Abstract

Agricultural machinery rental is a new service form that uses big data in agriculture to improve the utilization rate of agricultural machinery and promote the development of the agricultural economy. To realize agricultural machinery scheduling optimization in cloud services, a dynamic artificial bee-ant colony algorithm (DABAA) is proposed to solve the above problem. First, to improve the practicability of the mathematical model in agricultural production, a dynamic coefficient is proposed. Then the mutation operation is combined with the artificial bee colony (ABC) algorithm to improve the algorithm. Then, iterative threshold adjustment and optimal fusion point evaluation are used to combine the ABC algorithm with the ant colony optimization (ACO) algorithm, which not only improves the search precision but also improves the running speed. Finally, two groups of comparison experiments are carried out, and the results show that the DABAA can obviously improve the running speed and accuracy of cloud services in agricultural machinery rental.

1. Introduction

The weak purchasing power of agricultural machinery is China’s current condition, and the cost of large agricultural machinery is very high. Due to the small size of farmland and strong seasonal characteristics of crops in China, it is difficult for farmers who have bought agricultural machinery in a short time to make profits. Agricultural machinery idles for a long time, which is a waste of resources. In addition, the function of Chinese agricultural machinery is singular, and many different types of agricultural machinery are needed in the production of a crop. The role of a single type of agricultural machinery is extremely limited, so farmers are extremely unwise to buy large agricultural machinery.

Agricultural machinery rental is a new service form that can lighten the burden of buying agricultural machinery. This service improves the utilization rate of agricultural machinery and promotes the development of the agricultural economy. However, most agricultural machinery rental companies are still in the stage of immediate deployment. Staff only considers the time sequence when the agricultural machinery is deployed, so the efficiency is low in the busy season and the needs of farmers are difficult to meet. With the rise of network technology and vigorous development, digital technology has permeated all areas. Big data is starting to be used in agriculture, and cloud services are becoming more popular with agribusinesses [1]. Agricultural machinery rental services have also been combined with big data. Many local small agricultural machinery rental enterprises have started to develop cloud platforms in China. However, considering the traveling salesman problem (TSP) and scheduling method, it is still difficult to achieve large-scale agricultural machinery scheduling.

At present, there is little research on agricultural machinery scheduling. Luo et al. proposed a modified fuzzy hybrid genetic algorithm for agricultural machinery scheduling [2], but it is limited to genetic algorithms. To achieve an optimal schedule for sequential agricultural operations, Edwards et al. used a tabu search method for exploration and verification [3], but its scope of application is relatively small. Therefore, large-scale agricultural machinery scheduling needs to be developed.

With the development of artificial intelligence algorithms, various intelligent algorithms have been widely used in various optimization problems, such as genetic algorithms (GAs) [4,5], ACO algorithms [6,7], particle swarm optimization (PSO) [8,9], ABC algorithms [10,11] and firefly algorithms (FAs) [12,13]. Kumar et al. proposed a generalized ant colony optimizer algorithm (GACO) to solve the cloud resource allocation problem [14]. Alabbadi et al. proposed multi-objective task scheduling optimization (MOTSO) to find the optimal solution [15], which solved the optimization problem well. Cao et al. proposed a depth optimization analysis method based on the GA algorithm [16]. Zhou et al. realized the optimization and application of agricultural machinery rental in cloud manufacturing services based on the reliability feedback update strategy and the dynamic coefficient strategy [17]. All the above studies on solving problems with artificial intelligence algorithms have achieved good results, but there are few applications in agriculture.

Artificial intelligence algorithms are introduced in agricultural machinery rental optimization by using agricultural big data, so a DABAA is proposed in this paper. First, to enhance the accuracy of the mathematical model, a dynamic coefficient is added to the Quality of Service (QoS) evaluation model. Then, to further improve the global search capability, the mutation operation is added to the ABC algorithm. Additionally, to combine ABC with the max-min ant system (MMAS), a method capable of iterative threshold adjustment and optimal fusion evaluation is adopted. Finally, to verify the convergence of the DABAA, this paper proves that the algorithm has good performance through experimental simulations and theoretical derivation.

2. Task Description and Mathematical Model of Agricultural Machinery Rental

2.1. Task Description of Agricultural Machinery Rental

Agricultural production has a strong seasonality. During periods of concentrated agricultural production, rental orders tend to appear in a concentrated manner. Under the premise of large-scale orders, to improve the efficiency of agricultural machinery rental, it is indispensable to adopt a reasonable scheduling optimization method [18]. Since expected time for each rental assignment varies, the time needs of all farmers must be balanced, so urgent orders must be given priority. All indicators should be considered to reduce costs and achieve profit maximization. Moving a certain machine to a certain location designated by the farmer is a rental task. In reality, a farmer’s order may require a certain type of machine be moved to multiple locations or multiple machines to multiple locations, that is, an order contains multiple tasks. This paper takes the task as the solution unit, so the size of the order does not affect the validity of the research. The following steps are the specific process of the rental process.

- 1.

- Upload of rental orders: The farmers place orders through the client, and the geographical location, expected time, size of farmland, working conditions and other information are uploaded to the cloud service platform for analysis and calculation;

- 2.

- Calculation of evaluation indices: The information of each order is transformed into a calculation index to making the scheduling scheme;

- 3.

