Abstract

In Estonia, hardwoods form approximately 50% of all forest area, where the main species are birch (30%), gray alder (9%), aspen (6%) and black alder (4%). Birch has been extensively used by the veneer-based industry, but species like black alder, gray alder and aspen have not been commonly used by the veneer-based products industry due to the lower quality of this resource. The aim of this research is to determine the effect of different lay-up schemes and usages of gray alder, black alder and aspen on the mechanical properties of plywood, by replacing birch veneer in the plywood core with alternative wood species. The main veneer and plywood characteristics will be evaluated according to the current standards, e.g., veneer strength perpendicular to grain, plywood bonding and bending strength, and modulus of elasticity. All processing parameters will be kept similar to those used generally by birch plywood manufacturers. The results showed that birch and black alder plywood panels had generally the highest bending strength properties, followed by grey alder and aspen. It was also found that, for proper gluing, birch veneers had the lowest glue consumption, 152 g/m2, and aspen had the highest glue consumption, 179 g/m2. It was found that when lower density wood was used in the plywood, the product density increased. Low density wood veneers had higher glue consumption, and also higher compaction in thickness than birch veneers under the same pressure. Overall, it was shown that the wood species used in this study have slightly lower strength properties, but with proper lay-up schemes, these wood species could be successfully used by the veneer-based products industry.

Keywords:

plywood; lay-up; birch; grey alder; black alder; aspen; density; bonding strength; bending strength 1. Introduction

In northern Europe, the veneer-based industry plays an important role in the sustainable usage of wood from hardwood species. With the latest concerns about climate change, the focus also falls onto underused and low-quality wood species in Europe. In Estonia, hardwoods form approximately 50% of all forest area, where the main species are birch (30%), gray alder (9%), aspen (6%) and black alder (4%) [1]. The total amount of hardwood harvested in Estonia by wood species is the following: birch, 2,693,000 m3 (22.9%); grey alder, 675,000 m3 (5.8%); black alder, 712,000 m3 (6.1%); and aspen, 660,000 m3 (5.6%) [2]. In the case of birch, this opportunity has been noticed, and the effect of its usage on the climate, by the forest-based industry sector, has been evaluated [3]. Birch has also been extensively used by the veneer-based products industry, but wood species like black alder, gray alder and aspen have not been commonly used in plywood products. The reason is not only the availability, but also the lower quality of this resource [4]. On the other hand, the price of birch logs is rather expensive compared to these alternative species, which commonly have comparable mechanical properties. However, these hardwood species also contain tension wood [5,6], false heartwood, etc., which decreases the economical usability of this wood material, and affects the quality of obtained products [7].

In the veneer-based product industry, raw material will go through different processing stages, e.g., log soaking, veneer peeling and drying, which all have effects on the obtained veneer’s properties and final product quality. It is shown that birch wood processing for veneer-based products affects birch wood’s physical [8,9] and chemical properties ([10,11,12]), as well as on lathe checks development [13], the integrity of veneer [14], and finally on the bonding quality ([15,16]) and mechanical properties of veneer-based products [17]. However, similar comprehensive knowledge regarding the effect of processing on alder spp.’s and aspen’s veneer quality for the veneer-based industry is not available. Moreover, there are only a few studies on the different lay-up schemes, mainly for birch and softwood plywood, which could be an optimal way to enhance plywood panels’ mechanical properties for special applications [18,19]. However, combinations of different hardwood species in one plywood panel are rare. The above-mentioned optimization could be achieved without any significant changes in the current technology or the processing parameters in plywood factory.

The aim of this research is to determine the effect of different lay-up schemes and usages of gray alder, black alder and aspen on the plywood’s mechanical properties, by replacing birch veneer in the plywood core with alternative wood species. The main veneer and plywood characteristics will be evaluated according to current standards, e.g., veneer strength perpendicular to grain, plywood bonding and bending strength, and modulus of elasticity. All processing parameters will be kept similar to those generally used by birch plywood manufacturers. Hence, this could allow veneer-based industries to use these results without significant changes in current technology or processing parameters.

2. Materials and Methods

2.1. Wood Species and Plywood Lay-Up Schemes

In this study four different wood species were used to produce the plywood: birch (Betula pendula Roth, density of 640 kg/m3), grey alder (Alnus incana L, density of 467 kg/m3), black alder (Alnus glutinosa L., density of 495 kg/m3) and aspen (Populus tremula L., density of 466 kg/m3) [20,21,22,23]. All logs were freshly felled in March, 2019, at Piirsalu, Lääne County, Estonia, by State Forest Management Centre. Grey alder and black alder trees were cut into logs with nominal length of 2.7 cm, and for birch and aspen a length of 3.2 m. Logs with quality classes B and C [24] were randomly selected for the research. The weighted (by area) average stand age of the birch trees was 81 years, grey alder 55 years, black alder 70 years and aspen 74 years. The average diameters of logs peeled in this study were measured from both ends of the peeler logs, average diameter was calculated and results were as follows: birch 25 cm, grey and black alder 20 cm and for aspen 40 cm. The average width of the annual growth rings for birch was 1.7 mm, grey alder was 3.2 mm, black alder was 2.7 mm and aspen was 4.7 mm. Logs were brought to the TalTech Laboratory of Wood Technology and kept in the same log yard before processing. Thanks to the prevailing climatic conditions (temperature around 0 °C, high relative humidity of the air was between 70% and 90%) it was possible to keep the wood in a wet condition, free of end checks.

