Residual Ductility and Microstructural Evolution in Continuous-Bending-under-Tension of AA-6022-T4

Abstract

:1. Introduction

2. Microstructure and Tensile Properties of AA-6022-T4

3. Continuous-Bending-under-Tension Experiments

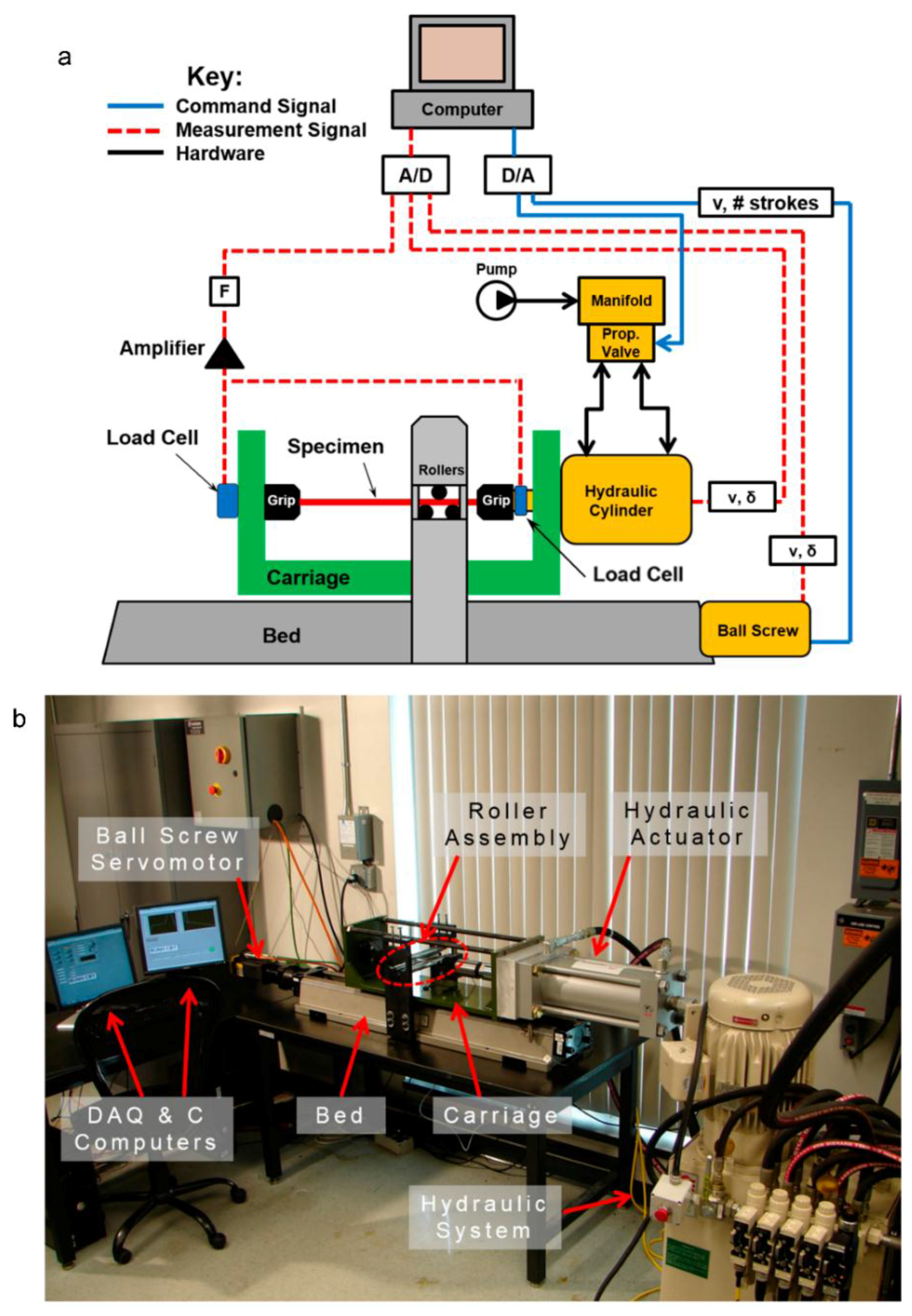

3.1. Custom CBT Testing Equipment

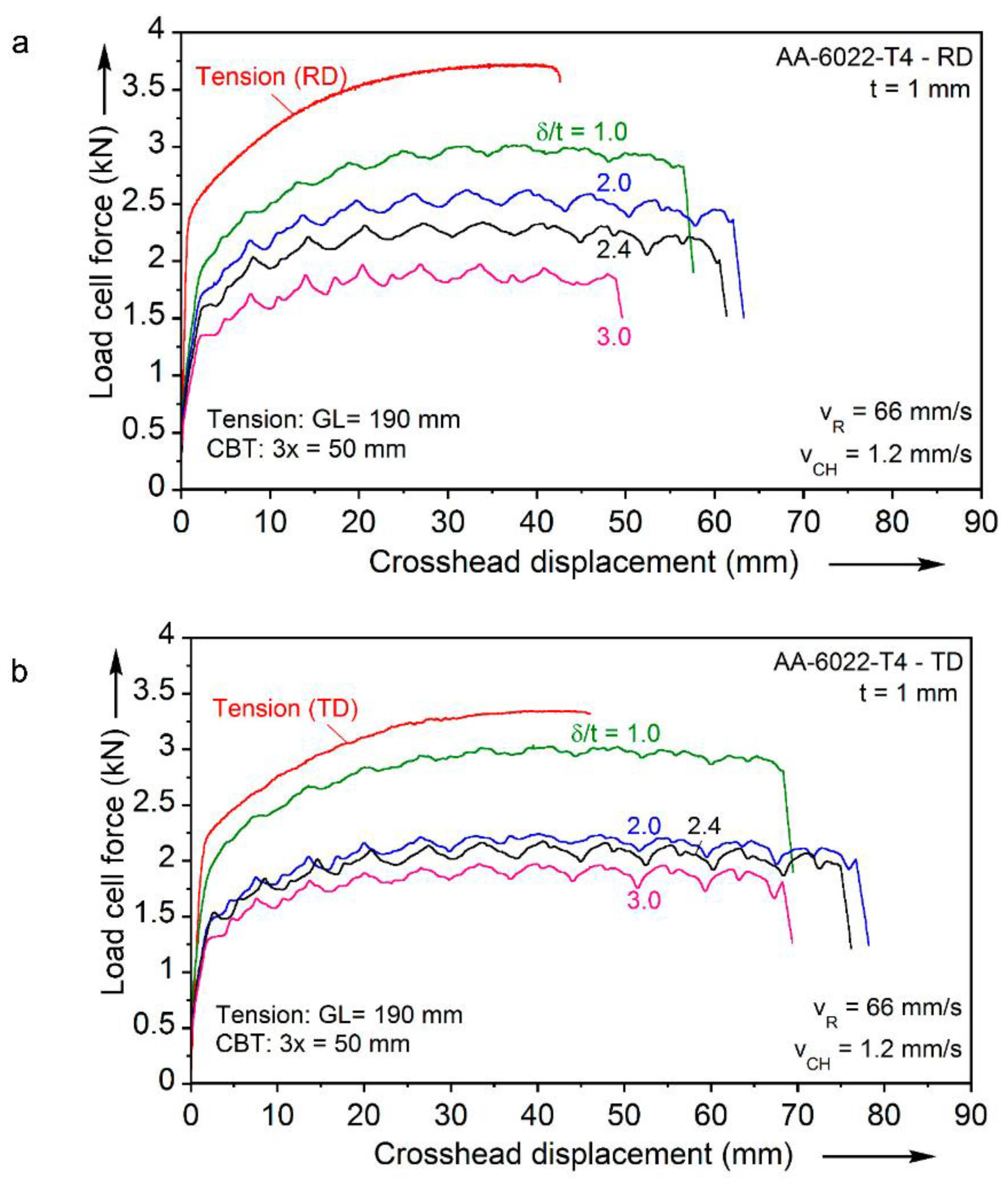