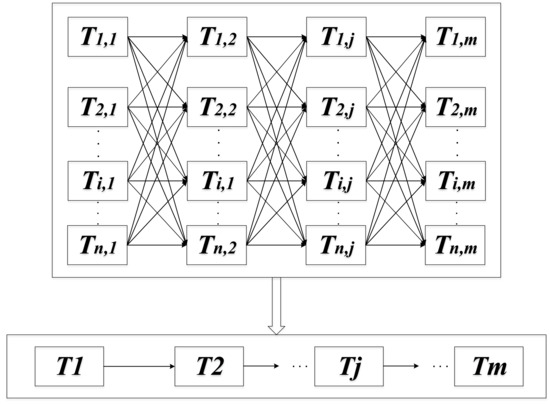

- Determination of the scheduling sequence: After analyzing the evaluation indices of all orders, the optimal scheduling sequence is obtained by using the QoS evaluation model and algorithm. The composition process of the scheduling sequence is described in Figure 1, where n represents the number of total rental tasks, m represents the number of tasks in the scheduling sequence, T represents the rental task, j represents the j-th task in the scheduling sequence () and i represents the i-th task in all rental tasks ();

- 4.

- Generation of the optimal scheduling sequence: The scheduling sequences of multiple-agricultural machinery are obtained by task assignment.

Figure 1.

Multitasking composition process.

2.2. QoS Evaluation Model

To solve various optimal combination problems, QoS evaluation models are often used [19] and have a great effect. Therefore, the QoS evaluation model is used in the paper. Due to the universality of the calculation method, to establish a QoS evaluation model, this paper only uses urgency of time (), working conditions (), size () and distance () to achieve this goal. The evaluation will also involve terrain, planting characteristics, weather and other factors under special circumstances. This paper only considers several common factors that are suitable for standardized farmland without special circumstances, which is not much different from reality.

- Urgency of time (): Urgency of time is mainly determined by the optimal harvest time. The rental task that is closer to the optimal harvest time will have a greater urgency of time. This task must be given priority to avoid delaying farming production;

- Working conditions (): Working conditions are mainly determined by soil conditions, traffic conditions and all kinds of farm crop conditions. The preliminary data are given by farmers;

- Size (): The size of farmland can represent the profit that can be obtained in the rental service. In a rental service, the larger the size of the farmland is, the higher the profit, which is also the ideal situation in the agricultural machinery rental service. data are given by farmers;

- Distance (): The cost loss in the scheduling process is represented by the . The coordinate position is uploaded by farmers through the client;

- Dynamic Coefficient (P): A key indicator in the QoS evaluation model is urgency of time. Therefore, the purpose of setting the dynamic coefficient is to adjust the proportion of urgency of time in the QoS evaluation model. To avoid the emergence of discontinuities and fluctuations, fixed coefficients cannot be adopted to control the proportion of urgency of time. Therefore, to solve this problem, this paper proposes a dynamic coefficient.

According to data analysis, there is a certain functional relationship between the dynamic coefficient and the urgency of time; that is, the higher the of a task is, the greater the proportion of the of the task in the QoS evaluation model. According to the research of Zhou et al. [17] and the verification of this paper, the calculation method of the dynamic coefficient P is shown in Equation (1):

Since the quantitative unit and range interval of each evaluation index are different, the same quantitative method is used for data processing to improve the accuracy of the evaluation model. The data can be divided into two categories: positive and negative attributes [20]. For positive attributes (), including urgency of time, working conditions and size, Equation (2) is the calculation method. For the negative attribute (), including distance, Equation (3) is the calculation method.

Each agricultural machine executes many tasks consecutively, and the QoS evaluation model can be described as follows:

The aggregation of the individual evaluation index is the QoS model combination evaluation index [21]. The aggregation method depends on the task structure of the model. The tasks are sequential structures in this paper, so the combination evaluation index is the sum of the evaluation indices for each task. Table 1 shows the specific aggregation formula. Equation (5) is the calculation method of QoS, where , , and are given by experts.

In general, once the maximum value of the function is found, the optimal agricultural machinery scheduling solution will be found.

Table 1.

QoS aggregate formula.

Table 1.

QoS aggregate formula.

| Urgency of Time (UT) | Working Conditions (WC) | Size (SE) | Distance (DT) |

|---|---|---|---|

3. Basic Algorithm

Artificial intelligence algorithms are widely applied to optimization problems and have achieved good results. The DABAA is improved from the traditional ABC algorithm and ACO algorithm. Therefore, the ABC algorithm and the MMAS are introduced in this section.

3.1. Artificial Bee Colony Algorithm

The ABC algorithm was proposed by Karaboga [22]. With its powerful global search capabilities, the ABC algorithm has been successfully applied to combinatorial and optimization problems. ABC is an optimization method that simulates the behavior of bees, and it is a specific application of swarm intelligence. The main feature of the ABC algorithm is that it does not need to know the special information of the problem, but only pays attention to the quality of the solution. It has the advantages of stable convergence and few parameters. Nectar sources, employed bees, scout bees and onlooker bees are the four basic elements of the ABC algorithm [23,24,25,26].

- 1.

- Nectar sources: Each nectar source means a feasible solution to a problem, and the quality of the feasible solution is determined by the fitness value of the nectar source;

- 2.

- Employed bees: The bees that are mining nectar sources will pass the information of the nectar sources onto other bees;

- 3.

- Scout bees: Scout bees search the nectar sources randomly;

- 4.

- Onlooker bees: Onlooker bees are bee that wait in the hive to obtain information about the nectar sources brought back by the employed bees. Based on the quality of nectar sources, onlooker bees select employed bees to follow by the following probability.

Table 2 shows the basic operations of ABC, such as the following probability and detection and the fitness function of the nectar sources. In ABC, the search scope is randomly determined, which enhances its global search capability. However, the disadvantages are obvious. The search accuracy is not high, and the convergence speed is slow in the late stage.

