Algorithmic Advances for 1.5-Dimensional Two-Stage Cutting Stock Problem

Abstract

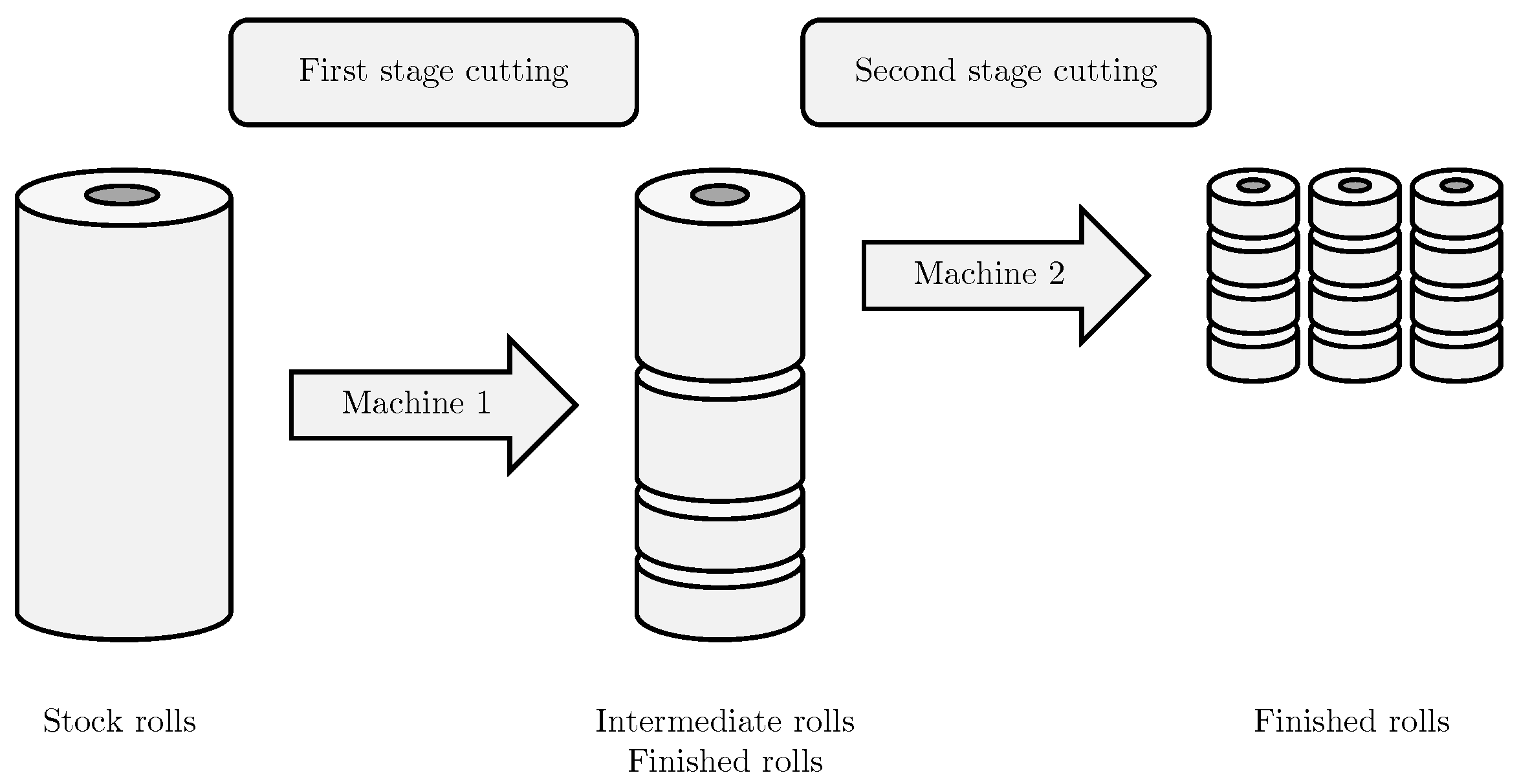

1. Introduction

- Case 1: The first and second stages have the same length. This scenario reduces to a one-dimensional problem, which has been extensively studied in the literature.

- Case 2: Only one length is present in the first stage and only one length at the second stage, but they are different. Each unit of intermediate product must always produce the same number of patterns in the second stage.

- Case 3: Multiple lengths are present in both the first and second stages, which are different and cannot be mixed. In each pattern, the length must be fixed.

