Abstract

Vehicle safety risk can be decreased by diagnosing the lithium-ion battery system of electric road vehicles. Real-time cell diagnostics can avoid unexpected occurrences. However, lithium-ion batteries in electric vehicles can significantly differ in design, capacity, and chemical composition. In addition, the battery monitoring systems of the various vehicles are also diverse, so communication across the board is not available or can only be achieved with significant difficulty. Hence, unique type-dependent data queries and filtering are necessary in most cases. In this paper, a Volkswagen e-Golf electric vehicle is investigated; communication with the vehicle was implemented via an onboard diagnostic port (so-called OBD), and the data stream was recorded. The goal of the research is principally to filter out, identify, and localize defective/weak battery cells. Numerous test cycles (constant and dynamic measurements) were carried out to identify cell abnormalities (so-called deviations). A query and data filtering process was designed to detect defective battery cells. The fault detection procedure is based on several cell voltage interruptions at various loading levels. The methodology demonstrated in this article uses a fault diagnosis technique based on voltage abnormalities. In addition, it employs a hybrid algorithm that executes calculations on measurement and recorded data. In the evaluation, a status line comprising three different categories was obtained by parametrizing and prioritizing (weighting) the individual measured values. It allows the cells to be divided into the categories green (adequate region), yellow (to be monitored), and red (possible error). In addition, several querying strategies were developed accordingly to clarify and validate the measurement results. The several strategies were examined individually and analyzed for their strengths and weaknesses. Based on the results, a data collection, processing, and evaluation strategy for an electric vehicle battery system have been developed. The advantage of the developed algorithm is that the method can be adapted to any electric or hybrid vehicle battery.

1. Introduction

Today, road vehicles operating with lithium-ion batteries, either partially (hybrid) or fully (rechargeable), have become more and more common [1,2,3]. The “spread” of electric passenger cars has also been propelled by the increase in battery capacity, which has changed significantly since 2010 [4,5,6]. Increasingly stringent emission standards will further accelerate this “spread” process [7]. In addition, efficient use has recently become a vital issue as energy prices rise [8]. It is not possible to operate electric vehicles in the optimal range and monitor and control the condition of the battery system [9]. Due to the growing demand, condition assessment and diagnostics is currently a priority research area [10,11,12]. The expansion of electric vehicles will also bring with it the electrification of public transport [13,14,15].

During their use, battery cells continuously lose their storage capacity and age, as well as change specific parameters [16]. In most cases, it can be observed if a battery cell reaches the minimum or maximum threshold voltage sooner; for example, it is submerged faster during intense acceleration and charged more quickly during charging. Using cells without supervision (BMS—Battery Management System) is accident-prone and, in the worst case, can even cause a fire during charging [17]. The BMS monitors the state of the cells, determines the maximum power that can be drawn from the battery, the maximum charging current, aggregates the voltage values, the state of charge (SOC), and also estimates the state of health (SOH) of the cells [18,19,20,21,22]. These data are transmitted to the engine controller or the battery charging station. If a faulty cell is found in the battery pack, for safety reasons, the vehicle can no longer be used. However, this fault will or may disappear after the car has been rested or restarted once the cell voltages have equalized. However, the fault phenomenon may recur later, depending on use, and the risk of an accident may be increased. Depending on this, the vehicle can be made operational again without replacing the whole pack, simply by replacing the modules [23]. The cost of this is much lower than replacing the entire pack. It is recommended to carry out preliminary tests and more targeted vehicle diagnostics to ensure that a possible cell failure does not further deteriorate the other cells’ condition and, thus, the system’s total performance [24]. Early and accurate detection of voltage faults based on real-time battery parameters is of great importance for improving the safety of electric vehicles [25]. To increase the reliability and safety of lithium-ion batteries, researchers are proposing different methods for diagnosing failures, which can be divided into three groups: (i) experience-based, (ii) model-based, and (iii) data-driven methods [26,27]. During the charging and discharging process, cells interact with each other, which means that individual cells are not entirely independent of each other, which can affect diagnostics. Locating the faulty cell or cells can be conducted with or without disassembling the battery pack. Disassembling tests usually give more accurate results for the battery SOH [22,28,29,30], but they come with a loss of guarantee.

In the case of non-disassembling tests, the vehicle’s BMS or ECU (Electronic Control Unit) needs to communicate, which is not always easy. A further difficulty of battery diagnostics is that, in most cases, the classic (OBD—On-board diagnostics) readout only allows voltage monitoring at a system level; the cell-by-cell analysis is not possible and is usually disabled. Factory diagnostic tools may already be suitable for cell-level monitoring, but these tools are expensive and limited in availability. The aim is to create a test method that can be carried out relatively quickly, in an easy-to-implement way, without expensive equipment or a test station. A further difficulty is a need for a large amount of measurement data, in which each element has to be tested individually, which is both time and resource-consuming. Accurate prediction also requires diagnostics of systems in different states. Fault detection is currently a popular area of research, with several methods available in the literature [31,32,33,34,35,36].

Determining an accurate range in good condition is difficult for vehicle manufacturers, as many factors can influence it. These include temperature, driving style, terrain, heat exchange systems, and other consumers. There are various standards [37,38,39] and tests NEDC (New European Driving Cycle), WLTP (World Harmonized Light Vehicle Test Procedure), and EPA (U.S. Environmental Protection Agency) to determine the range of vehicles. Still, these values are mostly applicable to new vehicles [40]. In addition, the various dealerships review the condition of the cells annually; however, troubleshooting is limited to a quick test, and the whole system or module is replaced in case of a fault. Thus, many cells still in good condition end up as waste. At present, fault finding only very rarely covers cell-level fault finding. However, there are several types of analysis in the search for the causes of failure, such as the 23-month study presented by Barré et al. The test on a test bench, on a test track, and under storage conditions found that the latter was one of the most critical factors [41]. In addition, statistical [42], big data analysis methods [43], and voltage fault detection methods [31] are applied to detect faulty cases.

