Streamlined Life Cycle Assessment of an Innovative Bio-Based Material in Construction: A Case Study of a Phase Change Material Panel

Abstract

1. Introduction

2. Materials and Methods

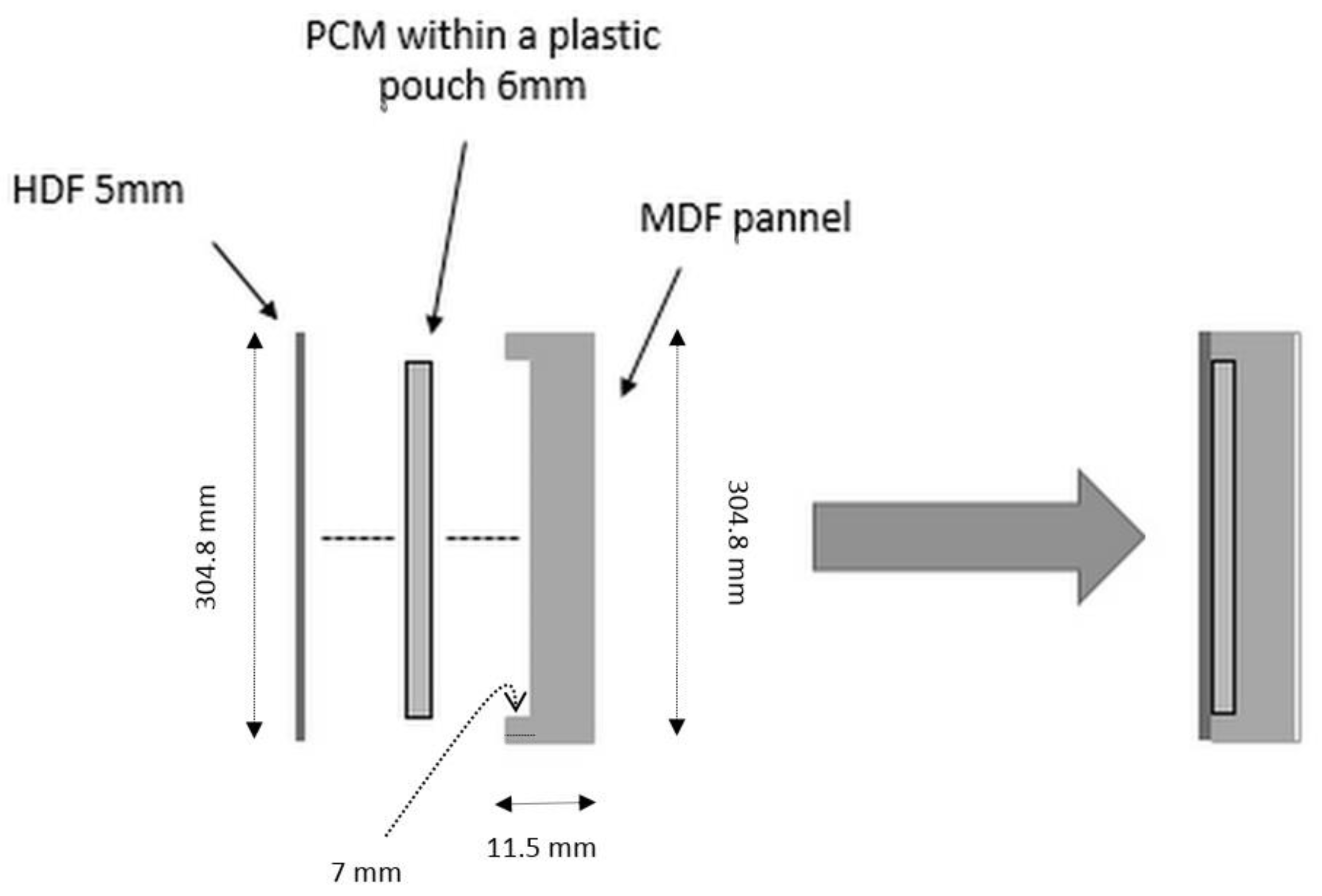

2.1. PCM Panel

2.2. Full LCA

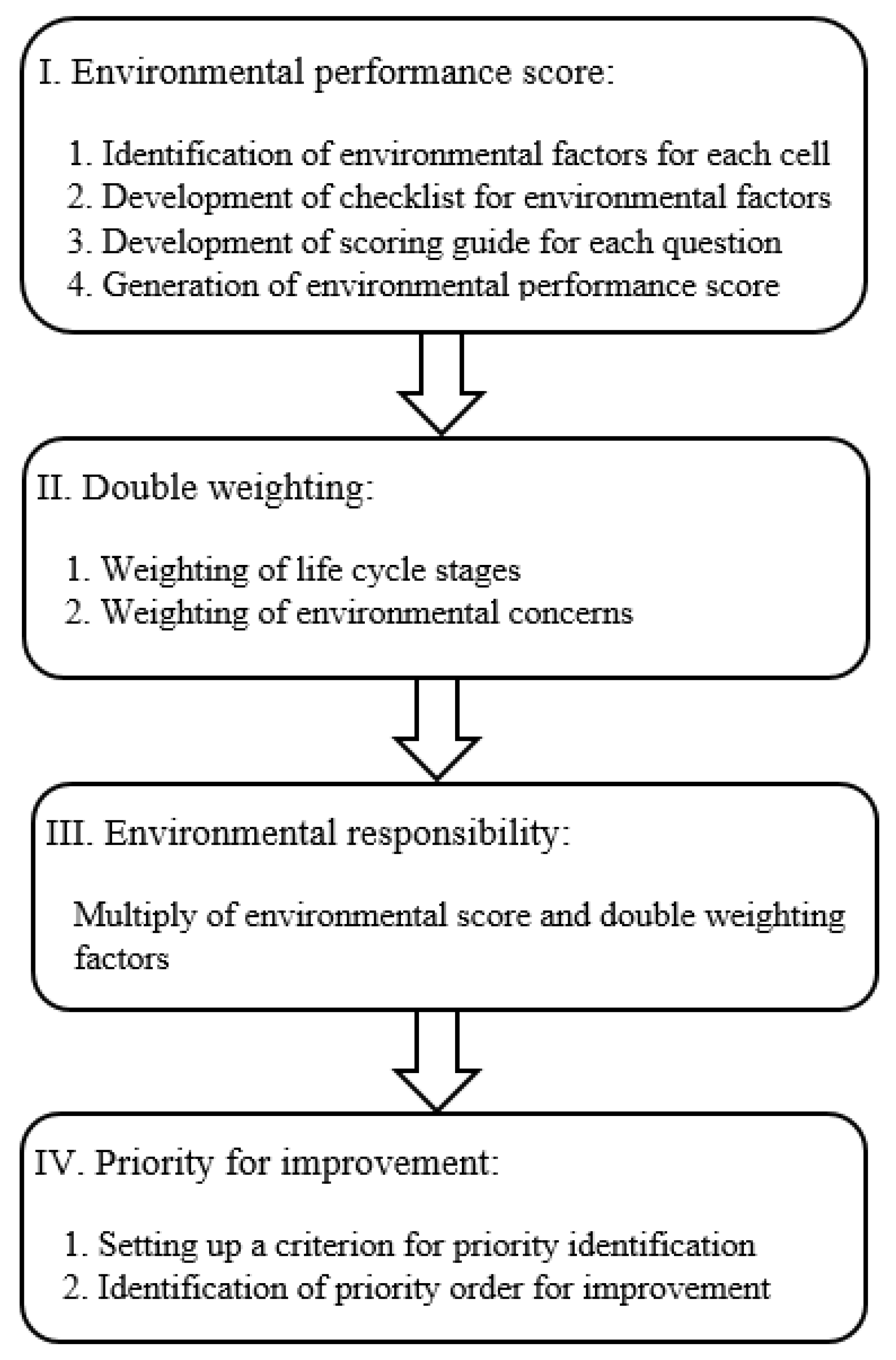

2.3. Matrix-Based LCA/Environmentally Responsible Product Assessment (ERPA)

2.4. Bilan Produit Tool

3. Results and Discussion

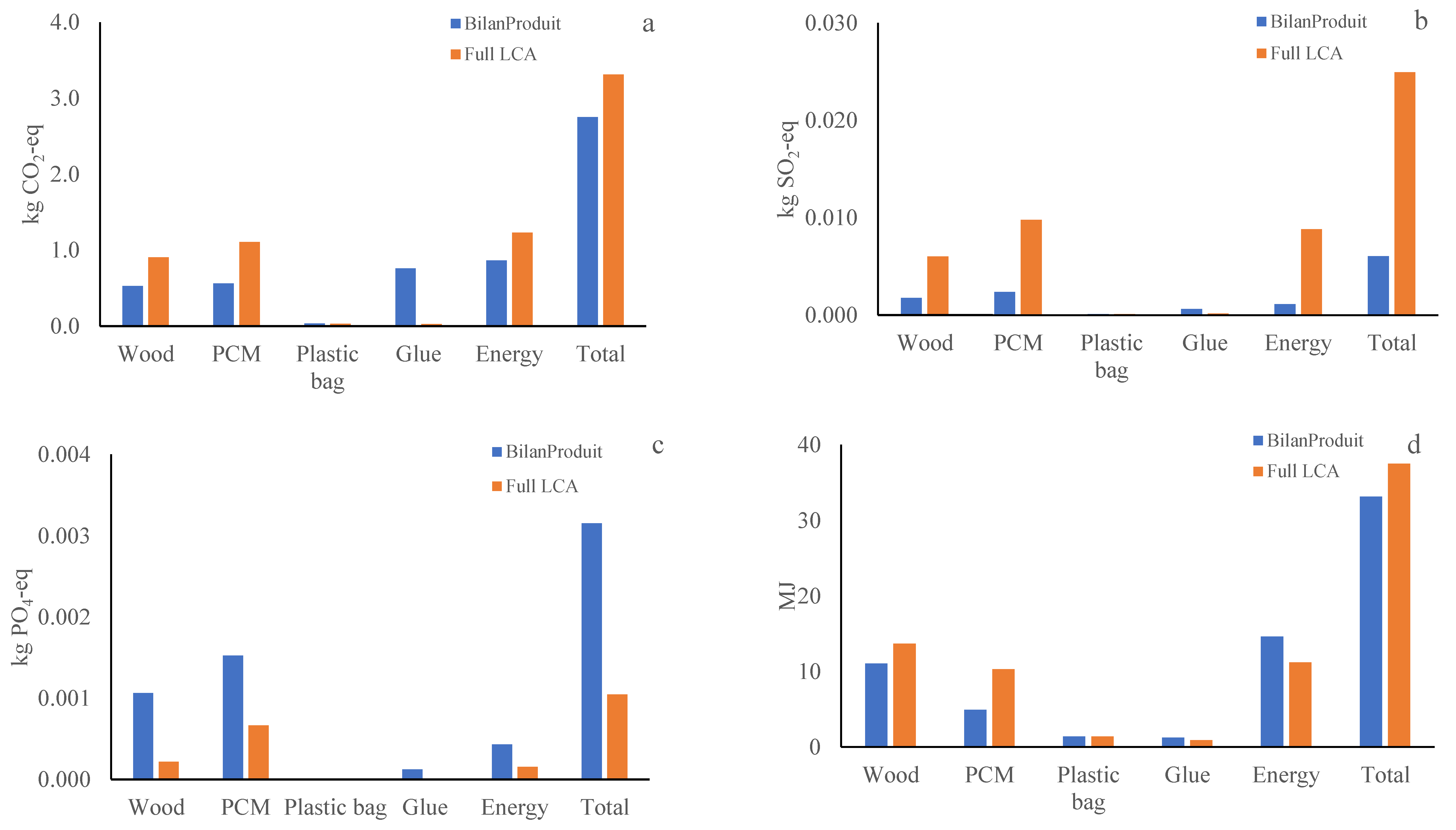

3.1. Full LCA Results

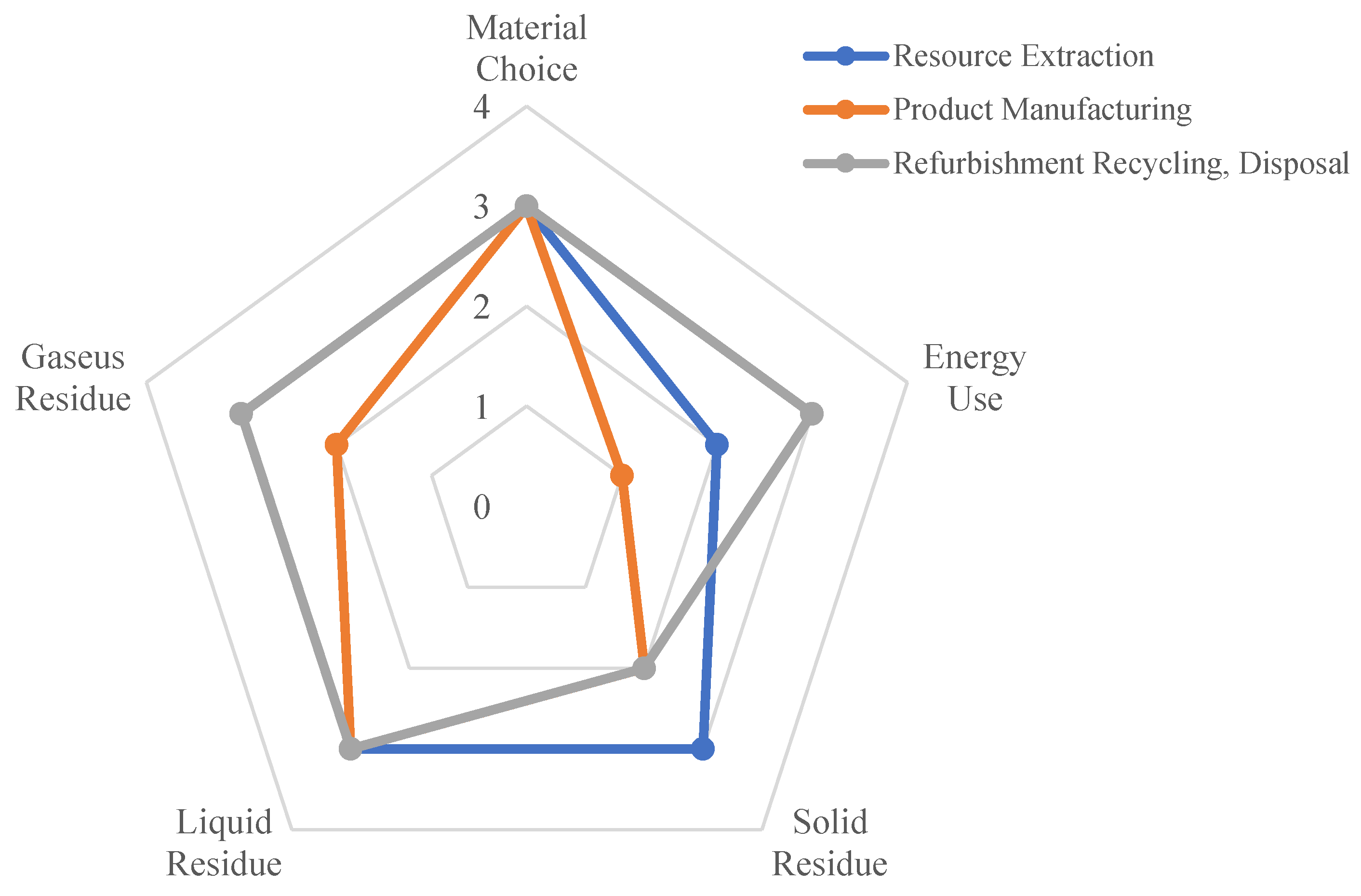

3.2. Matrix-Based LCA Results

3.3. Bilan Produit Tool Results

3.4. Challenges With the Streamlined Life Cycle Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Skodras, G.; Grammelis, P.; Kakaras, E.; Sakellaropoulos, G.P. Evaluation of the environmental impact of waste wood co-utilisation for energy production. Energy 2004, 29, 2181–2193. [Google Scholar] [CrossRef]

- Petersen, A.K.; Solberg, B. Environmental and economic impacts of substitution between wood products and alternative materials: A review of micro-level analyses from Norway and Sweden. For. Policy Econ. 2005, 7, 249–259. [Google Scholar] [CrossRef]