Table 2.

ABC design method.

3.2. Max-Min Ant System

The ant colony optimization (ACO) algorithm was first applied to traveling salesman problem (TSP). It has the advantages of simple implementation, positive feedback and parallel distributed computing. However, the ACO algorithm also has the disadvantages of a long search time and easy restriction to local optimal solutions [27,28,29,30]. In view of the above disadvantages, Stutzle and Hoos proposed the MMAS in 2000 [31]. It is improved based on the ACO algorithm, which effectively improves the performance of the ACO algorithm. The difference between the MMAS and ant system (AS) is mainly reflected in the following aspects:

- 1.

- The MMAS first adopts an elite strategy to update pheromones. The MMAS updates pheromones by using the iterative optimal solution compared with the AS, so the global optimization capability of the algorithm is improved and premature convergence is avoided. To ensure the effectiveness of pheromones, it is necessary for the MMAS to update the pheromones according to Equation (6), where i and j represent the optimal paths for this iteration;

- 2.

- is the limit interval of the pheromone value, where is the upper bound of the pheromone and represents the lower bound. Due to this improvement measurement, the possibility of the algorithm falling into a stagnation state in the later stage is reduced, and the algorithm’s global optimization capability is also improved;

- 3.

- The MMAS initializes the pheromone to and sets a smaller volatilization rate ;

- 4.

- To avoid premature convergence of the MMAS algorithm to the global optimal solution, the smoothing mechanism of pheromones is used to enhance performance.

The operation steps of the MMAS include parameter initialization, pheromone initialization, a heuristic function, a state transition rule, a fitness function, a pheromone update, etc. The specific operations are shown in Table 3. After the improvement, the MMAS has several advantages, and the following are the main advantages:

- 1.

- The algorithm has three advantages: strong robustness, high operating efficiency and parallelism;

- 2.

- The global searching capability is strengthened, and stagnation is avoided.

Table 3.

MMAS design method.

Table 3.

MMAS design method.

| Basic Operations | Methods |

|---|---|

| Parameter initialization | Parameter initialization generates parameters randomly. |

| Pheromone initialization | Pheromone initialization sets the pheromone for all paths to . |

| Heuristic function | A heuristic function () provides heuristic information for state transitions. Taking = , where is the QoS value between the two tasks. |

| State transition rule | The state transition rule is the probability of selecting the next task, and the method is as follows: . |

| Fitness value | The fitness values are calculated by Equation (5). |

| Pheromone update | The optimal path update and global update are two aspects of the pheromone update. The optimal path update is shown in Equation (6). The global update method is: , where i and j are the non-optimal paths of this iteration. |

4. Design of the Dynamic Artificial Bee-Ant Colony Algorithm

By analyzing the performances of ABC and MMAS, a DABAA is proposed in the paper. Then, the DABAA is modified in three aspects based on the traditional ACO and ABC algorithms.

- 1.

- By improving the traditional ABC algorithm, an ABC algorithm with mutation is formed, so it can directly update the unsatisfactory nectar sources, which further strengthens the global search ability of the ABC;

- 2.

- When the phenomenon of stagnation appears in the later stage of the ABC, to improve the speed of convergence, the optimal fusion evaluation method is used;

- 3.

- When the feasible solution is close to the optimal solution, to increase the population number of ant colonies, an iterative adjustment threshold is used.

4.1. Mutation Artificial Bee Colony Algorithm

When the number of mining operations reaches the upper limit, the ABC algorithm updates the nectar sources. To reduce the number of calculations, the ABC algorithm with mutation directly updates the nonideal nectar sources in the process of mining. The following are the specific steps.

- 1.

- Judgment of the similarity of nectar sources: The higher the similarity of the nectar sources is, the more prone they are to stagnation and the waste of computing resources. Equation (7) is the judgment method;

- 2.

- Nectar sources update method: When > is satisfied, mining is not needed. The mutation operation is executed, and nectar source updates can be directly executed by Equation (8).

4.2. Optimal Fusion Evaluation

The fixed number of iterations is also used to control the combination of the ABC and MMAS in the hybrid algorithm. When the convergence speed and effect are unsatisfactory, the algorithm must continue before the MMAS is executed, so the convergence speed of the hybrid algorithm is low. To increase the running efficiency, the optimal fusion evaluation is introduced. When the ABC algorithm exhibits the stagnation phenomenon, the MMAS will be used to save computing resources. The following are the specific steps for the optimal fusion evaluation.

- 1.

- The maximum and minimum iterations of the ABC are set to and , respectively;

- 2.

- When the conditional in Equation (9) is met, the ABC will be terminated and the MMAS will be used.

4.3. Iterative Adjustment Threshold

The accuracy of the MMAS is closely related to the number of ant colonies. The larger the population is, the more accurate the search ability, but the number of computations will increase rapidly. To minimize the calculation complexity while improving the accuracy of the DABAA, iterative adjustment is used to improve accuracy in the paper. To control the time of increasing the ant colony population size, a threshold is designed to achieve this goal. The value of can be calculated by Equation (10).

where is the adjustment coefficient and represents the maximum number of iterations. When is less than the number of iterations in the MMAS, it will lead to an increase in the population size of ant colonies, thereby further searching for the optimal solution.

