Wood Chip Storage in Small Scale Piles as a Tool to Eliminate Selected Risks

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Experimental Piles

2.2. Laboratory Analysis

- Cultivation features—observed on the identification agars (shape of the colony, size of the colony, speed of colony growth, colony color, production of exudates on the colony surface, production and excretion of pigments into the environment);

- Micromorphologic features—observed in the amounts with lactoferrin (occurrence of asexual spores, their size, shape, method of creation and arrangement; type of the vegetative fructification structure, its arrangement, and shape; the occurrence of special structures; the occurrence of sexual fructification structures and spores, their size, shape, and arrangement).

- mw—wet fuel sample weight [kg];

- m0—weight of fuel sample after drying [kg].

3. Results

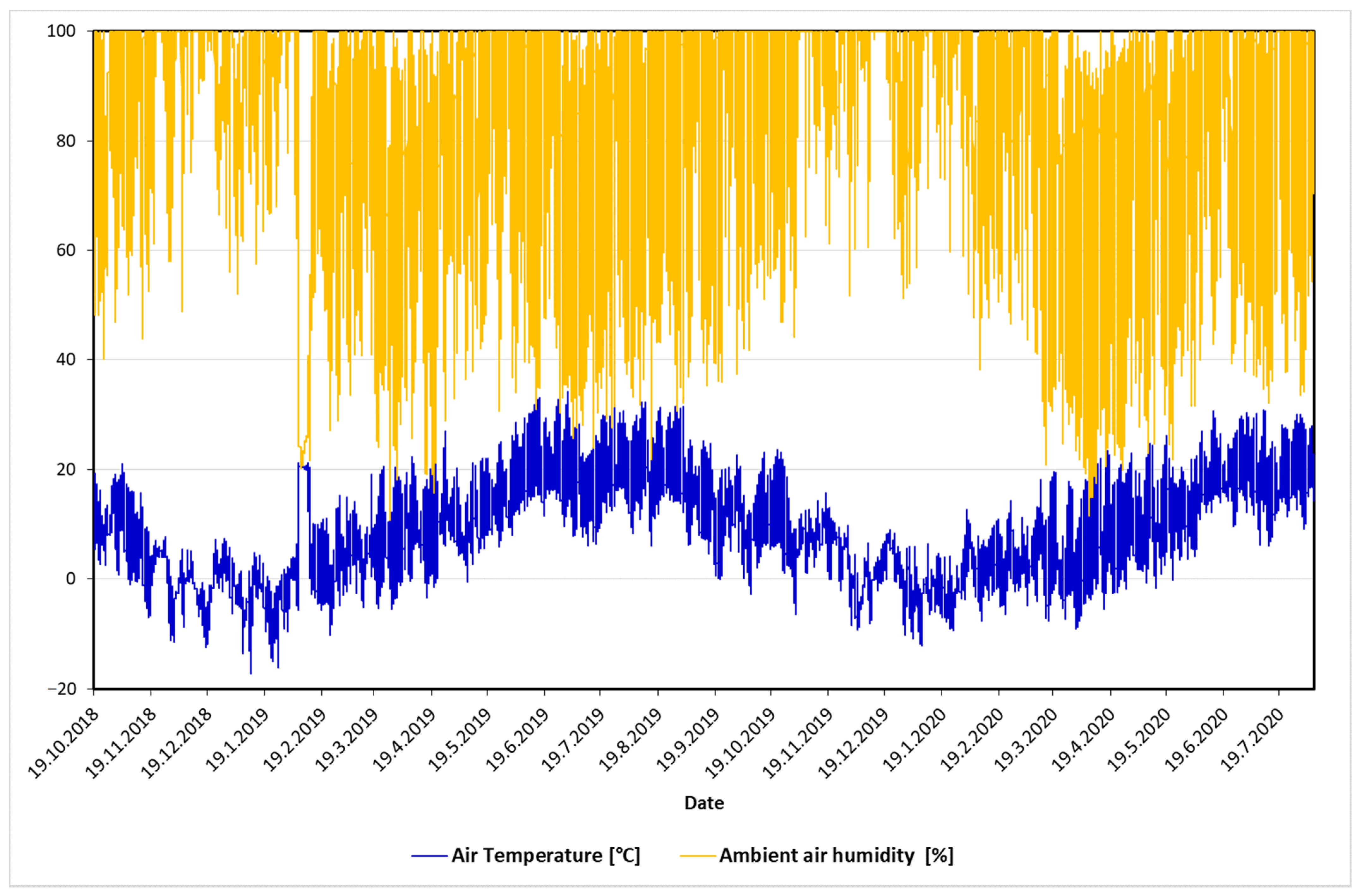

3.1. The Development of Atmospheric Temperature and Relative Air Humidity

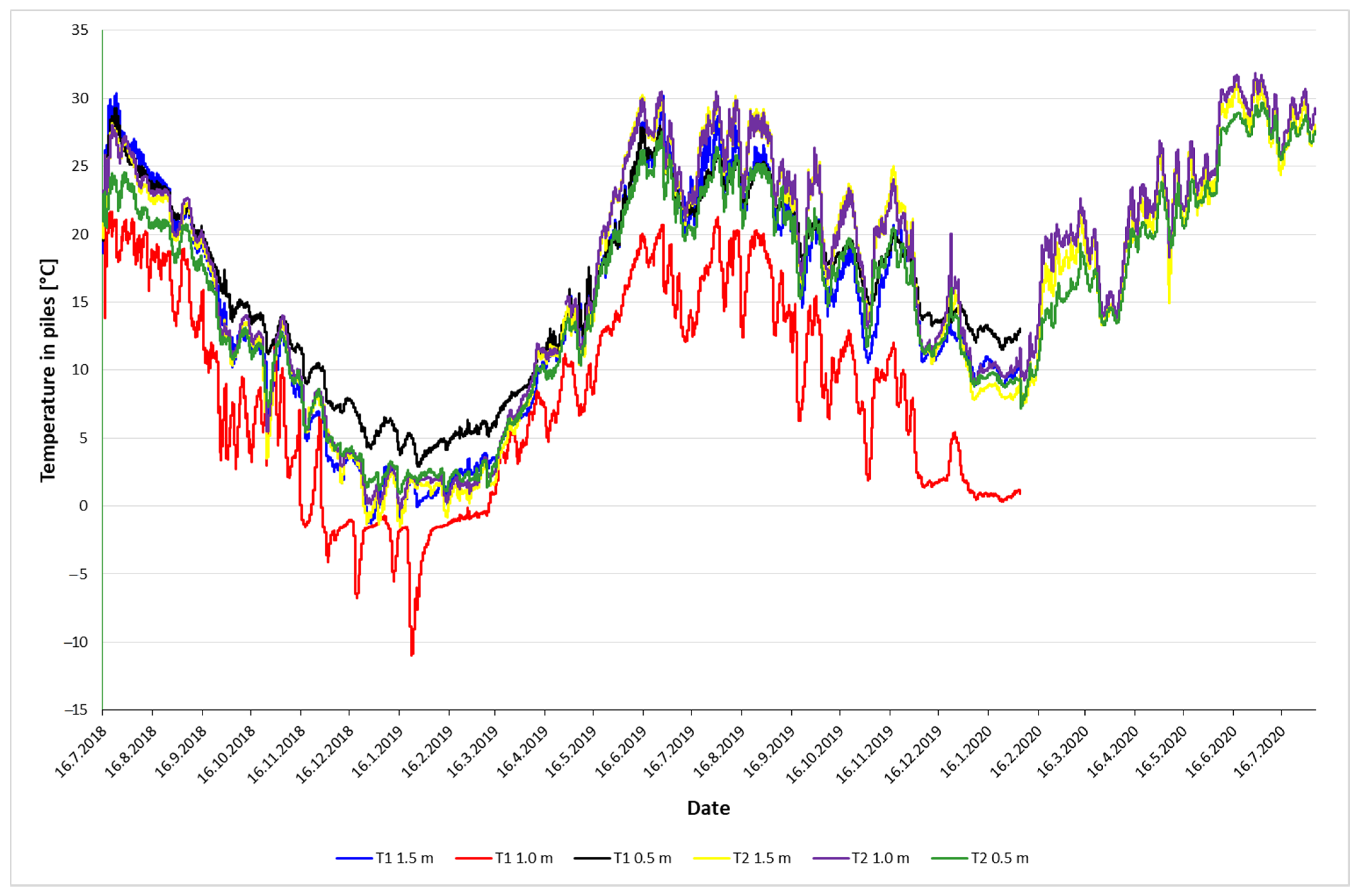

3.2. Heat Development in Experimental Piles

3.3. Development of Energy Parameters in Experimental Piles

3.4. Fungal Activity in Experimental Piles

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banja, M.; Sikkema, R.; Jégard, M.; Motola, V.; Dallemand, J.-F. Biomass for energy in the EU-The support framework. Energy Policy 2019, 131, 215–228. [Google Scholar] [CrossRef]