3.2. Representative CBT Experiment

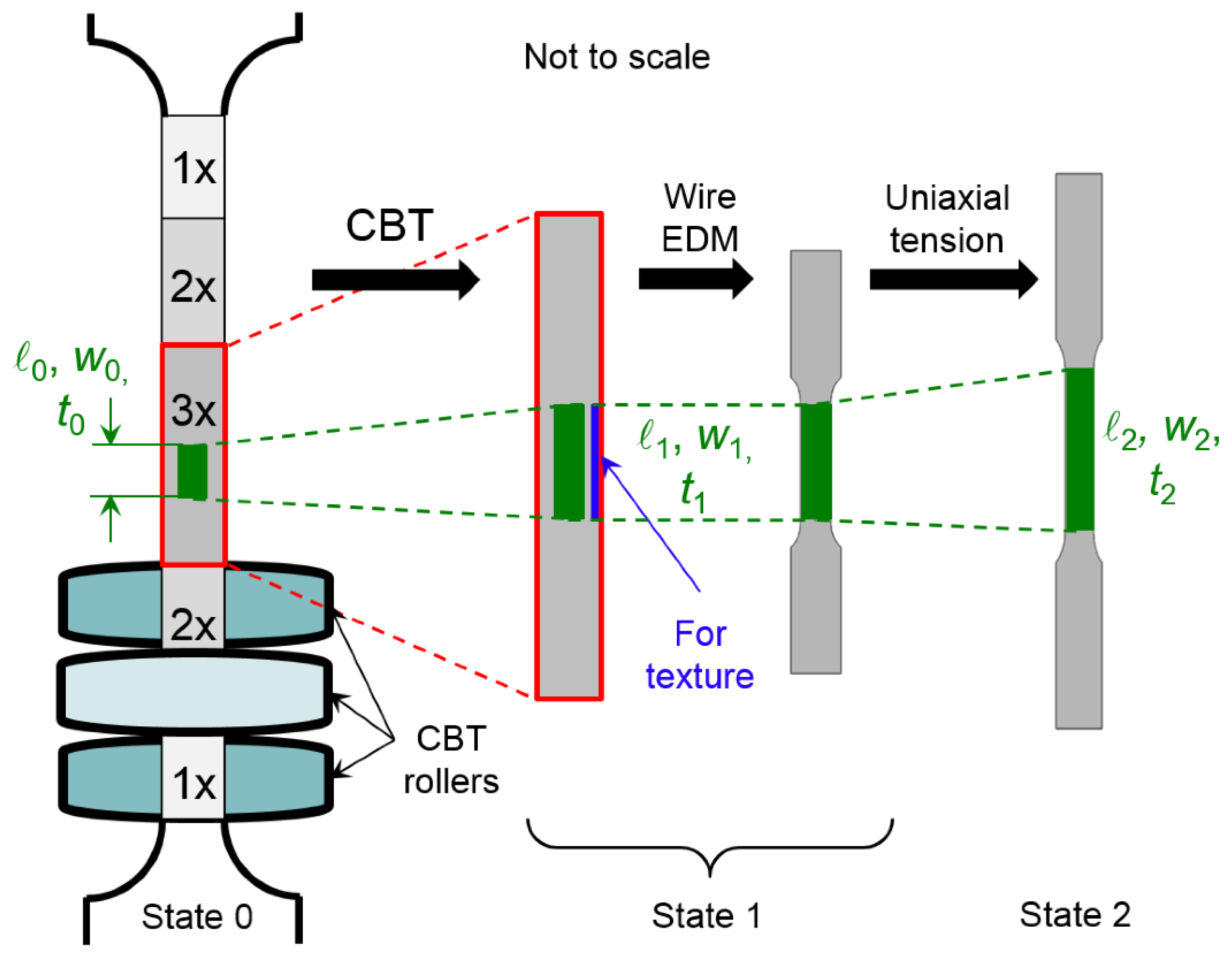

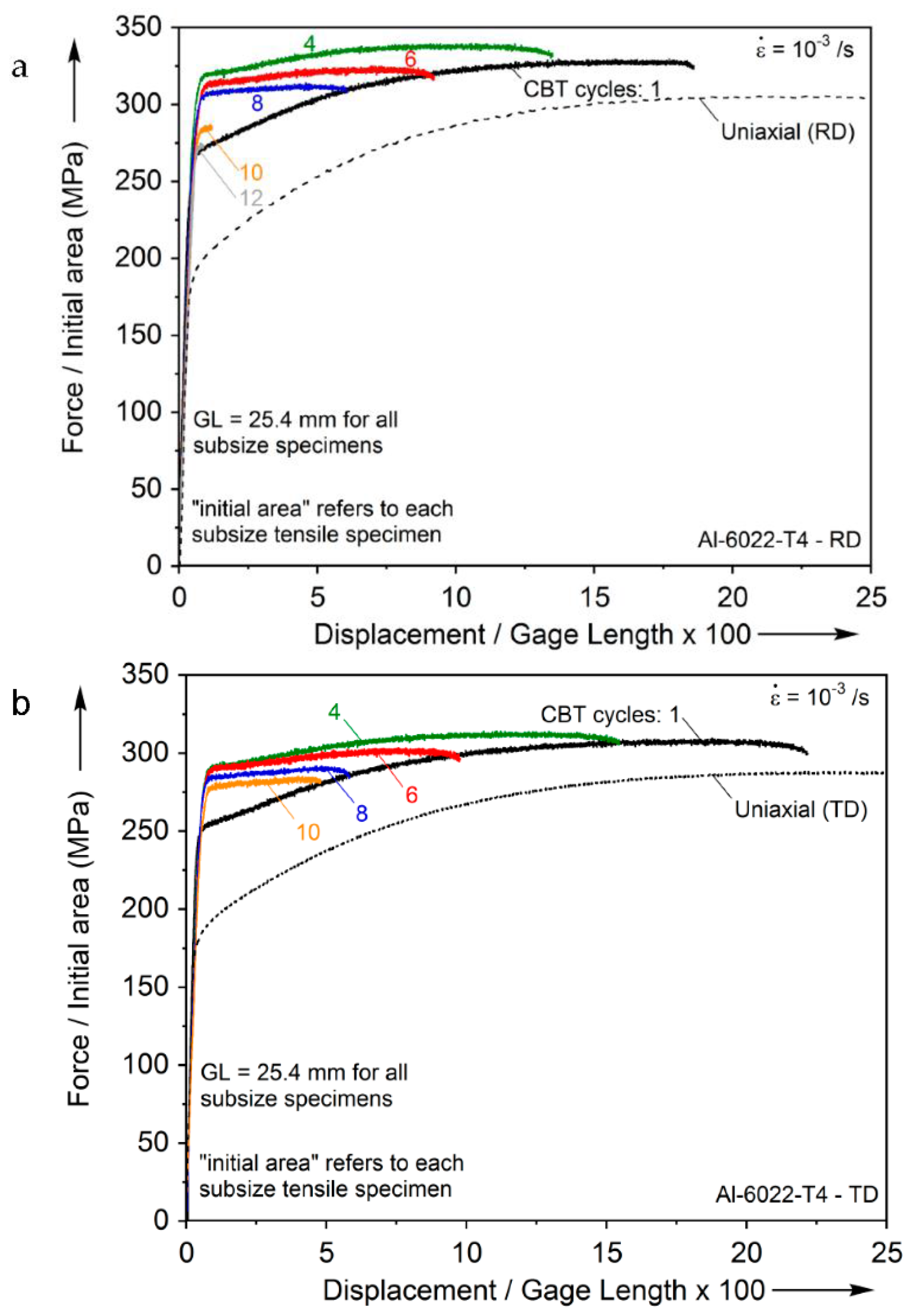

3.3. Interrupted CBT Experiments

4. Microstructural Characterization of Deformed Material

5. Conclusions and Outlook

- (a)

- The CBT process postpones the onset of necking. Experiments on 1 mm thick AA-6022-T4 showed increased elongation in CBT over conventional simple tension. Uniform depletion of ductility over the entire gauge length is possible using CBT.

- (b)

- The CBT tests show decreasing axial load with increasing roller depth, which is significant for achieving innovative forming processes at reduced load capacity requirements.

- (c)

- Subsize tensile samples extracted from the CBT specimens gave a higher yield stress and decreased elongation response relative to the simple tension response of the as-received material. The strength initially increases after CBT processing to a certain number of cycles, but then decreases with less elongation achieved for increasing numbers of CBT cycles.

- (d)

