Structural Analysis and Application of Non-Standard Components Based on Genetic Algorithm

Abstract

:1. Introduction

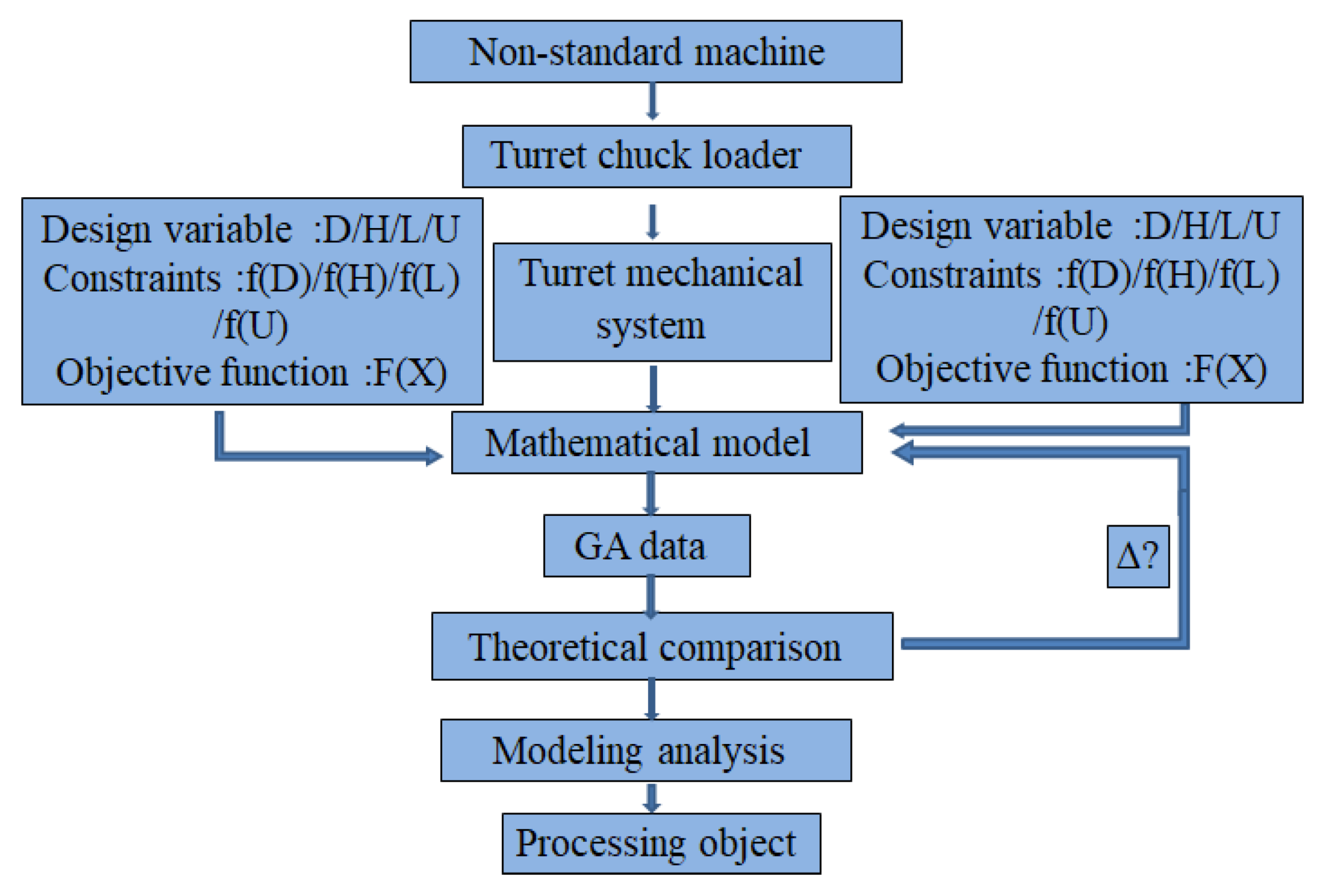

2. Research Framework and Overall Structure Design

2.1. Overall Research Framework

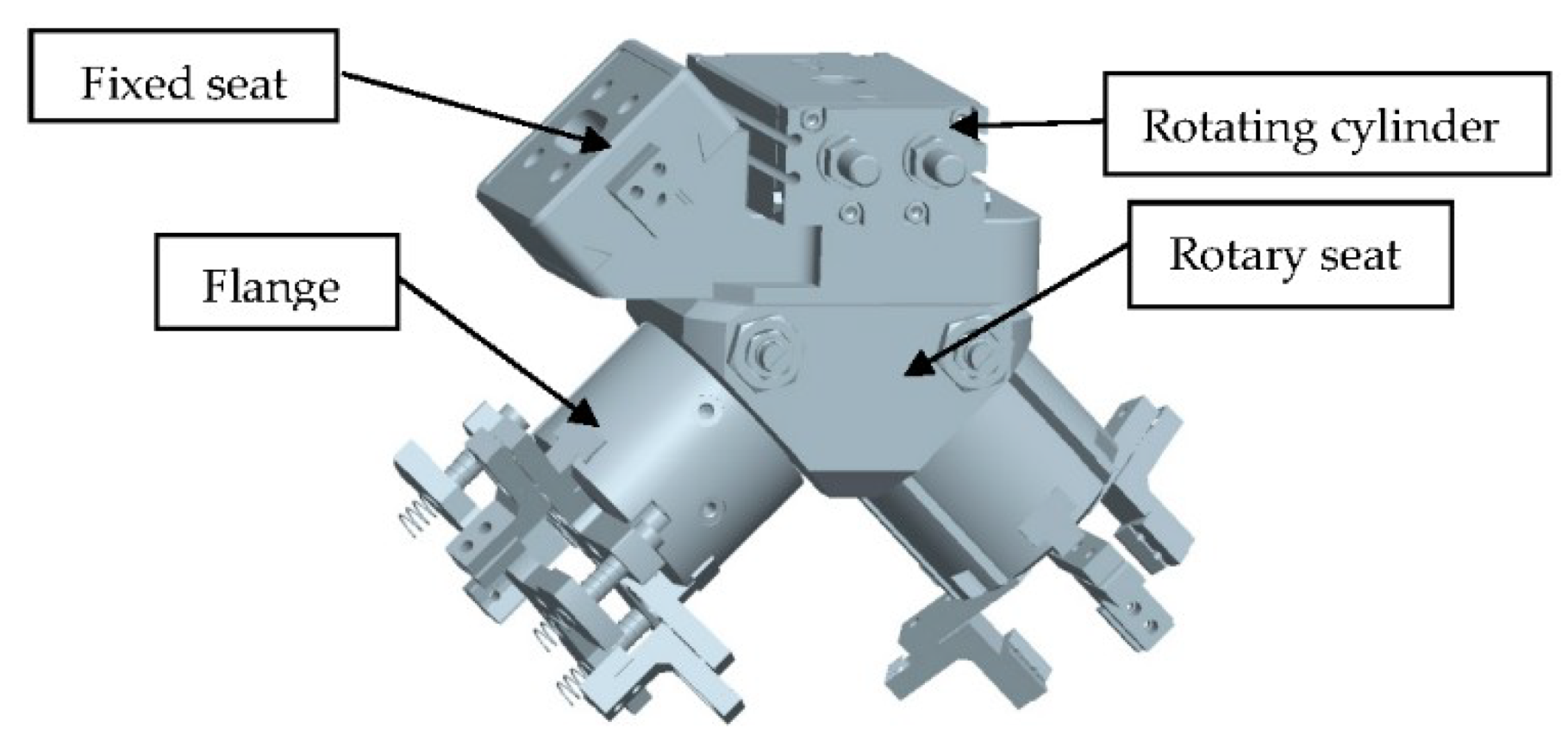

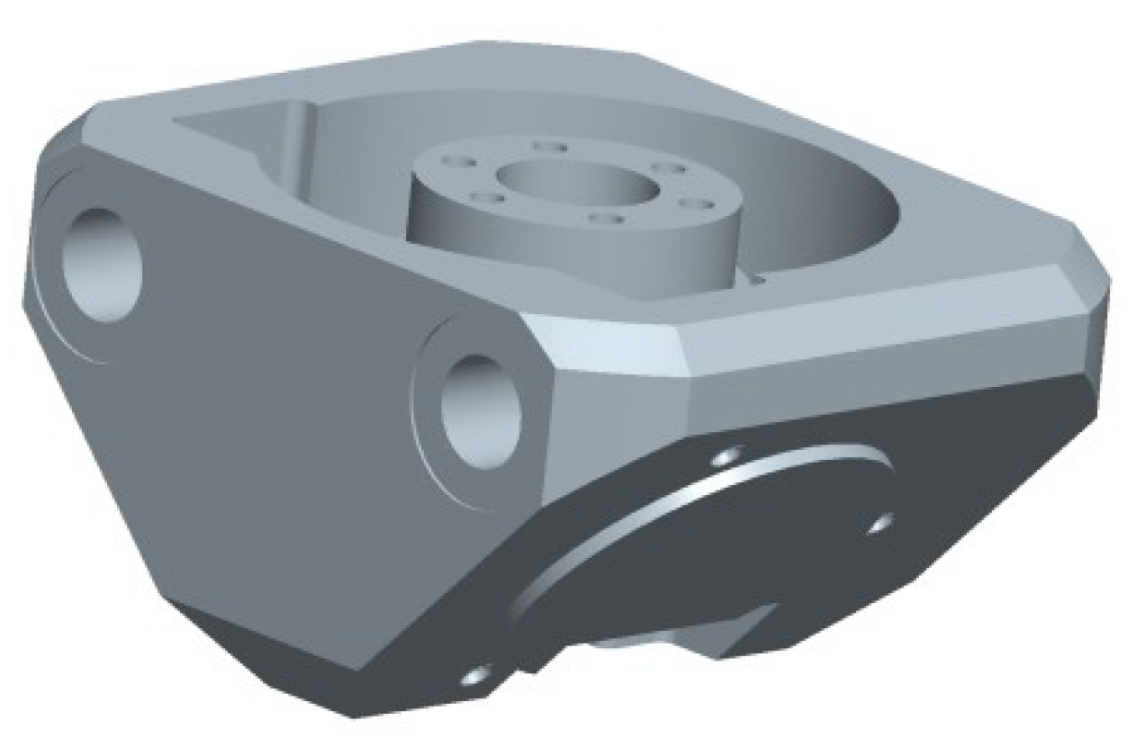

2.2. Overall Structure Design of Non-Standard Components

3. Theoretical Analysis

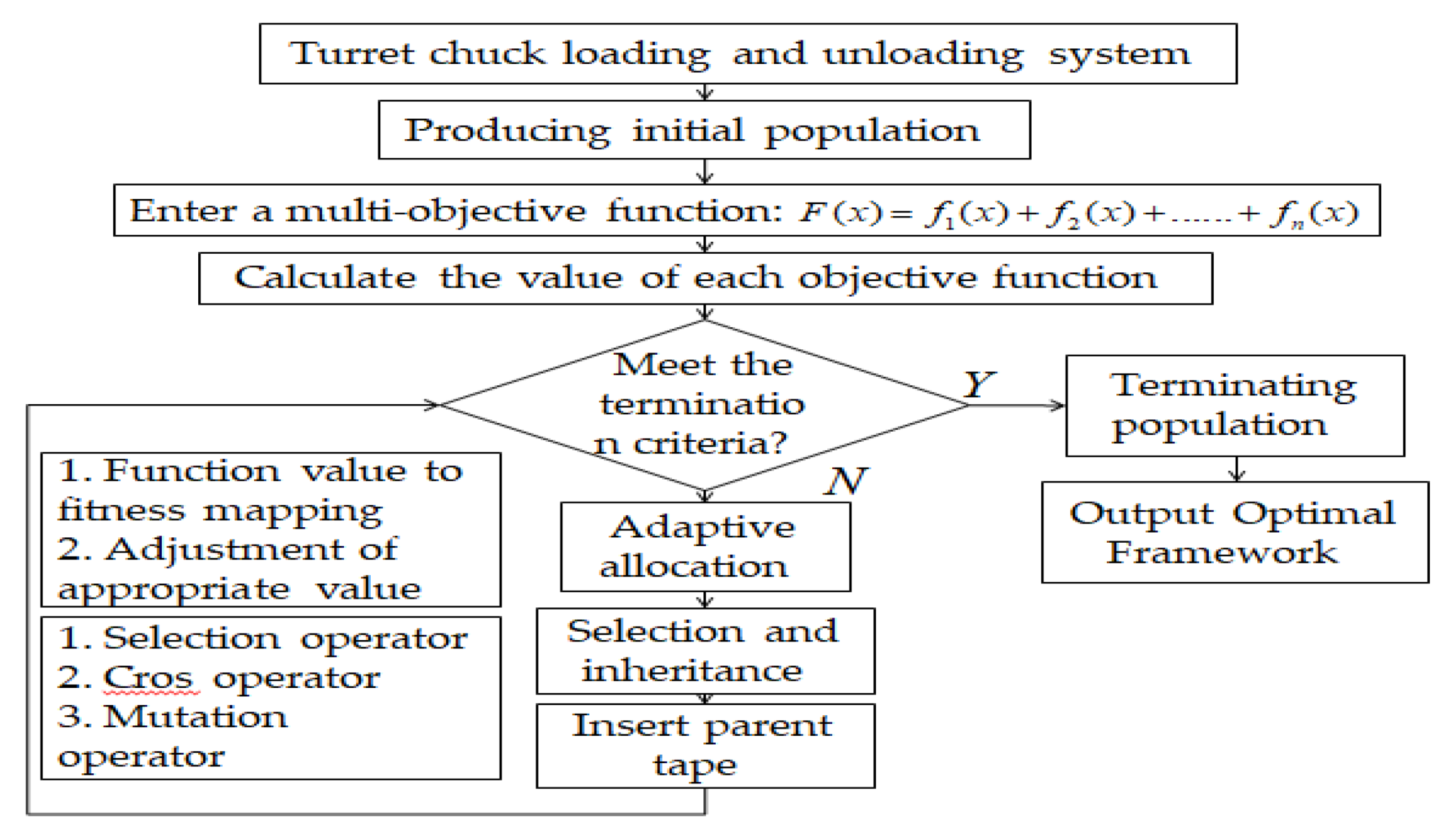

3.1. GA Theory

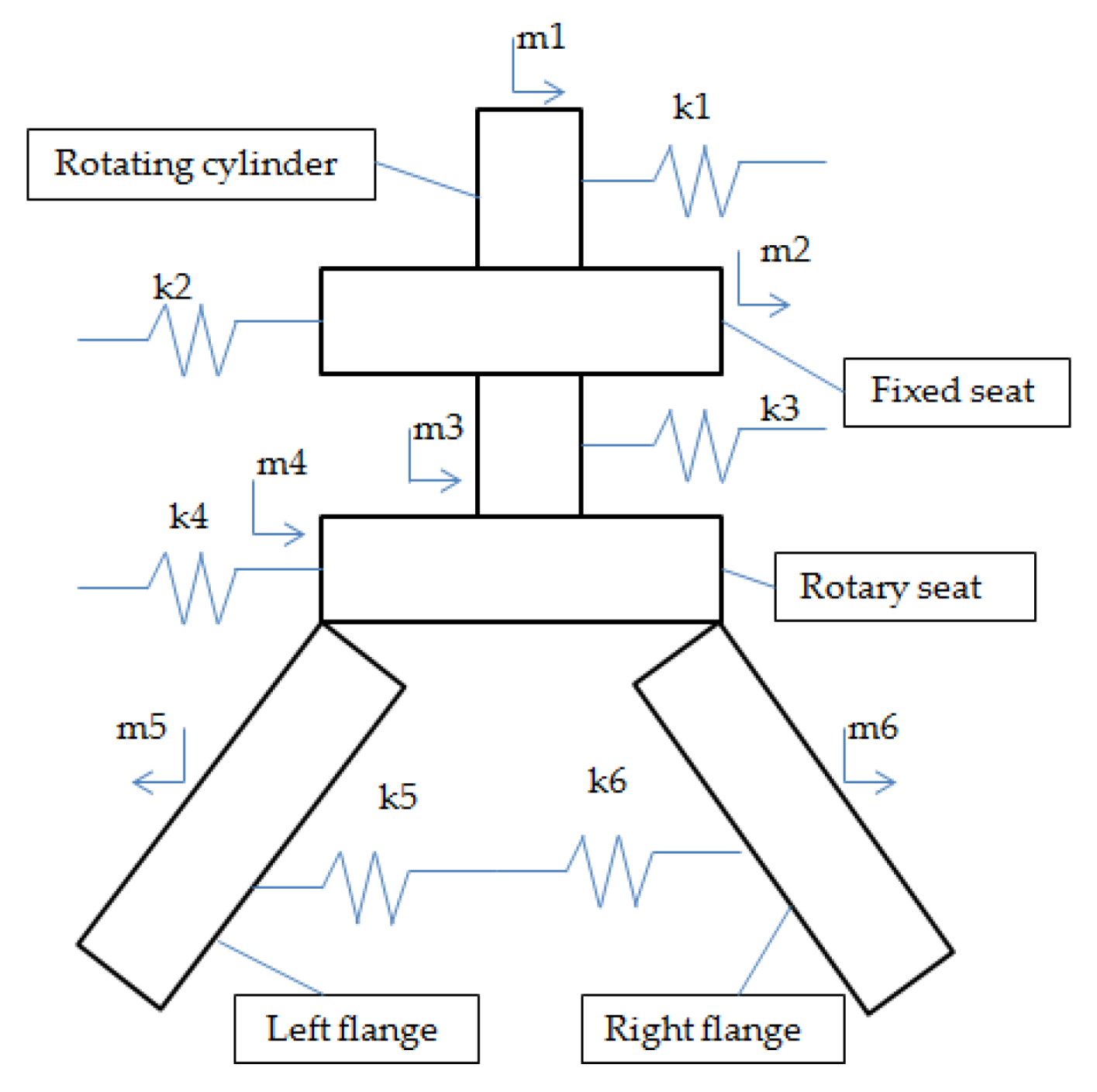

3.2. Establishment of Modal Theory Model

