Parametric Analysis to Study the Influence of Aerogel-Based Renders’ Components on Thermal and Mechanical Performance

Abstract

:1. Introduction

2. Literature Review

3. Experimental Work

3.1. Render Production

- Pour the air entrainers into a mixing glass;

- Insert the aggregates in the same recipient;

- Pour 80% of the mixing water (when liquid resin was used; otherwise, pour 100% of the water);

- Stir the recipient in the vortex mixer device (model “VWR VV3”) at a moderate speed for 4 min;

- Insert the cement;

- Mix with the drill (at the minimum rotating speed possible) for 1 min;

- Scrape the left-over material and mix manually with a trowel;

- Add the resin previously mixed with 20% of the mixing water (when liquid resin was used);

- Add the rheological agent;

- Mix again with the drill (at the minimum rotating speed possible) for 1 min.

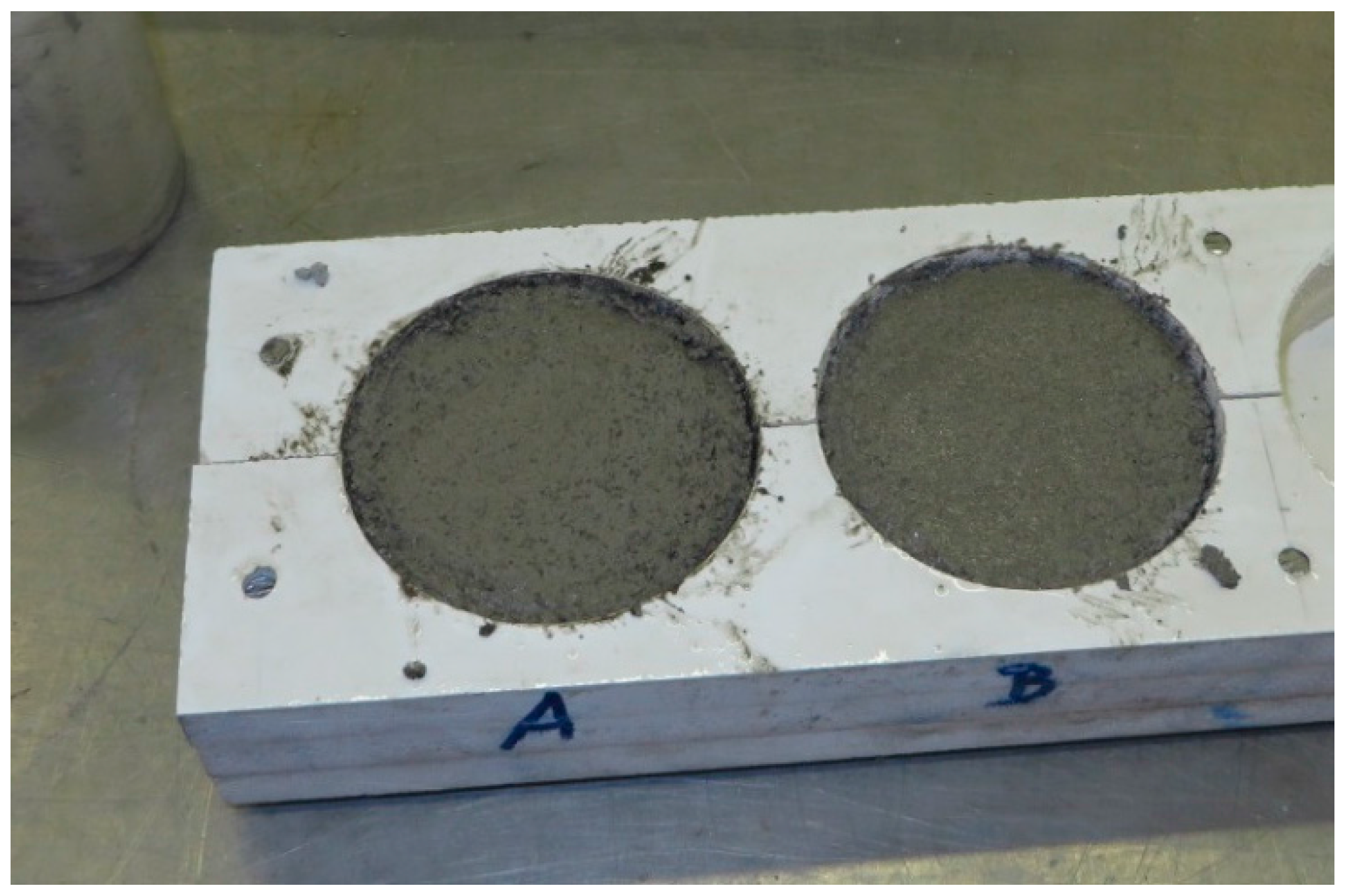

3.2. Thermal Conductivity Test

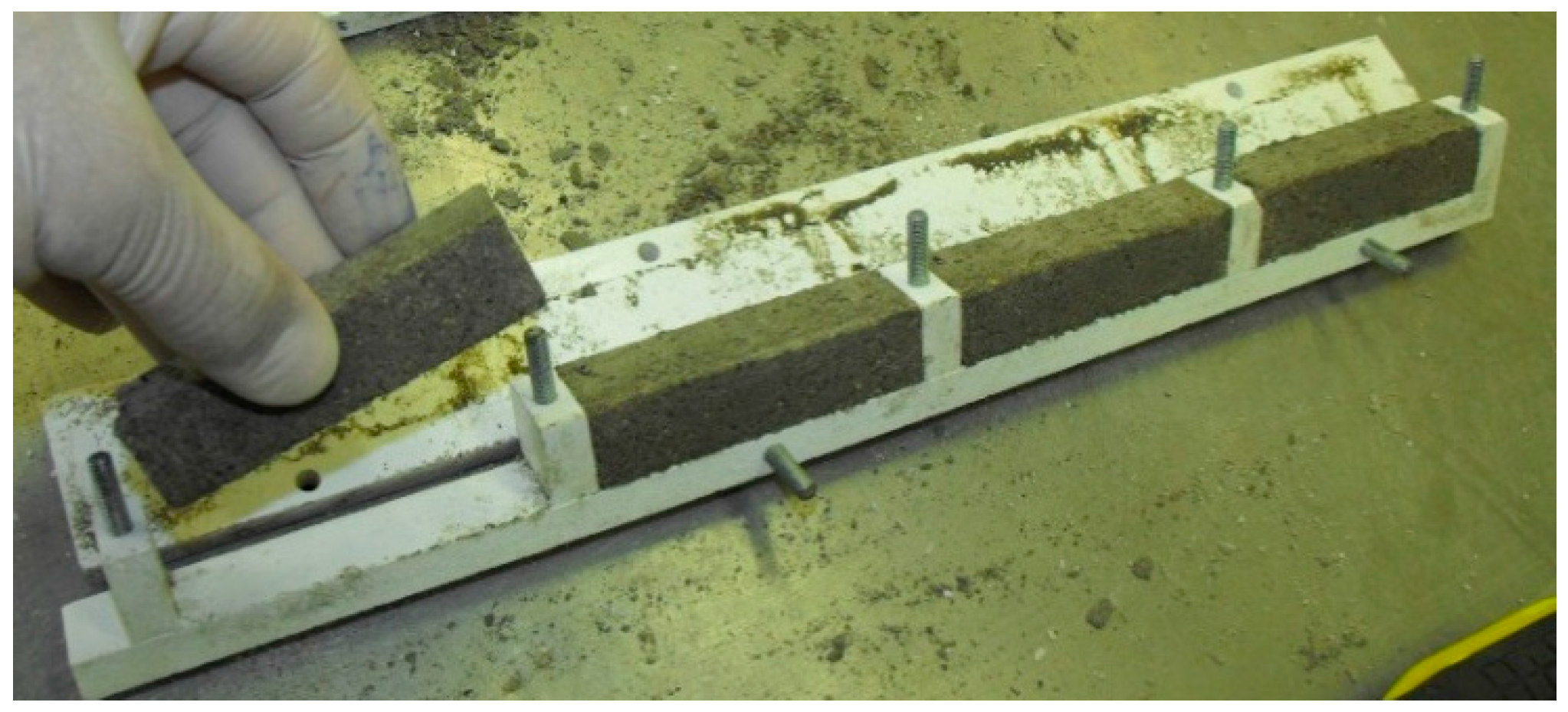

3.3. Compressive Strength

4. Statistical Modelling

4.1. Principles

- r (Pearson correlation coefficient)—measures the correlation degree between variables and ranges from −1 and 1; a correlation coefficient equal to 1 in absolute value indicates a “perfect” linear correlation between the variables (i.e., revealing that all the points in the dataset coincide with the regression line);

- R2 (determination coefficient)—measures the fraction of variability of the dependent variable that may be explained by the obtained regression model;

- Adjusted R2 (adjusted determination coefficient)—the determination coefficient increases as new independent variables are added; thus, the adjusted determination coefficient only increases if the addition of a new variable to the regression model leads to an improvement of its adjustment;

- Standard-error—represents the standard deviation of the error.

