Abstract

Tree peony is a deciduous shrub endemic to China, and peony seed oil (PSO) is an important plant oil resource. However, at present, pruning and fruits harvesting of oil tree peony are mainly completed by manual work, which has seriously affected production efficiency. By the need to develop efficient pruning and harvesting equipment for oil tree peony, this study investigated the effect of cutting tool geometric parameters and cutting speed on cutting force and energy. A cutting device was set up, and six cutting tools with different blade angle and sliding-cutting angle were prepared for this research. Stems in different growth stages (anthesis and fructescence) were collected for cutting experiments. In this paper, four blade angles (25°, 30°, 35°, and 40°), three sliding-cutting angles (0°, 10°, and 20°), and four cutting speeds (25 mm/min, 50 mm/min, 100 mm/min, and 200 mm/min) were considered in the experiments. The results showed that cutting force and energy are positively related to blade angle, and the minimum cutting force and energy are required in cutting with 25° blade angle. Compared to straight cutting (sliding-cutting angle is 0°), sliding cutting can obviously reduce the cutting force and energy. Furthermore, the best sliding-cutting angles of cutting tools have discrepancies dependent on the stems in different growth stages. In fructescence, 10° sliding cutting required the lowest cutting force and energy. In contrast, the best sliding-cutting angle of stems in anthesis was 20°. On the other hand, the cutting force and energy were obviously proportional to the cutting speed, which increased by the cutting speed increasing. Therefore, under the condition of ensuring the cutting efficiency, reducing the cutting speed can effectively reduce the power consumption. These results are an important basis for pruning and harvesting machine development for oil tree peony.

1. Introduction

Tree Peony, which belongs to Paeoniaceae, genus Paeonia, and Sect. Moutan DC, is a woody deciduous shrub endemic to China, since the Eastern Jin Dynasty [1]. Its fruit contains dark oval seeds characterized by various unsaturated fatty acids (UFAs) and a high proportion of n-3 fatty acids [2]. Therefore, in addition to being an ornamental plant, peony is being widely promoted as an oil crop. Peony seed oil (PSO) was declared as a new resource food for its high level of α-linolenic acid (ALA) in China from 2011. In the past few years, tree peony has been considered as an economic plant, and some species (such as Paeonia rockii, and Paeonia ostii) are widely planted in China, with a potential annual seed production of 60,000 tons in the next decade [3,4]. The key to increase the output of PSO is to prune branches reasonably in the growing process and to harvest fruits in time during the fructescence. The major challenge for the industrialization development of PSO is the development of pruning machines and fruit harvesting machines [5,6]. Research and development of this equipment needs to be based on research of stem cutting mechanisms.

As a kind of perennial deciduous shrub, studies on peony stem are still very scarce, although recent research on the mechanical properties of wood materials has been relatively sufficient [7]. The planting and growth characteristics of deciduous shrub determine that the pruning and harvesting equipment are different from the general forestry machines [8]. At present, although there are few studies on the cutting of peony stems, the research on shrub cutting is widely used in biomass energy, such as Salix psammophila [9]. Research shows that the quality of shrub cutting directly affects the cost of biomass direct combustion power generation [10,11]. These researches investigated the influence of various factors such as tree species, cutting tool angles, and cutting speed on shrub cutting [9,12].

In general, plant and wood materials are viscoelastic; therefore, they possess no strictly defined relationship between stress and deformation [13]. Wood materials have different responses under dynamic or static loading and also under tensile or compressive force [14]. Cutting of the plant stem is a dynamic process containing multiple forms of tissue failure and deformation. During the cutting process, significant localized plastic deformation caused by initial knife penetration occurs in the contact part between the stem and the knife, followed by buckling and deformation as the knife advances [15]. As the cutting tool continues to advance, the fibers in the stem are deflected and eventually fail in tension [16].

