Influence of Board Density on the Physical and Mechanical Properties of Bamboo Oriented Strand Lumber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

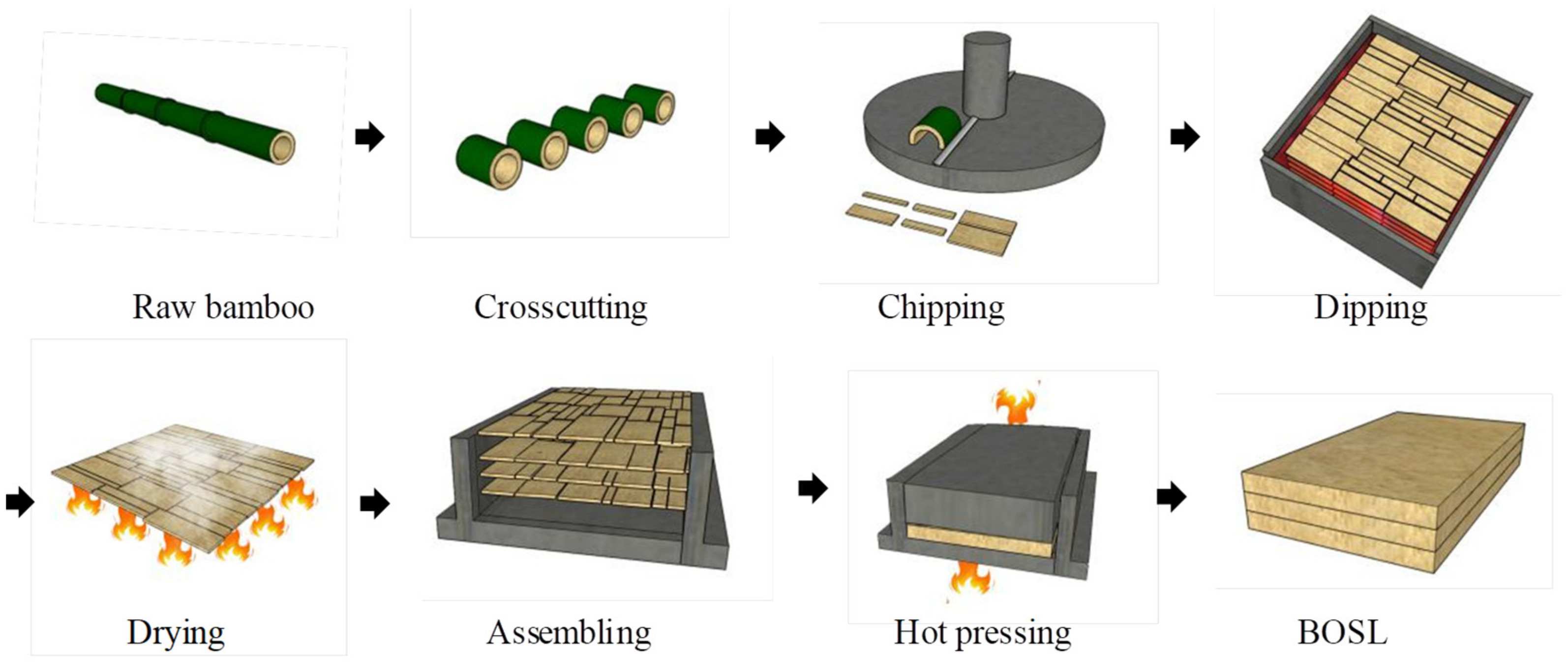

2.2. Experimental Design and Preparation of BOSL

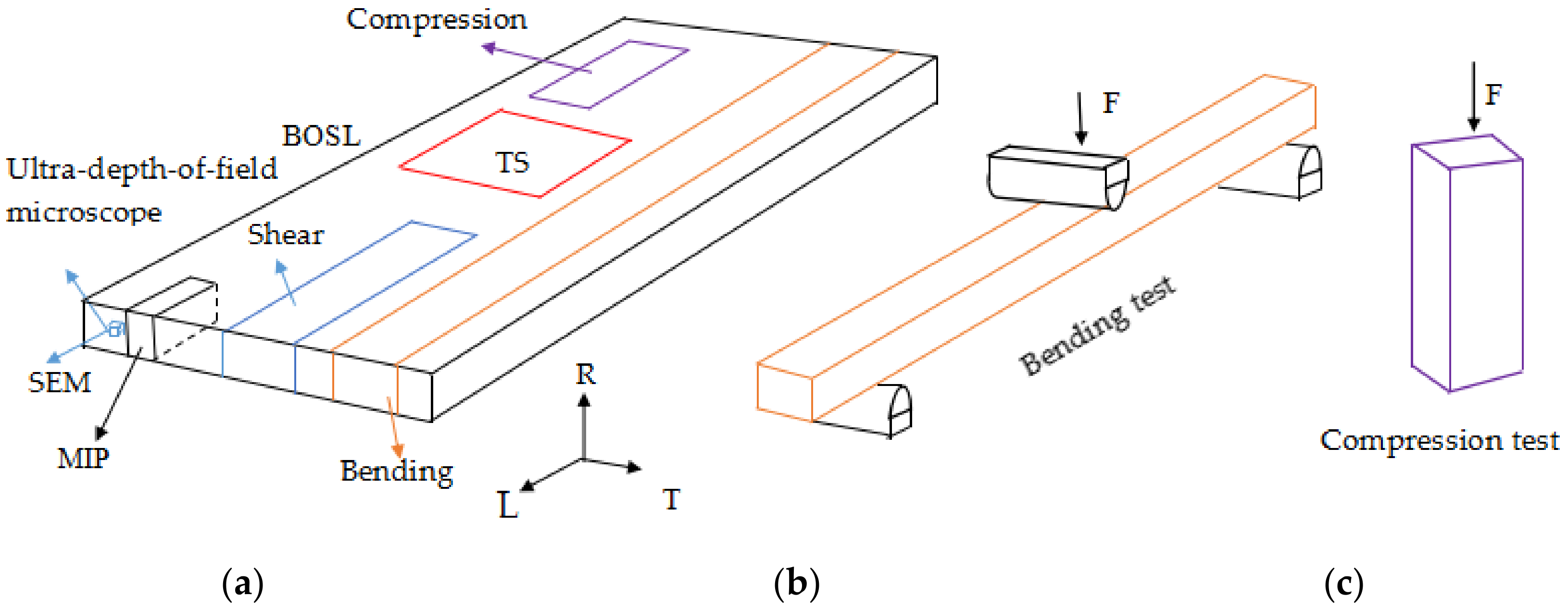

2.3. Physical and Mechanical Properties Test