4.4. DABAA Operation Process

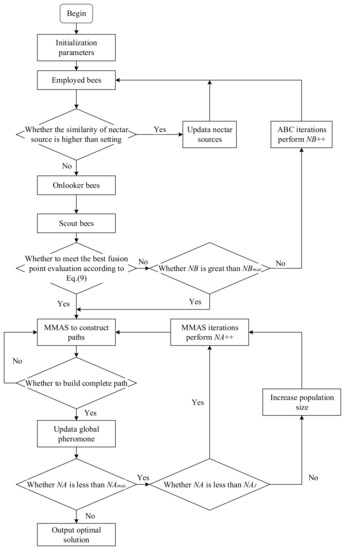

First, taking advantage of the powerful global search function of the ABC, the pheromone is updated for the ACO algorithm to reduce the computational load. Then, the iterative threshold adjustment is adopted to switch the algorithm. Finally, the DABAA fully exploits the high-precision advantages of the MMAS to obtain the optimal solution. The specific steps of the algorithm are shown in the flow chart of the DABAA in Figure 2:

Step 1: Various parameters are initialized.

Step 2: The ABC algorithm frist enters the employed bee stage. According to the evaluation indices, the ABC algorithm calculates the fitness value.

Step 3: The similarity of nectar sources is judged. If the similarity of nectar sources is too high, the ABC algorithm updates the nectar sources and returns to step 2; otherwise, it proceeds to step 4.

Step 4: The ABC algorithm then enters the onlooker bee stage. Onlooker bees select nectar sources according to the roulette method.

Step 5: The ABC algorithm enters the scout bee stage. Scout bees will randomly explore new nectar sources.

Step 6: Whether the optimal fusion evaluation is invoked is determined. If so, the ABC algorithm stops, and the MMAS is called; otherwise, the algorithm returns to step 2.

Step 7: The ant colony path is constructed. The pheromone is updated according to the ABC solution.

Step 8: Whether reaches the adjustment threshold is judged, and the population of the ant colony is increased if it is satisfied; otherwise, the iteration is repeated according to the original ant colony scale.

Step 9: Whether reaches the maximum iteration is judged, and the optimal solution is output if it is satisfied; otherwise, the algorithm returns to step 8.

Figure 2.

DABAA flow chart.

4.5. Time Complexity Analysis of the DABAA

An important indicator of the algorithm operating efficiency is the time complexity. In the DABAA, n is the number of tasks in a scheduling scheme, k is the population number of ant and bee colonies, and m is the total rental orders received by the cloud platform. The calculation method of ABC’s time complexity is , and the calculation method of MMAS’s time complexity is . Thus, the calculation method of DABAA’s time complexity is .

4.6. Convergence Analysis of the DABAA

In the DABAA based on the ACO algorithm and ABC algorithm, the ABC algorithm is only embedded in the MMAS, so the structural unity of the MMAS is not damaged. Therefore, the convergence speeds and effects of the DABAA and MMAS are the same. The ABC algorithm is convergent, while Equation (11) is satisfied [32]. Therefore, the DABAA is verified to be convergent according to Equation (11) [33].

5. Simulation and Experiment

5.1. Simulation

To ensure that agricultural production is not delayed, a large number of simulation experiments are designed in this paper to verify the effectiveness and reliability of the DABAA. The following are the specific steps of the simulation.

- 1.

- The agricultural machines in the rental service are numbered 1 to 6, and the number of scheduling tasks for each agricultural machine is determined to be 10;

- 2.

- The 600 rental orders received by the cloud platform are numbered, and then, according to the QoS evaluation model, data processing is performed on the , , , and other indicators of each order. This paper sets ∈ [0.8,0.95] and ∈ [0.6,0.75], and the corresponding , , and are 0.35, 0.3, 0.2 and 0.15, respectively [34];

- 3.

- Table 4 shows the initial parameters [17,35,36]. All experiments are performed using a PC with an Intel core i5-6500 CPU at 3.20 GHz, 8 GB of memory, a Windows 10 operating system, and MATLAB 2015b software;

- 4.

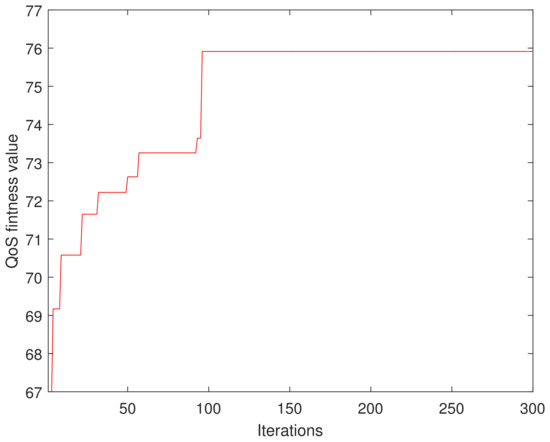

- Figure 3 shows the optimization process of the agricultural machinery rental service. It shows that this algorithm tends to converge after 100 iterations, and this experimental result corresponds to the previous convergence analysis. The unit of the vertical axis is %;

- 5.

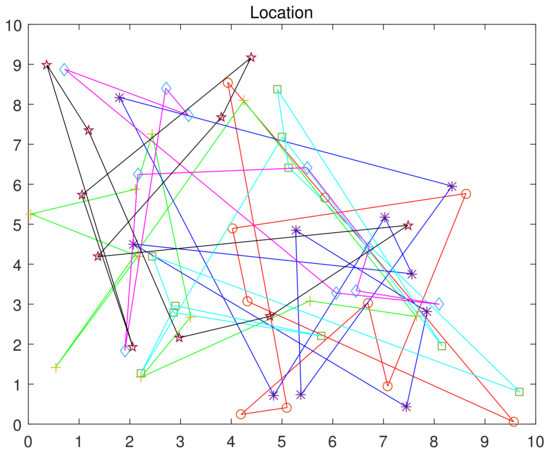

- Tasks assigned for each agricultural machine. After completing a scheduling sequence that has 10 rental tasks, each agricultural machine will receive a new scheduling sequence from the task pool. The smaller the number of tasks scheduled for each deployment is, the less time it takes to execute the tasks and the higher the real-time performance. Figure 4 shows the result of task assignment, where the axes indicate the virtual plane coordinates, each color line indicates a complete scheduling plan for each agricultural machine, and each point represents a coordinate given by the rental order.

