Properties of Plywood Made from Perforated Veneers

Abstract

:1. Introduction

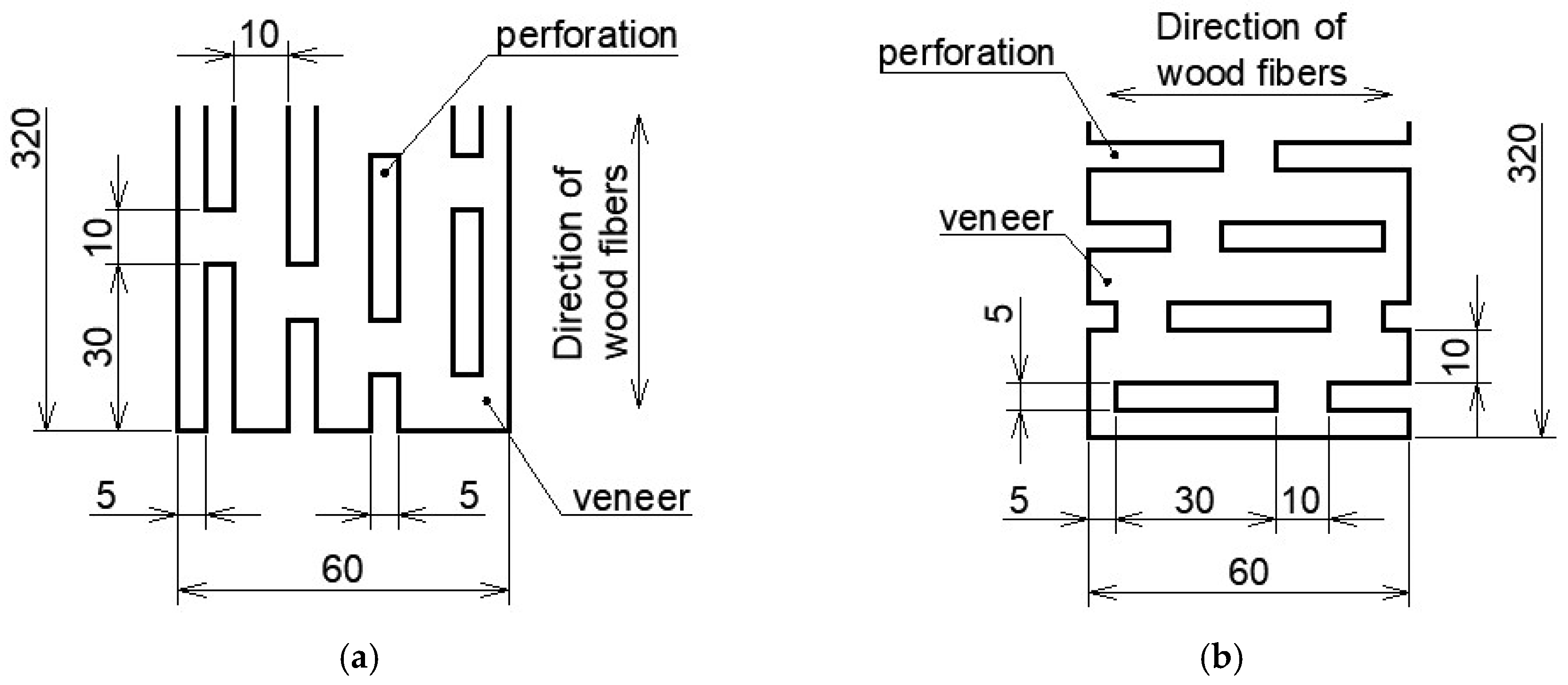

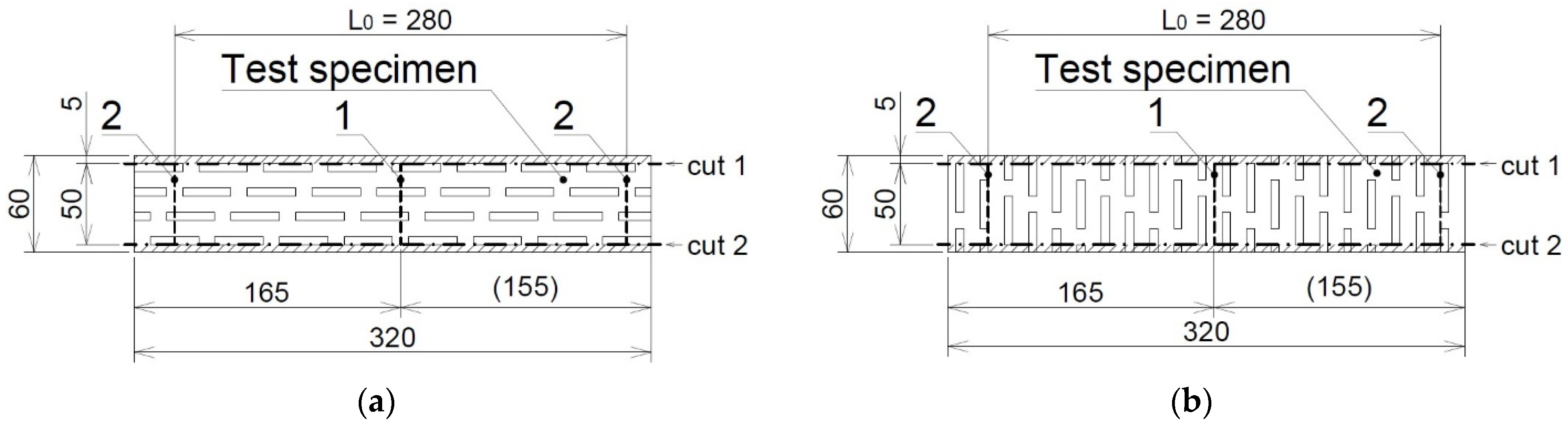

