Aluminium Electrodeposition from Ionic Liquid: Effect of Deposition Temperature and Sonication † †

Abstract

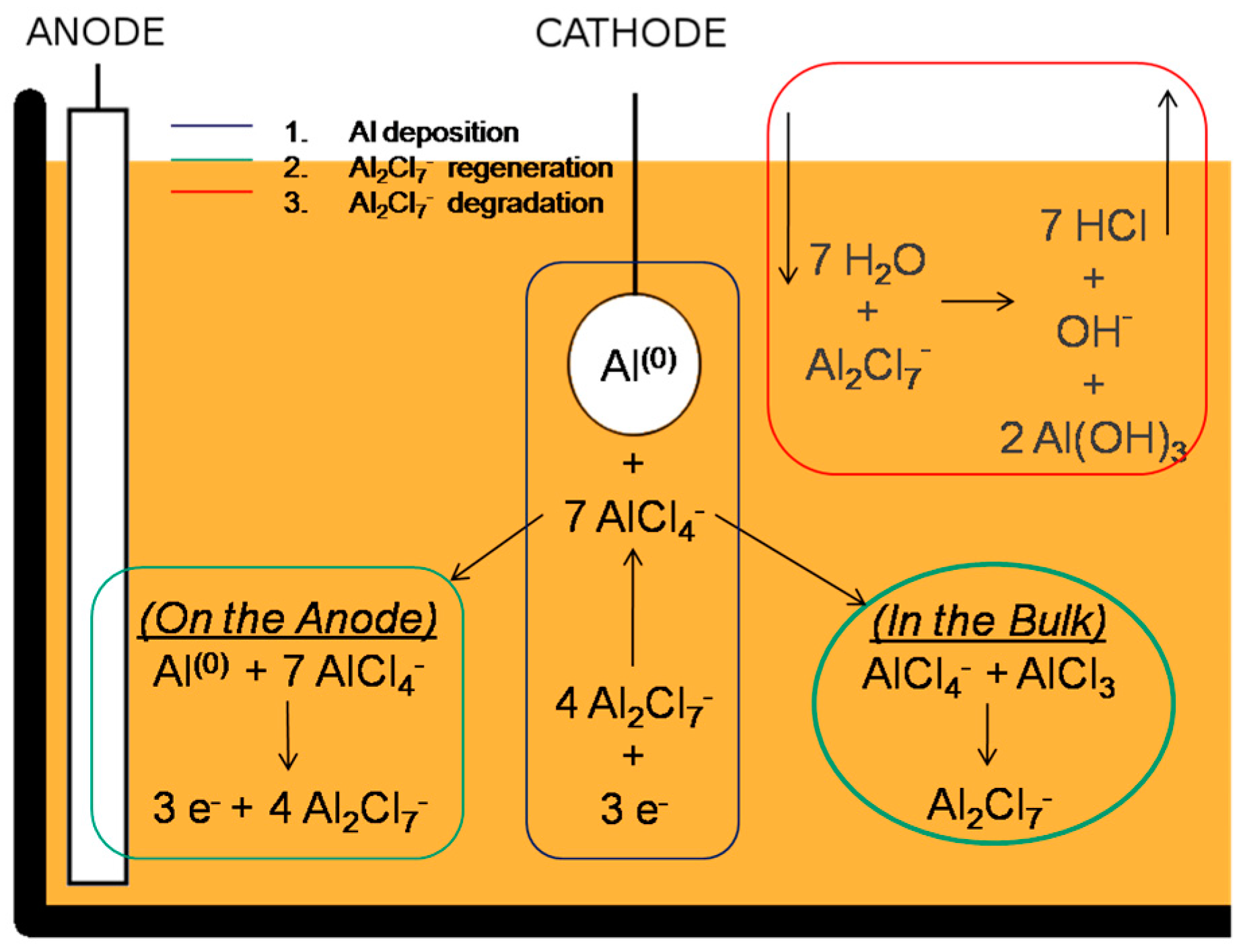

:1. Introduction

2. Materials and Methods

2.1. Chemicals

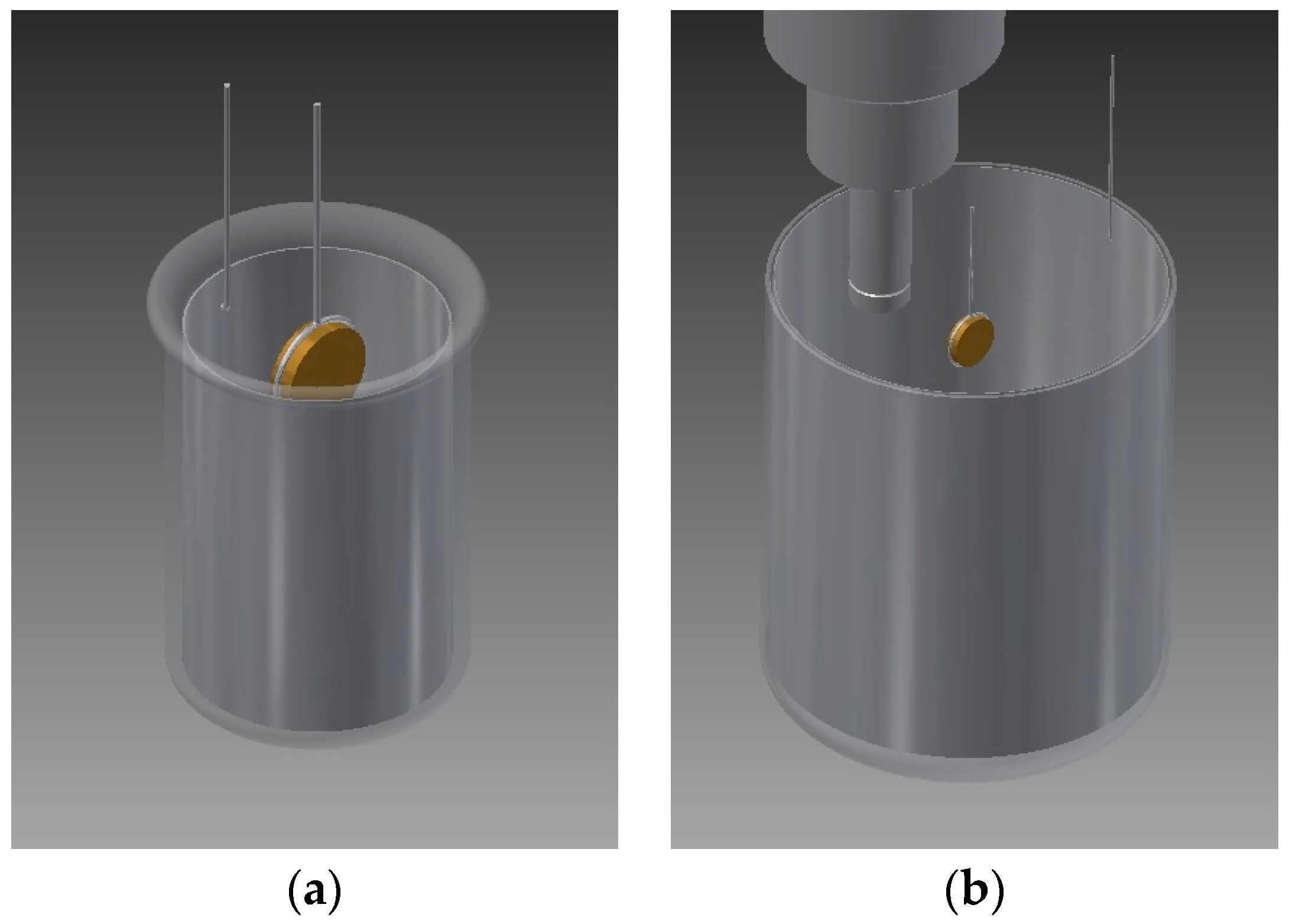

2.2. Electrode Materials

2.3. Deposition Parameters

2.4. Characterization of the Deposits

2.5. Process Yield

2.6. XRD Analysis

2.7 Electrochemical Corrosion Test

3. Results

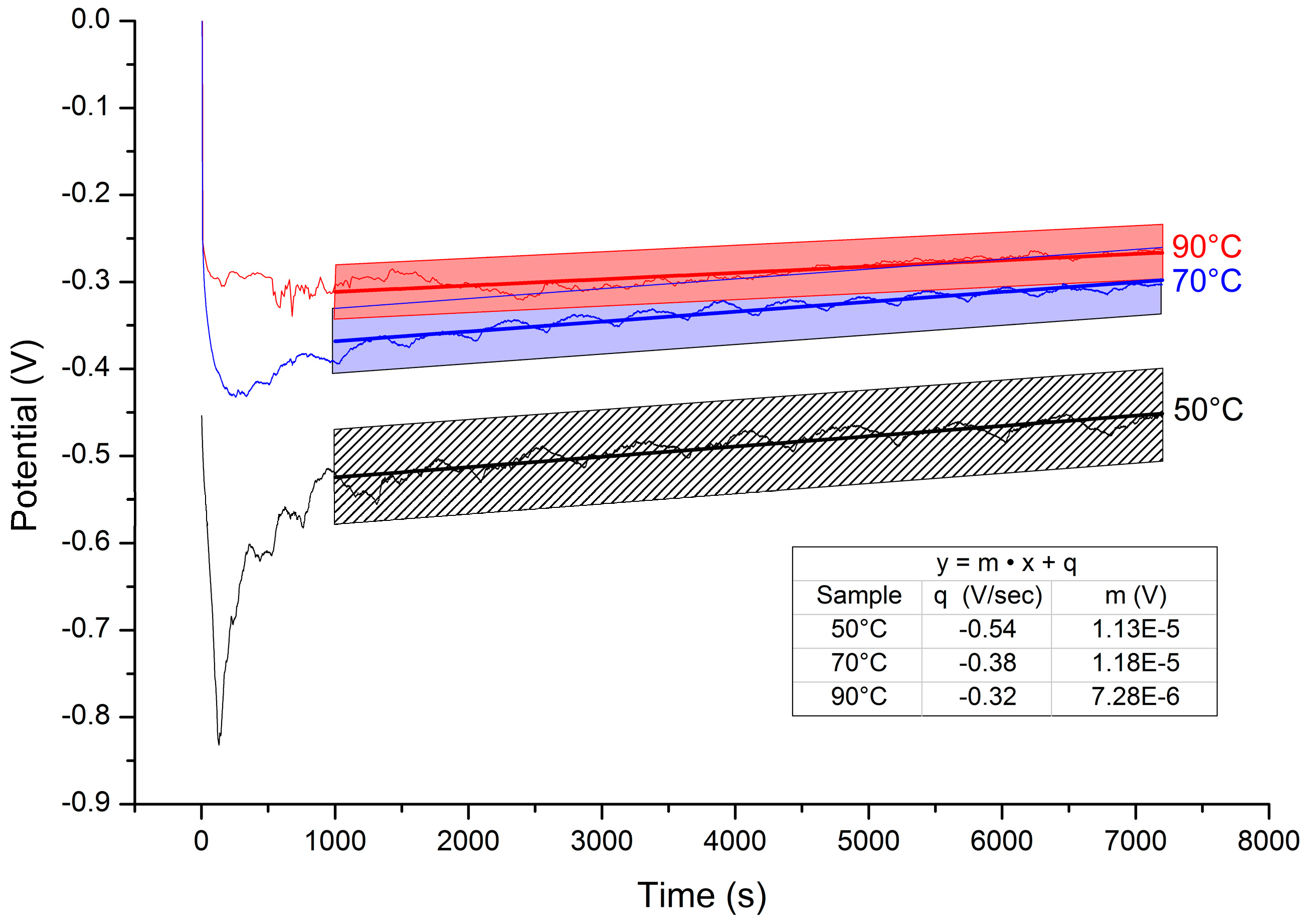

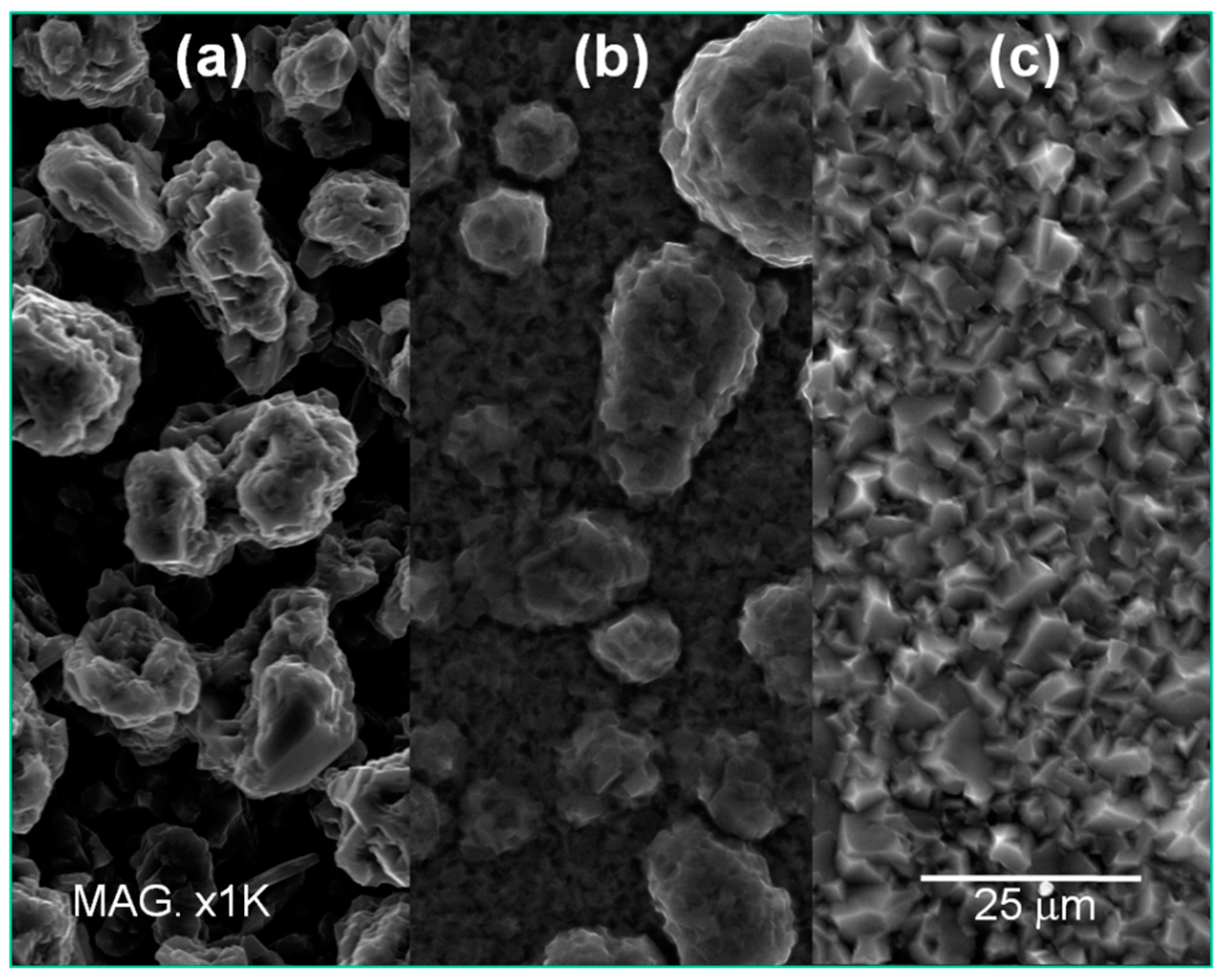

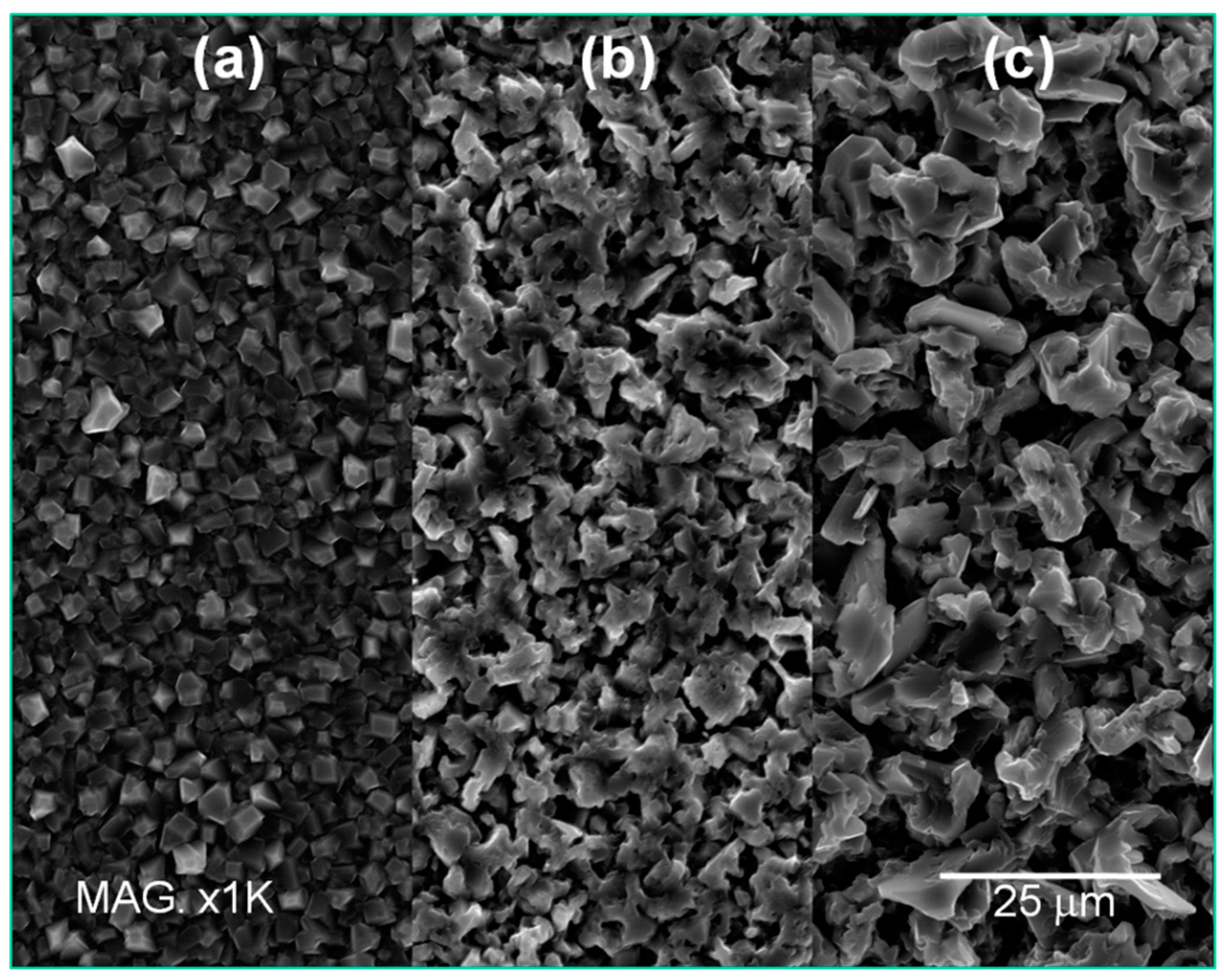

