Decommissioning of Offshore Platforms in Adriatic Sea: The Total Removal Option from a Life Cycle Assessment Perspective

Abstract

1. Introduction

2. Materials and Methods

- -

- Definition of the Goal and Scope;

- -

- Life Cycle Inventory;

- -

- Life Cycle Impact Assessment;

- -

- Life Cycle Interpretation.

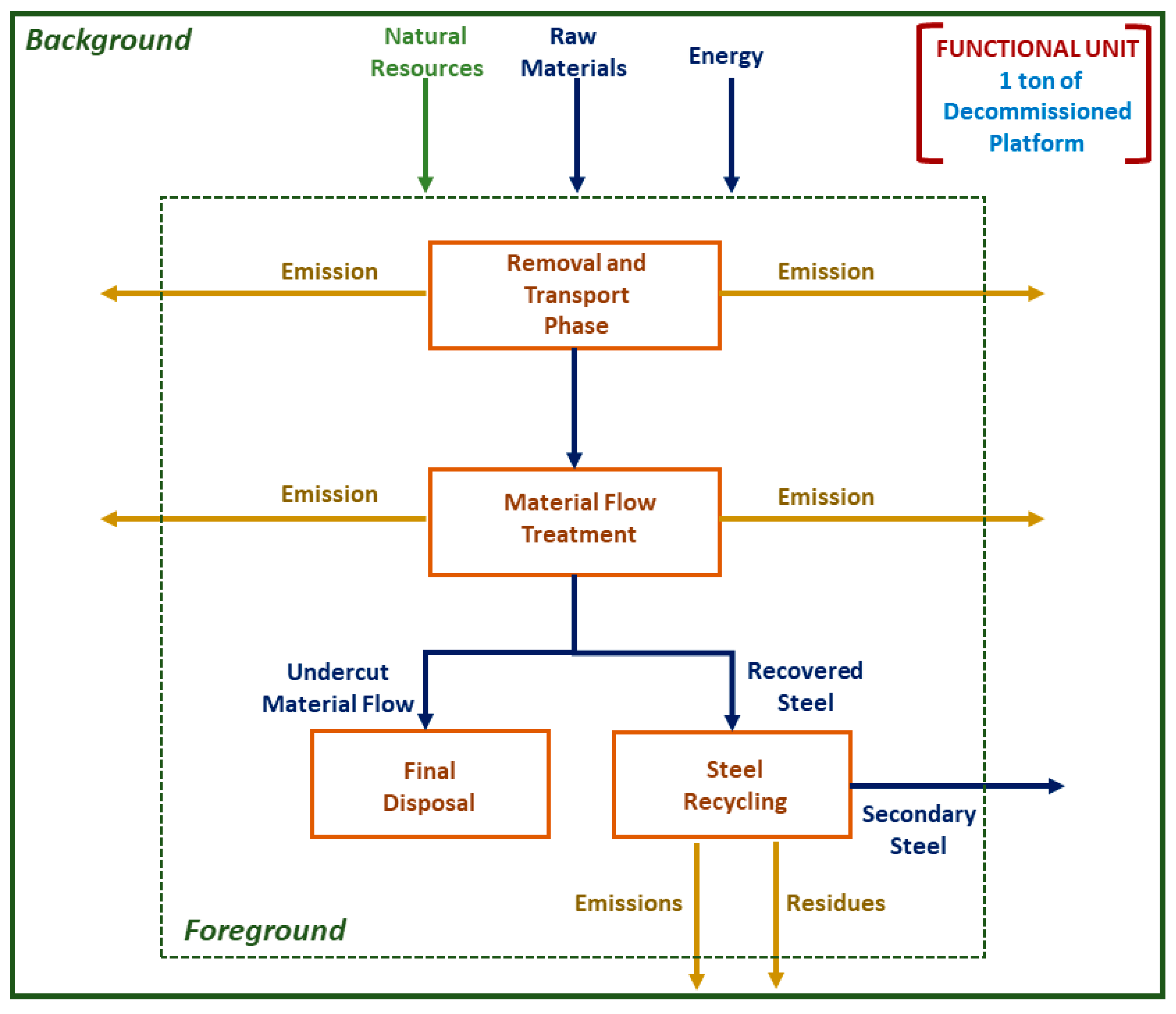

2.1. Definition of Goal and Scope

- -

- The foreground system includes the processes whose choice and mode of management are directly influenced by the decisions based on the LCA study.

- -

- The background system includes all other processes that interact with the foreground system, usually by supplying it with materials and energy or by receiving materials and energy from it.

2.2. Life Cycle Inventory

2.2.1. Primary Steelmaking

2.2.2. Decommissioning Operations

- Pier and landing stage removal;

- Protection jacket removal;

- Cleaning of cutting and anchoring points;

- Lifting bollards positioning;

- Digging a trench of almost 1.5 m depth from the mudline to allow the cutting operations;

- Cutting with a diamond wire machine, divers, and ROV;

- Monotubular lifting and positioning on dumb barge;

- Transporting the dumb barge to shore using the tug boat;

- Ei = total annual emission;

- Fcm,j = type m fuel consumption by a type j engine vessel;

- EFi,m,j = type i pollutant average emission factor for type m fuel consumption by a type j engine vessel, calculated by adopting average utilization and travel conditions.

2.2.3. Steel Recycling

- -

- Cement and concrete;

- -

- Steel, iron, and type Fe510C-EU25 alloys;

- -

- Coatings and linings;

- -

- Miscellaneous waste, including marine growth estimated at 10% of cement weight.

