Wood Surface Changes of Heat-Treated Cunninghamia lanceolate Following Natural Weathering

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Wood Samples

2.2. Natural Weathering Conditions

2.3. Color Measurements

2.4. Statistical Analysis

2.5. Low-Vacuum Scanning Electron Microscopy (LVSEM)

3. Results

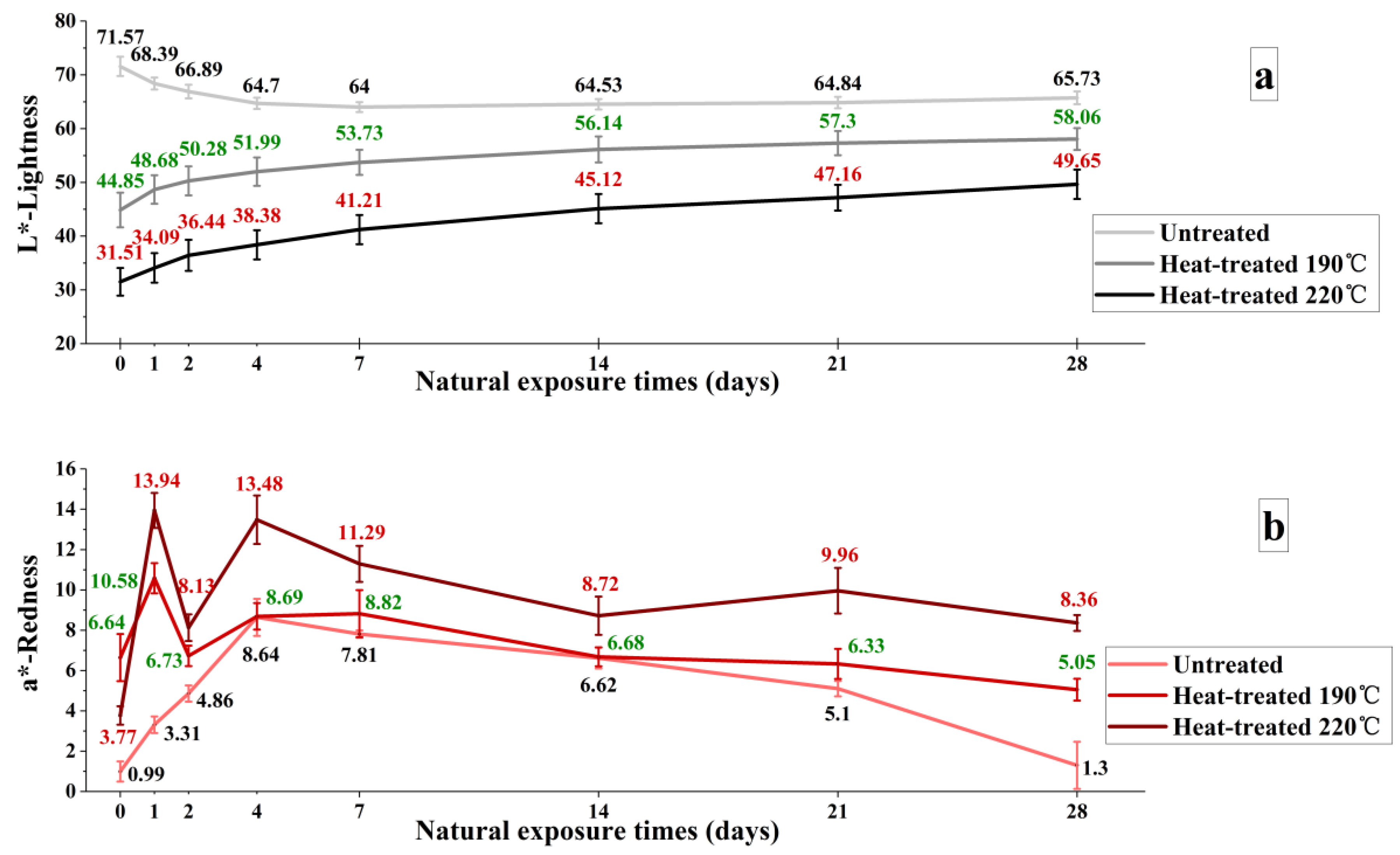