Many studies have investigated the effect of cutting speed on cutting force and energy, and relevant studies are briefly summarized here. For maize stem cutting, Prasad and Gupta reported a distinct minimum energy requirement was found at a cutting velocity of 2.65 m/s [17]. This was not the case for forage grasses, where the cutting energy monotonically decreased with cutting speed [18]. The cutting energy required to cut sorghum stems showed a minimum at 2.9 m/s cutting speed and it increased as the cutting speed increased above 2.9 m/s [19]. O’Dogherty and Gale found that the critical cutting speed for grass was 25–30 m/s, and lower speed resulted in large stem deflections and higher stubble heights [20]. Dauda reported that for kenaf-stem, high cutting speeds as compared to impact cutting system at similar speeds required less cutting force and energy [21].

Many other studies examined the effect of blade angle and blade design on the stem cutting. The cutting force required for cutting sugarcane stem depended on the blade design, and a difference of 26% was reported between the two designs tested [22]. A study of corn stalk cutting showed that a cutting blade oriented parallel to a stalk (0°) compared to perpendicular (90°) resulted in a significant reduction in the specific cutting energy to one-tenth for internodes and about one-fifth for nodes [23]. A study of energy cane stems illustrated that a straight cut required more cutting force and energy than a 60° oblique cut [24]. Zhang reported that the cutting stress of millet stem was decreased with the increase of blade oblique angle, but the cutting energy was decreased firstly and then increased [25].

The analysis of literature surveyed indicates that cutting speed and tool geometric parameters play key roles in the tree peony stem cutting process. However, according to recent studies, the effects of these parameters on different plant material cutting are not uniform or regular. The effect of cutting speed on cutting force and energy could be opposite due to the different stems, and the best blade angle and sliding-cutting angle of different stems are not the same. Therefore, in order to provide basis for the design of pruning and harvesting machines, oil tree stems in anthesis and fructescence were collected for a cutting experiment. The objectives of this paper were to investigate the effect of blade angle, sliding-cutting angle, and cutting speed on the cutting force and energy required for stem cutting. This study will provide proofs of cutting tool and cutting parameters of oil tree peony and other similar shrubs cutting.

2. Materials and Methods

2.1. Preparation of Stem

The stems used for this study were collected from the same kind of tree oil peony plants (Paeonia rockii) that were planted in the same field in the peony garden of Jiufeng National Forest Park, Haidian District, Beijing. All these stems were collected from 15 oil peony plants with similar growth state. Stems with good growth and no mechanical damages were selected randomly from the plants and cut from about 50 cm below to the top. Then, leaves and side branches on the stem were removed, and each stem was cut into 12–15 cm.

For tree peony, pruning and harvesting are in different growth stages, so it is necessary to study the cutting performance of stem in different growth stages. Therefore, in this experiment, stems in anthesis and fructescence (in the same year) were collected and cut by the same cutting tools, which can be seen in Table 1.

Table 1.

Preparation of oil tree peony stem.

2.2. Stem Cutting Experiment

2.2.1. Cutting Device and Cutting Tools

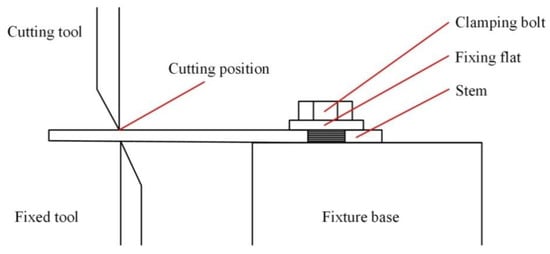

A cut device including the fixture base and the cutting tool was set up for this experiment and installed on an electronic universal testing machine (Figure 1). A tool carrier was linked on the loader of the testing machine that can install and freely replace different tools with different geometric parameters. During the cutting experiment, the impact force to the cutting tool was provided through the loader by the test machine and controlled on a computer.

Figure 1.

Shear device set up for the experiment.