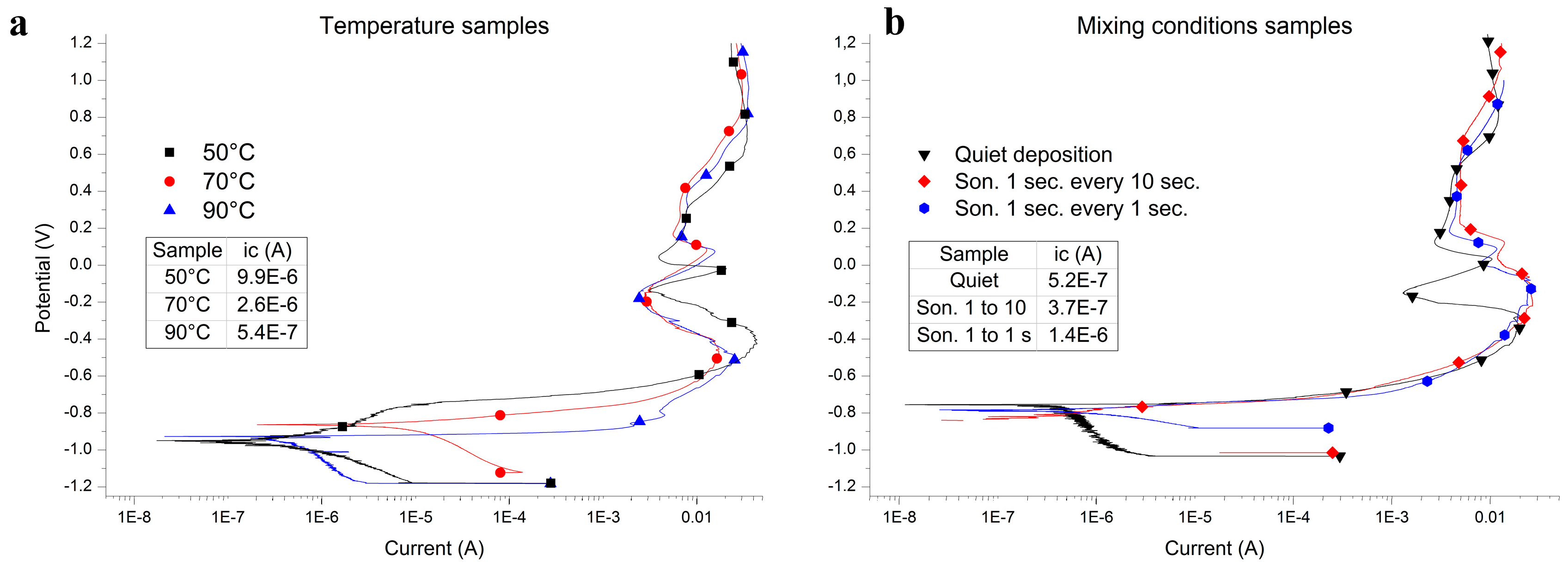

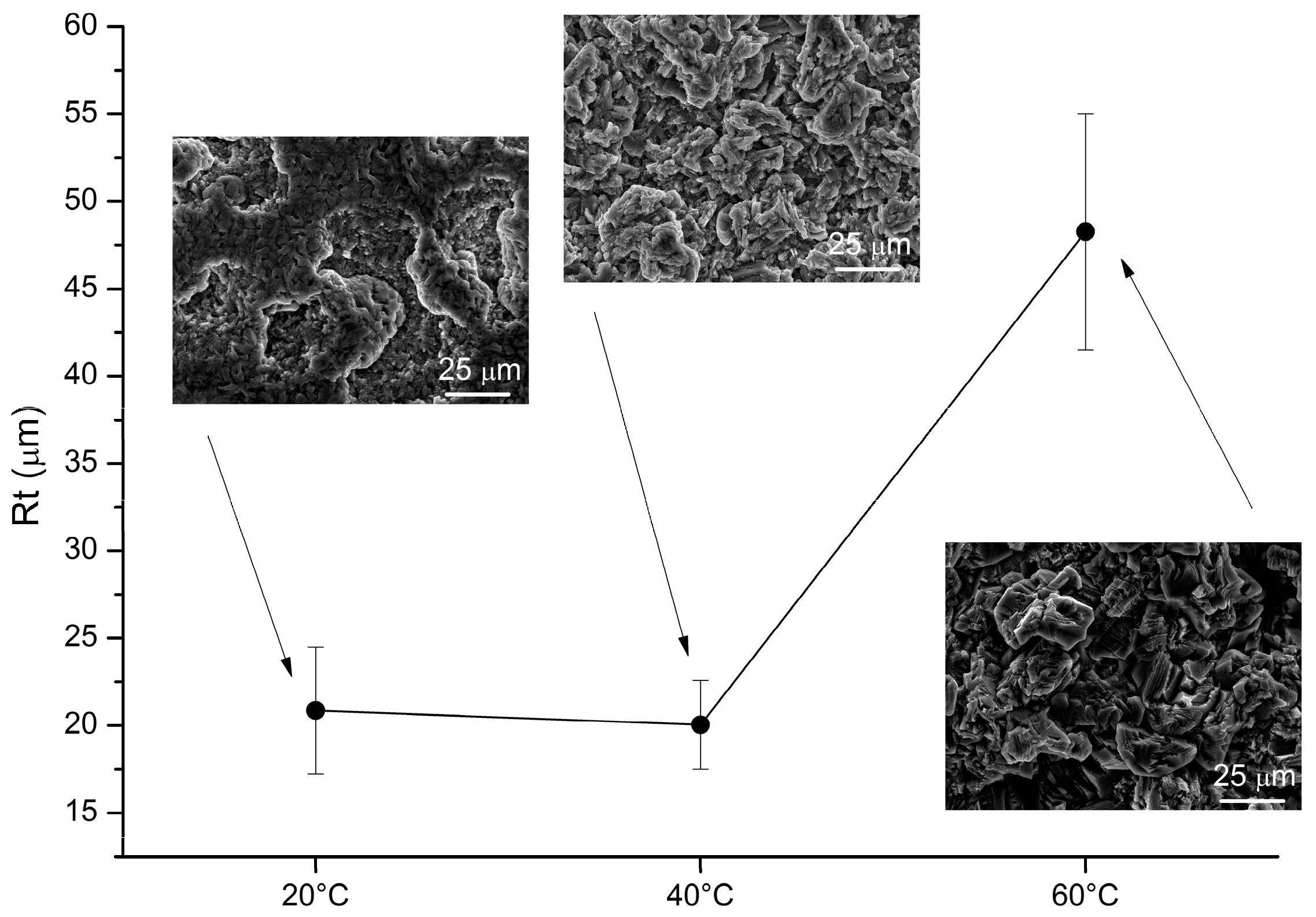

3.1. Effect of Temperature

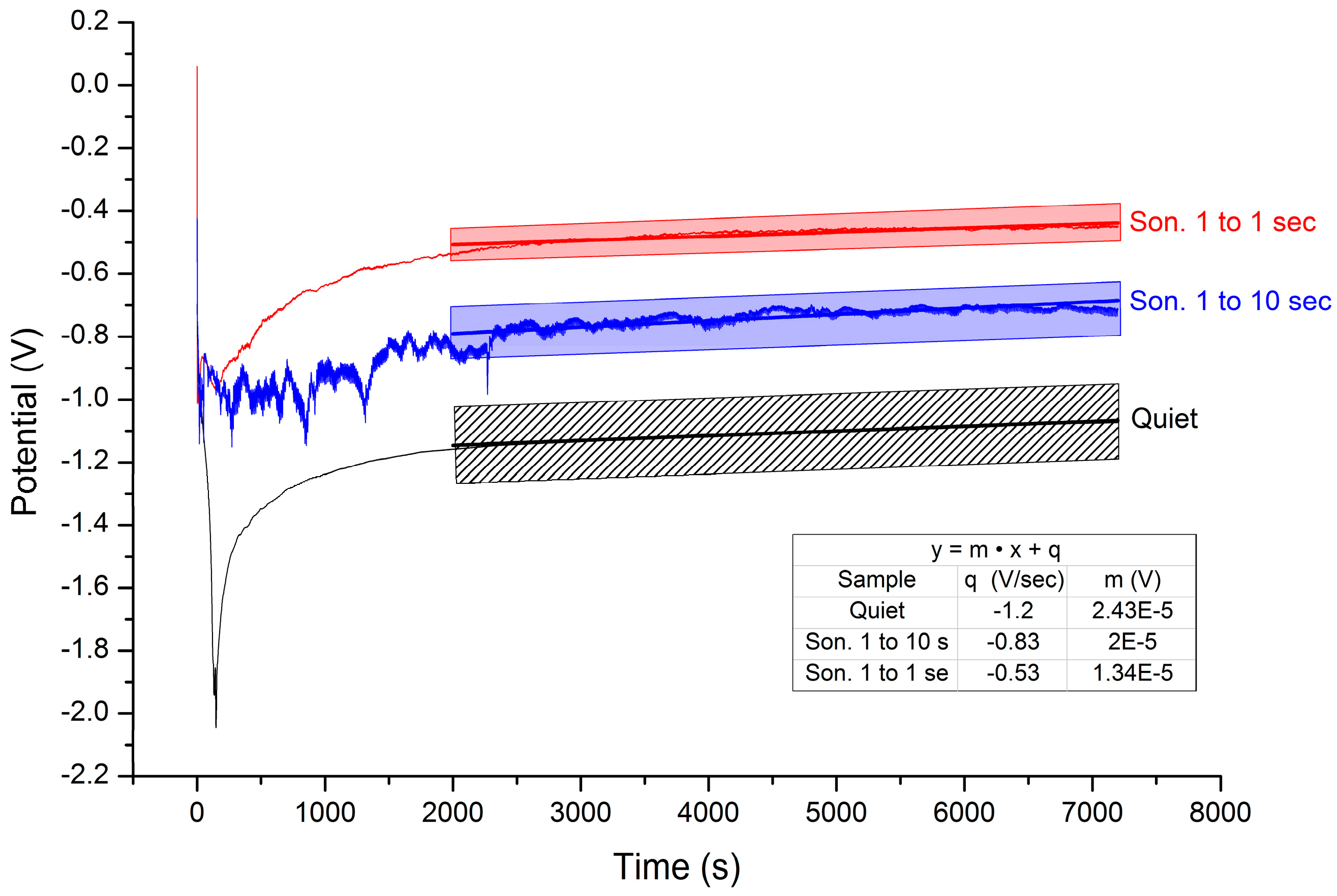

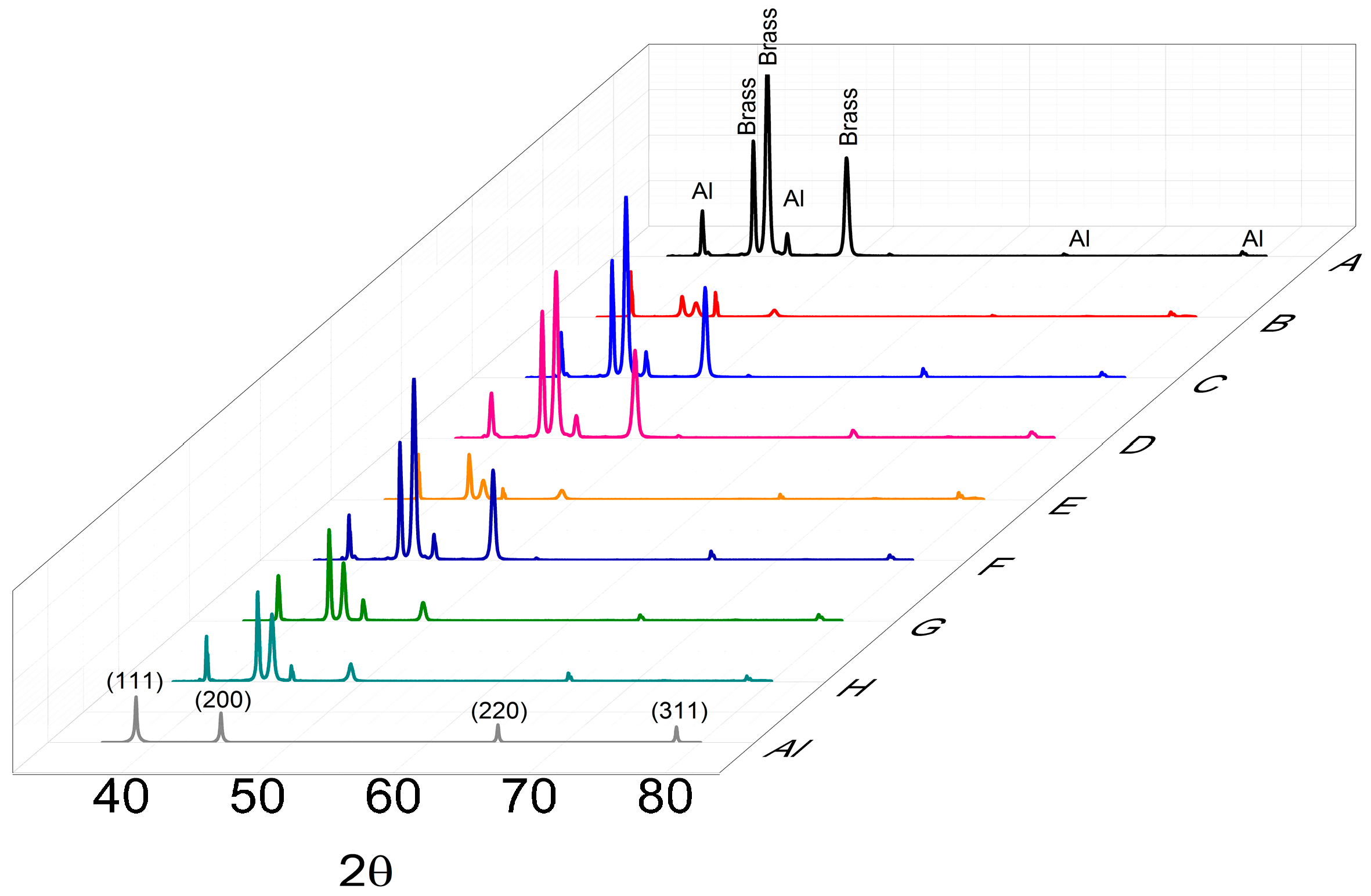

3.2. Effect of Sonication

Corrosion Tests

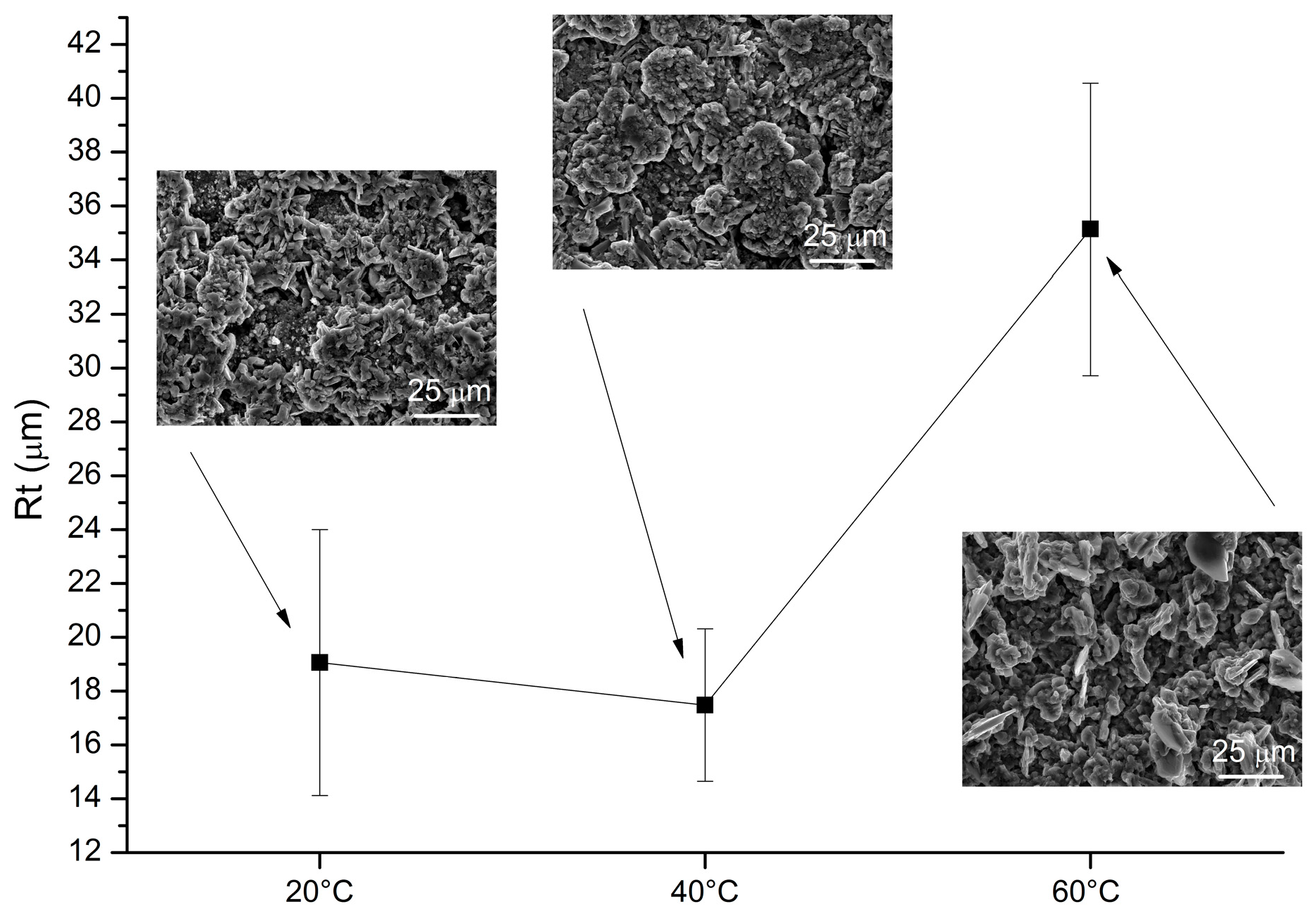

3.3. Combined Effects

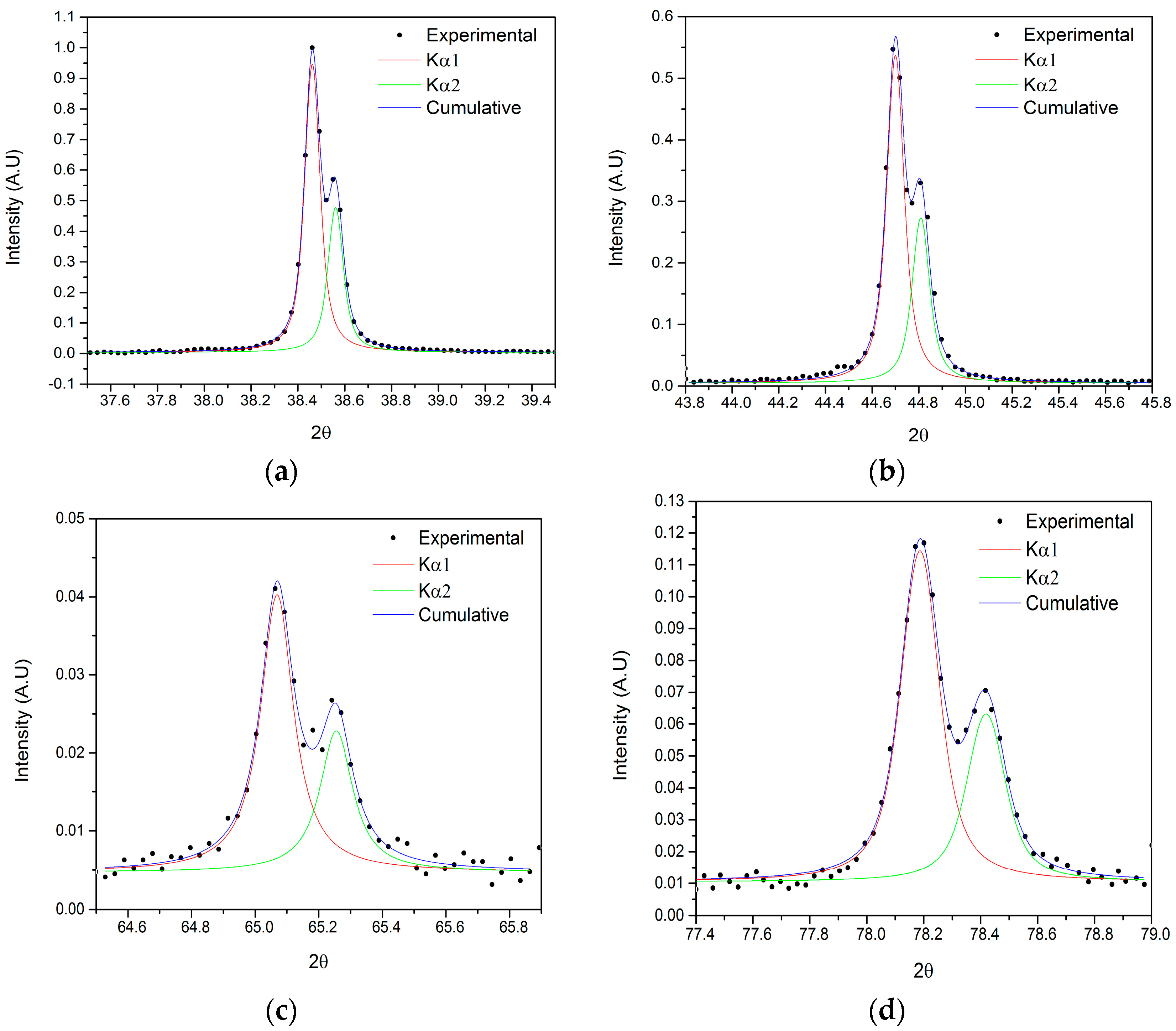

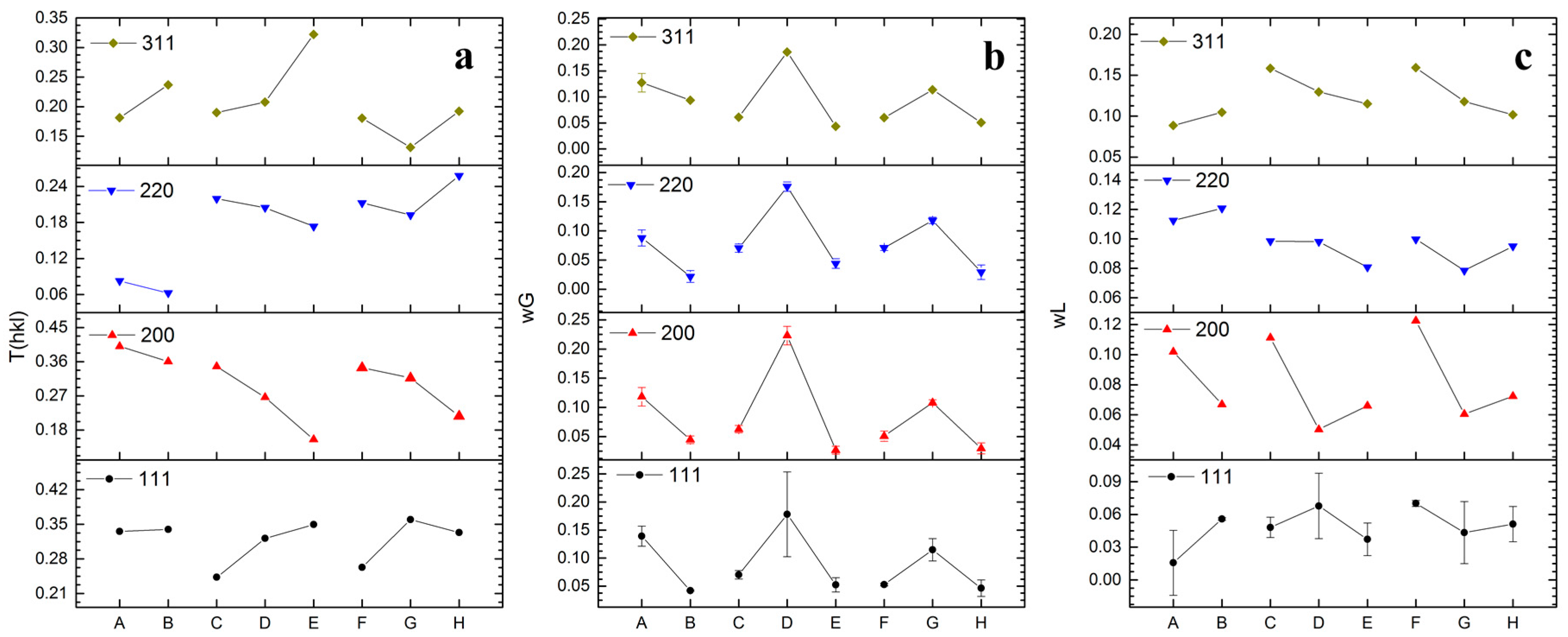

Structural Investigation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| IL | Ionic liquid |

| Bmim | 1-Butyl-3-methyl-imidazolium |

| SCE | Standard calomel electrode |

