Neutron Radiography Based Visualization and Profiling of Water Uptake in (Un)cracked and Autonomously Healed Cementitious Materials

Abstract

:1. Introduction

2. Materials

2.1. Mortar

2.2. Capsules

2.3. Healing Agent

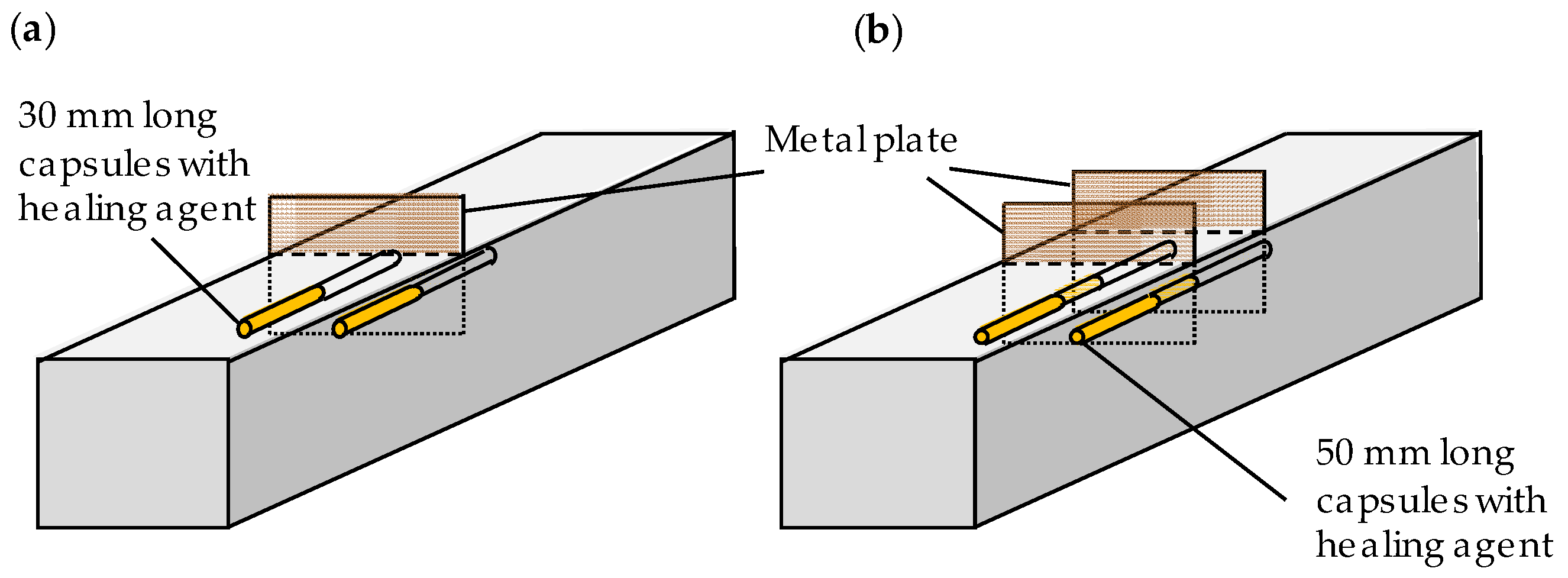

2.4. Mortar Prisms with(out) Encapsulated Healing Agent

3. Methods

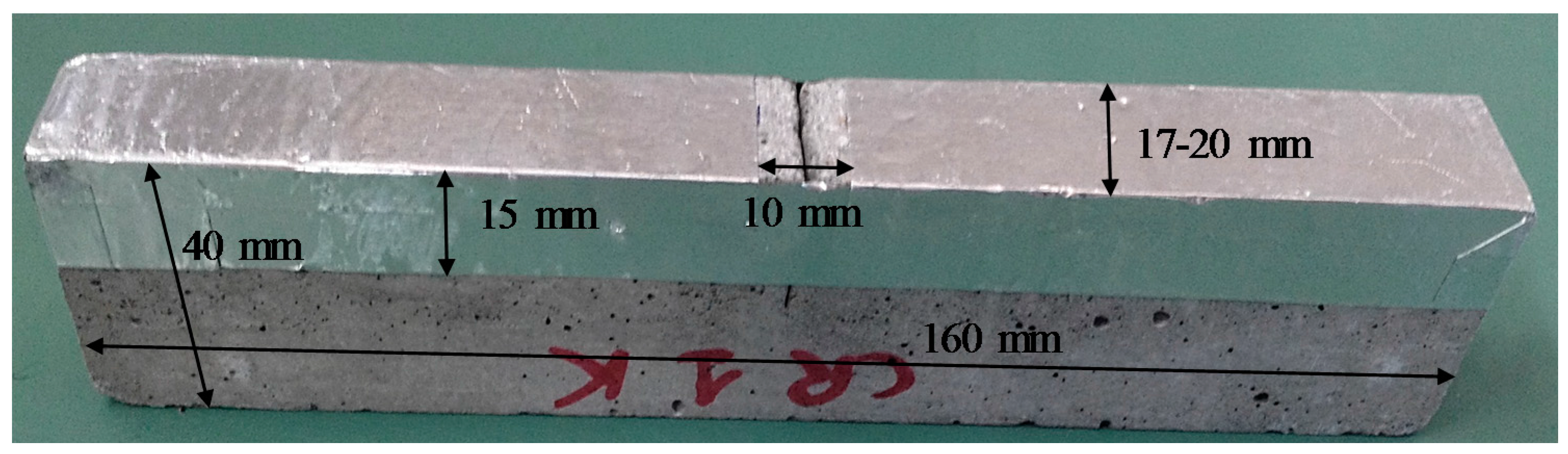

3.1. Crack Creation and Healing

3.2. Sample Preparation

3.3. Visualization of Water Ingress

3.3.1. Neutron Radiography Facility

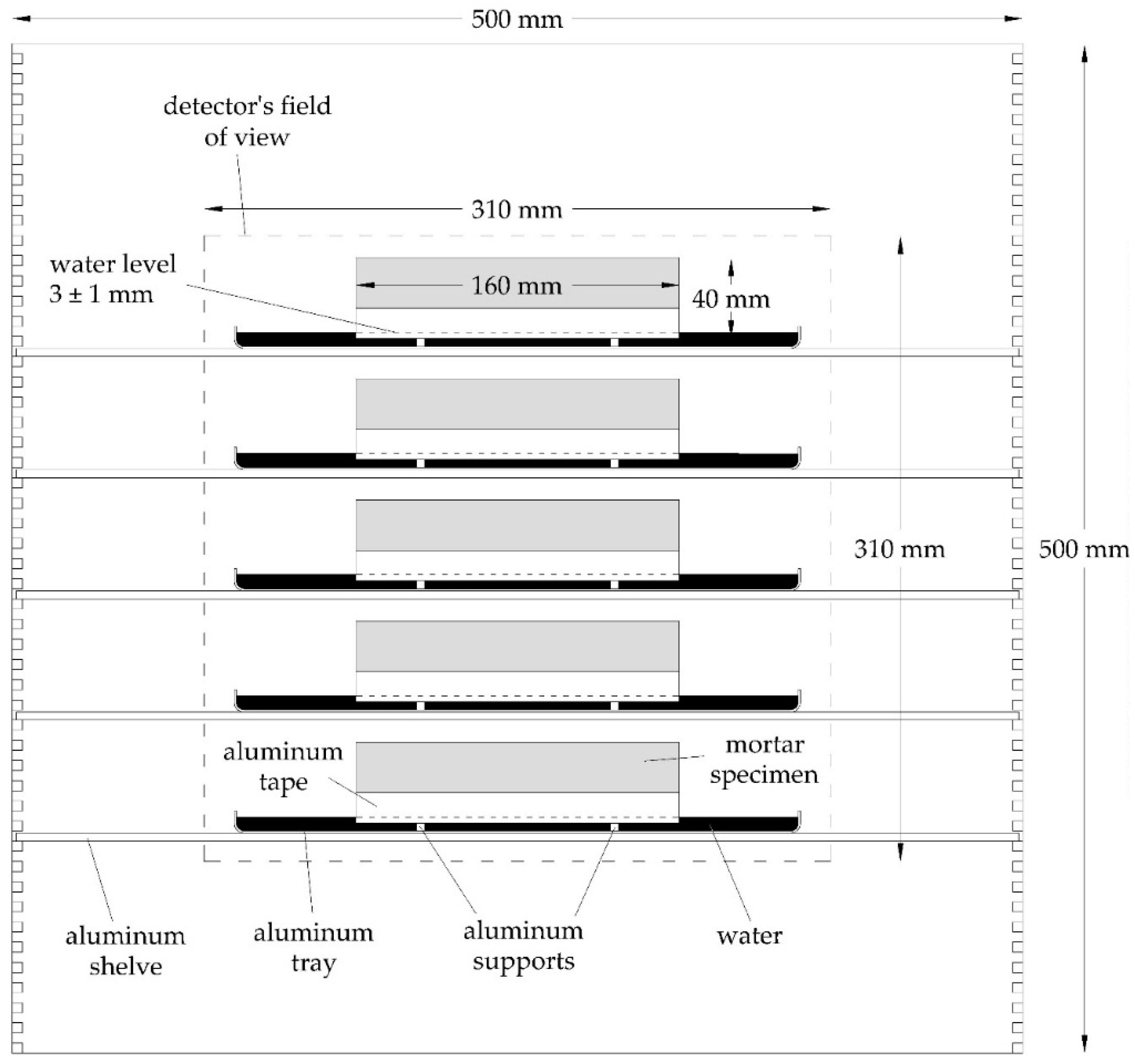

3.3.2. Water Uptake during Scanning

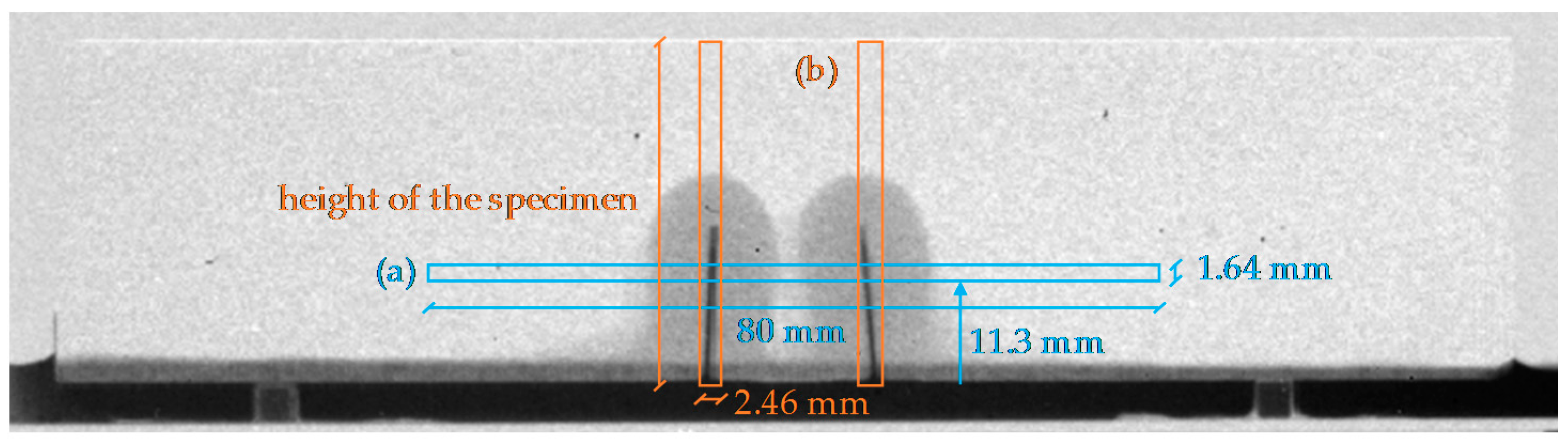

3.4. Image Analysis