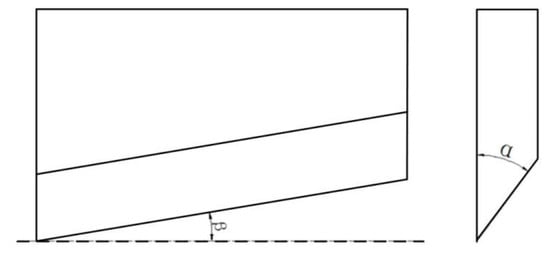

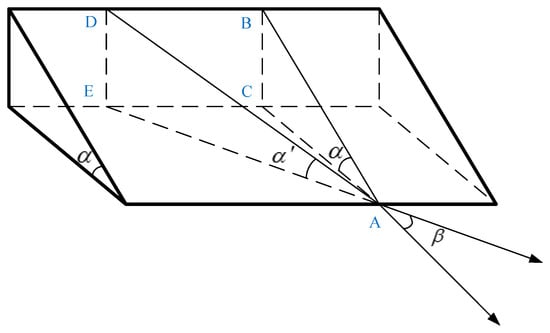

Cutting tools with different geometric parameters, including blade angle and sliding-cutting angle, were designed for this experiment. Figure 2 shows the geometric parameters of tools in this paper (α = blade angle; β = sliding-cutting angle). Six cutting tools were manufactured for this research with different blade angles and sliding-cutting angles, which can be seen in Table 2.

Figure 2.

Geometric parameters of cutting tool (α = blade angle; β = sliding-cutting angle).

Table 2.

Geometric parameters of cutting tool.

For investigating the effect of blade angle and sliding-cutting angle of tools on cutting force and energy, 8 stems in each growth stage with very similar average diameter (about 5 cm) were cut by every tool in the experiment. Cutting speed was set to the same 25 mm/min and the average value of maximum cutting force of each stem was calculated after the test.

2.2.2. Cutting Speed

Relevant research shows that cutting speed has a significant effect on stem cutting. In some research, self-made cutting devices were used to study the dynamic mechanical properties of different materials and the influence of cutting speed on cutting force and energy. Other studies of the dynamic properties of woods under different strain rates by changing the test strain rate (for example, using separate Hopkinson bar [26]) showed that strain rate effect is the main reason for the change of material strength under different loading rates [27].

In this paper, cutting speed was considered as an important factor, and its specific effect on cutting force and energy of oil tree peony is not clear. For testing the effect of cutting speed, four speeds (25 mm/min, 50 mm/min, 100 mm/min, and 200 mm/min) were set in the experiments by using three different cutting tools, as shown in Table 3. In each group of tests, 8 stems in fructescence were cut and the average value of maximum cutting force was calculated.

Table 3.

Cutting experiment with different cutting speed and cutting tool.

2.2.3. Experiment Process

At the beginning of the cutting test, the stem was fixed on the fixture base and covered with fixing flat on the one side, and the length of the extension side should be 10 cm, as shown in Figure 3. During the experiment, cutting position of each stem should be consistent at 2 cm from the end of the extension side, which can be seen in Figure 3.

Figure 3.

Schematic diagram of stem fixing in the cutting experiment.

Cutting force was loaded by the testing machine and cutting process was controlled by computer. The cutting force and tool displacement during the process was measured by the sensor of the loader on the testing machine, and the cutting energy can be determined as:

where = cutting energy (mJ); S = tool displacement (mm); = force applied by testing machine; = tool displacement when contact with the stem at the first time (mm); and = tool displacement when cut off the stem.

3. Results

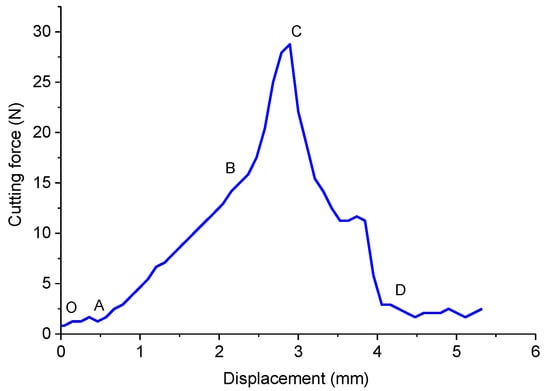

3.1. Cutting Force

A force-displacement curve was recorded in each test, and Figure 4 shows an example. As can be seen, point O represents the beginning of the cutting and point D represents the displacement of the tool during the whole cutting process. The process can be divided into the following stages: (1) elastic deformation stage (OA), where cutting force is increasing slowly; (2) plastic deformation stage (AC), where the cutting tool penetrates the stem and results in localized plastic deformation, and the cutting force is increasing obviously; and (3) stem breaking stage (CD), where the stem has broken into two pieces, and the cutting force decreases immediately to near zero.