4. Analysis of Optimal Mathematical Model

4.1. Establishment of Non-Standard Mechanical Mathematical Model

4.1.1. Multi-Objective Mathematical Model of Structural System Optimization

4.1.2. Optimization Multi-Objective Function

4.1.3. Constraints

4.2. Algorithm Analysis Result

5. Simulation and Experimental Analysis

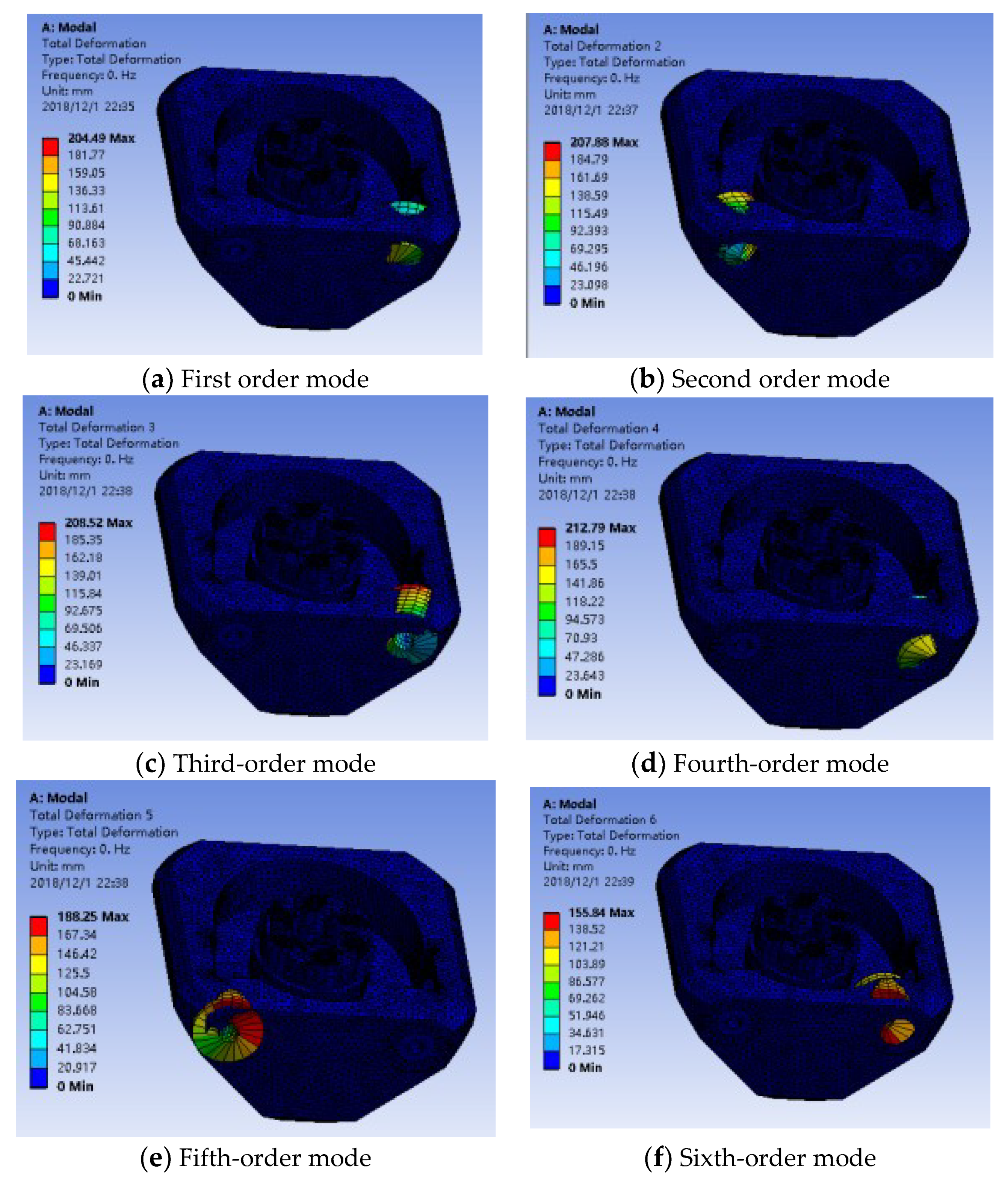

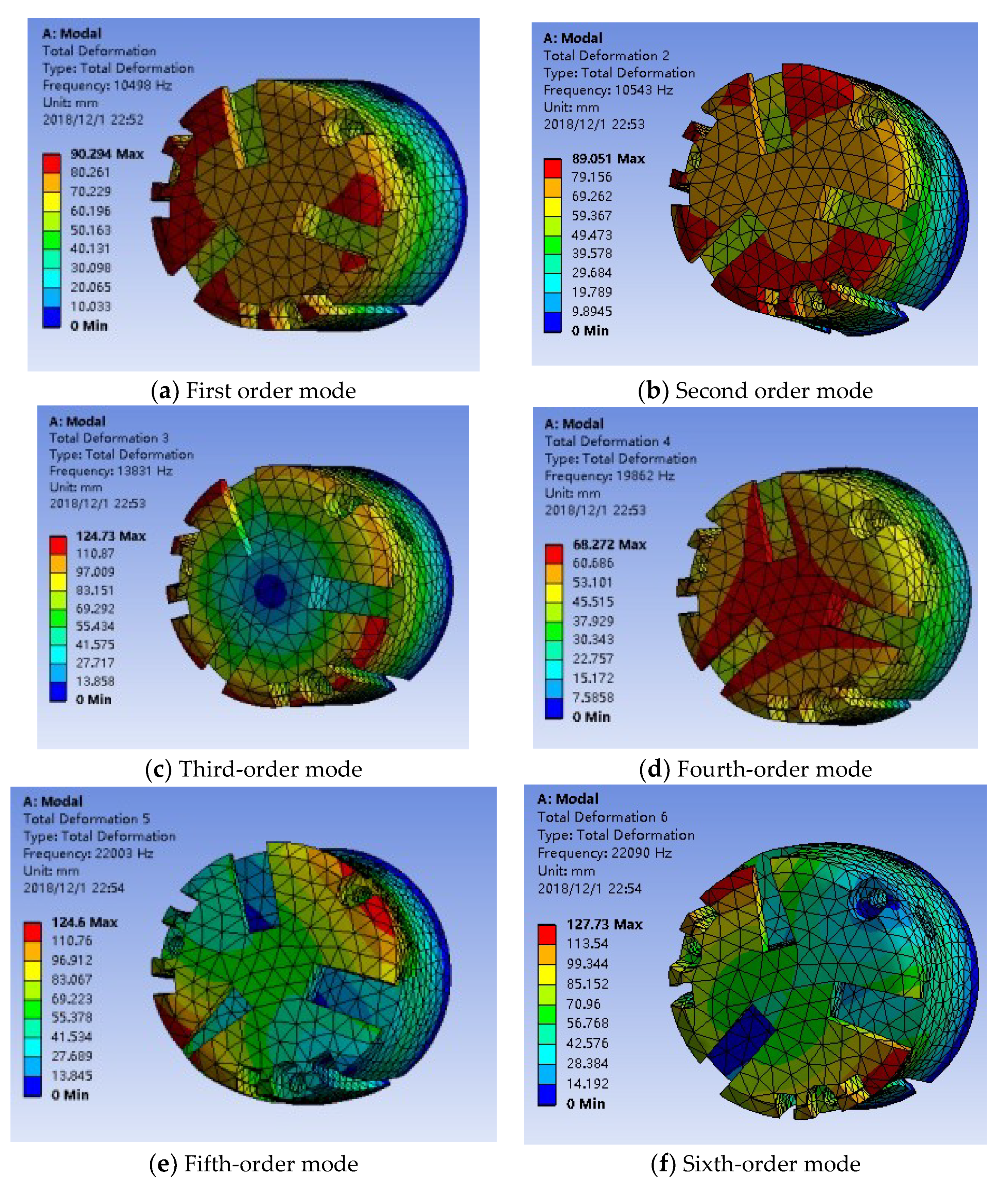

5.1. Simulation Analysis

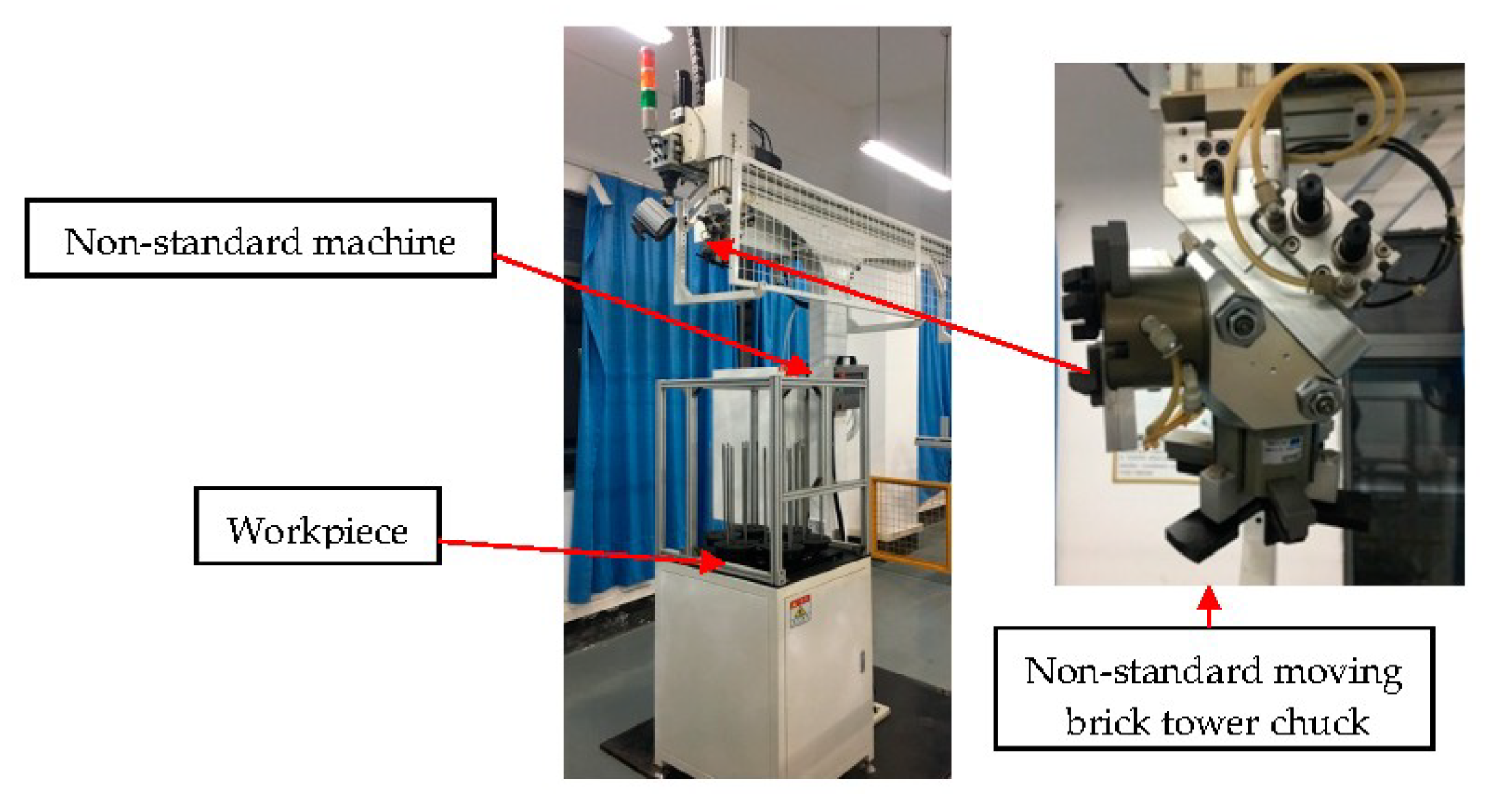

5.2. Physical Verification