In general, the process of agricultural machinery rental is as follows. The number of tasks is determined for each schedule according to the maintenance time of the machine and the real-time performance of the scheduling tasks (i.e., 10 above), and the optimal scheduling sequence is generated for each machine based on the evaluation model through the DABAA. Since the optimal scheduling sequence makes the execution distance of the machine the shortest, the machine executes tasks in sequence according to the order and typically moves to the location of task 2 after executing task 1. This paper assumes that there are no emergencies during the movement; that is, the machine can reach the destination smoothly within the specified time. After the machine completes the current scheduling sequence, it is returned to the factory for maintenance and inspection, and then, a new scheduling sequence is generated for it until all tasks are completed.

Table 4.

Algorithm parameter setting.

Table 4.

Algorithm parameter setting.

| Algorithm | Parameters |

|---|---|

| GA | Cross probability is 0.7, mutation probability is 0.15, population size (P) = 40, and maximum number of iterations (M) = 300. |

| ABC | P = 40, M = 300, and the limit of mining operations is 40. |

| MMAS | Heuristic factor =1, expectation factor = 4, pheromone range , volatilization rate = 0.002, P = 40, and M = 300. |

| DABAA | = 60, = 150, and adjustment coefficient = 0.85. The other parameters and settings are the same as those of the MMAS and ABC. |

Figure 3.

Process of optimization.

5.2. Comparison Experiment

5.2.1. Comparison with Basic Algorithms

To verify the effectiveness and superiority of the DABAA for large-scale scheduling in an agricultural machinery rental service, the performance of the DABAA is compared with the performances of the GA, ABC and MMAS, among them, the GA algorithm has been applied to many fields because of its strong global search ability and fast convergence speed. Tested on nine large-scale problems for all four algorithms, the parameter settings of each algorithm are shown in Table 4. Table 5 shows the size of the test, T(n, m) is the size of the task, where n represents the total number of tasks in the scheduling task pool, and m represents the number of tasks in a scheduling scheme. According to the evaluation index of the task, the optimal scheduling scheme is generated, and all rental tasks are completed through multiple scheduling schemes. In this paper, m∈ 10, 20, 30 to verify the performance of the DABAA through different scales. In actual tasks, m is determined according to the actual maintenance time. When the number of machines is insufficient, the number of tasks (i.e., m) of a machine in one scheduling sequence can be reduced to increase the coverage and real-time performance of task scheduling.

Figure 4.

Route of multiple agricultural machine rental.

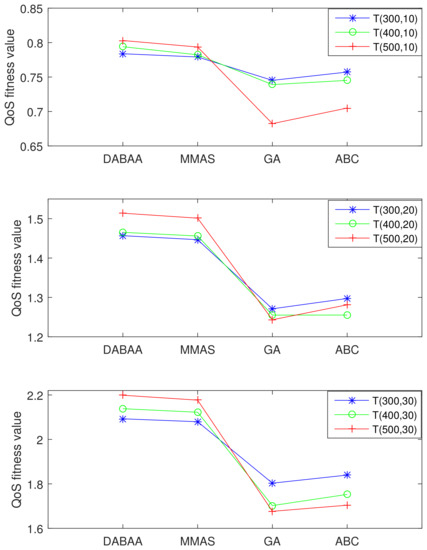

All algorithms run 20 times for the 9 tasks in Table 5. Table 6 shows the data statistics of experimental results, which are statistics of QoS fitness values, including the optimal and average QoS fitness value obtained by the experiment in this paper. It can be seen that DABAA has better convergence accuracy compared with other algorithms. Figure 5 is a comparison of the accuracy of the four algorithms. Figure 5 shows that DABAA performs better in solving problems than other algorithms. As the amount of data increases, the advantage of the DABAA is more obvious, and the precision of convergence increase. Therefore, the performance of the DABAA is superior to that of the other three algorithms, and the DABAA is more conducive to solving large-scale problems in agricultural machinery rental.

Table 5.

Task size.

Table 5.

Task size.

| Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| n | 300 | 400 | 500 | 300 | 400 | 500 | 300 | 400 | 500 |

| m | 10 | 10 | 10 | 20 | 20 | 20 | 30 | 30 | 30 |

Table 6.

The optimal and average QoS fitness values.

Table 6.

The optimal and average QoS fitness values.

| Scale | The Optimal QoS Fitness Value | The Average QoS Fitness Value | ||||||

|---|---|---|---|---|---|---|---|---|

| DABAA | MMAS | GA | ABC | DABAA | MMAS | GA | ABC | |

| T(300,10) | 0.782 | 0.779 | 0.746 | 0.758 | 0.666 | 0.638 | 0.631 | 0.625 |

| T(400,10) | 0.794 | 0.783 | 0.741 | 0.747 | 0.691 | 0.677 | 0.632 | 0.659 |

| T(500,10) | 0.803 | 0.794 | 0.681 | 0.703 | 0.749 | 0.720 | 0.604 | 0.585 |

| T(300,20) | 1.455 | 1.443 | 1.262 | 1.304 | 1.371 | 1.350 | 1.124 | 1.203 |

| T(400,20) | 1.464 | 1.455 | 1.251 | 1.252 | 1.393 | 1.366 | 1.117 | 1.135 |

| T(500,20) | 1.511 | 1.502 | 1.243 | 1.289 | 1.401 | 1.385 | 1.099 | 1.186 |

| T(300,30) | 2.085 | 2.063 | 1.802 | 1.835 | 1.962 | 1.944 | 1.647 | 1.668 |

| T(400,30) | 2.165 | 2.144 | 1.693 | 1.738 | 2.073 | 2.051 | 1.548 | 1.622 |

| T(500,30) | 2.201 | 2.175 | 1.668 | 1.688 | 2.095 | 2.058 | 1.483 | 1.596 |

Figure 5.