Current research also aims to develop a general data extraction and processing strategy that is as universal as possible. The data retrieval is unique for each vehicle since each cell has a unique CAN ID, but the retrieval process is already generalizable. In this article, the authors will focus on a data retrieval strategy where no factory readout unit is available; all data are accessed individually. The retrieval process is conducted through the CAN network in a request and response structure. In this paper publication, the authors have also analyzed the speed and errors of the responses received. The authors also further investigate the cellular voltage deviations and possible errors of the e-Golf [44]. Several conventional algorithms are used in battery condition assessment and estimation, summarized in the following publication [45]. The approach is based on a computational hybrid algorithm detecting and locating the faulty cell. In the method the authors implemented, a fault diagnosis based on voltage deviation was performed a posteriori with the data already collected.

The measurement methods and the tests carried out are presented in the second section, along with the data extraction and storage methodology and its limitations. In the third section, the evaluation of the measurement results and the search for errors are presented in detail. A specific weighting factor is used to determine the results, the effectiveness of which is validated. In the fourth section, the different outcomes are compared. Finally, in the fifth section, the authors briefly summarize the results and draw conclusions.

2. Materials and Methods

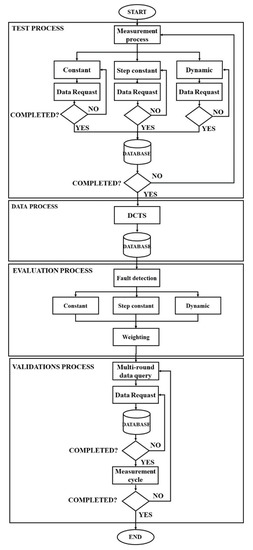

When developing the measurement method, the authors ensured the procedure was unique but easily reproducible and applicable. The main objective in developing the process is to detect and locate defective/weak cells based on the following algorithm (Figure 1).

Figure 1.

Faulty cell detection and localization algorithm.

The steps shown in the flowchart (Figure 1) were applied to develop the fault cell search. The process is composed of four main steps. The first two steps are the test and data processes (DCTS—Data Cleaning Transformation and Shorting) in this section. The other two steps are described in detail in Section 3.

2.1. Test Process

The tests were executed on the dynamic platform of the ZalaZONE Automotive Test Track in Hungary [46,47]. Fault diagnosis requires many measurements from each cell, a time and resource-consuming process. In addition, the test results can be affected by several factors, such as external temperature, driving style, terrain conditions, heat exchange systems, and the operation of other onboard consumers. Therefore, test cycles were performed under the authors’ defined test conditions. The structure of the test measures is defined according to different criteria and factors. First, to test the stability of the high voltage battery system’s specific data extraction and storage process. Three different cases were considered in the measurement methodology:

- constant speed: 30 km/h, 40 km/h, and 50 km/h;

- stepped constant: 30–40–50 km/h;

- dynamically variable speed.

It is important to note that each test was carried out separately, first with three steady constant progress tests, followed by two stepped constants, and finally, three dynamic tests. Furthermore, the vehicle was placed on the test track in a fully charged condition. The tests were uniformly 900 s in duration, and the diagnostic data to be observed and logged from the CAN network were as follows:

- system voltage [V];

- current [A];

- 88 cell voltages [V];

- four separated battery temperature values [°C];

- vehicle speed [km/h];

- GPS (Global Positioning System) speed [km/h].

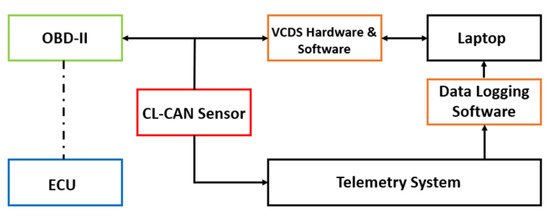

The system-level voltage represents the voltage of the entire system, with all modules connected in series and parallel. The 2020 Volkswagen e-Golf lithium-ion battery used for the measurements has a nominal capacity of 35.8 kWh, of which 32 kWh can be used. The battery pack has a 3p88s structure, so it contains 264 cells (type: NCM333), of which three are connected in parallel and 88 in series. The 400 V architecture has a nominal voltage of 325 V. During data collection, information can be extracted from 88 cells, i.e., elements connected in a row. In order to monitor and record the data coming over the CAN (controller area network) during the measurements, it is necessary to decrypt the car’s communication system and use a CAN BUS (controller area network bus) decoder file. When mapping the vehicle communication system, the CAN communication of the vehicle’s Central Gateway control unit was first observed as contactless, but little battery cell-specific data were accessed. In the second procedure, without a galvanic connection, the communication between the VAG-COM VCDS interface and the Central Gateway was investigated, through which it was possible to retrieve cell information; the schematic of the method is shown in Figure 2. As soon as the cell voltages were requested via the VAG-COM software, messages were displayed on the CAN bus.

Figure 2.

Data query schematic.

Network access, serial communication conversion from CAN communication, message reading, and information exchange with external sensors are all provided by this telemetry system based on the CAN protocol. The following elements and devices were applied in the measurement system: Kvaser (Mölndal, Sweden) Memorator R-SemiPro CAN USB Interface; AEM (Hawtrone, CA, USA) 30-2206 GPS Sensor; ELM (London, ON, Canada) 327 OBD-II Interface; VW e-Golf MK7 Vehicle Central Gateway; Murcal Terminating Resistor 120 Ω (Palmdale, CA, USA); 12 V Power Supply; CAN Hub (Velké Poříčí, Czech Republic). Experience has shown that it is not enough to monitor the CAN BUS network but to send a CAN message to the central gateway to retrieve the data. Then the parameters of the data retrieval were analyzed, where it was found that the voltage of each cell has to be retrieved from the BMS individually, i.e., a requesting CAN message is needed, which is answered by a CAN message with the voltage value of the desired battery cell. The simultaneous query cannot obtain the desired data; therefore, the query messages must be sent one by one in rotation. It is probably necessary to avoid overloading the bus, and the method cannot be changed. The query is conducted over a CAN network in a request and response structure. Based on this knowledge, the *.dbc database file for decoding the messages and the Simulink program, which is responsible for sending, receiving, and logging CAN bus messages, were prepared. One by one, the program queries the desired parameters and waits for the answer. During testing, it was found that the vehicle can process one request code at a time; otherwise, data are lost, and the response speed was volatile, with a maximum query rate of 100 Hz without data loss.

