 3 | 4 | 3 | 4 | 2 | 3 | 3 | 75.39 | 5127.064 | 24.9 | 5127.064 | 0.000000% |

| 8 | 4 | 4 | 4 | 3 | 3 | 4 | 4 | 4 | 4 | 2 | 3 | 3 | 129.42 | 8315.462 | 49.23 | 8316.462 | 0.012026% |

| 9 | 4 | 4 | 4 | 3 | 3 | 4 | 5 | 4 | 5 | 2 | 3 | 4 | 444.76 | 15,095.095 | 74.41 | 15,095.1 | 0.000000% |

| 10 | 5 | 4 | 4 | 4 | 3 | 4 | 5 | 5 | 5 | 2 | 4 | 4 | 1079.61 | 27,951.095 | 131.91 | 27,955.1 | 0.014311% |

| 11 | 5 | 5 | 4 | 4 | 4 | 5 | 6 | 5 | 5 | 3 | 4 | 5 | 1921.409 | 36,034.463 | 264.91 | 36,038.46 | 0.011100% |

| 12 | 5 | 5 | 5 | 4 | 4 | 5 | 6 | 6 | 5 | 3 | 5 | 6 | - | - | 417.92 | 44,262.347 | - |

| 13 | 6 | 5 | 6 | 5 | 4 | 6 | 7 | 6 | 6 | 3 | 5 | 6 | - | - | 579.24 | 48,501.57 | - |

| 14 | 6 | 6 | 7 | 5 | 5 | 7 | 7 | 7 | 7 | 4 | 6 | 7 | - | - | 742.09 | 59,607.84 | - |

| 15 | 7 | 8 | 7 | 5 | 6 | 7 | 8 | 7 | 8 | 5 | 7 | 8 | - | - | 1099.11 | 65,212.84 | - |

| Gi | Value |

|---|---|

| 1 | 1 |

| 2 | 1 |

| 3 | 0 |

| 4 | 0 |

| 5 | 0 |

| 6 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baghizadeh, K.; Zimon, D.; Jum’a, L. Modeling and Optimization Sustainable Forest Supply Chain Considering Discount in Transportation System and Supplier Selection under Uncertainty. Forests 2021, 12, 964. https://doi.org/10.3390/f12080964

Baghizadeh K, Zimon D, Jum’a L. Modeling and Optimization Sustainable Forest Supply Chain Considering Discount in Transportation System and Supplier Selection under Uncertainty. Forests. 2021; 12(8):964. https://doi.org/10.3390/f12080964

Chicago/Turabian StyleBaghizadeh, Komeyl, Dominik Zimon, and Luay Jum’a. 2021. "Modeling and Optimization Sustainable Forest Supply Chain Considering Discount in Transportation System and Supplier Selection under Uncertainty" Forests 12, no. 8: 964. https://doi.org/10.3390/f12080964

APA StyleBaghizadeh, K., Zimon, D., & Jum’a, L. (2021). Modeling and Optimization Sustainable Forest Supply Chain Considering Discount in Transportation System and Supplier Selection under Uncertainty. Forests, 12(8), 964. https://doi.org/10.3390/f12080964