3.5. Analysis of the Spread Region of the Healing Agents in the Crack

4. Results and Discussion

4.1. Neutron Radiography Imaging of Crack Healing

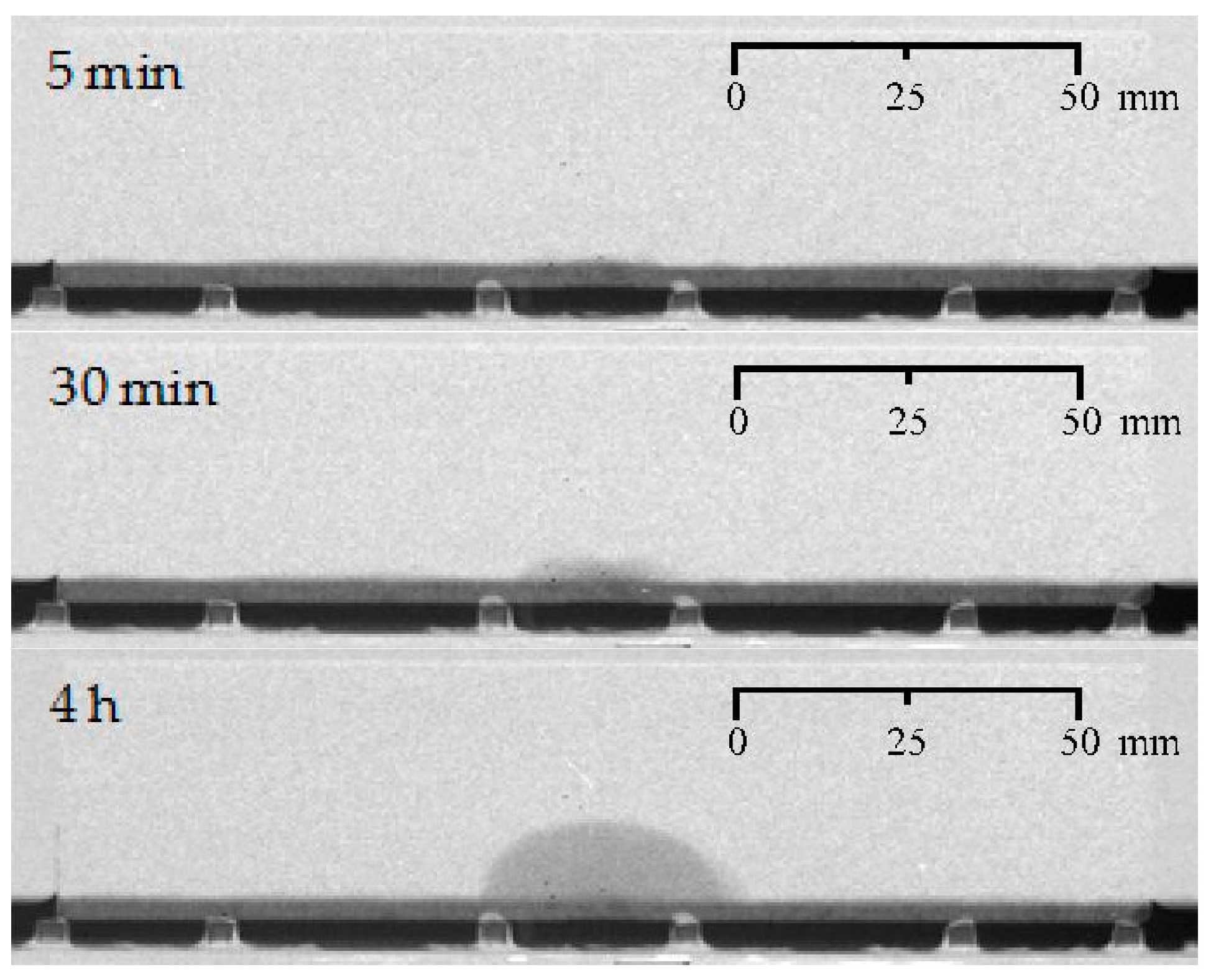

4.1.1. (Un)cracked Condition

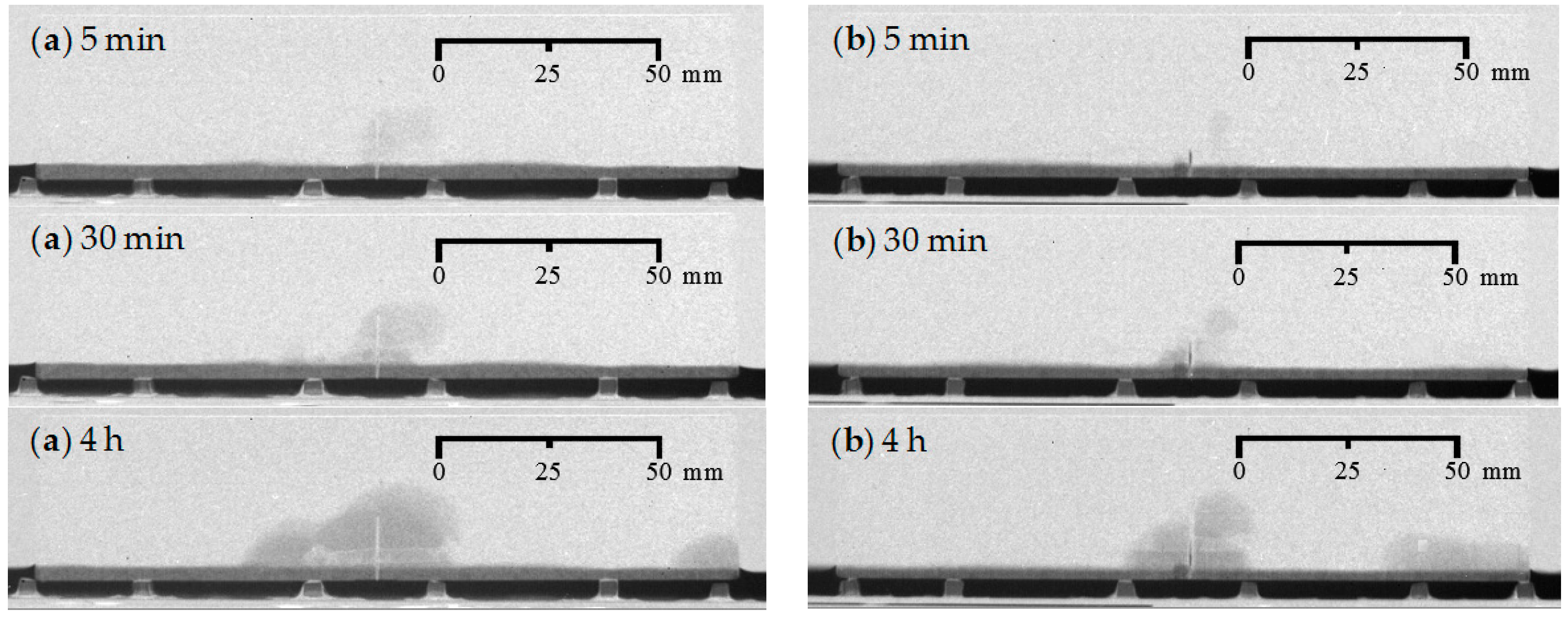

4.1.2. Healing of One Crack

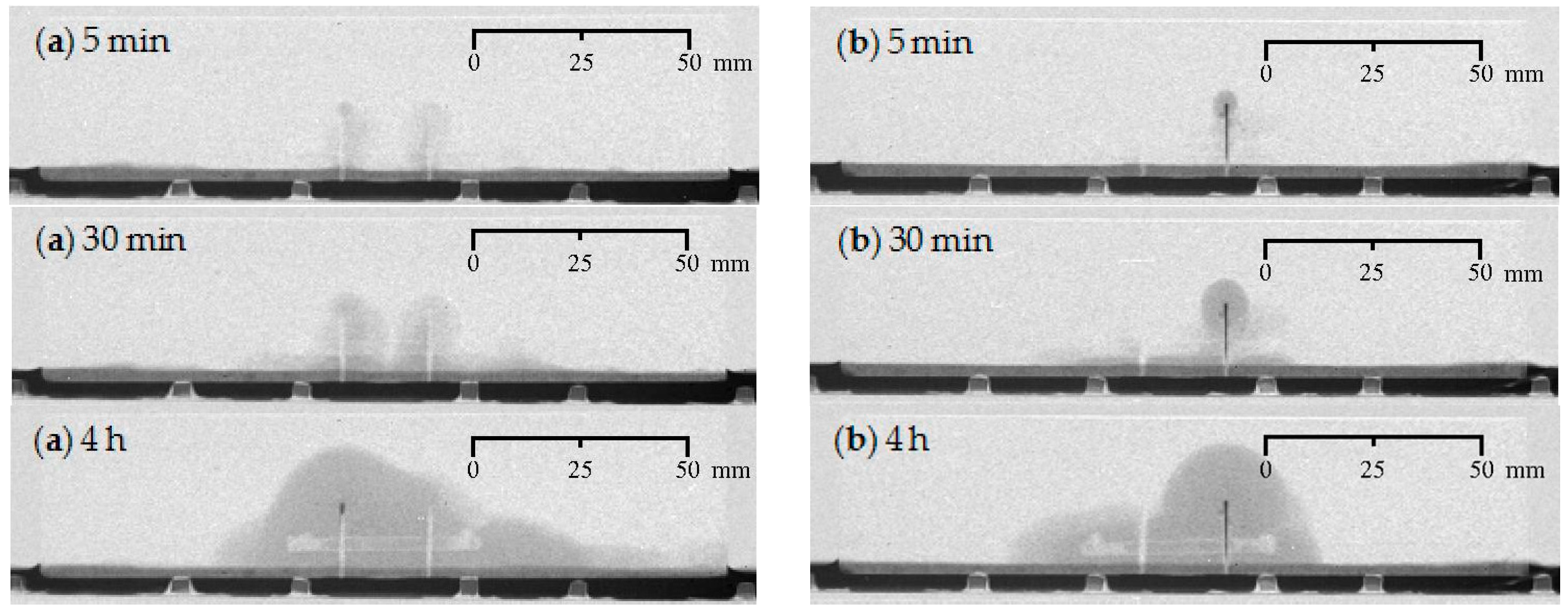

4.1.3. Healing of Two Cracks

4.1.4. Water Front/Sample Cross-Section Area Ratios

4.2. Water Profiling of Crack Healing Perpendicular to the Crack(s)

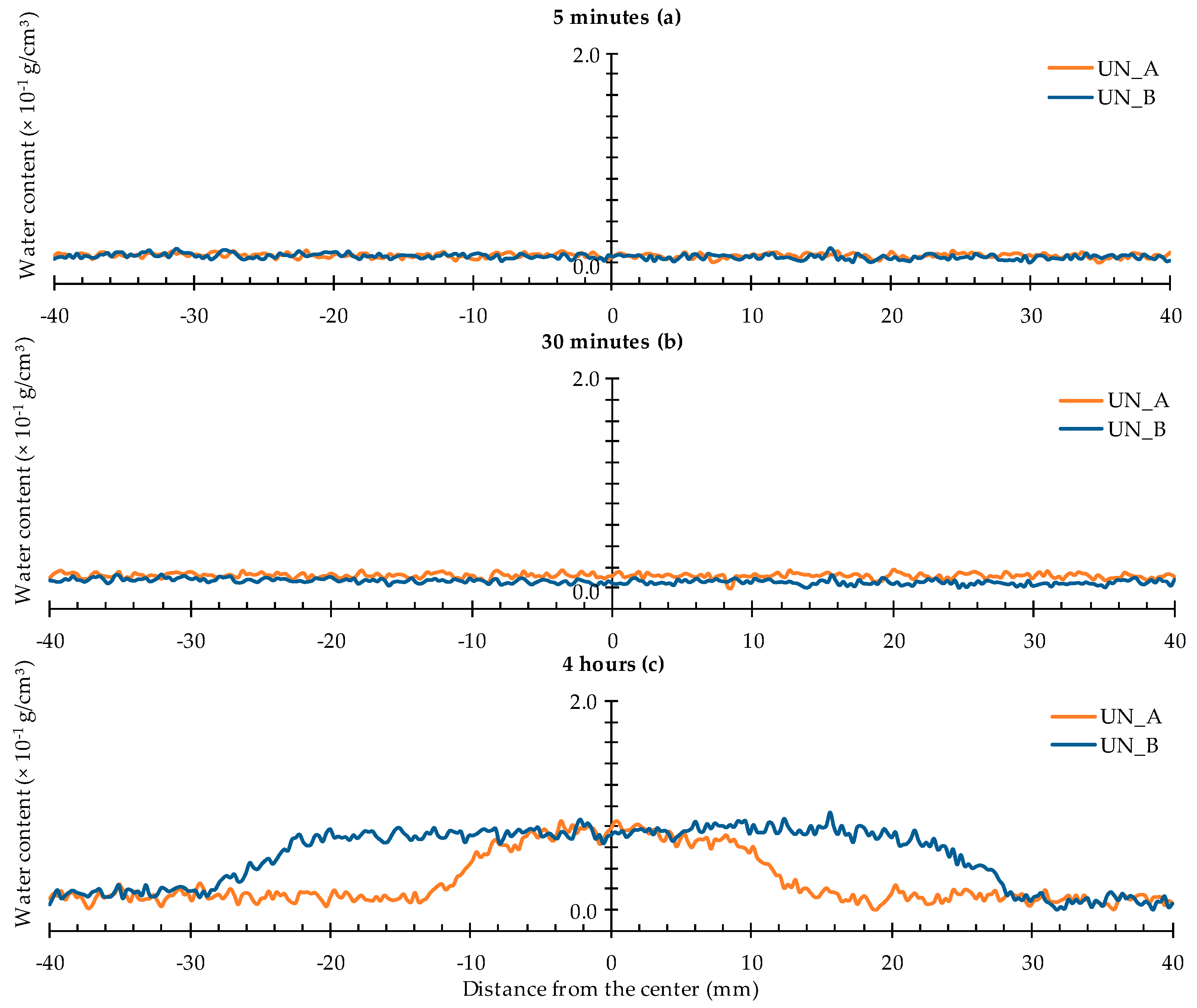

4.2.1. (Un)cracked Condition

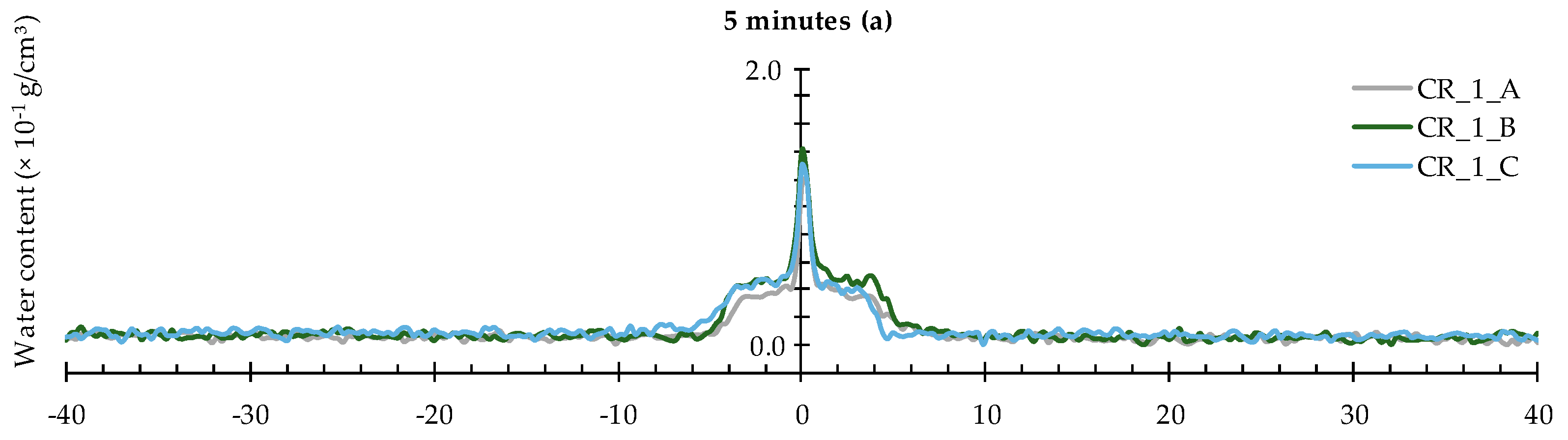

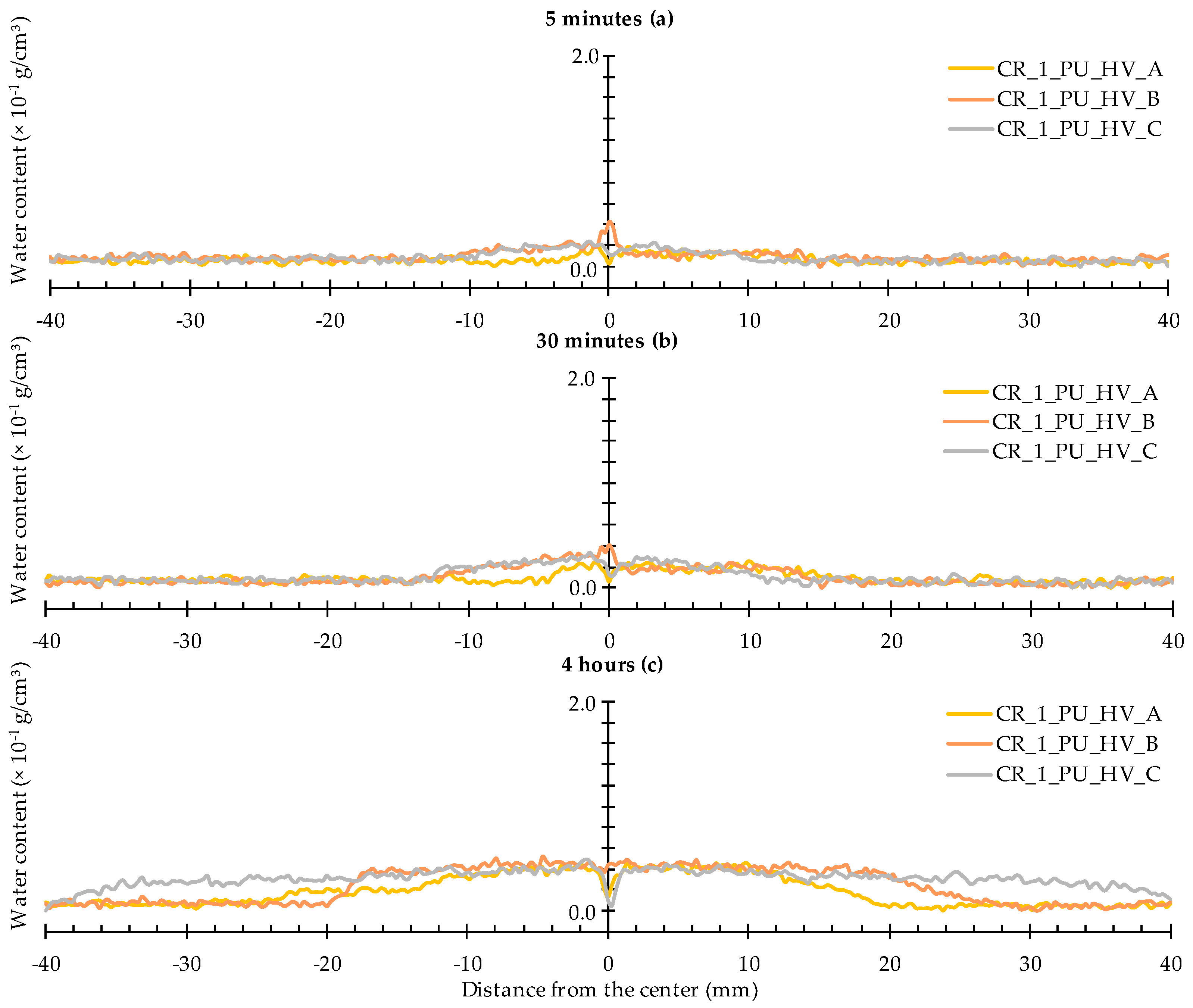

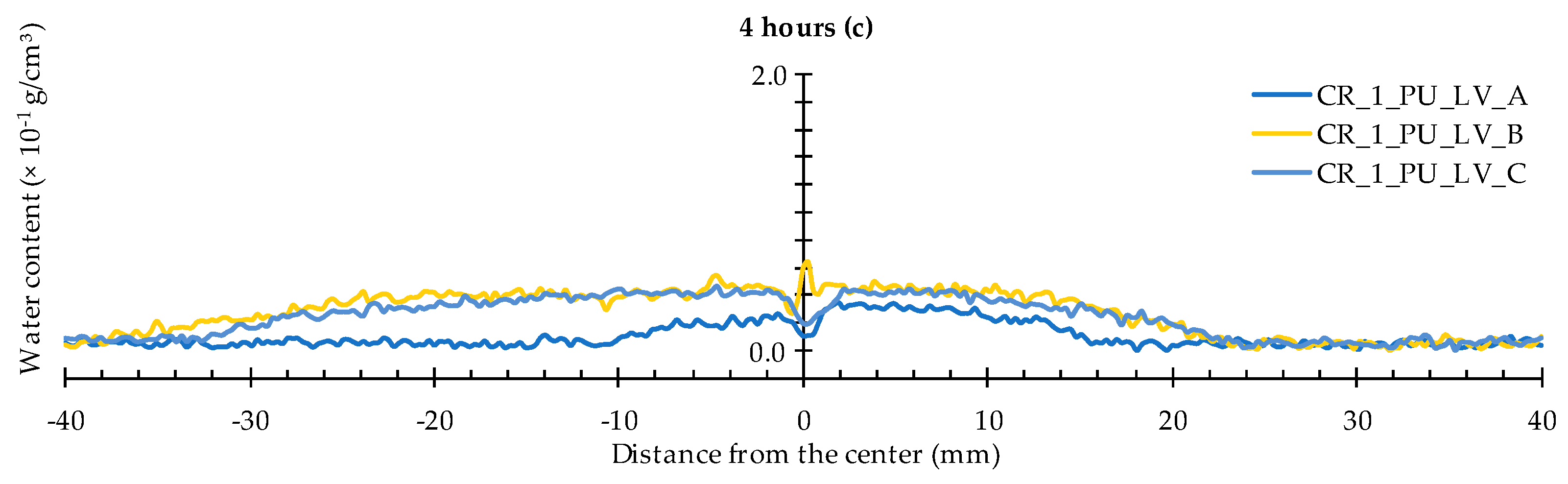