- Stael, G.; Tavares, M.I.; d’Almeida, J.R. Impact behavior of sugarcane bagasse waste–EVA composites. Polym. Test. 2001, 20, 869–872. [Google Scholar] [CrossRef]

- Anonymous Biomass in a low-carbon economy, Committee on Climate Change. 2018. Available online: https://www.theccc.org.uk/publication/biomass-in-a-low-carbon-economy (accessed on 15 November 2018).

- Ferro, F.S.; Silva, D.A.L.; Rocco Lahr, F.A.; Argenton, M.; González-García, S. Environmental aspects of oriented strand boards production. A Brazilian case study. J. Clean. Prod. 2018, 183, 710–719. [Google Scholar] [CrossRef]

- Kam-Biron, M.; Podesto, L. The Growing Role of Wood in Building Sustainability. In Proceedings of the AEI 2011; American Society of Civil Engineers: Reston, VA, USA, 2011; pp. 318–326. [Google Scholar]

- Piccardo, C.; Magliocco, A. The Environmental Profile of Wood in the Building Industry Today: Comments on the Results of Some LCA Studies. Am. J. Civ. Eng. Archit. 2013, 1, 122–128. [Google Scholar] [CrossRef]

- Ross, S.; Evans, D. Use of Life Cycle Assessment in Environmental Management. Environ. Manage. 2002, 29, 132–142. [Google Scholar] [CrossRef] [PubMed]