Figure 4.

Force-displacement curve of stem cutting.

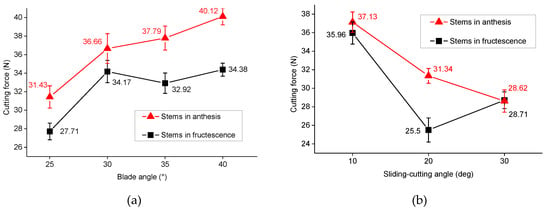

Figure 5a shows the average cutting force with different blade angle of the cutting tool. For stems in anthesis and fructescence, both the average cutting force increased with the increasing of blade angle. It is well pronounced that the smaller blade angle can reduce the cutting force when cutting the stem. In this experiment, cutting with 25 blade angle required the lowest average cutting force: 27.71 N in fructescence and 31.43 N in anthesis. For the discrepancy of growth stages of the stem, it can be found obviously that stems cut by the same tool in anthesis required higher cutting force.

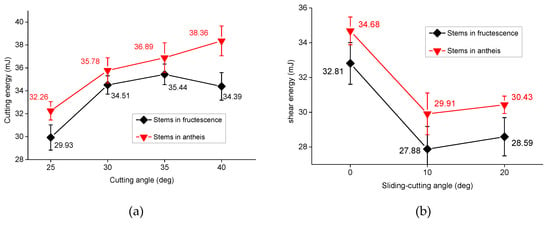

Figure 5.

Effect of cutting tool geometric parameters on cutting force: (a) effect of blade angle; (b) effect of sliding-cutting angle.

The effect of sliding-cutting angle on cutting force is illustrated in Figure 5b. As can be seen, the cutting force can be reduced more obviously in sliding cutting than in straight cutting. For both the stems in anthesis and fructescence, the maximum cutting force was required for the straight cutting (0° sliding-cutting angle). It can also be concluded from the figure that stems in different growth stages have different cutting properties. For stems in anthesis, the least average cutting force was required when cutting with 20° sliding-cutting angle. However, for stems in fructescence, cutting with 10° sliding-cutting angle required the lowest cutting force.

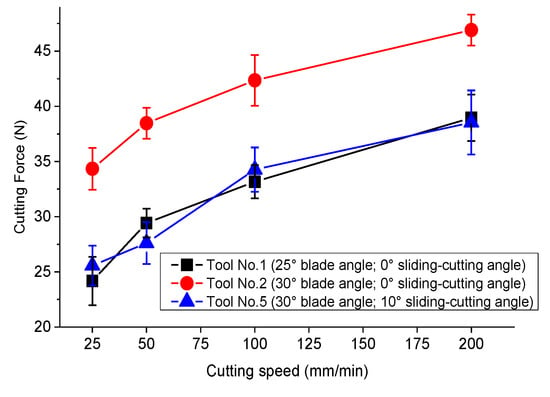

The effect of cutting speed is shown in Figure 6. In general, as cutting speed increased more cutting force was required. The average cutting force of all three tools increased more than 30% as the cutting speed increased from 25 mm/min to 200 mm/min. The 30° straight cut at 200 mm/min required the highest cutting force. The result obviously showed that cutting with lower speed can reduce the required cutting force.

Figure 6.

Effect of cutting speed on cutting force.

3.2. Cutting Energy

To calculate the cutting energy in the cutting experiment, the data in the force-displacement curve (Figure 4 shows an example) of every stem was used in Equation (1). An average value of each test was calculated, and the result are shown in Figure 7.

Figure 7.

Effect of cutting tool geometric parameters on cutting energy: (a) effect of blade angle; (b) effect of sliding-cutting angle.

The effect of blade angle on cutting energy is shown in Figure 7a. Similar to cutting force, with the increase of blade angle, the average cutting energy increased significantly. For both the stems in anthesis and fructescence, cutting with the 25° blade angle required the lowest cutting energy: 32.26 mJ in anthesis and 29.93 mJ in fructescence. Moreover, it can be found from the figure that the average cutting energy of stems cutting in anthesis is significantly higher than that in fructescence. It can be concluded that cutting power consumption can be effectively reduced by reducing cutting edge angle.