2.2. Data Process

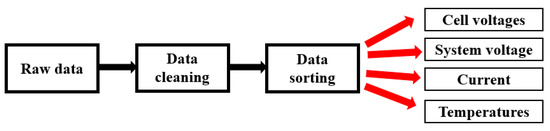

In one cycle, approximately one-hundred parameters are queried. Therefore, it was necessary to clean the logged data to extract relevant information from the raw data set. Data from the diagnostic port were logged using a computer and Matlab software. Data cleaning aims to extract relevant information from the raw data set. ETL (Extract, transform, load) tools essentially allow data to be loaded from multiple data sources, combined, and converted into a format that can be loaded into a database for further query. Communication and data recording with the e-Golf BMS system is performed with Simulink, and the resulting log file with the *.txt format is processed. The KNIME software was applied for data analysis, a free and open-source data analysis, reporting, and integration platform. The data processing structure using the KNIME is shown in Figure 3.

Figure 3.

The structure of data processing.

First, unnecessary data are removed from the raw data file. Then the resulting format is sorted according to a defined system (e.g., cell values with the same ID are put into a single column). At the end of the process, the extracted data are saved in an Excel file format. The next step in processing data is to check the time of data saving.

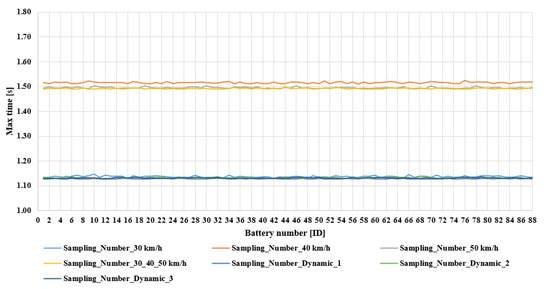

It is important to note that during the readout, all cell values, continuously mounted, along with current and temperature information, were approximately one-hundred data per readout cycle. Figure 4 shows the average readout time for a cell with a given ID.

Figure 4.

Average readout time per cell.

Figure 4 shows the readout time and ID of all 88 cells. The results show that the readout value per cell was approximately the same. Thus, the same amount of data was received from all battery cells, the only difference being the readout speed. Cell information was obtained in an average of 1.5 s for constant measurements and 1.2 s for dynamic measurements. Fewer data would be sufficient for the constant load cases, but a more significant amount is needed for the dynamic tests to analyze the transient values better. Therefore, the information retrieval was set to 1.2 s, as this does not involve data dropout. From a cell diagnostic point of view, the measurement response time was also set to a sufficient speed.

In Section 3, the cleaned data are analyzed in detail, and the battery cells considered to be the worst are selected based on the results.

3. Results

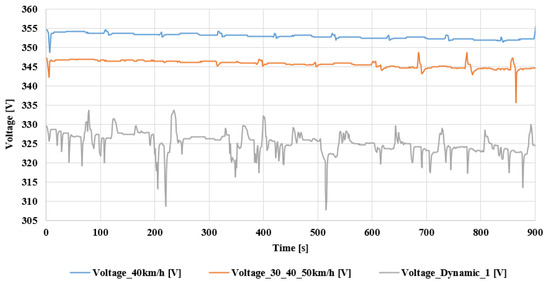

During the evaluation, the goal is to analyze the changes in voltage values that occur under different loads and observe the differences between the system’s cells. While examining the deviations of the cells, the elements of the vehicle’s battery system with the worse condition were identified and localized. In addition, deviations from the average voltage were analyzed, and seemingly faulty cases were highlighted. As the first step of the analysis, the current and voltage values of the various tests are presented. Figure 5 shows the results of a constant load (40 km/h), a stepped constant (30 km/h–40 km/h–50 km/h), and a dynamic measurement.

Figure 5.

The voltage of the e-golf system under different loads.

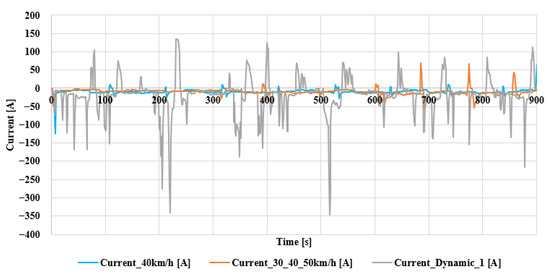

Based on Figure 5, it can be concluded that there is no significant difference in the voltage change during the constant load and the stepped constant load. The intense voltage variation during dynamic loading is more beneficial for diagnostic purposes (critical cells are easier to detect). Figure 6 shows current profiles for voltage values.

Figure 6.

The current of the e-Golf system under different loads.

In Figure 6, the current profile of the different loads can be observed; it can be seen that the dynamic case includes several regenerative braking. The dynamic loads marked in grey show the highest displacements. It is a characteristic of the dynamic driving style of continuous acceleration and braking. Positive values on the y-axis in the figure are due to energy recoveries from regenerative braking, and negative values are due to vehicle acceleration.

3.1. Data Analysis—Evaluation Process

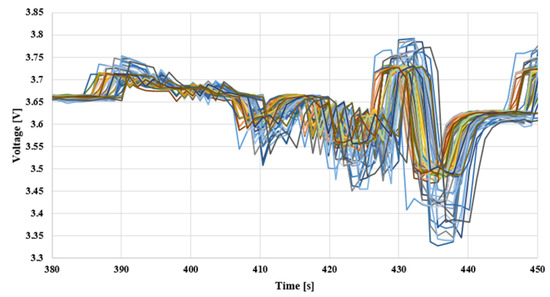

The next step in the analysis was to fit the data in the row and look for possible errors. No significant variation in cell voltages was observed for constant vehicle speeds, so the dynamic case was highlighted. Figure 7 shows the voltage values from the dynamic test.

Figure 7.

Data slippage analysis in Dynamic test 2 (the different color lines indicate the 88 battery cells).