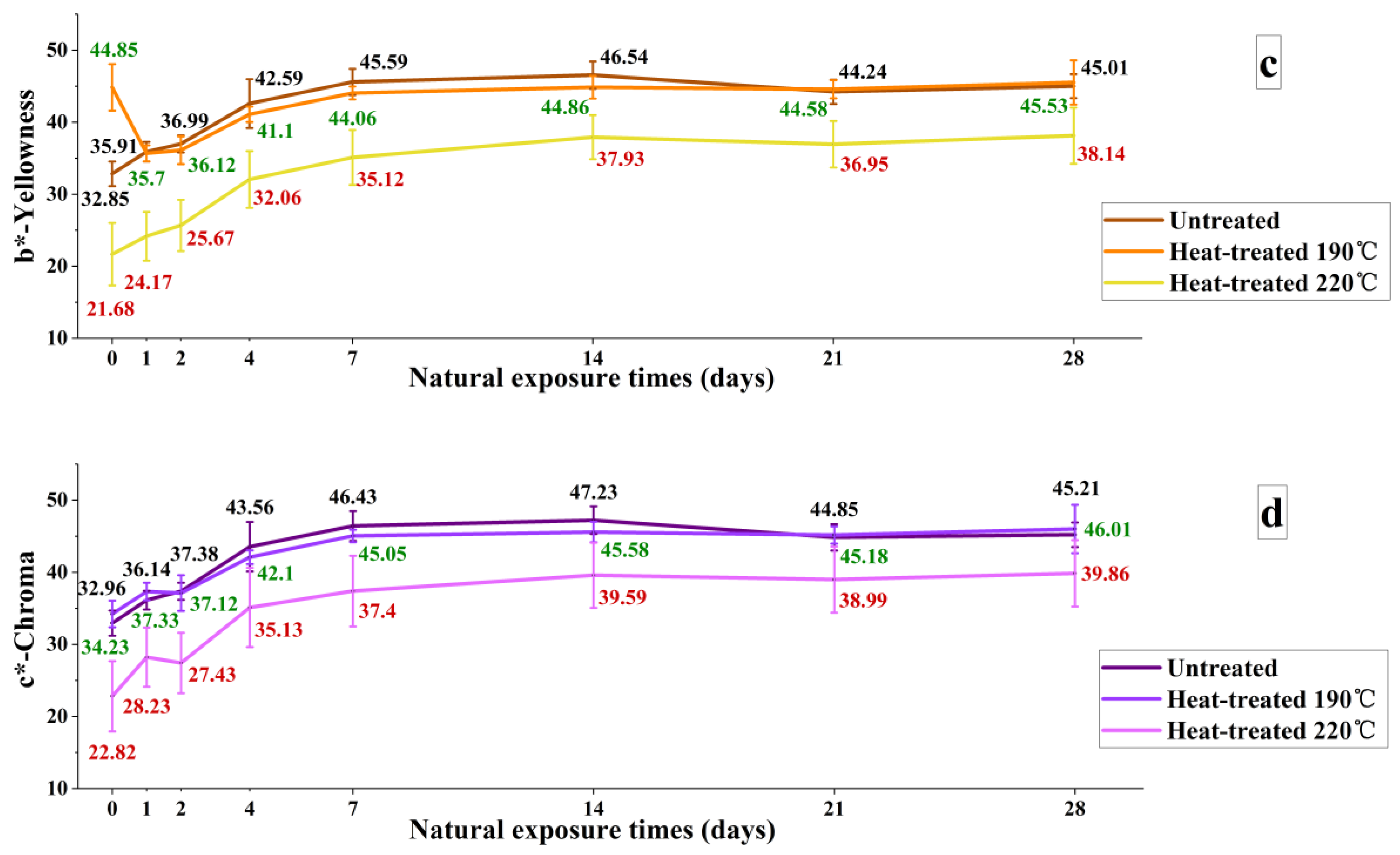

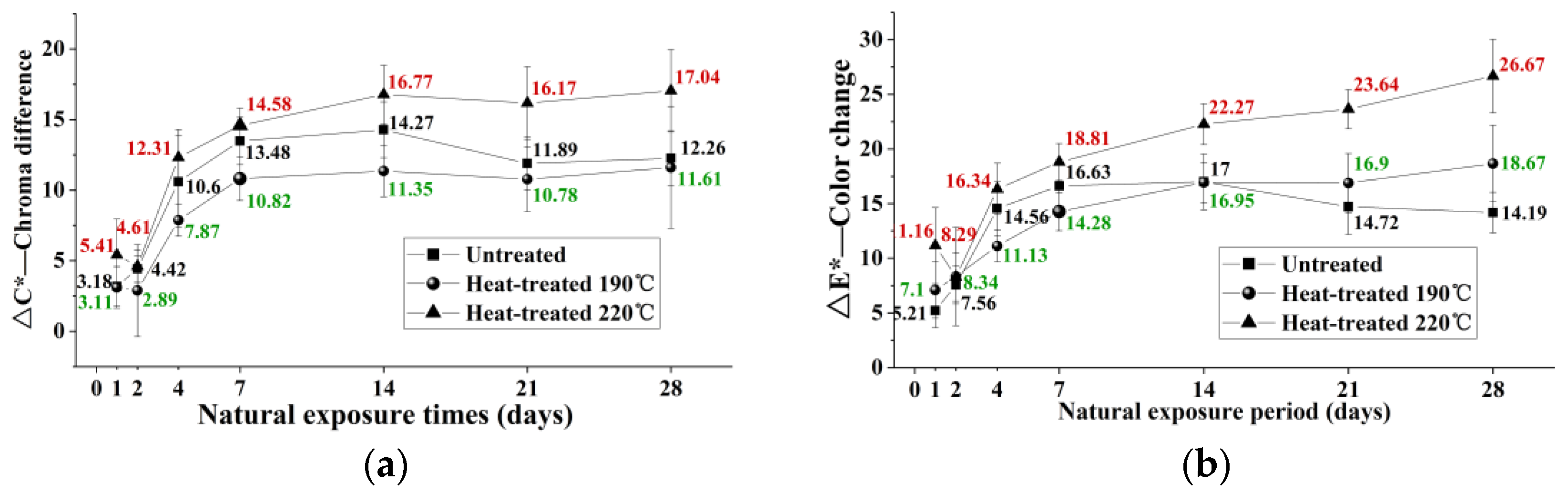

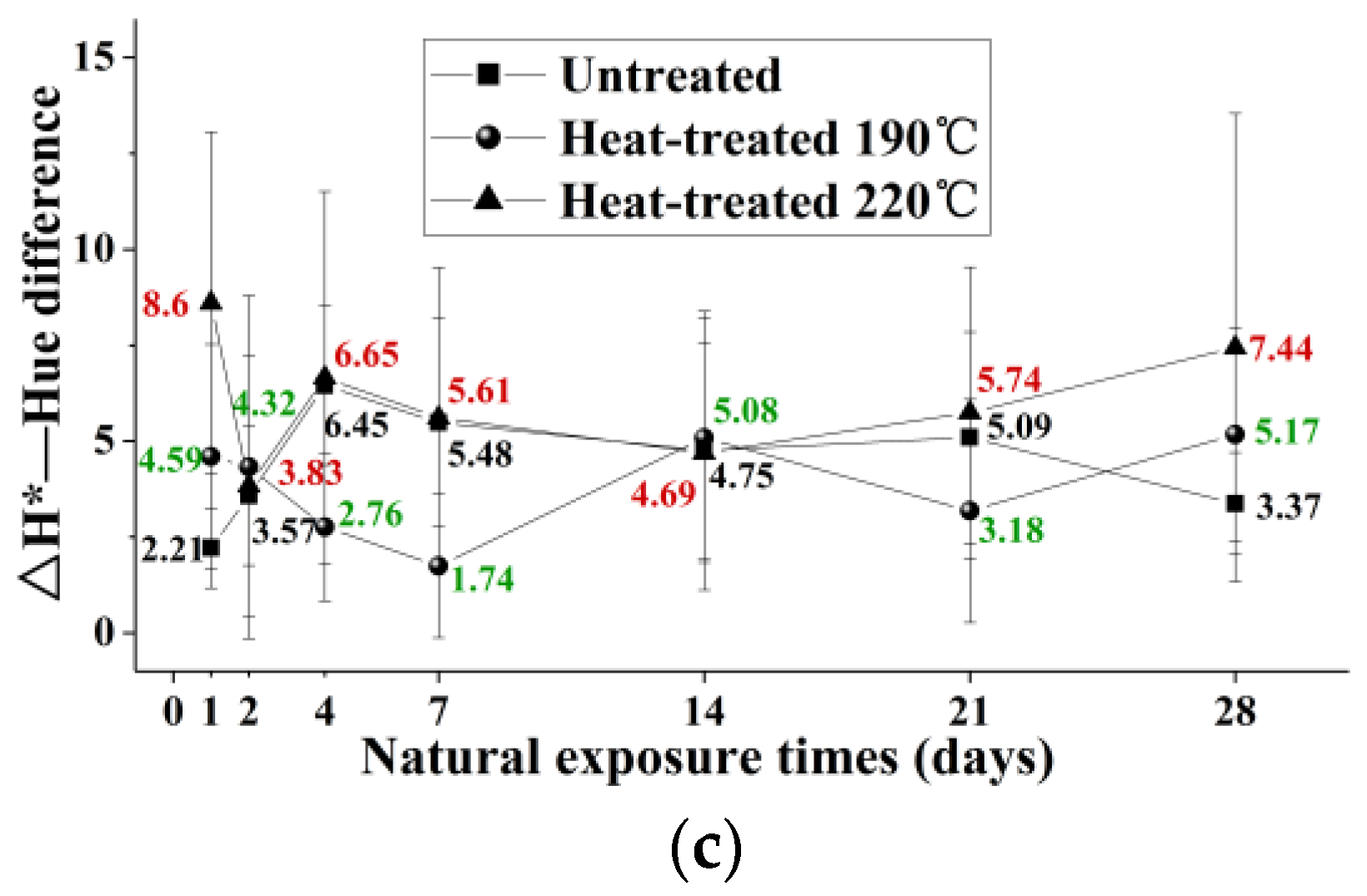

3.1. Discoloration of Wood Surfaces