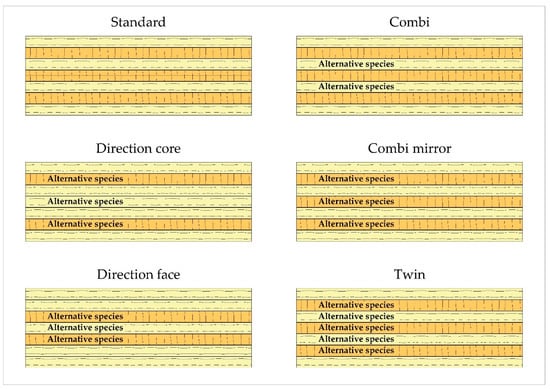

Plywood lay-up schemes were made using either only birch veneers, or placing between birch face veneers other hardwood species in the core, for the same lay-up scheme. Six different layups were used: standard, combi, combi mirror, twin, direction face and direction core. Description of the lay-up schemes is given inTable 1 and Table 2 and on Figure 1. Plywood products were chosen so that it would be possible to compare birch face veneer lay-ups with different species in the core to birch plywood. Plywood lay-up schemes standard, combi, combi mirror and twin all have the same construction, varying only in wood species. Plywood lay-up schemes’ direction face and direction core have the same number of veneers in the same direction, which only changes when it is in the core or on the face layers.

Table 1.

Veneer colors in lay-up.

Table 2.

Plywood lay-up samples.

Figure 1.

Plywood lay-up schemes, where the main wood species used is birch and the alternative wood species are grey alder, black alder or aspen.

2.2. Plywood Processing

Birch, grey alder and black alder logs from the log-yard were cut into peeler blocks nominally 1.4 m in length, and then completely immersed into water tanks at 40 °C for 24 h. As aspen wood is very soft it does not need soaking, therefore the aspen logs were peeled without soaking and directly brought from the log-yard. After soaking, the logs were debarked with the debarking knives to remove any foreign objects like sand and soil, which get stuck on the log surface in the bark and may dull the peeling knife. Subsequently, the logs were rotary peeled on an industrial scale lathe, manufactured by the Raute Corporation (Model 3HV66; Raute Oyj, Lahti, Finland), into veneer with nominal thickness of 1.5 mm. Peeling speed was 60 m/min, knife angle 21° and compression rate 10%. After peeling, the veneers were visually graded. The whole veneer ribbon was used for plywood making and the leftover from the peeling was 70 mm from the center of the wood trunk. Veneers were characterized by the presence of the lathe checks, which appeared on the side where the peeler knife had cut. The depth of the lathe checks directly affected the quality of veneers. The veneer side where the lathe checks appear is called loose side, and the side without lathe checks is called the tight side. Then the veneer mat was cut into sheets with dimensions of 900 mm by 400 mm using the guillotine. Veneer sheets where dried to target moisture content of 4.5% ± 1.5% in a laboratory scale veneer dryer (Raute Oyj, Lahti, Finland) at 180 °C, where humidity inside the dryer was 500–600 g/kg. After drying, the veneers where conditioned at relative humidity of 20% and temperature of 20 °C in order to maintain the target moisture content.

The plywood was bonded with commercially available (Prefere Resins Finland Oy, Hamina, Finland) phenolic (PF) adhesive consisting of liquid phenol-formaldehyde resin (Prefere 14J021) with solids content of 49%. The adhesive was spread (average glue spread of 160 g/m2) on the veneers with the roller glue spreader (Black Brothers. Co., Mendota, IL, USA). For each plywood sample, the veneers were selected randomly. After lay-up, the 7-ply plywood panels with nominal thickness of 9 mm were produced with laboratory hot press at temperature of 130 °C for 7 min. Pressure was controlled automatically and the pressing cycle was as follows: 1 min—1.8 MPa, then 5 min—1.4 MPa, and then 1 min—0.4 MPa. The panels where then conditioned at 20 °C and 50% relative humidity for one week before machining the specimens. Altogether 4 panels were made from each sample.

2.3. Analysis Methods

2.3.1. Veneer Crosswise Tensile Strength

To determine the crosswise tensile strength of veneers, 12 test specimens were cut from each species. The test was carried out based on the standard GOST 20800-75, but following the Finnish and Estonian plywood company method in terms of specimen size. Test specimens were cut with a clipper from different veneer sheets into sizes 50 × 150 mm. The test was conducted on a universal testing machine (Instron 5866). The distance between clamps was 50 mm and test speed was 2 mm/min. Prior to testing, the test specimens were conditioned at 20 °C and 50% relative humidity.