- Jolliet, O.; Saadé-Sbeih, M.; Shaked, S.; Jolliet, A.; Crettaz, P. Environmental Life Cycle Assessment; Taylor & Francis: New York, NY, USA, 2015; ISBN 9781439887660. [Google Scholar]

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 1 July 2006).

- Weston, N.; Clift, R.; Holmes, P.; Basson, L.; White, N. Streamlined Life Cycle Approaches for Use at Oil Refineries and Other Large Industrial Facilities. Ind. Eng. Chem. Res. 2011, 50, 1624–1636. [Google Scholar] [CrossRef]

- Schary, P.B.; Skjott-Larsen, T. Managing the Global Supply Chain; Copenhagen Business School Press: Copenhagen, Denmark, 2001; ISBN 8716135008. [Google Scholar]

- Arzoumanidis, I.; Raggi, A.; Petti, L. Considerations when applying simplified LCA approaches in the wine sector. Sustainability 2014, 6, 5018–5028. [Google Scholar] [CrossRef]

- Wu, H.; Duan, H.; Wang, J.; Wang, T.; Wang, X. Quantification of carbon emission of construction waste by using streamlined LCA: A case study of Shenzhen, China. J. Mater. Cycles Waste Manag. 2015, 17, 637–645. [Google Scholar] [CrossRef]

- Lawania, K.K.; Biswas, W.K. Achieving environmentally friendly building envelope for Western Australia’s housing sector: A life cycle assessment approach. Int. J. Sustain. Built Environ. 2016, 5, 210–224. [Google Scholar] [CrossRef]

- Biswas, W.K. Carbon footprint and embodied energy assessment of a civil works program in a residential estate of Western Australia. Int. J. Life Cycle Assess. 2014, 19, 732–744. [Google Scholar] [CrossRef]

- Santos, P.; Gervásio, H.; da Silva, L.S. A simplified tool to evaluate the sustainability of buildings in steel in early stages of design. Matériaux Tech. 2016, 104, 103. [Google Scholar] [CrossRef]

- Danilecki, K.; Mrozik, M.; Smurawski, P. Changes in the environmental profile of a popular passenger car over the last 30 years—Results of a simplified LCA study. J. Clean. Prod. 2017, 141, 208–218. [Google Scholar] [CrossRef]

- Moriarty, P.; Honnery, D. The prospects for global green car mobility. J. Clean. Prod. 2008, 16, 1717–1726. [Google Scholar] [CrossRef]

- Sundaravaradan, N.; Marwah, M.; Shah, A.; Ramakrishnan, N. Data mining approaches for life cycle assessment. In Proceedings of the 2011 IEEE International Symposium on Sustainable Systems and Technology; Institute of Electrical and Electronics Engineers (IEEE): Chicago, IL, USA, 2011; pp. 1–6. [Google Scholar]