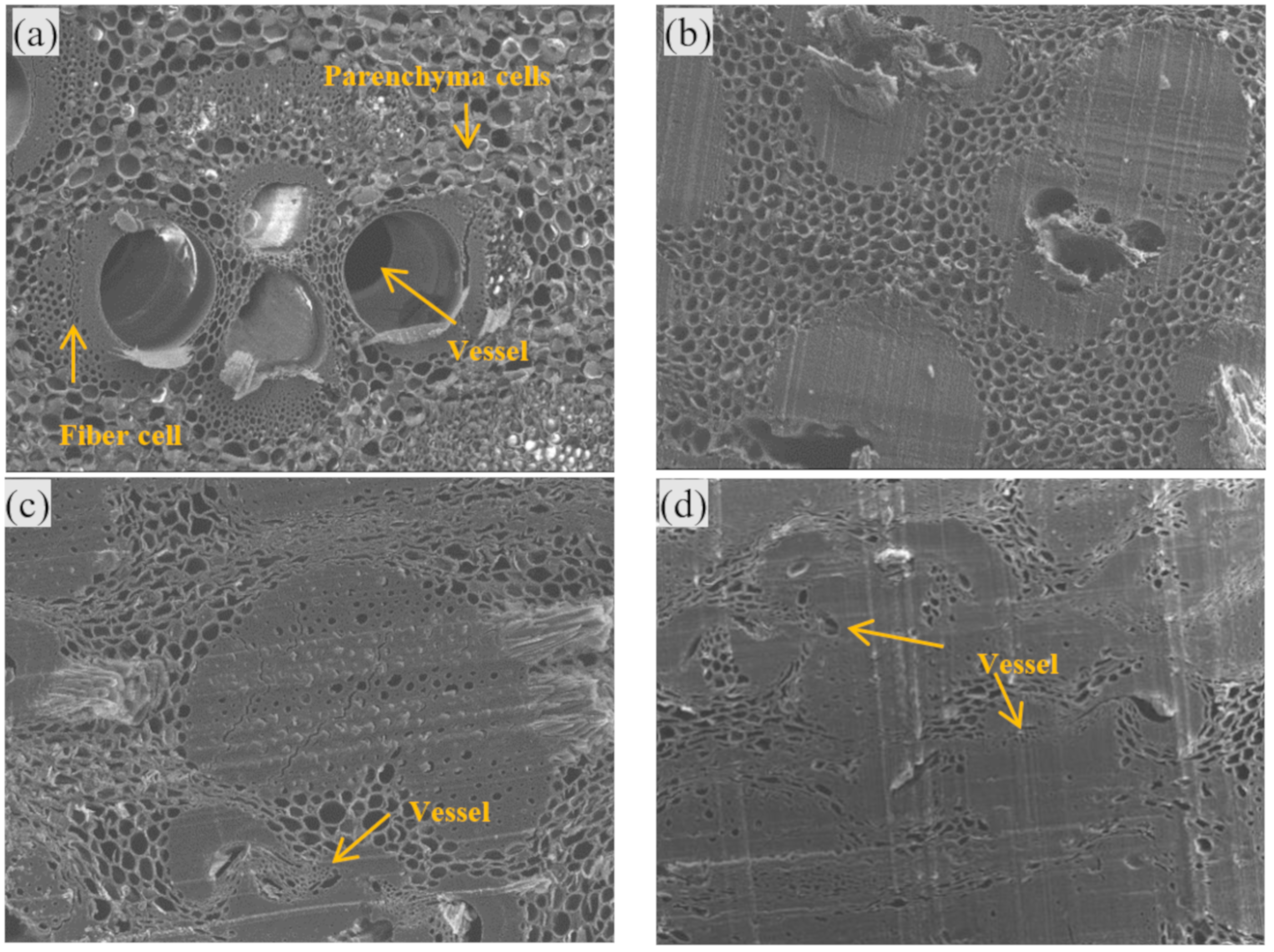

2.4. Morphological Characterizations

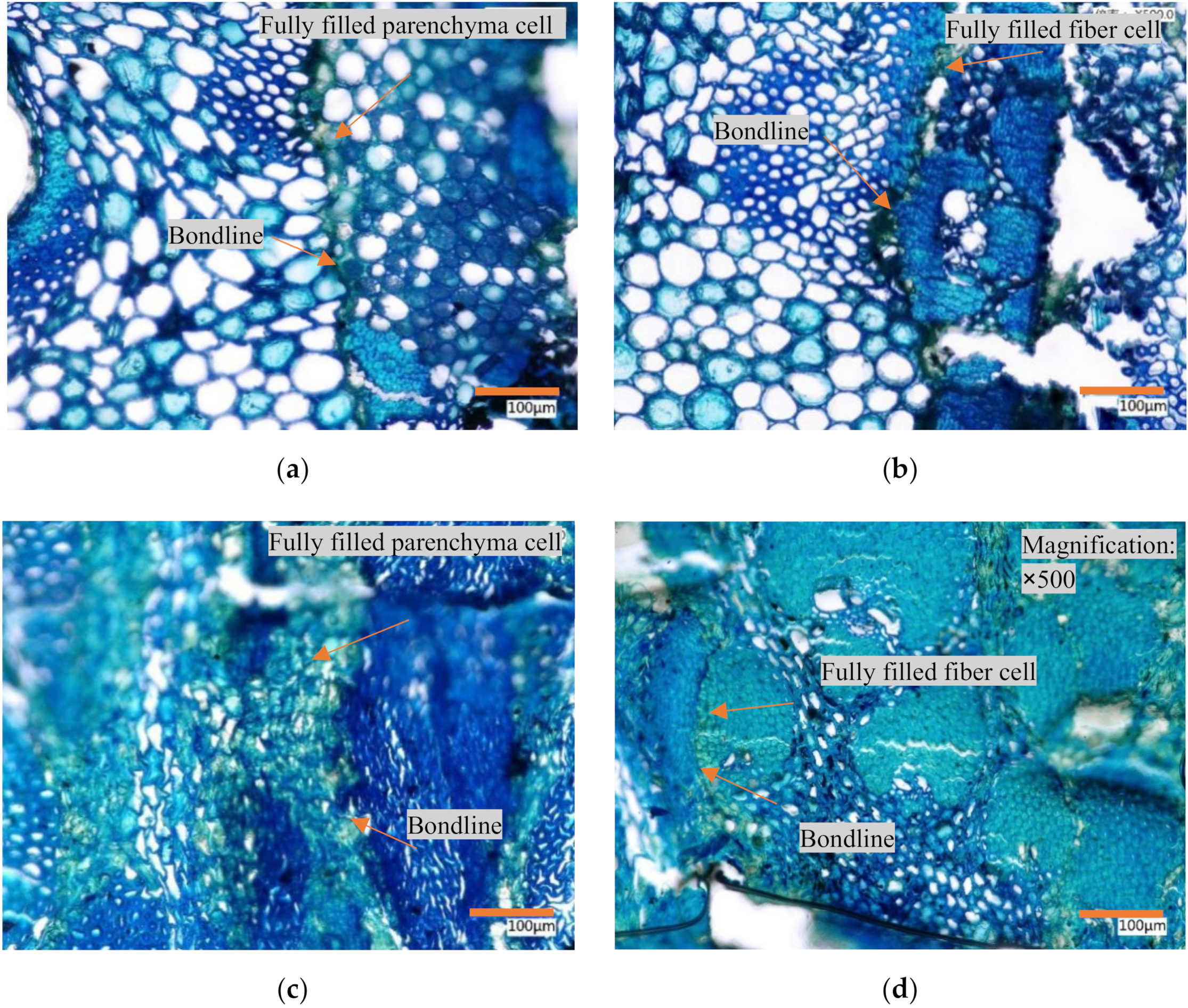

2.5. Interface Observation by