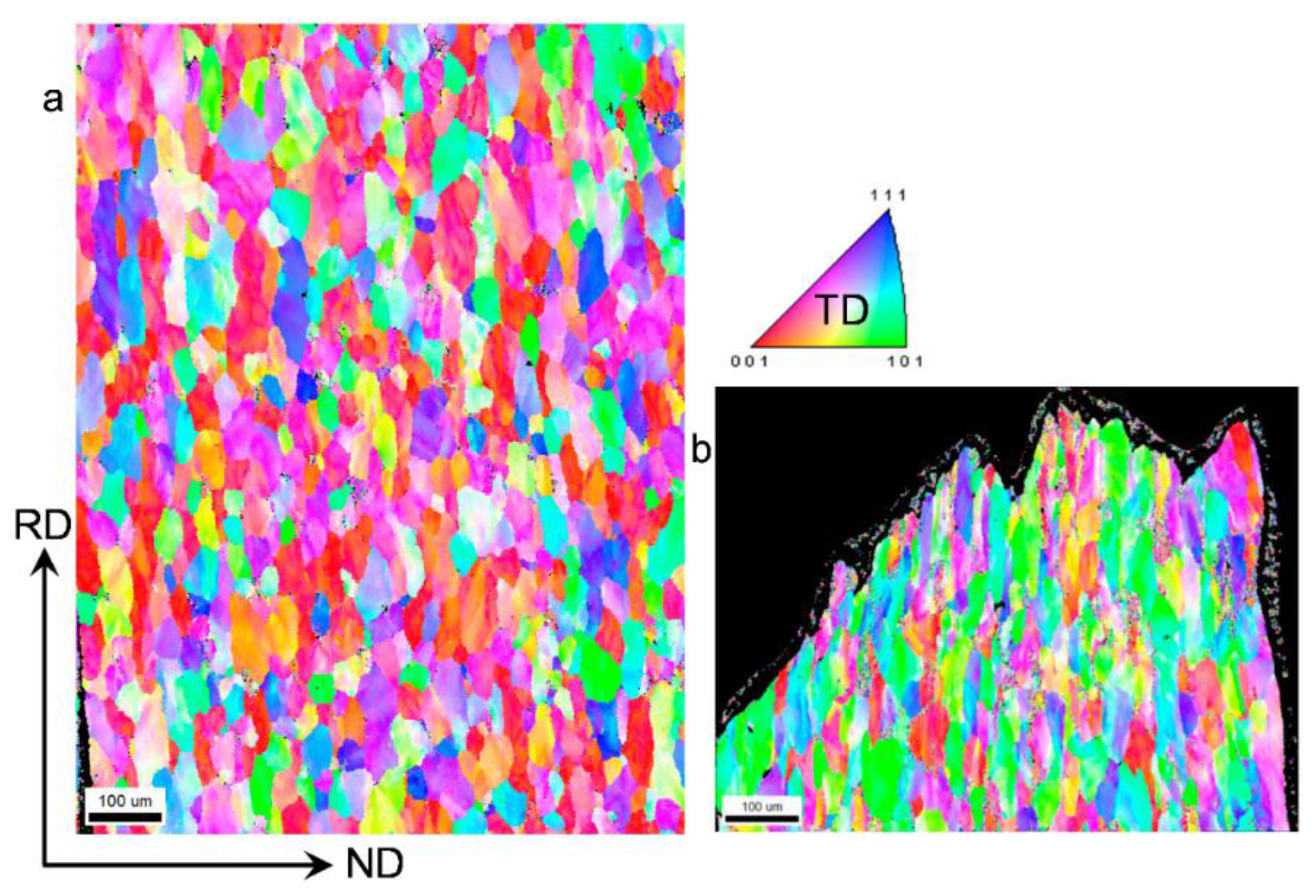

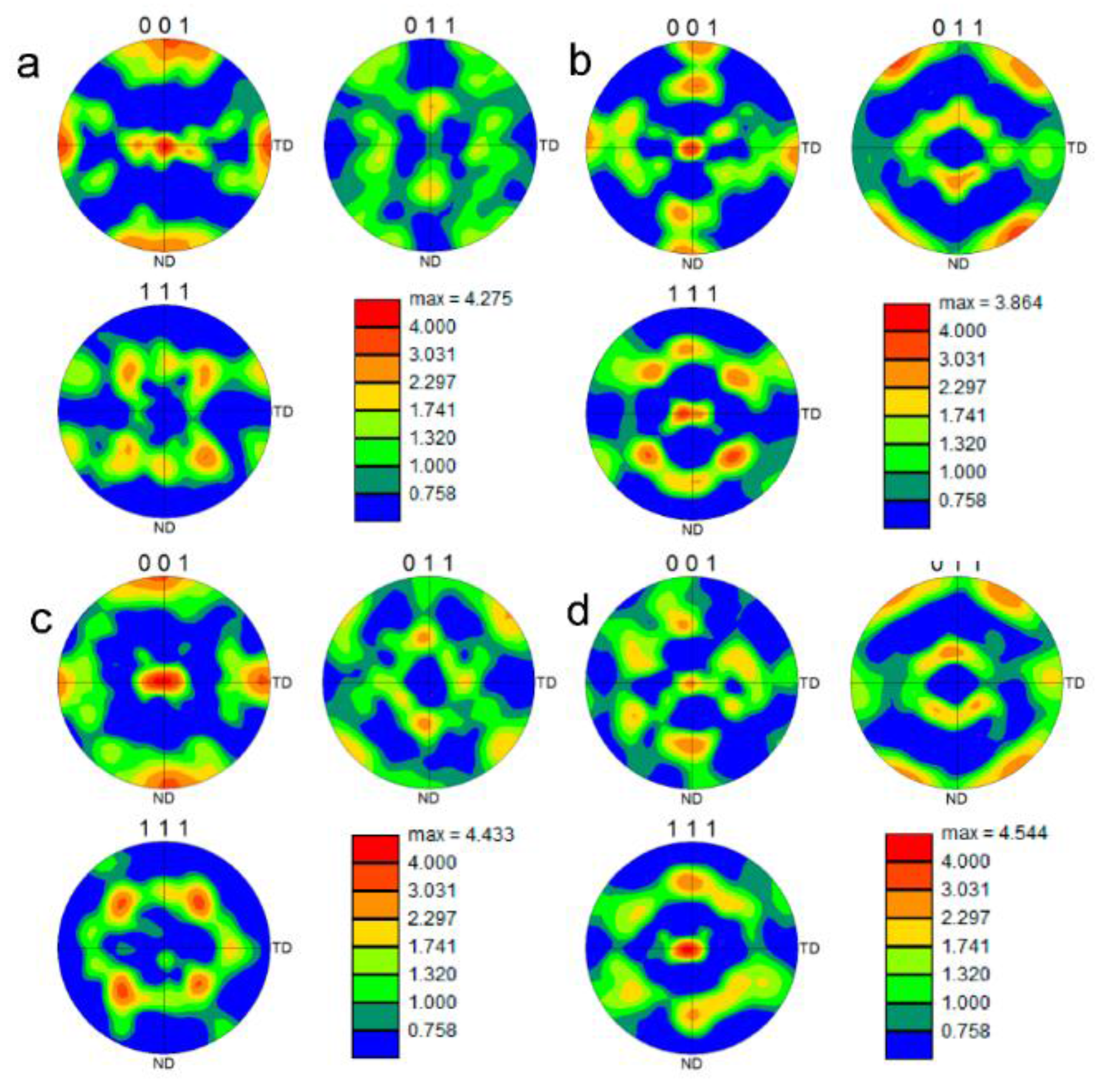

- Microstructure characterization revealed that the material under CBT preserves higher integrity to large plastic strains than under simple tension. In the former case damage is distributed uniformly throughout the material while in the latter case damage evolves rapidly in a localized region leading to necking and fracture.

- (e)