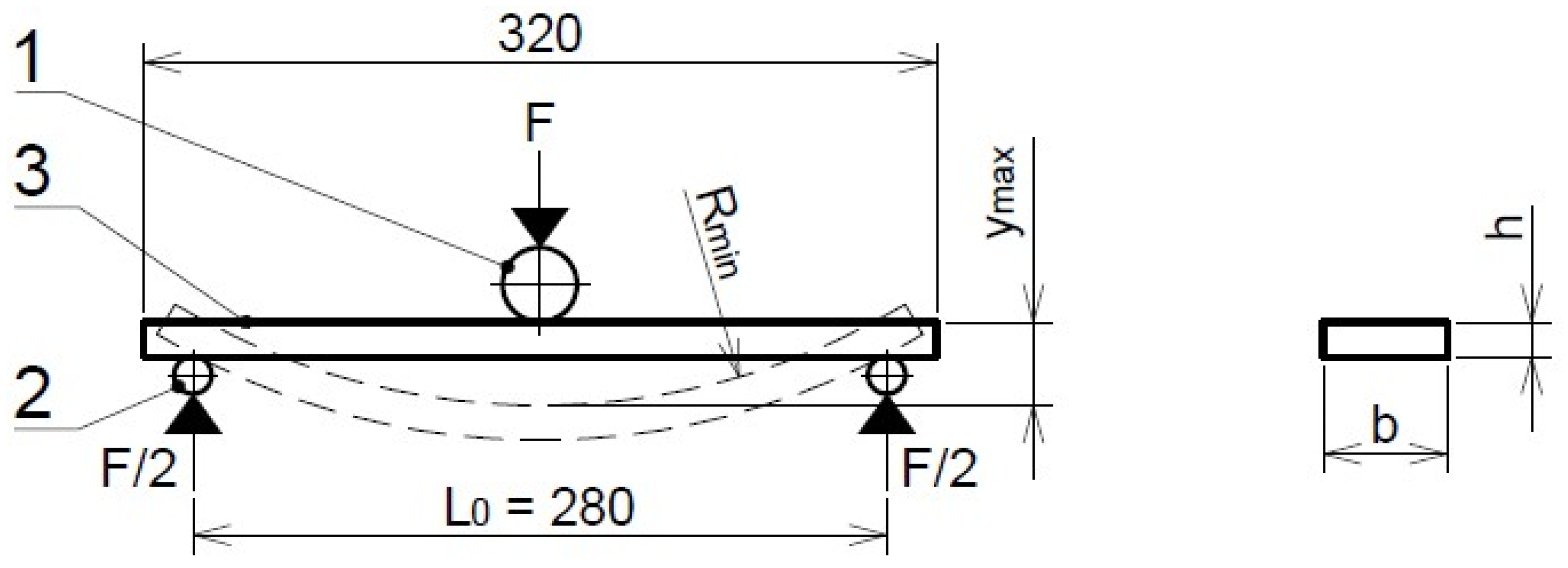

2. Materials and Methods

- two types of standard plywood Figure 2a,b

- four types of lightweight plywood:

