Hierarchical Coordination Control of Distributed Drive Intelligent Vehicle Based on TSMPC and Tire Force Optimization Allocation

Abstract

1. Introduction

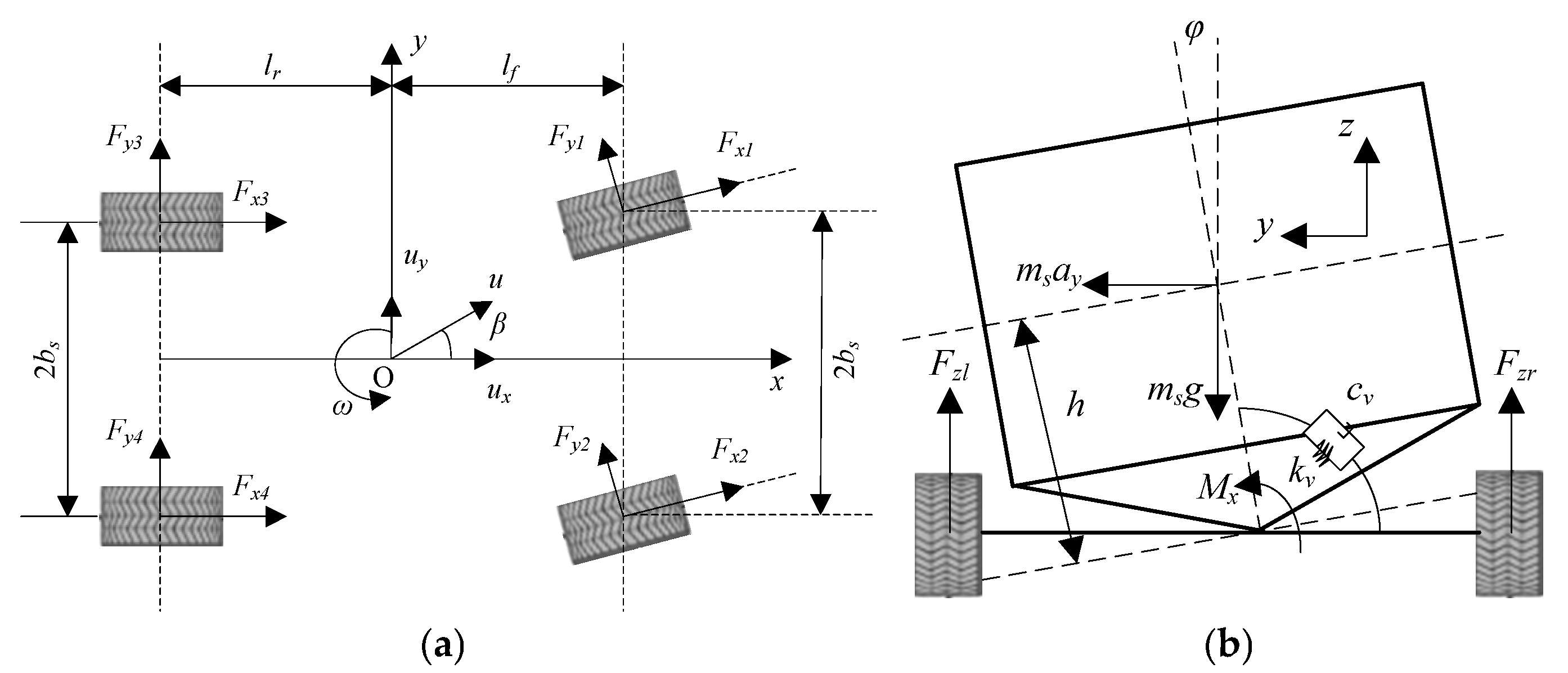

2. Intelligent Vehicle Dynamics Model

2.1. Vehicle Dynamic Model

2.2. Trajectory Tracking Model

3. Layered Coordinated Vehicle Control Method Based on TSMPC and Tire Force Optimization Allocation

3.1. Hierarchical Control Strategy

3.2. Design of Time Delay State Feedback Model Predictive Controller with Incremental Prediction

- (1)

- Initialization: the prediction horizon length p and control horizon length m are set with initial values u(–1) = 0 and x(–1) = 0. Then S1, S2, S3, Sd are calculated.