| WG | Gaussian width |

| WL | Lorentzian width |

| OCP | Open circuit potential |

| PD | potentiodynamic |

Appendix A. Roughness

References

- Grjotheim, K.; Halvor, K. Introduction to Aluminium Electrolysis: Understanding the Hall-Hérloult Process, 2nd ed.; Aluminium-Verlag: Düsseldorf, Germany, 1993. [Google Scholar]

- Markiewicz, M.; Hupka, J.; Joskowska, M.; Jungnickel, C.H. Potential application of ionic liquids in aluminium production—Economical and ecological assessment. Physicochem. Probl. Miner. Process. 2009, 43, 73–84. [Google Scholar]

- Takahashi, S.; Koura, N.; Kohara, S.; Saboungi, M.L.; Curtiss, L. Technological and scientific issues of room-temperature molten salts. Plasmas Ions 1999, 2, 91–105. [Google Scholar] [CrossRef]

- Abbott, A.P.; Harris, R.C.; Hsieh, Y.T.; Ryder, K.S.; Sun, I.W. Aluminium electrodeposition under ambient conditions. Phys. Chem. Chem. Phys. 2014, 16, 14675–14681. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Yoshii, K.; Jiang, X.; Sun, X.G.; Tsuda, T.; Mehio, N.; Dai, S. An AlCl3 based ionic liquid with a neutral substituted pyridine ligand for electrochemical deposition of aluminum. Electrochim. Acta 2015, 160, 82–88. [Google Scholar] [CrossRef]