- Šupín, M.; Kaputa, V.; Parobek, J. Wood Biomass as a Renewable Resources Market Development in the EU. In more Wood, Better Management, Increasing Effectiveness: Starting Points and Perspective. Proc. Sci. Pap. 2017, 1, 25–32. [Google Scholar]

- Shamsi, M.; Babazadeh, R.; Solimanpur, M. Optimization of biomass-to-bioenergy logistics network design problem: A case study. Int. J. Chem. React. Eng. 2018, 16, 20170251. [Google Scholar] [CrossRef]

- Guo, X.; Voogt, J.; Annevelink, B.; Snels, J.; Kanellopoulos, A. Optimizing resource utilization in biomass supply chains by creating integrated biomass logistics centers. Energies 2020, 13, 6153. [Google Scholar] [CrossRef]

- Civitarese, V.; Faugno, S.; Picchio, R.; Assirelli, A.; Sperandio, G.; Saulino, L.; Crimaldi, M.; Sannino, M. Production of selected short-rotation wood crop species and quality of obtained biomass. Eur. J. Res. 2018, 137, 541–552. [Google Scholar] [CrossRef]

- Jappinen, E.; Korpinen, O.; Ranta, T. The effects of local biomass availability and possibilities for truck and train transportation on the greenhouse gas emissions of a small-diameter energy wood supply chain. Bioenergy Res. 2013, 6, 166–177. [Google Scholar] [CrossRef]

- Barwicki, J.; Marczuk, A.; Misztal, W. Wood chips biomass storage problems and some experimental work concerning such existing processes. Fresen. Environ. Bull. 2020, 29, 36–42. [Google Scholar]

- Nunes, L.J.; Da Costa, J.T.P.; Godina, R.; Matias, J.C.; Catalão, J.P. A logistics management system for a biomass-to-energy production plant storage park. Energies 2020, 13, 5512. [Google Scholar] [CrossRef]

- Kamimura, K.; Kuboyama, H.; Yamamoto, K. Wood biomass supply costs and potential for biomass energy plants in Japan. Biomass Bioenergy 2012, 36, 107–115. [Google Scholar] [CrossRef]

- Paolotti, L.; Martino, G.; Marchini, A.; Boggia, A. Economic and environmental assessment of agro-energy wood biomass supply chains. Biomass Bioenergy 2017, 97, 172–185. [Google Scholar] [CrossRef]

- Spinelli, R.; Pari, L.; Magagnotti, N. New biomass products, small-scale plants and vertical integration as opportunities for rural development. Biomass Bioenergy 2018, 115, 244–252. [Google Scholar] [CrossRef]

- Lindgren, R.M.; Eslyn, W. Biological deterioration of pulpwood and pulp chips during storage. Tappi J. 1961, 44, 419–429. [Google Scholar]

- Ampessan, C.G.J.; Rios, P.D.; Brand, M.A.; Vieira, H.C.; Knies, D.D. Optimization of the storage time of Pinus taeda and Pinus elliottii chips for pulp and paper production. Sci. For. 2015, 108, 885–893. [Google Scholar]

- Ramnath, L.; Sithole, B.; Govinden, R. The effects of wood storage on the chemical composition and indigenous microflora of eucalyptus species used in the pulping industry. Bioresources 2017, 13, 86–103. [Google Scholar] [CrossRef]

- Thörnqvist, T. Drying and storage of forest residues for energy production. Biomass 1985, 7, 125–134. [Google Scholar] [CrossRef]

- Lehtikangas, P.; Jirjis, R. Storage of Logging Residue in Bales. In Proceedings of the 10th European Conference and Technology Exhibition, Biomass for Energy and Industry, Würzburg, Germany, 8–11 June 1998. [Google Scholar]

- Thörnquist, T.; Lundström, H. Health hazards caused by fungi in stored wood chips. Forest Prod. J. 1982, 32, 29–32. [Google Scholar]

- Schweier, J.; Schnitzler, J.-P.; Becker, G. Selected environmental impacts of the technical production of wood chips from poplar short rotation coppice on marginal land. Biomass Bioenergy 2016, 85, 235–242. [Google Scholar] [CrossRef]