Figure 7 shows the voltage values of all 88 cells as a function of time with different color lines. In the figure (Figure 7), one section of the whole measurement is highlighted to observe the data shift better. It can be stated that the cell voltages are very similar, but they show a time shift. The reason for the shift is due to the continuous request-response messages. While voltage values of each cell are queried, in turn, a load arrives in the meantime (vehicle accelerates), and thus, the voltage of intermediate cells differs. For example, if a cell with ID 1…33 is sampled at a constant load of 10 A, but at the moment of acceleration, a load of 100 A occurs, cells with ID 34…88 are sampled at a lower voltage. A problem can arise when these values are assigned to the same time value. However, the unit time is unavoidable as it is the best way to determine the cell voltage difference. Figure 8 shows the exact measurement as before, presented over an even smaller time range.

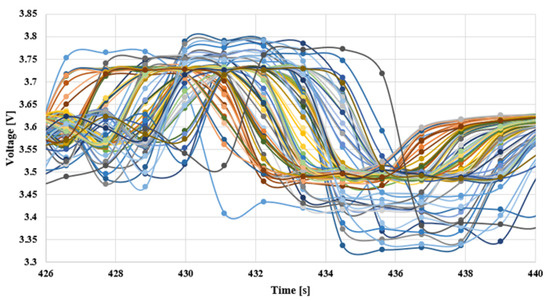

Figure 8.

Data slip analysis in a short time range in Dynamic test 2 (the different color lines indicate the 88 battery cells).

In Figure 8, a relatively small 14 s section has been analyzed, in which case the cell voltage values for the time point can be plotted. It can be seen that the voltage value associated with a time instant has a relatively large scatter. It is important to note that the recorded time point was always the last timestamp of the last data read or the maximum time read during a sampling round. However, significant deviations can occur if the cell voltage deviations are examined simultaneously, and many good battery cells can be misclassified. (A solution could be to increase the query speed, but in the question/answer procedure, this is set to maximum, see Section 2). Figure 9 shows the differences in the measurements.

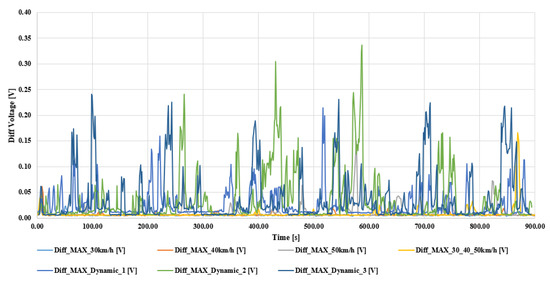

Figure 9.

Deviation from the average voltage under different loads.

Figure 9 shows all measurements, dynamic and constant cases. It indicates that there are significant deviations, in some cases up to 0.3 V, most likely due to the data mentioned above the readout slip. One solution to “smoothing” out the differences is to average the individual cell data. In this approach, the voltage values for a given cell (ID) are averaged over three or five data points, and the window continuously shifts in time. Figure 10 summarizes the results of the various averaging.

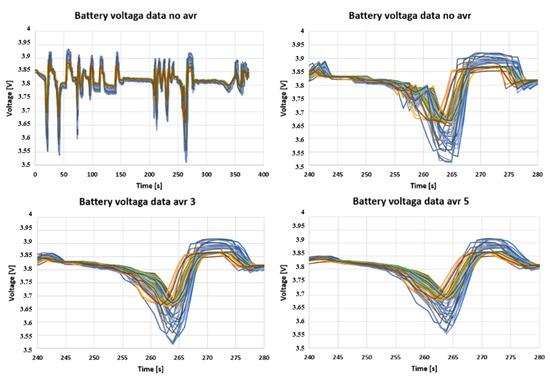

Figure 10.

Different ways of averaging the voltage values of the measurements (the different color lines indicate the 88 battery cells).

The upper left corner of the figure (Figure 10) shows the raw measurement data; the other sub-figures show the 240 s…280 s region at magnification. It is the region where the most significant load has been applied and is, therefore, the most likely to have the most significant variations in cell voltages. The upper right part shows the raw data values; the lower left sub-figure shows the values from averaging the three data (that is, the average of the previous and next values is used to determine the voltage value). Moreover, in the bottom right plot, the value under the test is substituted as the average of the two values preceding and following (averaging the five data). However, it is essential to note that this type of aggregation also involves data loss and those individual cell discrepancies are less likely to be detected.

3.2. Faulty Cell Localization

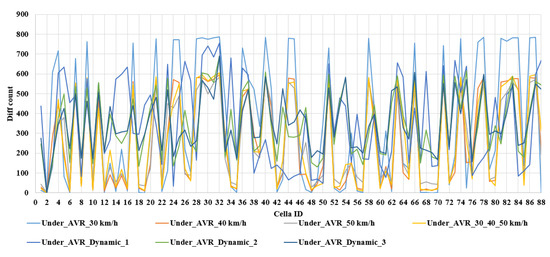

The dynamic tests found the most significant differences in positive and negative directions. The constant case indicates a good condition for all battery cells. Thus, the more significant outliers occurred in the dynamic case but may not necessarily represent a faulty cell. Next, the deviation of different cells from the average voltage was investigated to determine the defective cases. For the first case, the number of times the cells deviated from the average voltage during different measurements was analyzed, see Figure 11.

Figure 11.

Number of deviations from the average voltage.

Figure 11 indicates the number of discrepancies on the vertical axis and the cell ID on the horizontal axis. A relatively large number of cells deviate from the mean, and some deviate in 90% of the measurements. However, in this analysis, deviations of smaller orders of magnitude of mV (‘millivolt’) are also counted. Therefore, in the following, the authors have examined the difference between the average voltage of 12 mV (1% of the measurement range), 60 mV (5% of the measurement range), and 120 mV (10% of the measurement range), i.e., how many times the cells deviate during the different tests; see Figure 12.