3.2. Wood Structure Changes

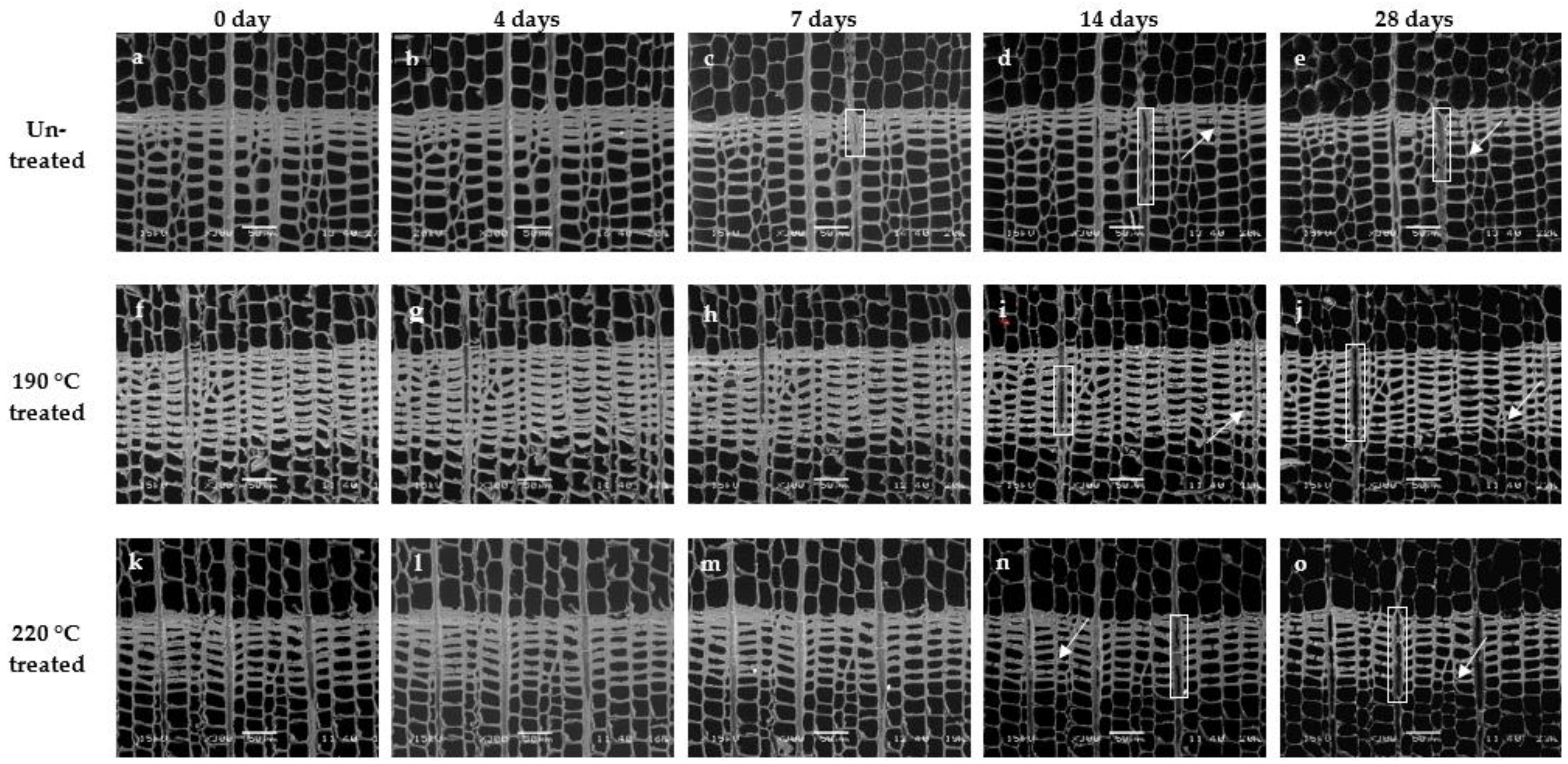

3.2.1. Cell Wall

3.2.2. Rays

3.2.3. Cross-Field

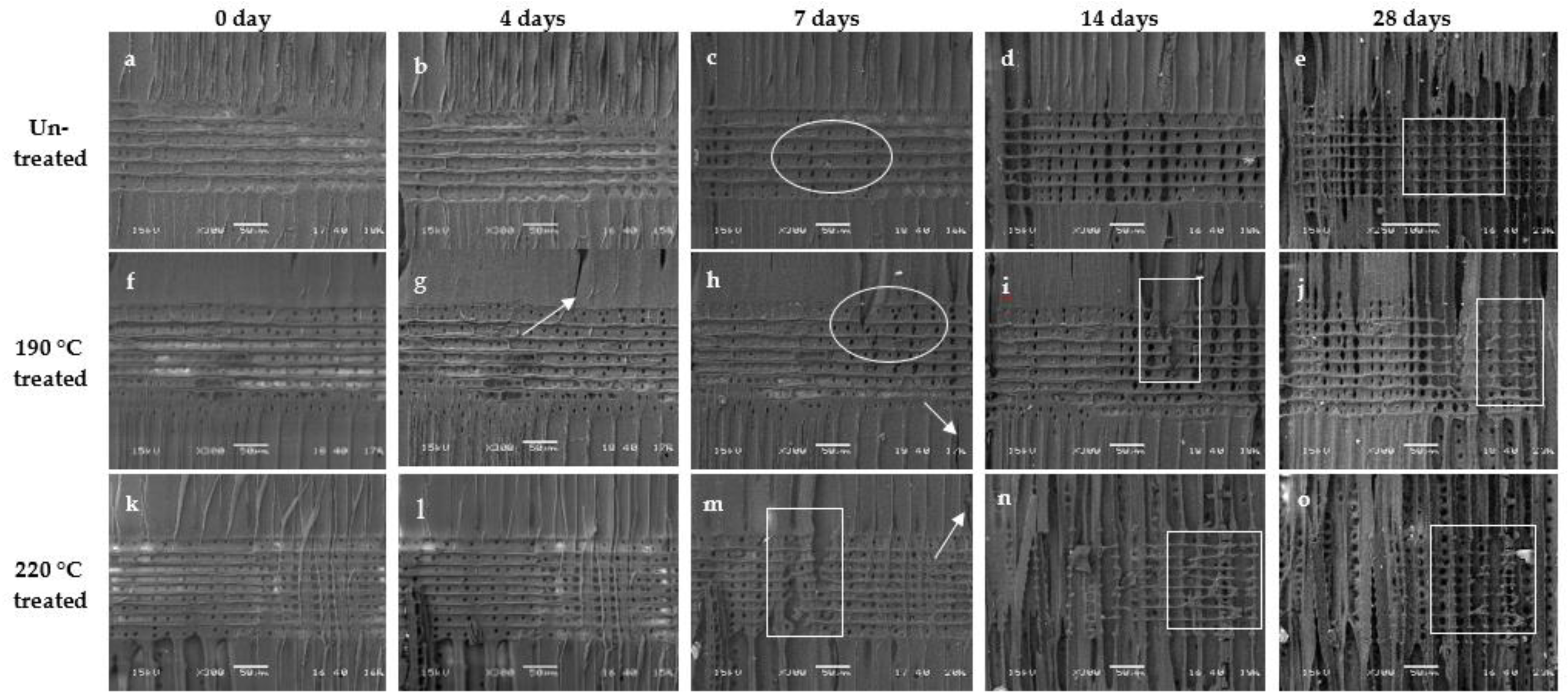

3.2.4. Tracheids

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alfred, J.S.; Horace, K.B.; Albert, A.K. Staybwood—Heat-stabilized wood. Ind. Eng. Chem. 1946, 38, 630–634. [Google Scholar]