The effect of sliding-cutting angle is shown in Figure 7b. As can be seen, it is well pronounced that sliding cutting required less cutting energy than straight cutting (0° sliding-cutting angle). As the same situation in cutting force test, cutting the stems in anthesis required higher cutting energy than stems in fructescence. Furthermore, both for the stems in anthesis and fructescence, 10° sliding cutting was the best parameter for energy saving.

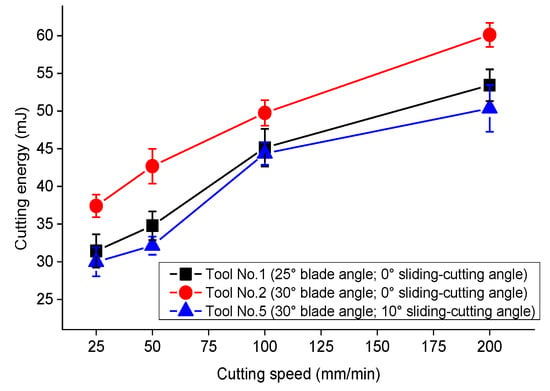

The effect of cutting speed is shown in Figure 8. As can be seen, cutting energy is positively correlated with cutting speed. For all three tools, cutting with 10° sliding-cutting angle and 30° blade angle required the lowest average energy, and cutting with 25 mm/min required the lowest cutting energy. In general, increasing cutting speed will significantly increase cutting power consumption.

Figure 8.

Effect of cutting speed on cutting energy.

4. Discussion

4.1. Theoretical Analysis of Cutting Tool Geometric Parameters

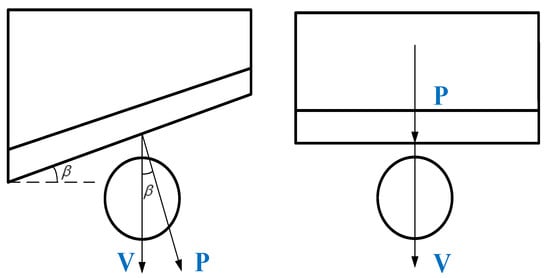

In this study, two geometric parameters of tool were considered: blade angle and sliding-cutting angle. The results of cutting experiments showed these parameters have a significant influence in stem cutting. For the sliding-cutting angle of the cutting tool, as shown in Figure 9, the cutting process will become sliding cutting when the sliding-cutting angle is not 0° and straight cutting when the sliding-cutting angle is 0°.

Figure 9.

Sliding cutting and straight cutting.

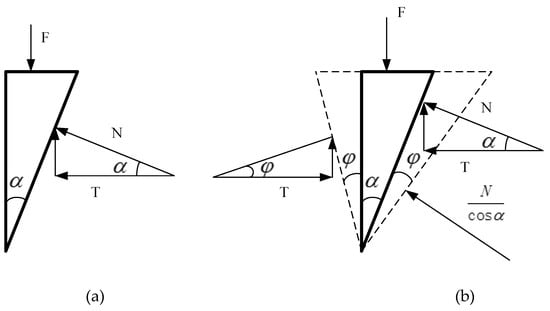

Some research has reported that sliding cutting needs lower cutting force compared to straight cutting, which is mainly because the sliding cutting has smaller effective blade angle [28,29]. As shown in Figure 10, a cutting tool with the blade angle is and the sliding cutting angle is , the effective blade angle () in sliding cutting can be calculated as:

Figure 10.

Sliding cutting and straight cutting.

It can be concluded from Equation (2) that is smaller than (0° to 90°), and the effective blade angle will decrease with the increasing of sliding cutting angle. During the sliding cutting process, although the actual blade angle (design blade angle) of the cutting tool is , the effective cutting blade angle becomes , which is obviously less than . Therefore, in the cutting process, it is equivalent to cutting with a sharper cutting tool, which can significantly reduce the cutting force. However, too large sliding cutting angle will result in increasing of cutting force, which means it is necessary to find out the best angle for each specific material.