3. Results and Discussion

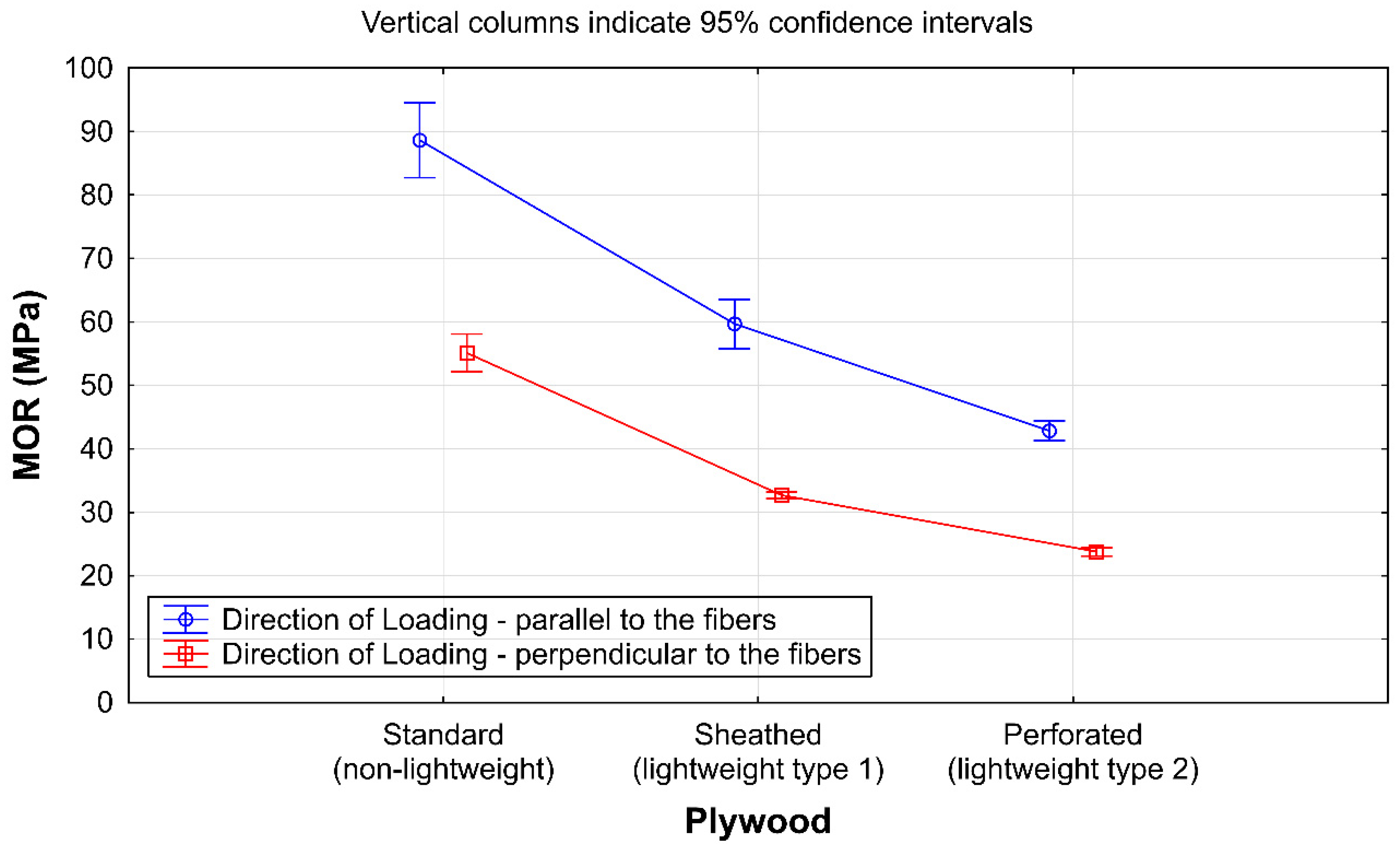

3.1. Bending Strength (MOR)

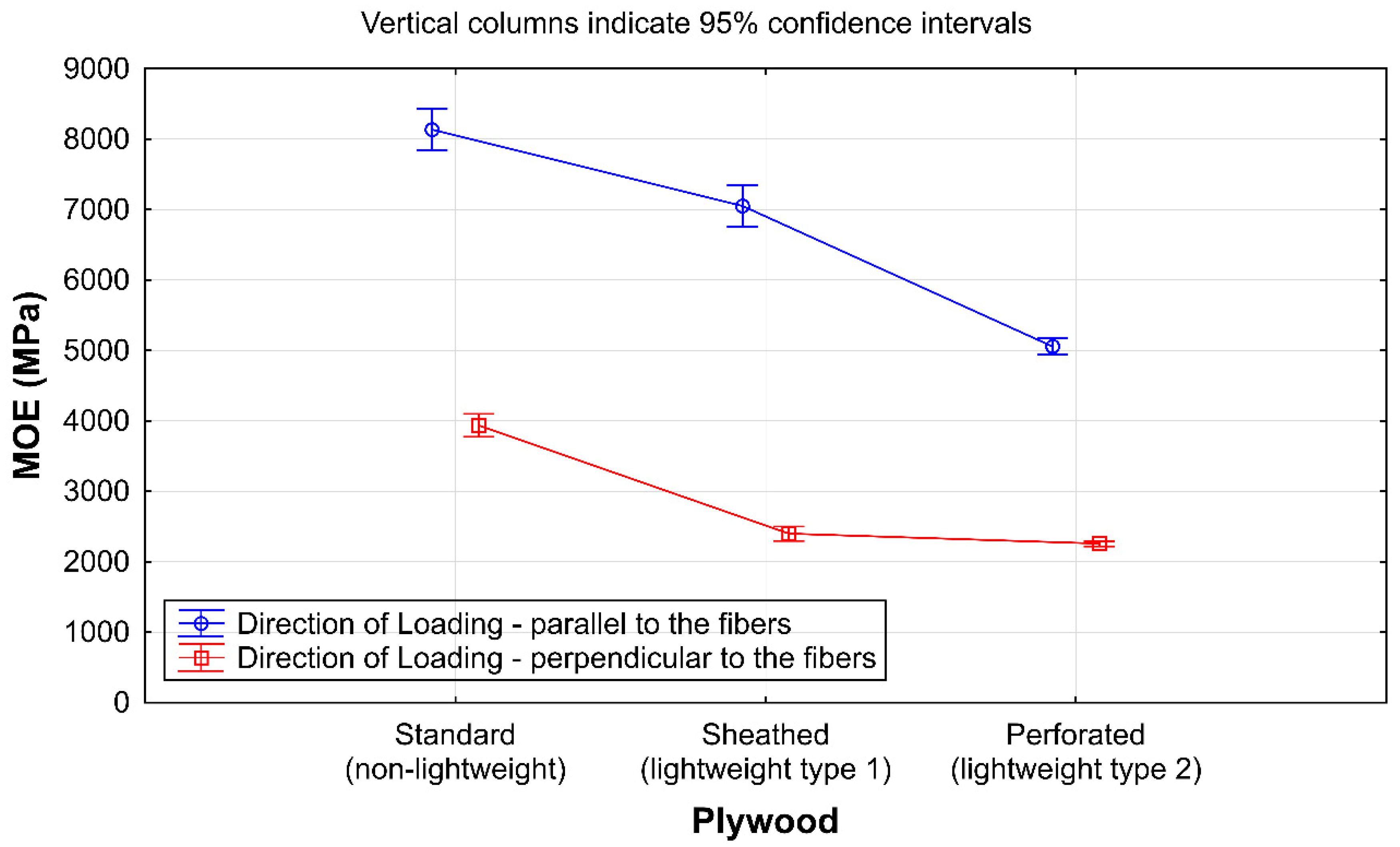

3.2. Modulus of Elasticity in Bending (MOE)

3.3. Degree of Weight Reduction

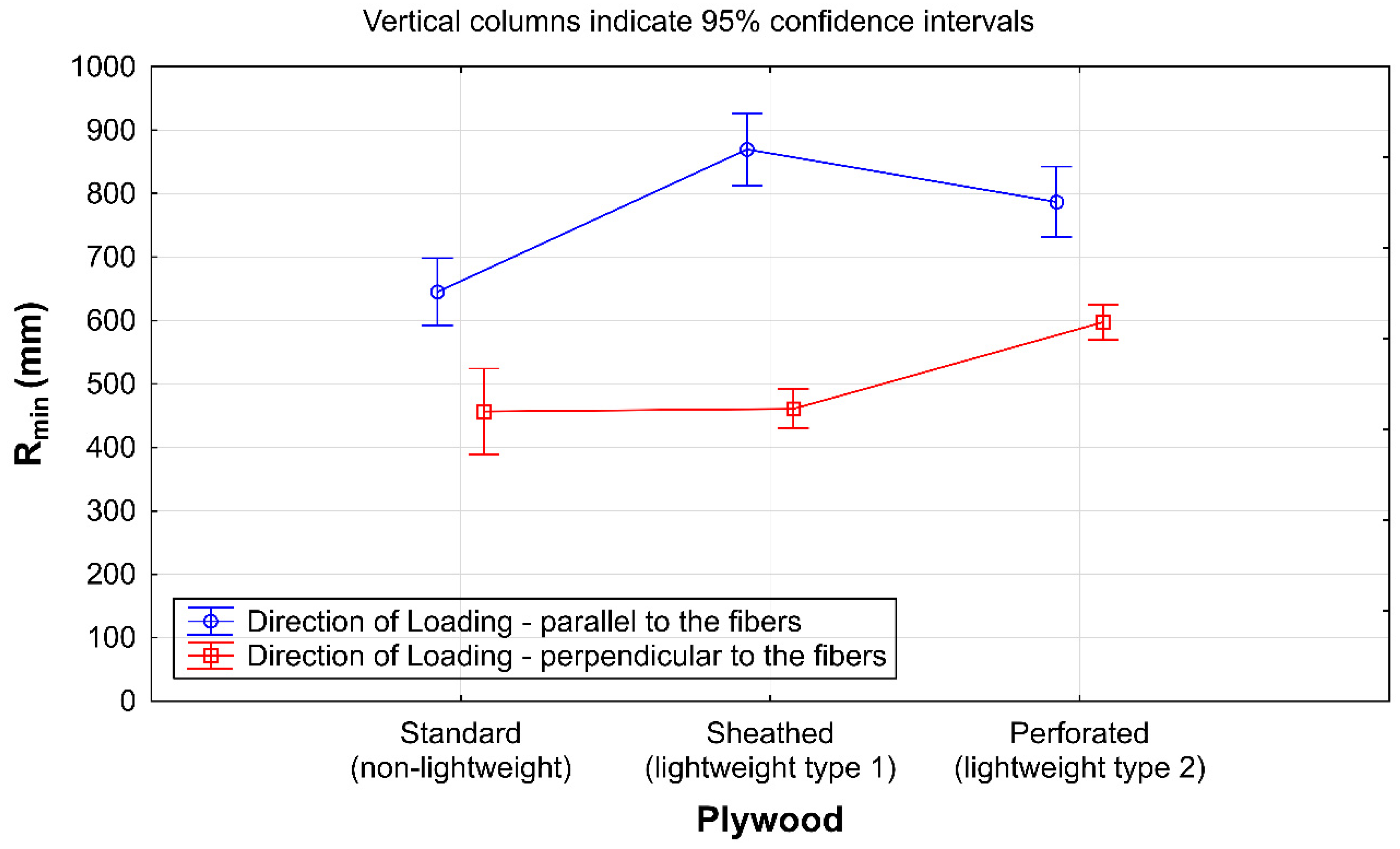

3.4. Bendability of Plywood

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- V&A. A Short History of Plywood in Ten-Ish Objects. Available online: https://www.vam.ac.uk/articles/a-history-of-plywood-in-ten-objects (accessed on 10 September 2021).

- A Brief History of Plywood and How It Helped Win the War. Available online: https://www.famitchell.com.au/brief-history-plywood-helped-win-war/ (accessed on 10 September 2021).

