Evaluation of the Influence of Specific Surface Treatments of RBA on a Set of Properties of Concrete

Abstract

:1. Introduction

2. Materials and Methods

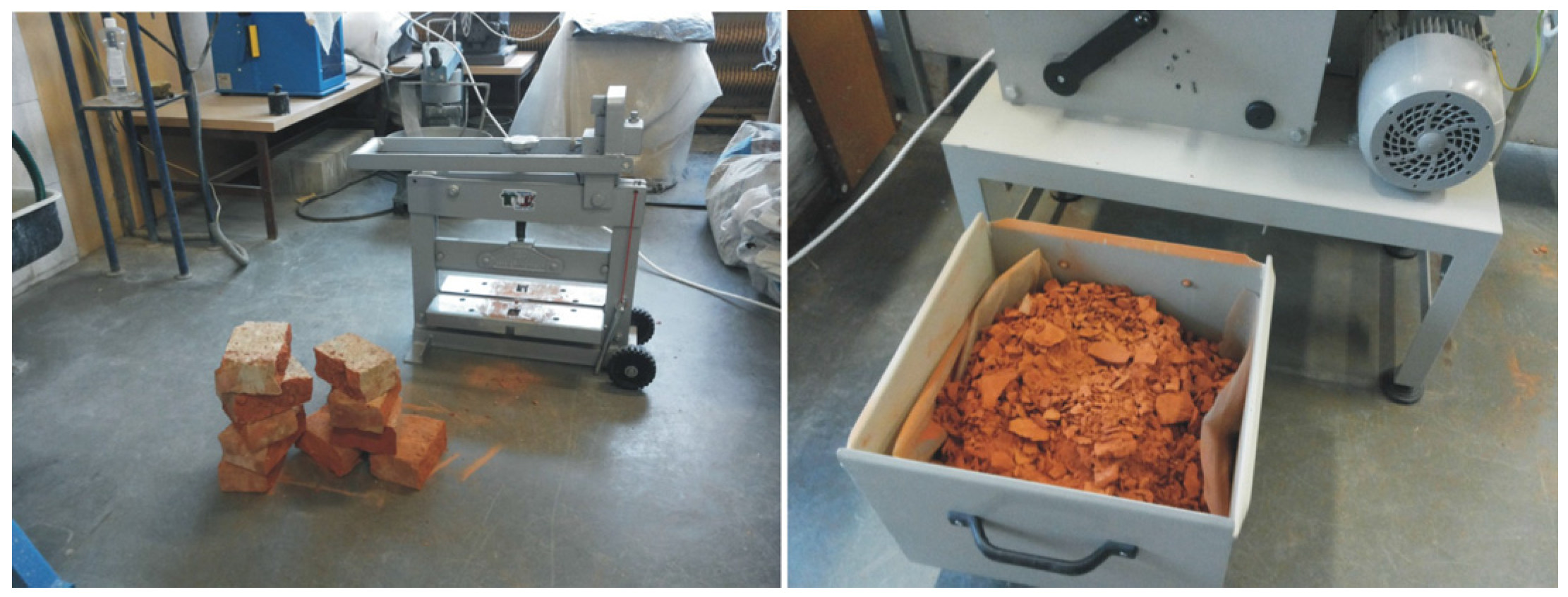

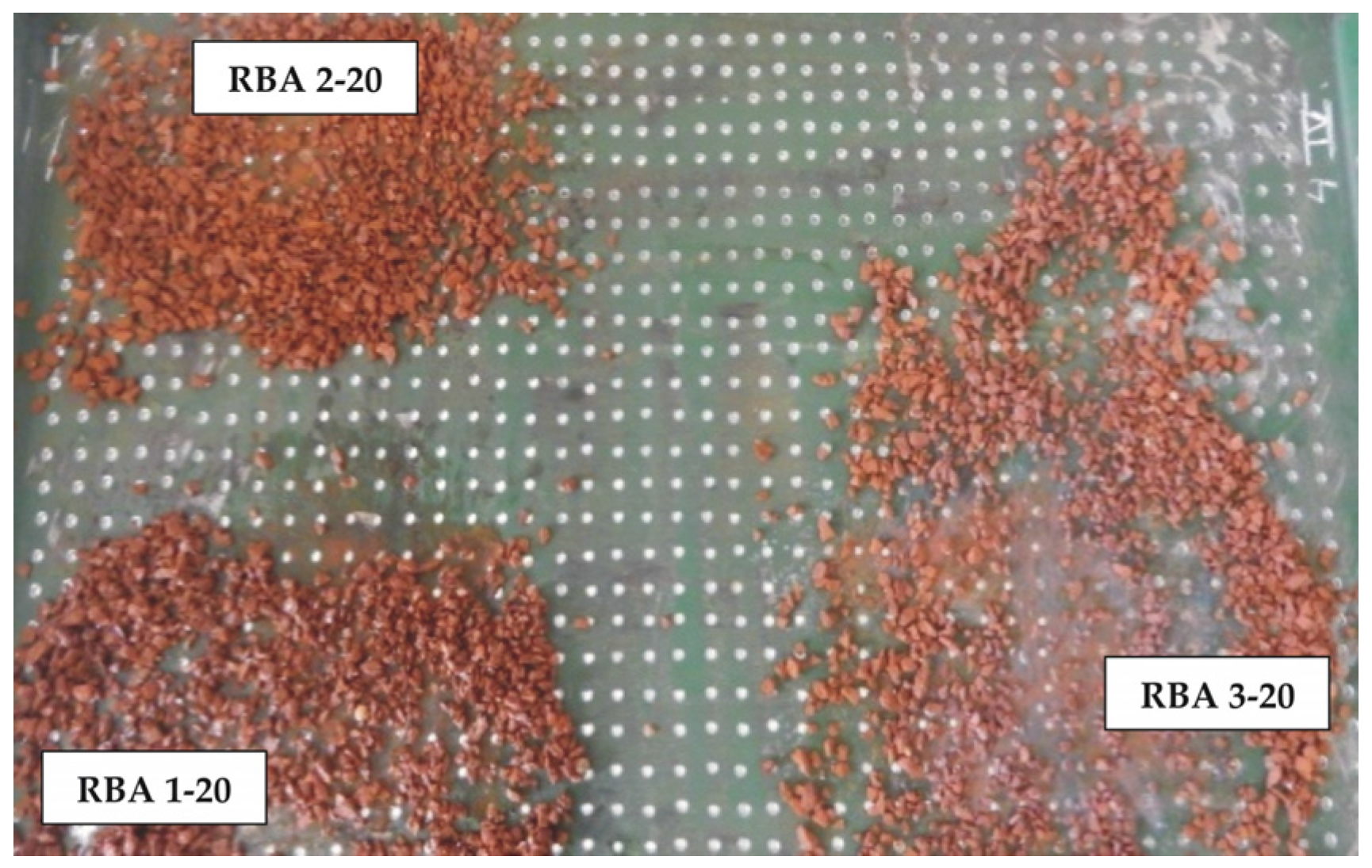

2.1. Recycled Brick Aggregate (RBA) Treatments

2.2. Concrete Mixtures with RBAs

2.3. Methods of Testing the Properties of Hardened Concrete

- Flexural strength (MPa)

- Compressive strength (MPa)

- Capillarity due to capillary moisture content mc after 90 min

- Total water absorption capacity (%)

- Depth of water penetration under pressure (mm)

- Frost resistance (frost resistance coefficient, expressed as a percentage of strength before testing) (%)