- Arena, M.; Azzone, G.; Conte, A. A streamlined LCA framework to support early decision making in vehicle development. J. Clean. Prod. 2013, 41, 105–113. [Google Scholar] [CrossRef]

- Duan, H.; Wang, J. Quantification of the Carbon Emission of Road and Highway Construction in China Using Streamlined LCA. In Proceedings of the 19th International Symposium on Advancement of Construction Management and Real Estate; Springer: Berlin, Germany, 2015; pp. 181–191. [Google Scholar]

- Andrae, A.S.G. Life-Cycle Assessment of Consumer Electronics: A review of methodological approaches. IEEE Consum. Electron. Mag. 2016, 5, 51–60. [Google Scholar] [CrossRef]

- Padey, P.; Girard, R.; Le Boulch, D.; Blanc, I. From LCAs to simplified models: A generic methodology applied to wind power electricity. Environ. Sci. Technol. 2013, 47, 1231–1238. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Zamagni, A.; Raggi, A.; Petti, L.; Magazzeni, D. Chapter 7—The Implementation of Simplified LCA in Agri-Food SMEs; Springer: Dordrecht, The Netherlands, 2013; pp. 151–173. [Google Scholar]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is there a simplified LCA tool suitable for the agri-food industry? An assessment of selected tools. J. Clean. Prod. 2017, 149, 406–425. [Google Scholar] [CrossRef]

- Bellon-Maurel, V.; Short, M.D.; Roux, P.; Schulz, M.; Peters, G.M. Streamlining life cycle inventory data generation in agriculture using traceability data and information and communication technologies - Part I: Concepts and technical basis. J. Clean. Prod. 2014, 69, 60–66. [Google Scholar] [CrossRef]

- Bellon-Maurel, V.; Peters, G.M.; Clermidy, S.; Frizarin, G.; Sinfort, C.; Ojeda, H.; Roux, P.; Short, M.D. Streamlining life cycle inventory data generation in agriculture using traceability data and information and communication technologies e part II: Application to viticulture. J. Clean. Prod. 2015, 87, 119–129. [Google Scholar] [CrossRef]

- Sanjuán, N.; Stoessel, F.; Hellweg, S. Closing Data Gaps for LCA of Food Products: Estimating the Energy Demand of Food Processing. Environ. Sci. Technol. 2014, 48, 1132–1140. [Google Scholar] [CrossRef]

- Castellani, V.; Sala, S.; Benini, L. Hotspots analysis and critical interpretation of food life cycle assessment studies for selecting eco-innovation options and for policy support. J. Clean. Prod. 2016, 140, 556–568. [Google Scholar] [CrossRef]

- Castell, A.; Pérez, G. 13—Life Cycle Assessment (LCA) of Phase Change Materials (PCMs) Used in Buildings. In Eco-efficient Construction and Building Materials; Woodhead Publishing: Cambridge, UK, 2014; pp. 287–310. ISBN 9780857097675. [Google Scholar]

- Lamnatou, C.; Motte, F.; Notton, G.; Chemisana, D.; Cristofari, C. Cumulative energy demand and global warming potential of a building-integrated solar thermal system with/without phase change material. J. Environ. Manage. 2018, 212, 301–310. [Google Scholar] [CrossRef] [PubMed]

- Lamnatou, C.; Motte, F.; Notton, G.; Chemisana, D.; Cristofari, C. Building-integrated solar thermal system with/without phase change material: Life cycle assessment based on ReCiPe, USEtox and Ecological footprint. J. Clean. Prod. 2018, 193, 672–683. [Google Scholar] [CrossRef]

- De Falco, M.; Capocelli, M.; Losito, G.; Piemonte, V. LCA perspective to assess the environmental impact of a novel PCM-based cold storage unit for the civil air conditioning. J. Clean. Prod. 2017, 165, 697–704. [Google Scholar] [CrossRef]

- Noël, J.A.; Allred, P.M.; White, M.A. Life cycle assessment of two biologically produced phase change materials and their related products. Int. J. Life Cycle Assess. 2015, 20, 367–376. [Google Scholar] [CrossRef]

- Menoufi, K.; Castell, A.; Farid, M.M.; Boer, D.; Cabeza, L.F. Life Cycle Assessment of experimental cubicles including PCM manufactured from natural resources (esters): A theoretical study. Renew. Energy 2013, 51, 398–403. [Google Scholar] [CrossRef]

- Rivela, B.; Moreira, M.T.; Feijoo, G. Wood and Other Renewable Resources Life Cycle Inventory of Medium Density Fibreboard. Int. J. Life Cycle Assess. 2007, 12, 143–150. [Google Scholar] [CrossRef]

- Werner, F.; Althaus, H.-J.; Richter, K.; Scholz, R.W. Post-Consumer Waste Wood in Attributive Product LCA Context specific evaluation of allocation procedures in a functionalistic conception of LCA. Int. J. LCA 2007, 12, 12–160. [Google Scholar]

- Kline, D.E. CORRIM: Phase I Final Report, Module E: SOUTHEASTERN ORIENTED STRANDBOARD PRODUCTION. 2004. Available online: https://corrim.org/wp-content/uploads/2018/03/oriented-strandboard-us.pdf (accessed on 1 June 2014).