- Alfred, J.S. Thermal degradation of wood and cellulose. Ind. Eng. Chem. 1956, 48, 413–417. [Google Scholar]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. Bioresources 2009, 4, 370–404. [Google Scholar]

- Militz, H. Heat Treatment of Wood: European Processes and Their Background. In International Research Group Wood Pre, Section 4-Processes; Nº IRG/WP; International Research Group on Wood Protection: Stockholm, Sweden, 2002; p. 40241. [Google Scholar]

- Kocaefe, D.; Poncsak, S.; Doré, G.; Younsi, R. Effect of heat treatment on the wettability of white ash and soft maple by water. Holz Roh. Werkst. 2008, 66, 355–361. [Google Scholar] [CrossRef]

- Bengtsson, C.; Jermer, J.; Brem, F. Bending Strength of Heat-Treated Spruce and Pine Timber. In International Research Group Wood Pre, Section 4-Processes; Nº IRG/WP; International Research Group on Wood Protection: Stockholm, Sweden, 2002; p. 40242. [Google Scholar]

- Syrjänen, T.; Kangas, E. Heat-Treated Timber in Finland. In International Research Group Wood Pre, Section 4-Processes; Nº IRG/WP; International Research Group on Wood Protection: Stockholm, Sweden, 2000; p. 40158. [Google Scholar]

- Williams, R.S. Weathering of wood. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 139–185. [Google Scholar]

- William, C.F.; David, N.S.H. Chemistry of weathering and protection. In The Chemistry of Solid Wood, Advances in Chemistry Series 207; Rowell, R.M., Ed.; American Chemical Society: Washington, DC, USA, 1984; pp. 401–451. [Google Scholar]

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Color stability of heat–treated wood during artificial weathering. Holz Roh. Werkst. 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Deka, M.; Humar, M.; Rep, G.; Kričej, B.; Šentjurc, M.; Petrič, M. Effects of UV light irradiation on colour stability of thermally modified, copper ethanolamine treated and non-modified wood: EPR and DRIFT spectroscopic studies. Wood Sci. Technol. 2008, 42, 5–20. [Google Scholar] [CrossRef]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Pichette, A. Study of the degradation behavior of heat-treated jack pine (Pinus banksiana) under artificial sunlight irradiation. Polym. Degrad. Stabil. 2012, 97, 1197–1214. [Google Scholar] [CrossRef]

- Yildiz, S.; Tomak, E.D.; Yildiz, U.C.; Ustaomer, D. Effect of artificial weathering on the properties of heat reated wood. Polym. Degrad. Stabil. 2013, 98, 1419–1427. [Google Scholar] [CrossRef]

- Todaro, L.; D’Auria, M.; Langerame, F.; Salvi, A.M.; Scopa, A. Surface characterization of untreated and hydro-thermally pre-treated Turkey oak woods after UV-C irradiation. Surf. Interface Anal. 2015, 47, 206–215. [Google Scholar] [CrossRef]

- Xing, D.; Wang, S.; Li, J. Effect of Artificial weathering on the properties of industrial-scale thermally modified wood. BioResources 2015, 10, 8238–8252. [Google Scholar] [CrossRef]

- Shen, H.; Cao, J.; Sun, W.; Peng, Y. Influence of post-extraction on photostability of thermally modified scots pine wood during artificial weathering. BioResources 2016, 11, 4512–4525. [Google Scholar] [CrossRef]

- Evans, P.D.; Thay, P.D.; Schmalzl, K.J. Degradation of wood surfaces during natural weathering. Effects on lignin and cellulose and on the adhesion of acrylic latex primers. Wood Sci. Technol. 1996, 30, 411–422. [Google Scholar] [CrossRef]

- Li, K.F.; Yong, F.Y.; Robert, R.M. Taxodiaceae. Flora China 1999, 4, 54–61. [Google Scholar]

- Cao, Y.; Jiang, J.; Lu, J.; Huang, R.; Jiang, J.; Wu, Y. Color change of Chinese fir through steam-heat treatment. Bioresources 2012, 7, 2809–2819. [Google Scholar]

- Cheng, D.L. The Study on Technics and Properties of Heat Treated Fir Wood. Master’s Thesis, Nanjing Forest University, Nanjing, China, June 2007. [Google Scholar]

- Japan Meteorological Agency. Available online: https://www.jma.go.jp/jma/index.html (accessed on 1–31 August 2018).