- Case 4: Multiple lengths are present in both the first and second stages. Within a single pattern, there can be at most two different lengths, provided that one is an integer multiple of the other.

2. Comprehensive Technical Review of Relevant Literature

3. Problem Formulation

3.1. Multi-Stage Master Problem

- The diagonal blocks for are the canonical cutting stock matrices for the s-th stage. Each column in corresponds to a cutting pattern at stage s, and each row corresponds to an order at that stage. The element indicates the quantity of order i produced by pattern j.

- The off-diagonal blocks for represent the consumption of intermediate stock rolls between stages. These blocks are called connection matrices. For , captures the consumption of stock rolls from stage by patterns at stage .

3.2. Two-Stage Master Problem

4. Solution Approach

4.1. Generate-and-Solve Algorithm

- Pattern Generation Iterations: In this phase, the algorithm focuses on generating new cutting patterns for both the first and second stages without altering the set of intermediate orders. The goal is to improve the current solution by exploring new combinations of existing orders.

- Order Generation Iterations: When pattern generation no longer yields significant improvements, the algorithm transitions to this phase, where new intermediate orders are introduced. By expanding the set of intermediate orders, the solution space gets enlarged, allowing for potentially better solutions that were not possible with the previous set of orders.

- PatternGenIter: A boolean flag indicating whether the current iteration is a pattern generation iteration (True) or an order generation iteration (False).

- PatternGenAttempts and OrderGenAttempts: Counters for the remaining attempts in each phase before switching or terminating. These are initialized to a maximum value (MaxAttempts).

- UpdateLimit: A predefined threshold for considering an iteration successful, based on the relative improvement in the objective function.

| Algorithm 1: Generate-and-Solve Generation Algorithm. |

|

- Algorithm Efficiency It mitigates combinatorial explosion by restricting patterns and orders, and using a countdown mechanism to remove unused patterns.

- Computational Resource Allocation Priority-based exploration ensures efficient allocation of resources, focusing on patterns with the highest potential for improvement.

- Solution Quality Improvement Flexibility to introduce new intermediate orders allows the algorithm to navigate the solution space more effectively, overcoming local optima.

4.2. Row-and-Column Generation Algorithm

- First-Stage Pricing Subproblem (1S-CG-PSP): searches for a new column of that have negative reduced costs with respect to the current set of constraints in the Relaxed Restricted Master Problem (RSRMP).

- Second-Stage Pricing Subproblem (2S-CG-PSP): searches for a new column of that have negative reduced costs with respect to the current set of constraints in the Relaxed Restricted Master Problem (RSRMP).

- Row-Generating Pricing Subproblem (RCG-PSP): searches for new intermediate orders (rows) and their associated columns and for , and .

| Algorithm 2: Row-and-Column Generation Algorithm. |

|

4.2.1. First-Stage Column-Generating PSP

4.2.2. Second-Stage Column-Generating PSP

4.2.3. Row-Generating PSP

- The lengths of the intermediate rolls are unknown, as are their widths.

- The dual variables associated with these new intermediate rolls are not known in advance, except that they are non-negative in any feasible dual solution. These dual variables must be accurately estimated to effectively incorporate them into the solution of the row-generating PSP effectively.

- Multiple second-stage cutting patterns can be produced from a single intermediate roll.

- Multiple intermediate rolls may need to be generated simultaneously.

- is the new column corresponding to the first-stage cutting pattern.

- is the new column corresponding to the second-stage cutting pattern produced from intermediate order k.

- is included to account for the number of times the intermediate order k is used in the newly created first-stage cutting pattern.

- s the non-zero term placed at the position corresponding to the intermediate order k in the linking constraint row.

5. Computational Results

5.1. Experimental Setting

5.2. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CSP | Cutting Stock Problem |

| 1.5-D | One-and-a-Half-Dimensional |

| TSCSP | Two-Stage Cutting Stock Problem |

| G&S | Generate-and-Solve |

| CG | Column Generation |

| R&CG | Row-and-Column Generation |

| RCG | Row-and-Column Generation |

| C&CG | Column-and-Constraint Generation |

| RRMP | Relaxed and Restricted Master Problem |

| RSRMP | Relaxed Short and Restricted Master Problem |

| RSRDP | Relaxed Short and Restricted Dual Problem |

| PSP | Pricing Subproblem |

| UR | Uniform Range |

| US | Uniform Set |

References

- Dyckhoff, H. A typology of cutting and packing problems. Eur. J. Oper. Res. 1990, 44, 145–159. [Google Scholar] [CrossRef]