2.3.2. Density

The density of plywood panels was measured according to standard EN 323:2002. Length, width and thickness measurements were taken with a sliding caliper, with accuracy of 0.01 mm. Test specimens were weighed on balance, with accuracy of 0.001 g. The test specimens were cut to a square shape, with nominal side length 50 mm. Altogether, eight samples from each plywood board were tested. For constant mass, the test specimens were conditioned in an atmosphere with a relative humidity of 50% and a temperature of 20 °C.

2.3.3. Plywood Bond Strength

Plywood bond quality was tested according to standards EN 314-1:2005 and EN 314-2:1999, class 2 (soaking in water at 20 ± 3 °C for 24 h, followed by immersion in boiling water for 6 h, after that cooling at 20 ± 3 °C for 1 h). The plywood specimens were then tested with a universal testing machine (Instron 5866) at room temperature (20 °C) and 50% humidity. The test speed was set to a constant rate of 2 mm/min. At least 10 specimens from each plywood panel were tested.

2.3.4. Plywood Bending Properties

Plywood bending properties were tested according to the EN 310:2002 with the universal testing machine (Instron 5866) at room temperature (20 °C) and 50% humidity. Bending strength and modulus of elasticity (MOE) were calculated. Test speed was set to a constant rate of 15 mm/min. At least 10 specimens from each plywood panel were tested.

2.3.5. Data Analysis

In all conducted tests, the significance of the differences between the means of the different groups was evaluated by analysis of variance (ANOVA). The differences among means were segregated and compared by Tukey’s test (p < 0.05). The linear correlations were determined based on the standard Pearson’s method. Statistical analysis of the results was conducted with Statistix 10 (Analytical Software, Tallahassee, FL, USA).

3. Results

3.1. Veneer Crosswise Tensile Strength

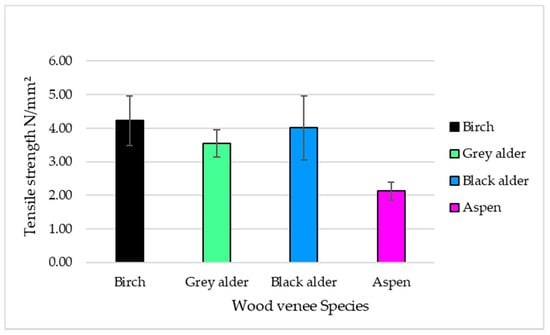

The veneer crosswise tensile strengths results are in correlation with the wood species’ densities and strength properties, according to previous researchers ([22,23,24,25]). In Figure 2, it can be seen that aspen had the lowest test results, followed by grey alder. The lowermost tensile strength for aspen was 1.68 N/mm2 and highest tensile strength was 2.52 N/mm2. The results for grey alder were 2.78 and 4.41 N/mm2, correspondingly. The highest variation of test results was found in black alder, which had a lowest result of 1.73 N/mm2 and a topmost result of 5.09 N/mm2. Birch had the tensile strength results of 2.93 N/mm2 and 5.60 N/mm2, respectively. However, according to ANOVA, only aspen had a statistically significantly different tensile strength compared to other wood species.

Figure 2.

Crosswise tensile strength of different wood species veneers.

3.2. Density

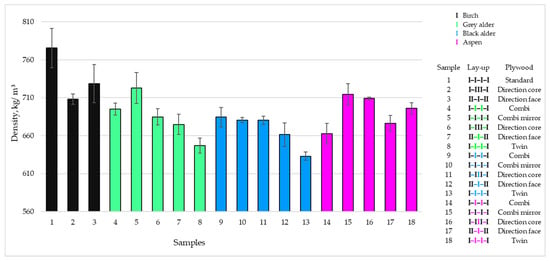

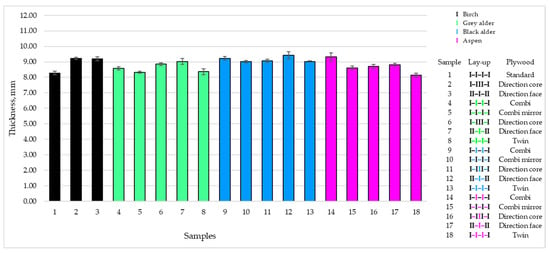

In the Figure 3 and Figure 4, it is shown that the thickness of the plywood panel decreases when using lower density wood species in the plywood core. The results showed that the highest density products have the lowest thickness, and vice versa. In this research, the lowest thickness, on sample 18, is placed in seventh position with regards to highest densities. All the veneer sheets of the different species underwent the same conditions concerning the gluing process. The results are shown in Table 3, where birch has the lowest glue consumption, with 152 g/m2, alder veneer had the glue consumption around 160 g/m2, and aspen had 18% higher glue consumption, with 179 g/m2. The density measuring results showed that the combi mirror lay-up scheme (samples 5, 10 and 15) gave the highest density for the plywood combined with different wood species. The lowest density was achieved with the twin lay-up scheme (samples 8, 13), where higher amounts of lower density wood species were available. Statistical analysis of the results showed that there are three (3) density groups, in which the means are not significantly different from one another. The first group is formed from plywood made solely from birch veneers (standard layup scheme), and has the highest density. The second group is formed from all the other lay-up schemes, and the third group is formed from the twin lay-up scheme, which has the lowest density.