- Clark, C.R. Plywood, its History, Manufacture, and Use in Specific Industrial Arts Areas. Plan B Pap. 1961, 224. Available online: https://thekeep.eiu.edu/plan_b/224 (accessed on 10 September 2021).

- Bekhta, P.; Sedliačik, J.; Bekhta, N. Effect of veneer-drying temperature on selected properties and formaldehyde emission of birch plywood. Polymers 2020, 12, 593. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bekhta, P.; Salca, E.A.; Lunguleasa, A. Some properties of plywood panels manufactured from combinations of thermally densified and non-densified veneers of different thicknesses in one structure. J. Build. Eng. 2020, 29, 101116. [Google Scholar] [CrossRef]

- Kallakas, H.; Rohumaa, A.; Vahermets, H.; Kers, J. Effect of Different Hardwood Species and Lay-Up Schemes on the Mechanical Properties of Plywood. Forests 2020, 11, 649. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Hosseini, S.B.; Ghahri, S.; Ghofrani, M.; Papadopoulos, A.N. Formaldehyde Emission in Micron-Sized Wol-lastonite-Treated Plywood Bonded with Soy Flour and Urea-Formaldehyde Resin. Appl. Sci. 2020, 10, 6709. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Noshchenko, G.; Kačík, F.; Bekhta, N. Characteristics of beech bark and its effect on properties of UF adhesive and on bonding strength and formaldehyde emission of plywood panels. Eur. J. Wood Prod. 2021, 79, 423–433. [Google Scholar] [CrossRef]