Results of accuracy with different task sizes.

5.2.2. Comparison with Other Improved Algorithms

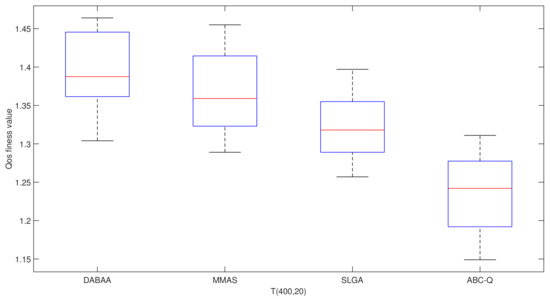

To further prove the advantages of DABAA, this paper compares DABAA with SLGA and ABC-Q algorithms. SLGA algorithm [36] is an improved GA algorithm, Chen et al. combined GA algorithm with SARSA and Q-learning to reduce the number of iterations of GA and improve the performance of GA algorithm. ABC-Q algorithm [26] is an improved ABC algorithm, Long et al. combined ABC algorithm with Q-learning to dynamically adjust the update dimension of ABC algorithm and improve its convergence accuracy. Table 7 shows the data statistics obtained after the four algorithms for running 9 tasks for 20 times, including the optimal QoS fitness value and average time consumption. Figure 6 shows the distribution of 20 QoS fitness values obtained by the four algorithms for solving the task T(400,20). It can be seen that the convergence accuracy of DABAA algorithm is better than the other three improved algorithms.

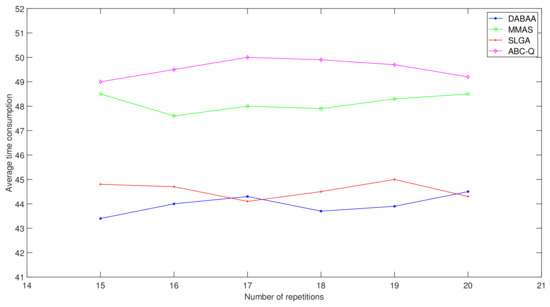

The average time consumption for DABAA, MMAS, SLGA and ABC-Q is shown in Figure 7. It can be seen that the average consumption time of DABAA is less than the other three algorithms, this is because DABAA accelerates the convergence speed through the optimal fusion evaluation strategy, avoids the invalid iterations. According to Figure 6 and Figure 7, it can be seen that the performance of DABAA is better than other algorithms, with better convergence speed and accuracy.

Table 7.

Statistics of the running results of the four algorithms.

Table 7.

Statistics of the running results of the four algorithms.

| Number | Scale | The Optimal QoS Fitness Value | The Average Time Consumption | ||||||

|---|---|---|---|---|---|---|---|---|---|

| DABAA | MMAS | SLGA | ABC-Q | DABAA | MMAS | SLGA | ABC-Q | ||

| 1 | T(300,10) | 0.782 | 0.779 | 0.763 | 0.767 | 36.11 | 39.85 | 38.59 | 41.89 |

| 2 | T(400,10) | 0.794 | 0.783 | 0.775 | 0.762 | 36.28 | 40.33 | 38.74 | 42.16 |

| 3 | T(500,10) | 0.803 | 0.794 | 0.781 | 0.756 | 37.84 | 42.13 | 39.07 | 43.59 |

| 4 | T(300,20) | 1.455 | 1.443 | 1.409 | 1.368 | 39.45 | 42.71 | 40.58 | 44.12 |

| 5 | T(400,20) | 1.464 | 1.455 | 1.397 | 1.311 | 43.97 | 48.13 | 44.57 | 49.55 |

| 6 | T(500,20) | 1.511 | 1.502 | 1.359 | 1.308 | 44.18 | 50.39 | 46.72 | 53.34 |

| 7 | T(300,30) | 2.085 | 2.063 | 1.983 | 1.945 | 43.28 | 50.75 | 48.02 | 52.58 |

| 8 | T(400,30) | 2.165 | 2.144 | 2.034 | 1.897 | 45.74 | 51.26 | 48.39 | 55.96 |

| 9 | T(500,30) | 2.201 | 2.175 | 2.108 | 1.993 | 47.31 | 53.79 | 49.44 | 57.43 |

Figure 6.

Boxplot of QoS fitness values.

Figure 7.

Average time consumption.

6. Conclusions

Due to the small farmland sizes and strong seasonal crops in China, large-scale agricultural machinery scheduling is difficult to realize in the rental industry. To solve this problem, a DABAA is proposed in this paper. First, the dynamic coefficient is introduced to balance the time demand of farmers, so the applicability of the model is enhanced in the farming season. Then, the traditional ABC algorithm is modified to obtain the ABC algorithm with mutation, which further improves the global search ability. Additionally, optimal fusion evaluation is performed to combine the ABC with the MMAS to reduce computation time, and the iterative threshold adjustment method improves the accuracy of the optimal solution. Therefore, these improvements enhance the global search capability of the algorithm in the early stage and increase the convergence speed in the later stage. The comparison experiments on the ABC, GA, MMAS and DABAA show that the DABAA is superior to the other algorithms.