- Pulletikurthi, G.; Bödecker, B.; Borodin, A.; Weidenfeller, B.; Endres, F. Electrodeposition of Al from a 1-butylpyrrolidine-AlCl3 ionic liquid. Prog. Nat. Sci. Mater. Int. 2015, 25, 603–611. [Google Scholar] [CrossRef]

- Su, C.J.; Hsieh, Y.T.; Chen, C.C.; Sun, I.W. Electrodeposition of aluminium wires from the Lewis acidic AlCl3/trimethylamine hydrochloride ionic liquid without using a template. Electrochem. Commun. 2013, 34, 170–173. [Google Scholar] [CrossRef]

- Endo, A.; Miyake, M.; Hirato, T. Electrodeposition of aluminium from 1,3-dimethyl-2-imidazolidinone/AlCl3 baths. Electrochim. Acta 2014, 137, 470–475. [Google Scholar] [CrossRef]

- Hadi, M.A.; Abood, N.L.D. Morphology of electrodeposited aluminium metal from aluminium chloride-urea room temperature ionic liquid (RTIL) at variable parameter. Int. J. Sci. Res. 2015, 4, 753–760. [Google Scholar]

- Wang, Q.; Chen, B.; Zhang, Q.; Lu, X.; Zhang, S. Aluminium deposition from lewis acidic 1-butyl-3-methylimidazolium chloroaluminate ionic liquid ((Bmim)Cl/AlCl3) modified with methyl nicotinate. ChemElectroChem 2015, 2, 1794–1798. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Q.; Chen, B.; Lu, X.; Zhang, S. Electrodeposition of bright Al coatings from 1-butyl-3-methylimidazolium chloroaluminate ionic liquids with specific additives. J. Electrochem. Soc. 2015, 162, D320–D324. [Google Scholar] [CrossRef]

- Yue, G.; Lu, X.; Zhu, Y.; Zhang, X.; Zhang, S. Surface morphology, crystal structure and orientation of aluminium coatings electrodeposited on mild steel in ionic liquid. Chem. Eng. J. 2009, 147, 79–86. [Google Scholar] [CrossRef]