- (2)

- At time k ≥ 0, the state x(k) and the estimation disturbance d(k) are measured. Then, yc(k) is calculated from Equation (1), and the error Ep(k + 1) is calculated from Equation (22).

- (3)

- The variations in the control variable Δu*(k) are calculated.

- (4)

- The equation u(k) = u(k–1) + Δu*(k) is implemented in the control system.

- (5)

- At the subsequent sampling instant k + 1, the updated state vector of x(k + 1) and measurable disturbance d(k + 1) are measured, the time index is incremented, and the algorithm returns to stage (2) for the next iteration.

3.3. Optimization Allocation of Tire Force Based on the IABC Algorithm

- (1)

- Set the maximum search count for the optimization algorithm. The maximum search count is set as the product of the population size and the dimension of the resolution space. In this article, the population size is configured at 200 individuals with a maximum iteration count of 50 cycles.

- (2)

- Determine the fitness function. In the optimization process, the quality of the honey source needs to be evaluated by the fitness function value. Therefore, it is necessary to first determine the optimization fitness function of the weight coefficients of the tire force optimization allocation control objective function.

- (3)

- Lead the bees to search. Lead bees to randomly search and optimize the current honey source and decide whether to update the current honey source through a greedy selection strategy.

- (4)

- Follow the bees to search. Follow the bee to perform a local search using the search strategy in Equation (6) and decide whether to update the current honey source through a greedy selection strategy.

- (5)

- Search for reconnaissance bees. When the search frequency reaches its maximum, the reconnaissance bee performs an update operation.

- (6)

- Determine termination conditions. Determine whether the number of algorithm iterations has exceeded, and if the conditions are met, end the calculation; if not, repeat steps (3) to (5) until convergence is achieved, at which point the optimized weighting parameter matrix is generated as output.

4. Result Verification

5. Conclusions

- (1)

- A comprehensive vehicular dynamics representation was developed, incorporating propulsion, lateral, and rotational motion characteristics while accounting for critical state variables, including the chassis mass slip angle, rotational velocity, and roll displacement. A vehicle path tracking model was constructed, using lateral deviation and heading deviation as evaluation indicators for path tracking performance, and relevant dynamic equations were derived.