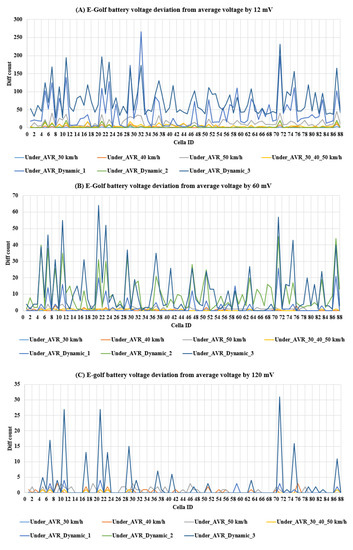

Figure 12.

Number of deviations from the average voltage of 12 mV/60 mV/120 mV.

The deviation from 12 mV in part (a), from 60 mV in part (b), and from 120 mV in part (c) have been analyzed (see Figure 12). It can be seen that as the deviation limit is increased, the number of deviations from the average voltage is continuously reduced. When analyzing 60 mV, it can be seen that there is almost no deviation at constant loads. The best range for analyzing very critical/large deviations is 120 mV (measurement range 10%), which may also indicate a possible battery cell error. Even then, there is a probability that a large transient load will cause a significant cell voltage drop, which is strongly influenced by the reading timing. However, the readout sequence always started with cell No. 1 and ended with cell ID No. 88, and an additional twelve data (temperature, current, voltage, etc.) have been read. They would increase the possibility of a significant mismatch region forming in the first or last part of the stack. Therefore, the different measurements were weighted and averaged to select the faulty battery cells and compensate for possible erroneous cases. For weighting and averaging, the results from the 0 mV measurement were aggregated first; see Equation (1).

In Equation (1), X1…X2…Xn, represents cells with different IDs. In 0 means the deviation from the average voltage, C-constant is the load, and the number after it is the speed. SC indicates a stepped constant, and D means a dynamic test. Based on Equation (1), all cells with the same index were summed, but the constant and dynamic cases were weighted separately. Constant cases were weighted 1/3 and dynamic cases 2/3. The procedure was quite similar for 12 mV, 60 mV, and 120 mV cases; see Equations (2)–(4).

From the formulae, it can be observed that the below-average tests were recalculated in all three cases. It is based on 12—the 12 mV deviation, 60—the 60 mV deviation, and 120—the 120 mV deviation. So, in all cases, the dynamic loads were given more weight and the constant cases less. The next step was aggregating the results; see Equation (5).

In the aggregation, care was taken to ensure that cases tested for higher voltage deviation were given a higher weighting factor. Thus, a deviation of 120 mV is more critical than a deviation of 0 mV. Although the approach provides lower weight, it also considers cases where the cell voltage is consistently below the given limit. So, if a cell continuously deviates from the 60 mV limit, it will already receive a ‘solid’ error signal. Figure 13 summarizes the error factor obtained from the calculation.

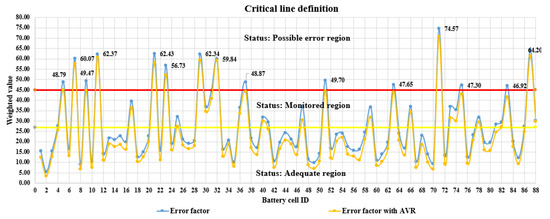

Figure 13.

Aggregate error factor assigned to the cell ID.

Figure 13 depicts the results without averaging in blue and those with averaging in yellow. The data were averaged as shown in Figure 10 (see data avr 3). Error factor cut-offs were determined by 5% and 3% of the data set. The cell IDs which were detected with an average voltage greater than 5% based on the aggregate measurement results were included in the possible error category (results above the red line). The cells flagged for further monitoring were more than 3% but less than 5% below the average voltage in the overall results (the values between the red and yellow lines). In the adequate region, less than 3% were below average voltage (values below the yellow line). In all cases, the avr data yielded a smaller error value, which could be due to averaging. (The impact of this will be further analyzed later.)

In the next section (Section 3.3), fewer cells are sampled over several measurements at higher frequencies during validation. Finally, the discussion section (Section 4) presents a comparison of the results.

3.3. Validation Process

A modified procedure for validation has been defined. The 88 battery cells, the pack voltage, and the load current were found to be sufficient. The resulting query block was divided into eight smaller units; see Table 1.

Table 1.

Query order divided into cycles (the values mean the IDs of the battery packs).

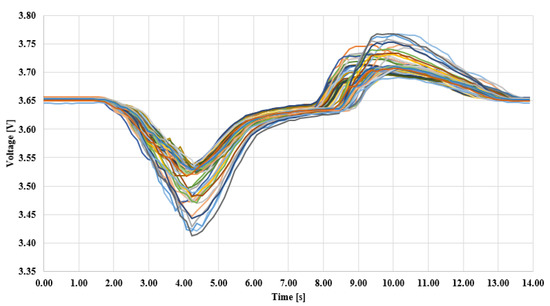

In Table 1, the numbers in columns indicate the order of the cycle, which data were retrieved during the tests. The numbers are the cell IDs, and the total voltage with load current is retrieved in each cycle. Considering the acceleration capability of the car, the following series is defined for one lap: after the measurement is started, the vehicle remains stationary for 2 s, then accelerates to 50 km/h at the maximum acceleration value available when starting, from there it performs intensive, regenerative braking, followed by a 2-s stop. The time available to complete each measurement is 14 s, with a 30-s rest period between measurements to allow the cells to regenerate. The short measurement cycles are critical to avoid significant changes in the pack voltage, which can lead to the misidentification of a cell. The superimposition of voltage profile results is shown in Figure 14.

Figure 14.

The voltage of the e-Golf system during the test cycles (the different color lines indicate the 88 battery cells).

Figure 14 illustrates that the peak load occurred around 4–5 s because—at this point—a steeply decreasing phase in the voltage values can be observed. During the test 14 s, ninety data were sampled from each cell. The evaluation process was similar to previous ones. Figure 15 shows the definition of the critical line.

