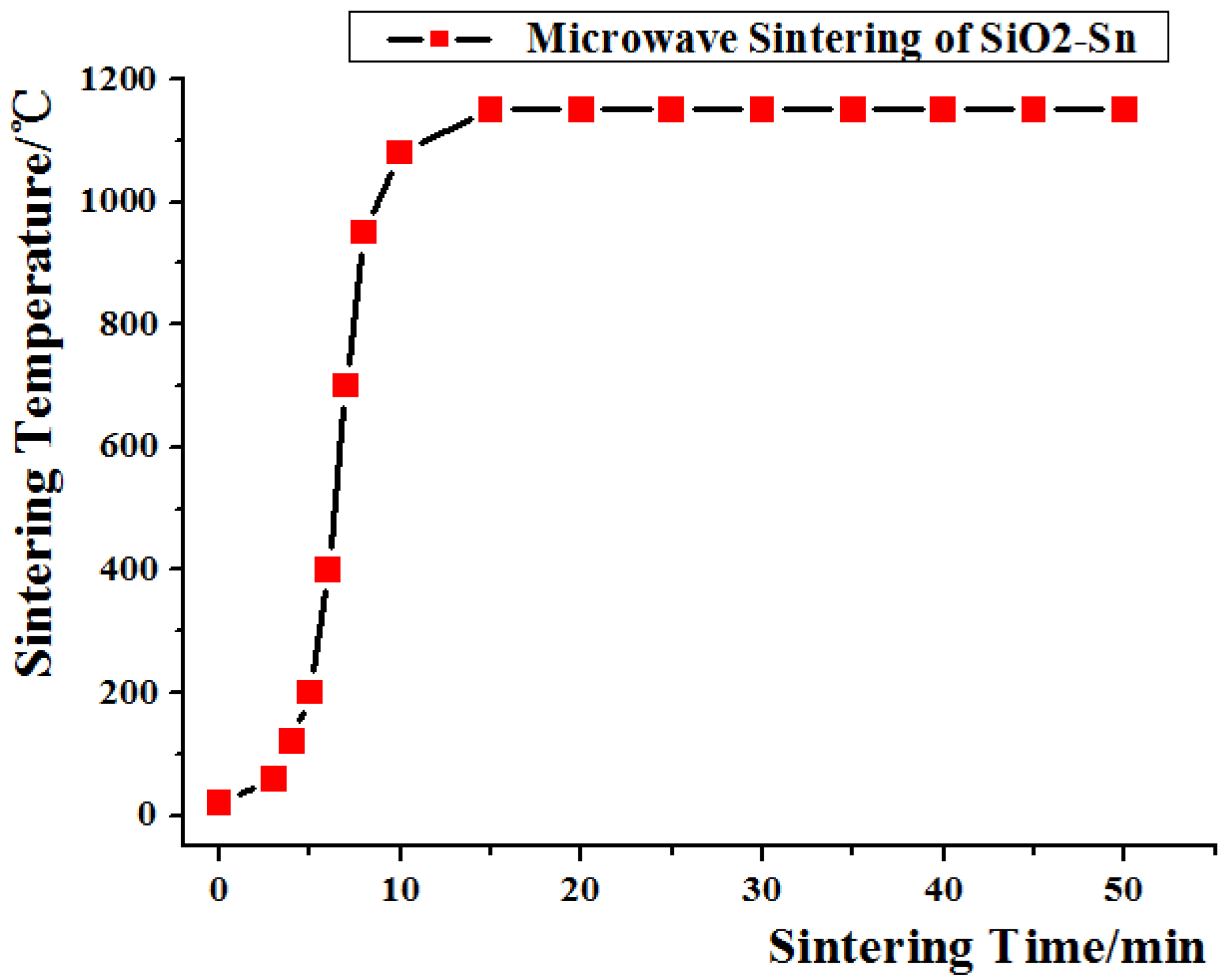

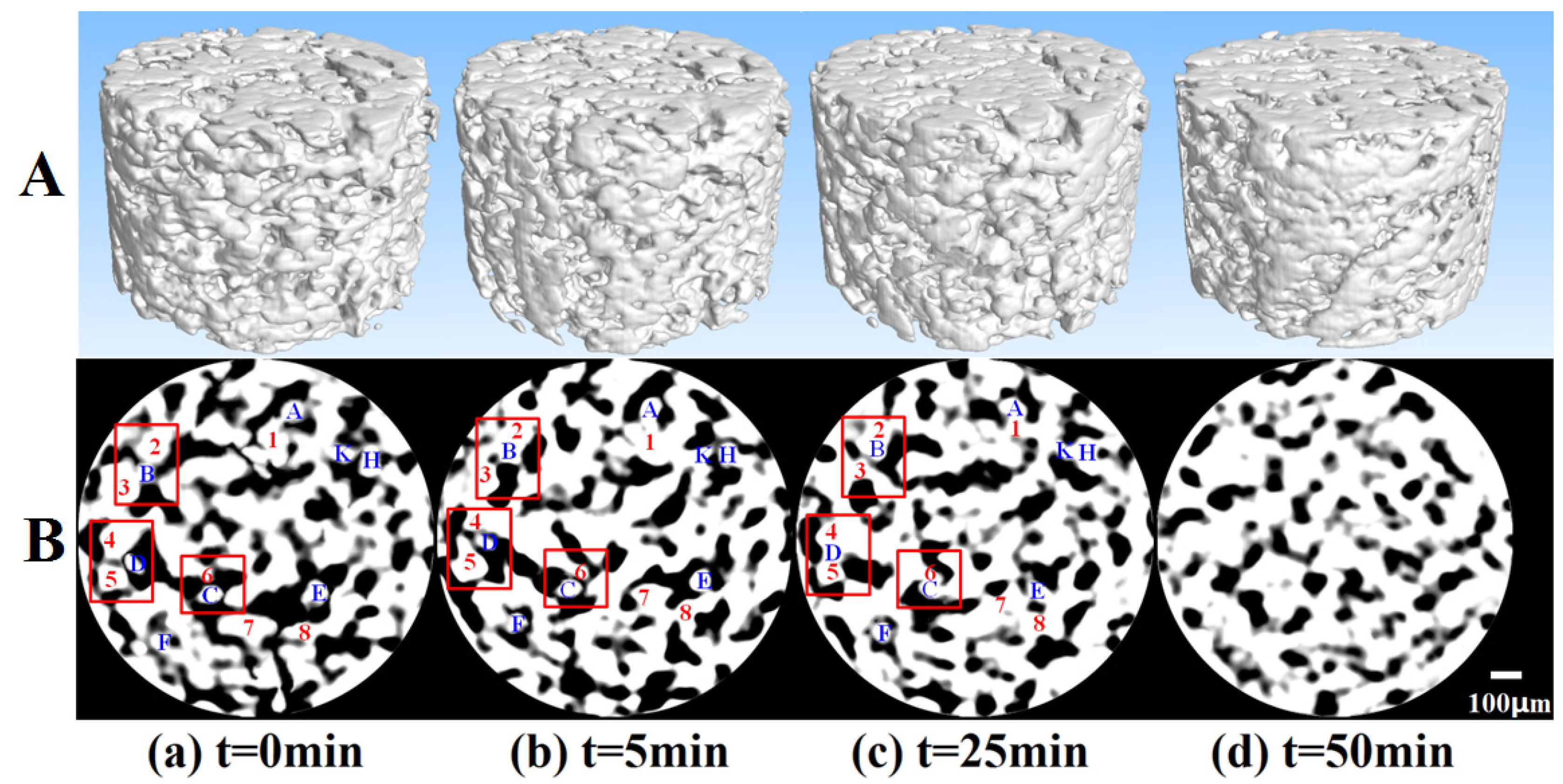

Figure 2 shows the microstructure evolution of the same 3-D and cross-section of SiO

2-Sn atdifferent sintering times. Grayscale range is from 0 to 255; the closer to 255, the higher the relative density, which means that white represents particles and black represents pores. In