- Wäscher, G.; Haußner, H.; Schumann, H. An improved typology of cutting and packing problems. Eur. J. Oper. Res. 2007, 183, 1109–1130. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Kruse, H.J.; Abel, D.; Gal, T. Trim loss and related problems. Omega 1985, 44, 145–159. [Google Scholar] [CrossRef]

- Haessler, R.W. A Procedure for Solving the 1.5-Dimensional Coil Slitting Problem. AIIE Trans. 1978, 10, 700–775. [Google Scholar] [CrossRef]

- Gilmore, P.C.; Gomory, R.E. A Linear Programming Approach to the Cutting-Stock Problem. Oper. Res. 1961, 9, 849–859. [Google Scholar] [CrossRef]

- Gilmore, P.C.; Gomory, R.E. A Linear Programming Approach to the Cutting Stock Problem-Part II. Oper. Res. 1963, 11, 863–888. [Google Scholar] [CrossRef]

- Vance, P.H.; Barnhart, C.; Johnson, E.L.; Nemhauser, G.L. Solving binary cutting stock problems by column generation and branch-and-bound. Comput. Optim. Appl. 1994, 3, 111–130. [Google Scholar] [CrossRef]

- Vanderbeck, F. A Nested Decomposition Approach to a Three-Stage, Two-Dimensional Cutting-Stock Problem. Manag. Sci. 2001, 47, 735–879. [Google Scholar] [CrossRef]

- Saraç, T.; Özdemir, M.S. A Genetic Algorithm for 1,5 Dimensional Assortment Problems with Multiple Objectives. In Developments in Applied Artificial Intelligence: 16th International Conference on Industrial and Engineering Applications of Artificial Intelligence and Expert Systems, IEA/AIE 2003 Loughborough, UK, June 23–26, 2003 Proceedings; Springer: Berlin/Heidelberg, Germany, 2003; pp. 41–51. [Google Scholar]

- Alves, C.; Valério de Carvalho, J.M. Accelerating column generation for variable sized bin-packing problems. Eur. J. Oper. Res. 2007, 183, 1333–1352. [Google Scholar] [CrossRef]

- Kallrath, J.; Rebennack, S.; Kusche, R. Solving real-world cutting stock-problems in the paper industry: Mathematical approaches, experience and challenges. Eur. J. Oper. Res. 2014, 238, 374–389. [Google Scholar] [CrossRef]

- Yu, T.Y.; Yang, J.C.; Lai, Y.L. Applying an Enhanced Heuristic Algorithm to a Constrained Two-Dimensional Cutting Stock Problem. Appl. Math. Inf. Sci. 2014, 9, 179–187. [Google Scholar] [CrossRef]

- Zak, E.J. Row and column generation technique for a multistage cuttingstock problem. Comput. Oper. Res. 2002, 29, 1143–1156. [Google Scholar] [CrossRef]

- Zak, E.J. Modeling multistage cutting stock problems. Eur. J. Oper. Res. 2002, 141, 313–327. [Google Scholar] [CrossRef]

- Muter, İ.; Birbil, Ş.İ.; Bülbül, K. Simultaneous Row-and-Column generation for large-scale linear programs with column-dependent-rows. Math. Program. 2013, 10, 47–82. [Google Scholar] [CrossRef]

- Muter, İ.; Birbil, Ş.İ.; Bülbül, K. Benders decomposition and Row-and-Column generation for solving large-scale linear programs with column-dependent-rows. Eur. J. Oper. Res. 2018, 264, 29–45. [Google Scholar] [CrossRef]

- Muter, İ.; Sezer, Z. Algorithms for the one-dimensional two-stage cutting stock problem. Eur. J. Oper. Res. 2018, 271, 20–32. [Google Scholar] [CrossRef]

- Wang, D.; Xiao, F.; Zhou, L.; Liang, Z. Two-dimensional skiving and cutting stock problem with setup cost based on Row-and-Column generation. Eur. J. Oper. Res. 2020, 286, 547–563. [Google Scholar] [CrossRef]

- Sá Santos, J.V.; Nepomuceno, N. Computational Performance Evaluation of Column Generation and Generate-and-Solve Techniques for the One-Dimensional Cutting Stock Problem. Algorithms 2022, 15, 394. [Google Scholar] [CrossRef]