2.3. Life Cycle Impact Assessment

2.3.1. Climate Change

2.3.2. Human Toxicity, Cancer Effects

2.3.3. Land Use

2.3.4. Marine Eutrophication

2.3.5. Particulate Matter

2.3.6. Water Resource Depletion

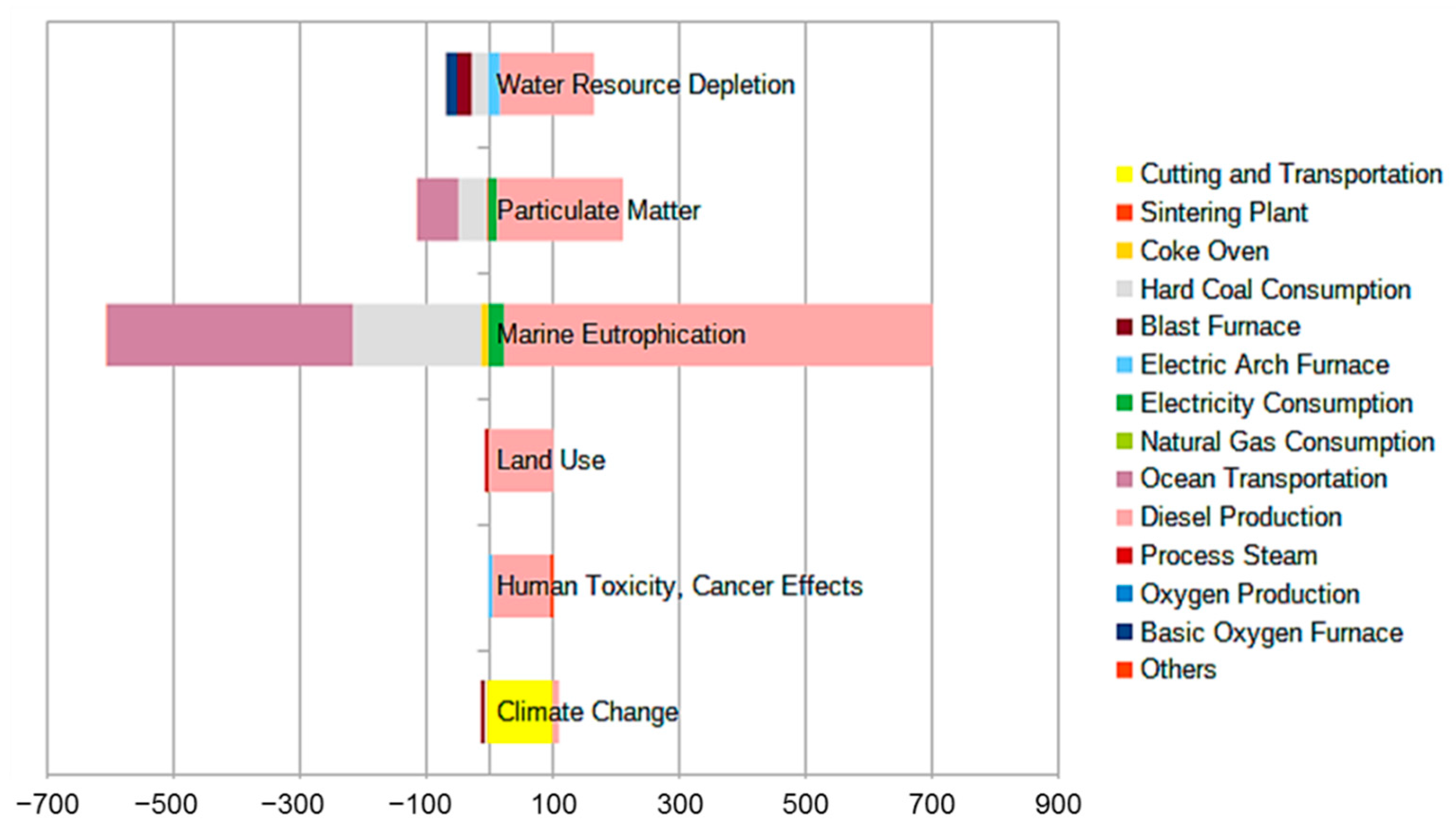

2.4. Contribution Analysis

2.5. Life Cycle Interpretation

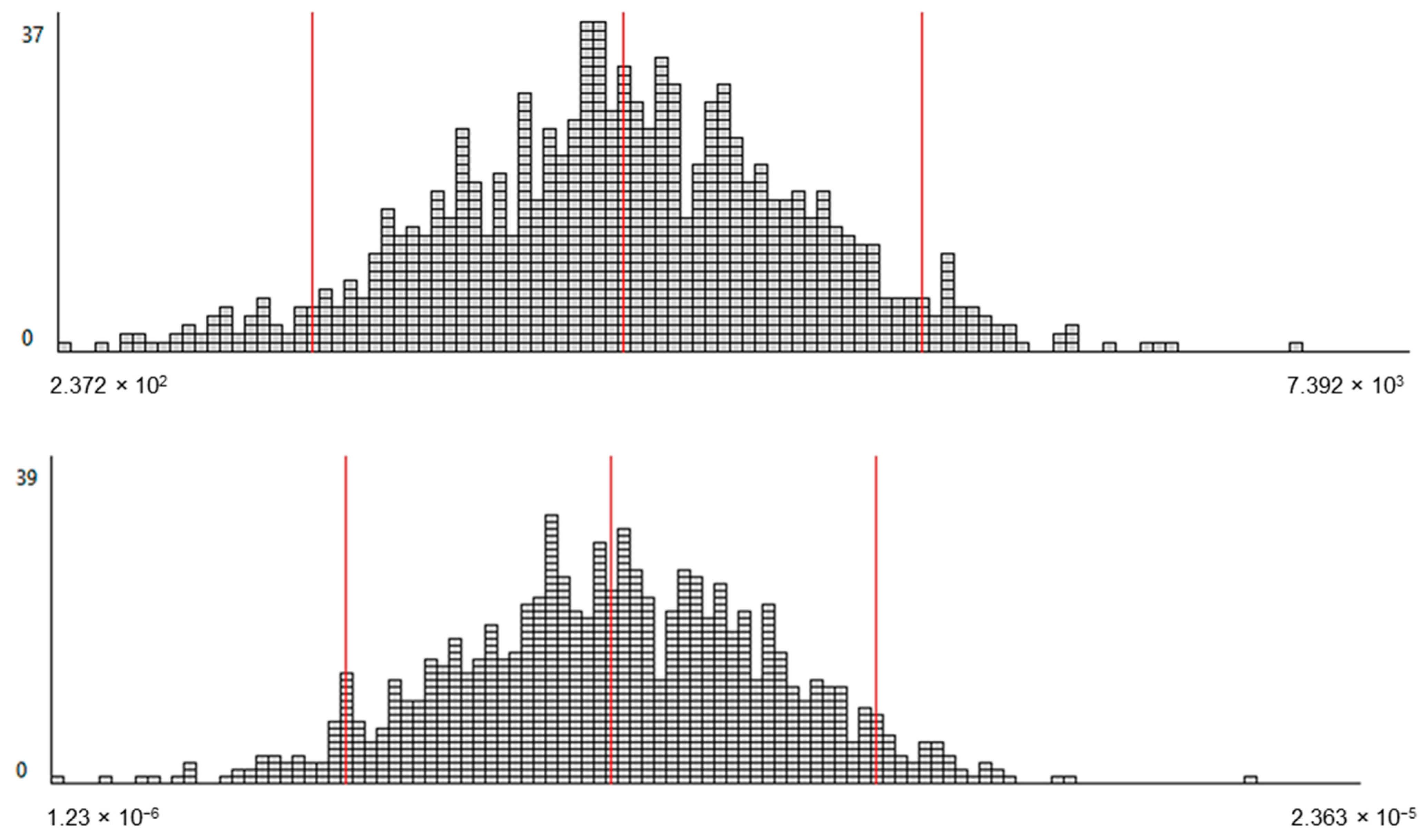

2.5.1. Uncertainty Analysis

2.5.2. Data Quality Check

2.5.3. Sensitivity Analysis

3. Economic Impact Assessment

3.1. Preparatory Phase

3.2. Removal Phase

- -

- 1 dumb barge;

- -

- 1 crane vessel/work barge with ROV;

- -

- 1 supply vessel;

- -

- 1 tug boat.