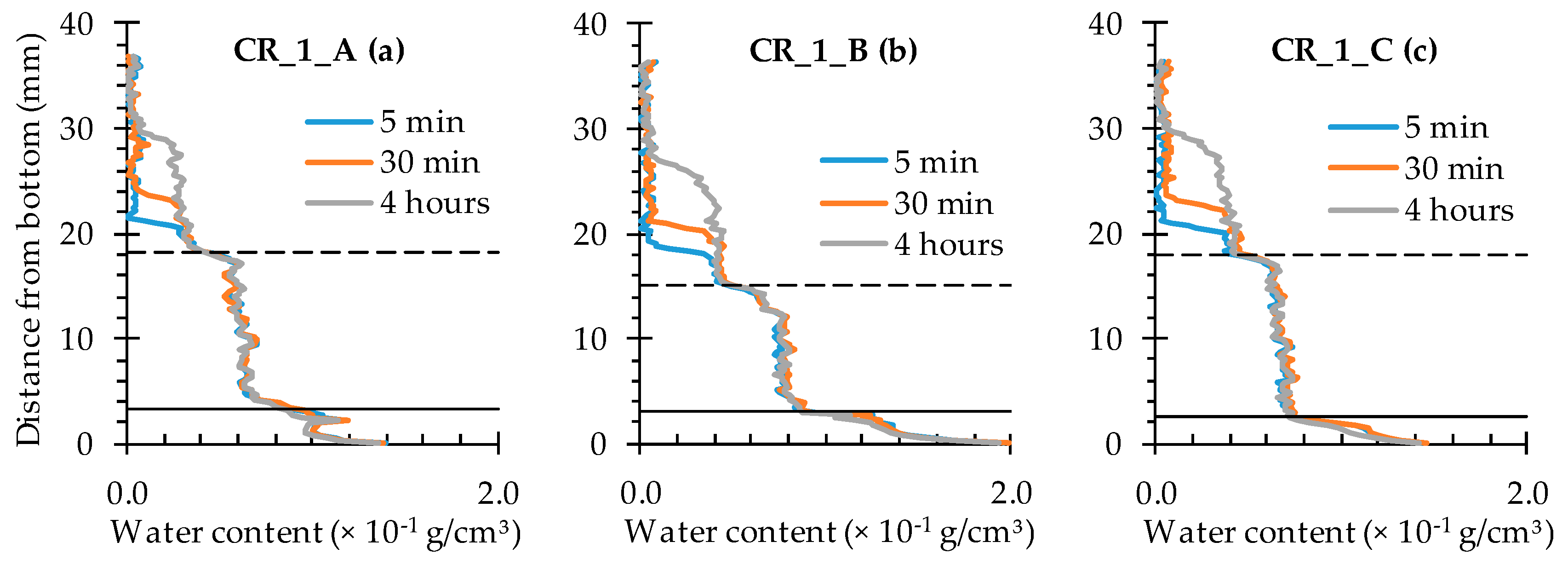

4.2.2. Healing of One Crack

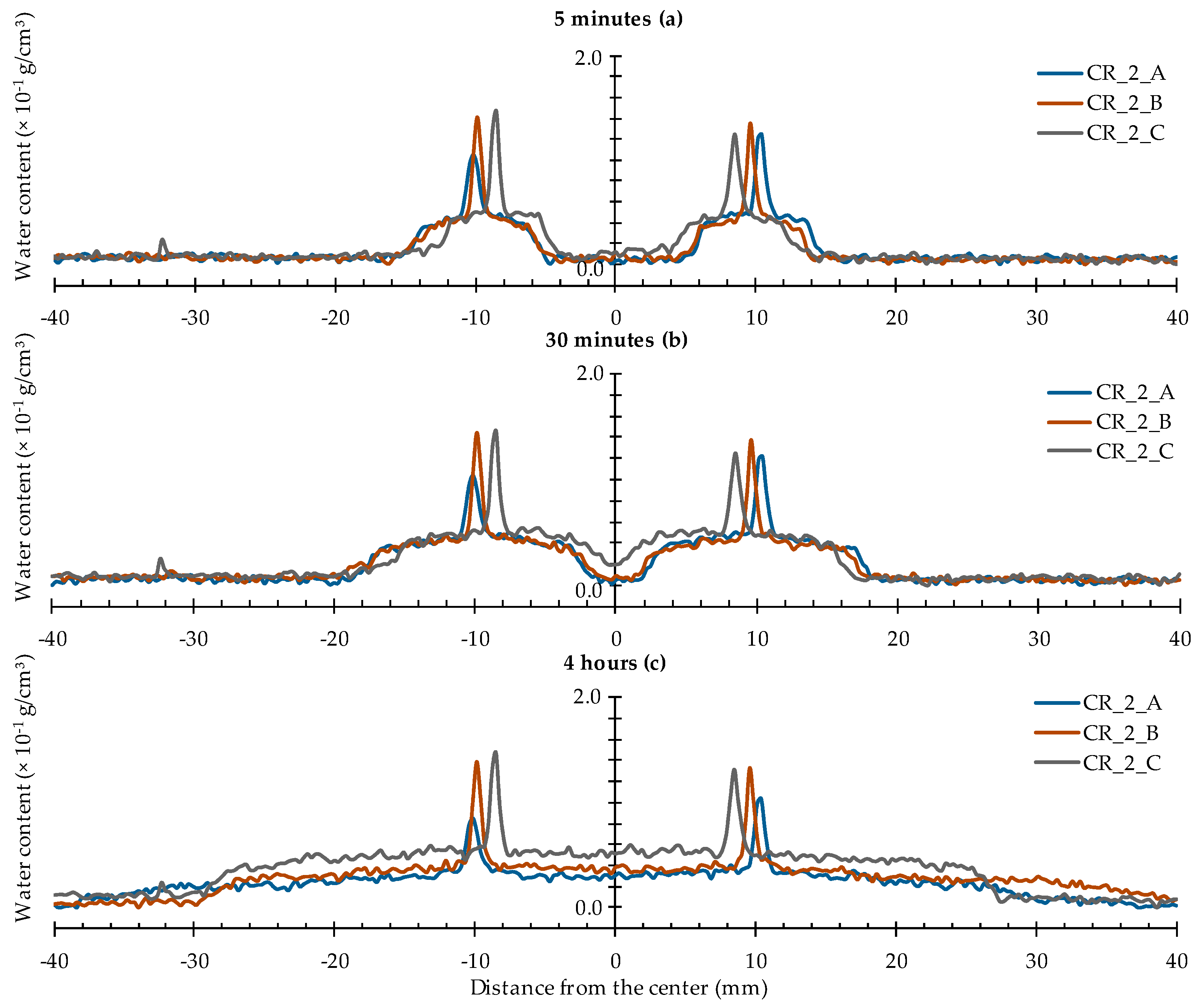

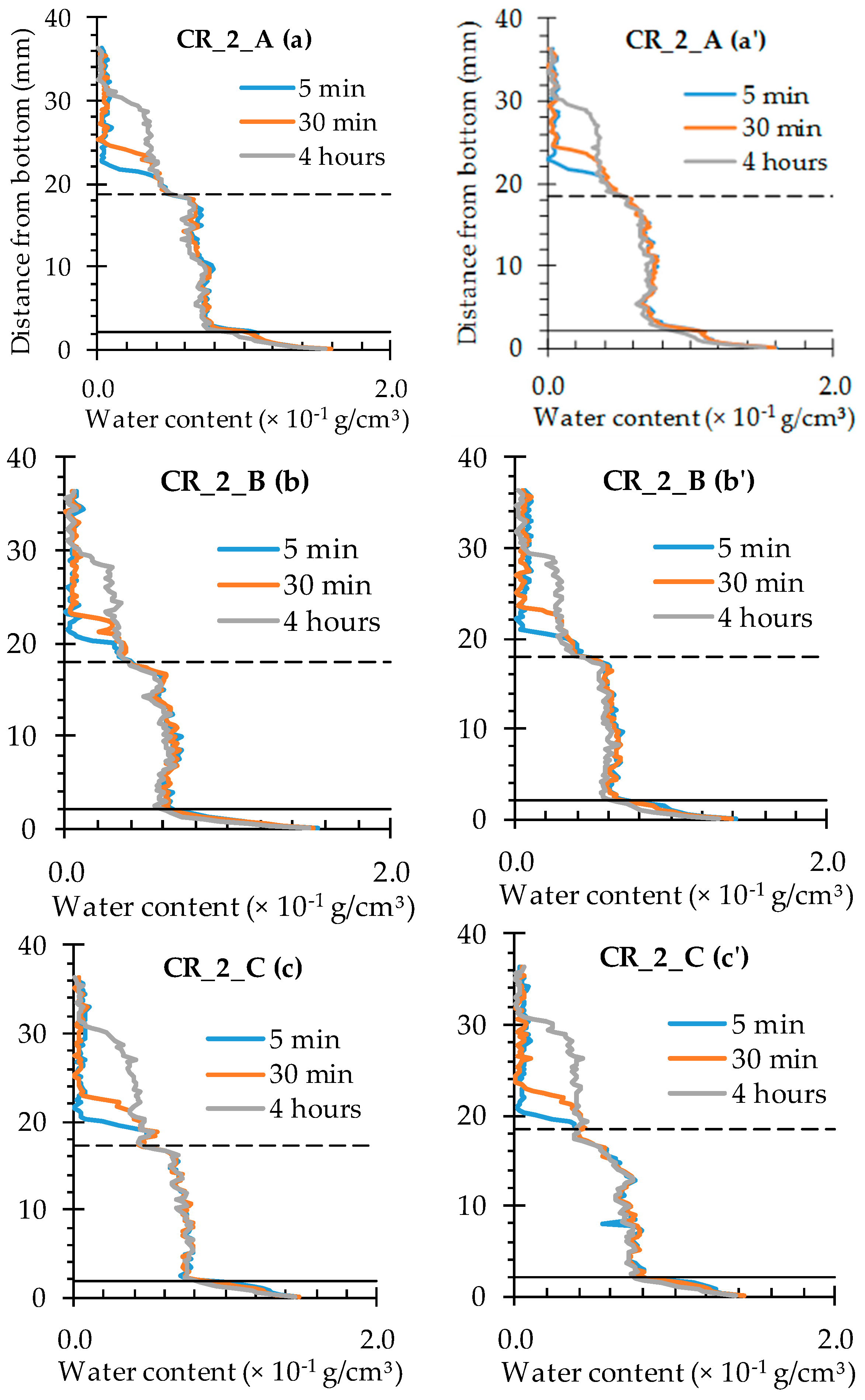

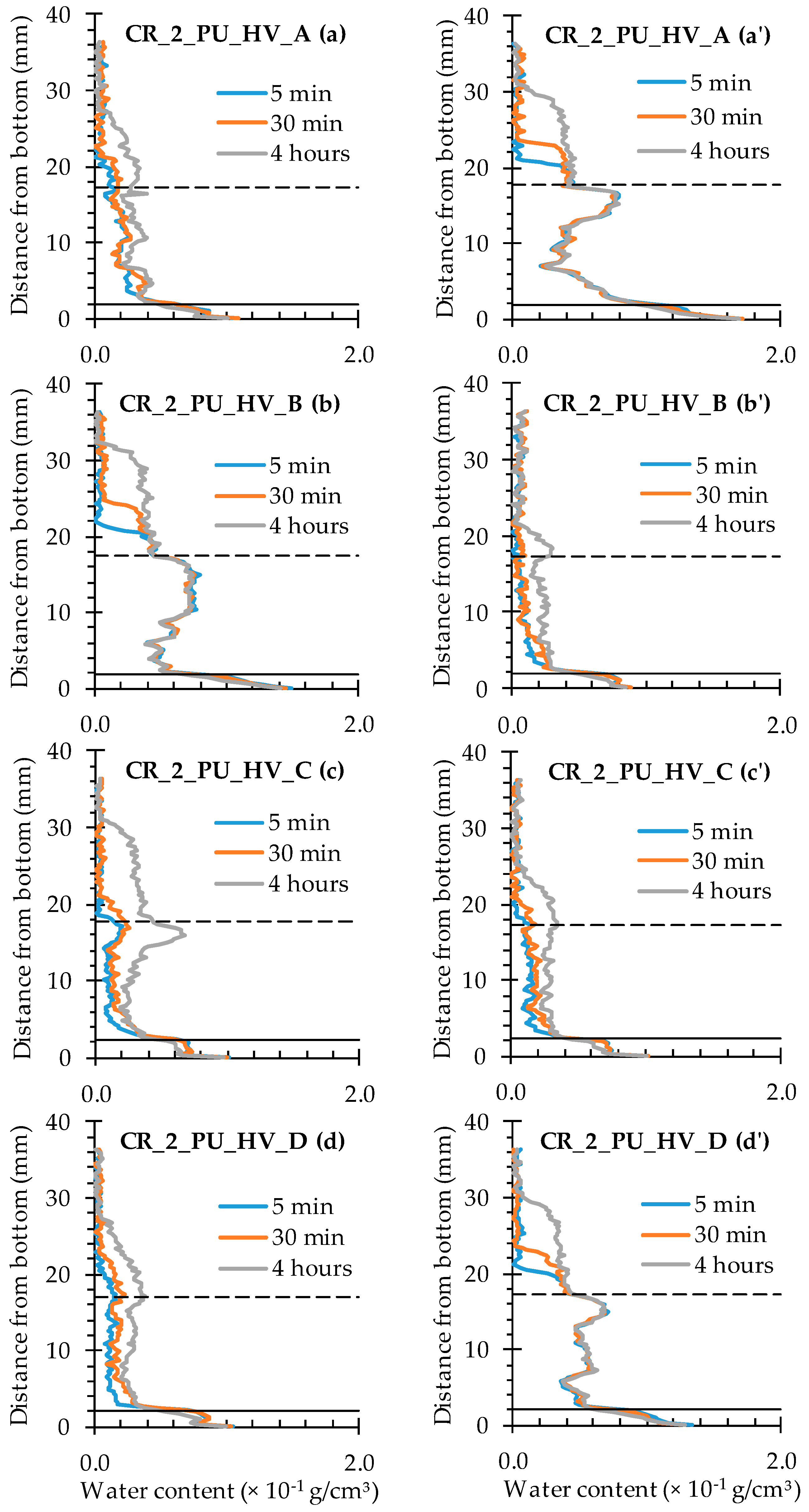

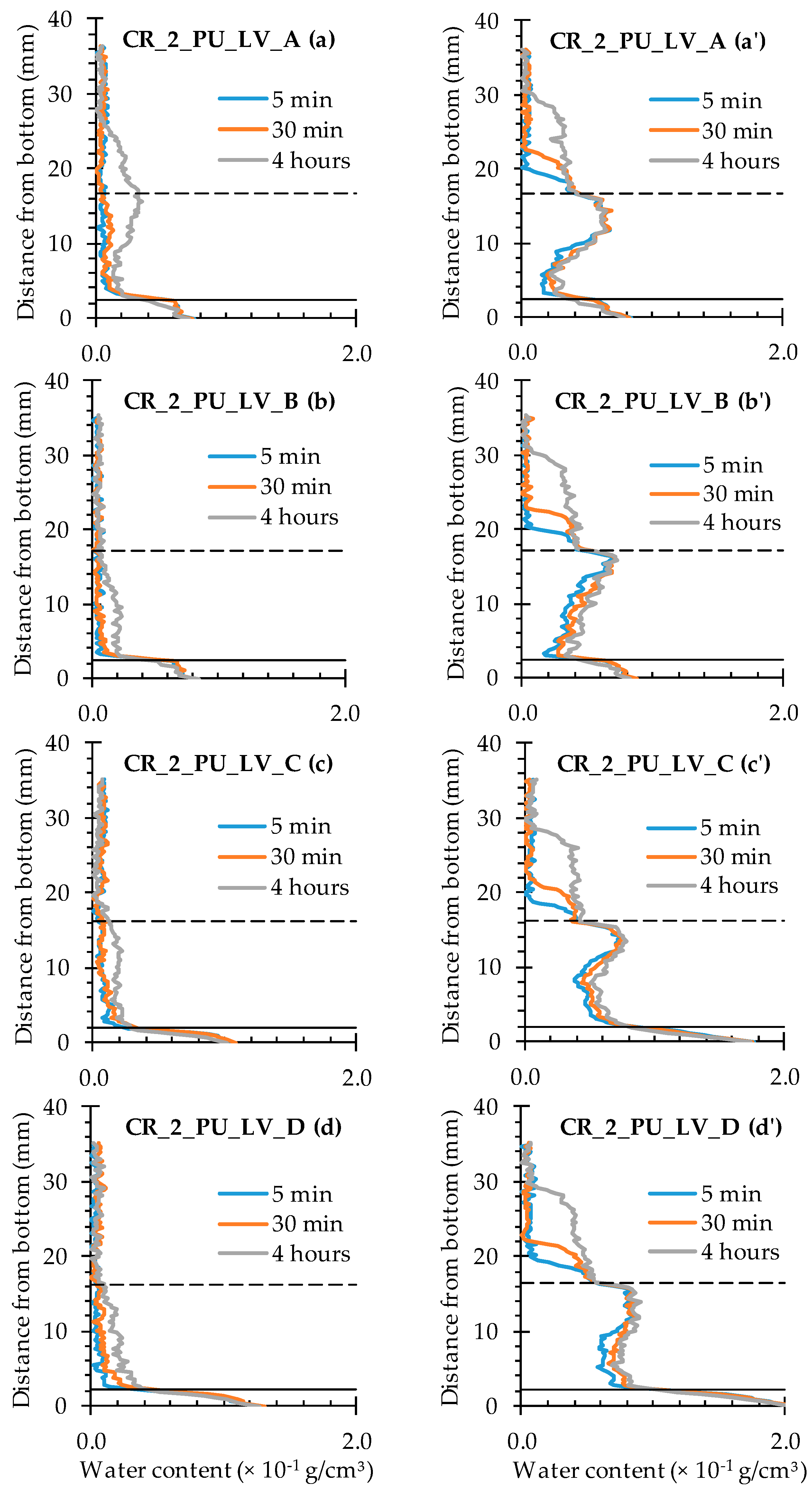

4.2.3. Healing of Two Cracks

4.2.4. Water Profile Integrals

4.3. Water Profiling of Crack Healing along the Crack(s)

4.3.1. Cracked Condition

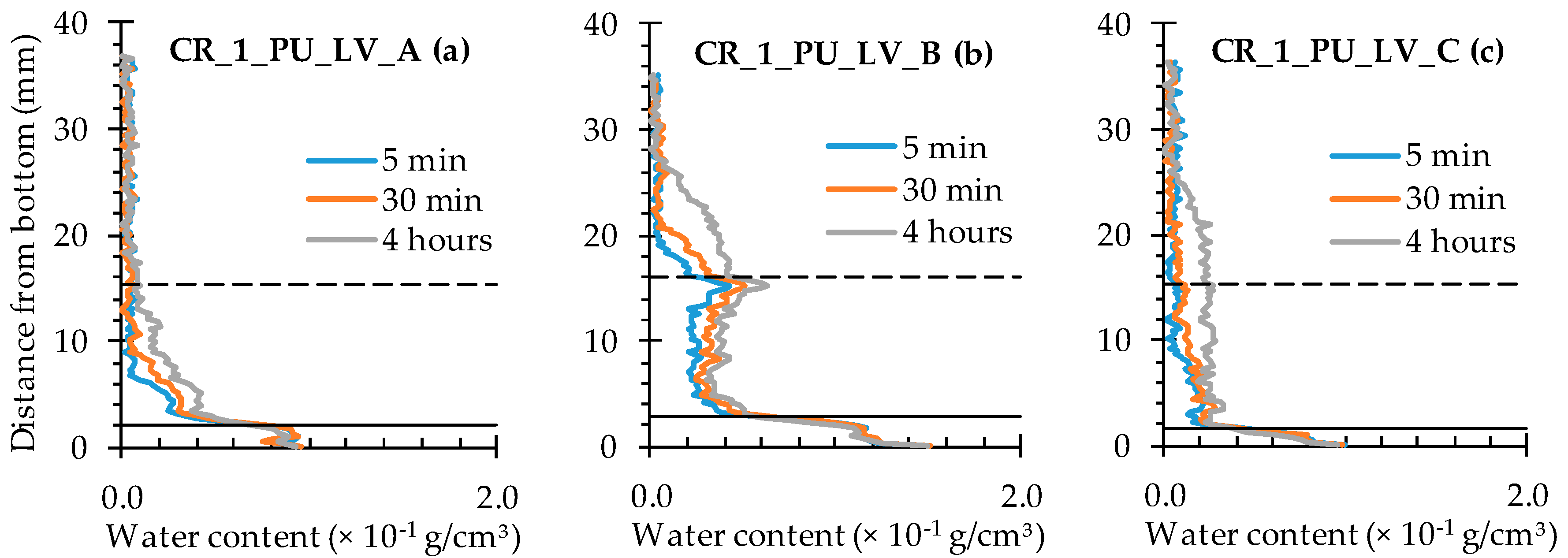

4.3.2. Healing of One Crack

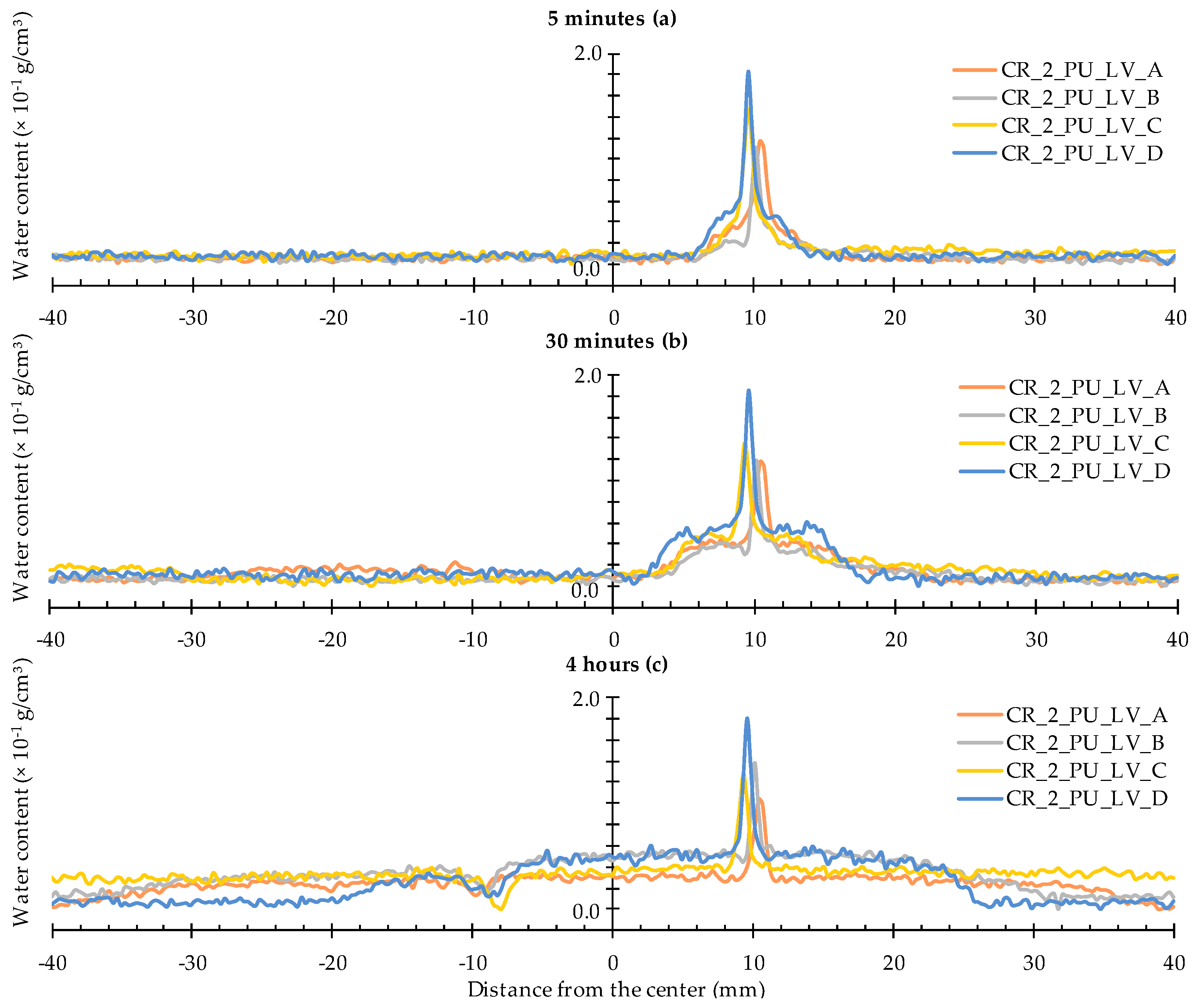

4.3.3. Healing of Two Cracks

4.4. Spread Region of the Healing Agents in the Crack

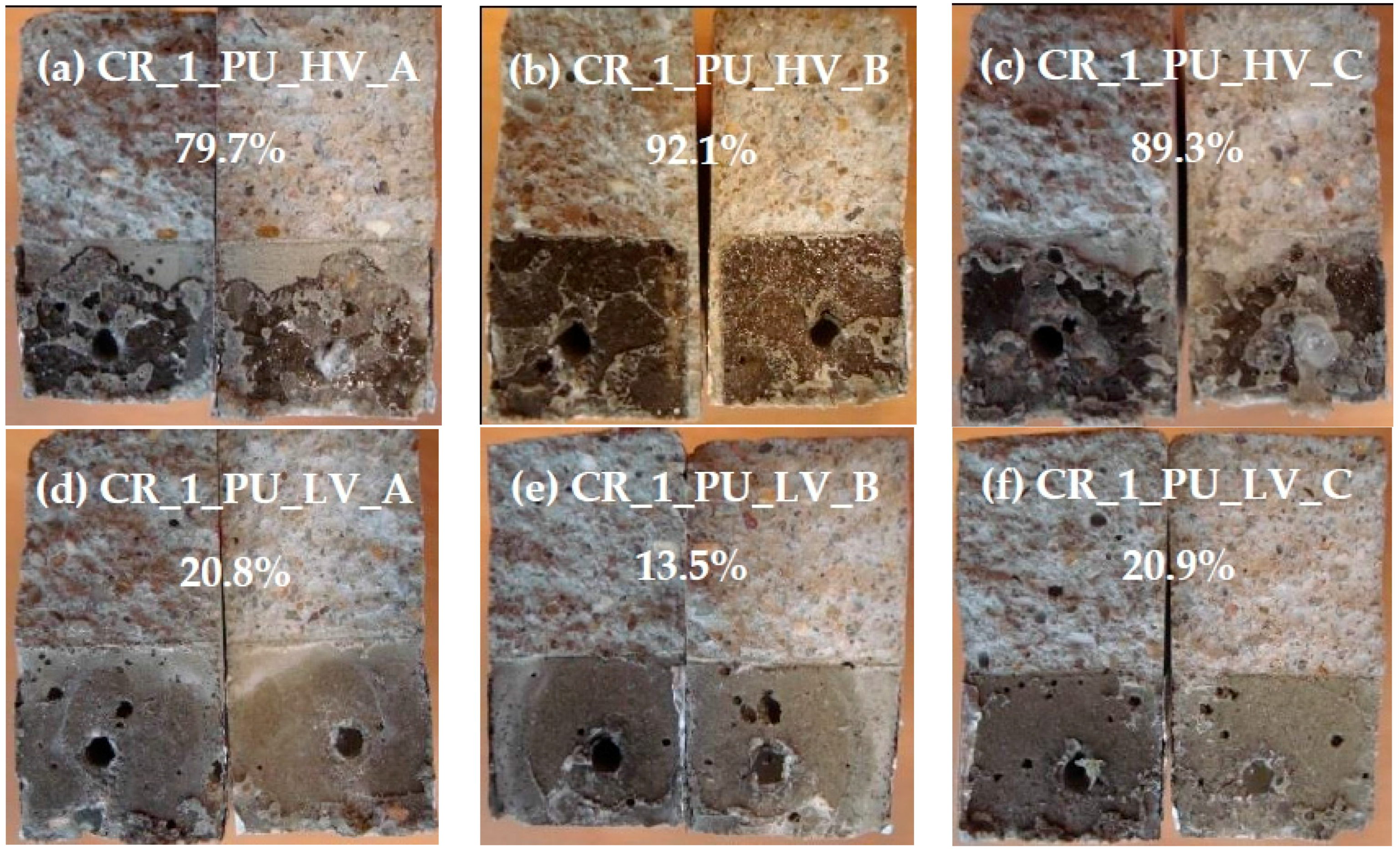

4.4.1. Healing of One Crack