According to the researches of the analysis of cutting force during the cutting process, the test results [29] of blade angle in this paper can be explained as follows. For the cutting force analysis, as shown in Figure 11a, it is assumed that the object to be cut is homogeneous and the micro unevenness of the tool surface is ignored. When the cutting tool cuts in a constant speed, without concern of friction, the cutting force (F) can be calculated as:

In Equation (3), T is the connecting force between the cutting surfaces (a force determined by the physical and mechanical properties of the object to prevent it from being cut off) [29], and N is the normal pressure on the cutting tool.

Figure 11.

Analysis of cutting force. (a) situation that ignored friction; (b) situation that considered friction.

Concerning friction, assume the friction factor between the cutting tool and object is f and define the friction angle as , which is equivalent to increasing the edge angle by a degree, as shown in Figure 11b. The cutting force (F) can be calculated as:

Define variable K as:

Then the Equation (5) can be changed into:

Because the value of T is only related to the properties of the material to be cut, the value under different blade angles () can be described as Equation (8):

From Equation (8) we can get:

It can be concluded from Equation (9) that the cutting force is positively related to the blade angle of the cutting tools. To reduce the cutting force, the blade angle should be as small as possible.

4.2. Cutting Tool Geometric Parameters in Shrub Cutting

It can be found that the results of experiments in this paper are consistent with the theoretical analysis results. In addition, research has reported the similar conclusion on geometric parameters of cutting tool in shrub cutting, such as salix psammophila [9] and chestnut logs [10]. From this paper and related studies [9,10,11,12], it can be concluded that, for shrub cutting, the geometric parameters of cutting tools have a significant effect on cutting force and cutting energy. Cutting with smaller blade angle can obviously reduce the required cutting force and energy consumption. Furthermore, in shrub stem cutting process, although the best sliding-cutting angle is different for different species, sliding cutting required the lower cutting force and energy than straight cutting. Sliding cutting can effectively reduce energy consumption in cutting process. Therefore, for shrub cutting, it is important to select the suitable blade angle and sliding cutting angle to improve efficiency and reduce power consumption.

In particular, for oil tree peony stem, based on the needs of pruning and harvesting operations, the different cutting mechanism of stems in different growth stages (anthesis and fructescence) should be considered in this study. The experiment results show that the best geometric parameters of cutting tools used for oil tree peony stem cutting are different for different growth stage of stems. For stems in anthesis, the best sliding-cutting angle is 20°, while the best sliding-cutting angle is 10° for stems in fructescence. Therefore, for pruning and harvesting machines, different cutters should be designed. Moreover, this study indicated the discrepancies of cutting properties of stems in different growth stages. These discrepancies are probably due to the changes of stem moisture content and microstructure in different growth stages. This should be considered in research of cutting mechanism of other shrubs and wood materials and needs further study.

4.3. About Cutting Speed

In this paper, cutting speed is considered to be an important factor affecting cutting force and energy of stem cutting. The result shows that the cutting force and energy are positively correlated with cutting speed. For cutting tools with different geometric parameters, the lowest cutting force and energy are required at the cutting speed of 25 mm/min, which should be the best cutting speed for saving energy. However, the lower cutting speed will reduce the production efficiency and the quality of the incision. Therefore, for cutting speed, it is important to reduce the cutting speed while ensuring the cutting efficiency to reduce the energy consumption.

Furthermore, the mechanism of the effect of cutting speed on cutting force and energy still lacks clear explanation, and some studies even showed the opposite effect of cutting speed on different plant stems. The further study found the microstructure of oil tree peony stem belongs to a typical porous cellular structure in terms of the form of tissue arrangement, and wood materials with the same microstructure have an obvious strain rate effect under dynamic loading. The study on spruce shows that the micro morphology of porous cell structure leads to the relationship between the macro dynamic mechanical properties and loading rate [30]. These studies indicated strain rate effect is the main reason for the increase of ultimate strength of materials with the increase of loading rate and that is considered the influence mechanism of cutting speed in shrub cutting and should be further studied.