4.2. Selected Sample

4.3. Resulting Models

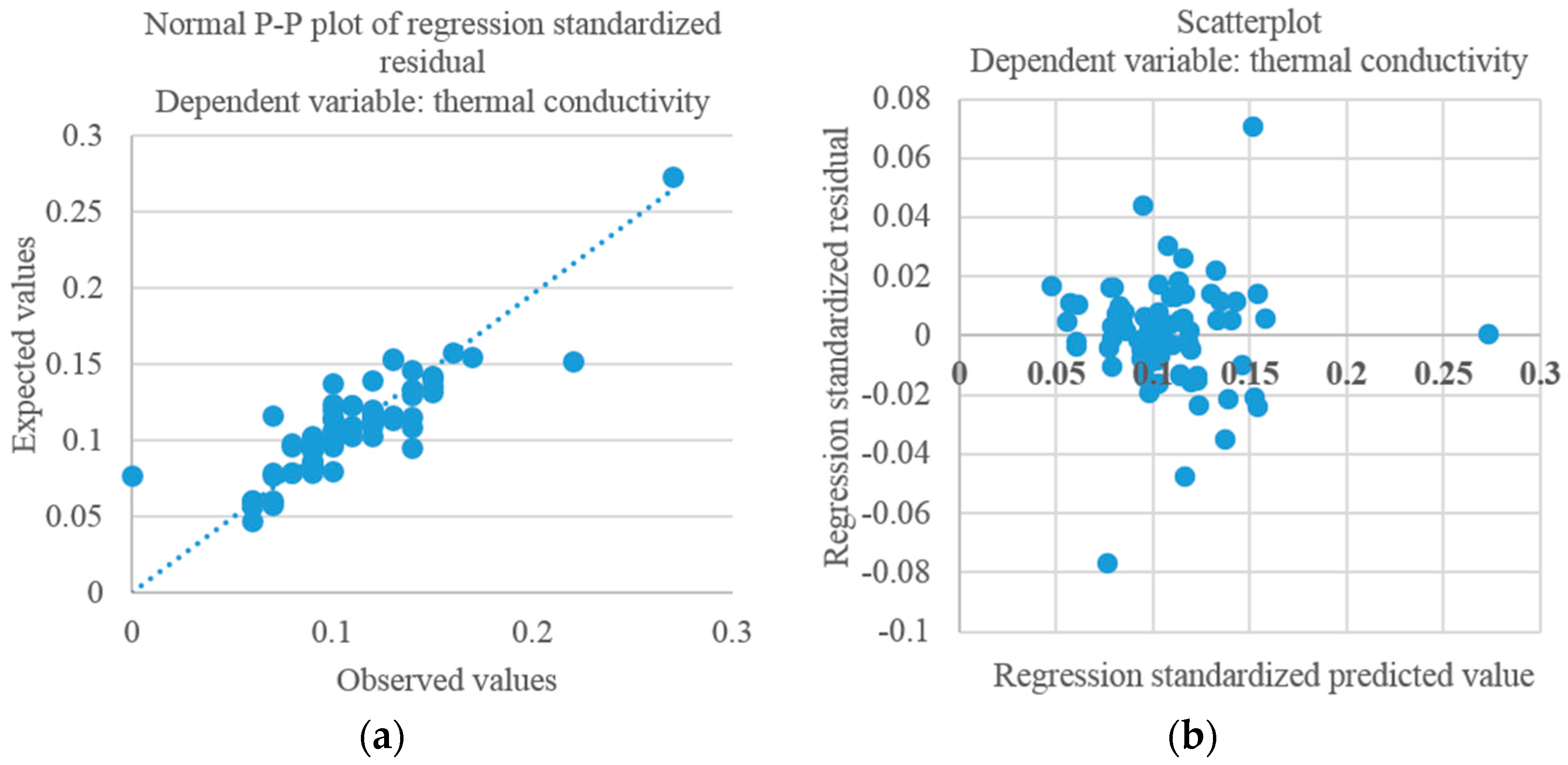

4.3.1. Model 1 (Whole Sample)

4.3.2. Thermal Conductivity of Aerogel-Based Mortars in Function of Aerogel Type

4.3.3. Model 2 (CA3 Aerogel)

4.3.4. Model 3 (HYB-C Aerogel)

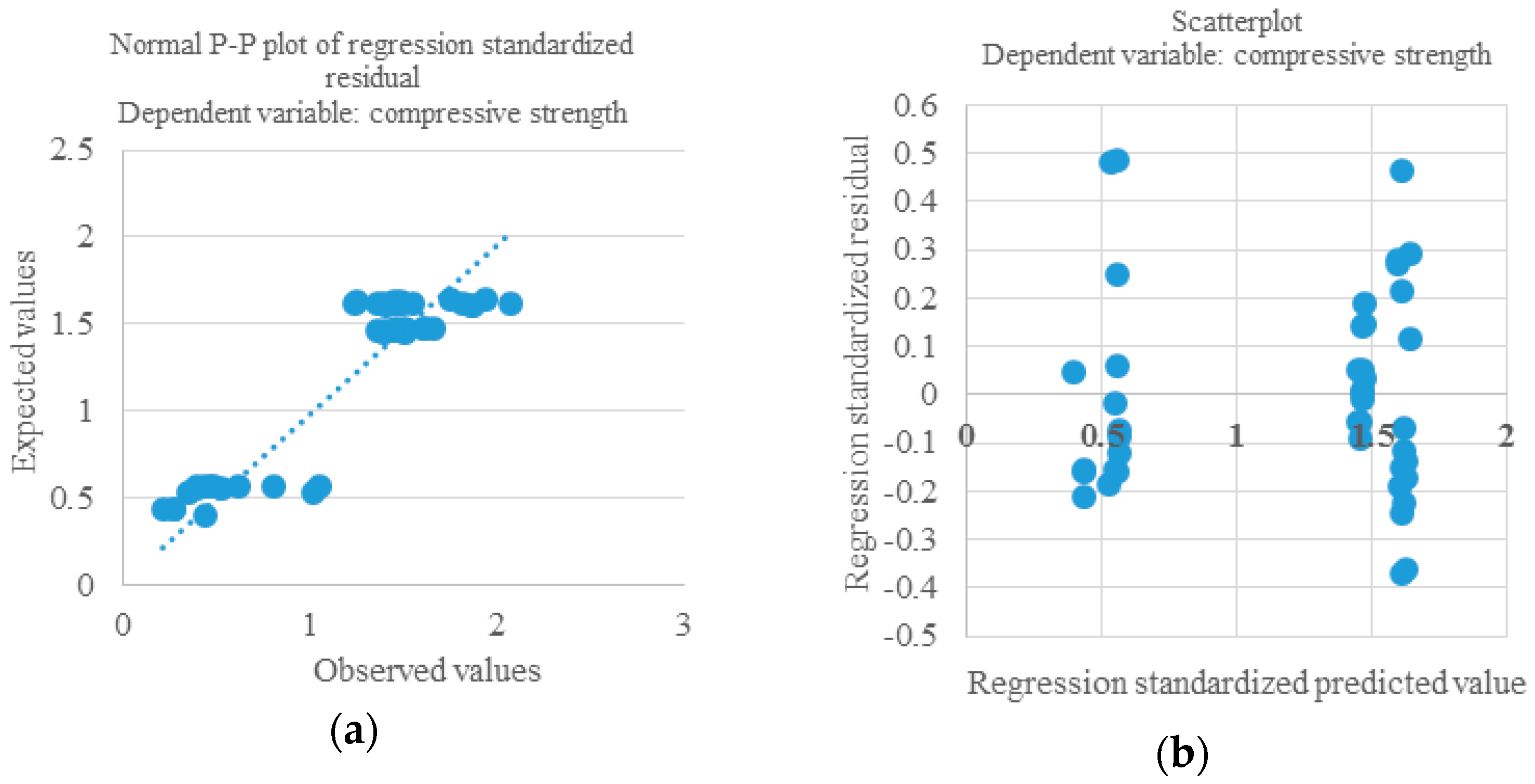

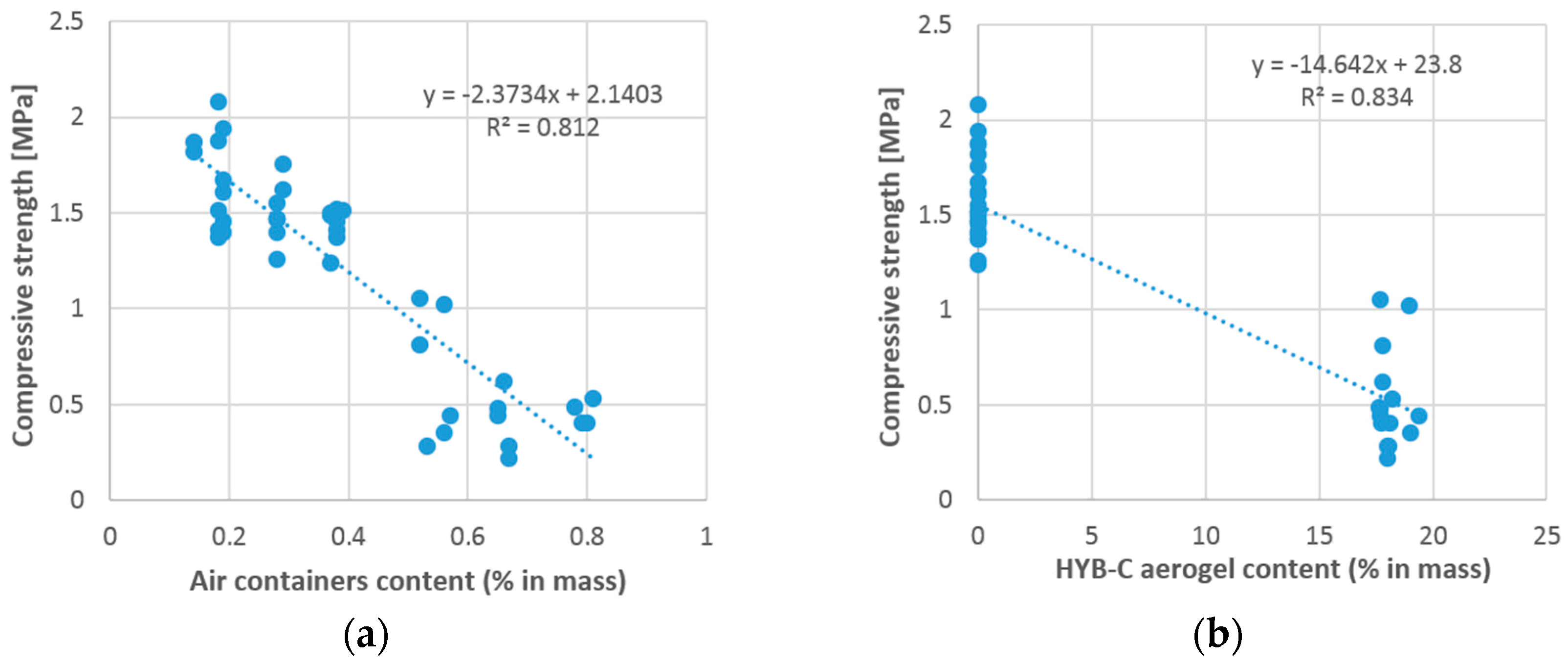

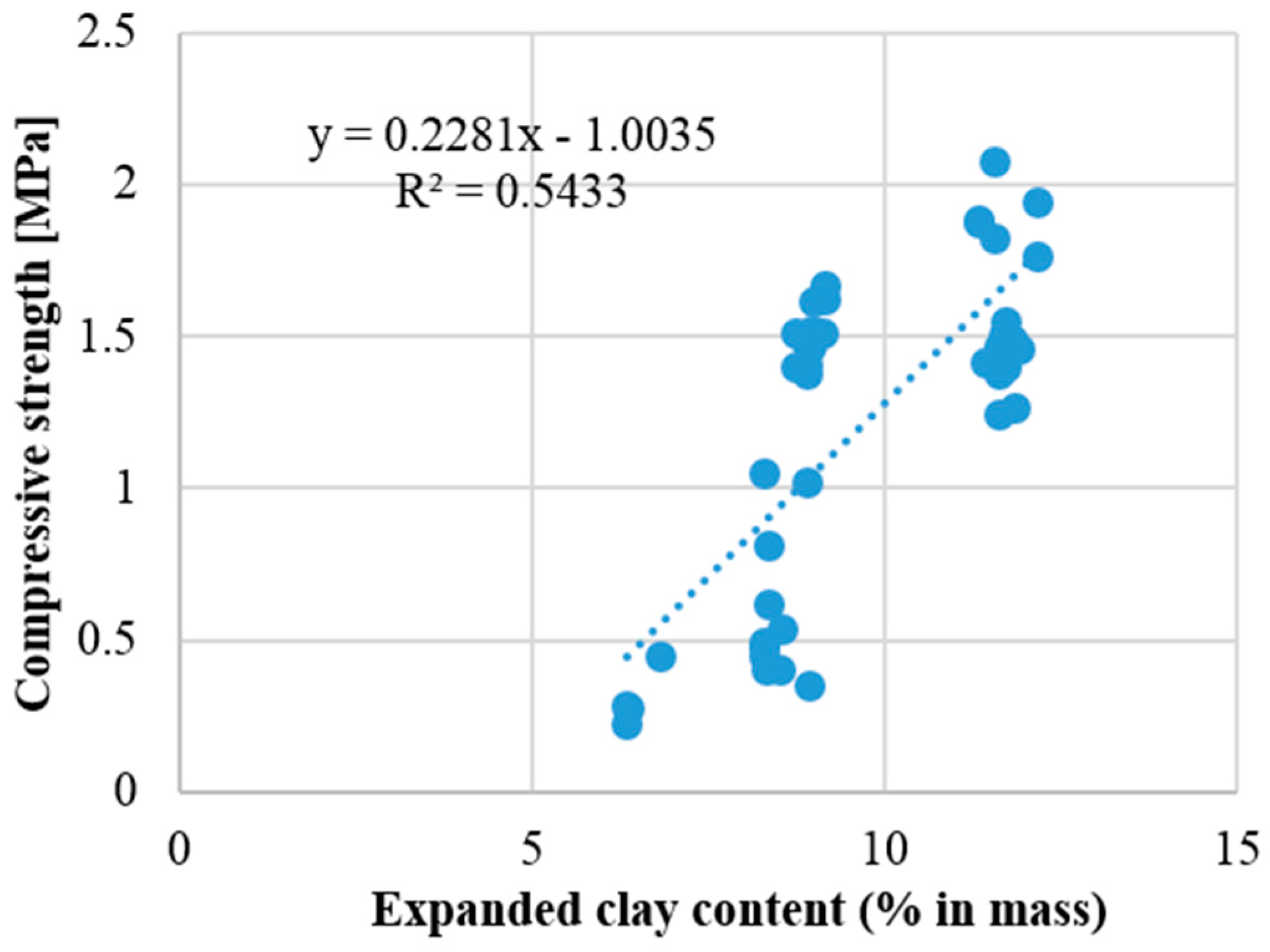

4.3.5. Model 4 (Compressive Strength)

5. Results Discussion

5.1. Influence of the Components on the Thermal Conductivity Coefficient (λ)

5.2. Influence of the Components on Compressive Strength (Cs)

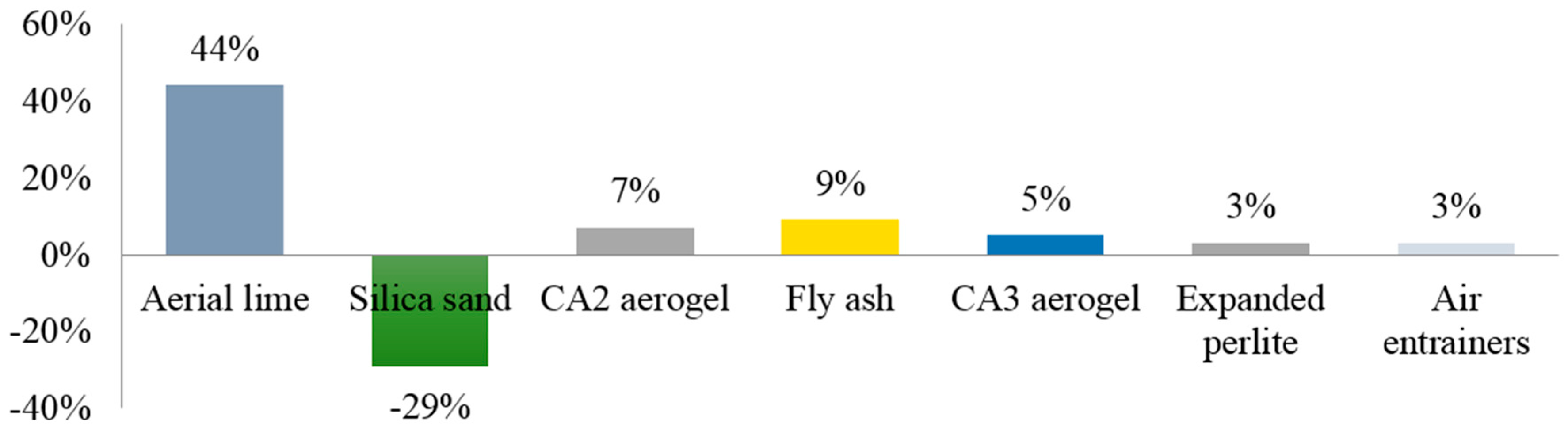

5.3. Relative Importance of the Components

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| MD | CEM II/B-L 32,5N | CEM I 42,5R | CEM I 52,5R | FA | L | W/B | SS | EC | HYB-C | CA1 | CA2 | CA3 | ECG | P | AE | PR | LR | RA | W | λ | Cs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 47.54 | 0 | 0 | 0 | 0 | 0.85 | 0 | 0 | 0 | 0 | 0 | 11.74 | 0 | 0 | 0.24 | 0 | 0 | 0.03 | 40.41 | 0.068 | - |

| 2 | 22.2 | 0 | 0 | 0 | 22.2 | 1 | 0 | 0 | 0 | 0 | 0 | 10.96 | 0 | 0 | 0.22 | 0 | 0 | 0.03 | 44.39 | 0.073 | - |

| 3 | 23.77 | 0 | 0 | 23.77 | 0 | 0.85 | 0 | 0 | 0 | 0 | 0 | 11.74 | 0 | 0 | 0.24 | 0 | 0 | 0.03 | 40.41 | 0.071 | - |