- Nurmi, J. The storage of logging residue for fuel. Biomass Bioenergy 1999, 17, 41–47. [Google Scholar] [CrossRef]

- Hartmann, H.; Reisinger, K.; Turowski, P.; Rossmann, P. Handbuch Bioenergie—Kleinanlagen, 3rd ed.; Fachagentur Na-chwachsende Rohstoffe: Gülzow, Germany, 2013; p. 195. [Google Scholar]

- Barontini, M.; Crognale, S.; Scarfone, A.; Gallo, P.; Gallucci, F.; Petruccioli, M.; Pesciaroli, L.; Pari, L. Airborne fungi in biofuel wood chip storage sites. Int. Biodeterior. Biodegrad. 2014, 90, 17–22. [Google Scholar] [CrossRef]

- Lieskovský, M.; Gejdoš, M.; Messingerová, V.; Danihelová, Z.; Moravčíková, V.; Němec, M. Biological risks from long-term storage of wood chips. Pol. J. Environ. Stud. 2017, 26, 2633–2641. [Google Scholar] [CrossRef]

- Suchomel, J.; Belanová, K.; Gejdoš, M.; Němec, M.; Danihelová, A.; Mašková, Z. Analysis of fungi in wood chip storage piles. Bioresources 2014, 9, 4410–4420. [Google Scholar] [CrossRef]

- Gejdoš, M.; Lieskovský, M.; Slančík, M.; Němec, M.; Danihelová, Z. Storage and fuel quality of coniferous wood chips. BioResources 2015, 10, 5544–5553. [Google Scholar] [CrossRef]

- Afzal, M.T.; Bedane, A.H.; Sokhansanj, S.; Mahmood, W. Storage of comminuted and uncomminuted forest biomass and its effect on fuel quality. Bioresources 2010, 5, 55–69. [Google Scholar]

- Jirjis, R. Effects of particle size and pile height on storage and fuel quality of comminuted Salix viminalis. Biomass Bioenergy 2005, 28, 193–201. [Google Scholar] [CrossRef]

- Anerud, E.; Jirjis, R.; Larsson, G.; Eliasson, L. Fuel quality of stored wood chips—Influence of semi-permeable covering material. Appl. Energy 2018, 231, 628–634. [Google Scholar] [CrossRef]

- Ashman, J.; Jones, J.; Williams, A. Some characteristics of the self-heating of the large scale storage of biomass. Fuel Process. Technol. 2018, 174, 1–8. [Google Scholar] [CrossRef]

- Therasme, O.; Eisenbies, M.H.; Volk, T.A. Overhead protection increases fuel quality and natural drying of leaf-on woody biomass storage piles. Forests 2019, 10, 390. [Google Scholar] [CrossRef]

- Labbé, R.; Carey, P.; Trincado, G.; Thiers, O. Natural drying of forest biomass: Effect of stack height and cover in the province of Valdivia, Chile. Bosque 2018, 39, 449–456. [Google Scholar] [CrossRef]

- Krzyżaniak, M.; Stolarski, M.J.; Niksa, D.; Tworkowski, J.; Szczukowski, S. Effect of storage methods on willow chips quality. Biomass Bioenergy 2016, 92, 61–69. [Google Scholar] [CrossRef]

- Pari, L.; Brambilla, M.; Bisaglia, C.; Del Giudice, A.; Croce, S.; Salerno, M.; Gallucci, F. Poplar wood chip storage: Effect of particle size and breathable covering on drying dynamics and biofuel quality. Biomass Bioenergy 2015, 81, 282–287. [Google Scholar] [CrossRef]

- ISO. STN ISO 21527–2: 2010 Microbiology of Food and Animal Feeding Stuffs. Horizontal Method for the Enumeration of Yeasts and Moulds Part 2: Colony Count Technique in Products with Water Activity Less than or Equal to 0,95; European Committee for Standardization (CEN-CENELEC): Brussels, Belgium, 2018. [Google Scholar]

- ISO. STN 56 0100: 1968 Microbiological Examination of Foodstuffs, Articles of Current Use and Environment of Food Establishments; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 1968. [Google Scholar]

- Fassati, O. Plísně a Vláknité Houby v Technické Mikrobiologii (Fungi and Filamentous Fungi in Technical Microbiology), 1st ed.; SNTL: Prague, Czech Republic, 1979; p. 211. [Google Scholar]