- Kataoka, Y.; Kiguchi, M. Weatherability of water-borne wood preservation semi-transparent coatings (I)—Coating performance during 24 months of natural weathering. Wood Preserv. 2009, 35, 204–214. [Google Scholar] [CrossRef][Green Version]

- Robertson, A.R. The CIE 1976 color-difference formulae. Color Res. Appl. 1977, 2, 7–11. [Google Scholar] [CrossRef]

- Tolvaj, L.; Faix, O. Artificial ageing of wood monitored by DRIFT spectroscopy and CIE L*a*b* color measurements. I. Effect of UV light. Holzforschung 1995, 49, 397–404. [Google Scholar] [CrossRef]

- Hatae, F.; Kataoka, Y.; Kiguchi, M.; Matsunaga, H.; Matsumura, J. In Site Visualization of Wood Degradation during Artificial Weathering by Variable Pressure Scanning Electron Microscopy. In Proceedings of the 11th Pacific Rim Bio-Based Composites Symposium (BIOCOMP 2012), Shizuoka, Japan, 27–30 November 2012; pp. 226–232. [Google Scholar]

- Hatae, F.; Kataoka, Y.; Kiguchi, M.; Matsunaga, H.; Matsumura, J. Use of Variable Pressure Scanning Electron Microscopy for in Situ Observation of Degradation of Wood Surfaces during Artificial Weathering. In Proceedings of the International Research Group on Wood Protection, IRG/WP 12-20489, Kuala Lumpur, Malaysia, 6–10 May 2012. [Google Scholar]

- Pandey, K.K. Study of the effect of photo-irradiation on the surface chemistry of wood. Polym. Degrad. Stabil. 2005, 90, 9–20. [Google Scholar] [CrossRef]

- Mitsui, K.; Tsuchikawa, S. Low atmospheric temperature dependence on photodegradation of wood. J. Photochem. Photobiol. B 2005, 81, 84–88. [Google Scholar] [CrossRef]

- Miklecic, J.; Jirouš-Rajković, V.; Antonović, A.; Španić, N. Discoloration of thermally modified wood during simulated indoor sunlight exposure. BioResources 2011, 6, 434–446. [Google Scholar]

- Funaoka, M.; Kako, T.; Abe, I. Condensation of lignin during heating of wood. Wood Sci. Technol. 1990, 24, 277–288. [Google Scholar] [CrossRef]

- Masanori, K.; Nakano, T. Artificial weathering of tropical woods. Part 2: Color change. Holzforschung 2004, 58, 558–565. [Google Scholar]

- Dubey, M.K.; Pang, S.; Walker, J. Color and dimensional stability of oil heat-treated radiata pinewood after accelerated UV weathering. Forest Prod. J. 2010, 60, 453–459. [Google Scholar] [CrossRef]

- Temiz, A.; Terziev, N.; Jacobsen, B.; Eikenes, M. Weathering, water absorption, and durability of silicon, acetylated, and heat-treated wood. J. Appl. Polym. Sci. 2006, 102, 4506–4513. [Google Scholar] [CrossRef]

- Cheng, S.; Huang, A.; Wang, S.; Zhang, Q. Effect of different heat treatment temperatures on the chemical composition and structure of Chinese fir wood. BioResources 2016, 11, 4006–4016. [Google Scholar] [CrossRef]

- Xing, D.; Li, J. Effects of heat treatment on thermal decomposition and combustion performance of Larix spp. Wood. BioResources 2014, 9, 4274–4287. [Google Scholar] [CrossRef]

- Svetlana, B.; Marko, H.; Timo, K. Weathering of wood-polypropylene composites containing pigments. Eur. J. Wood Prod. 2012, 70, 719–726. [Google Scholar]

- Hyvärinen, M.; Butylina, S.; Kärki, T. Accelerated and natural weathering of wood-polypropylene composites containing pigments. Adv. Mater. Res. 2015, 1077, 139–145. [Google Scholar] [CrossRef]