2.3.1. Flexural Strength

2.3.2. Compressive Strength

2.3.3. Capillary Moisture Content

2.3.4. Water Absorption Capacity

2.3.5. Depth of Penetration of Water under Pressure

2.3.6. Frost Resistance

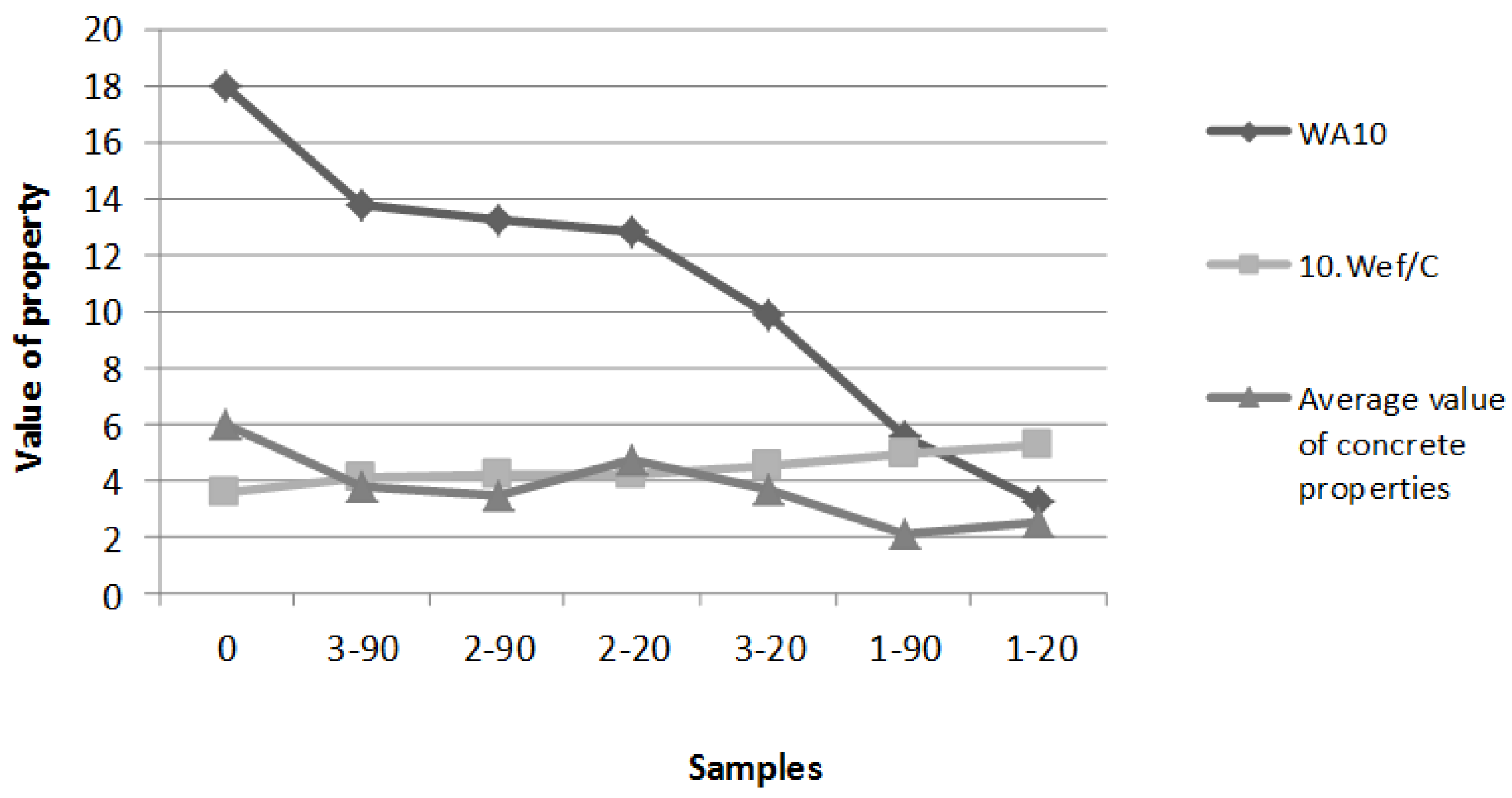

3. Results and Discussion

4. Conclusions

- The relation between water absorption of RBA, the effective amount of water, and set of concrete properties was confirmed: at a constant amount of mixing water, decline in water absorption of the RBA led to higher w/c ratio, and lower quality of concrete.

- When applying RBA in various surface treatments, it is necessary to work with actual water absorption and the effective w/c ratio by adjusting the amount of mixing water to be absorbed by the RBA.

- Out of all the tested surface treatments of the RBA, treatment by sodium water glass is the most effective in decreasing absorption. Therefore, it has the best potential for adjusting the mixing water and reduction of the w/c ratio, thus improving the quality of the concrete.

- When surface treatments by impregnation are applied, it is better from a practical point of view to dry at lower temperatures, meaning part of the water stays in the porous system of the RBA.

- Keeping the effective w/c ratio within standard limits, concretes containing treated RBA are possible to be specified for various exposure classes and manufacturing in practice.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| RBA | Recycled Brick Aggregate |

| C&DW | Construction and Demolition Wastes |

| RA | Recycled Aggregate |

| CRBA | Concrete based on treated Recycled Brick Aggregate |

| WAtot | Total water absorption capacity |

| Wtot | Total mixing water |

| WA10 | Water absorption capacity in 10 min |

References

- Bhanbhro, R.; Memon, I.; Ansari, A.; Shah, A.; Memon, B. Properties evaluation of concrete using local used bricks as coarse aggregate. Engineering 2014, 6, 211–216. [Google Scholar] [CrossRef]

- Tempest, B.; Cavalline, T.; Gergely, J.; Weggel, D. Construction and demolition waste used as recycled aggregates in concrete: Solutions for increasing the marketability of recycled aggregate concrete. In Proceedings of the Concrete Sustainability Conference, Tempe, AZ, USA, 13–15 April 2010.