3.3. Monitoring Phase

4. Conclusions and Future Work

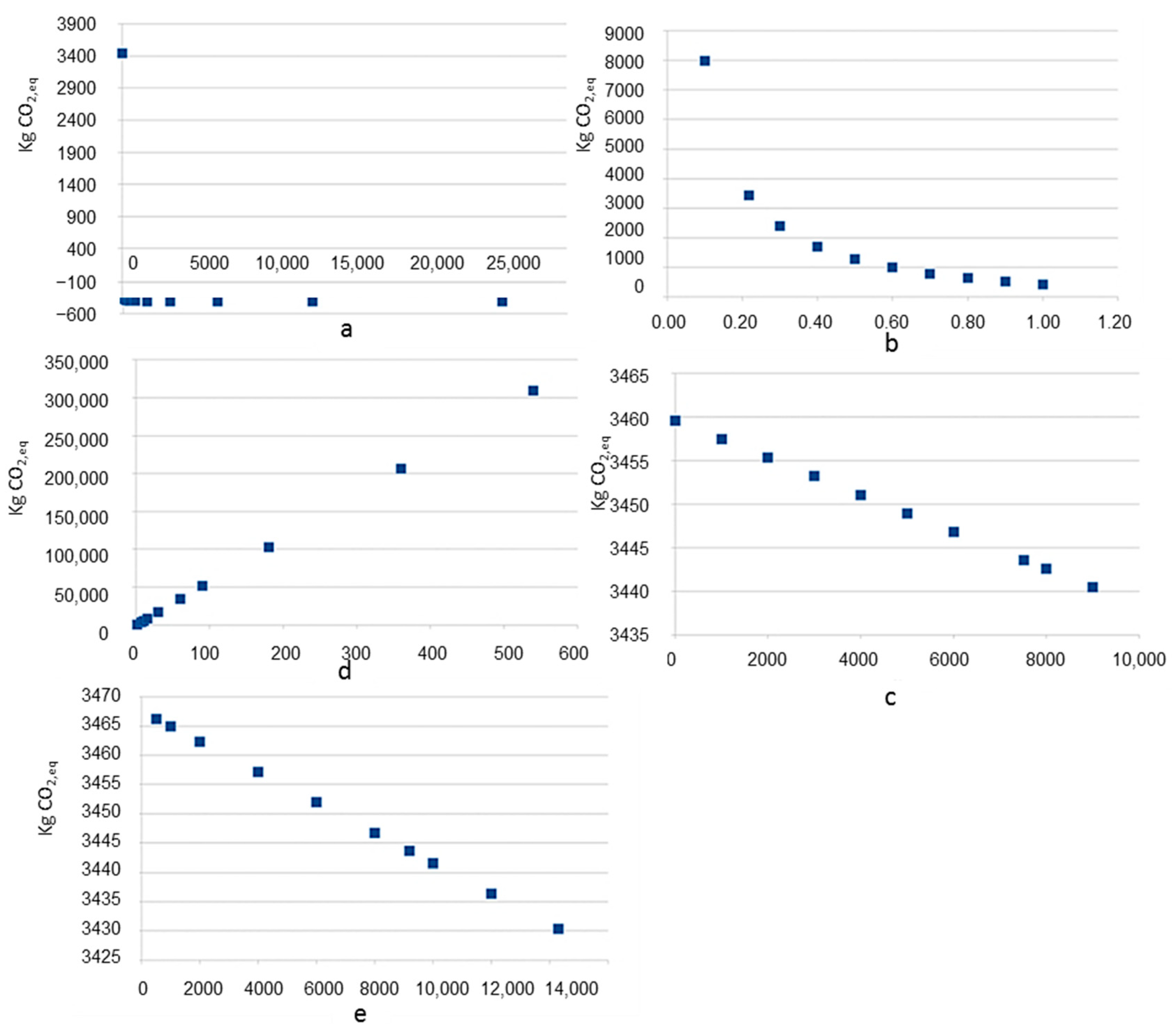

- Tons of platform decommissioned, represented by parameter a, are decreasingly hyperbolic linked to all impact categories.

- Steel content of platform, represented by parameter b, is decreasingly hyperbolic linked to all impact categories.

- Average number of vessel days of effective operation, represented by parameter c, is positively linearly linked to all impact categories.

- Primary steel iron ore supply distance and primary steel coal supply distance, represented, respectively, by parameters d and e, are inversely and linearly linked to all impact categories, but Land Use that does not change the parameters e and d varies.

- As expected, final results of the LCA are mainly influenced by platform type and structure as well as its distance from the shore yard.

- Most of environmental impacts are linked to marine vessel operations for platform removal and the relative fuel production and consumption.

- The entire processes of steel recycling may play an important role in the final environmental performance assessment as avoided impacts, recalling that the more impacting (economically and environmentally) the primary steel production, the more sustainable the choice of recycling platform steel through electric route.

- As a consequence of the previous point, material flow steel content obtainable from platform dismantling strongly affects the total avoided impacts and it represents a decisive parameter to assess the environmental sustainability of this kind of project.

- Concerning the economic analysis, the major costs are expected to be connected to offshore operations and marine vessel and working crew rentals.

Author Contributions

Funding

Conflicts of Interest

References

- Leporini, M.; Marchetti, B.; Corvaro, F.; Polonara, F. Reconversion of offshore oil and gas platforms into renewable energy sites production: Assessment of different scenarios. Renew. Energy 2019, 135, 1121–1132. [Google Scholar] [CrossRef]

- Liu, X.; Liu, G.; Yang, Z.; Chen, B.; Ulgiati, S. Comparing national environmental and economic performances through emergy sustainability indicators: Moving environmental ethics beyond anthropocentrism toward ecocentrism. Renew. Sustain. Energy Rev. 2016, 58, 1532–1542. [Google Scholar] [CrossRef]

- ENI S.p.A. Valutazione Preliminare ai Sensi dell’art. 6, Comma 9, del d.lgs.152/2006 e ss.mm.ii., Relativa al Progetto di Decommissioning Della Piattaforma Denominata “Ada 3”, in Concessione di Coltivazione di Idrocarburi Liquidi e Gassosi “a.c9.ag.”. Proponente: Eni s.p.a. Nota Tecnica. e Anche Documentazione Richiesta ai Sensi Dell’art. 14 dm 15/02/2019 (Allegato 3)-Piattaforma ada 3; 2019. Available online: https://va.mite.gov.it/en-GB/Oggetti/Documentazione/7649/11092 (accessed on 20 February 2021).

- ENI S.p.A. Doc. 195/Presc—Studio di Fattibilità Decommissioning Bonaccia nw. 2015. Available online: https://va.mite.gov.it/it-IT/Oggetti/Documentazione/539/633 (accessed on 22 June 2021).

- Poremski, H.-J. Life Cycle Assessment—Development Planning through Decommissioning. Presented at the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998. [Google Scholar]

- Gorman, D.G.; Neilson, J. Decommissioning Offshore Structures; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Vestas Wind Systems A/S. Life Cycle Assessment of Offshore and Onshore Sited Wind Farms; Vestas Wind Systems A/S: Aarhus, Denmark, 2004. [Google Scholar]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Weidema, B.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.; Wernet, G. Overview and Methodology: Data Quality Guideline for the Ecoinvent Database Version 3; Aalborg University: Aalborg, Denmark, 2013. [Google Scholar]

- Remus, R.; Aguado Monsonet, M.; Roudier, S.; Delgado Sancho, L. Best Available Techniques (BAT) Reference Document for Iron and Steel Production: Industrial Emissions Directive 2010/75/EU: Integrated Pollution Prevention and Control; Publications Office of the European Union: Luxembourg, 2012. [Google Scholar]

- Burchart, D. Life cycle assessment of steel production in poland: A case study. J. Clean. Prod. 2013, 54, 235–243. [Google Scholar] [CrossRef]

- Liang, T.; Wang, S.; Lu, C.; Jiang, N.; Long, W.; Zhang, M.; Zhang, R. Environmental impact evaluation of an iron and steel plant in China: Normalized data and direct/indirect contribution. J. Clean. Prod. 2020, 264, 121697. [Google Scholar] [CrossRef]

- Renzulli, P.; Notarnicola, B.; Tassielli, G.; Arcese, G.; Capua, R. Life cycle assessment of steel produced in an italian integrated steel mill. Sustainability 2016, 8, 719. [Google Scholar] [CrossRef]

- Ministero dello Sviluppo Economico—Direzione Generale per le Infrastrutture e la Sicurezza dei Sistemi Energetici e Geominerari. La Situazione Energetica Nazionale nel 2019; Ministero dello Sviluppo Economico: Rome, Italy, 2020. [Google Scholar]