| 4 | 21.26 | 0 | 0 | 4.23 | 17.03 | 1.1 | 0 | 0 | 0 | 0 | 0 | 10.5 | 0 | 0 | 0.21 | 0 | 0 | 0.03 | 46.77 | 0.069 | - |

| 5 | 0 | 0 | 0 | 0 | 39.98 | 1.25 | 0 | 0 | 0 | 0 | 0 | 9.87 | 0 | 0 | 0.2 | 0 | 0 | 0.03 | 49.97 | 0.064 | - |

| 6 | 8.46 | 0 | 0 | 0 | 34.05 | 1.1 | 0 | 0 | 0 | 0 | 0 | 10.5 | 0 | 0 | 0.21 | 0 | 0 | 0.03 | 46.77 | 0.061 | 0.45 |

| 7 | 0 | 8.12 | 0 | 0 | 32.67 | 1.3 | 0 | 0 | 0 | 0 | 0 | 10.07 | 0 | 0 | 0.2 | 0 | 0 | 0.03 | 53.03 | 0.059 | 0.57 |

| 8 | 0 | 0 | 8.12 | 0 | 32.67 | 1.3 | 0 | 0 | 0 | 0 | 0 | 10.07 | 0 | 0 | 0.2 | 0 | 0 | 0.03 | 53.03 | 0.057 | 0.53 |

| 9 | 0 | 0 | 0 | 0 | 41.16 | 1.2 | 0 | 0 | 0 | 0 | 0 | 6.1 | 3.15 | 0 | 0.2 | 0 | 0 | 0.03 | 49.4 | 0.069 | - |

| 10 | 48.77 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 12.07 | 0 | 0 | 0.25 | 0 | 0 | 0 | 39.01 | 0.129 | - |

| 11 | 49.87 | 0 | 0 | 0 | 0 | 0.75 | 0 | 0 | 0 | 0 | 0 | 12.34 | 0 | 0 | 0.25 | 0 | 0 | 0 | 37.41 | 0.131 | - |

| 12 | 51.57 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 0 | 12.76 | 0 | 0 | 0.26 | 0 | 2.62 | 0.04 | 34.03 | 0.125 | - |

| 13 | 48.18 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 11.92 | 0 | 0 | 0.24 | 0 | 2.41 | 0.02 | 38.54 | 0.142 | - |