5. Conclusions

The aim of this study was to examine the cutting mechanism of oil tree peony stems, which is the most important basis for pruning and harvesting machine development. Then, a cutting device was set up and used for oil tree peony stem cutting experiments. On the one hand, the result shows that the blade angle and sliding-cutting angle of cutting tool have an obvious effect on stem cutting. The experiment results showed cutting with 25° blade angle required lowest cutting force and energy. For stem cutting of shrubs like tree peony, both the cutting force and energy are positively related to blade angle. On the other hand, sliding cutting can effectively improve cutting efficiency and reduce power consumption. Moreover, especially for oil tree peony, the cutting properties show discrepancies in different growth stages. In general, cutting stems in anthesis required more cutting force and energy than in fructescence. For peony stems in anthesis, cutting with 25° blade angle and 20° sliding-cutting angle requires the lowest cutting force and energy. For stems in fructescence, cutting with 25° blade angle and 10° sliding-cutting angle requires the lowest cutting force and energy. These should be considered in cutting tool design for pruning and harvesting machines.

On the other hand, cutting speed has a significant effect on cutting force and energy, which were increased by the cutting speed increasing. In this paper, with the same cutting tool, cutting with 200 mm/min required the highest energy consumption. This characteristic is related to the strain rate effect and dynamic response in the process of plastic deformation of wood. The findings demonstrate that reducing cutting speed as possible will result in cutting energy savings under the premise of ensuring work efficiency. This study also further indicates the need to study the effect of internal factors, whether it is the same species or not, such as stem moisture content and microstructure on cutting properties.

Author Contributions

D.Z. and J.Z. conceived this study. J.L. proposed the experiment. J.L. and D.Z. conducted the experiments. J.L. wrote the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The study was supported by Fundamental Research Fund for the Central Universities (Grant No. 2015ZCQ-GX-02 and Grant No. 2018ZY08); Beijing Natural Science Foundation (Grant No. 20182045) and Key R & D and transformation in Qinghai Province (Grant No. 2019-NK-118).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sun, X.; Li, W.; Li, J.; Zu, Y.; Hse, C.; Xie, J. Process optimisation of microwave-assisted extraction of peony (Paeonia suffruticosa Andr.) seed oil using hexane-ethanol mixture and its characterisation. Int. J. Food Sci. Technol. 2016, 51, 2663–2673. [Google Scholar] [CrossRef]

- Su, J.; Ma, C.; Liu, C.; Gao, C.; Nie, R.; Wang, H. Hypolipidemic activity of peony seed oil rich in α-linolenic, is mediated through inhibition of lipogenesis and upregulation of fatty acid β-oxidation. J. Food Sci. 2016, 81, H1001–H1009. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Han, J.; Tian, F.; Tang, X.; Hu, Y.; Guan, Y. Chemical composition analysis, sensory, and feasibility study of tree peony seed. J. Food Sci. 2017, 82, 553–561. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, X.; Fang, Z.; Wu, Y.; Tao, J. Physiological and transcriptomic analysis of tree peony (Paeonia Section Moutan DC.) in response to drought stress. Forests 2019, 10, 135. [Google Scholar] [CrossRef]

- Zhang, D. Design and Implementation of Oil Peony Fruit Picking Device; Beijing Forestry University: Beijing, China, 2016. [Google Scholar]

- Zhang, Y. Design and Implementation of Self-Propelled Oil Peony Fruit Picking Machine; Beijing Forestry University: Beijing, China, 2017. [Google Scholar]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of physical and mechanical properties of unthinned and unpruned plantation-grown Eucalyptus nitens H.Deane & maiden lumber. Forests 2019, 10, 1949. [Google Scholar] [CrossRef]

- Felker, P.; McLauchlan, R.A.; Conkey, A.; Brown, S. Case study: Development of a swath harvester for small diameter (. Biomass Bioenergy 1999, 17, 1–17. [Google Scholar] [CrossRef]

- Fen, C.; Gao, Z.; Yu, G.; Liu, Y. Effect of cutting machine parameters on salix branch’s peak cutting force. J. For. Environ. 2019, 39, 107–112. [Google Scholar]

- Facello, A.; Cavallo, E.; Magagnotti, N.; Paletto, G.; Spinelli, R. The effect of chipper cut length on wood fuel processing performance. Fuel Process. Technol. 2013, 116, 228–233. [Google Scholar] [CrossRef]