- Khan, R.; Pruncu, C.I.; Khan, A.S.; Naeem, K.; Abas, M.; Khalid, Q.S.; Aziz, A. A Mathematical Model for Reduction of Trim Loss in Cutting Reels at a Make-to-Order Paper Mill. Appl. Sci. 2020, 10, 5274. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, J.; Gao, P.; Zhang, R.; Liu, L.; Wang, S.; Cheng, L.; Wang, W.; Yang, S. Two-stage robust optimization for prosumers considering uncertainties from sustainable energy of wind power generation and load demand based on nested C&CG algorithm. Sustainability 2023, 15, 9769. [Google Scholar] [CrossRef]

- Zhu, H.; Pei, Z. Two-Stage Robust Liner Container Booking with Uncertain Customer Demand. Mathematics 2023, 11, 1819. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, H.; Wang, C.; Li, H.; Chen, Y.; Chen, Q. Robust Optimization for the Two-Dimensional Strip-Packing Problem with Variable-Sized Bins. Mathematics 2023, 11, 4781. [Google Scholar] [CrossRef]

- Widjaja, D.; Kim, S. Reducing rebar cutting waste and rebar usage of beams: A two-stage optimization algorithm. Buildings 2023, 13, 2279. [Google Scholar] [CrossRef]

- Fang, J.; Rao, Y.; Luo, Q.; Xu, J. Solving One-Dimensional Cutting Stock Problems with the Deep Reinforcement Learning. Mathematics 2023, 11, 1028. [Google Scholar] [CrossRef]

| Parameter | I1 | I2 |

|---|---|---|

| Stock size | 10,000 | 10,000 |

| Intermediate order width range | (1250; 2500) | (2000; 3000) |

| Length ratios | 20 | |

| Order width | UR(300; 500) | UR(100; 500) |

| Order length | 1 | US |

| Order amount | UR(10; 100) | UR(10; 100) |

| First stage min trim | 0 | 100 |

| Second stage min trim | 50 | 30 |

| Instance | G&S | R&CG | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Avg. | Avg. | Avg. | Avg. | Avg. | Avg. | Avg. Int. Obj. Value | Avg. Tot. Time (s) | ||

| I1 | 10 | 27.0 | 21,857.4 | 1.0 | 2.0 | 36.1 | 1.0 | +0.7 | −5.6 |

| I1 | 20 | 26.0 | 42,098.3 | 1.0 | 2.0 | 82.5 | 1.0 | −0.2 | −45.5 |

| I1 | 30 | 34.0 | 51,636.1 | 1.0 | 2.0 | 113.9 | 1.0 | −43.3 | −232.0 |

| I1 | 40 | 26.5 | 39,165.6 | 1.0 | 2.0 | 155.1 | 1.0 | −86.1 | +3.1 |

| I1 | 50 | 25.6 | 39,207.0 | 1.0 | 2.0 | 192.2 | 1.0 | −86.1 | −64.7 |

| I2 | 10 | 25.3 | 39,604.3 | 5.0 | 17.9 | 98.5 | 17.9 | −59.9 | −362.8 |

| I2 | 20 | 19.9 | 165,498.6 | 5.0 | 18.0 | 236.4 | 18.0 | −75.8 | −169.0 |

| I2 | 30 | 19.0 | 248,692.0 | 5.0 | 18.0 | 351.1 | 18.0 | −85.8 | −332.0 |

| I2 | 40 | 23.9 | 343,933.2 | 5.0 | 18.0 | 485.3 | 18.0 | −87.6 | −443.5 |

| I2 | 50 | 14.0 | 815,093.0 | 10.0 | 18.0 | 644.0 | 18.0 | −82.2 | −595.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grieco, A.; Caricato, P.; Margiotta, P. Algorithmic Advances for 1.5-Dimensional Two-Stage Cutting Stock Problem. Algorithms 2025, 18, 3. https://doi.org/10.3390/a18010003

Grieco A, Caricato P, Margiotta P. Algorithmic Advances for 1.5-Dimensional Two-Stage Cutting Stock Problem. Algorithms. 2025; 18(1):3. https://doi.org/10.3390/a18010003

Chicago/Turabian StyleGrieco, Antonio, Pierpaolo Caricato, and Paolo Margiotta. 2025. "Algorithmic Advances for 1.5-Dimensional Two-Stage Cutting Stock Problem" Algorithms 18, no. 1: 3. https://doi.org/10.3390/a18010003

APA StyleGrieco, A., Caricato, P., & Margiotta, P. (2025). Algorithmic Advances for 1.5-Dimensional Two-Stage Cutting Stock Problem. Algorithms, 18(1), 3. https://doi.org/10.3390/a18010003