- Moubarik, A.; Allal, A.; Pizzi, A.; Charrier, F.; Charrier, B. Characterization of a formaldehyde-free cornstarch-tannin wood adhesive for interior plywood. Eur. J. Wood Prod. 2010, 68, 427–433. [Google Scholar] [CrossRef] [Green Version]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef]

- Negro, F.; Cremonini, C.; Zanuttini, R.; Properzi, M.; Pichelin, F. A new wood-based lightweight composite for boatbuilding. Wood Res. 2011, 56, 257–266. [Google Scholar]

- Shalbafan, A.; Luedtke, J.; Welling, J.; Thoemen, H. Comparison of foam core materials in innovative lightweight wood-based panels. Eur. J. Wood Prod. 2012, 70, 287–292. [Google Scholar] [CrossRef]

- Bajzová, L.; Bekhta, P.; Iždinský, J.; Sedliačik, J. The effect of veneering on the properties of lightweight particleboard with expanded polystyrene. Acta Fac. Xylologiae Zvolen 2018, 60, 93–100. [Google Scholar]

- Gößwald, J.; Barbu, M.C.; Petutschnigg, A.; Krišťák, Ľ.; Tudor, E.M. Oversized planer shavings for the core layer of lightweight particleboard. Polymers 2021, 13, 1125. [Google Scholar] [CrossRef]

- Gáborík, J.; Vilhanová, A. Selected mechanical properties of lightened plywood. Ann. WULS-SGGW 2016, 94, 205–211. [Google Scholar]

- Jivkov, V.; Simeonova, R.; Kamenov, P.; Marinova, A. Strength properties of new lightweight panels for furniture and interiors. In Proceedings of the 23rd International Scientific Conference. Wood Is Good—With Knowledge and Technology to a Competitive Forestry and Wood Technology Sector, Zagreb, Croatia, 12 October 2012; pp. 49–58. [Google Scholar]

- Smardzewski, J. Mechanical properties of wood-based sandwich panels with a wavy core. In Proceedings of the 27th International Conference: Research for Furniture Industry, Ankara, Turkey, 17–18 September 2015; pp. 242–255. [Google Scholar]

- Smardzewski, J.; Gajęcki, A.; Wojnowska, M. Investigation of elastic properties of paper honeycomb panels with rectangular cells. BioResources 2019, 14, 1435–1451. [Google Scholar]

- Słonina, M.; Dziurka, D.; Smardzewski, J. Experimental Research and Numerical Analysis of the Elastic Properties of Paper Cell Cores before and after Impregnation. Materials 2020, 13, 2058. [Google Scholar] [CrossRef]

- The Patented Lightweight Board Made from Wood… and Air! Available online: https://schweitzer-austria.com/en/products/aerowood (accessed on 31 March 2021).

- Čapka, R. Interzum 2019: Více vystavovatelů i návštěvníků (Interzum 2019: More exhibitors and visitors). Drevársky Magazín 2019, 20, 36–42. [Google Scholar]

- Kalama, A.M.; Tzoni, D.; Symeonidou, I. Kerf bending: A genealogy of cutting patterns for single and double curvature. In Proceedings of the 7th International Conference on Geometry and Graphics, Belgrade, Serbia, 18–21 September 2020. [Google Scholar]

- Capone, M.; Lanzara, E. Kerf bending: Ruled double curved surfaces manufacturing. Blucher 2018, 5, 653–660. [Google Scholar] [CrossRef]

- Ľahké Panely na Nábytok. Available online: https://www.panelsystems.co.uk/advice-centre/lightweight-composite-and-honeycomb-panels/what-are-lightweight-furniture-panels-their-uses-and-benefits (accessed on 19 July 2021).

- Jivkov, V.; Simeonova, R.; Antov, P.; Marinova, A.; Petrova, B.; Kristak, L. Structural Application of Lightweight Panels Made of Waste Cardboard and Beech Veneer. Materials 2021, 14, 5064. [Google Scholar] [CrossRef]

- Berger, G.; Barbu, M.C.; Huber, H.; Berger, J.; Schwarzmann, G. Applying Biomimicry in Lightweight Wood Panel Development. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. Conference Paper 8p. [Google Scholar]

- Holouš, Z.; Máchová, E. Konstrukce Nábytku I (Furniture Constructions I); Mendelova Univerzita v Brně: Brno, Czech Republic, 2013; 144p. [Google Scholar]

- Zemiar, J.; Gáborík, J.; Muzikář, Z.; Navrátil, V.; Ružinská, E.; Šebo, N. Technológia Výroby Nábytku (Furniture Production Technology), 2nd ed.; Technical University in Zvolen: Zvolen, Slovakia, 2016; 287p. [Google Scholar]