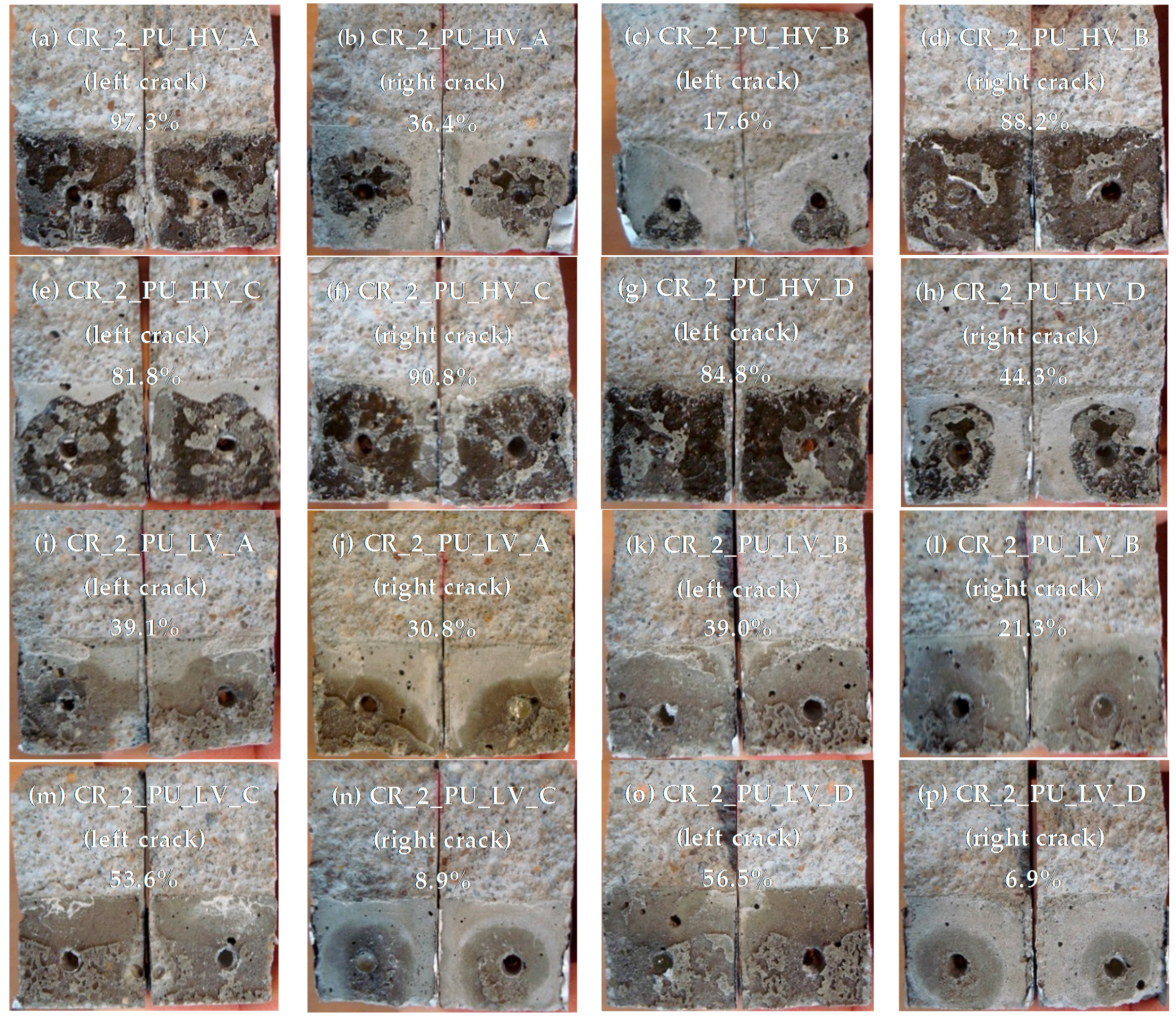

4.4.2. Healing of Two Cracks

4.5. Water Uptake Immediately after Triggering the Healing Mechanism

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CR | Cracked |

| HV | High viscosity |

| LV | Low viscosity |

| PSI | Paul Scherrer Institute |

| PU | Polyurethane |

| UN | Uncracked |

| WFA/SCA | Water front/sample cross-section area ratio |

References

- Van Tittelboom, K.; De Belie, N. Self-healing in cementitious materails—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; Van Loo, D.; Jacobs, J. Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Maes, M.; Van Tittelboom, K.; De Belie, N. The efficiency of self-healing