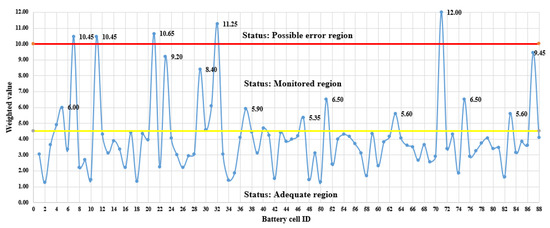

Figure 15.

Aggregated error factor assigned to the cell identifier in the cyclical measurement.

In Figure 15, the error factor cut-offs are set at 10% and 5% of the data set. The possible error category was assigned to the cell IDs, which were detected with an average voltage higher than 10% based on the aggregate measurement results (results above the red line). Cells flagged for further monitoring were more than 5% but less than 10% below the average voltage based on the summary results (the values between the red and yellow lines). In the adequate region, they were below the mean voltage by less than 5% of the time (values below the yellow line). Based on the outcomes, it can be stated that five different cells caused real outliers. The evaluation of the results and comparison with the previous ones will be presented in the discussion section (Section 4).

4. Discussion

The tests were performed in three different scenarios: constant, stepped constant, and dynamic. During the initial constant tests, the car was accelerated to 30 km/h, 40 km/h, and 50 km/h, respectively, and kept this speed for 900 s to collect data. A pretty bad cell condition would have been detected already in this case. Still, during these tests, the aim was to set up data collection and saving. As expected, slight variations were observed between battery cells. The step was held at 30 km/h, 40 km/h, and 50 km/h during constant load, with each case sampled for 300 s.

Thus, there were some transient conditions already during the measurements. During the evaluation, it was found that 1.5 s data saving was insufficient and more efficient to use 1.2 s data saving. The last step was the dynamic load measurements, which lasted 900 s, but included several accelerations and braking (also regenerative). From a battery diagnostic point of view, these are the most helpful measurement and related analyses because the more significant load peaks caused several transients that can be investigated. Based on the results, it was discovered that serial data readout could return several errors to the system. The major problem was that voltage values sorted under the same time stamp showed a significant deviation from each other. This is due to the high probability of a load arriving during each cell’s serial readout during a cycle in the dynamic case. Thus, the cell values read out before they give a higher voltage value than those sampled after the load. A solution to this problem could be the windowing (clustering) method, whereby the three adjacent values of the incoming are filtered through the entire measurement data set. The advantage of this method is that the number of hits is significantly reduced; the disadvantage is that the number of possible false/faulty cases is reduced due to the specificity of the method. The other method is to vary the data readout, whereby fewer cell voltage values are tested but sampled more than once. In this way, cells that are considered to be faulty are targeted. The disadvantage of this method is that new measurements have to be taken. Both methodologies can be used to solve the problem, but the most effective way to solve the problem will likely be to unify the two.

Both methods were applied in the tests. The results from three constants, one stepped constant, and three dynamic measurements were applied as a baseline test. Averaging was performed on these tests; the multiple-cycle measurements were presented as a validation test. Table 2 summarizes the critical values defined during each measurement.

Table 2.

Critical cells by ID in the different tests (based on Figure 13).

Table 2 shows the results of the three different evaluations. The first column shows the cell ID, the second column shows the results without averaging, and the third column shows the AVR values (for the differences between the two solutions, see Figure 10) according to Figure 13. The fourth column shows the results of the validation measurements. It is important to note that only critical cases (ID) have been included in Table 2. Red highlighting indicates cells with failures in that aspect of the assessment, and yellow indicates those that require further monitoring. From the comparison, it can be seen that several failures in the AVR results were also moved to the adequate category. It could be due to data loss, but it could also be due to a possible incorrect classified case. Based on the validation test, both cases could be present, e.g., the cell with the IDs 7, 32, and 71 did not appear to be faulty after averaging, but based on the validation, it clearly seems to be faulty. The cells with IDs 5, 40, and 63 appear to be defective based on the first measurement, but the validation test and averaging suggested only monitoring.

The solution could be applying a combination of the three methods, weighting and artificial intelligence, to select the cells with errors. The proposed method is based on these three dynamic tests and averaging, followed by a short validation measurement. Finally, a combination of the three solutions is used to evaluate the results.

The current post-processing will be transferred to a microcontroller in future work, where, after a longer dynamic measurement, the device will autonomously select the cells (IDs) to be sampled at higher frequencies. Initially, critical and monitoring cells are also included in the range of cells tested at higher frequencies, and further narrowed down as selected above.

5. Conclusions

A data collection, processing, and evaluation strategy for an electric vehicle battery system was developed. The advantage of the developed algorithm is that the method can be adapted to any electric or hybrid vehicle battery. Based on the results, it is possible to assess whether any of the cells in the battery system are faulty or weaker. Furthermore, its place becomes localizable. Several tests were executed with constant, stepped constant and dynamic measurements to check and evaluate the method. On this basis, it was concluded that for battery diagnostic purposes, dynamic loads could be applied; the higher load peaks create many transients that can be tested. According to the results, it can be observed that serial data readout can introduce errors in the system.

The major problem is that voltage values sorted under the same timestamp showed high deviation from each other. It is due to the high probability of a load arriving during the serial readout of each cell during a cycle in the dynamic case. Thus, in turn, the cell values read out first give a higher voltage value than those sampled after the load. The solution to this problem is to vary the data readout, whereby fewer cell voltage values are sampled but sampled more. It allows targeted testing of cells that are taken into consideration to be faulty. The disadvantage of this method is that more measurements have to be performed. The authors have applied both the raw measurement data and solutions in this article. The results of the different approaches were evaluated in aggregate. The results showed that all three solutions marked the same cells as weaker. However, several good cells were placed in the possible error category without averaging.

In contrast, with the averaging (AVR) method, several cells that appeared to be faulty were put into the adequate category. For multi-cycle analysis, however, the short measurement range is the bottleneck. Therefore, using all three methods together is recommended for proper defective cell detection.