Figure 3.

Plywood densities by wood species and lay-up schemes.

Figure 4.

Plywood thicknesses by wood species and lay-up schemes.

Table 3.

Veneer glue consumption of different wood species.

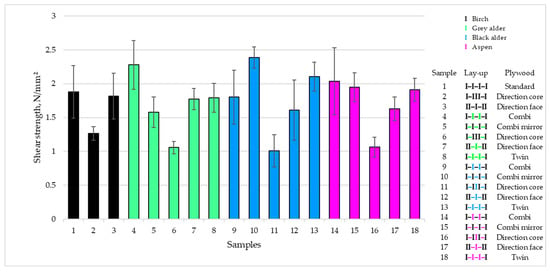

3.3. Bonding Quality

As shown by the results in Figure 5, the best shear strength (2.39 N/mm2) was achieved by the combi mirror samples combining the birch and black alder wood veneers (sample 10). Almost all of the lowest results in the groups of species came from the lay-up with direction core. As all the bonding quality tests were performed on the middle layer, the direction core was the only lay-up scheme wherein the glue line was pulled between layers that were parallel to each other. For all the specimens, wood fiber failure was determined to an accuracy of 10%. Starting from the lowest, the wood fiber failure outcomes were: 43.3% for black alder, 46.3% for birch, 61.8% for aspen and 79.8% for grey alder. According to these results, grey alder showed very good bonding with PF glue, followed by aspen. Black alder and birch were on the same level. While aspen had higher glue consumption and shear strength, its apparent cohesive wood failure was also higher. The results showed that the best bonding quality was achieved with the combi, combi mirror and twin lay-up schemes with all the wood species, which, according to ANOVA analysis, are not significantly different from each other. However, the lay-up scheme using the direction core showed the lowest values, and it was statistically significantly different from the other lay-up schemes used in this study.

Figure 5.

Plywood shear strength by wood species and lay-up schemes.

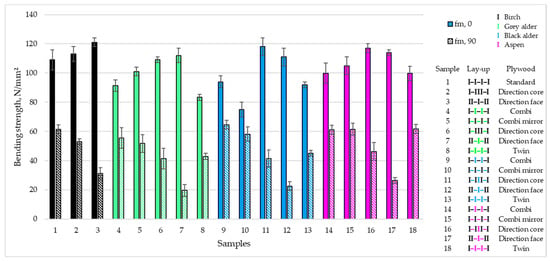

3.4. Bending Properties

The bending test results showed that the lowest bending strength (fm) values were obtained in the crosswise direction [see Figure 6 (fm, 90)], and they belong to the direction face lay-up samples (31.1 N/mm2 for birch, 19.5 N/mm2 for grey alder, 22.5 N/mm2 for black alder and 26.4 N/mm2 for aspen). In the parallel direction [see Figure 6 (fm, 0)], birch sample 3 had the highest bending strength with the direction face lay-up (121 N/mm2). The highest compressive extension came from the same sample in a crosswise direction: 29.4 mm (Figure 6). Despite high compressive extension in the crosswise direction, sample 3 is placed in 15th position out of 18 according to its bending strength in this direction. In the crosswise direction (Figure 6), the combi plywood lay-up sample 9, with birch and black alder, had the highest bending strength (64.6 N/mm2). In the parallel direction, the average bending strength results are: 99.3 N/mm2 for grey alder, 98.0 N/mm2 for black alder, 107.1 N/mm2 for aspen and 114.3 N/mm2 for birch. In the crosswise direction, the average bending strength results are: 42.2 N/mm2 for grey alder, 46.3 N/mm2 for black alder, 51.4 N/mm2 for aspen and 48.5 N/mm2 for birch.

Figure 6.

Plywood bending strength by wood species and lay-up schemes in parallel (fm, 0) and crosswise (fm, 90) wood grain directions.