Figure 2B, some typical particles were marked with numbers and letters (particles in blue color represent Sn, and red color represents SiO

2). From these images, the evolution of the same microstructurecan be tracked. For example, after microwave processing for some minutes, most of separated particles in

Figure 2B(a) connected with each other and sinteringnecks formed in

Figure 2B(b). The pores were interconnected with each other in

Figure 2B(a), while in

Figure 2B(d) the shape of pores changed and became closed and isolated. This means the specimen gradually changed from loose to dense. These phenomena were in accordance with the sintering theory and can also be observed insolid microwave sintering (e.g., Al-SiC, [

17]). In addition, there were some special sintering phenomena. For example, the microstructure evolution can be well tracked during solid microwave sintering of Al-SiC [

17]. However, in the microwave sintering of SiO

2-Sn, the rearrangement and rotation of particles were more frequent, and it wasvery hard to track the same microstructure during sintering. As we know, in microwave sintering the heat is derived from the direct interaction between microwave and material. This means the heating characteristic within the material is inevitably related to the microstructure and itsmaterial evolution. In order to investigate microwave sintering mechanisms, quantitative analysis of microstructure evolution parameters is an effective and important method.

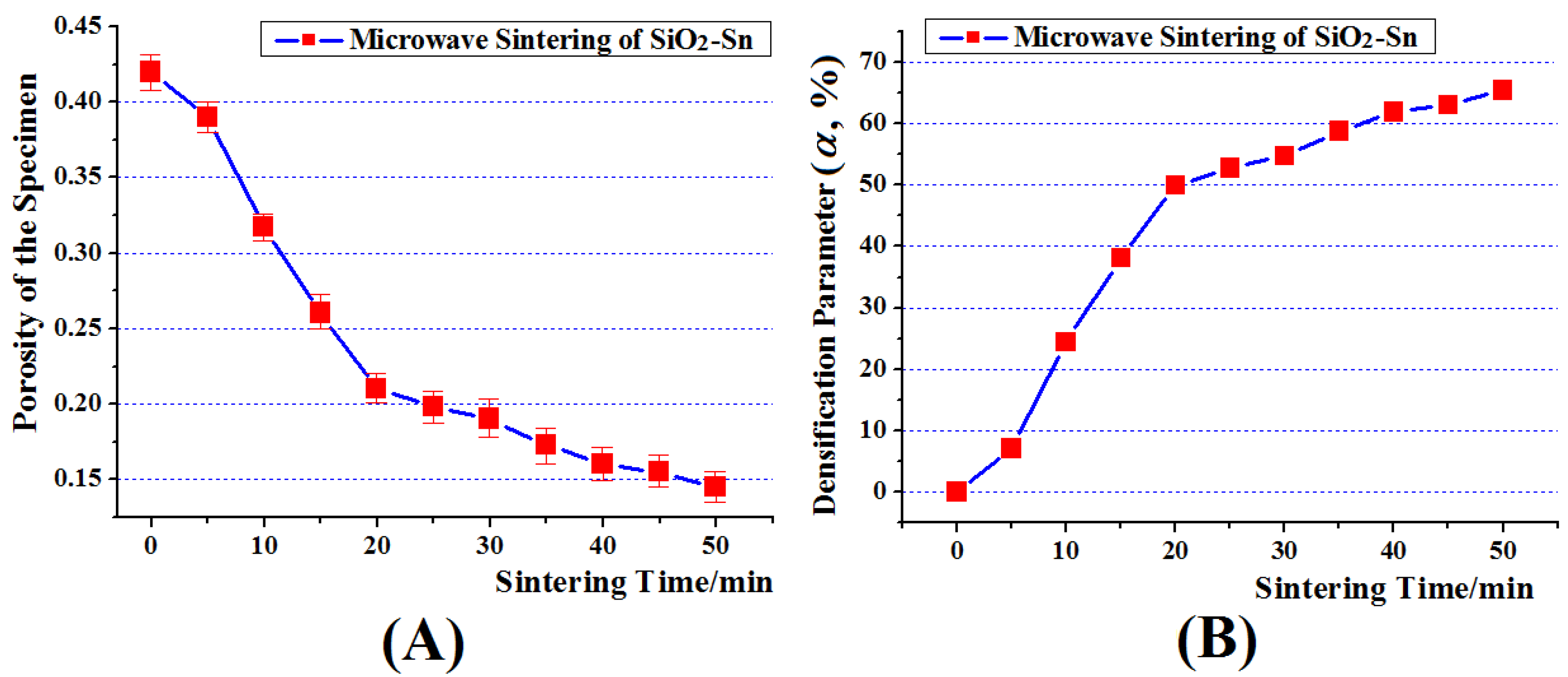

In this section, the statistics of the porosity of specimen in the differenttimes were carried out. The porosity represents the local bulk percentage of pore in the specimen. It is the averageof several similar cross-sections. The results are shown in

Figure 3A. In the sintering theory, the densification parameter

is usually adopted to analyze the densification process of sintering. It can be described as follows,

Here

represents true porosity, and

represents the porosity of the green body. Inorder to study the densification process of SiO

2-Sn during microwave sintering, the relationship between

and sintering time is shown in

Figure 3B. In

Section 3.1, the densification process and sintering mechanisms ofthe microstructure evolutionof the specimen will be discussed.

3.1. Densification below the Melting Point of Sn Induced by Microwave E-Fields

Figure 3B shows the change in

at different sintering times. It can be seen that the densification rate was very largefrom the 5th to 20th minute, and declined gradually from the 20th to 50th minute. Moreover, at the beginning, the value of

began to rise from 0 to 7.08 in the first 5 minute. However, the highest sintering temperature during this period was only 200 °C, which was below the melting point of Sn (231 °C). Although the sintering would occur between particles of Sn at this temperature, the volume ratio of Sn is only 1/11, and most Sn particles were separated by SiO

2 particles. How did the decline of porosity occur?