cementitious materials by means of encapsulated polyurethane in chloride containing environments. Constr. Build. Mater. 2014, 71, 528–537. [Google Scholar] [CrossRef]

- Feiteira, J.; Gruyaert, E.; De Belie, N. Self-healing of dynamic concrete cracks using polymer precursors as encapsulated healing agents. In Proceedings of the Concrete Solutions 5th International Conference on Concrete Repair, Belfast, UK, 1–3 September 2014; pp. 65–69.

- Aldea, C.-M.; Shah, S.P.; Karr, A. Permeability of cracked concrete. Mater. Struct. 1999, 32, 370–376. [Google Scholar] [CrossRef]

- Wang, K.; Jansen, D.C.; Shah, S.P.; Karr, A.F. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Wang, L.C. Experimental study on water absorption by concrete damaged by uniaxial loading. In Proceedings of the 4th International Conference on the Durability of Concrete Structures, West Lafayette, IN, USA, 23–26 July 2014; pp. 198–204.

- Van Belleghem, B.; Rodrigo, M.; Dewanckele, J.; Van den Steen, N.; De Graeve, I.; Deconinck, J.; Cnudde, V.; Van Tittelboom, K.; De Belie, N. Capillary water absorption in cracked and uncracked mortar—A comparison between experimental study and finite element analysis. Constr. Build. Mater. 2016, 110, 154–162. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Dewanckele, J.; De Belie, N.; Cnudde, V. Analysis and visualization of water uptake in cracked and healed mortar by water absorption tests and X-ray radiography. In Proceedings of the 4th International Conference on Concrete Repair, Rehabilitation and Retrofitting, Leipzig, Germany, 5–7 October 2015; pp. 45–53.

- Audenaert, K. Transport mechanisms of self-compacting concrete related to carbonation and chloride penetration. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2006. [Google Scholar]

- Aldea, C.-M.; Ghandehari, M.; Shah, S.P.; Karr, A.F. Combined effect of cracking and water permeability of concrete. In Proceedings of the 14th Engineering Mechanics Conference, Austin, TX, USA, 21–24 May 2000.