Ultra-Depth-Of-Field Microscope

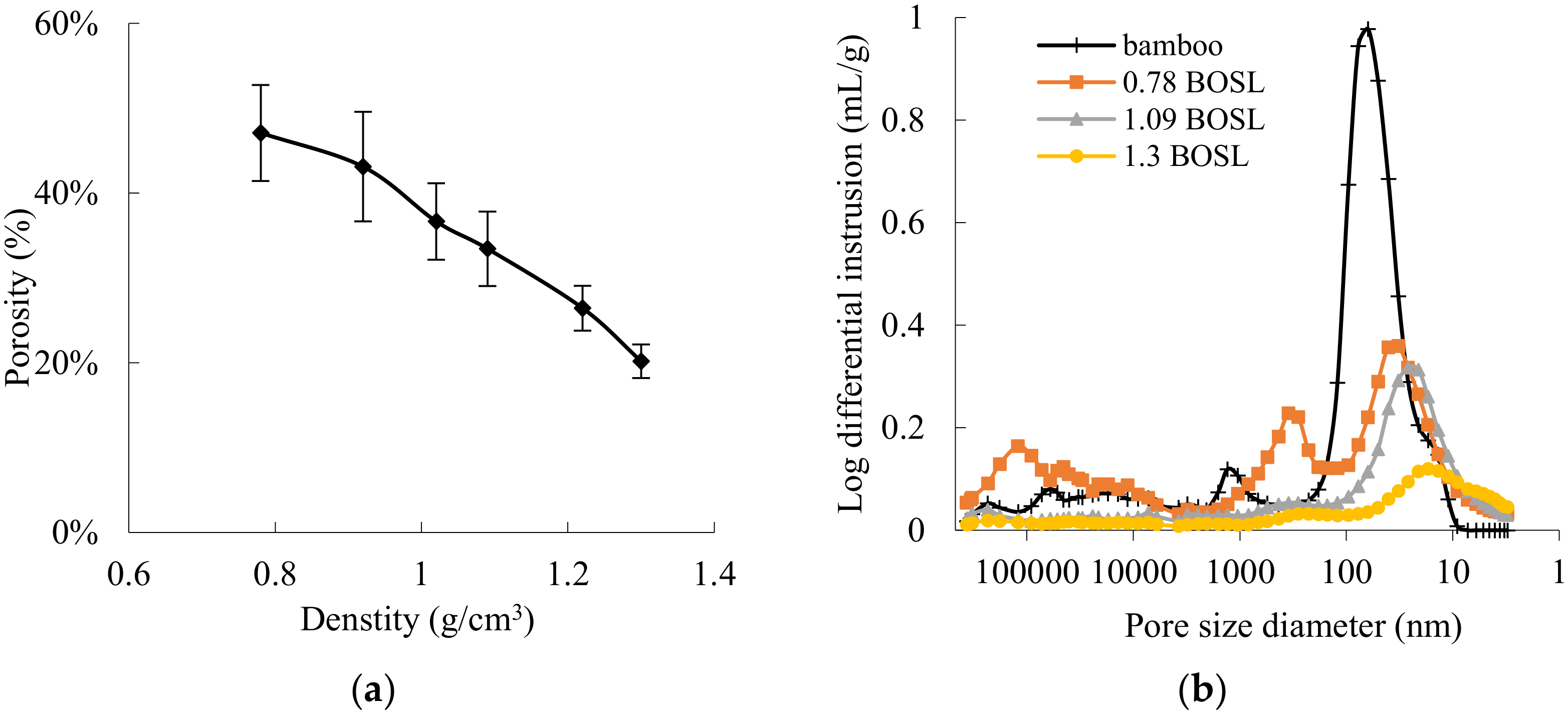

2.6. Mercury Intrusion Porosimetry (MIP)

3. Results and Discussions

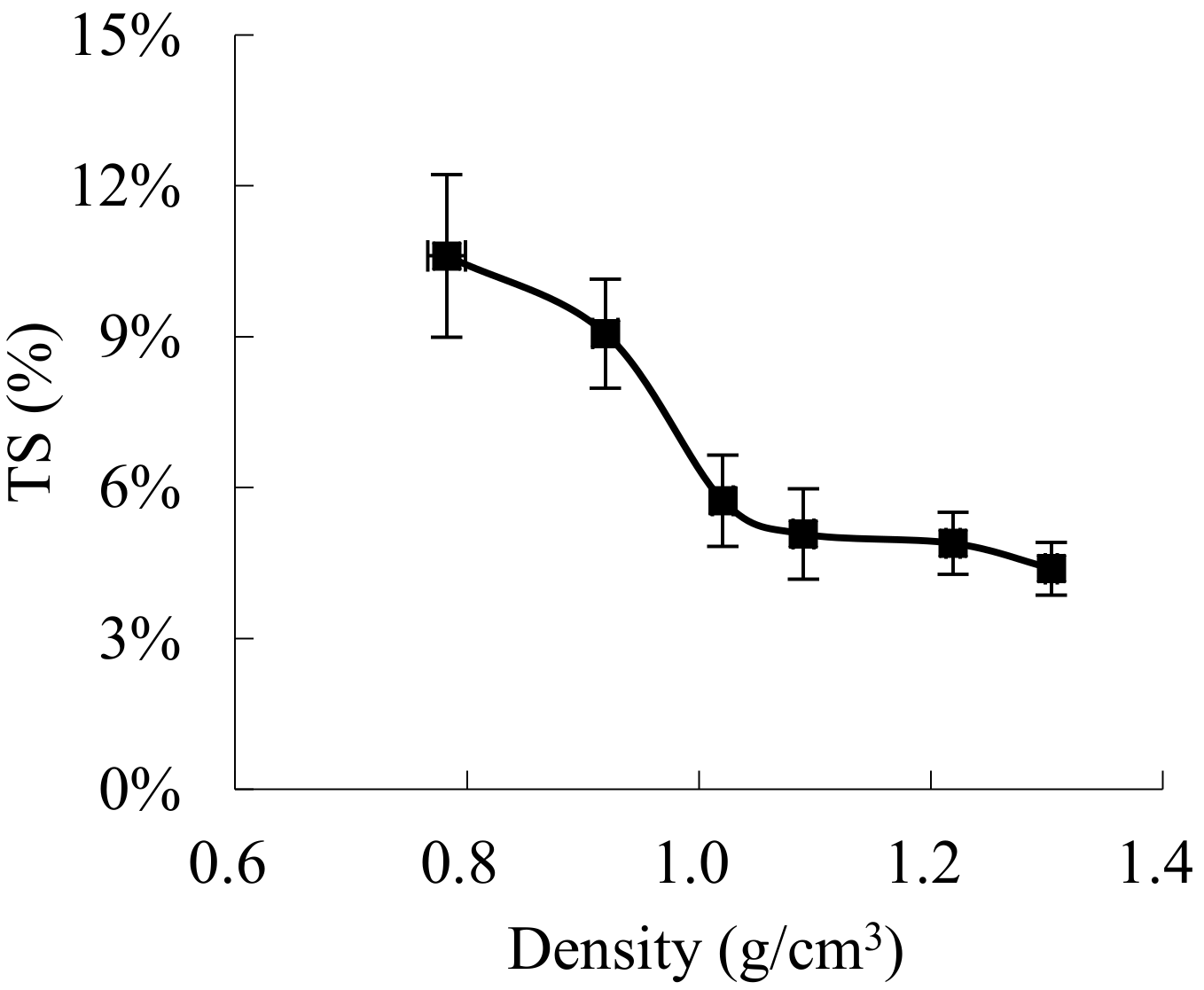