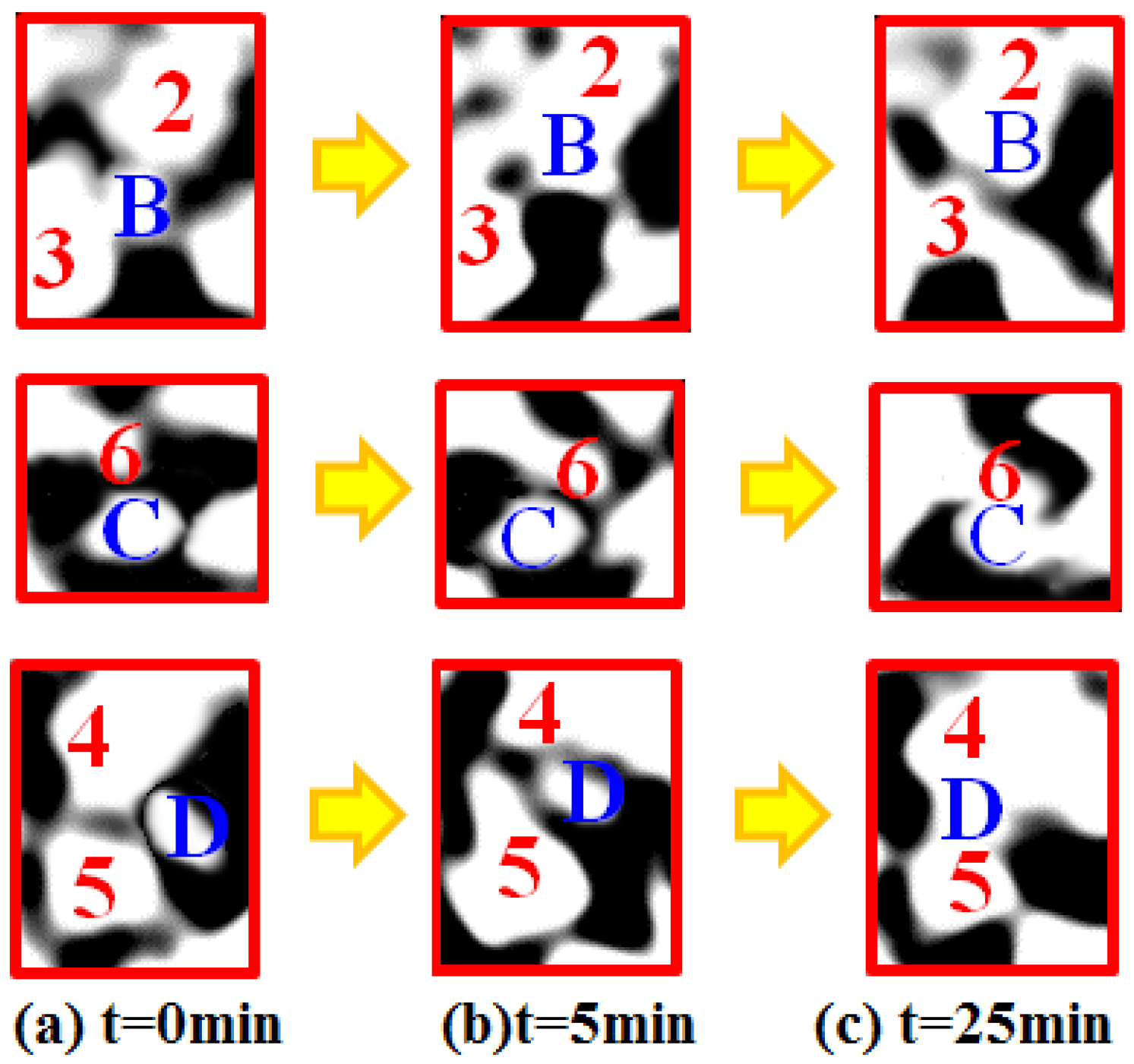

Figure 3 shows that the main densification began to occurin the first 5 minute. The corresponding microstructure evolution during this period is shown in

Figure 2B(a,b). From these images, the microstructure evolution can be clearly observed. For example, particle B was separated from particles 2 and 3 at the beginning. However, until the 5th minute, particle B was sintered together with particles 2 and 3. The local amplification images of these particles are shown in

Figure 4a similar microstructure evolution phenomenon was also observed on the other cross-section of the sample. This will inevitably lead to the densification of specimen.This phenomenon may be induced by the spark sintering. The explanation is that, as

Figure 4b shows, the sintering has happened between particles B, 2 and 3. This rapid sintering in such a short time and below the melting point of Sn indicates that there was a lot of heat deposition between particles induced by microwave fields, which then led to the high temperature within the local connection regions between particles. This highly energy deposition and high temperature is most likely due to the spark sintering caused by microwave electric fields.

As we know, spark sintering is a rapid sintering method viaelectric spark between particles induced by current. Yet in microwave sintering, the microwave energy is the direct energy source for the sintering process. This meansspark sintering likely must be closely related to the intensity distribution of microwave E-fields. In order to further study the reasons for spark sintering, it is necessary to research the intensity distribution of microwave E-fields within the specimen.