- Rivela, B.; Hospido, A.; Moreira, T.; Feijoo, G. Life Cycle Inventory of Particleboard: A Case Study in the Wood Sector (8 pp). Int. J. Life Cycle Assess. 2006, 11, 106–113. [Google Scholar] [CrossRef]

- Wilson, J.B.; Dancer, E.R. Gate-to-gate lyfe-cycle inventory of laminated veneer lumber production. Spec. Issue 2005, 37, 114–127. [Google Scholar]

- Llorach-Massana, P.; Peña, J.; Rieradevall, J.; Montero, J.I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef]

- De Gracia, A.; Rincón, L.; Castell, A.; Jiménez, M.; Boer, D.; Medrano, M.; Cabeza, L.F. Life Cycle Assessment of the inclusion of phase change materials (PCM) in experimental buildings. Energy Build. 2010, 42, 1517–1523. [Google Scholar] [CrossRef]

- Menoufi, K.; Castell, A.; Navarro, L.; Pérez, G.; Boer, D.; Cabeza, L.F. Evaluation of the environmental impact of experimental cubicles using Life Cycle Assessment: A highlight on the manufacturing phase. Appl. Energy 2012, 92, 534–544. [Google Scholar] [CrossRef]

- Aranda-Usón, A.; Ferreira, G.; López-Sabirón, A.M.; Mainar-Toledo, M.D.; Zabalza Bribián, I. Phase change material applications in buildings: An environmental assessment for some Spanish climate severities. Sci. Total Environ. 2013, 444, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Rincon, L.; Castell, A.; Perez, G.; Sole, C.; Boer, D.; Cabeza, L.F. Evaluation of the environmental impact of experimental buildings with different constructive systems using Material Flow Analysis and Life Cycle Assessment. Appl. Energy 2013, 109, 544–552. [Google Scholar] [CrossRef]

- Serrano, S.; Barreneche, C.; Rincón, L.; Boer, D.; Cabeza, L.F. Optimization of three new compositions of stabilized rammed earth incorporating PCM: Thermal properties characterization and LCA. Constr. Build. Mater. 2013, 47, 872–878. [Google Scholar] [CrossRef]

- Castell, A.; Menoufi, K.; de Gracia, A.; Rincón, L.; Boer, D.; Cabeza, L.F. Life Cycle Assessment of alveolar brick construction system incorporating phase change materials (PCMs). Appl. Energy 2013, 101, 600–608. [Google Scholar] [CrossRef]

- de Gracia, A.; Navarro, L.; Castell, A.; Boer, D.; Cabeza, L.F. Life cycle assessment of a ventilated facade with PCM in its air chamber. Sol. Energy 2014, 104, 115–123. [Google Scholar] [CrossRef]

- Vasco, D.A.; Salinas-Lira, C.; Barra-Reyes, I.; Elustondo, D.M. Kinematic characterization of the pressure-dependent PCM impregnation process for radiata pine wood samples. Eur. J. Wood Wood Prod. 2018, 76, 1461–1469. [Google Scholar] [CrossRef]

- Li, J.; Xue, P.; Ding, W.; Han, J.; Sun, G. Micro-encapsulated paraffin/high-density polyethylene/wood flour composite as form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2009, 93, 1761–1767. [Google Scholar] [CrossRef]

- Liang, J.; Zhimeng, L.; Ye, Y.; Yanjun, W.; Jingxin, L.; Changlin, Z. Fabrication and characterization of fatty acid/wood-flour composites as novel form-stable phase change materials for thermal energy storage. Energy Build. 2018, 171, 88–99. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Lagière, P.; Landry, V.; Mathis, D.; Blanchet, P.; Lagière, P.; Landry, V. Performance of Wood-Based Panels Integrated with a Bio-Based Phase Change Material: A Full-Scale Experiment in a Cold Climate with Timber-Frame Huts. Energies 2018, 11, 3093. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Thermal characterization of bio-based phase changing materials in decorative wood-based panels for thermal energy storage. Green Energy Environ. 2019, 4, 56–65. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P.; Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Impregnation of Wood with Microencapsulated Bio-Based Phase Change Materials for High Thermal Mass Engineered Wood Flooring. Appl. Sci. 2018, 8, 2696. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; van Zelm, R.; ReCiPe. A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level, Report I: Characterization; RIVM Report 2016-0104: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Pre-sustainability SimaPro 8.4.1.4. Available online: https://www.pre-sustainability.com (accessed on 1 April 2018).

- Graedel, T.E.; Lanzano, T.; Pott, W. Multiscale Life-Cycle Assessment. Available online: http://environment.yale.edu/publication-series/documents/downloads/v-z/wp_6_multiscale_lifecycle.pdf (accessed on 1 September 2005).