- EMEP/EEA. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; Update December 2021; EMEP: Houston, TX, USA; EEA: Copenhagen, Denmark, 2019. [Google Scholar]

- European Commission. Quantification of Emissions from Ships Associated with Ship Movements between Ports in the European Community; Publications Office of the European Union: Luxembourg, 2002. [Google Scholar]

- Borghi, G.; Pantini, S.; Rigamonti, L. Life cycle assessment of non-hazardous construction and demolition waste (cdw) management in lombardy region (Italy). J. Clean. Prod. 2018, 184, 815–825. [Google Scholar] [CrossRef]

- Somers, J. Technologies to Decarbonise the EU Steel Industry; EUR 30982 EN; Publications Office of the European Union: Luxembourg, 2022; ISBN 978-92-76-47147-9. [Google Scholar] [CrossRef]

- EEA. Annual European Union Greenhouse Gas Inventory 1990–2019 and Inventory Report 2021—Submission to the UNFCCC Secretariat; European Environment Agency: Copenhagen, Denmark, 2021. [Google Scholar]

- Giorgi, S.; Lavagna, M.; Campioli, A. Procedure di Allocazione Nella Metodologia lca e Tendenze Settoriali Verso Un’economia Circolare. 2017. Available online: https://www.researchgate.net/profile/Serena-Giorgi/publication/333377827_Procedure_di_allocazione_nella_metodologia_LCA_e_tendenze_settoriali_verso_un'economia_circolare/links/5ce95bf6299bf14d95bb0030/Procedure-di-allocazione-nella-metodologia-LCA-e-tendenze-settoriali-verso-uneconomia-circolare.pdf (accessed on 15 February 2022).

- Backes, J.; Suer, J.; Pauliks, N.; Neugebauer, S.; Traverso, M. Lifecycle assessment of an integrated steel mill using primary manufacturing data: Actual environmental profile. Sustainability 2021, 13, 3443. [Google Scholar] [CrossRef]

- Pardo, N.; Moya, J.A.; Vatopoulos, K. Prospective Scenarios on Energy Efficiency and CO2 Emissions in the EU Iron & Steel Industry; Publications Office of the European Union: Luxembourg, 2012. [Google Scholar]

- Bowyer, J.; Bratkovich, S.; Fernholz, K.; Frank, M.; Groot, H.; Howe, J.; Pepke, E. Understanding Steel Recovery and Recycling Rates and Limitations to Recycling; Dovetail Partners Inc.: Minneapolis, MN, USA, 2015; pp. 1–12. [Google Scholar]

- Acero, A.P.; Rodríguez, C.; Ciroth, A. LCIA Methods—Impact Assessment Methods in Life Cycle Assessment and Their Impact Categories; GreenDelta GmbH: Berlin, Germany, 2015. [Google Scholar]

- Ærtebjerg, G.; Carstensen, J.; Dahl, K.; Hansen, J.; Nygaard, K.; Rygg, B.; Sorensen, K.; Severinsen, G.; Casartelli, S.; Schrimpf, W.; et al. Eutrophication in Europe’s Coastal Waters; European Environment Agency: Copenhagen, Denmark, 2001. [Google Scholar]

- Cosme, N.; Verones, F.; Hauschild, M. Marine Eutrophication. Chapter 9. Available online: https://lc-impact.eu/doc/method/Chapter9_Marine%20Eutrophication_20190207.pdf (accessed on 6 February 2022).

- Raudsepp, U.; Maljutenko, I.; Kõuts, M.; Granhag, L.; Wilewska-Bien, M.; Hassellöv, I.M.; Eriksson, K.M.; Johansson, L.; Jalkanen, J.-P.; Karl, M.; et al. Shipborne nutrient dynamics and impact on the eutrophication in the Baltic Sea. Sci. Total Environ. 2019, 671, 189–207. [Google Scholar] [CrossRef]

- GSE. Composizione del Mix Iniziale Nazionale Utilizzato per la Produzione Dell’energia Elettrica Immessa nel Sistema Elettrico Italiano nel 2020 (Preconsuntivo). 2020. Available online: https://www.gse.it/servizi-per-te/news/fuel-mix-determinazione-del-mix-energetico-per-gli-anni-2020-2021 (accessed on 15 July 2021).

- Côté, I.; Gill, J.; Gardner, T.; Watkinson, A. Measuring coral reef decline through meta-analyses. Philosophical transactions of the Royal Society of London. Ser. B Biol. Sci. 2005, 360, 385–395. [Google Scholar] [CrossRef]

- Perrow, M. Wildlife and Wind Farms—Conflicts and Solutions, Volume 4. Offshore: Monitoring and Mitigation; Pelagic Publishing Ltd.: London, UK, 2019. [Google Scholar]

- Bull, A.; Love, M.; Schroeder, D. Artificial reefs as fishery conservation tools: Contrasting roles of offshore structures between the gulf of mexico and the southern california bight. Trans. Am. Fish. Soc. 2008, 49, 899–915. [Google Scholar]

- Inger, R.; Attrill, M.; Bearhop, S.; Broderick, A.; Grecian, W.; Hodgson, D.; Mills, C.; Sheehan, E.; Votier, S.; Witt, M.; et al. Marine renewable energy: Potential benefits to biodiversity? an urgent call for research. J. Appl. Ecol. 2009, 46, 1145–1153. [Google Scholar] [CrossRef]

- Claisse, J.T.; Pondella, D.J.; Love, M.S.; Laurel, M.; Zahn, A.; Williams, C.A.; Bull, A.S. Impacts from partial removal of decommissioned oil and gas platforms on fish biomass and production on the remaining platform structure and surrounding shell mounds. PLoS ONE 2015, 10, e0135812. [Google Scholar] [CrossRef]