| 14 | 52.81 | 0 | 0 | 0 | 0 | 0.61 | 0 | 0 | 0 | 0 | 12.54 | 0 | 0 | 0 | 0.27 | 0 | 5.28 | 0.04 | 32.21 | 0.092 | - |

| 15 | 51.2 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.15 | 0 | 0 | 0 | 0.26 | 0 | 5.12 | 0.04 | 33.79 | 0.091 | - |

| 16 | 51.98 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.05 | 0 | 0 | 0 | 0.26 | 0 | 2.64 | 0.04 | 34.31 | 0.140 | - |

| 17 | 53.11 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 7.4 | 0 | 4.08 | 0 | 0.27 | 0 | 0 | 0 | 35.05 | 0.117 | - |

| 18 | 50.54 | 0 | 0 | 0 | 0 | 0.76 | 0 | 0 | 0 | 0 | 7.04 | 0 | 3.88 | 0 | 0.26 | 0 | 0 | 0 | 38.41 | 0.104 | - |

| 19 | 47.37 | 0 | 0 | 0 | 0 | 0.86 | 0 | 0 | 0 | 0 | 6.6 | 0 | 3.64 | 0 | 0.24 | 0 | 2.88 | 0.04 | 40.74 | 0.109 | - |

| 20 | 46.48 | 0 | 0 | 0 | 0 | 0.86 | 0 | 0 | 0 | 0 | 6.48 | 0 | 3.57 | 0 | 0.23 | 0 | 4.71 | 0.04 | 39.97 | 0.108 | - |

| 21 | 46.05 | 0 | 0 | 0 | 0 | 0.86 | 0 | 0 | 0 | 0 | 6.42 | 0 | 3.54 | 0 | 0.23 | 0 | 8.37 | 0.03 | 39.6 | 0.100 | - |

| 22 | 50.45 | 0 | 0 | 0 | 0 | 0.81 | 0 | 0 | 0 | 0 | 7.03 | 0 | 0 | 0 | 0.25 | 0 | 2.52 | 0.04 | 40.87 | 0.115 | - |

| 23 | 39.32 | 0 | 0 | 0 | 0 | 0.76 | 0 | 25.22 | 0 | 0 | 5.48 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 29.88 | 0.144 | - |