To study the intensity distribution of microwave E-fields, the TE101 mode resonator (109.2 mm × 54.6 mm × 74 mm) was used. With this resonator, the distribution of microwave electric fieldwas analysed by using the HFSS finite element analysis software. The TE101 mode resonator is a single-mode microwave resonator. It sets a 1 and 1 standing wave cycle of the electric fields in the direction of the x and z axes, respectively, and sets the electric field to be uniform and parallel to the y axis. In this way, an investigation into the propagation characteristics of microwave E-fields in a certain direction can be performed by using this resonator. To compare the obtained results with those obtained experimentally, the microwave frequency is set to 2.45 GHz, and the solution type is set to driven modal. The ceramic particle of SiO2 with a diameter of 150 μm and metallic particle Sn with a diameter of 75 μm is selected as the material model, which is identical to that used experimentally.Using this model, the E-field distribution between two of the connected particles was examined. Appropriate relative permittivity and relative magnetic permeability of 9.8 and 1.0, respectively, are assigned to the ceramic particles of SiO2. The appropriate relative permittivity and relative magnetic permeability of 1.0 and 1.0, respectively, are assigned to the metallic particle of Sn. Note that other values can be chosen for these two parameters if other materials are simulated. To investigate the behaviour of the microwave E-fields independently, the particles were placed in the region where the E-fields are at a maximum and where the H-fields are almost zero.