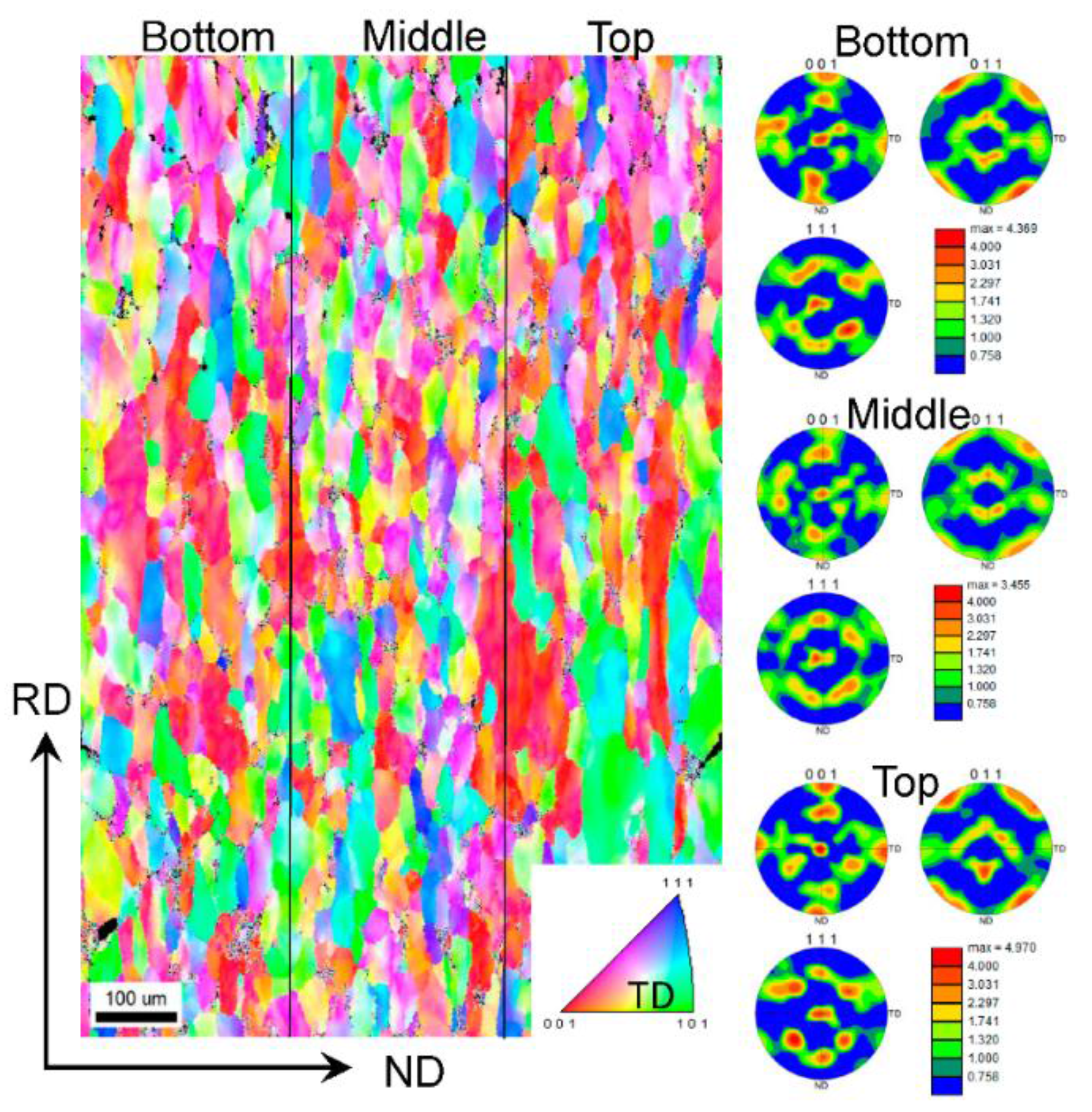

- The ability to delay ductile fracture during CBT processing to large plastic strains results in formation of a strong <111> fiber texture, which forms uniformly throughout the material. Therefore, the texture resulting from CBT deformation was similar to that around the neck in uniaxial tension.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- 2017–2025 Model Year Light-Duty Vehicle GHG Emissions and CAFE Standards: Supplemental. In STP Standard Temperature and Pressure TC Torque Converter TCC Torque Converter Clutch 2011; National Highway Traffic Safety Administration: Washington, DC, USA, 2011; pp. 1–33.

- Wagoner, R.; Kim, J.; Sung, J. Formability of advanced high strength steels. Int. J. Mater. Form. 2009, 2, 359–362. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. TRIP-Assisted steels? ISIJ Inter. 2002, 42, 1059–1060. [Google Scholar] [CrossRef]

- Shi, M.F.; Gelisse, S. Issues on the AHSS forming limit determination. In Proceedings of the IDDRG International Conference, Porto, Portugal, 19–21 June 2006.

- Nikhare, C.; Hodgson, P.D.; Weiss, M. Necking and fracture of advanced high strength steels. Mater. Sci. Eng. A 2011, 528, 3010–3013. [Google Scholar] [CrossRef]

- Swift, H.W. Plastic bending under tension. Engineering 1948, 166, 333–359. [Google Scholar]

- Benedyk, J.C.; Stawarz, D.; Parikh, N.M. A method for increasing elongation values for ferrous and nonferrous sheet metals. J. Mater. 1971, 6, 16–29. [Google Scholar]

- Emmens, W.C.; van den Boogaard, A.H. Incremental forming by continuous bending under tension—An experimental investigation. J. Mater. Proc. Technol. 2009, 209, 5456–5463. [Google Scholar] [CrossRef]

- Emmens, W.C.; van den Boogaard, A.H. Cyclic Stretch-bending: Mechanics, Stability, and Formability. J. Mater. Proc. Technol. 2011, 211, 1965–1981. [Google Scholar] [CrossRef]

- Emmens, W.C.; van den Boogaard, A.H. Material Characterization at High Strain by Adapted Tensile Tests. Exp. Mech. 2012, 52, 1195–1209. [Google Scholar] [CrossRef]

- Nikhare, C.; Korkolis, Y.P.; Kinsey, B.L. Numerical Investigation of Residual Formability and Deformation Localization during Continuous-Bending-under-Tension. In Proceedings of International Manufacturing Science and Engineering Conference, Notre Dame, IN, USA, 4–8 June 2012.

- Toda, H.; Oogo, H.; Horikawa, K.; Uesugi, K.; Takeuchi, A.; Suzuki, Y.; Nakazawa, M.; Aoki, Y.; Kobayashi, M. The true origin of ductile fracture in aluminum alloys. Metall. Mater. Trans. A 2014, 45, 765–776. [Google Scholar] [CrossRef]

- Miao, W.; Laughlin, D. Precipitation hardening in aluminum alloy 6022. Scr. Mater. 1999, 40, 873–878. [Google Scholar] [CrossRef]

- Roemer, T.J.; Kinsey, B.L.; Korkolis, Y.P. Design of a Continuous-Bending-Under-Tension Machine and Initial Experiments on Al-6022-T4. In Proceedings of the International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–11 June 2015.