| 24 | 36.41 | 0 | 0 | 0 | 0 | 0.86 | 0 | 23.36 | 0 | 0 | 5.08 | 0 | 0 | 0 | 0.18 | 0 | 3.68 | 0.03 | 31.32 | 0.154 | - |

| 25 | 52.94 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 34.94 | 0.100 | - |

| 26 | 52.93 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.3 | 0 | 0 | 0 | 0.01 | 0 | 0 | 0 | 34.94 | 0.111 | - |

| 27 | 52.93 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.3 | 0 | 0 | 0 | 0.03 | 0 | 0 | 0 | 34.93 | 0.104 | - |

| 28 | 52.91 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.29 | 0 | 0 | 0 | 0.05 | 0 | 0 | 0 | 34.92 | 0.093 | - |

| 29 | 52.8 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 0 | 12.27 | 0 | 0 | 0 | 0.27 | 0 | 0 | 0 | 34.85 | 0.086 | - |

| 30 | 36.72 | 0 | 0 | 0 | 0 | 0.95 | 0 | 0 | 24.84 | 0 | 0 | 0 | 2.81 | 0 | 0.73 | 0 | 0 | 0.03 | 34.89 | 0.103 | - |

| 31 | 29.56 | 0 | 0 | 0 | 0 | 1.05 | 0 | 18.81 | 19.99 | 0 | 0 | 0 | 0 | 0 | 0.59 | 0 | 0 | 0.02 | 31.04 | 0.154 | - |

| 32 | 21.43 | 0 | 0 | 0 | 0 | 1 | 42.2 | 0 | 14.49 | 0 | 0 | 0 | 0 | 0 | 0.43 | 0 | 0 | 0.02 | 21.43 | 0.273 | - |

| 33 | 32.93 | 0 | 0 | 0 | 0 | 0.9 | 0 | 0 | 37.22 | 0 | 0 | 0 | 0 | 0 | 0.25 | 0 | 0 | 0 | 29.64 | 0.169 | - |

| 34 | 30.85 | 0 | 0 | 0 | 0 | 1.1 | 0 | 0 | 34.87 | 0 | 0 | 0 | 0 | 0 | 0.31 | 0 | 0 | 0.02 | 33.93 | 0.223 | - |

| 35 | 29.94 | 0 | 0 | 0 | 0 | 1.2 | 0 | 0 | 33.84 | 0 | 0 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 35.92 | 0.132 | - |

| 36 | 31.79 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 35.93 | 0 | 0 | 0 | 0 | 0 | 0.48 | 0 | 0 | 0 | 31.79 | 0.137 | - |

| 37 | 31.74 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 35.88 | 0 | 0 | 0 | 0 | 0 | 0.64 | 0 | 0 | 0 | 31.74 | 0.146 | - |

| 38 | 33.92 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 38.34 | 0 | 0 | 0 | 0 | 0 | 0.69 | 0 | 0 | 0 | 27.13 | 0.118 | - |

| 39 | 31.69 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 35.82 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 31.69 | 0.147 | - |

| 40 | 33.86 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 38.27 | 0 | 0 | 0 | 0 | 0 | 0.85 | 0 | 0 | 0 | 27.09 | 0.139 | - |

| 41 | 29.76 | 0 | 0 | 0 | 0 | 1.2 | 0 | 0 | 33.6 | 0 | 0 | 0 | 0 | 0 | 0.15 | 0 | 1.51 | 0.02 | 35.71 | 0.164 | - |

| 42 | 0 | 14.07 | 0 | 2.82 | 11.25 | 1.5 | 0 | 8.96 | 19.04 | 0 | 0 | 0 | 1.08 | 0 | 0.56 | 0 | 0 | 0.02 | 42.2 | 0.121 | 0.35 |

| 43 | 0 | 14.31 | 0 | 2.86 | 11.44 | 1.5 | 0 | 6.83 | 19.37 | 0 | 0 | 0 | 1.1 | 0.58 | 0.57 | 0 | 0 | 0.02 | 42.93 | 0.120 | 0.44 |

| 44 | 0 | 13.99 | 0 | 2.8 | 11.19 | 1.5 | 0 | 8.91 | 18.94 | 0 | 0 | 0 | 1.07 | 0 | 0.56 | 0.56 | 0 | 0.02 | 41.97 | 0.130 | 1.02 |

| 45 | 0 | 13.14 | 0 | 2.63 | 10.51 | 1.75 | 0 | 8.37 | 17.79 | 0 | 0 | 0 | 1.01 | 0 | 0.52 | 0 | 0 | 0.04 | 45.98 | 0.115 | 0.81 |

| 46 | 0 | 13.34 | 0 | 2.67 | 10.67 | 1.75 | 0 | 6.37 | 18.07 | 0 | 0 | 0 | 1.02 | 0.54 | 0.53 | 0 | 0 | 0.04 | 46.7 | 0.104 | 0.28 |

| 47 | 0 | 13.07 | 0 | 2.62 | 10.45 | 1.75 | 0 | 8.32 | 17.69 | 0 | 0 | 0 | 1 | 0 | 0.52 | 0.52 | 0 | 0.04 | 45.74 | 0.121 | 1.05 |

| 48 | 0 | 13.12 | 0 | 2.63 | 10.5 | 1.75 | 0 | 8.36 | 17.77 | 0 | 0 | 0 | 1.01 | 0 | 0.66 | 0 | 0 | 0.02 | 45.93 | 0.101 | 0.62 |

| 49 | 0 | 13.33 | 0 | 2.67 | 10.66 | 1.75 | 0 | 6.37 | 18.04 | 0 | 0 | 0 | 1.02 | 0.54 | 0.67 | 0 | 0 | 0.02 | 46.65 | 0.101 | 0.28 |

| 50 | 0 | 13.06 | 0 | 2.61 | 10.45 | 1.75 | 0 | 8.32 | 17.68 | 0 | 0 | 0 | 1 | 0 | 0.65 | 0.52 | 0 | 0.02 | 45.71 | 0.120 | 0.44 |

| 51 | 0 | 13.12 | 0 | 2.63 | 10.49 | 1.75 | 0 | 8.36 | 17.76 | 0 | 0 | 0 | 1.01 | 0 | 0.66 | 0 | 0 | 0.04 | 45.92 | 0.100 | - |

| 52 | 0 | 13.33 | 0 | 2.67 | 10.66 | 1.75 | 0 | 6.37 | 18.04 | 0 | 0 | 0 | 1.02 | 0.54 | 0.67 | 0 | 0 | 0.04 | 46.64 | 0.094 | 0.22 |

| 53 | 0 | 13.05 | 0 | 2.61 | 10.44 | 1.75 | 0 | 8.31 | 17.67 | 0 | 0 | 0 | 1 | 0 | 0.65 | 0.52 | 0 | 0.04 | 45.68 | 0.119 | 0.48 |

| 54 | 0 | 13.46 | 0 | 2.69 | 10.77 | 1.65 | 0 | 8.57 | 18.22 | 0 | 0 | 0 | 1.03 | 0 | 0.81 | 0 | 0 | 0.02 | 44.42 | 0.139 | 0.53 |

| 55 | 0 | 13.39 | 0 | 2.68 | 10.71 | 1.65 | 0 | 8.52 | 18.12 | 0 | 0 | 0 | 1.03 | 0 | 0.8 | 0.53 | 0 | 0.02 | 44.18 | 0.112 | 0.40 |

| 56 | 0 | 13.1 | 0 | 2.62 | 10.48 | 1.75 | 0 | 8.34 | 17.74 | 0 | 0 | 0 | 1 | 0 | 0.79 | 0 | 0 | 0.04 | 45.86 | 0.123 | 0.40 |

| 57 | 0 | 13.03 | 0 | 2.61 | 10.42 | 1.75 | 0 | 8.3 | 17.64 | 0 | 0 | 0 | 1 | 0 | 0.78 | 0.52 | 0 | 0.04 | 45.62 | 0.107 | 0.49 |