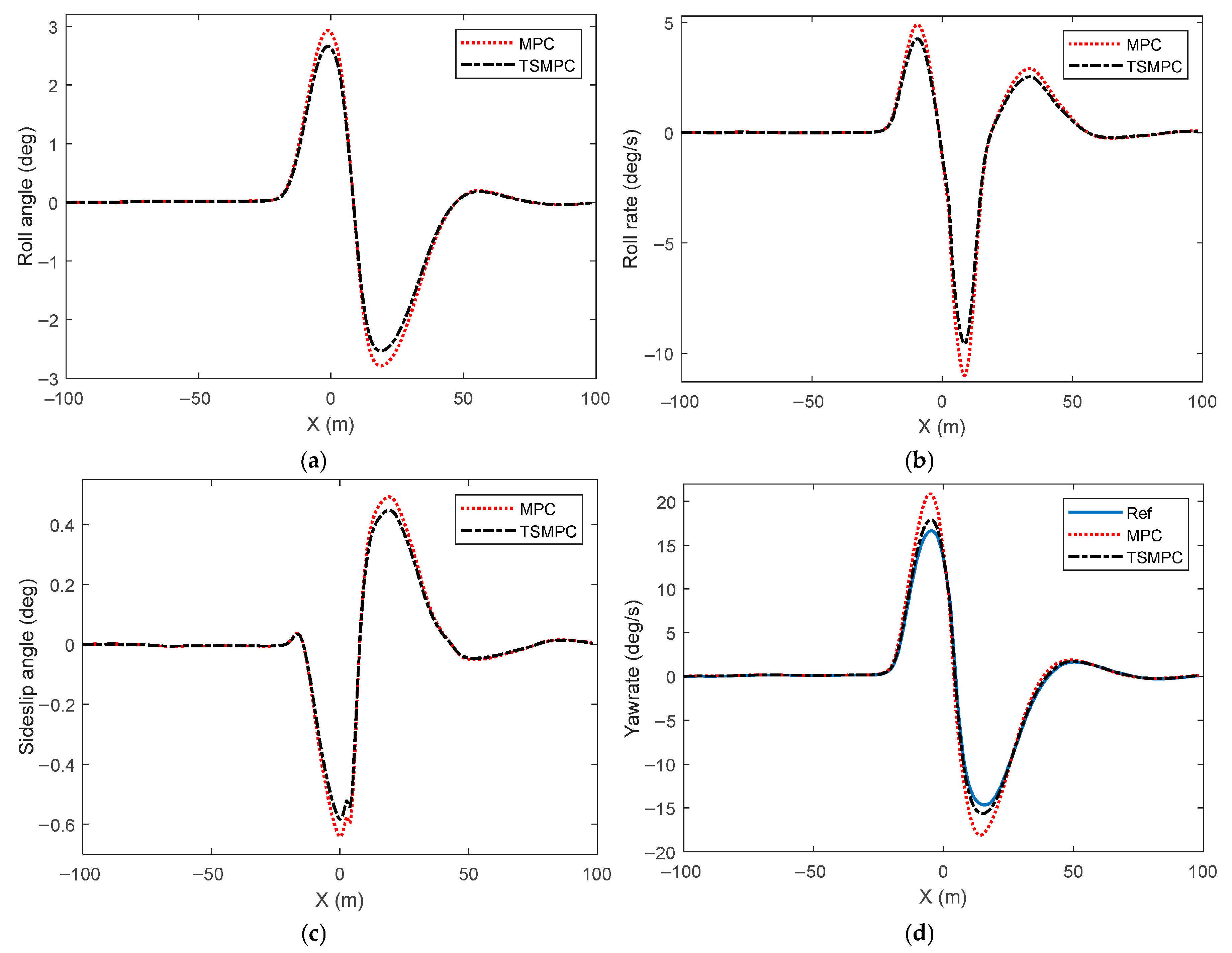

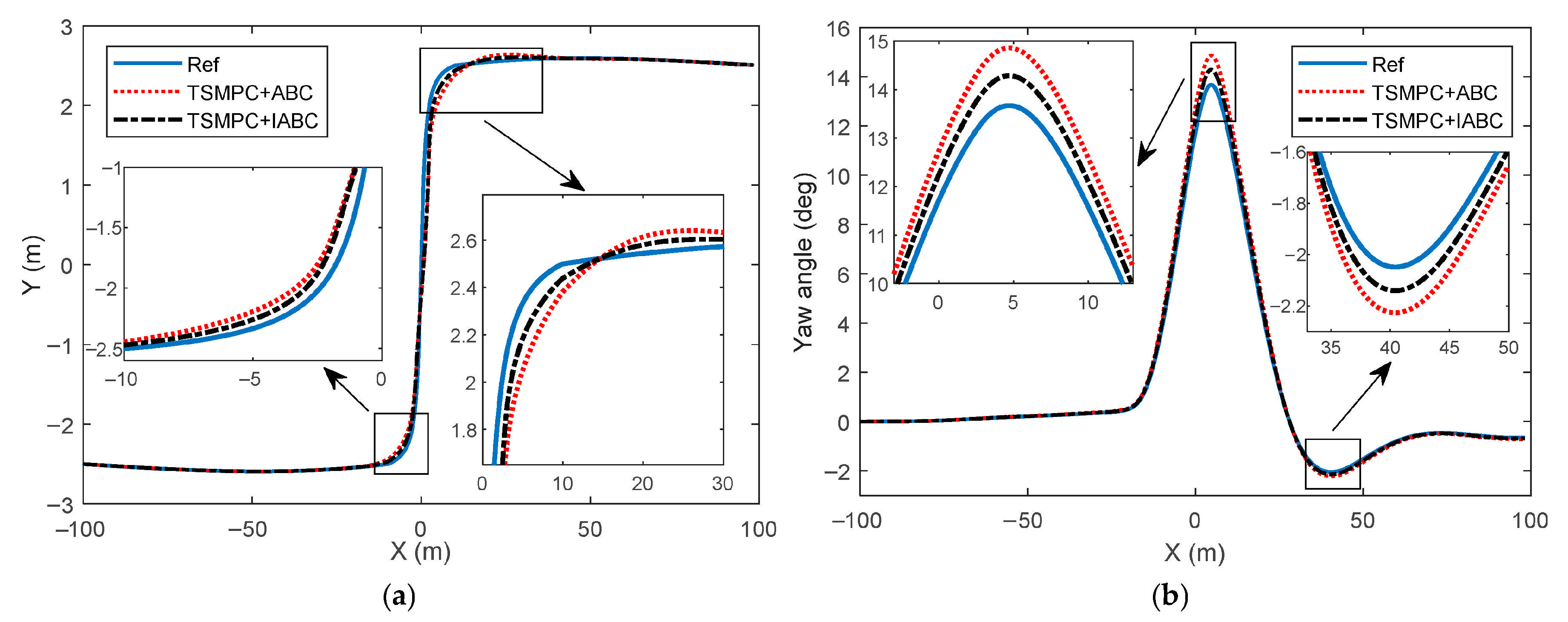

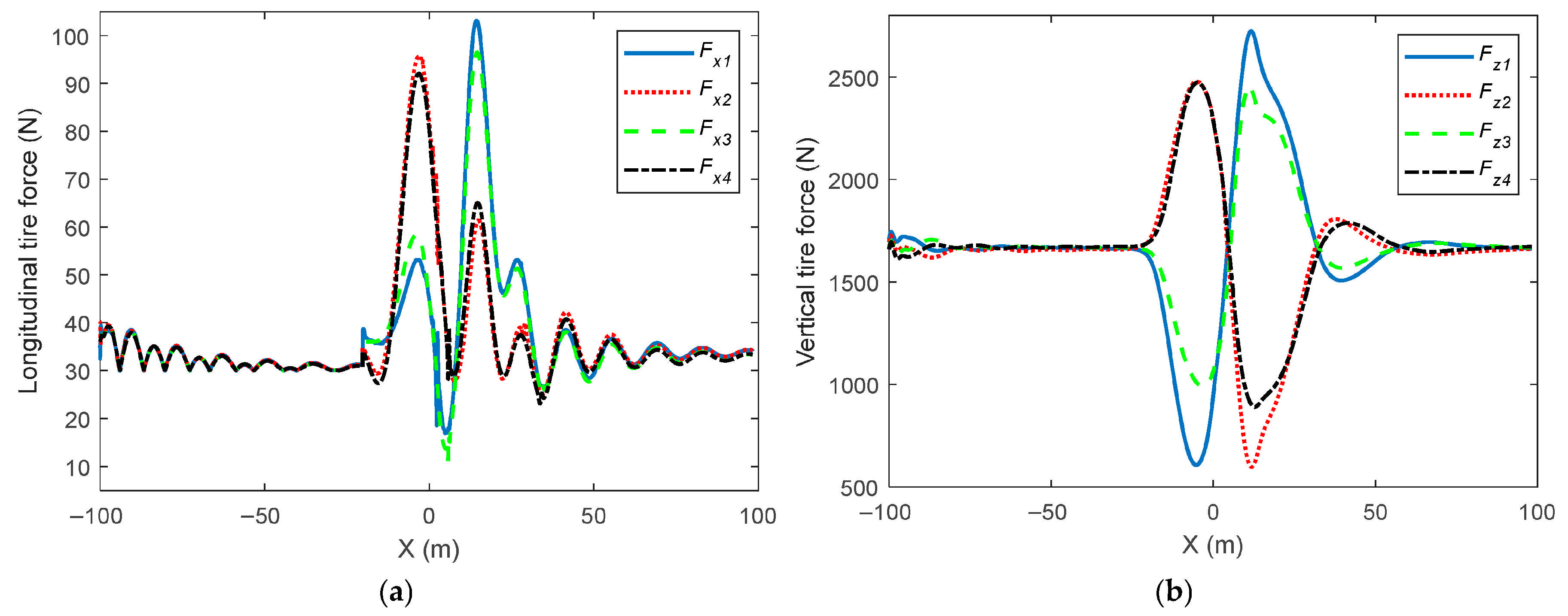

- (2)

- This study presents a two-tiered control framework that stratifies vehicular control into supervisory and actuation layers. The supervisory module orchestrates trajectory following and dynamic stabilization, whereas the actuation module performs optimal tire force distribution. The supervisory control layer implements an incremental predictive TSMPC methodology, capable of addressing time delay systems and multi-constrained optimization challenges while enhancing path-following precision and dynamic stabilization capabilities. The actuation layer adopts an IABC to optimize tire force distribution and meet the lateral and lateral moment requirements specified by the supervisory controller while enhancing vehicular dynamic response characteristics.