3.1. Effect of Density on Physical Properties of BOSL

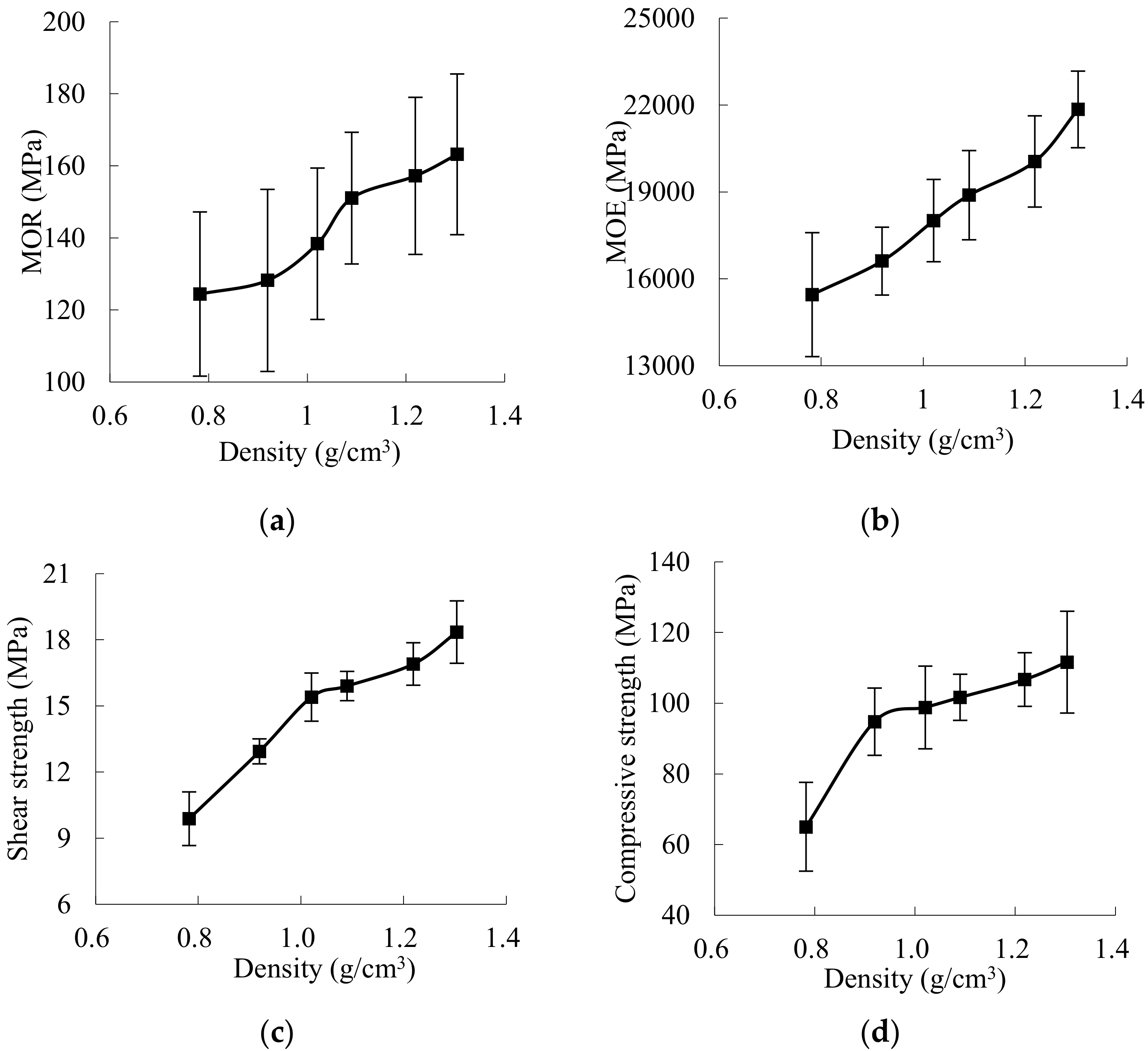

3.2. Effect of Density on Mechanical Properties