| 58 | 51.01 | 0 | 0 | 0 | 0 | 0.66 | 0 | 0 | 0 | 13.71 | 0 | 0 | 0 | 0 | 0.26 | 0 | 2.59 | 0.04 | 33.66 | 0.130 | - |

| 59 | 0 | 19.12 | 0 | 3.83 | 15.3 | 1.1 | 0 | 12.18 | 0 | 0 | 0 | 5.67 | 1.47 | 0 | 0.19 | 0 | 0 | 0.03 | 42.07 | 0.104 | 1.94 |

| 60 | 0 | 18.42 | 0 | 3.69 | 14.73 | 1.2 | 0 | 11.73 | 0 | 0 | 0 | 5.46 | 1.41 | 0 | 0.19 | 0 | 0 | 0.05 | 44.21 | 0.102 | 1.40 |

| 61 | 0 | 19.12 | 0 | 3.83 | 15.29 | 1.1 | 0 | 12.17 | 0 | 0 | 0 | 5.67 | 1.47 | 0 | 0.29 | 0 | 0 | 0.03 | 42.06 | 0.103 | 1.76 |

| 62 | 0 | 18.4 | 0 | 3.68 | 14.72 | 1.2 | 0 | 11.72 | 0 | 0 | 0 | 5.46 | 1.41 | 0 | 0.28 | 0 | 0 | 0.05 | 44.17 | 0.101 | 1.55 |

| 63 | 0 | 18.74 | 0 | 3.75 | 14.99 | 1.15 | 0 | 11.93 | 0 | 0 | 0 | 5.56 | 1.44 | 0 | 0.38 | 0 | 0 | 0.03 | 43.1 | 0.09 | 1.46 |

| 64 | 0 | 18.39 | 0 | 3.68 | 14.71 | 1.2 | 0 | 11.71 | 0 | 0 | 0 | 5.45 | 1.41 | 0 | 0.37 | 0 | 0 | 0.05 | 44.13 | 0.089 | 1.50 |

| 65 | 0 | 18.29 | 0 | 3.66 | 14.63 | 1.2 | 0 | 11.65 | 0 | 0 | 0 | 5.43 | 1.4 | 0 | 0.18 | 0.73 | 0 | 0.03 | 43.91 | 0.086 | 1.37 |

| 66 | 0 | 17.96 | 0 | 3.59 | 14.36 | 1.25 | 0 | 11.44 | 0 | 0 | 0 | 5.33 | 1.38 | 0 | 0.18 | 0.72 | 0 | 0.05 | 44.9 | 0.096 | 1.41 |

| 67 | 0 | 18.62 | 0 | 3.73 | 14.89 | 1.15 | 0 | 11.85 | 0 | 0 | 0 | 5.52 | 1.43 | 0 | 0.28 | 0.74 | 0 | 0.03 | 42.82 | 0.079 | 1.26 |

| 68 | 0 | 18.27 | 0 | 3.66 | 14.61 | 1.2 | 0 | 11.63 | 0 | 0 | 0 | 5.42 | 1.4 | 0 | 0.28 | 0.73 | 0 | 0.05 | 43.85 | 0.09 | 1.47 |

| 69 | 0 | 18.6 | 0 | 3.72 | 14.88 | 1.15 | 0 | 11.84 | 0 | 0 | 0 | 5.52 | 1.43 | 0 | 0.37 | 0.74 | 0 | 0.03 | 42.78 | 0.086 | 1.49 |

| 70 | 0 | 18.25 | 0 | 3.65 | 14.6 | 1.2 | 0 | 11.62 | 0 | 0 | 0 | 5.41 | 1.4 | 0 | 0.37 | 0.73 | 0 | 0.05 | 43.81 | 0.082 | 1.24 |

| 71 | 0 | 19.2 | 0 | 3.84 | 15.36 | 1.15 | 0 | 9.17 | 0 | 0 | 0 | 5.7 | 1.47 | 0.78 | 0.19 | 0 | 0 | 0.03 | 44.16 | 0.093 | 1.67 |

| 72 | 0 | 18.83 | 0 | 3.77 | 15.06 | 1.2 | 0 | 9 | 0 | 0 | 0 | 5.59 | 1.44 | 0.77 | 0.19 | 0 | 0 | 0.05 | 45.2 | 0.089 | 1.61 |

| 73 | 0 | 19.18 | 0 | 3.84 | 15.34 | 1.15 | 0 | 9.16 | 0 | 0 | 0 | 5.69 | 1.47 | 0.78 | 0.29 | 0 | 0 | 0.03 | 44.12 | 0.097 | 1.62 |

| 74 | 0 | 18.81 | 0 | 3.77 | 15.05 | 1.2 | 0 | 8.99 | 0 | 0 | 0 | 5.58 | 1.44 | 0.77 | 0.28 | 0 | 0 | 0.05 | 45.15 | 0.089 | 1.47 |

| 75 | 0 | 18.8 | 0 | 3.76 | 15.03 | 1.2 | 0 | 8.98 | 0 | 0 | 0 | 5.58 | 1.44 | 0.76 | 0.38 | 0 | 0 | 0.05 | 45.11 | 0.095 | 1.52 |

| 76 | 0 | 18.7 | 0 | 3.74 | 14.95 | 1.2 | 0 | 8.93 | 0 | 0 | 0 | 5.55 | 1.43 | 0.76 | 0.19 | 0.75 | 0 | 0.03 | 44.87 | 0.094 | 1.46 |

| 77 | 0 | 18.35 | 0 | 3.67 | 14.67 | 1.25 | 0 | 8.76 | 0 | 0 | 0 | 5.44 | 1.41 | 0.75 | 0.18 | 0.73 | 0 | 0.05 | 45.86 | 0.088 | 1.51 |

| 78 | 0 | 18.68 | 0 | 3.74 | 14.94 | 1.25 | 0 | 8.92 | 0 | 0 | 0 | 5.54 | 1.43 | 0.76 | 0.28 | 0.75 | 0 | 0.03 | 46.7 | 0.087 | 1.47 |

| 79 | 0 | 18.33 | 0 | 3.67 | 14.66 | 1.25 | 0 | 8.76 | 0 | 0 | 0 | 5.44 | 1.41 | 0.75 | 0.28 | 0.73 | 0 | 0.05 | 45.82 | 0.091 | 1.40 |

| 80 | 0 | 18.66 | 0 | 3.73 | 14.93 | 1.2 | 0 | 8.91 | 0 | 0 | 0 | 5.54 | 1.43 | 0.76 | 0.38 | 0.75 | 0 | 0.03 | 44.79 | 0.079 | 1.37 |

| 81 | 0 | 18.66 | 0 | 3.73 | 14.92 | 1.2 | 0 | 8.91 | 0 | 0 | 0 | 5.53 | 1.43 | 0.76 | 0.38 | 0.75 | 0 | 0.05 | 44.77 | 0.082 | 1.41 |

| 82 | 0 | 18.16 | 0 | 3.63 | 14.52 | 1.2 | 0 | 11.56 | 0 | 0 | 0 | 5.39 | 1.39 | 0 | 0.18 | 1.45 | 0 | 0.03 | 43.58 | 0.103 | 2.08 |

| 83 | 0 | 17.83 | 0 | 3.57 | 14.26 | 1.25 | 0 | 11.35 | 0 | 0 | 0 | 5.29 | 1.37 | 0 | 0.18 | 1.42 | 0 | 0.05 | 44.57 | 0.100 | 1.88 |

| 84 | 0 | 18.17 | 0 | 3.64 | 14.53 | 1.2 | 0 | 11.57 | 0 | 0 | 0 | 5.39 | 1.39 | 0 | 0.14 | 1.45 | 0 | 0.03 | 43.6 | 0.100 | 1.82 |

| 85 | 0 | 17.83 | 0 | 3.57 | 14.26 | 1.25 | 0 | 11.36 | 0 | 0 | 0 | 5.29 | 1.37 | 0 | 0.14 | 1.43 | 0 | 0.05 | 44.58 | 0.104 | 1.87 |

References

- Garrido, R.; Silvestre, J.; Flores-Colen, I. Economic life cycle assessment of thermal renders. In Proceedings of the 3rd European Mortar Summit 2015 Conference, Lisbon, Portugal, 21–22 May 2015.