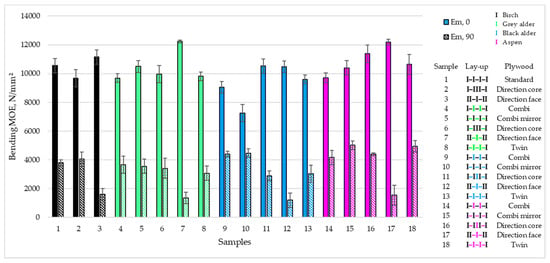

The same as with the bending strength results, the four lowest results for modulus of elasticity [MOE (Figure 7)] belong to the crosswise direction face lay-up (1614 N/mm2 for birch, 1361 N/mm2 for grey alder, 1206 N/mm2 for black alder and 1543 N/mm2 for aspen samples). In the parallel direction (Figure 7), the birch and grey alder plywood sample 7 had the highest bending MOE, with the direction face lay-up (12,239 N/mm2), while in the crosswise direction (Figure 7), the combi mirror plywood lay-up sample 15 and the twin lay-up sample 18, both with birch and aspen, had the highest bending MOE (5019 N/mm2 and 4937 N/mm2, respectively). In the parallel direction, the average bending MOE results are: 10,440.4 N/mm2 for grey alder, 9377.4 N/mm2 for black alder, 10,864.8 N/mm2 for aspen and 10,460.0 N/mm2 for birch. In the crosswise direction, the average bending MOE results are: 3010.8 N/mm2 for grey alder, 3201.8 N/mm2 for black alder, 4011.8 N/mm2 for aspen and 3157.7 N/mm2 for birch. The analysis of results based on the standard Pearson’s method shows that there is strong correlation between bending strength and MOE. The correlation coefficient in the parallel (fm, 0) wood grain direction was r = 0.77, and for the crosswise wood grain direction (fm, 90) it was r = 0.93.

Figure 7.

Plywood bending MOE by wood species and lay-up schemes in parallel (fm, 0) and crosswise (fm, 90) wood grain direction.

4. Discussion

The veneer crosswise tensile strengths were according to expectations, as birch had the highest tensile strength of the species and aspen the lowest. In addition, it was shown that grey alders tensile strength results were weaker than black alder’s. Black alder showed higher variation in crosswise tensile strength results. These higher variations in results may be due to the log and veneer quality. Previous studies have shown that the quality variation in these wood species is higher, and they might contain some quantity of false heartwood, which has different properties, e.g., density and higher moisture content [26]. Another explanation of the result variation could also be the different strength properties of the earlywood and latewood in the veneer yield, which have different strength properties.

One of the main reasons why some products have a higher density comes from its nature, as density is the ratio of mass to volume. All the plywood panels were pressed with the same pressing cycle and parameters. This means that veneers peeled from lower density wood species were more compressed than higher density wood species. The density results showed that highest density products have the lowest thickness, and vice versa. The analysis of results based on the standard Pearson’s method showed that the thickness and density of veneer panels are negatively correlated (r = −0.41). This can be explained via the densification effect of the low-density wood species, where the permanent deformation of wood cells occurs during the exertion of higher pressures [26,27,28,29]. Therefore, in panel number 18, the high density and low thickness were mainly caused by the five layers of low-density aspen veneer in the core of panel. Due to the compression of the low density aspen veneers, the overall density of the plywood increased due to the densification effect [27,30]. Another factor that influences the density of the plywood is the glue consumption of different wood species’ veneers. Increasing the glue consumption also increases the density of the plywood panel. The higher glue consumption is attributed to the surface roughness of the different wood species. This surface roughness affects the gluing, where greater surface roughness means the consumption of greater amounts of glue, which could therefore also affect bonding quality [30,31,32,33,34].

The bonding quality results showed (Figure 5) that all the plywood lay-up combinations passed the required 1 N/mm2 value, according to standard EN 314-2 (1999), which means there are no requirements for apparent cohesive wood failure [35]. This shows that all the combinations with lower density wood species bonded well. The best shear strength of sample 10 (combi mirror of birch and black alder) is because of the similar densities of birch and black alder wood, and the slightly higher glue consumption of the black alder veneers (Table 3), which all together gives the highest shear strength in this research. The same trend was seen with the combi plywood with grey alder (sample 4), where the higher glue consumption of grey alder veneers increased the plywood shear strength, and led to the second-best shear strength value of 2.28 N/mm2. The higher shear strength values of lower density wood species (black alder, grey alder and aspen) compared to birch can be attributed to the fact that they all achieved higher glue consumption than birch. Previous research has also stated that lower density wood needs more adhesive to glue [36]. Higher glue consumption increases the shear strength of the plywood [31,36,37,38]. Therefore, the lowest density wood—aspen—had the highest values of shear strength. In this research, all plywood panels with the combi mirror lay-up scheme had the highest apparent cohesive wood failure, since the veneers in their cores are from lower density wood species. For example, aspen and grey alder showed 100%, and black alder 80%, apparent cohesive wood failure in combi mirror products.