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Lu, C.; Zhang, H.; Fang, Z.F. Workshop layout optimization based on differential cellular multi-objective genetic algorithm. Comput. Integr. Manuf. 2013, 19, 727–734. [Google Scholar]

- Li, L.; Gu, W. Mechanical Reliability Design and Analysis; National Defence Industry Press: Beijing, China, 1998. [Google Scholar]

- Wirsching, T.Y.T.; Martin, W.S. Advanced fatigue reliability analysis. Int. J. Fatigue 1991, 13, 389–394. [Google Scholar] [CrossRef]

- Sinha, A.; Deb, K. Towards understanding evolutionary bilevel multi-objective optimization algorithm. In IFAC Workshop on Control Applications of Optimization; (IFAC-2009); IFAC: Prague, Czech Republic, 2009; Volume 42, pp. 338–343. [Google Scholar]

- Li, G.; Long, X.; Zhou, M. A new design method based on feature reusing of the non-standard cam structure for automotive panels stamping dies. J. Intell. Manuf. 2017, 30, 2085–2100. [Google Scholar] [CrossRef]

- Jinghua, X.U. Design method of non-standard structure for MEMS based on multi-granularity macro-modeling. J. Mech. Eng. 2011, 47, 97. [Google Scholar]

- Pedrero, J.I.; Sánchez, M.B.; Pleguezuelos, M. Load sharing model for non-standard involute spur gears. In New Trends in Mechanism and Machine Science; Springer: Amstrdam, The Netherlands, 2013. [Google Scholar]

- Zak, P.; Dynybyl, V. Design and testing of gears with non-standard profile. In Proceedings of the ASME 2007 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers, Seattle, DC, USA, 11–15 November 2007; pp. 105–112. [Google Scholar]

- Hedlund, J.; Lehtovaara, A. A parameterized numerical method for generating discrete helical gear tooth surface allowing non-standard geometry. Proc. Inst. Mech. Eng. Part C 2008, 222, 1033–1038. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, X.; Chen, W.; Xu, F.; Cao, B. Optimal sliding mode control for an active suspension system based on a genetic algorithm. Algorithms 2018, 11, 205. [Google Scholar] [CrossRef]

- Knust, J.; Podszus, F.; Stonis, M. Preform optimization for hot forging processes using genetic algorithms. Int. J. Adv. Manuf. Technol. 2017, 89, 1623–1634. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G. Optimization of texture shape based on genetic algorithmunder unidirectional sliding. Tribol. Int. 2017, 115, 222–232. [Google Scholar] [CrossRef]

- Huang, H.Z.; Qu, J.; Zuo, M.J. Genetic-algorithm-based optimal apportionment of reliability and redundancy under multiple objectives. Iie Trans. 2009, 41, 287–298. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Ribeiro, M.L. Stacking sequence optimization in composite tubes under internal pressure based on genetic algorithm accounting for progressive damage. Compos. Struct. 2017, 178, 20–26. [Google Scholar] [CrossRef]