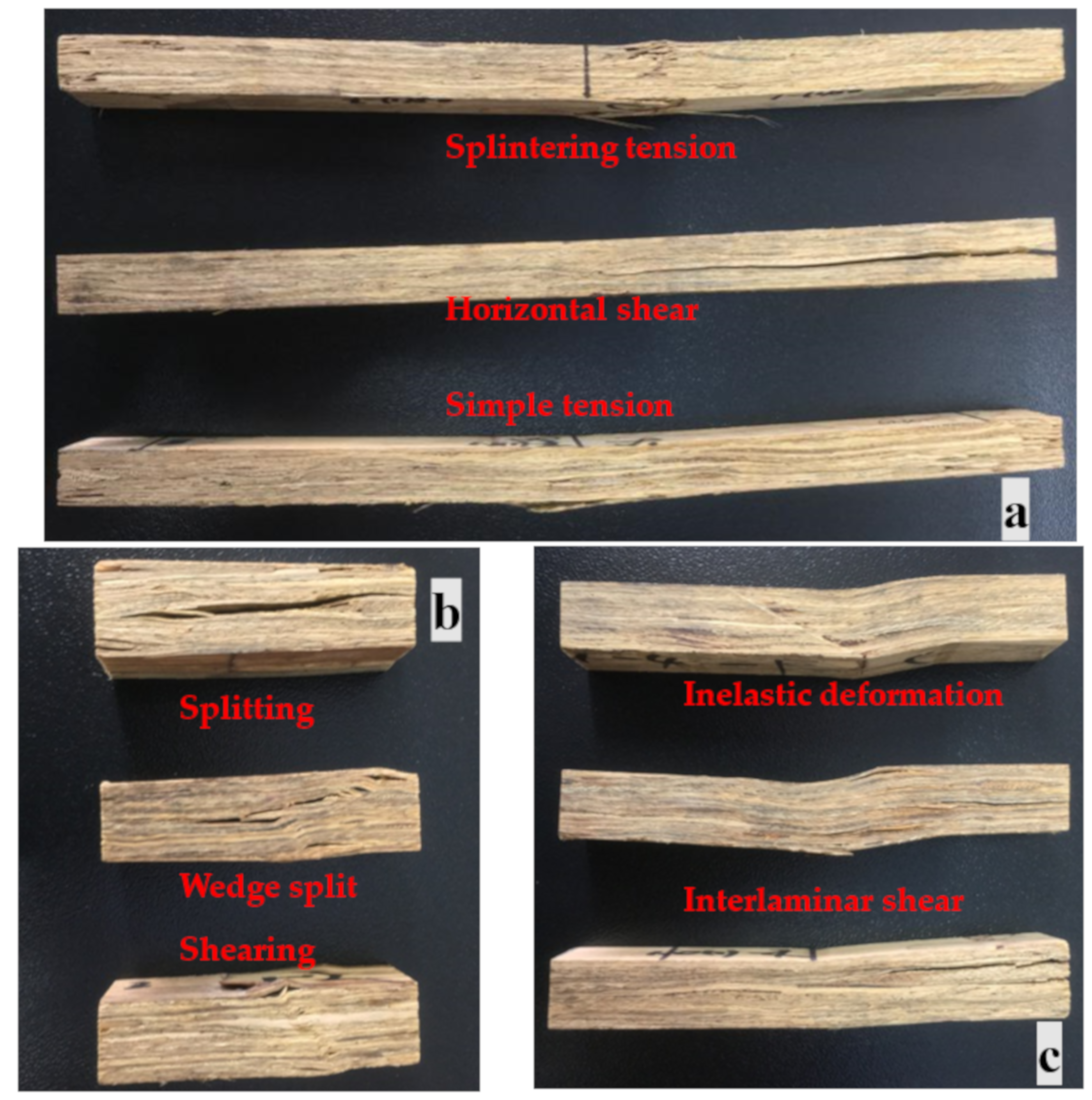

3.3. Failure Mode

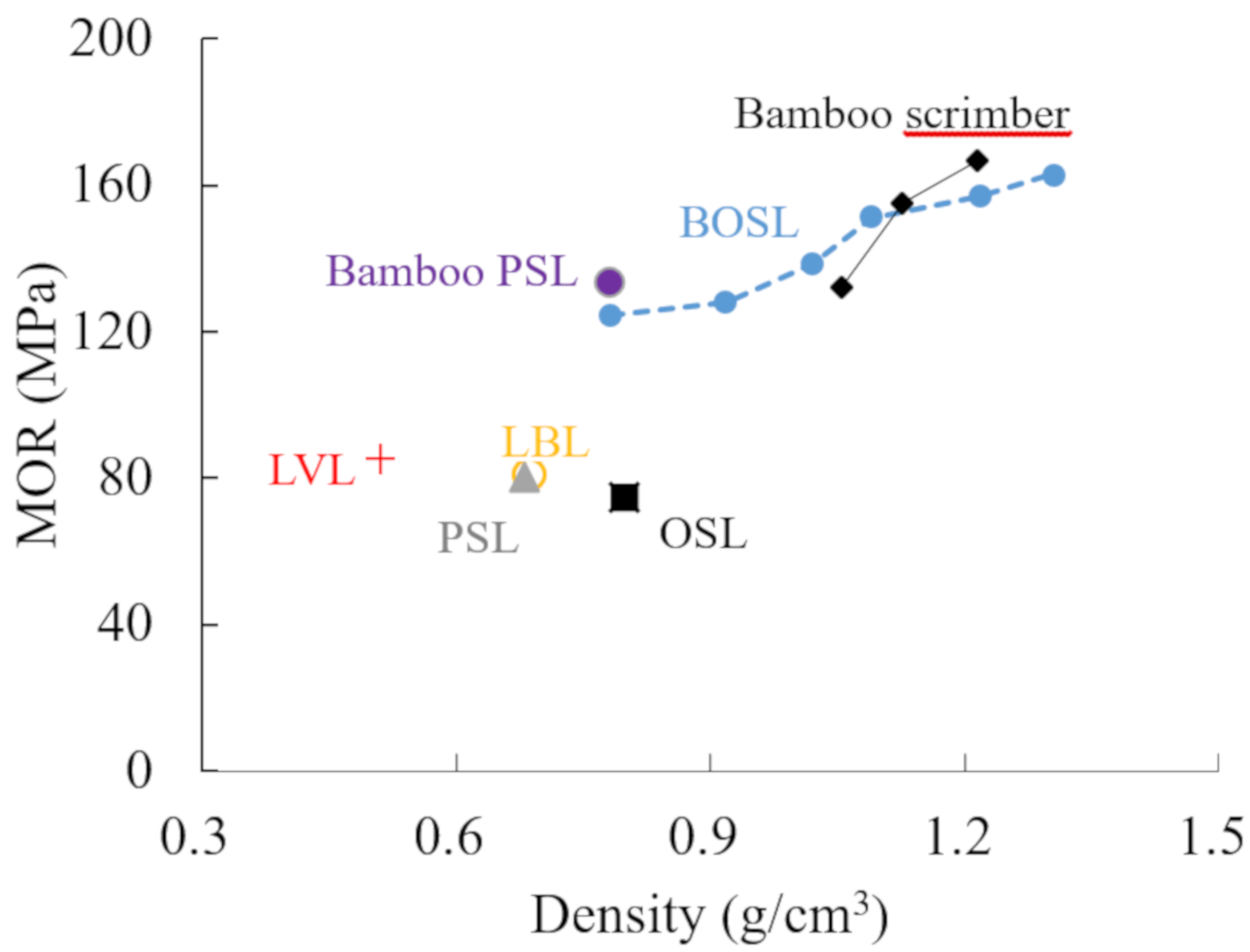

3.4. Comparison of Mechanical Properties

4. Conclusions

- (1)