- Schwerin, D.E.; Cavalline, T.L.; Weggel, D.C. Use of recycled brick masonry aggregate and recycled brick masonry aggregate concrete in sustainable construction. KICEM J. Constr. Eng. Proj. Manag. 2013, 3, 28–34. [Google Scholar] [CrossRef]

- Spisakova, M.; Kozlovska, M. Deconstruction of buildings—Sustainable ways of construction. In Proceedings of the 13th International Multidisciplinary Scientific Geoconference: Energy and Clean Technologies, Albena, Bulgaria, 16–22 June 2013.

- Akhtaruzzaman, A.A.; Hasnat, A. Properties of concrete using crushed brick as aggregate. Concr. Int. 1983, 5, 58–63. [Google Scholar]

- Khaloo, A.R. Properties of concrete using crushed clinker brick as coarse aggregate. ACI Mater. J. 1994, 91, 401–407. [Google Scholar]

- Mansur, M.A.; Wee, T.H.; Cheran, L.S. Crushed bricks as coarse aggregate for concrete. ACI Mater. J. 1999, 96, 478–484. [Google Scholar]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M.A. A general relationship between porosity and uniaxial strength of engineering materials. Can. J. Civ. Eng. 2003, 30, 644–658. [Google Scholar] [CrossRef]

- Otoko, R.G. Use of crushed clay bricks as aggregate in concrete. Int. J. Eng. Technol. Res. 2014, 2, 1–9. [Google Scholar]

- Angulo, S.C.; Carrijo, P.M.; Figueiredo, A.D.; Chaves, A.P.; John, V.M. On the classification of mixed construction and demolition waste aggregate by porosity and its impact on the mechanical performance of concrete. Mater. Struct. 2010, 43, 519–528. [Google Scholar] [CrossRef]

- Zong, L.; Fei, Z.; Zhang, S. Permeability of recycled aggregate concrete containing fly ash and clay brick waste. J. Clean. Prod. 2014, 70, 175–182. [Google Scholar] [CrossRef]

- Kesegić, I.; Netinger, I.; Bjegović, D. Recycled clay brick as an aggregate for concrete: Overview. Tech. Gaz. 2008, 15, 35–40. [Google Scholar]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra-Romero, M.I. Pre-saturation technique of the recycled aggregates: Solution to the water absorption drawback in the recycled concrete manufacture. Materials 2014, 7, 6224–6236. [Google Scholar] [CrossRef]

- Paul, S.; Dey, G. Use of crushed brick aggregate in structural concrete: Properties and performance. In Construction Materials and Structures; IOS Press Ebooks: Amsterdam, The Netherland, 2014; pp. 378–383. [Google Scholar]

- Zhang, S.; Zong, L. Properties of concrete made with recycled coarse aggregate from waste brick. Environ. Prog. Sustain. Energy 2013, 33, 1283–1289. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd-Elmoaty, A.-E.M.; Hassan, H.H. Utilization of crushed clay brick in concrete industry. Alex. Eng. J. 2014, 53, 151–168. [Google Scholar] [CrossRef]

- Rashid, M.A.; Salam, M.A.; Shill, S.K.; Hasan, M.K. Effect of replacing natural coarse aggregate by brick aggregate on the properties of concrete. Dhaka Univ. Eng. Technol. J. 2012, 1, 17–22. [Google Scholar]

- Sadek, D.M. Physico-mechanical properties of solid cement bricks containing recycled aggregates. J. Adv. Res. 2012, 3, 253–260. [Google Scholar] [CrossRef]

- Janković, K.; Bojović, D.; Nikoloć, D.; Loncar, L.; Romakov, Z. Frost resistance of concrete with crushed brick as aggregate. Facta Univ. 2010, 8, 155–162. [Google Scholar] [CrossRef]

- Miličević, I.; Štirmer, N.; Bjegović, D. Optimisation of concrete mixtures made with crushed clay bricks and roof tiles. Mag. Concr. Res. 2015, 67, 109–120. [Google Scholar] [CrossRef]

- Bolouri-Bazaz, J.; Khayati, M. Properties and performance of concrete made with recycled low-quality crushed brick. J. Mater. Civ. Eng. 2012, 24, 330–338. [Google Scholar] [CrossRef]