In the TE101 rectangular single-mode cavity, an operating frequency of 2.45 GHz will produce a wavelength around 122.5 mm, and the half wavelength of the standing wave are 109.2mm and 74mm in the direction of the x and z axes, respectively. Comparing the size of the particles (diameter 0.075 mm) with the half wavelength of the standing wave, the microwave E-fields in the sample can be considered to be approximately homogeneous prior to the introduction of the particles.

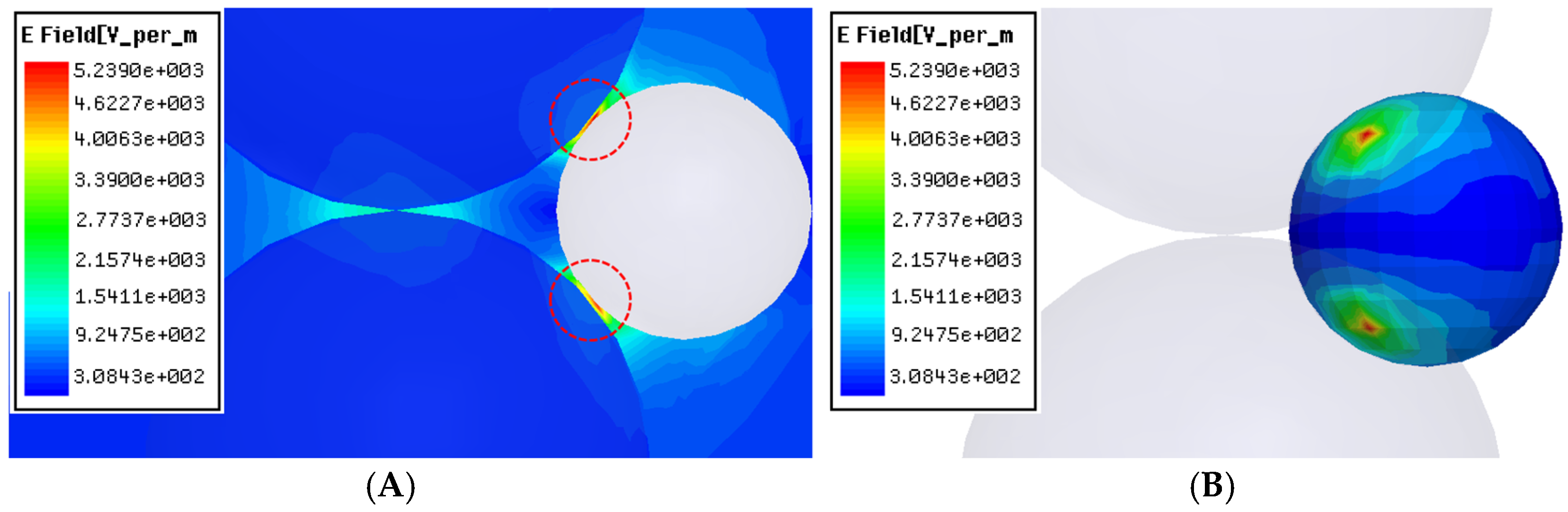

Figure 5 shows the intensity distribution of microwave E-fields when the particle Sn is located within the sintering neck of SiO

2, which is similar to the case of particles B, C and D located within the sintering neck of SiO

2 particles 2 to 6.