- STN EN 310. Dosky na báze dreva. In Zisťovanie Modulu Pružnosti v Ohybe a Pevnosti v Ohybe. (Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength); Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 1998. [Google Scholar]

- Gáborík, J.; Dudas, J. Vlastnosti lamelového dreva (The properties of laminated wood). In Proceedings of the Trieskové a Beztrieskové Obrábanie Dreva 2006 (Chip and Chipless Woodworking Processes 2006), Starý Smokovec, Slovakia, 12–14 October 2006; pp. 129–134. [Google Scholar]

- Buchelt, B.; Wagenführ, A. The mechanical behaviour of veneer subjected to bending and tensile loads. Holz Roh Werkst. 2008, 66, 289–294. [Google Scholar] [CrossRef]

- Gáborík, J.; Fekiač, J. Effect of structure of laminated wood on bending strength after cyclic loading. Ann. WULS-SGGW 2019, 105, 20–29. [Google Scholar] [CrossRef]

- Reinprecht, L.; Kmeťová, L.; Iždinský, J. Fungal decay and bending properties of beech plywood overlaid with tropical veneers. J. Trop. For. Sci. 2012, 24, 490–497. Available online: https://www.jstor.org/stable/23617095 (accessed on 12 July 2021).

- Ružiak, I.; Igaz, R.; Krišťák, Ľ.; Réh, R.; Mitterpach, J.; Očkajová, A.; Kučerka, M. Influence of urea-formaldehyde adhesive modification with beech bark on chosen properties of plywood. Bioresources 2017, 12, 3250–3264. [Google Scholar] [CrossRef] [Green Version]

- Bal, B.C.; Bektas, I. Some mechanical properties of plywood produced from eucalyptus, beech, and poplar veneer. Maderas Cienc. Tecnol. 2014, 16, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Merhar, M. Determination of dynamic and static modulus of elasticity of beech plywood. Les/Wood 2020, 69, 59–69. [Google Scholar] [CrossRef]

- Štefko, J.; Joščák, P. Construction of Wood Products, 1st ed.; Technical University in Zvolen: Zvolen, Slovakia, 2013; p. 95. [Google Scholar]

- Buchelt, B.; Wagenführ, A. Influence of the adhesive layer on the mechanical properties of thin veener-based composite materials. Eur. J. Wood Prod. 2010, 68, 475–477. [Google Scholar] [CrossRef] [Green Version]

- Vilhanová, A.; Dudas, J. Návrh konštrukcie vyľahčenej preglejky (The construction design of lightweight plywood). In Proceedings of the Pokroky vo Výrobe a Použití Lepidiel v Drevopriemysle (Adhesives in Woodworking Industry): XXI. Symposium, Zvolen, Slovakia, 26–28 June 2013; Technical University in Zvolen: Zvolen, Slovakia, 2013; pp. 193–198. [Google Scholar]

- Vilhanová, A.; Gáborík, J. Vplyv zníženia hmotnosti preglejovanej dosky na mechanické vlastnosti (The effect of reducing the weight of the plywood board on mechanical properties). In Proceedings of the Nábytok a Výrobky z Dreva 2018: Medzinárodný Vedecko-Odborný Seminár (Furniture and Wood Products 2018: The International Scientific-Professional Seminar), Zvolen, Slovakia, 18 October 2018; Technical University in Zvolen: Zvolen, Slovakia, 2018; pp. 61–65. [Google Scholar]

| Source of Variability | Sum of Squares | Degrees of Freedom | Variance | Fisher’s F-Test | Significance Level (p) |

|---|---|---|---|---|---|

| Overall Average | 183,338.73 | 1 | 183,338.73 | 7141.515 | 0.000 * |

| Direction of Loading | 12,682.67 | 1 | 12,682.67 | 494.023 | 0.000 * |

| Plywood Structure | 18,514.06 | 2 | 9257.03 | 360.585 | 0.000 * |

| Direction of Loading × Plywood Structure | 630.46 | 2 | 315.23 | 12.279 | 0.000 * |

| Random Factors | 1694.37 | 66 | 25.67 |

| Number | Direction of Loading | Plywood Structure | (1) 88.65 ** | (2) 59.71 ** | (3) 42.84 ** | (4) 55.12 ** | (5) 32.67 ** | (6) 23.78 ** |