- Zettler, M.; Pollehne, F. The Impact of Wind Engine Constructions on Benthic Growth Patterns in the Western Baltic. In Offshore Wind Energy; Springer: Berlin/Heidelberg, Germany, 2006; pp. 201–222. [Google Scholar]

- Sammarco, P.; Kolian, S.; Warby, R.; Bouldin, J.; Subra, W.; Porter, S. Distribution and concentrations of petroleum hydrocarbons associated with the bp/deepwater horizon oil spill, gulf of mexico. Mar. Pollut. Bull. 2013, 73, 129–143. [Google Scholar] [CrossRef] [PubMed]

- Farr, H.; Ruttenberg, B.I.; Walter, R.K.; Wang, Y.-H.; White, C. Potential environmental effects of deepwater floating offshore wind energy facilities. Ocean. Coast. Manag. 2021, 207, 105611. [Google Scholar] [CrossRef]

- Wilhelmsson, D.; Langhamer, O. The Influence of Fisheries Exclusion and Addition of Hard Substrata on Fish and Crustaceans. In Humanity and the Sea: Marine Renewable Energy Technology and Environmental Interactions; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Hammar, L.; Perry, D.; Gullström, M. Offshore wind power for marine conservation. Open J. Mar. Sci. 2016, 6, 66–78. [Google Scholar] [CrossRef]

- Degraer, S.; Carey, D.; Coolen, J.; Hutchison, Z.; Kerckhof, F.; Rumes, B.; Vanaverbeke, J. Offshore wind farm artificial reefs affect ecosystem structure and functioning: A synthesis. Oceanography 2020, 33, 48–57. [Google Scholar] [CrossRef]

- Dannheim, J.; Bergstro, L.; Birchenough, S.N.R.; Brzana, R.; Boon, A.R.; Coolen, J.W.P.; Dauvin, J.-C.; de Mesel, I.; Derweduwen, J.; Gill, A.B.; et al. Benthic effects of offshore renewables: Identification of knowledge gaps and urgently needed research. ICES J. Mar. Sci. 2020, 77, 1092–1108. [Google Scholar] [CrossRef]

- Pondella, D.; Zahn, L.; Love, M.; Siegel, D.; Bernstein, B. Modeling fish production for southern california’s petroleum platforms. Integr. Environ. Assess. Manag. 2015, 11, 584–593. [Google Scholar] [CrossRef]

- Coolen, J.; Boon, A.; Crooijmans, R.; Pelt, H.; Kleissen, F.; Gerla, D.; Beermann, J.; Birchenough, S.; Becking, L.; Luttikhuizen, P. Marine stepping-stones: Connectivity of mytilus edulis populations between offshore energy installations. Mol. Ecol. 2020, 29, 686–703. [Google Scholar] [CrossRef]

- Slavik, K.; Lemmen, C.; Zhang, W.; Kerimoglu, O.; Klingbeil, K.; Wirtz, K. The large scale impact of offshore windfarm structures on pelagic primary production in the southern north sea. Hydrobiologia 2019, 845, 11. [Google Scholar] [CrossRef]

- Christensen, E.; Johnson, M.; Sorensen, O.; Hasager, C.; Badger, M.; Larsen, S. Transmission of wave energy through an offshore wind turbine farm. Coast. Eng. 2013, 82, 25–46. [Google Scholar] [CrossRef]

- Clark, S.; Schroeder, F.; Baschek, B. The Influence of Large Offshore Wind Farms on the North Sea and Baltic Sea—A Comprehensive Literature Review; Report No. HZG (Report 2014-6); Helmholtz-Zentrum Geesthacht: Geesthacht, Germany, 2014. [Google Scholar]

- Ludewig, E. On the Effect of Offshore Wind Farms on the Atmosphere and Ocean Dynamics; Springer: Cham, Switzerland, 2015; Volume 31. [Google Scholar]

- Carpenter, J.; Merckelbach, L.; Callies, U.; Clark, S.; Gaslikova, L.; Baschek, B. Potential impacts of offshore wind farms on north sea stratification. PLoS ONE 2016, 11, e0160830. [Google Scholar] [CrossRef] [PubMed]

- Grashorn, S.; Stanev, E. Kármán vortex and turbulent wake generation by wind park piles. Ocean. Dyn. 2016, 66, 11. [Google Scholar] [CrossRef]

- Floeter, J.; van Beusekom, J.E.; Auch, D.; Callies, U.; Carpenter, J.; Dudeck, T.; Eberle, S.; Eckhardt, A.; Gloe, D.; Hänselmann, K.; et al. Pelagic effects of offshore wind farm foundations in the stratified North Sea. Prog. Oceanogr. 2017, 156, 154–173. [Google Scholar] [CrossRef]

- Van Berkel, J.; Burchard, H.; Christensen, A.; Mortensen, L.O.; Petersen, O.S.; Thomsen, F. The effects of offshore wind farms on hydrodynamics and implications for fishes. Oceanography 2020, 33, 108–117. [Google Scholar] [CrossRef]

- Kirchgeorg, T.; Weinberg, I.; Hörnig, M.; Baier, R.; Schmid, M.; Brockmeyer, B. Emissions from corrosion protection systems of offshore wind farms: Evaluation of the potential impact on the marine environment. Mar. Pollut. Bull. 2018, 136, 257–268. [Google Scholar] [CrossRef]

- Defingou, M.; Bils, F.; Horchler, B.; Liesenjohann, T.; Nehls, G. Pharos4mpas—Safeguarding Marine Protected Areas in the Growing Mediterranean Blue Economy; Capitalization Report for the Offshore Wind Energy Sector; International Atomic Energy Agency: Vienna, Austria, 2019. [Google Scholar]