- Afify, M.R.; Soliman, N.M. Improvement properties of recycle concrete using clay brick as a coarse aggregate. Int. J. Curr. Eng. Technol. 2014, 4, 119–127. [Google Scholar]

- Mohammed, T.U.; Hasnat, A.; Awal, M.A.; Bosunia, S.Z. Recycling of brick aggregate concrete as coarse aggregate. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, X.N. Experimental study on the mixture ratio and the compressive strength of concrete with recycle crushed brick coarse aggregate. Appl. Mech. Mater. 2014, 584–586, 1362–1365. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, Y.; Dong, H.; Zhou, Z.; Qiao, Q. Experimental study on the seismic performance of recycled concrete brick walls embedded with vertical reinforcement. Materials 2014, 7, 5934–5958. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 206-1: 2002 Concrete. Specification, Performance, Production and Conformity; European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- Ondova, M.; Sicakova, A.; Karoli, D. Modification the properties of recycled brick aggregate in respect on the workability of fresh concrete. In Proceedings of the 15th International Multidisciplinary Scientific Geoconference on Nano, Bio and Green: Technologies for Sustainable Future, Albena, Bulgaria, 18–24 June 2015.

- European Committee for Standardization. EN 12390-5: 2011 Testing Hardened Concrete. Part 5: Flexural Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. EN 12390-3: 2010 Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. EN 1015-18: 2003 Methods of Test for Mortar for Masonry. Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- Slovak Standards Institute. STN 73 1316: 1989 Determination of Moisture Content, Absorptivity and Capillarity of Concrete; Slovak Standards Institute: Bratislava, Slovakia, 1989. [Google Scholar]

- European Committee for Standardization. EN 12390-8: 2011 Testing Hardened Concrete. Part 8: Depth of Penetration of Water Under Pressure; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. EN 12390-9: 2006 Testing Hardened Concrete. Part 9: Freeze-Thaw Resistance. Scaling; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- Yehia, S.; Helal, K.; Abusharkh, A.; Zaher, A.; Istaitiyeh, H. Strength and durability evaluation of recycled aggregate concrete. Int. J. Concr. Struct. Mater. 2015, 9, 219–239. [Google Scholar] [CrossRef]

- Ryou, J.S.; Lee, Y.S. Characterization of recycled coarse aggregate (RCA) via a surface coating method. Int. J. Concr. Struct. Mater. 2014, 8, 165–172. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Influence of surface-treated coarse recycled concrete aggregate on compressive strength of concrete. World Acad. Sci. Eng. Technol. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2014, 8, 862–866. [Google Scholar]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directive. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32008L0098 (accessed on 24 February 2016).

- Descarrega, A. Quality Improvement of the Recycled Aggregates through Surface Treatment. Master’s Thesis, Universitat Politecnica de Catalunya, Barcelona, Spain, 2011. [Google Scholar]

| Sample of RBA | Treatment Method |

|---|---|

| RBA 0 | Control sample with no any treatment |

| RBA 1–20 | Impregnator: Sodium water glass Drying: 20 °C |

| RBA 1–90 | Impregnator: Sodium water glass Drying: 90 °C |

| RBA 2–20 | Impregnator: sodium water glass and water, proportion 1:1 Drying: 20 °C |

| RBA 2–90 | Impregnator: sodium water glass and water, proportion 1:1 Drying: 90 °C |

| RBA 3–20 | Impregnator: hydrophobic emulsion of silanes and siloxanes Drying: 20 °C |

| RBA 3–90 | Impregnator: hydrophobic emulsion of silanes and siloxanes Drying: 90 °C |

| Component | Amount for 1 m3 of Ready-Mixed Concrete |

|---|---|

| Cement (kg/m3) | 370 |

| Natural aggregates fraction 0/4 (kg/m3) | 1100 |

| Treated RBA, fraction 4/8 (kg/m3) | 425 |

| Water total (L) | 210 |

| Polycarboxilate type of plasticizing admixture (%) | 1.0 |

| Samples of RBA | WA10 (%) | Samples of Corresponding Concrete Mixture | Wef/C |