- Hoog De, G.S.; Guarro, J.; Gené, J.; Figueras, M.J. Atlas of Clinical Fungi, 2nd ed.; Centralbureau voor Schimmelcultures: Utrecht, The Netherlands, 2001; p. 1160. [Google Scholar]

- Klich, M.A. Identification of Common Aspergillus Species, 1st ed.; Centralbureau voor Schimmelcultures: Utrecht, The Netherlands, 2002; p. 116. [Google Scholar]

- Samson, R.A.; Houbraken, J.; Summerbell, R.C.; Flannigan, B.; Miller, J.D. Common and Important Species of Fungi and Acti-nomycetes in Indoor Environments. In Microorganisms in Home and Indoor Work Environments, 2nd ed.; Flannigan, B., Samson, R.A., Miller, J.D., Eds.; CRC Press: New York, NY, USA, 2011; pp. 287–292. [Google Scholar]

- González, H.H.L.; Pacin, A.; Resnik, S.L.; Martínez, E.J. Deoxynivalenol and contaminant mycoflora in freshly harvested Argentinian wheat in 1993. Mycopathologia 1996, 135, 129–134. [Google Scholar] [CrossRef] [PubMed]

- ISO. EN ISO 7218 Microbiology of Food and Animal Feeding Stuffs—General Requirements and Guidance for Microbiological Examinations; European Committee for Standardization (CEN-CENELEC): Brussels, Belgium, 2007. [Google Scholar]

- ISO. STN ISO 1928 Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method, and Calculation of Net Calorific Value; European Committee for Standardization (CEN-CENELEC): Brussels, Belgium, 2003. [Google Scholar]

- Österreichisches Normung-sinstitut ÖNORM. M 7132 Energy-Economical Utilization of Wood and Bork as Fuel—Definitions and Properties; Österreichisches Normung-Sinstitut: Vienna, Austria, 1998. [Google Scholar]

- ISO. STN ISO 1171 Solid Mineral Fuels—Determination of Ash; European Committee for Standardization (CEN-CENELEC): Brussels, Belgium, 2003. [Google Scholar]

- ISO. STN EN ISO 18122 Solid Biofuels: Determination of Ash Content; European Committee for Standardization (CEN-CENELEC): Brussels, Belgium, 2016. [Google Scholar]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santangelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Szulc, J.; Otlewska, A.; Okrasa, M.; Majchrzycka, K.; Sulyok, M.; Gutarowska, B. Microbiological contamination at workplaces in a combined heat and power (CHP) station processing plant biomass. Int. J. Environ. Res. Public Health 2017, 14, 99. [Google Scholar] [CrossRef] [PubMed]

- Laitinen, S.; Laitinen, J.; Fagernäs, L.; Korpijärvi, K.; Korpinen, L.; Ojanen, K.; Aatamila, M.; Jumpponen, M.; Koponen, H.; Jokiniemi, J.; et al. Exposure to biological and chemical agents at biomass power plants. Biomass Bioenergy 2016, 93, 78–86. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Krišťák, Ľ.; Igaz, R.; Réh, R. Occupational exposure to dust produced when milling thermally modified wood. Int. J. Environ. Res. Public Health 2020, 17, 1478. [Google Scholar] [CrossRef] [PubMed]

- Vetráková, M.; Hitka, M.; Potkány, M.; Lorincová, S.; Smerek, L. Corporate sustainability in the process of employee recruitment through social networks in conditions of slovak small and medium enterprises. Sustainability 2018, 10, 1670. [Google Scholar] [CrossRef]

| Energy Parameter | Sample Height/Date of Dismantling the Pile | ||

|---|---|---|---|

| Pile 1 Sampling 6 February 2019 | |||

| 0.5 m | 1.0 m | 1.5 m | |

| Moisture content (%) | 28.1 | 34.4 | 48.4 |

| Combustion heat (MJ.kg−1) | 19.335 | 19.175 | 19.222 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 by moisture 0% | 17.993 | 17.833 | 17.880 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 in delivered condition | 12.257 | 10.869 | 8.036 |

| Calorific value (MJ.kg−1) determined by STN ISO 1928 in delivered condition | 12.373 | 10.987 | 8.158 |

| Ash content (%) | 0.60 | 0.51 | 0.54 |

| Pile 2 Sampling 12 August 2019 | |||

| Moisture content (%) | 39.9 | 49.1 | 55.0 |

| Combustion heat (MJ.kg−1) | 19.175 | 19.045 | 19.112 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 by moisture 0% | 17.833 | 17.703 | 17.770 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 in delivered condition | 9.736 | 7.811 | 6.660 |