- Mooney, T.; Andersson, M.; Stanley, J. Acoustic impacts of offshore wind energy on fishery resources: An evolving source and varied effects across a wind farm’s lifetime. Oceanography 2020, 33, 82–95. [Google Scholar] [CrossRef]

- Colaleo, G.; Contestabile, P.; Bellezze, T.; Margheritini, L.; Dell’Anno, A.; Vicinanza, D. Prototype experiments of the low voltage mineral deposition technology as eco-friendly solution for improving the sustainability of offshore platforms at the end of their production life. Environ. Technol. Innov. 2022, 27, 102412. [Google Scholar] [CrossRef]

- Margheritini, L.; Colaleo, G.; Contestabile, P.; Bjørgård, T.L.; Simonsen, M.E.; Lanfredi, C.; Dell’Anno, A.; Vicinanza, D. Development of an Eco-Sustainable Solution for the Second Life of Decommissioned Oil and Gas Platforms: The Mineral Accretion Technology. Sustainability 2020, 12, 3742. [Google Scholar] [CrossRef]

| Element | Weight [t] |

|---|---|

| External tube | 28 |

| Cement | 154.8 |

| Guide tube | 15.7 |

| Coating | 2.5 |

| Conductor centering | 1 |

| Anodes | 1 |

| Pier and landing stage | 5 |

| Marine growth | 15 |

| Total | 223 |

| Impact Category | Result |

|---|---|

| Climate change | 3.5 × 103 kg CO2,eq |

| Human toxicity, cancer effects | 1.2 × 10−5 CTUh |

| Land use | 1.6 × 103 kg Cdeficit |

| Marine eutrophication | 9.5 × 10−2 kg N,eq |

| Particulate matter | 8.5 × 10−2 kg PM2.5,eq |

| Water resource depletion | 1.5 × 10 m3 water,eq |

| Climate Change | Human Toxicity, Cancer Effects | Land Use | Marine Eutrophication | Particulate Matter | Water Resource Depletion | |

|---|---|---|---|---|---|---|

| Cutting and transportation | 101.8% | |||||

| Sintering plant | −2.57% | −2.28% | ||||

| Coke oven | −3.43% | −11.48% | ||||

| Hard coal consumption | −5.02% | −0.59% | −2.59% | −202.53% | −44.92% | −26.29% |