- Tolvaj, L.; Faix, O. Artificial ageing Colom, X.; Carrillo, F.; Nogue’s, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stabil. 2003, 80, 543–549. [Google Scholar]

- Pandey, K.K.; Vuorinen, T. Comparative study of photodegradation of wood by a UV laser and a xenon light source. Polym. Degrad. Stabil. 2008, 93, 2138–2146. [Google Scholar] [CrossRef]

- Preklet, E.; Papp, G.; Barta, E.; Tolvaj, L.; Berkesi, O.; Bohus, J.; Szatmári, S. Changes in DRIFT spectra of wood irradiated by lasers of different wavelength. J. Photochem. Photobiol. B 2012, 112, 43–47. [Google Scholar] [CrossRef] [PubMed]

- Calienno, L.; Monaco, A.L.; Pelosi, C.; Picchio, R. Colour and chemical changes on photodegraded beech wood with or without red heartwood. Wood Sci. Technol. 2014, 48, 1167–1180. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Rijsdijk, J.F.; Sander, C.; Kegel, E.; Tjeerdsma, B.; Militz, H.; Acker, J.V.; Stevens, M. Microstructural and physical aspects of heat treated wood. Part 1. Softwoods. Maderas Cienc. Tecnol. 2006, 8, 193–208. [Google Scholar] [CrossRef]

- Rowell, R.M.; Roger, P.; James, S.H.; Jeffrey, S.R.; Mandla, A.T. Cell wall chemistry. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 35–74. [Google Scholar]

| N | Mean Rank | Sum of Ranks | |||

|---|---|---|---|---|---|

| ∆C* | 190 °C heat-treated–untreated | Negative ranks | 48 a | 37.11 | 1781.50 |

| Positive ranks | 20 b | 28.23 | 564.50 | ||

| Ties | 0 c | ||||

| Total | 68 | ||||

| 220 °C heat-treated–untreated | Negative ranks | 17 a | 22.12 | 376.00 | |

| Positive ranks | 53 b | 39.79 | 2109.00 | ||

| Ties | 0 c | ||||

| Total | 70 | ||||

| ∆E* | 190 °C heat-treated–untreated | Negative ranks | 39 a | 30.74 | 1199.00 |

| Positive ranks | 29 b | 39.55 | 1147.00 | ||

| Ties | 0 c | ||||

| Total | 68 | ||||

| 220 °C heat-treated–untreated | Negative ranks | 4 a | 14.50 | 203.00 | |

| Positive ranks | 56 b | 40.75 | 2282.00 | ||

| Ties | 0 c | ||||

| Total | 70 | ||||

| ∆H* | 190 °C heat-treated–untreated | Negative ranks | 41 a | 35.30 | 1447.50 |

| Positive ranks | 27 b | 33.28 | 898.50 | ||

| Ties | 0 c | ||||

| Total | 68 | ||||

| 220 °C heat-treated–untreated | Negative ranks | 28 a | 30.20 | 845.50 | |

| Positive ranks | 42 b | 39.04 | 1639.50 | ||

| Ties | 0 c | ||||

| Total | 70 |

| ∆C* | ∆E* | ∆H* | ||||

|---|---|---|---|---|---|---|

| 190 °C | 220 °C | 190 °C | 220 °C | 190 °C | 220 °C | |

| Z | −3.718 b | −5.071 b | −0.159 b | −6.083 b | −1.677 b | −2.323 b |

| Asymp. Sig. (2-talled) | ** | ** | 0.874 | ** | 0.093 | * |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, X.; Matsumura, J. Wood Surface Changes of Heat-Treated Cunninghamia lanceolate Following Natural Weathering. Forests 2019, 10, 791. https://doi.org/10.3390/f10090791

Cui X, Matsumura J. Wood Surface Changes of Heat-Treated Cunninghamia lanceolate Following Natural Weathering. Forests. 2019; 10(9):791. https://doi.org/10.3390/f10090791

Chicago/Turabian StyleCui, Xinjie, and Junji Matsumura. 2019. "Wood Surface Changes of Heat-Treated Cunninghamia lanceolate Following Natural Weathering" Forests 10, no. 9: 791. https://doi.org/10.3390/f10090791

APA StyleCui, X., & Matsumura, J. (2019). Wood Surface Changes of Heat-Treated Cunninghamia lanceolate Following Natural Weathering. Forests, 10(9), 791. https://doi.org/10.3390/f10090791