| Calorific value (MJ.kg−1) determined by STN ISO 1928 in delivered condition | 9.855 | 7.934 | 6.785 |

| Ash content (%) | 0.97 | 1.44 | 0.94 |

| Pile 3 Sampling 5 February 2020 | |||

| Moisture content (%) | 60.2 | 58.9 | 60.5 |

| Combustion heat (MJ.kg−1) | 19.207 | 18,198 | 18.457 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 by moisture 0% | 17.865 | 16.856 | 17.115 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 in delivered condition | 5.641 | 5.485 | 5.286 |

| Calorific value (MJ.kg−1) determined by STN ISO 1928 in delivered condition | 5.768 | 5.611 | 5.413 |

| Ash content (%) | 0.93 | 0.65 | 0.61 |

| Pile 4 Sampling 5 August 2020 | |||

| Moisture content (%) | 55.5 | 60.3 | 58.9 |

| Combustion heat (MJ.kg−1) | 18.541 | 18.103 | 18.961 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 by moisture 0% | 17.199 | 16.761 | 17.619 |

| Calorific value (MJ.kg−1) determined by ÖNORM M 7132 in delivered condition | 6.309 | 5.183 | 5.806 |

| Calorific value (MJ.kg−1) determined by STN ISO 1928 in delivered condition | 6.434 | 5.310 | 5.932 |

| Ash content (%) | 0.97 | 0.87 | 0.68 |

| Pile Nr./Sampling Date | Sample Height | ||

|---|---|---|---|

| Identified Microorganisms | |||

| 0.5 m | 1.0 m | 1.5 m | |

| Pile Nr. 1, sampling 6 February 2019 | Penicillium citrinum; Penicillium sp.; Aspergillus brasiliensis; Mycelia sterilia; Mucor piriformis; Rhizomucor sp. | Penicillium citrinum; Penicillium sp.; Aspergillus brasiliensis; Mycelia sterilia; Cladosporium herbarum | Geotrichum candidum; Aspergillus brasiliensis; Penicillium sp.; Cladosporium herbarum; Mycelia sterilia; Mucor piriformis; Rhizomucor sp. |

| Pile Nr. 2, sampling 12 August 2019 | Penicillium expansum; Penicillium sp.; Mycelia sterilia; Paecilomyces sp. | Penicillium italicum; Penicillium expansum; Penicillium sp.; Mycelia sterilia | Penicillium expansum; Penicillium sp.; Mycelia sterilia |

| Pile Nr. 3, sampling 5 February 2020 | Aspergillus brasiliensis; Penicillium frequentans; Penicillium sp.; Mycelia sterilia | Aspergillus brasiliensis; Penicillium frequentans; Penicillium sp.; Mycelia sterilia | Aspergillus brasiliensis; Penicillium frequentans; Penicillium sp.; Aspergillus sp.; Mycelia sterilia |

| Pile Nr. 4, sampling 5 August 2020 | Penicillium diversum; Mycelia sterilia; Penicillium frequentans; Aspergillus flavus; Gliocladium catenulatum; Yeasts | Mycelia sterilia; Penicillium sp.; Gliocladium catenulatum; Penicillium expansum; Yeasts | Aspergillus brasiliensis; Penicillium expansum; Penicillium frequentans; Penicillium flavus; Yeasts |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gejdoš, M.; Lieskovský, M. Wood Chip Storage in Small Scale Piles as a Tool to Eliminate Selected Risks. Forests 2021, 12, 289. https://doi.org/10.3390/f12030289

Gejdoš M, Lieskovský M. Wood Chip Storage in Small Scale Piles as a Tool to Eliminate Selected Risks. Forests. 2021; 12(3):289. https://doi.org/10.3390/f12030289

Chicago/Turabian StyleGejdoš, Miloš, and Martin Lieskovský. 2021. "Wood Chip Storage in Small Scale Piles as a Tool to Eliminate Selected Risks" Forests 12, no. 3: 289. https://doi.org/10.3390/f12030289

APA StyleGejdoš, M., & Lieskovský, M. (2021). Wood Chip Storage in Small Scale Piles as a Tool to Eliminate Selected Risks. Forests, 12(3), 289. https://doi.org/10.3390/f12030289