|---|---|---|---|

| RBA 0 | 18.0 | CRBA 0 | 0.36 |

| RBA 1–20 | 3.3 | CRBA 1–20 | 0.53 |

| RBA 1–90 | 5.6 | CRBA 1–90 | 0.50 |

| RBA 2–20 | 12.8 | CRBA 2–20 | 0.42 |

| RBA 2–90 | 13.2 | CRBA 2–90 | 0.42 |

| RBA 3–20 | 9.9 | CRBA 3–20 | 0.45 |

| RBA 3–90 | 13.8 | CRBA 3–90 | 0.41 |

| Samples RBA/CRBA | WA10 | Flexural Strength | Compressive Strength | Capillary Moisture Content | Total Water Absorption Capacity | Depth of Water Penetration | Frost Resistance Coefficient | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | STDEV * | (MPa) | STDEV * | (MPa) | STDEV * | (kg/m2) | STDEV * | (%) | STDEV * | (mm) | STDEV * | (%) | STDEV * | |

| 0 | 18.0 | 0.4 | 9.0 | 0.6 | 45.3 | 1.3 | 2.9 | 0.6 | 6.0 | 0.3 | 12 | 0.2 | 101.7 | 0.4 |

| 1–20 | 3.3 | 0.6 | 7.1 | 0.5 | 32.7 | 0.8 | 4.0 | 0.4 | 8.0 | 0.7 | 33 | 0.7 | 95.7 | 0.9 |

| 1–90 | 5.6 | 0.7 | 7.4 | 0.8 | 33.8 | 0.8 | 3.8 | 0.4 | 7.6 | 0.7 | 13 | 0.3 | 106.2 | 0.4 |

| 2–20 | 12.8 | 0.5 | 6.8 | 0.3 | 31.4 | 0.8 | 4.1 | 0.9 | 6.6 | 1.0 | 20 | 0.3 | 132.1 | 1.1 |

| 2–90 | 13.2 | 0.4 | 4.3 | 0.5 | 41.4 | 1.2 | 2.6 | 0.4 | 5.1 | 0.6 | 23 | 0.5 | 102.4 | 0.4 |

| 3–20 | 9.9 | 0.8 | 5.7 | 0.1 | 23.0 | 1.0 | 3.6 | 0.3 | 5.4 | 0.8 | 22 | 0.2 | 99.1 | 0.7 |

| 3–90 | 13.8 | 0.5 | 7.8 | 0.8 | 37.8 | 0.6 | 2.6 | 0.3 | 3.9 | 0.6 | 14 | 0.4 | 109.5 | 0.5 |

| Samples RBA/CRBA | Strength Class | Wef/C | Exposure Class | |

|---|---|---|---|---|

| Limit | Actual | |||

| 0 | C 35/45 | 0.45 | 0.36 | all |

| 2–90 3–90 | C 30/37 C 30/37 | 0.55 0.50 0.45 | 0.42 0.41 | XC 3, XD 1, XD 2, XF 1 XC 4, XS 1, XF 3 XF 4, XA 2 |

| 1–20 1–90 2–20 | C 25/30 C 25/30 C 25/30 | 0.60 0.55 | 0.53 0.50 0.42 | XC 2 XF 2 |

| 3–20 | C 16/20 | - | 0.45 | X 0 |

| Order of WA10 | Average Value of Concrete Properties | Respective Order of Concrete Properties | Sample of RBA/CRBA |

|---|---|---|---|

| 1 | 6.00 | 7 | 1–20 |

| 2 | 3.83 | 5 | 1–90 |

| 3 | 3.50 | 3 | 3–20 |

| 4 | 4.70 | 6 | 2–20 |

| 5 | 3.75 | 4 | 2–90 |

| 6 | 2.10 | 1 | 3–90 |

| 7 | 2.50 | 2 | 0 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ondova, M.; Sicakova, A. Evaluation of the Influence of Specific Surface Treatments of RBA on a Set of Properties of Concrete. Materials 2016, 9, 156. https://doi.org/10.3390/ma9030156

Ondova M, Sicakova A. Evaluation of the Influence of Specific Surface Treatments of RBA on a Set of Properties of Concrete. Materials. 2016; 9(3):156. https://doi.org/10.3390/ma9030156

Chicago/Turabian StyleOndova, Marcela, and Alena Sicakova. 2016. "Evaluation of the Influence of Specific Surface Treatments of RBA on a Set of Properties of Concrete" Materials 9, no. 3: 156. https://doi.org/10.3390/ma9030156

APA StyleOndova, M., & Sicakova, A. (2016). Evaluation of the Influence of Specific Surface Treatments of RBA on a Set of Properties of Concrete. Materials, 9(3), 156. https://doi.org/10.3390/ma9030156