- Sharfman, M.; Graedel, T.E.; Allenby, B.R. Industrial Ecology. Acad. Manag. Rev. 1995, 20, 1090. [Google Scholar] [CrossRef]

- Wilson, J. Life-cycle inventory of medium density fiberboard in terms of resources, emissions, energy and carbon. Wood Fiber Sci. 2010, 42, 107–124. [Google Scholar]

- Kylili, A.; Fokaides, P.A. Life Cycle Assessment (LCA) of Phase Change Materials (PCMs) for building applications: A review. J. Build. Eng. 2016, 6, 133–143. [Google Scholar] [CrossRef]

- Graedel, T.E. Designing the ideal green product: Lca/SCLA in reverse. Int. J. Life Cycle Assess. 1997, 2, 25–31. [Google Scholar] [CrossRef]

- Hochschorner, E.; Finnveden, G. Evaluation of two simplified Life Cycle assessment methods. Int. J. Life Cycle Assess. 2003, 8, 119–128. [Google Scholar] [CrossRef]

- Bewa, H.; Bloch, R.; Boniface, L.; Rethore, O.; Gillmann, M. Study for a Simplified LCA Methodology Adapted to Bioproducts. Study Performed for the ADEME by BIO Intelligence Service.; Agence de l’Environnement et de la Maîtrise de l’Énergie (ADEME): Paris, France, 2009. [Google Scholar]

- Base Impacts BilanProduit. Available online: http://www.base-impacts.ademe.fr/bilan-produit (accessed on 1 April 2018).

- Moberg, A.; Borggren, C.; Ambell, C.; Finnveden, G.; Guldbrandsson, F.; Bondesson, A.; Malmodin, J.; Bergmark, P. Simplifying a life cycle assessment of a mobile phone. Int. J. Life Cycle Assess. 2014, 19, 979–993. [Google Scholar] [CrossRef]

- Lee, J.; Kim, I.; Kwon, E.; Hur, T. Comparison of Simplified LCA and Matrix Methods in Identifying the Environmental Aspects of Products. In Proceedlngs d EcoDesignZ—Third lnternational Sympslum on Envimnmentaliy Conscious Design and Inverse Manufaduring; Institute of Electrical and Electronics Engineers (IEEE): Tokyo, Japan, 2003; pp. 682–686. [Google Scholar]

- Hur, T.; Lee, J.; Ryu, J.; Kwon, E. Simplified LCA and matrix methods in identifying the environmental aspects of a product system. J. Environ. Manage. 2005, 75, 229–237. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hendriks, H.W.M.; Hungehbuhler, K.; Hendriks, A.J. Cumulative energy demand as predictor for the environmental burden of commodity production. Environ. Sci. Technol. 2010, 44, 2189–2196. [Google Scholar] [CrossRef]

- Lasvaux, S.; Lebert, A.; Achim, F.; Grannec, F.; Hoxha, E.; Nibel, S.; Schiopu, N.; Chevalier, J. Towards guidance values for the environmental performance of buildings: Application to the statistical analysis of 40 low-energy single family houses’ LCA in France. Int. J. Life Cycle Assess. 2017, 22, 657–674. [Google Scholar] [CrossRef]

- Todd, J.A.; Curran, M.A. Streamlined Life-Cycle Assessment: A Final Report from the SETAC North America Streamlined LCA Workgroup. 1999. Available online: https://pdfs.semanticscholar.org/8ca0/ac01b77b5f68a96df0de7b4d59cfc827b125.pdf (accessed on 1 June 1999).

- Niero, M.; Di Felice, F.; Ren, J.; Manzardo, A.; Scipioni, A. How can a life cycle inventory parametric model streamline life cycle assessment in the wooden pallet sector? Int. J. Life Cycle Assess. 2014, 19, 901–918. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Width | m | 1.65 × 10−2 |

| Length | m | 3.05 × 10−1 |

| Height | m | 3.05 × 10−1 |

| Volume | m3 | 1.53 × 10−3 |

| Density | Kg/m3 | 889.90 |

| Melting point onset | °C | 20.6 |

| Heat of fusion | J/g | 47.5 |

| Solidifying point | °C | 20.5 |

| Heat of solidification | J/g | 49.8 |

| Component | Name in the Database Ecoinvent Corresponding to the Component | Unit | Value |

|---|---|---|---|

| MDF | Medium density fibreboard | m3 | 5.19 × 10−4 |

| HDF | Fibreboard, hard | m3 | 4.65 × 10−1 |

| PCM | Fatty acid | kg | 0.336 |

| Glue | Vinyl acetate | kg | 0.0140 |

| Plastic bag | Polyethylene, high density, granulate | kg | 0.018 |

| Electricity | Electricity, medium voltage | kWh | 1.420 |

| Heat | Heat, district or industrial, other than natural gas | MJ | 9.960 |

| Approach/Tool | Full LCA | Matrix LCA | Bilan Produit * |

|---|---|---|---|

| Results type (Quantitative/Qualitative) | Quantitative | Semi-quantitative | Quantitative |

| Streamlining level | Both LCI and LCIA level | LCIA level | LCI level |

| Indicators | 15–18 midpoint and Three to four endpoint impact categories | Five environmental concerns: 1. Material Choice 2. Energy Use 3. Solid Residue 4. Liquid Residue 5. Gaseous Residue | Eight impact categories: 1. Acidification 2. Aquatic Ecotoxicity 3. Climate Change 4. Energy consumption 5. Eutrophication 6. Human Toxicity 7. Photochemical pollution 8. Resources consumption |