| Blast furnace | −23.16% | |||||

| Electric arc furnace | 6.95% | 18.81% | ||||

| Electricity consumption | 0.45% | 25.05% | 14.19% | |||

| Natural gas consumption | ||||||

| Ocean transportation | −0.16% | −388.35% | −65.02% | |||

| Diesel production | 9.88% | 93.3% | 102.58% | 678.57% | 198.6% | 148.41% |

| Process steam | ||||||

| Oxygen production | ||||||

| Basic oxygen furnace | −17.16% | |||||

| Others | −0.65% | 0.05% | −1.26% | −0.56% | −0.6% |

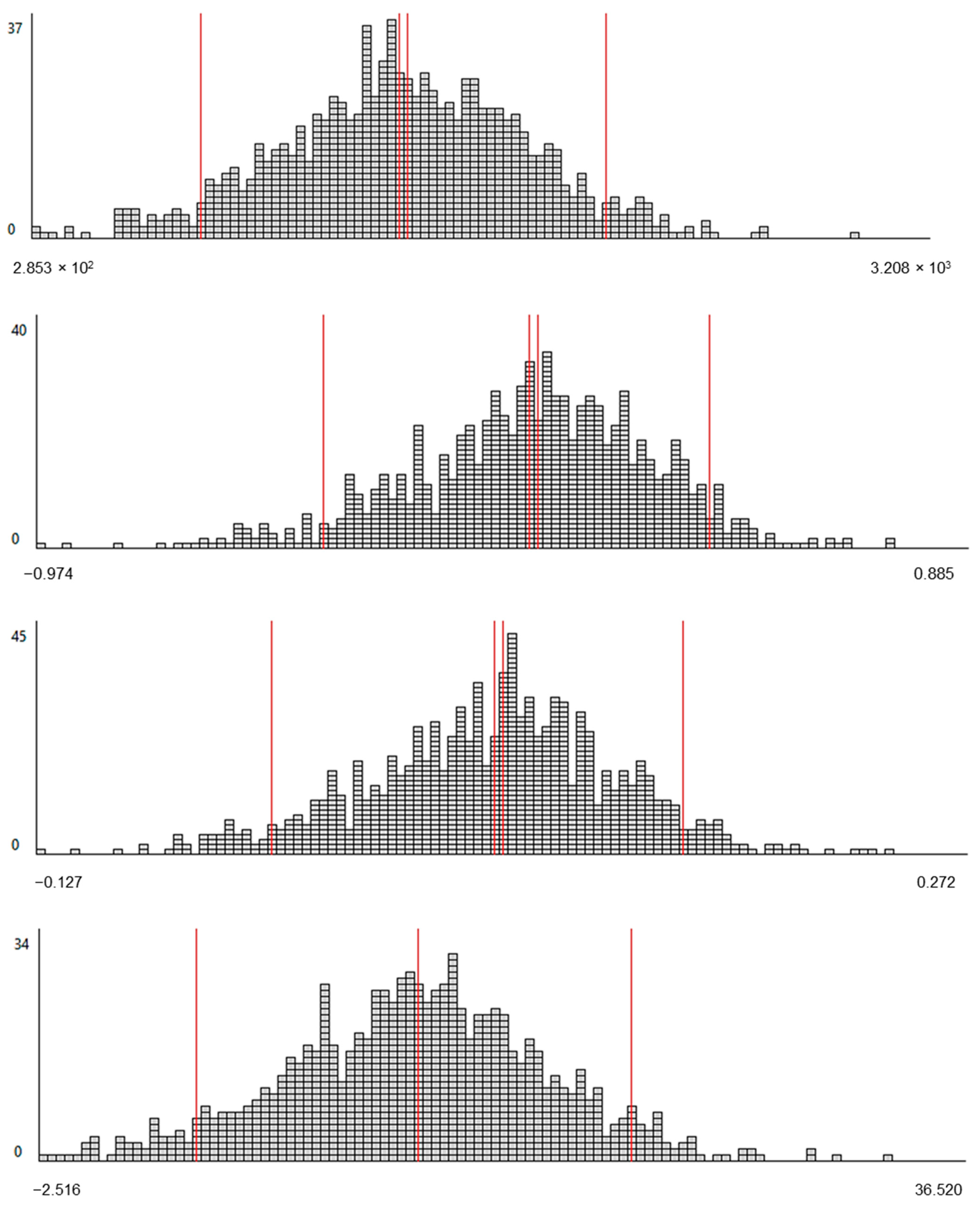

| Mean | St. Deviation | Median | 5% Percentile | 9% Percentile | |

|---|---|---|---|---|---|

| Climate change | 3.5 × 103 | 1.04 × 103 | 3.5 × 103 | 1.74 × 103 | 5.24 × 103 |

| Human toxicity, cancer effects | 1.17 × 10−5 | 2.99 × 10−6 | 1.17 × 10−5 | 6.72 × 10−6 | 1.65 × 10−5 |

| Land use | 1.6 × 103 | 4.33 × 102 | 1.59 × 103 | 8.85 × 102 | 2.32 × 103 |

| Marine eutrophication | 0.102 | 0.261 | 0.119 | −0.344 | 0.494 |

| Particulate matter | 0.085 | 0.058 | 0.09 | −0.016 | 0.175 |

| Water resource depletion | 14.75 | 5.94 | 14.9 | 4.62 | 24.49 |

| Class\Indicator | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Reliability | Verified data based on measurements | Verified data partly based on assumptions or non-verified data based on measurements | Non-verified data partly based on qualified estimates | Qualified estimate (e.g., by an industrial expert) | Non-qualified estimates |

| Completeness | Representative data from all sites relevant to the market is considered over an adequate period to even out normal fluctuations | Representative data from > 50% of the sites relevant for the market is considered over an adequate period to even out normal fluctuations | Representative data from only some sites (<<50%) relevant for the market is considered or >50% of sites but from shorter periods | Representative data from only one site relevant for the market is considered or some sites but from shorter periods | Representativeness unknown or data from a small number of sites and shorter periods |

| Temporal Correlation | Less than 3 years of difference in the period of the data set | Less than 6 years of difference in the period of the data set | Less than 10 years of difference in the period of the data set | Less than 15 years of difference in the period of the data set | Age of data unknown or more than 15 years of difference to the period of the data set |