- (3)

- A delay state feedback model predictive controller based on incremental prediction was designed. By defining incremental variables and prediction equations, the system delay problem was solved, and a dual-loop feedforward–feedback architecture was implemented to enhance control precision and computational efficiency. The IABC optimization technique accelerates convergence rates and strengthens global search capabilities through enhanced weight coefficient adaptation during the objective function exploration process.

- (4)

- Comparative analyses between TSMPC and conventional MPC methodologies demonstrated superior path-following precision, error attenuation, and dynamic stabilization capabilities for the TSMPC approach. Furthermore, the evaluation of the enhanced artificial bee colony technique against its conventional counterpart revealed improved vehicular control performance through optimized tire force distribution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boada, B.L.; Viadero-Monasterio, F.; Zhang, H.; Boada, M.J.L. Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Integral-Based Event-Triggered H∞ Observer Considering Intravehicle Communications. IEEE Trans. Veh. Technol. 2023, 72, 4411–4425. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, H. Stability, scalability, speedability, and string stability of connected vehicle systems. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 2819–2832. [Google Scholar] [CrossRef]

- Huang, C.; Tang, W.; Wang, J.; Zhang, Z. An Improved Adaptive Car-Following Model Based on the Unscented Kalman Filter for Vehicle Platoons’ Speed Control. Machines 2025, 13, 569. [Google Scholar] [CrossRef]

- Jiang, Y.; Meng, H.; Chen, G.P.; Yang, C.N.; Xu, X.J.; Zhang, L.; Xu, H.J. Differential-steering based path tracking control and energy-saving torque distribution strategy of 6WID unmanned ground vehicle. Energy 2022, 254, 124209. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, B.W. A Novel Adaptive Non-Singular Fast Terminal Sliding Mode Control for Direct Yaw Moment Control in 4WID Electric Vehicles. Sensors 2025, 25, 941. [Google Scholar] [CrossRef] [PubMed]

- Park, J.Y.; Na, S.; Cha, H.; Yi, K. Direct yaw moment control with 4WD torque-vectoring for vehicle handling stability and agility. Int. J. Automot. Technol. 2022, 23, 555–565. [Google Scholar] [CrossRef]

- Wang, X.; Chen, T.; Lu, J. Longitudinal Tire Force Estimation Method for 4WIDEV Based on Data-Driven Modified Recursive Subspace Identification Algorithm. Algorithms 2025, 18, 409. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, W.; Bai, H.; Jiang, R.; Ding, H.; Wei, L. A Sigmoid-Based Car-Following Model to Improve Acceleration Stability in Traffic Oscillation and Following Failure in Free Flow. IEEE Trans. Intell. Transp. Syst. 2024, 25, 9039–9057. [Google Scholar] [CrossRef]

- Zhao, W.Q. Real-Time Model Predictive Control of Path-Following for Autonomous Vehicles Towards Model Mismatch and Uncertainty. Control Eng. Pract. 2024, 142, 105678. [Google Scholar] [CrossRef]

- Cui, K.; He, J.; Yao, X.; Gu, X. Adaptive Model Predictive Control Based on Stability Index for Path Tracking of Autonomous Vehicles Considering Model Error. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 9372–9396. [Google Scholar] [CrossRef]

- Qi, G.X. Integrated Control Method for Path Tracking and Lateral Stability of Distributed Drive Electric Vehicles with Extended Kalman Filter-Based Tire Cornering Stiffness Estimation. J. Vib. Control 2024, 30, 567–582. [Google Scholar] [CrossRef]

- Li, H.; Li, B.; Yang, H.; Mu, C. Nonlinear Model Predictive Control for Time-Optimal Turning Around of an Autonomous Vehicle Under Steering Lag. IEEE/ASME Trans. Mechatron. 2025, 30, 577–586. [Google Scholar] [CrossRef]