- Abdallah, R.; Sébastien, A.; Pierre, J. Experimental study about the effects of disc chipper settings on the distribution of wood chip size. Biomass Bioenergy 2011, 35, 843–852. [Google Scholar] [CrossRef]

- Bello, S.R.; Onilude, M.A. Force relations and dynamics of cutting knife in a vertical disc mobile wood chipper. Leonardo Electron. J. Pract. Technol. 2011, 10, 17–34. [Google Scholar]

- Phillip, C.; Clairmont, L.; Sunil, K.; Tony, E.; Alan, C. Cutting energy characteristics of miscanthus x giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Sunil, K.; Tony, E.; Alan, C. Effect of blade oblique angle and cutting speed on cutting energy for energycane stems. Biosyst. Eng. 2015, 133, 64–70. [Google Scholar] [CrossRef]

- Persson, S. Mechanics of Cutting Plant Material; Asae Monograph No 7 (Book 7); American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1987. [Google Scholar]

- Srivastava, A.; Goering, C.; Rohrbach, R.; Buckmaster, D. Hay and forage harvesting. In Engineering Principles of Agricultural Machines, 2nd ed.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; pp. 325–402. [Google Scholar]

- Prasad, J.; Gupta, C. Mechanical properties of maize stalk as related to harvesting. J. Agric. Eng. Res. 1975, 21, 79–87. [Google Scholar] [CrossRef]

- McRandal, D.; McNulty, P. Impact cutting behaviour of forage crops. J. Agric. Eng. Res. 1978, 23, 313–328. [Google Scholar] [CrossRef]

- Yiljep, Y.; Mohammed, U. Effect of knife velocity on cutting energy and efficiency during impact cutting of sorghum stalk. Agric. Eng. Int. CIGR J. 2005, 8, 493–512. [Google Scholar]

- O’Doghekty, M.; Gale, G. Laboratory studies of the effect of blade parameters and stem configuration on the dynamics of cutting grass. J. Agric. Eng. Res. 1991, 49, 99–111. [Google Scholar] [CrossRef]

- Dauda, S.; Ahmad, D.; Khalina, A.; Jamarei, O. Effect of cutting speed on cutting torque and cutting power of varying kenaf-stem diameters at different moisture contents. Trop. Agric. Sci. 2015, 38, 549–561. [Google Scholar]

- Taghijarah, H.; Ahmadi, H.; Ghahderijani, M.; Tavakoli, M. Cutting forces and energy during an impact cut of sugarcane stalks. Aust. J. Crop Sci. 2011, 5, 630–634. [Google Scholar] [CrossRef]

- Clementson, C.; Hansen, A. Pilot study of manual sugarcane harvesting using biomechanical analysis. Trans. ASABE 2008, 14, 309–320. [Google Scholar] [CrossRef]

- Igathinathane, C.; Womac, A.; Sokhansanj, S. Corn stem orientation effect on mechanical cutting. Biosyst. Eng. 2010, 107, 97–106. [Google Scholar] [CrossRef]

- Zhang, Y.; Gui, Q.; Guo, Y. Experiment and analysis of cutting mechanical properties of millet stem. Trans. Chin. Soc. Agric. Mach. 2019, 50, 146–155,162. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Almusallam, T.; Ibrahim, S.; Abbas, H.; Alsayed, S. Rate dependent behavior and modeling of concrete based on shpb experiments. Cem. Concr. Compos. 2015, 55, 34–44. [Google Scholar] [CrossRef]

- Oudjene, M.; Khelifa, M. Elasto-plastic constitutive law for wood behaviour under compressive loadings. Constr. Build. Mater. 2013, 11, 3359–3366. [Google Scholar] [CrossRef]

- Pan, S. On the theory of sliding cutting and the choice of its angle. J. Huazhong Agric. Coll. 1982, 6, 64–69. [Google Scholar] [CrossRef]

- Xun, H. Research of the theory of sliding cutting. Trans. Chin. Soc. Agric. Mach. 1979, 10, 107–111. [Google Scholar]

- Zhong, W.; Den, Z.; Huang, X. Investigation on Anisotropic Behavior of Spruce Mechanical Properties Under Medium Strain Rate Loading Conditions. Eng. Mech. 2016, 33, 25–32. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).