As can be seen, the E-fields within the micro-region of sintering neck between SiO

2 are much larger than the average fields, which suggests that the E-fields are focused in this micro-region. However, it can also be seen that the E-fields within the micro-region of the sintering neck between SiO

2-Sn are much larger than even the E-fields between SiO

2, which indicates that the focusing effect of E-fields is much more significantin this local micro-region.In the simulation, we assume that the intensity of the applied field is 3.30 × 10

2 v/m. Then it can be determined that the peak E-field between SiO

2-Sn within the neck region is 5.24 × 10

3 v/m, which is about 15.88 times larger than the applied field. In the actual sintering, the intensity of the applied field will be very high, so the peak E-field within the neck region between SiO

2-Sn will be much higher. For example, if the average E-field during microwave sintering is 1 kV/cm (e.g., ZnO [

11]), the peak E-fields can be as high as 15.88 kV/cm. Because the square amplitude of the electric field

E2 is directly related to the power density of microwaves [

11], and thus the heating rate, the peak microwave energy is approximately 250 times greater than the applied microwave energy at the beginning of the sintering process, which may be large enough to cause microscopic ionization at atmospheric pressure and lead to spark sintering [

11,

18,

19]. Therefore, although the applied field is not very high and the overall sample temperature is below the melting point of Sn, the peak E-fields and temperature within the micro-region between SiO

2-Sn will be high enough and induce local spark sintering. As a result, mass diffusion will be increased and the sintering process will be accelerated as well. This factor may be an important mechanism for rapid preparation involving microwave sintering.

3.2. Rapid Densification of the Specimen in the Middle Sintering Period

As the sintering process wenton, the sintering temperature increasedrapidly (e.g., by the 10th minute the temperature reached 1080 °C)and thedensification rate became quite large. As shown in

Figure 2B, particles C and D were still separated fromparticles 6 and 4, 5 at the 5th minute. However, in the 25th minute these particles were sintered together.The local amplification images of particles B, C and D in

Figure 2B are shown in

Figure 4.

This phenomenon may also be due to thespark sintering, because there was initially a distance between particles C and 6, as well as between particles D and 4, 5. As the sintering process wenton, the particles Sn entered aliquid phase and the sample started to shrink. This may make these particles contact each other. This means spark sintering may occur, induced by the micro-focusing effect of microwave E-fields between these particles. This is the same as the case that happened between particles B and 2, 3 in the first 5 minutes. Besides, as the sintering neck between particles grew larger, there was still a focusing effect between particles.