- The results revealed that MOR, MOE, compressive strength and shear strength of BOSL, with density of 0.7–1.3 g/cm3, ranged from 124.42 to 163.2 MPa, 15,455 to 21,849 MPa, 65.02 to 111.63 MPa and 9.88 to 18.35 MPa, respectively. The range of TS value was 4.39–10.61%. The properties of BOSL significantly varied with its density, and it can be designed by controlling the density.

- (2)

- The performance of BOSL can be comparable to or surpass that of wood or bamboo products. In addition, it has the advantages of high utilization rate and high degree of automation, so it will be highly desirable in different fields.

- (3)

- The good water-resistance of BOSL with high density was primarily due to the enhanced gluing interface, and the reduced porosity and pore geometry. The high strength of BOSL with high density was primarily due to the increased volume fraction of elementary fibers, the reduced porosity, and the enhanced gluing interface.

Author Contributions

Funding

Conflicts of Interest

References

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A Strong, Tough, and Scalable Structural Material from Fast-Growing Bamboo. Adv. Mater. 2020, 32, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Chaowana, P. Bamboo: An Alternative Raw Material for Wood and Wood-Based Composites. J. Mater. Sci. Res. 2013, 2. [Google Scholar] [CrossRef]

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface 2014, 11, 20140321. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Zhu, R.; Wu, B.; Hu, Y.; Yu, W. Fabrication, material properties, and application of bamboo scrimber. Wood Sci. Technol. 2014, 49, 83–98. [Google Scholar] [CrossRef]

- Shangguan, W.; Zhong, Y.; Xing, X.; Zhao, R.; Ren, H. 2D Model of Strength Parameters for Bamboo Scrimber. Bioresources 2014, 9. [Google Scholar] [CrossRef]

- Li, H.-T.; Su, J.-W.; Zhang, Q.-S.; Deeks, A.; Hui, D. Mechanical performance of laminated bamboo column under axial compression. Compos. Part B Eng. 2015, 79, 374–382. [Google Scholar] [CrossRef]

- Feng, M.Z. Research on the Impact of Physical Mechanical Properties of Structure Strip Plybamboo Condition on Hot-Pressing. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2013. [Google Scholar]

- Verma, C.; Chariar, V. Development of layered laminate bamboo composite and their mechanical properties. Compos. Part B Eng. 2012, 43, 1063–1069. [Google Scholar] [CrossRef]

- Febrianto, F.; Hidayat, W.; Bakar, E.S.; Kwon, G.-J.; Kwon, J.-H.; Hong, S.-I.; Kim, N.-H. Properties of oriented strand board made from Betung bamboo (Dendrocalamus asper (Schultes.f) Backer ex Heyne). Wood Sci. Technol. 2010, 46, 53–62. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhang, P.K.; Smith, G.D. Hybrid oriented strand boards made from Moso bamboo (Phyllostachys pubescens Mazel) and Aspen (Populus tremuloides Michx.): Species-separated three-layer boards. Eur. J. Wood Wood Prod. 2015, 73, 527–536. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, Z.H.; Chen, F.M.; Cheng, H.T.; Sun, F.B. Manufacture situation and problem analysis on large size bamboo engineering material in China. China For. Prod. Ind. 2014, 41, 48–49. [Google Scholar]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Mirski, R.; Derkowski, A.; Dziurka, D. Influence of strand size, board density, and adhesive type on characteristics of oriented strand lumber boards manufactured from pine strands. Bioresources 2019, 14, 6686–6696. [Google Scholar]

- Bliem, P.; Frömel-Frybort, S.; Van Herwijnen, H.W.G.; Pinkl, S.; Krenke, T.; Mauritz, R.; Konnerth, J.; Van Herwijnen, H.W.G. Engineering of material properties by adhesive selection at the example of a novel structural wood material. J. Adhes. 2019, 96, 144–164. [Google Scholar] [CrossRef]

- Malanit, P. The Suitability of Dendrocalamus asper Backer for Oriented Strand Lumber. Ph.D. Thesis, Informatics and Natural Sciences University of Hamburg, Hamburg, Germany, 2009. [Google Scholar]

- Ferraz, J.M.; Del Menezzi, C.H.S.; Teixeira, D.E.; Okino, E.Y.A.; Souza, F.; Bravim, A.G. Properties of laminated strand panels used as an alternative to solid wood. Cerne 2009, 15, 67–74. [Google Scholar]

- Taghiyari, H.R.; Maleki, S.; Hassani, V. Effects of Nano-Silane on the Physical and Mechanical Properties of Oriented Strand Lumber (OSL). Bois For. Trop. 2017, 330, 49. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Malanit, P.; Barbu, M.C.; Frühwald, A. Physical and mechanical properties of oriented strand lumber made from an Asian bamboo (Dendrocalamus asper Backer). Eur. J. Wood Wood Prod. 2010, 69, 27–36. [Google Scholar] [CrossRef]