- Yours, A.; Alaa, C. Bechmark study of numerical methods for reliability-based design optimization. Struct. Multidiscip. Optim. 2010, 41, 277–294. [Google Scholar]

- Arkat, J.; Farahani, M.H.; Ahmadizar, F. Multi-objective genetic algorithmfor cell formation problemconsidering cellular layout and operations scheduling. Int. J. Comput. Integr. Manuf. 2012, 25, 625–635. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, A.; Dong, H.; Li, Z. An improved immune genetic algorithm for distribution network reconfiguration. In Proceedings of the 2nd International Conference on Information Management, Innovation Management and Industrial Engineering, Xi’an, China, 26–27 December 2009; pp. 218–223. [Google Scholar]

- Wang, X.; Gao, L.; Zhang, C.; Shao, X. A multi-objective genetic algorithm based on immune and entropy principle for flexible job-shop scheduling problem. Int. J. Adv. Manuf. Technol. 2010, 51, 757–767. [Google Scholar] [CrossRef]

- Wang, X.; Gao, L.; Zhang, C.; Li, X. A multi-objective genetic algorithm for fuzzy flexible job-shop scheduling problem. Int. J. Comput. Appl. Technol. 2012, 45, 115–125. [Google Scholar] [CrossRef]

- Wei, Q.; Zhu, B.; Jing, B.; Liu, H.; Liu, M. Optimization design of loader steering mechanism based on MATLAB. In Proceedings of the IEEE 10th International Conference on Computer-Aided Industrial Design & Conceptual Design, Wenzhou, China, 26–29 November 2009; pp. 751–754. [Google Scholar]

- Liu, J. Simulation of Sliding Mode Control Based on MATLAB; Tsinghua University Press: Beijing, China, 2015; pp. 4–25. [Google Scholar]

- Armentani, E.; Caputo, F.; Esposito, L.; Giannella, V.; Citarella, R. Multibody simulation for the vibration analysis of a turbocharged diesel engine. Appl. Sci. 2018, 8, 1192. [Google Scholar] [CrossRef]

- Chehouri, A.; Younes, R.; Khoder, J.; Perron, J.; Ilinca, A. A selection process for genetic algorithm using clustering analysis. Algorithms 2017, 10, 123. [Google Scholar] [CrossRef]

| Design Variable | Parameter Code | Initial Value/mm | Variation Range/mm |

|---|---|---|---|

| 70 | 65~80 | ||

| 40 | 35~50 | ||

| 25 | 15~35 | ||

| 80 | 65~100 | ||

| 1 | 0.2~5 | ||

| 60 | 50~80 | ||

| 50 | 40~75 | ||

| 20 | 17~35 | ||

| 100 | 80~120 | ||

| 90 | 80~110 |

| Algorithm | Value | Number of Iterations | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| GA | 78.34 | 40.77 | 20.34 | 70.90 | 1.23 | 61.56 | 52.36 | 22.57 | 112.4 | 92.25 | 50 |

| 71.97 | 46.56 | 19.44 | 86.56 | 3.45 | 78.44 | 75.49 | 19.25 | 98.56 | 82.33 | 169 | |

| 73.67 | 35.78 | 27.76 | 99.56 | 2.43 | 79.45 | 69.56 | 26.37 | 82.36 | 90.25 | 241 | |

| 74.56 | 47.45 | 26.94 | 95.56 | 0.56 | 69.22 | 63.58 | 31.07 | 98.4 | 100.5 | 70 | |

| 79.31 | 45.56 | 32.76 | 88.77 | 3.23 | 74.16 | 66.60 | 32.59 | 81.76 | 105.3 | 78 | |

| 77.89 | 44.43 | 32.34 | 76.56 | 4.34 | 71.13 | 71.51 | 33.35 | 119.8 | 109.4 | 91 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Z.; Lai, H.; Hua, Z.; Hua, C. Structural Analysis and Application of Non-Standard Components Based on Genetic Algorithm. Algorithms 2019, 12, 169. https://doi.org/10.3390/a12080169

Lei Z, Lai H, Hua Z, Hua C. Structural Analysis and Application of Non-Standard Components Based on Genetic Algorithm. Algorithms. 2019; 12(8):169. https://doi.org/10.3390/a12080169

Chicago/Turabian StyleLei, Zhao, Hu Lai, Zhang Hua, and Chen Hua. 2019. "Structural Analysis and Application of Non-Standard Components Based on Genetic Algorithm" Algorithms 12, no. 8: 169. https://doi.org/10.3390/a12080169

APA StyleLei, Z., Lai, H., Hua, Z., & Hua, C. (2019). Structural Analysis and Application of Non-Standard Components Based on Genetic Algorithm. Algorithms, 12(8), 169. https://doi.org/10.3390/a12080169