Author Contributions

Conceptualization, S.K.S. and A.A.; methodology, S.K.S. and G.S.; software, S.K.S., G.S. and A.A.; validation, S.K.S.; formal analysis, S.K.S.; investigation, S.K.S., I.L. and S.F.; resources, I.L.; data curation, S.K.S., G.S. and A.A.; writing—original draft preparation, S.K.S. and S.F.; writing—review and editing, S.K.S. and S.F.; visualization, S.K.S., G.S., A.A., S.F.; supervision, I.L. and S.F.; project administration, S.K.S.; funding acquisition, S.K.S. and I.L. All authors have read and agreed to the published version of the manuscript.

Funding

The research was supported by the European Union within the framework of the National Laboratory for Autonomous Systems (RRF-2.3.1-21-2022-00002).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| BMS | Battery Management System |

| CAN | Controller Area Network |

| CAN BUS | Controller Area Network BUS |

| DCTS | Data Cleaning Transformation and Shorting |

| ECU | Electronic Control Unit |

| EPA | US Environmental Protection Agency |

| ETL | Extract, Transform, Load |

| GPS | Global Positioning System |

| ID | Identification number |

| NEDC | New European Driving Cycle |

| OBD | On-Board Diagnostics port |

| SOC | State of Charge |

| SOH | State of Health |

| WLTP | World harmonized Light vehicle Test Procedure |

References

- Kihm, A.; Trommer, S. The new car market for electric vehicles and the potential for fuel substitution. Energy Policy 2014, 73, 147–157. [Google Scholar] [CrossRef]

- Goetzel, N.; Hasanuzzaman, M. An empirical analysis of electric vehicle cost trends: A case study in Germany. Res. Transp. Bus. Manag. 2022, 43, 100825. [Google Scholar] [CrossRef]

- Ma, S.C.; Xu, J.H.; Fan, Y. Characteristics and key trends of global electric vehicle technology development: A multi-method patent analysis. J. Clean. Prod. 2022, 338, 130502. [Google Scholar] [CrossRef]

- Beltrami, D.; Iora, P.; Tribioli, L.; Uberti, S. Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends. Energies 2021, 14, 5565. [Google Scholar] [CrossRef]

- International Energy Agency. Global EV Outlook 2022 Securing Supplies for an Electric Future. 2022. Available online: www.iea.org/t&c/ (accessed on 15 November 2022).

- Sanguesa, J.; Torres-Sanz, V.; Garrido, P.; Martinez, F.; Marquez-Barja, J. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. Etransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Przekota, G. Do High Fuel Prices Pose an Obstacle to Economic Growth? A Study for Poland. Energies 2022, 15, 6606. [Google Scholar] [CrossRef]

- Lipu, M.H.; Hannan, M.; Karim, T.F.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Miah, S.; Mahlia, T.I. Intelligent algorithms and control strategies for battery management system in electric vehicles: Progress, challenges and future outlook. J. Clean. Prod. 2021, 292, 126044. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Hossain Lipu, M.S.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Shah, F.A.; Sheikh, S.S.; Mir, U.I.; Athar, S.O. Battery Health Monitoring for Commercialized Electric Vehicle Batteries: Lithium-Ion. In Proceedings of the 2019 International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), Istanbul, Turkey, 26–27 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Santhanagopalan, S.; Zhang, Q.; Kumaresan, K.; White, R.E. Parameter Estimation and Life Modeling of Lithium-Ion Cells. J. Electrochem. Soc. 2008, 155, A345. [Google Scholar] [CrossRef]

- Shekhovtsov, A.; Więckowski, J.; Kizielewicz, B.; Sałabun, W. Towards Reliable Decision-Making in the Green Urban Transport Domain. Facta Univ. Ser. Mech. Eng. 2022, 20, 381–398. [Google Scholar] [CrossRef]

- Cipek, M.; Pavković, D.; Krznar, M.; Kljaić, Z.; Mlinarić, T.J. Comparative analysis of conventional diesel-electric and hypothetical battery-electric heavy haul locomotive operation in terms of fuel savings and emissions reduction potentials. Energy 2021, 232, 121097. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Sari, R.L.; Tripathi, S. Life cycle CO₂ footprint reduction comparison of hybrid and electric buses for bus transit networks. Appl. Energy 2022, 308, 118354. [Google Scholar] [CrossRef]

- Elliott, M.; Swan, L.G.; Dubarry, M.; Baure, G. Degradation of electric vehicle lithium-ion batteries in electricity grid services. J. Energy Storage 2020, 32, 101873. [Google Scholar] [CrossRef]

- Vezzini, A. 15—Lithium-Ion Battery Management. In Lithium-Ion Batteries; Pistoia, G., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 345–360. Available online: https://www.sciencedirect.com/science/article/pii/B9780444595133000157 (accessed on 15 November 2022).

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Pattipati, B.; Sankavaram, C.; Pattipati, K. System Identification and Estimation Framework for Pivotal Automotive Battery Management System Characteristics. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2011, 41, 869–884. [Google Scholar] [CrossRef]

- Pillai, P.; Sundaresan, S.; Kumar, P.; Pattipati, K.R.; Balasingam, B. Open-Circuit Voltage Models for Battery Management Systems: A Review. Energies 2022, 15, 6803. [Google Scholar] [CrossRef]

- Komsiyska, L.; Buchberger, T.; Diehl, S.; Ehrensberger, M.; Hanzl, C.; Hartmann, C.; Hölzle, M.; Kleiner, J.; Lewerenz, M.; Liebhart, B.; et al. Critical Review of Intelligent Battery Systems: Challenges, Implementation, and Potential for Electric Vehicles. Energies 2021, 14, 5989. [Google Scholar] [CrossRef]

- Li, Y.; Guo, J.; Pedersen, K.; Gurevich, L.; Stroe, D.-I. Recent Health Diagnosis Methods for Lithium-Ion Batteries. Batteries 2022, 8, 72. [Google Scholar] [CrossRef]

- Chen, W.; Liang, J.; Yang, Z.; Li, G. A Review of Lithium-Ion Battery for Electric Vehicle Applications and Beyond. Energy Procedia 2019, 158, 4363–4368. [Google Scholar] [CrossRef]

- Földesi, P.; Kóczy, L.T.; Szauter, F.; Csikor, D.; Szürke, S.K. Hierarchical Diagnostics and Risk Assessment for Energy Supply in Military Vehicles. Energies 2022, 15, 4791. [Google Scholar] [CrossRef]