Bending properties were tested in the parallel and crosswise directions relative to the wood grain. In crosswise bending, the veneers were weak, as in these samples (3, 7, 12, 17) there are two outer layers parallel to the weakest grain direction. Therefore, these two parallel veneer layers will break easily under tension. On the other hand, they gave some of the best results in the parallel grain direction with the direction core lay-up. The bending strength test results showed that the grey alder plywood had the weakest bending strength properties, which can be explained via the low modulus of rupture of gray alder itself [20]. Oddly, aspen showed high bending test results, which could be explained via the high glue consumption and the densification effect of the low-density aspen layers during the plywood making process, which increasing the strength of the aspen plywood samples. It is generally known that densification and higher glue consumption increase the density and strength properties of wood [27,29,36,37,39]. Due to this, the aspen and birch combined plywood panels are comparable with all the birch layered plywood panels with regards to bending strength. The same trends were found in the bending MOE values (Figure 7), where the plywood panels with highest MOE in the parallel wood grain direction showed the lowest results in the crosswise direction. Birch, gray alder and black alder have similar MOE values, while aspen showed the highest values for MOE. This effect can be explained via the higher glue consumption and greater compression of aspen veneer layers (densification effect) during the plywood production process. Another reason could be that the aspen itself has higher MOE values than gray alder and black alder, but these are still lower than the birch [23]. The results showed that the bending strength increases in the parallel direction when there are more parallel layers in the plywood, and at the same time decreases in the crosswise direction for all the wood species. The stiffness is affected by glue consumption and the number of lower density wood layers in the plywood, which are compressed more densely together than the birch layers (densification of the lower density wood).

5. Conclusions

The aim of the research was to determine the effect of different hardwood species and lay-up schemes on the mechanical properties of plywood. Birch, grey alder, black alder and aspen wood species were used in the research. Plywood panels were made from either birch veneers only, or from birch combined with other wood species. In total, six lay-up schemes were used: standard, combi, combi mirror, twin, direction face and direction core.

Based on the study, the following conclusions can be made:

- The test results showed that birch, gray alder and black alder veneers had similar tensile strength values, whereas aspen veneer had significantly lower tensile strength.

- It was found that the birch veneers had the lowest glue consumption, 152 g/m2, and aspen had the highest glue consumption, 179 g/m2. Plywood density was found to increase when lower density wood (mainly aspen) was used in the plywood, due to the higher glue consumption and higher compression of the lower density wood veneers when under the same pressure as birch wood.

- Birch and black alder combination plywood, with the combi mirror lay-up scheme, was found to have the highest glued joint shear strength (2.39 N/mm2), because of the similar densities of birch and black alder, and the slightly higher glue consumption of the black alder veneers. The lay-up scheme of direction core had the lowest shear strength values.

- Birch plywood panels showed the highest average bending strength (114.3 N/mm2) in parallel to wood grain direction. Interestingly, the second highest bending strength (107.1 N/mm2) was achieved with aspen plywood, due to the highest glue consumption and the densification effect of the low-density aspen layers during the plywood making process, which increases the strength and stiffness of the aspen plywood samples.

- This study’s results showed that the best alternative combination to birch plywood, based on the bending properties, could be the direction core with a combination of alder and birch wood (sample 11). Overall, the best plywood combination could be twin or combi, with the combination of alder and birch wood (samples 9 and 13).

- Overall, it was shown that the hardwood species used in this study have slightly lower strength properties, but with the proper lay-up scheme, these wood species could be successfully used by the veneer-based industry.

Author Contributions

Conceptualization, J.K. and A.R.; methodology, H.K. and J.K.; validation, H.K., J.K. and A.R.; formal analysis, H.K. and A.R.; investigation, H.V.; resources, J.K.; data curation, H.V.; writing—original draft preparation, H.V.; writing—review and editing, H.K. and A.R.; visualization, H.K.; supervision, H.K.; project administration, J.K.; funding acquisition, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Regional Development Fund and granted by Estonian Research Council grants (PRG820) and Mobilitas Pluss (MOBTP123).

Acknowledgments

The European Regional Development Fund and Estonian Research Council grants (PRG820) and Mobilitas Pluss (MOBTP123) are hereby acknowledged for supporting the research. State Forest Management Centre Estonia is also acknowledged for helping to obtain the wood material for this research.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Eesti Statistika Kvartalikiri. 2/18. Quarterly Bulletin of Statistics Estonia—Statistics Estonia. Available online: https://www.stat.ee/publication-2018_quarterly-bulletin-of-statistics-estonia-2-18 (accessed on 10 May 2020).