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-based thermal superinsulation: An overview. J. Sol Gel Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef]

- Matias, G.; Faria, P.; Torres, I. Lime mortars with ceramic wastes: Characterization of components and their influence on the mechanical behavior. Constr. Build. Mater. 2014, 73, 523–534. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Behaviour of cementitious mortars containing different kinds of recycled aggregate. Constr. Build. Mater. 2009, 23, 289–294. [Google Scholar] [CrossRef]

- Brás, A.; Gomes, V. LCA implementation in the selection of thermal enhanced mortars for energetic rehabilitation of school buildings. Energy Build. 2015, 92, 1–9. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.; Metaxa, Z.; Shah, S. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Lucolano, F.; Liguori, B.; Caputo, D.; Colangelo, F.; Cioffi, R. Recycled plastic aggregate in mortars composition: Effect on physical and mechanical properties. Mater. Des. 2013, 52, 916–922. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Ayuso, J.; López, M.; Fernández, J.M.; de Brito, J. Use of fine recycled aggregates from ceramic waste in masonry mortar manufacturing. Constr. Build. Mater. 2013, 40, 679–690. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical behavior of masonry assemblages manufactured with recycled-aggregate mortars. Cem. Concr. Compos. 2009, 31, 505–510. [Google Scholar] [CrossRef]

- Demirboğa, R. Thermo-mechanical properties of sand and high volume mineral admixtures. Energy Build. 2003, 35, 435–439. [Google Scholar] [CrossRef]

- Ibrahim, M.; Wurtz, E.; Biwole, P.H. Hygrothermal performance of exterior walls covered with aerogel-based insulating rendering. Energy Build. 2014, 84, 241–251. [Google Scholar] [CrossRef]

- Directive 2002/91/EC of European Parliament and of the Council of 16 December 2002 on the Energy Performance of Buildings; 4.1.2003, L 1/65-L 1/71; European Union: Brussels, Belgium, 2002.

- Directive 2010/31/EU of European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings; 18.6.2010, L 153/13-L 153/35; European Union: Brussels, Belgium, 2010.

- CEN (Comité Européen de Normalisation). Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar; EN 998-1; CEN: Brussels, Belgium, 2011. [Google Scholar]

- Hanus, M.; Harris, A. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 2013, 58, 1056–1102. [Google Scholar] [CrossRef]

- Shekari, A.; Razzaghi, M. Influence of nanoparticles on durability and mechanical properties of high performance concrete. Procedia Eng. 2011, 14, 3036–3041. [Google Scholar] [CrossRef]

- Stahl, T.; Brunner, S.; Zimmermann, M.; Ghazi Wakili, K. Thermo-hygric properties of a newly developed aerogel based insulation rendering for both exterior and interior applications. Energy Build. 2012, 44, 114–117. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Fasihi, A.; Balalaei, F.; Haghi, A.K. Investigation of mechanical and physical properties of mortars containing silica fume and nano-SiO2. In Proceedings of the Third International Conference on Concrete and Development, Tehran, Iran, 27–29 April 2009; Building and Housing Research Center: Tehran, Iran, 2009; pp. 1153–1161. [Google Scholar]

- Soares, A.; Júlio, M.; Flores-Colen, I.; Ilharco, L.; de Brito, J.; Martinho, J. Water-resistance of mortars with lightweight aggregates. Key Eng. Mater. 2015, 634, 46–53. [Google Scholar] [CrossRef]

- Panesar, D.K.; Shindman, B. The mechanical, transport and thermal properties of mortar and concrete containing waste cork. Cem. Concr. Compos. 2012, 34, 982–992. [Google Scholar] [CrossRef]

- Bartolini, R.; Filippozzib, S.; Princib, E.; Schenonea, C.; Vicini, S. Acoustic and mechanical properties of expanded clay granulates consolidated by epoxy resin. Appl. Clay Sci. 2010, 48, 460–465. [Google Scholar] [CrossRef]

- Kalhori, E.M.; Yetilmezsoyb, K.; Uygurc, N.; Zarrabia, M.; Shmeis, R. Modeling of adsorption of toxic chromium on natural and surface modified lightweight expanded clay aggregate (LECA). Appl. Surf. Sci. 2013, 287, 428–442. [Google Scholar] [CrossRef]

- Rashad, A. A brief on high-volume Class F fly ash as cement replacement—A guide for Civil Engineer. Int. J. Sustain. Built Environ. 2015, 12, 278–306. [Google Scholar] [CrossRef]

- Torres, M.L.; García-Ruiz, P.A. Lightweight pozzolanic materials used in mortars: Evaluation of their influence on density, mechanical strength and water absorption. Cem. Concr. Compos. 2009, 31, 114–119. [Google Scholar] [CrossRef]

- Barbero-Barrera, M.M.; García-Santos, A.; Neila-González, F.J. Thermal conductivity of lime mortars and calcined diatoms. Parameters influencing their performance and comparison with the traditional lime and mortars containing crushed marble used as renders. Energy Build. 2014, 76, 422–428. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D. Effects of silica fume, latex, methylcellulose, and carbon fibres on the thermal conductivity and specific heat of cement paste. Cem. Concr. Res. 1997, 27, 1799–1804. [Google Scholar] [CrossRef]

- Patural, L.; Marchal, P.; Govin, A.; Grosseau, P.; Ruot, B.; Devès, O. Cellulose ethers influence on water retention and consistency in cement-based mortars. Cem. Concr. Res. 2011, 41, 46–55. [Google Scholar] [CrossRef]

- Soares, A.; Flores-Colen, I.; de Brito, J. Nanorenders on building facades: Technical, economic and environmental performance. In Proceedings of the XIII International Conference on Durability of Building Materials, São Paulo, Brazil, 2–5 September 2014.

- Li, H.; Xiao, H.; Yuan, J.; Ou, J. Microstructure of cement mortar with nanoparticles. Compos. Part B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef]

- Silvestre, J.; Silvestre, N.; de Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civil. Eng. 2015, 20, 455–485. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.; Metaxa, Z.; Shah, S. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Moura, A.; Flores-Colen, I.; de Brito, J. Study of the effect of three anti-graffiti products on the physical properties of different substrates. Const. Build. Mater. 2016, 15, 157–164. [Google Scholar] [CrossRef]

- Cárdenas, C.; Tobón, J.; García, C.; Vila, J. Functionalized building materials: Photo-catalytic abatement of NOx by cement pastes blended with TiO2 nanoparticles. Constr. Build. Mater. 2012, 36, 820–825. [Google Scholar] [CrossRef]

- Rao, S.; Silva, P.; de Brito, J. Experimental study of the mechanical properties and durability of self-compacting mortars with nanomaterials (SiO2 and TiO2). Constr. Build. Mater. 2015, 96, 508–517. [Google Scholar] [CrossRef]

- Júlio, M.; Ilharco, L. Superhydrophobic hybrid aerogel powders from waterglass with distinctive applications. Microporous Mesoporous Mater. 2014, 199, 29–39. [Google Scholar] [CrossRef]

- Ibrahim, M.; Biwole, P.H.; Archard, P.; Wurtz, E. Areogel-based materials for improving the buildings envelope’s thermal behaviour: A brief review with a focus on a new aerogel-based rendering. In Energy Sustainability Trough Green Energy; Sharma, A., Kar, S.K., Eds.; Green Energy and Technology, Springer India: New Delhi, India, 2015; pp. 163–188. [Google Scholar]

- IPQ. Tests for Mechanical and Physical Properties of Aggregates-Part 3: Determination of Loose Bulk Density and Voids; NP EN 1097-3; Portuguese Institute of Quality: Lisboa, Portugal, 2002. (In Portuguese) [Google Scholar]

- Methods of Testing Cement—Part 2: Chemical Analysis of Cement; EN 196-2; Comité Européen de Normalisation: Brussels, Belgium, 2013.

- Methods of Testing Cement—Part 21: Determination of the Chloride, Carbon Dioxide and Alkali Content of Cement; EN 196-21; Comité Européen de Normalisation: Brussels, Belgium, 1992.