|---|---|---|---|---|---|---|---|---|

| 1. | Parallel | Standard | ||||||

| 2. | Parallel | Sheathed | 0.000 * | |||||

| 3. | Parallel | Perforated | 0.000 * | 0.000 * | ||||

| 4. | Perpendicular | Standard | 0.000 * | 0.030 * | 0.000 * | |||

| 5. | Perpendicular | Sheathed | 0.000 * | 0.000 * | 0.000 * | 0.000 * | ||

| 6. | Perpendicular | Perforated | 0.000 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Source of Variability | Sum of Squares | Degrees of Freedom | Variance | Fisher’s F-Test | Significance Level (p) |

|---|---|---|---|---|---|

| Overall Average | 1.66 × 109 | 1 | 1.66 × 109 | 17,928.161 | 0.000 * |

| Direction of Loading | 2.72 × 108 | 1 | 2.72 × 108 | 2930.911 | 0.000 * |

| Plywood Structure | 6.82 × 107 | 2 | 3.41 × 107 | 367.946 | 0.000 * |

| Direction of Loading × Plywood Structure | 1.12 × 107 | 2 | 5.60 × 106 | 60.415 | 0.000 * |

| Random Factors | 6.12 × 106 | 66 | 9.27 × 104 |

| Number | Direction of Loading | Plywood Structure | (1) 8137.1 ** | (2) 7050.7 ** | (3) 5055.7 ** | (4) 3934.5 ** | (5) 2397.1 ** | (6) 2255.0 ** |

|---|---|---|---|---|---|---|---|---|

| 1. | Parallel | Standard | ||||||

| 2. | Parallel | Sheathed | 0.000 * | |||||

| 3. | Parallel | Perforated | 0.000 * | 0.000 * | ||||

| 4. | Perpendicular | Standard | 0.000 * | 0.000 * | 0.000 * | |||

| 5. | Perpendicular | Sheathed | 0.000 * | 0.000 * | 0.000 * | 0.000 * | ||

| 6. | Perpendicular | Perforated | 0.000 * | 0.000 * | 0.000 * | 0.000 * | 0.257 |

| Source of Variability | Sum of Squares | Degrees of Freedom | Variance | Fisher’s F-Test | Significance Level (p) |

|---|---|---|---|---|---|

| Overall Average | 29,136,283 | 1 | 29,136,283 | 4574.543 | 0.000 * |

| Direction of Loading | 1,239,161 | 1 | 1,239,161 | 194.554 | 0.000 * |

| Plywood Structure | 269,618 | 2 | 134,809 | 21.166 | 0.000 * |

| Direction of Loading × Plywood Structure | 193,041 | 2 | 96,521 | 15.154 | 0.000 * |

| Random Factors | 420,369 | 66 | 6369 |

| Number | Direction of Loading | Plywood Structure | (1) 645.35 ** | (2) 869.71 ** | (3) 786.92 ** | (4) 456.64 ** | (5) 460.88 ** | (6) 597.33 ** |

|---|---|---|---|---|---|---|---|---|

| 1. | Parallel | Standard | ||||||

| 2. | Parallel | Sheathed | 0.000 * | |||||

| 3. | Parallel | Perforated | 0.000 * | 0.014 * | ||||

| 4. | Perpendicular | Standard | 0.000 * | 0.000 * | 0.000 * | |||

| 5. | Perpendicular | Sheathed | 0.000 * | 0.000 * | 0.000 * | 0.897 | ||

| 6. | Perpendicular | Perforated | 0.145 | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Direction of Loading | Plywood Structure | koh (−) |

|---|---|---|

| Parallel | Standard | 0.022 |

| Parallel | Sheathed | 0.016 |

| Parallel | Perforated | 0.018 |

| Perpendicular | Standard | 0.033 |

| Perpendicular | Sheathed | 0.030 |

| Perpendicular | Perforated | 0.023 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fekiač, J.; Gáborík, J.; Vojtkuliak, M. Properties of Plywood Made from Perforated Veneers. Forests 2021, 12, 1709. https://doi.org/10.3390/f12121709

Fekiač J, Gáborík J, Vojtkuliak M. Properties of Plywood Made from Perforated Veneers. Forests. 2021; 12(12):1709. https://doi.org/10.3390/f12121709

Chicago/Turabian StyleFekiač, Jozef, Jozef Gáborík, and Marek Vojtkuliak. 2021. "Properties of Plywood Made from Perforated Veneers" Forests 12, no. 12: 1709. https://doi.org/10.3390/f12121709

APA StyleFekiač, J., Gáborík, J., & Vojtkuliak, M. (2021). Properties of Plywood Made from Perforated Veneers. Forests, 12(12), 1709. https://doi.org/10.3390/f12121709