Our team has been engaged in the agricultural machinery industry for many years and has discovered the realistic requirements of agricultural machinery rental from actual situations. Based on the team’s agricultural practical experience, the model in this paper is not much different from the actual situation. Moreover, the research in this paper is based on big data; it is meaningless to experiment with a small range of small data, which does not reflect the advantages of the algorithm. At present, the domestic agricultural machinery environment in China restricts large-scale scheduling experiments, such as the lack of large agricultural machinery rental companies and the differences in agricultural machinery standards in different regions. Carrying out large-scale leasing experiments requires the government to formulate supporting policies and unified standards and the cooperation of agricultural machinery companies and farmers. At present, the research in this paper provides theoretical and model support for future practical applications, and the team is conducting research on the agricultural machinery rental platform. In the future, the team will contact appropriate agricultural machinery companies to jointly develop agricultural machinery rental platforms and negotiate with the government to apply the proposed system of this paper to actual verification.

In general, especially in China, the combination of cloud manufacturing and agricultural machinery rental is still immature. There is still much room for improvement in the optimization of agricultural machinery rental in cloud services. Various intelligent algorithms need to be further optimized and improved. Deep learning (DL) and reinforcement learning (RL) algorithms can also be combined with the ABC and other algorithms for application in the scheduling and optimization of agricultural machinery rentals. In addition, in the construction of the evaluation model, cloud service technology should be further combined with agricultural production. Therefore, research on agricultural machinery rentals in cloud manufacturing needs to be further deepened, and agricultural machinery rental service platforms based on cloud services need further research.

Author Contributions

Conceptualization: J.Z.; Data curation: J.Z. and W.W.; Methodology: J.Z. and K.Z.; Formal analysis: J.Z.; Writing—original draft preparation: J.Z. and W.W.; Writing—review and editing: J.Z. and W.W.; Funding acquisition: K.Z., T.J. and J.H.; Investigation: J.Z.; Project administration: K.Z.; Resources: J.H.; Software: J.Z. and W.W.; Validation: J.Z. and K.Z.; Visualization: J.Z. and W.W.; Supervision: K.Z. and T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R & D Program of China (2018YFB1308700), the Agriculture Research System of China (CARS-24-D-01), the China Postdoctoral Science Foundation (2019M662410), and the University-Industry Collaborative Education Program (202101321011, 202102430015).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The code in this article cannot be published due to privacy, and can be obtained from the corresponding author upon reasonable request.

Conflicts of Interest

All authors declare there is no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| DABAA | Dynamic artificial bee-ant colony algorithm |

| ABC | Artificial bee colony |

| ACO | Ant colony optimization |

| MMAS | Max-min ant system |

| QoS | Quality of Service |

References

- Khanna, A.; Rodrigues, J.; Gupta, N.; Swaroop, A.; Gupta, D. Local Mutual Exclusion algorithm using fuzzy logic for Flying Ad hoc Networks. Comput. Commun. 2020, 156, 101–111. [Google Scholar] [CrossRef]

- Luo, X.W.; Zhang, L.Y. The optimal scheduling model for agricultural machinery resources with time-window constraints. Int. J. Simul. Model. 2016, 15, 721–731. [Google Scholar] [CrossRef]

- Edwards, G.; Sorensen, C.G.; Bochtis, D.D.; Munkholm, L.J. Optimised schedules for sequential agricultural operations using a Tabu Search method. Comput. Electron. Agric. 2015, 117, 102–113. [Google Scholar] [CrossRef]

- Tan, W.; Zhao, Y. Web service composition based on chaos genetic algorithm. Comput. Integr. Manuf. Syst. 2018, 24, 1822–1829. [Google Scholar]

- Ghomi, E.J.; Rahmani, A.M.; Qader, N.N. Service load balancing, scheduling, and logistics optimization in cloud manufacturing by using genetic algorithm. Concurr. Comput. Pract. Exp. 2019, 31, e5329. [Google Scholar]

- Zhang, W.; Pan, X.H.; Liu, Z.; Dong, T.Y.; Zhang, L. Manufacturing service scheduling strategy based on cloud model ant colony optimization. Comput. Integr. Manuf. Syst. 2012, 18, 201–207. [Google Scholar]

- Al-shihabi, S.T.; AIDurgam, M.M. A max–min ant system for the finance-based scheduling problem. Comput. Ind. Eng. 2017, 110, 264–276. [Google Scholar] [CrossRef]

- Li, L.; Cheng, F.; Cheng, X.; Pan, T. Enterprise manufacturing logistics network optimization based on modified multi-objective particle swarm optimization algorithm. Comput. Integr. Manuf. Syst. 2018, 24, 2122–2132. [Google Scholar]

- Liu, J.W.; Guo, Y.; Zha, S.S.; Wang, F.L.; Zhang, S.C. Multi station assembly sequence planning based on improved particle swarm optimization algorithm. Comput. Integr. Manuf. Syst. 2018, 24, 2701–2711. [Google Scholar]

- Gao, W.F.; Liu, S.Y. A modified artificial bee colony algorithm. Comput. Oper. Res. 2012, 39, 687–697. [Google Scholar] [CrossRef]

- Zhou, J.J.; Yao, X.F. A hybrid artificial bee colony algorithm for optimal selection of QoS based cloud manufacturing service composition. Int. J. Adv. Manuf. Technol. 2017, 88, 3371–3387. [Google Scholar] [CrossRef]