- Meng, D.; Chu, H.; Tian, M.; Gao, B.; Chen, H. Real-Time High-Precision Nonlinear Tracking Control of Autonomous Vehicles Using Fast Iterative Model Predictive Control. IEEE Trans. Intell. Veh. 2024, 9, 3644–3657. [Google Scholar] [CrossRef]

- Liang, J.; Tian, Q.; Feng, J.; Pi, D.; Yin, G. A Polytopic Model-Based Robust Predictive Control Scheme for Path Tracking of Autonomous Vehicles. IEEE Trans. Intell. Veh. 2024, 9, 3928–3939. [Google Scholar] [CrossRef]

- Wan, Z.; Xu, C.; Li, B.; Li, Y.; Ye, F. Trajectory Tracking Method of Four-Wheeled Independent Drive and Steering AGV Based on LSTM-MPC and Fuzzy PID Cooperative Control. Electronics 2025, 14, 2000. [Google Scholar] [CrossRef]

- Huang, K.; Wei, K.; Li, F.; Yang, C.; Gui, W. LSTM-MPC: A Deep Learning Based Predictive Control Method for Multimode Process Control. IEEE Trans. Ind. Electron. 2022, 70, 11544–11554. [Google Scholar] [CrossRef]

- Guo, N.; Zhang, X.; Zou, Y.; Lenzo, B.; Du, G.; Zhang, T. A Supervisory Control Strategy of Distributed Drive Electric Vehicles for Coordinating Handling, Lateral Stability, and Energy Efficiency. IEEE Trans. Transp. Electrif. 2021, 7, 2488–2504. [Google Scholar] [CrossRef]

- Hua, X.; Xiang, K.; Cheng, X.; Ning, X. An Adaptive Compound Control Strategy of Electric Vehicles for Coordinating Lateral Stability and Energy Efficiency. Appl. Sci. 2025, 15, 3347. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.; Ma, R.; He, C. Cascade-Free Predictive Wheel Slip Control with Discrete-Valued Inputs for Automotive Hydraulic Anti-lock Braking Systems. IEEE Trans. Transp. Electrif. 2024, 11, 6048–6059. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, B.W. Improving Direct Yaw-Moment Control via Neural-Network-Based Non-Singular Fast Terminal Sliding Mode Control for Electric Vehicles. Sensors 2024, 24, 4079. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Tao, Y.; Ge, C.; Feng, H.; Xue, H.; Yao, M.; Tang, H.; Liao, Z.; Chen, P. A novel approach for adaptively separating and extracting compound fault features of the in-wheel motor bearing. ISA Trans. 2025, 159, 337–351. [Google Scholar] [CrossRef] [PubMed]

- Micheli, F.; Bersani, M.; Arrigoni, S.; Braghin, F.; Cheli, F. NMPC Trajectory Planner for Urban Autonomous Driving. Veh. Syst. Dyn. 2023, 61, 1387–1409. [Google Scholar] [CrossRef]

- Zou, T.; You, Y.; Meng, H.; Chang, Y. Research on Six-Wheel Distributed Unmanned Vehicle Path Tracking Strategy Based on Hierarchical Control. Biomimetics 2022, 7, 238. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Zhou, X.Y.; Wang, J.M. Extremum-Seeking-Based Adaptive Model-Free Control and Its Application to Automated Vehicle Path Tracking. IEEE-ASME Trans. Mechatron. 2022, 27, 3874–3884. [Google Scholar] [CrossRef]

- Picotti, E.; Mion, E.; Libera, A.D.; Pavlovic, J.; Censi, A.; Frazzoli, E.; Beghi, A.; Bruschetta, M. A Learning-Based Nonlinear Model Predictive Controller for a Real Go-Kart Based on Black-Box Dynamics Modeling Through Gaussian Processes. IEEE Trans. Control Syst. Technol. 2023, 31, 2034–2047. [Google Scholar] [CrossRef]

- Pinho, J.; Costa, G.; Lima, P.U.; Ayala Botto, M. Learning-Based Model Predictive Control for Autonomous Racing. World Electr. Veh. J. 2023, 14, 163. [Google Scholar] [CrossRef]