- Valgepea, M.; Raudsaar, M.; Siimon, K.L. Yearbook Forest 2018; Keskkonnaagentuur: Tallinn, Finland, 2019. [Google Scholar]

- Dubois, H.; Verkasalo, E.; Claessens, H. Potential of Birch (Betula pendula Roth and B. pubescens Ehrh.) for Forestry and Forest-Based Industry Sector within the Changing Climatic and Socio-Economic Context of Western Europe. Forests 2020, 11, 336. [Google Scholar] [CrossRef]

- Kärki, T.; Maltamo, M.; Eerikäinen, K. Diameter distribution, stem volume and stem quality models for grey alder (Alnus incana) in eastern Finland. New For. 2000, 20, 65–86. [Google Scholar] [CrossRef]

- Olsson, A.-M.; Bjurhager, I.; Gerber, L.; Sundberg, B.; Salmen, L. Ultra-structural organisation of cell wall polymers in normal and tension wood of aspen revealed by polarisation FTIR microspectroscopy. Planta 2011, 233, 1277–1286. [Google Scholar] [CrossRef] [PubMed]

- Wilson, B.F.; Gartner, B.L. Lean in red alder (Alnus rubra): Growth stress, tension wood, and righting response. Can. J. For. Res. 1996, 26, 1951–1956. [Google Scholar] [CrossRef]

- Kallakas, H.; Ayansola, G.S.; Tumanov, T.; Goljandin, D.; Poltimäe, T.; Krumme, A.; Kers, J. Influence of Birch False Heartwood on the physical and mechanical properties of wood-plastic composites. BioResources 2019, 14, 3554–3566. [Google Scholar]

- Dupleix, A.; Denaud, L.E.; Bleron, L.; Marchal, R.; Hughes, M. The effect of log heating temperature on the peeling process and veneer quality: Beech, birch, and spruce case studies. Eur. J. Wood Wood Prod. 2013, 71, 163–171. [Google Scholar] [CrossRef]

- Rohumaa, A.; Hunt, C.G.; Frihart, C.R.; Saranpää, P.; Ohlmeyer, M.; Hughes, M. The influence of felling season and log-soaking temperature on the wetting and phenol formaldehyde adhesive bonding characteristics of birch veneer. Holzforschung 2014, 68, 965–970. [Google Scholar] [CrossRef]

- Yamamoto, A.; Rohumaa, A.; Kontturi, E.; Hughes, M.; Vuorinen, T. Chemical characteristics of squeezable sap of hydrothermally treated silver birch logs (Betula pendula): Effect of treatment time and the quality of the soaking water in pilot scale experiment. Wood Sci. Technol. 2015, 49, 289–302. [Google Scholar] [CrossRef]

- Yamamoto, A.; Rohumaa, A.; Kontturi, E.; Hughes, M.; Vuorinen, T. The Effect of Hydrothermal Treatment on the Color Stability and Chemical Properties of Birch Veneer Surfaces. BioResources 2015, 10. [Google Scholar] [CrossRef]

- Yamamoto, A.; Rohumaa, A.; Kontturi, E.; Hughes, M.; Vuorinen, T. The chemical characteristics of squeezable sap from silver birch (Betula pendula) logs hydrothermally treated at 70 °C: The effect of treatment time on the concentration of water extracts. Wood Sci. Technol. 2015, 49, 1295–1306. [Google Scholar] [CrossRef]

- Rohumaa, A.; Viguier, J.; Girardon, S.; Krebs, M.; Denaud, L. Lathe check development and properties: Effect of log soaking temperature, compression rate, cutting radius and cutting speed during peeling process of European beech (Fagus sylvatica L.) veneer. Eur. J. Wood Wood Prod. 2018, 76, 1653–1661. [Google Scholar] [CrossRef]

- Rohumaa, A.; Antikainen, T.; Hunt, C.G.; Frihart, C.R.; Hughes, M. The influence of log soaking temperature on surface quality and integrity performance of birch (Betula pendula Roth) veneer. Wood Sci. Technol. 2016, 50, 463–474. [Google Scholar] [CrossRef]

- Rohumaa, A.; Hunt, C.G.; Hughes, M.; Frihart, C.R.; Logren, J. The influence of lathe check depth and orientation on the bond quality of phenol-formaldehyde—Bonded birch plywood. Holzforschung 2013, 67, 779–786. [Google Scholar] [CrossRef]

- Rohumaa, A.; Yamamoto, A.; Hunt, C.G.; Frihart, C.R.; Hughes, M.; Kers, J. Effect of log soaking and the temperature of peeling on the properties of Rotary-cut birch (Betula pendula Roth) veneer bonded with phenol-formaldehyde adhesive. BioResources 2016, 11, 5829–5838. [Google Scholar] [CrossRef]

- Pot, G.; Denaud, L.E.; Collet, R. Numerical study of the influence of veneer lathe checks on the elastic mechanical properties of laminated veneer lumber (LVL) made of beech. Holzforschung 2015, 69, 337–345. [Google Scholar] [CrossRef]

- Lipinskis, I.; Spulle, U. Research on mechanical properties of birch plywood with special veneer lay-up schemes. Drewno 2011, 185, 109–118. [Google Scholar]

- Popovska, V.J.; Iliev, B.; Zlateski, G. Utjecaj položaja furnira u strukturi furnirskih ploča na njihovu vlačnu čvrstoću. Drv. Ind. 2017, 68, 153–161. [Google Scholar]

- Spulle, U.; Tuherm, H.; Mioncinskis, U.; Kulins, L. Mechanical Characteristics of the Hardwoods. Latvijas Valsts koksnes ķīmijas Institūts, 2009. Available online: https://agris.fao.org/agris-search/search.do?recordID=LV2011000067 (accessed on 1 January 2020).