| Comparison of products | Yes | Yes | No |

| Database | Agri-footprint Ecoinvent v3.3 ELCD EU and Danish Input Output Industry data v.2 Swiss Input Output US LCI | No database | Ecoinvent v2 |

| Free access | No | Yes | Yes |

| Online software | No | No | Yes |

| Time requirements ** | Long | Short | Short |

| Cost | Expensive | Inexpensive | Inexpensive |

| Damage Category | Material Extraction | Manufacturing | Use | End of Life | |

|---|---|---|---|---|---|

| IMPACT2002+ | Human health (DALY) | 0.00 | 0.00 | --- * | 5.7 × 10−10 |

| Ecosystem quality (PDF.m2.y) | 4.69 | 0.28 | --- | 1.7 × 10−4 | |

| Climate change (kg CO2-eq) | 2.08 | 1.23 | --- | 4.8 × 10−3 | |

| Resources (MJ primary) | 26.38 | 11.21 | --- | 6.5 × 10−3 | |

| ReCiPe | Human Health (DALY) | 0.00 | 0.00 | --- | 1.8 × 10−8 |

| Ecosystems (PDF.m2.y) | 2.59 | 0.46 | --- | 1.5 × 10−3 | |

| Resources ($) | 0.15 | 0.03 | --- | 5.7 × 10−5 |

| Damage Category | MDF | HDF | PCM | Plastic Bag | Electricity | Heat | Waste Scenario | |

|---|---|---|---|---|---|---|---|---|

| IMPACT2002+ | Human health (DALY) | 6.1 × 10−7 | 4.9 × 10−7 | 1.9 × 10−6 | 2.8 × 10−8 | 2.0 × 10−7 | 9.8 × 10−7 | 5.7 × 10−10 |

| Ecosystem quality (PDF.m2.y) | 0.3 | 0.3 | 4.0 | 0.0 | 0.1 | 0.3 | 0.0 | |

| Climate change (kg CO2-eq) | 0.4 | 0.3 | 1.1 | 0.0 | 0.3 | 1.2 | 0.0 | |

| Resources (MJ primary) | 6.7 | 5.1 | 10.4 | 1.4 | 7.4 | 10.9 | 0.0 | |

| ReCiPe | Human Health (DALY) | 1.1 × 10−6 | 1.4 × 10−6 | 3.7 × 10−6 | 5.6 × 10−6 | 1.1 × 10−7 | 2.9 × 10−6 | 1.8 × 10−8 |

| Ecosystems (PDF.m2.y) | 0.3 | 0.5 | 1.8 | 0.0 | 0.0 | 0.4 | 0.0 | |

| Resources ($) | 0.0 | 0.0 | 0.1 | 0.0 | 0.0 | 0.0 | 0.0 |

| Indicators | Unit | Wood | PCM | Plastic Bag | Glue | Energy |

|---|---|---|---|---|---|---|

| Non-Renewable Energy | MJ-eq | 11.0558 | 19.3987 | 1.3638 | 1.2125 | 14.6172 |

| Resource consumption | kg Sb-eq | 0.0047 | 0.0086 | 0.0006 | 0.0005 | 0.0070 |

| GWP, 100 years | kg CO2-eq | 0.5290 | 0.2780 | 0.0343 | 0.0271 | 0.8638 |

| Acidification | kg SO2-eq | 0.0018 | 0.0017 | 0.0001 | 0.0001 | 0.0011 |

| Eutrophication (air, water, soil) | kg PO4-eq | 0.0011 | 0.0003 | 0.0000 | 0.0000 | 0.0004 |

| Photochemical pollution | kg C2H4 | 0.0001 | 0.0001 | 0.0000 | 0.0000 | 0.0001 |

| Aquatic ecotoxicity | kg 1,4-DB-eq | 0.1440 | 0.0414 | 0.0005 | 0.0057 | 0.0893 |

| Human Toxicity | kg 1,4-DB-eq | 0.2822 | 0.1523 | 0.0014 | 0.0256 | 0.3647 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heidari, M.D.; Mathis, D.; Blanchet, P.; Amor, B. Streamlined Life Cycle Assessment of an Innovative Bio-Based Material in Construction: A Case Study of a Phase Change Material Panel. Forests 2019, 10, 160. https://doi.org/10.3390/f10020160

Heidari MD, Mathis D, Blanchet P, Amor B. Streamlined Life Cycle Assessment of an Innovative Bio-Based Material in Construction: A Case Study of a Phase Change Material Panel. Forests. 2019; 10(2):160. https://doi.org/10.3390/f10020160

Chicago/Turabian StyleHeidari, Mohammad Davoud, Damien Mathis, Pierre Blanchet, and Ben Amor. 2019. "Streamlined Life Cycle Assessment of an Innovative Bio-Based Material in Construction: A Case Study of a Phase Change Material Panel" Forests 10, no. 2: 160. https://doi.org/10.3390/f10020160

APA StyleHeidari, M. D., Mathis, D., Blanchet, P., & Amor, B. (2019). Streamlined Life Cycle Assessment of an Innovative Bio-Based Material in Construction: A Case Study of a Phase Change Material Panel. Forests, 10(2), 160. https://doi.org/10.3390/f10020160