- Zeng, B.; Li, M.F.; Zhang, Y.; Ma, J.H. Research on Assembly Sequence Planning Based on Firefly Algorithm. J. Mech. Eng. 2013, 49, 177–184. [Google Scholar] [CrossRef]

- Omid, N.A.; Modjtaba, R. A new fuzzy membership assignment and model selection approach based on dynamic class centers for fuzzy SVM family using the firefly algorithm. Turk. J. Electr. Eng. Comput. Sci. 2016, 24, 1797–1814. [Google Scholar]

- Kumar, A.; Bawa, S. Generalized ant colony optimizer: Swarm-based meta-heuristic algorithm for cloud services execution. Computing 2018, 101, 1609–1632. [Google Scholar] [CrossRef]

- Alabbadi, A.A.; Abulkhair, M.F. Multi-Objective Task Scheduling Optimization in Spatial Crowdsourcing. Algorithms 2021, 14, 77. [Google Scholar] [CrossRef]

- Cao, B.W.; Liu, X.H.; Chen, W.; Zhang, Y.; Li, A.M. Depth Optimization Analysis of Articulated Steering Hinge Position Based on Genetic Algorithm. Algorithms 2019, 12, 55. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Wen, Y.Z.; Wu, W.Y.; Ni, Z.Y.; Jin, T.G.; Long, X.J.; Zaitseva, E. Cloud Service Optimization Method Based on Dynamic Artificial Ant-Bee Colony Algorithm in Agricultural Equipment Manufacturing. Math. Probl. Eng. 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Chen, Y.L.; Niu, Y.F.; Liu, J.; Zuo, L.D.; Wang, L. Task distribution optimization for multi-supplier collaborative production in cloud manufacturing. Comput. Integr. Manuf. Syst. 2019, 25, 1806–1816. [Google Scholar]

- Garg, S.; Modi, K.; Chaudhary, S. A QoS aware approach for runtime discovery, selection and composition of semantic web services. Int. J. Semant. Web Inf. Syst. 2016, 12, 177–200. [Google Scholar] [CrossRef]

- Wu, Q.W.; Ishikawa, F.; Zhu, Q.S. QoS-aware multigranularity service composition: Modeling and optimization. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 1565–1577. [Google Scholar] [CrossRef]

- Zeng, L.Z.; Benatallah, B.; Ngu, A.H.H.; Dumas, M.; Chang, H. QoS aware middleware for web services composition. IEEE Trans. Softw. Eng. 2004, 30, 449–470. [Google Scholar]

- Karaboga, D. Artificial bee colony algorithm. Scholarpedia 2010, 5, 6915. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. On the performance of artificial bee colony (ABC) algorithm. Appl. Soft. Comput. 2008, 8, 687–697. [Google Scholar] [CrossRef]

- Yan, Z.H.; Ding, Q.L. The appliance of wasp colony algorithm to realize dynamic job shop scheduling. Modul. Mach. Tool Autom. Manuf. Tech. 2004, 49–50. [Google Scholar]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Long, X.J.; Zhang, J.T.; Qi, X.; Xu, W.L.; Jin, T.G.; Zhou, K. A self-learning artificial bee colony algorithm based on reinforcement learning for a flexible job-shop scheduling problem. Concurr. Comput. Pract. Exp. 2021, e6658. [Google Scholar] [CrossRef]

- Duan, H.B.; Wang, D.B.; Zhu, J.Q.; Huang, X.H. Development on ant colony algorithm theory and its application. Control. Decis. 2004, 19, 1321–1326. [Google Scholar]

- Guo, P.; Yan, W.J. The Review of Ant Colony Algorithm Based on TSP. Comput. Sci. 2007, 34, 181–184. [Google Scholar]

- Wu, Q.H.; Zhang, Y.; Ma, Z.M. Review of Ant Colony Optimization. Microcomput. Inf. 2011, 27, 1–2. [Google Scholar]

- Yao, Y. Research for the Improvement of Max-Min Ant Colony Algorithm. Math. Pract. Theory 2014, 44, 242–247. [Google Scholar]

- Stutzle, T.; Hoos, H. MAX–MIN ant system. Futur. Gener. Comp. Syst. 2000, 16, 889–914. [Google Scholar] [CrossRef]

- Bansal, J.C.; Gopal, A.; Nagar, A.K. Analysing Convergence, Consistency, and Trajectory of Artificial Bee Colony Algorithm. IEEE Access 2018, 6, 73593–73602. [Google Scholar] [CrossRef]

- Stutzle, T.; Dorigo, M. A short convergence proof for a class of ACO algorithms. IEEE Trans. Evol. Comput. 2002, 6, 358–365. [Google Scholar] [CrossRef]

- Yang, Y.F.; Yang, B.; Wang, S.L.; Liu, F.; Wang, Y.K.; Shu, X. A dynamic ant-colony genetic algorithm for cloud service composition optimization. Int. J. Adv. Manuf. Technol. 2019, 102, 355–368. [Google Scholar] [CrossRef]

- Bashir, M.B.; Nadeem, A. Improved Genetic Algorithm to Reduce Mutation Testing Cost. IEEE Access 2017, 5, 3657–3674. [Google Scholar] [CrossRef]

- Chen, R.H.; Yang, B.; Li, S.; Wang, S.L. A Self-Learning Genetic Algorithm based on Reinforcement Learning for Flexible Job-shop Scheduling Problem. Comput. Ind. Eng. 2020, 149, 106778. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).