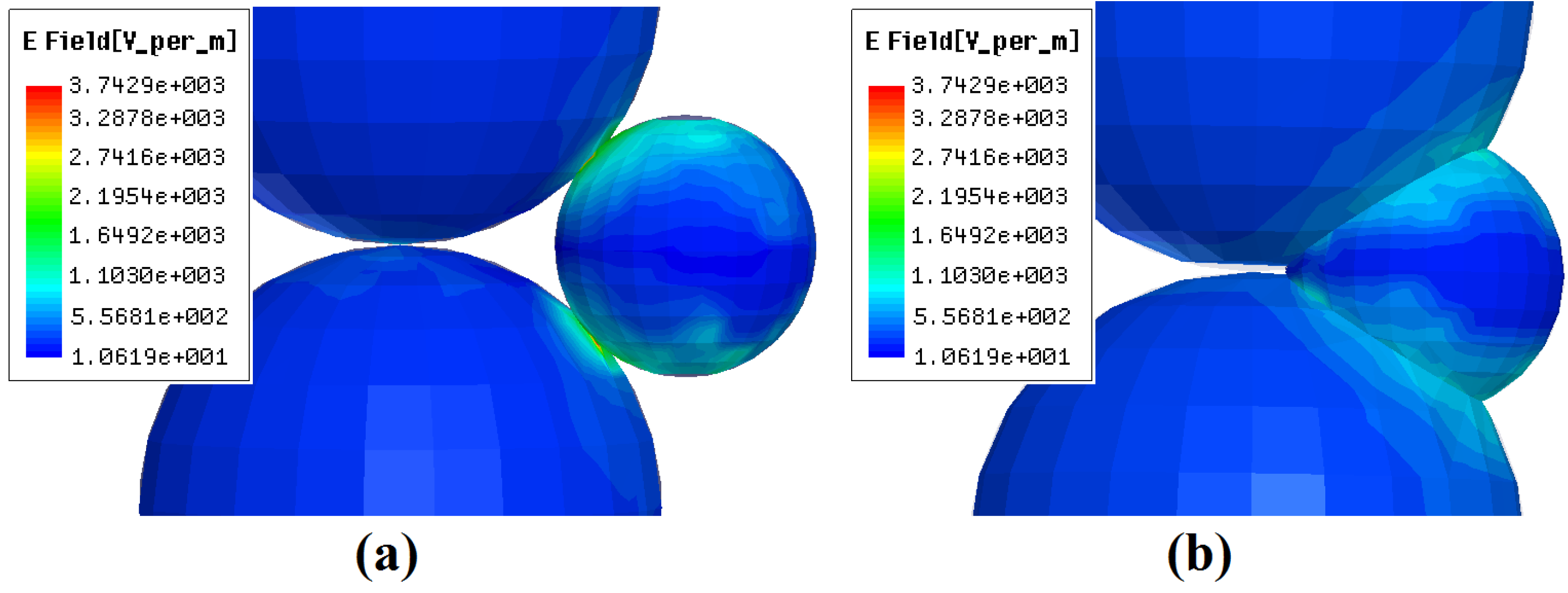

Figure 6a shows the distribution of microwave E-fields on the particle surface when the sinteringneck is 0.12 times the average of the radius of Sn and SiO

2 [there was still a pore between the particles of SiO

2-Sn and the sintering state is between the sintering states of

Figure 4b,c]. From

Figure 6a, it can be seen that there is still a focusing effect within the micro-region of the sintering neck between SiO

2-Sn. Here, the peak E-field between SiO

2-Sn within the neck region is 3.74×10

3 v/m, which is about 11.33 times larger than the applied field (3.30×10

2 v/m).This means that in the actual sintering, the intensity of the peak electric field within the neck region between SiO

2-Sn will be 11.33 times larger than the applied fields, and the peak

E2 field is approximately 128 times greater than the applied

E2 field, which may also cause microscopic ionization and lead to spark sintering.

3.3. Decline of Densification Rate when the Specimen Was not Dense Enough

Section 3.1 has discussed the rapid densification process of SiO

2-Sn during microwave sintering from the 5th to 25th minute. However, from the 20th minute, the densification rate declined a lot (as shown in

Figure 3B). This phenomenon also happens in the conventional liquid sintering, and usually happens when the densification parameter reaches about 75~80 [

20]. However, in this study the densification parameter of the specimen during this period was only 50~65. This means that there were still considerable pores and the specimen was not dense enough, like the image shown in

Figure 2B(d). There are some reasons for this phenomenon: Firstly,the highest sintering temperature is about 1150°C, which is a little lower than the usually sintering temperature of SiO

2 (>1200 °C). This means thatin the laterstage, the solid sintering rate between SiO

2 particles would be blocked because of the lower temperature. Secondly, due to the small volume fraction of Sn (10%), as the specimen became densethe distance between particles decreased at the same time, and the viscous flow of Sn and particle rearrangement would decline gradually.Besides, the decrease of the distance between particles will make the friction between particles increases, which will inhibit the further densification ofthe specimen. Thirdly, as the specimen became dense, the liquid phase of Sn penetrated the gap between particles. This will produce a change in microstructure configuration and may result in the reduction or disappearance of spark sintering.

Figure 6b shows the distribution of microwave E-fields on the particle surface of SiO

2-Sn (the distance between the centers of Sn-SiO

2 is 0.75 times of the sum of the radius of Sn and SiO

2). This sintering state is between the sintering states of

Figure 4b,c. From this figure, it can be seen that the peak E-field between SiO

2 and Sn within the neck region is 1.10 × 10

3 v/m. This means that the intensity of peak E-fields within the neck region between SiO

2 and Sn was only 3.33 times that of the applied fields, and cannot be large enough to cause microscopic ionization at atmospheric pressure and lead to spark sintering. This meansthe driving force for the mass diffusion decreased and the sintering process including the densification process declined as a result. These may be the reasons why the densification rate declined when the specimen was not dense enough.