- Wang, Z.; Hong, J.; Liu, P.; Zhang, L. Voltage fault diagnosis and prognosis of battery systems based on entropy and Z -score for electric vehicles. Appl. Energy 2017, 196, 289–302. [Google Scholar] [CrossRef]

- Tran, M.-K.; Fowler, M. A Review of Lithium-Ion Battery Fault Diagnostic Algorithms: Current Progress and Future Challenges. Algorithms 2020, 13, 62. [Google Scholar] [CrossRef]

- Fotouhi, A.; Auger, D.J.; Propp, K.; Longo, S.; Wild, M. A review on electric vehicle battery modelling: From Lithium-ion toward Lithium–Sulphur. Renew. Sustain. Energy Rev. 2016, 56, 1008–1021. [Google Scholar] [CrossRef]

- Wu, Y.; Saxena, S.; Xing, Y.; Wang, Y.; Li, C.; Yung, W.K.C.; Pecht, M. Analysis of Manufacturing-Induced Defects and Structural Deformations in Lithium-Ion Batteries Using Computed Tomography. Energies 2018, 11, 925. [Google Scholar] [CrossRef]

- Szalai, S.; Szürke, S.K.; Harangozó, D.; Fischer, S. Investigation of deformations of a lithium polymer cell using the Digital Image Correlation Method (DICM). Rep. Mech. Eng. 2022, 3, 206–224. [Google Scholar] [CrossRef]

- Rieger, B.; Schlueter, S.; Erhard, S.; Schmalz, J.; Reinhart, G.; Jossen, A. Multi-scale investigation of thickness changes in a commercial pouch type lithium-ion battery. J. Energy Storage 2016, 6, 213–221. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z. A novel fault diagnosis method for lithium-Ion battery packs of electric vehicles. Measurement 2018, 116, 402–411. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Z.; Li, D.; Liu, P.; Wang, Z. Battery Fault Prognosis for Electric Vehicles Based on AOM-ARIMA-LSTM in Real Time. In Proceedings of the 2022 5th International Conference on Energy, Electrical and Power Engineering (CEEPE), Chongqing, China, 22–24 April 2022; pp. 476–483. [Google Scholar] [CrossRef]

- Lin, T.; Chen, Z.; Zhou, S. Voltage-correlation based multi-fault diagnosis of lithium-ion battery packs considering inconsistency. J. Clean. Prod. 2022, 336, 130358. [Google Scholar] [CrossRef]

- Fang, W.; Chen, H.; Zhou, F. Fault diagnosis for cell voltage inconsistency of a battery pack in electric vehicles based on real-world driving data. Comput. Electr. Eng. 2022, 102, 108095. [Google Scholar] [CrossRef]

- Xue, Q.; Li, G.; Zhang, Y.; Shen, S.; Chen, Z.; Liu, Y. Fault diagnosis and abnormality detection of lithium-ion battery packs based on statistical distribution. J. Power Sources 2020, 482, 228964. [Google Scholar] [CrossRef]

- Fang, W.; Jiang, Y.; Lv, H. Implementation of Power Battery Voltage Fault Diagnosis System Based on Improved Shannon Entropy Algorithm. In Proceedings of the 2021 IEEE International Conference on Networking, Sensing and Control (ICNSC), Xiamen, China, 3–5 December 2021; Volume 1, pp. 1–6. [Google Scholar] [CrossRef]

- Freedom, C.A.R. Battery Test Manual for Power-Assist Hybrid Electric Vehicles; INEEL: Cuernavaca, Mexico, 2003. [Google Scholar]

- Castillo, E.C. Standards for electric vehicle batteries and associated testing procedures. In Advances in Battery Technologies for Electric Vehicles; Woodhead: Sawston, UK, 2015; pp. 469–494. [Google Scholar] [CrossRef]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van Den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, F.; Hao, H.; Chen, K.; Liu, Z. From NEDC to WLTP: Effect on the Energy Consumption, NEV Credits, and Subsidies Policies of PHEV in the Chinese Market. Sustainability 2020, 12, 5747. [Google Scholar] [CrossRef]

- Barré, A.; Suard, F.; Gérard, M.; Montaru, M.; Riu, D. Statistical analysis for understanding and predicting battery degradations in real-life electric vehicle use. J. Power Sources 2014, 245, 846–856. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, P.; Wang, Z.; Hong, J. Electric Vehicle Battery Fault Diagnosis Based on Statistical Method. Energy Procedia 2017, 105, 2366–2371. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, P.; Wang, Z.; Zhang, L.; Hong, J. Fault and defect diagnosis of battery for electric vehicles based on big data analysis methods. Appl. Energy 2017, 207, 354–362. [Google Scholar] [CrossRef]

- Merkle, L.; Pöthig, M.; Schmid, F. Estimate e-Golf Battery State Using Diagnostic Data and a Digital Twin. Batteries 2021, 7, 15. Available online: https://www.researchgate.net/publication/348415206_Estimate_e-Golf_Battery_State_Using_Diagnostic_Data_and_a_Digital_Twin (accessed on 15 November 2022). [CrossRef]

- Llerandi, J.D.L.P.; de Mingo, C.S.; Ibáñez, J.C. Continuous Battery Health Diagnosis by On-Line Internal Resistance Measuring. Energies 2019, 12, 2836. [Google Scholar] [CrossRef]

- Cao, H.; Zöldy, M. An Investigation of Autonomous Vehicle Roundabout Situation. Period. Polytech. Transp. Eng. 2019, 48, 236–241. [Google Scholar] [CrossRef]

- Gangel, K.; Hamar, Z.; Háry, A.; Horváth, Á.; Jandó, G.; Könyves, B.; Panker, D.; Pintér, K.; Pataki, M.; Szalai, M.; et al. Modelling the ZalaZONE Proving Ground: A benchmark of State-of-the-art Automotive Simulators PreScan, IPG CarMaker, and VTD Vires. Acta Tech. Jaurinensis 2021, 14, 488–507. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).