- Sumardi, I.; Suzuki, S.; Rahmawati, N. Effect of Board Type on Some Properties of Bamboo Strandboard. J. Math. Fundam. Sci. 2015, 47, 51–59. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhang, P.K.; Smola, M.; Smith, G.D. Hybrid Oriented Strand Boards made from Moso bamboo (Phyllostachys pubescens Mazel) and Aspen (Populus tremuloides Michx.): Uniformly mixed single layer uni-directional boards. Eur. J. Wood Wood Prod. 2015, 73, 515–525. [Google Scholar] [CrossRef]

- Zhong, Y.; Wu, G.; Ren, H.; Jiang, Z. Bending properties evaluation of newly designed reinforced bamboo scrimber composite beams. Constr. Build. Mater. 2017, 143, 61–70. [Google Scholar] [CrossRef]

- Peng, L.M.; Wang, D.; Fu, F.; Song, B.Q. Analysis of wood pore characteristics with mercury intrusion porosimetry and X-ray micro-computed tomography. Wood Res. 2015, 60, 857–864. [Google Scholar]

- Ding, W.-D.; Koubaa, A.; Chaala, A.; Belem, T.; Krause, C. Relationship between wood porosity, wood density and methyl methacrylate impregnation rate. Wood Mater. Sci. Eng. 2008, 3, 62–70. [Google Scholar] [CrossRef]

- Yu, Y.L. Manufacturing Technology and Mechanism of High Performance Bamboo-Based Fiber Composites. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2014. [Google Scholar]

- Lian, C.P.; Liu, R.; Zhang, S.Q. Research Progress on Anatomical Structure of Bamboo Vascular Bundles. China For. Prod. Ind. 2018, 9, 8–12. [Google Scholar]

- Liu, X.E.; Liu, Z.; Wang, Y.H. Investigation on main anatomical characteristics of Dendrocalamus giganteus. J. Anhui Agric. Univ. 2012, 39, 890–893. [Google Scholar]

- Wang, Y.; Zhan, H.; Ding, Y.; Lin, S. Variability of Anatomical and Chemical Properties with Age and Height in Dendrocalamus brandisii. Bioresources 2015, 11, 1202–1213. [Google Scholar] [CrossRef]

- Liu, R. Characteristics of Pits in Bamboo (Phyllostachys edulis) Revealed by Resin Casting. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2017. [Google Scholar]

- Gavrilovic-Grmusa, I.; Dunky, M.; Djiporovic-Momcilovic, M.; Popović, M. Influence of Pressure on the Radial and Tangential Penetration of Adhesive Resin into Poplar Wood and on the Shear Strength of Adhesive Joints. Bioresources 2016, 11. [Google Scholar] [CrossRef]

- Frederick, A.K.; Jong, N.L. Adhesive penetration in wood—A review. Wood Fiber Sci. 2007, 39, 205–220. [Google Scholar]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Li, B.; Zhao, M.Y.; Wang, X.P. Influence of irregular-void on transverse tensile mechanical properties of composites. Acta Mater. Compos. Sin. 2019, 36, 94–99. [Google Scholar]

- Krause, J.Q.; Silva, F.D.A.; Ghavami, K.; Gomes, O.; Filho, R.D.T. On the influence of Dendrocalamus giganteus bamboo microstructure on its mechanical behavior. Constr. Build. Mater. 2016, 127, 199–209. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Li, Z.; He, M.; Tao, D.; Li, M. Experimental buckling performance of scrimber composite columns under axial compression. Compos. Part B Eng. 2016, 86, 203–213. [Google Scholar] [CrossRef]

- Bayatkashkoli, A.; Faegh, M. Evaluation of mechanical properties of laminated strand lumber and oriented strand lumber made from Poplar wood (Populus deltoides) and Paulownia (Paulownia fortunei) with urea formaldehyde adhesive containing nanoclay. Int. Wood Prod. J. 2014, 5, 192–195. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

| Material | Adhesive Type and Amount | Density (g/cm3) | MOR (MPa) | MOE (MPa) | Shear Strength (MPa) | Compression Strength (MPa) |

|---|---|---|---|---|---|---|

| BOSL a | PF 15% | 0.78 | 124.42 | 15,455 | 9.88 | 65.02 |

| 1.22 | 157.22 | 20,050 | 16.9 | 106.71 | ||

| BOSL b | pMDI 10% | 0.76 | 62.5 | 10,497 | ||

| OSL c | UF 10% | 0.80 | 74.31 | 10,817 | 12.67 | |

| Bamboo scrimber d | PF 15–17% | 1.22 | 166.5 | 18,650 | 17.00 | 115.7 |

| LBL e | 0.69 | 80 | 12,000 | 16 | 77 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhang, Y.; Huang, Y.; Wei, X.; Yu, W. Influence of Board Density on the Physical and Mechanical Properties of Bamboo Oriented Strand Lumber. Forests 2020, 11, 567. https://doi.org/10.3390/f11050567

Sun Y, Zhang Y, Huang Y, Wei X, Yu W. Influence of Board Density on the Physical and Mechanical Properties of Bamboo Oriented Strand Lumber. Forests. 2020; 11(5):567. https://doi.org/10.3390/f11050567

Chicago/Turabian StyleSun, Yuhui, Yahui Zhang, Yuxiang Huang, Xiaoxin Wei, and Wenji Yu. 2020. "Influence of Board Density on the Physical and Mechanical Properties of Bamboo Oriented Strand Lumber" Forests 11, no. 5: 567. https://doi.org/10.3390/f11050567

APA StyleSun, Y., Zhang, Y., Huang, Y., Wei, X., & Yu, W. (2020). Influence of Board Density on the Physical and Mechanical Properties of Bamboo Oriented Strand Lumber. Forests, 11(5), 567. https://doi.org/10.3390/f11050567