- Silver Birch|The Wood Database—Lumber Identification (Hardwood). 2019. Available online: https://www.wood-database.com/silver-birch/ (accessed on 15 April 2019).

- European Alder|The Wood Database—Lumber Identification (Hardwood). Available online: https://www.wood-database.com/european-alder/ (accessed on 17 April 2020).

- The Timber Measurement Council Regulations for Measuring of Roundwood Recommended by the Timber Measurement Council. Available online: http://ny.sdc.se/admin/PDF/pdffiler_VMUVMK/M%C3%A4tningsinstruktioner/M%C3%A4tningsinstruktioner%20f%C3%B6r%20rundvirkessortiment%20VMR%201-99%2C%20engelska.pdf (accessed on 17 April 2019).

- Stalnaker, J.J.; Harris, E.C. Wood Structure and Properties. In Structural Design in Wood; Springer: Boston, MA, USA, 1997; pp. 11–31. [Google Scholar]

- Sepp, B. Improvement of the Adhesive Joint of the Birch Veneer from False Heartwood. Master’s Thesis, Tallinn University of Technology, Tallinn, Estonia, 2015. [Google Scholar]

- Seborg, R.M.; Millett, M.A.; Stamm, A.J. Heat-Stabilized Compressed Wood (Staypak); Forest Products Laboratory, Forest Service, U.S. Department of Agriculture: Madison, WI, USA, 1956.

- Rautkari, L.; Kutnar, A.; Hughes, M.; Kamke, F.A. Wood Surface Densification Using Different Methods. In Proceedings of the 11th World Conference on Timber Engineering, Trentino, Italy, 20–24 June 2015; pp. 3121–3125. [Google Scholar]

- Ruponen, J.; Rautkari, L.; Belt, T.; Hughes, M. Factors influencing properties of parallel laminated binderless bonded plywood manufactured from rotary cut birch ( Betula pendula L.). Int. Wood Prod. J. 2014, 5, 11–17. [Google Scholar] [CrossRef]

- Cristescu, C.; Sandberg, D.; Ekevad, M.; Karlsson, O. Influence of pressing parameters on mechanical and physical properties of self-bonded laminated beech boards. Wood Mater. Sci. Eng. 2015, 10, 205–214. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliacik, J.; Novak, I.; Mamonova, M. Effects of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater. Sci. Eng. 2017, 12, 40–54. [Google Scholar] [CrossRef]

- Kurowska, A.; Borysiuk, P.; Mamiński, M.; Zbieć, M. Veneer Densification as a Tool for Shortening of Plywood Pressing Time Stlačivanje furnira kao metoda skraćenja vremena prešanja furnirskih ploča. Drv. Ind. 2010, 61, 193–196. [Google Scholar]

- Rohumaa, A.; Hunt, C.G.; Frihart, C.R.; Kers, J.; Denaud, L.; Hughes, M. The Impact of Log Heating on Veneer Quality and Plywood Performance. In Proceedings of the International Scientific Conference on Hardwood Processing (ISCHP2017), Lahti, Finland, 25–28 September 2017; pp. 184–190. [Google Scholar]

- Sogutlu, C. Determination of the Effect of Surface Roughness on the Bonding Strength of Wooden Materials. BioResources 2017, 12. [Google Scholar] [CrossRef]

- EVS-EN 314-2:1999—Eesti Standardikeskus. Available online: https://www.evs.ee/et/evs-en-314-2-1999. (accessed on 5 May 2020).

- Bourreau, D.; Aimene, Y.; Beauchêne, J.; Thibaut, B. Feasibility of glued laminated timber beams with tropical hardwoods. Eur. J. Wood Wood Prod. 2013, 71, 653–662. [Google Scholar] [CrossRef]

- Kurt, R. Effect of glue line thickness on shear strength of wood-to-wood joints. Wood Res. 2006, 51, 59–66. [Google Scholar]

- Li, R.; Guo, X.; Ekevad, M.; Marklund, B.; Cao, P. Investigation of glueline shear strength of pine wood bonded with PVAc by response surface methodology. BioResources 2015, 10, 3831–3838. [Google Scholar] [CrossRef][Green Version]

- Follrich, J.; Vay, O.; Veigel, S.; Müller, U. Bond strength of end-grain joints and its dependence on surface roughness and adhesive spread. J. Wood Sci. 2010, 56, 429–434. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Mamonova, M.; Pinkowski, G.; Lis, B. Effect of thermomechanical densification on surface roughness of wood veneers. Wood Mater. Sci. Eng. 2014, 9, 233–245. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).