- Hall, C. Water sorptivity of mortars and concretes: A review. Mag. Concr. Res. 1989, 14, 51–61. [Google Scholar] [CrossRef]

- McCarter, W.J.; Ezirim, H.; Emerson, M. Absorption of water and chloride into concrete. Mag. Concr. Res. 1992, 44, 31–37. [Google Scholar] [CrossRef]

- Hall, C.; Tse, T.K.-M. Water movement in porous building materials—VII. The sorptivity of mortars. Build. Environ. 1986, 21, 113–118. [Google Scholar] [CrossRef]

- Martys, N.S.; Ferraris, C.F. Capillary transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- Castro, J.; Bentz, D.; Weiss, J. Effecto of sample conditioning on the water absorption of concrete. Cem. Concr. Compos. 2011, 33, 805–813. [Google Scholar] [CrossRef]

- Schröfl, C.; Mechtcherine, V.; Kaestner, A.; Vontobel, P.; Hovind, J.; Lehmann, E. Transport of water through strain-hardening cement-based composite (SHCC) applied on top of cracked reinforced concrete slabs with and without hydrophobization of cracks—Investigation by neutron radiography. Constr. Build. Mater. 2015, 76, 70–86. [Google Scholar] [CrossRef]

- Lieboldt, M.; Mechtcherine, V. Capillary transport of water through textile-reinforced concrete applied in repairing and/or strengthening cracked RC structures. Cem. Concr. Res. 2013, 52, 53–62. [Google Scholar] [CrossRef]

- Gardner, D.; Jefferson, A.; Hoffman, A. Investigation of capillary flow in discrete cracks in cementitious materials. Cem. Concr. Res. 2012, 42, 972–981. [Google Scholar] [CrossRef]

- Dewanckele, J.; De Kock, T.; Fronteau, G.; Derluyn, H.; Vontobel, P.; Dierick, M.; Van Hoorebeke, L.; Jacobs, P.; Cnudde, V. Neutron radiography and X-ray computed tomography for quantifying weathering and water uptake processes inside porous limestone used as building material. Mater. Charact. 2014, 88, 86–99. [Google Scholar] [CrossRef]

- Cnudde, V.; Dierick, M.; Vlassenbroeck, J.; Masschaele, B.; Lehmann, E.; Jacobs, P.; Van Hoorebeke, L. High-speed neutron radiography for monitoring the water absorption by capillarity in porous materials. Nucl. Instrum. Meth. B 2008, 266, 155–163. [Google Scholar] [CrossRef]

- Roels, S.; Carmeliet, J.; Hens, H.; Adan, O.; Brocken, H.; Cerny, R.; Pavlik, Z.; Ellis, A.T.; Hall, C.; Kumaran, K.; et al. A comparison of different techniques to quantify moisture content profiles in porous building materials. J. Therm. Envel. Build. Sci. 2004, 27, 261–276. [Google Scholar] [CrossRef]

- Baker, P.H.; Bailly, D.; Campbell, M.; Galbraith, G.H.; McLean, R.C.; Poffa, N.; Sanders, C.H. The application of X-ray absorption to building moisture transport studies. Measurement 2007, 40, 951–959. [Google Scholar] [CrossRef]

- Pleinert, H.; Sadouki, H.; Wittmann, F.H. Determination of moisture distributions in porous building materials by neutron transmission analysis. Mater. Struct. 1998, 31, 218–224. [Google Scholar] [CrossRef]

- Brew, D.R.M.; de Beer, F.C.; Radebe, M.J.; Nshimirimana, R.; McGlinn, P.J.; Aldridge, L.P.; Payne, T.E. Water transport through cement-based barriers—A preliminary study using neutron radiography and tomography. Nucl. Instrum. Meth. A 2009, 605, 163–166. [Google Scholar] [CrossRef]

- El Abd, A.; Czachor, A.; Milczarek, J. Neutron radiography determination of water diffusivity in fired clay brick. Appl. Radiat. Isot. 2009, 67, 556–559. [Google Scholar] [CrossRef] [PubMed]

- Weiss, J.; Geiker, M.R.; Hansen, K.K. Using X-ray transmission/attenuation to quantify fluid absorption in cracked concrete. Int. J. Mater. Struct. Int. 2015, 9, 3–20. [Google Scholar] [CrossRef]

- Roels, S.; Carmeliet, J. Analysis of moisture flow in porous building materials using microfocus X-ray radiography. Int. J. Heat Mass Transf. 2006, 49, 4762–4772. [Google Scholar] [CrossRef]

- Roels, S.; Vandersteen, K.; Carmeliet, J. Measuring and simulating moisture uptake in a fractured porous medium. Avd. Water Resour. 2003, 26, 237–246. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Snoeck, D.; Vontobel, P.; Wittmann, F.H.; De Belie, N. Use of neutron radiography and tomography to visualize the autonomous crack sealing efficiency in cementitious materials. Mater. Struct. 2013, 46, 105–121. [Google Scholar] [CrossRef]

- Snoeck, D.; Steuperaert, S.; Van Tittelboom, K.; Dubruel, P.; De Belie, N. Visualization of water penetration in cementitious materials with superabsorbent polymers by means of neutron radiography. Cem. Concr. Res. 2012, 42, 1113–1121. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Zhao, T.; Lehmann, E.H. Neutron imaging of water penetration into cracked steel reinforced concrete. Phys. B Condens. Matter 2010, 405, 1866–1871. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Zhao, T.; Lehmann, E.H.; Jin, Z. Visualization and quantification of water movement in porous cement-based materials by real time thermal neutron radiography: Theoretical analysis and experimental study. Sci. China Technol. Sci. 2010, 53, 1198–1207. [Google Scholar] [CrossRef]

- Kanematsu, M.; Maruyama, I.; Noguchi, T.; Iikura, H.; Tsuchiya, N. Quantification of water penetration into concrete through cracks by neutron radiography. Nucl. Instrum. Meth. A 2009, 605, 154–158. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Haist, M.; Müller, H.S.; Vontobel, P.; Zhao, T. Water penetration into micro-cracks in reinforced concrete. Restor. Build. Monum. 2014, 20, 85–94. [Google Scholar]

- Zhang, P.; Wittmann, F.H.; Zhao, T.; Lehmann, E.H.; Vontobel, P. Neutron radiography, a powerful method to determine time-dependent moisture distributions in concrete. Nucl. Eng. Des. 2011, 241, 4758–4766. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Wang, J.; Araujo, A.; Snoeck, D.; Gruyaert, E.; Debbaut, B.; Derluyn, H.; Cnudde, V.; Tsangouri, E.; Van Hemelrijck, D.; et al. Comparison of different approaches for self-healing concrete in a large-scale lab test. Constr. Build. Mater. 2016, 107, 125–137. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; De Backer, P.; Moerman, W.; De Belie, N. Self-repair of thermal cracks in concrete sandwich panels. Struct. Concr. 2015, 16, 273–288. [Google Scholar] [CrossRef]

| Code | Description Test Series | n |

|---|---|---|

| UN | Uncracked mortar samples | 2 a |

| CR_1 | Mortar samples with one standard crack | 3 a |

| CR_2 | Mortar samples with two standard cracks | 3 a |

| CR_1_PU_HV | Mortar samples with one standard crack autonomously healed with high viscosity healing agent | 3 a + 2 b |

| CR_1_PU_LV | Mortar samples with one standard crack autonomously healed with low viscosity healing agent | 3 a + 2 b |

| CR_2_PU_HV | Mortar samples with two standard cracks autonomously healed with high viscosity healing agent | 4 a |

| CR_2_PU_LV | Mortar samples with two standard cracks autonomously healed with low viscosity healing agent | 4 a |

| Sample | WFA/SCA (%) |

|---|---|

| UN | 10.8 ± 5.0 |

| CR_1 | 14.1 ± 0.6 |

| CR_1_PU_HV | 16.7 ± 3.5 |

| CR_1_PU_LV | 15.7 ± 4.5 |

| CR_2 | 26.9 ± 1.9 |

| CR_2_PU_HV | 25.3 ± 3.1 |

| CR_2_PU_LV | 24.0 ± 3.8 |

| Sample | Integral (×10−1 g/cm2) |

|---|---|

| UN | 1.6 ± 0.5 |

| CR_1 | 1.8 ± 0.1 |

| CR_1_PU_HV | 2.0 ± 0.3 |

| CR_1_PU_LV | 1.7 ± 0.4 |

| CR_2 | 2.4 ± 0.3 |

| CR_2_PU_HV | 2.3 ± 0.2 |

| CR_2_PU_LV | 2.4 ± 0.2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van den Heede, P.; Van Belleghem, B.; Alderete, N.; Van Tittelboom, K.; De Belie, N. Neutron Radiography Based Visualization and Profiling of Water Uptake in (Un)cracked and Autonomously Healed Cementitious Materials. Materials 2016, 9, 311. https://doi.org/10.3390/ma9050311

Van den Heede P, Van Belleghem B, Alderete N, Van Tittelboom K, De Belie N. Neutron Radiography Based Visualization and Profiling of Water Uptake in (Un)cracked and Autonomously Healed Cementitious Materials. Materials. 2016; 9(5):311. https://doi.org/10.3390/ma9050311

Chicago/Turabian StyleVan den Heede, Philip, Bjorn Van Belleghem, Natalia Alderete, Kim Van Tittelboom, and Nele De Belie. 2016. "Neutron Radiography Based Visualization and Profiling of Water Uptake in (Un)cracked and Autonomously Healed Cementitious Materials" Materials 9, no. 5: 311. https://doi.org/10.3390/ma9050311

APA StyleVan den Heede, P., Van Belleghem, B., Alderete, N., Van Tittelboom, K., & De Belie, N. (2016). Neutron Radiography Based Visualization and Profiling of Water Uptake in (Un)cracked and Autonomously Healed Cementitious Materials. Materials, 9(5), 311. https://doi.org/10.3390/ma9050311