| Geographical Correlation | Data from an area under study | Average data from a larger area in which the area under study is included | Data from an area with similar production conditions | Data from an area with slightly similar production conditions | Data from an unknown or distinctly different area (North America instead of the Middle East, OECD-Europe instead of Russia) |

| Further Technological Correlation | Data from enterprises, processes, and materials under study | Data from processes and materials under study (i.e., identical technology) but different enterprises | Data from processes and materials under study but different technology | Data on related processes or materials | Data on related processes on a laboratory scale or from different technology |

| Impact Category\Indicator | Reliability | Completeness | Temporal Correlation | Geographical Correlation | Further Technological Correlation |

|---|---|---|---|---|---|

| Climate change | 2 | 3 | 3 | 4 | 3 |

| Human toxicity, cancer effects | 2 | 2 | 2 | 3 | 2 |

| Land use | - | - | - | - | - |

| Marine eutrophication | 2 | 2 | 2 | 3 | 2 |

| Particulate matter | 2 | 2 | 2 | 3 | 2 |

| Water resource depletion | 2 | 2 | 2 | 3 | 2 |

| Item | Cost [€] |

|---|---|

| Engineering and project management | 180,000 |

| Marine vessels | 700,000 |

| Offshore operations | 1,200,000 |

| Removal, treatment and recycling | 70,000 |

| Insurance and other costs | 80,000 |

| Total | 2,230,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colaleo, G.; Nardo, F.; Azzellino, A.; Vicinanza, D. Decommissioning of Offshore Platforms in Adriatic Sea: The Total Removal Option from a Life Cycle Assessment Perspective. Energies 2022, 15, 9325. https://doi.org/10.3390/en15249325

Colaleo G, Nardo F, Azzellino A, Vicinanza D. Decommissioning of Offshore Platforms in Adriatic Sea: The Total Removal Option from a Life Cycle Assessment Perspective. Energies. 2022; 15(24):9325. https://doi.org/10.3390/en15249325

Chicago/Turabian StyleColaleo, Giuseppina, Federico Nardo, Arianna Azzellino, and Diego Vicinanza. 2022. "Decommissioning of Offshore Platforms in Adriatic Sea: The Total Removal Option from a Life Cycle Assessment Perspective" Energies 15, no. 24: 9325. https://doi.org/10.3390/en15249325

APA StyleColaleo, G., Nardo, F., Azzellino, A., & Vicinanza, D. (2022). Decommissioning of Offshore Platforms in Adriatic Sea: The Total Removal Option from a Life Cycle Assessment Perspective. Energies, 15(24), 9325. https://doi.org/10.3390/en15249325