- Benedyk, J.C.; Kinsey, B.L.; Korkolis, Y.P.; Roemer, T.J. Fundamental Studies of Continuous Bending Under Tension (CBT) and Potential Automotive Forming Applications. Mater. Today Proc. 2015, 2, 4998–5005. [Google Scholar] [CrossRef]

- Zecevic, M.; Knezevic, M. A dislocation density based elasto-plastic self-consistent model for the prediction of cyclic deformation: Application to AA6022-T4. Int. J. Plast. 2015, 72, 200–217. [Google Scholar] [CrossRef]

- Kuwabara, T.; Kumano, Y.; Ziegelheim, J.; Kurosaki, I. Tension–compression asymmetry of phosphor bronze for electronic parts and its effect on bending behavior. Int. J. Plast. 2009, 25, 1759–1776. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Hassan, T.; Kyriakides, S. Ratcheting of cyclically hardening and softening materials: I. Uniaxial behavior. Int. J. Plast. 1994, 10, 149–184. [Google Scholar] [CrossRef]

- Bari, S.; Hassan, T. Anatomy of coupled constitutive models for ratcheting simulation. Int. J. Plast. 2000, 16, 381–409. [Google Scholar] [CrossRef]

- Chaboche, J.L. A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 2008, 24, 1642–1693. [Google Scholar] [CrossRef]

- Music, O.; Allwood, J.M.; Kawai, K. A review of the mechanics of metal spinning. J. Mater. Process. Technol. 2010, 210, 3–23. [Google Scholar] [CrossRef]

- Wang, L.; Long, H. Investigation of material deformation in multi-pass conventional metal spinning. Mater. Des. 2011, 32, 2891–2899. [Google Scholar] [CrossRef]

- Emmens, W.C.; Sebastiani, G.; van den Boogaard, A.H. The technology of incremental sheet forming—A brief review of the history. J. Mater. Proc. Technol. 2010, 210, 981–997. [Google Scholar] [CrossRef]

- Allwood, J.M.; Shouler, D.R.; Tekkaya, A.E. The increased forming limits of incremental sheet forming processes. Key Eng. Mater. 2007, 344, 621–628. [Google Scholar] [CrossRef]

- Levy, B.S.; Green, D.E. Enhanced Forming Limit Diagram; Auto/Steel Partnership: Southfield, MI, USA. Available online: http://www.a-sp.org/~/media/Files/ASP/Lightweight%20Programs/Technology%20Report-Final.pdf (accessed on 15 October 1997).

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Tin | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.90 | 0.10 | 0.045 | 0.053 | 0.57 | 0.027 | 0.016 | 0.025 | <0.02 | balance |

| Test Conditions | Bending Depth | 1.75 mm |

| Cross-Head Velocity | 0.86 mm/s | |

| Carriage (Aka Roller) Velocity | 66 mm/s | |

| CBT Cycles Performed | RD (Rolling Direction) | 1, 4, 6, 8, 10, 12 |

| TD (Transverse Direction) | 1, 4, 6, 8, 10 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zecevic, M.; Roemer, T.J.; Knezevic, M.; Korkolis, Y.P.; Kinsey, B.L. Residual Ductility and Microstructural Evolution in Continuous-Bending-under-Tension of AA-6022-T4. Materials 2016, 9, 130. https://doi.org/10.3390/ma9030130

Zecevic M, Roemer TJ, Knezevic M, Korkolis YP, Kinsey BL. Residual Ductility and Microstructural Evolution in Continuous-Bending-under-Tension of AA-6022-T4. Materials. 2016; 9(3):130. https://doi.org/10.3390/ma9030130

Chicago/Turabian StyleZecevic, Milovan, Timothy J. Roemer, Marko Knezevic, Yannis P. Korkolis, and Brad L. Kinsey. 2016. "Residual Ductility and Microstructural Evolution in Continuous-Bending-under-Tension of AA-6022-T4" Materials 9, no. 3: 130. https://doi.org/10.3390/ma9030130

APA StyleZecevic, M., Roemer, T. J., Knezevic, M., Korkolis, Y. P., & Kinsey, B. L. (2016). Residual Ductility and Microstructural Evolution in Continuous-Bending-under-Tension of AA-6022-T4. Materials, 9(3), 130. https://doi.org/10.3390/ma9030130