- Chang, J.K.; Chen, S.Y.; Tsai, W.T.; Deng, M.J.; Sun, I.W. Electrodeposition of aluminium on magnesium alloy in aluminium chloride (AlCl3)–1-ethyl-3-methylimidazolium chloride (EMIC) ionic liquid and its corrosion behavior. Electrochem. Commun. 2007, 9, 1602–1606. [Google Scholar] [CrossRef]

- Bardi, U.; Caporali, S.; Craig, M.; Giorgetti, A.; Perissi, I.; Nicholls, J.R. Electrodeposition of aluminium film on P90 Li–Al alloy as protective coating against corrosion. Surf. Coat. Technol. 2009, 203, 1373–1378. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Zhang, S.; Lu, X.; Wang, Q.; Zuo, Y.; Liu, L. Low-temperature electrodeposition of aluminium from lewis acidic 1-allyl-3-methylimidazolium chloroaluminate ionic liquids. Chin. J. Chem. Eng. 2012, 20, 130–139. [Google Scholar] [CrossRef]

- Guikuan, Y.; Suojiang, Z.; Yanli, Z.; Xingmei, L.; Shucai, L.; Zengxi, L. A promising method for electrodeposition of aluminium on stainless steel in ionic liquid. AIChE J. 2009, 55, 783–796. [Google Scholar]

- Pradhan, D.; Reddy, R.G. Dendrite-free aluminium electrodeposition from AlCl3–1-ethyl-3-methyl-imidazolium chloride ionic liquid electrolytes. Metall. Mater. Trans. B 2012, 43, 519–531. [Google Scholar] [CrossRef]

- Choudhary, R.K.; Kain, V.; Hubli, R.C. Stirring effects on aluminium coatings electrodeposited in ionic liquids. Surf. Eng. 2014, 30, 562–567. [Google Scholar] [CrossRef]

- De Keijser, T.H.; Langford, J.I.; Mittemeijer, E.J.; Vogels, A.B.P. Use of the Voigt function 406 in a single-line method for the analysis of X-ray diffraction line broadening. J. Appl. Crystallogr. 1982, 15, 308–314. [Google Scholar] [CrossRef]

- Scardi, P.; Leoni, M.; Delhez, R. Line broadening analysis using integral breadth methods: A critical review. J. Appl. Crystallogr. 2004, 37, 381–390. [Google Scholar] [CrossRef]

- Balzar, D. Voigt-function model in diffraction line-broadening analysis, in defect and microstructure analysis from diffraction. Int. Union Crystallogr. Monogr. Crystallogr. 1999, 10, 94–126. [Google Scholar]

- Macrae, C.F.; Bruno, I.J.; Chisholm, J.A.; Edgington, P.R.; McCabe, P.; Pidcock, E.; Rodriguez-Monge, L.; Taylor, R.; van de Streek, J.; Wood, P.A. Mercury CSD 2.0—New features for the visualization and investigation of crystal structures. J. Appl. Crystallogr. 2008, 41, 466–470. [Google Scholar] [CrossRef]

- Wyckoff, R.W.G. Crystal Structures; Wiley: New York, NY, USA, 1963; pp. 7–83. [Google Scholar]

- Downs, R.T.; Hall-Wallace, M. The American mineralogist crystal structure database. Am. Mineral. 2003, 88, 247–250. [Google Scholar]

- Costa, C.; Doche, M.; Hihn, J.; Bisel, I.; Moisy, P.; Léveque, J. Hydrodynamic sono-voltammetry of ferrocene in (Tf2N)− based ionic liquid media. Ultrasonics 2010, 50, 323–328. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Dong, K.; Wang, Q.; Zhang, J.; Lu, X. Density, viscosity, and conductivity of lewis acidic 1-butyl- and 1-hydrogen-3-methylimidazolium chloroaluminate ionic liquids. J. Chem. Eng. Data 2013, 58, 32–42. [Google Scholar] [CrossRef]

- Stout, K.J. Surface roughness—Measurement, interpretation and significance of data. Mater. Eng. 1981, 2, 260–265. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

| Sample | Rt (μm) | Ra | RzISO (μm) | Rz (μm) | Yield (%) |

|---|---|---|---|---|---|

| Temp. 50 °C | 32.9 ± 1.2 | 3.7 ± 1.1 | 25.5 ± 4.1 | 23.3 ± 2.8 | 79 |

| Temp. 70 °C | 21.7 ± 10.5 | 2.1 ± 0.2 | 14.9 ± 5.8 | 13.4 ± 4.8 | 86 |

| Temp. 90 °C | 4.2 ± 0.1 | 0.3 ± 0.1 | 3.1 ± 0.1 | 2.90 ± 0.1 | 88 |

| Sample | Rt (μm) | Ra | RzISO (μm) | Rz (μm) | Yield (%) |

|---|---|---|---|---|---|

| Quiet deposit | 4.2 ± 0.3 | 0.4 ± 0.1 | 3.6 ± 0.2 | 3.4 ± 0.2 | 60 |

| Sonication 1 to 10 | 11.7 ± 1.3 | 0.7 ± 0.1 | 8.5 ± 0.8 | 7.2 ± 0.6 | 100 |

| Sonication 1 to 1 | 17.0 ± 1.2 | 1.7 ± 0.1 | 13.6 ± 0.6 | 12.7 ± 0.4 | 100 |

| Yield % | 20 °C | 40 °C | 60 °C |

|---|---|---|---|

| Quiet Deposits | – | A (45%) | B (69%) |

| Stirring 320 RPM | C (82%) | D (100%) | E (100%) |

| Sonication 1 to 10 | F (100%) | G (100%) | H (100%) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berretti, E.; Giaccherini, A.; Martinuzzi, S.M.; Innocenti, M.; Schubert, T.J.S.; Stiemke, F.M.; Caporali, S. Aluminium Electrodeposition from Ionic Liquid: Effect of Deposition Temperature and Sonication †. Materials 2016, 9, 719. https://doi.org/10.3390/ma9090719

Berretti E, Giaccherini A, Martinuzzi SM, Innocenti M, Schubert TJS, Stiemke FM, Caporali S. Aluminium Electrodeposition from Ionic Liquid: Effect of Deposition Temperature and Sonication †. Materials. 2016; 9(9):719. https://doi.org/10.3390/ma9090719

Chicago/Turabian StyleBerretti, Enrico, Andrea Giaccherini, Stefano M. Martinuzzi, Massimo Innocenti, Thomas J.S. Schubert, Frank M. Stiemke, and Stefano Caporali. 2016. "Aluminium Electrodeposition from Ionic Liquid: Effect of Deposition Temperature and Sonication †" Materials 9, no. 9: 719. https://doi.org/10.3390/ma9090719

APA StyleBerretti, E., Giaccherini, A., Martinuzzi, S. M., Innocenti, M., Schubert, T. J. S., Stiemke, F. M., & Caporali, S. (2016). Aluminium Electrodeposition from Ionic Liquid: Effect of Deposition Temperature and Sonication †. Materials, 9(9), 719. https://doi.org/10.3390/ma9090719