- Manzano, J.M.; Limon, D.; noz de la Peña, D.M.; Calliess, J.P. Robust learning-based MPC for nonlinear constrained systems. Automatica 2020, 117, 108948. [Google Scholar] [CrossRef]

- Feng, H.; Tao, Y.; Feng, J.; Zhang, Y.; Xue, H.; Wang, T.; Xu, X.; Chen, P. Fault-tolerant collaborative control of four-wheel-drive electric vehicle for one or more in-wheel motors’ faults. Sensors 2025, 25, 1540. [Google Scholar] [CrossRef]

- Sun, Y.; Ning, H.; Wang, H.; Wang, C.; Zheng, J. Trajectory Tracking Control Design for 4WS Vehicle Based on Particle Swarm Optimization and Phase Plane Analysis. Appl. Sci. 2024, 14, 3664. [Google Scholar] [CrossRef]

- Li, L.; Pei, W.; Zhang, Q. Research on Intelligent Vehicle Tracking Control and Energy Consumption Optimization Based on Dilated Convolutional Model Predictive Control. Energies 2025, 18, 2588. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, H.; Guo, K.; Zhang, N. A Hierarchical Control Strategy for FWID-EVs Based on Multi-Agent with Consideration of Safety and Economy. Energies 2022, 15, 9112. [Google Scholar] [CrossRef]

- Hewing, L.; Wabersich, K.P.; Menner, M.; Zeilinger, M.N. Learning-Based Model Predictive Control: Toward Safe Learning in Control. Annu. Rev. Control Robot. Auton. Syst. 2020, 3, 269–296. [Google Scholar] [CrossRef]

- Li, X.; Lan, Y.; Jiang, P.; Cao, H.; Zhou, J. An efficient computation for energy optimization of robot trajectory. IEEE Trans. Ind. Electron. 2021, 69, 11436–11446. [Google Scholar] [CrossRef]

- Rokonuzzaman, M.; Mohajer, N.; Nahavandi, S. Effective adoption of vehicle models for autonomous vehicle path tracking: A switched MPC approach. Veh. Syst. Dyn. 2023, 61, 1236–1259. [Google Scholar] [CrossRef]

- Hu, Y.; Fu, J.; Wen, G. Safe reinforcement learning for model-reference trajectory tracking of uncertain autonomous vehicles with model-based acceleration. IEEE Trans. Intell. Veh. 2023, 8, 2332–2344. [Google Scholar] [CrossRef]

- Napolitano Dell’Annunziata, G.; Ruffini, M.; Stefanelli, R.; Adiletta, G.; Fichera, G.; Timpone, F. Four-Wheeled Vehicle Sideslip Angle Estimation: A Machine Learning-Based Technique for Real-Time Virtual Sensor Development. Appl. Sci. 2024, 14, 1036. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Xiao, F.; Lin, Z.; Deng, C. Coordinated Control of Active Suspension and DYC for Four-Wheel Independent Drive Electric Vehicles Based on Stability. Appl. Sci. 2022, 12, 11768. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, F.; Guo, W.; Zhou, Z.; Miao, S.; Chen, T. Hierarchical Coordination Control of Distributed Drive Intelligent Vehicle Based on TSMPC and Tire Force Optimization Allocation. Algorithms 2025, 18, 508. https://doi.org/10.3390/a18080508

Li J, Wang F, Guo W, Zhou Z, Miao S, Chen T. Hierarchical Coordination Control of Distributed Drive Intelligent Vehicle Based on TSMPC and Tire Force Optimization Allocation. Algorithms. 2025; 18(8):508. https://doi.org/10.3390/a18080508

Chicago/Turabian StyleLi, Junmin, Fei Wang, Wenguang Guo, Zhengyong Zhou, Shuaike Miao, and Te Chen. 2025. "Hierarchical Coordination Control of Distributed Drive Intelligent Vehicle Based on TSMPC and Tire Force Optimization Allocation" Algorithms 18, no. 8: 508. https://doi.org/10.3390/a18080508

APA StyleLi, J., Wang, F., Guo, W., Zhou, Z., Miao, S., & Chen, T. (2025). Hierarchical Coordination Control of Distributed Drive Intelligent Vehicle Based on TSMPC and Tire Force Optimization Allocation. Algorithms, 18(8), 508. https://doi.org/10.3390/a18080508