- Vale, H.; Melo, H.; Soares, A.; Flores-Colen, I.; Glória Gomes, M. Performance of industrial thermal insulation renders. In Proceedings of the 9th International Masonry Conference, Guimarães, Portugal, 7–9 July 2014; pp. 1–11.

- Victor, R. Latex Modified Mortar and Concrete. U.S. Patent 5,185,389, 9 February 1993. [Google Scholar]

- Slagter, J. Polymer-Cement Composites and Methods of Making Same. U.S. Patent 6,569,923 B1, 27 May 2003. [Google Scholar]

- Silva, A.; Soares, A.; Flores-Colen, I.; de Brito, J. Mechanical characterization of lightweight mortars on small-scale samples. J. Test. Evaluation 2016, 44. [Google Scholar] [CrossRef]

- Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; EN 1015-11; Comité Européen de Normalisation: Brussels, Belgium, 1999.

- Building Materials and Products-Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; ISO 10456; International Organization for Standardization: Geneva, Switzerland, 2007.

- Thermal Properties Analyzer, User’s Guide Version 120712; ISOMET 2114; Applied Precision: Bratislava, Slovakia, 2011.

- Jerman, M.; Černý, R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Silva, G.N.; Campiteli, C.V. Dynamic Modulus of Elasticity of Renders; Ambiente Construído Patologia: Porto Alegre, Brazil, 2008; Volume 8, pp. 21–35. [Google Scholar]

- Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration; ASTM E 1876; American Society for Testing Materials: Philadelphia, PA, USA, 2009.

- Silva, A.; de Brito, J.; Gaspar, P.L. Application of the factor method to maintenance decision support for stone cladding. Autom. Constr. 2012, 22, 165–174. [Google Scholar] [CrossRef]

- Silva, A.; Neves, R.; de Brito, J. Statistical modelling of carbonation in reinforced concrete. Cem. Concr. Compos. 2014, 50, 73–81. [Google Scholar] [CrossRef]

- Mata, J. Interpretation of concrete dam behaviour with artificial neural network and multiple linear regression models. Eng. Struct. 2011, 33, 903–910. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis, 6th ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 2007. [Google Scholar]

- Cho, Y.; Awbi, H.B. A study of the effect of heat source location in a ventilated room using multiple regression analysis. Build. Environ. 2007, 42, 2072–2082. [Google Scholar] [CrossRef]

- Hu, B.; Shao, J. Generalized linear model selection using R2. J. Stat. Plan. Inf. 2008, 138, 3705–3712. [Google Scholar] [CrossRef]

- Leung Arthur, W.T.; Tam, C.M.; Liu, D.K. Comparative study of artificial neural networks and multiple regression analysis for predicting hoisting times of tower cranes. Build. Environ. 2001, 364, 457–467. [Google Scholar] [CrossRef]

| Components | Average Value (%) | Range (%) |

|---|---|---|

| Cement CEM II/B-L 32,5N | 40.45 | 8.46–53.11 |

| Cement CEM I 42,5R | 16.48 | 8.12–19.20 |

| Cement CEM I 52,5R | 8.12 | - |

| Fly ash | 3.80 | 2.61–23.77 |

| Aerial Lime | 15.81 | 10.42–41.16 |

| Water | 40.82 | 21.43–53.03 |

| Silica sand (<2 mm) | 42.20 | - |

| Expanded clay (0.5–2 mm) | 10.42 | 6.37–25.22 |

| Aerogel HYB-C subcritical (<0.5 mm) | 24.02 | 14.49–38.34 |

| Aerogel CA1 supercritical (<2 mm) | 13.71 | - |

| Aerogel CA2 supercritical (<2 mm) | 9.36 | 5.08–12.54 |

| Aerogel CA3 supercritical (<2 mm) | 7.19 | 5.29–12.76 |

| Expanded cork granules (0.5–2 mm) | 1.59 | 1.00–4.08 |

| Expanded perlite (1–300 µm) | 0.71 | 0.54–0.78 |

| Air entrainers (olefin sulphonate) | 0.36 | 0.01–0.85 |

| Powder resin | 0.81 | 0.52–1.45 |

| Liquid resin (copolymer styrene acrylic) | 3.69 | 1.51–8.37 |

| Rheological agent (methyl hydroxyethyl cellulose) | 0.03 | 0.02–0.05 |

| Water/binder ratio | 1.14 | 0.61–1.75 |

| Type of Cement | Composition | Properties/Testing Method/Specifications According to Standard |

|---|---|---|

| CEM I 42,5R | 95%–100% of clinker 0%–5% of minor component | Sulfate content (SO3)/EN 196-2 [39]/≤4.0% Chloride content (Cl)/EN 196-21 [40]/≤0.1% |

| CEM I 52,5R | 95%–100% of clinker 0%–5% of minor component | Sulfate content (SO3)/EN 196-2 [39]/≤4.0% Chloride content (Cl)/EN 196-21 [40]/≤0.1% |

| CEM II/B-L 32,5N | 65%–79% of clinker 21%–35% of limestone 0%–5% of minor component | Sulfate content (SO3)/EN 196-2 [39]/≤3.5% Chloride content (Cl)/EN 196-21 [40]/≤0.1% |

| Fly ash | SiO2; Al2O3; Fe2O3; CaO | - |

| Aerial Lime | Calcium hydroxide content (Ca(OH)2) ≥93% Magnesium content (MgO) ≤3% | - |

| Material | Size (mm) | |||||

|---|---|---|---|---|---|---|

| <0.063 | 0.063 to 0.125 | 0.125 to 0.250 | 0.250 to 0.500 | 0.500 to 1.000 | 1.000 to 2.000 | |

| Silica sand | 0.5 | 0.5 | 17.0 | 59.0 | 22.0 | 1.0 |

| Expanded clay | - | - | - | - | 17.7 | 82.3 |

| Expanded cork granules | - | - | - | - | 17.7 | 82.3 |

| Step a | r | R2 | Adjusted R2 | Square Root of the Average Square Error |

|---|---|---|---|---|

| 1 | 0.567 b | 0.322 | 0.314 | 0.029 |

| 2 | 0.732 c | 0.536 | 0.525 | 0.024 |

| 3 | 0.869 d | 0.592 | 0.577 | 0.023 |

| 4 | 0.810 e | 0.657 | 0.640 | 0.021 |

| 5 | 0.835 f | 0.697 | 0.678 | 0.020 |

| 6 | 0.847 g | 0.718 | 0.696 | 0.019 |

| 7 | 0.859 h | 0.738 | 0.714 | 0.019 |

| Step a | r | R2 | Adjusted R2 | Square Root of the Average Square Error |

|---|---|---|---|---|

| 1 | 0.914 b | 0.835 | 0.831 | 0.224 |

| 2 | 0.922 c | 0.851 | 0.844 | 0.216 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ximenes, S.; Silva, A.; Soares, A.; Flores-Colen, I.; De Brito, J. Parametric Analysis to Study the Influence of Aerogel-Based Renders’ Components on Thermal and Mechanical Performance. Materials 2016, 9, 336. https://doi.org/10.3390/ma9050336

Ximenes S, Silva A, Soares A, Flores-Colen I, De Brito J. Parametric Analysis to Study the Influence of Aerogel-Based Renders’ Components on Thermal and Mechanical Performance. Materials. 2016; 9(5):336. https://doi.org/10.3390/ma9050336

Chicago/Turabian StyleXimenes, Sofia, Ana Silva, António Soares, Inês Flores-Colen, and Jorge De Brito. 2016. "Parametric Analysis to Study the Influence of Aerogel-Based Renders’ Components on Thermal and Mechanical Performance" Materials 9, no. 5: 336. https://doi.org/10.3390/ma9050336

APA StyleXimenes, S., Silva, A., Soares, A., Flores-Colen, I., & De Brito, J. (2016). Parametric Analysis to Study the Influence of Aerogel-Based Renders’ Components on Thermal and Mechanical Performance. Materials, 9(5), 336. https://doi.org/10.3390/ma9050336