An Investigation on the Wear Resistance and Fatigue Behaviour of Ti-6Al-4V Notched Members Coated with Hydroxyapatite Coatings

Abstract

:1. Introduction

2. Experimental Section

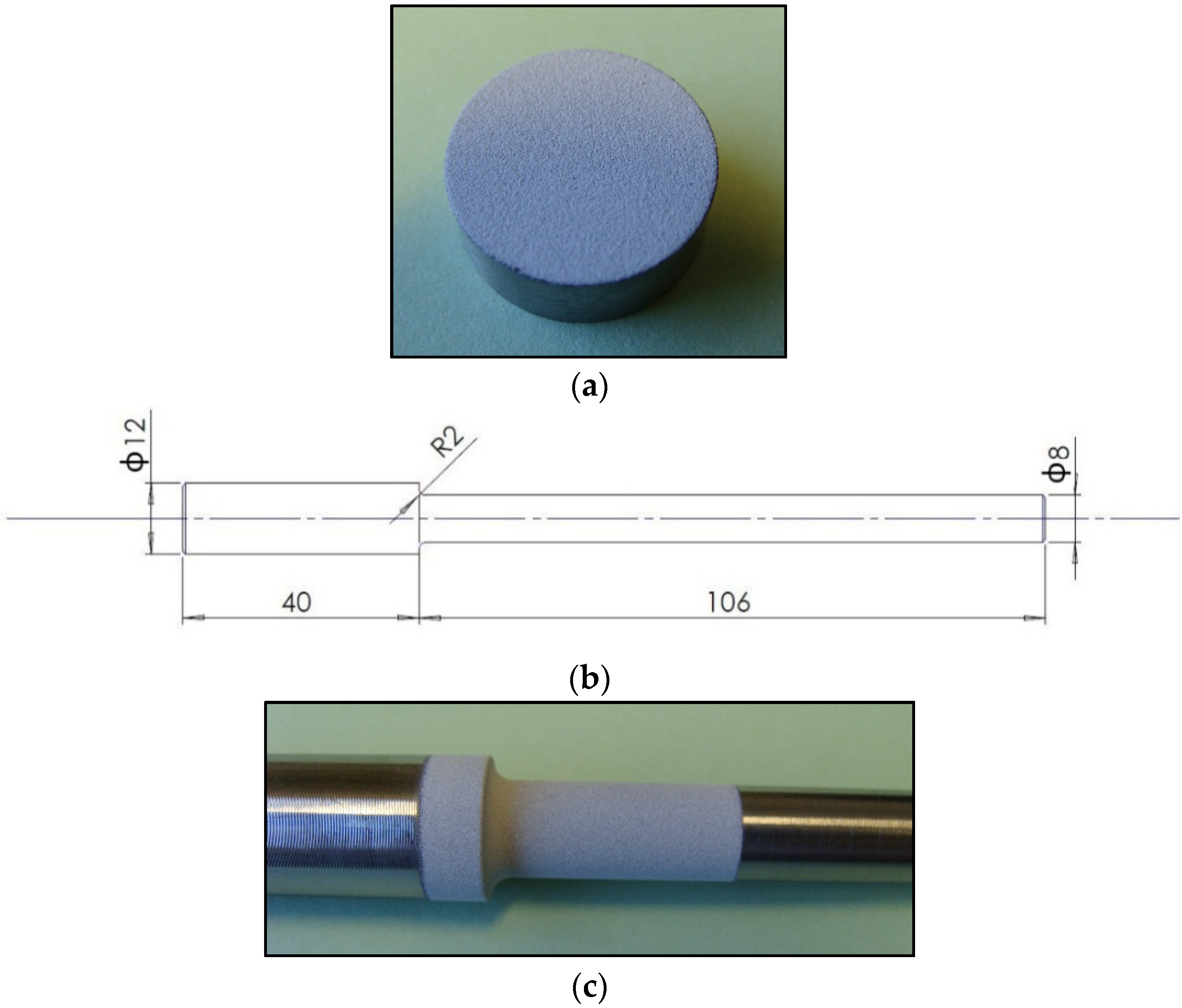

2.1. Sample Preparation

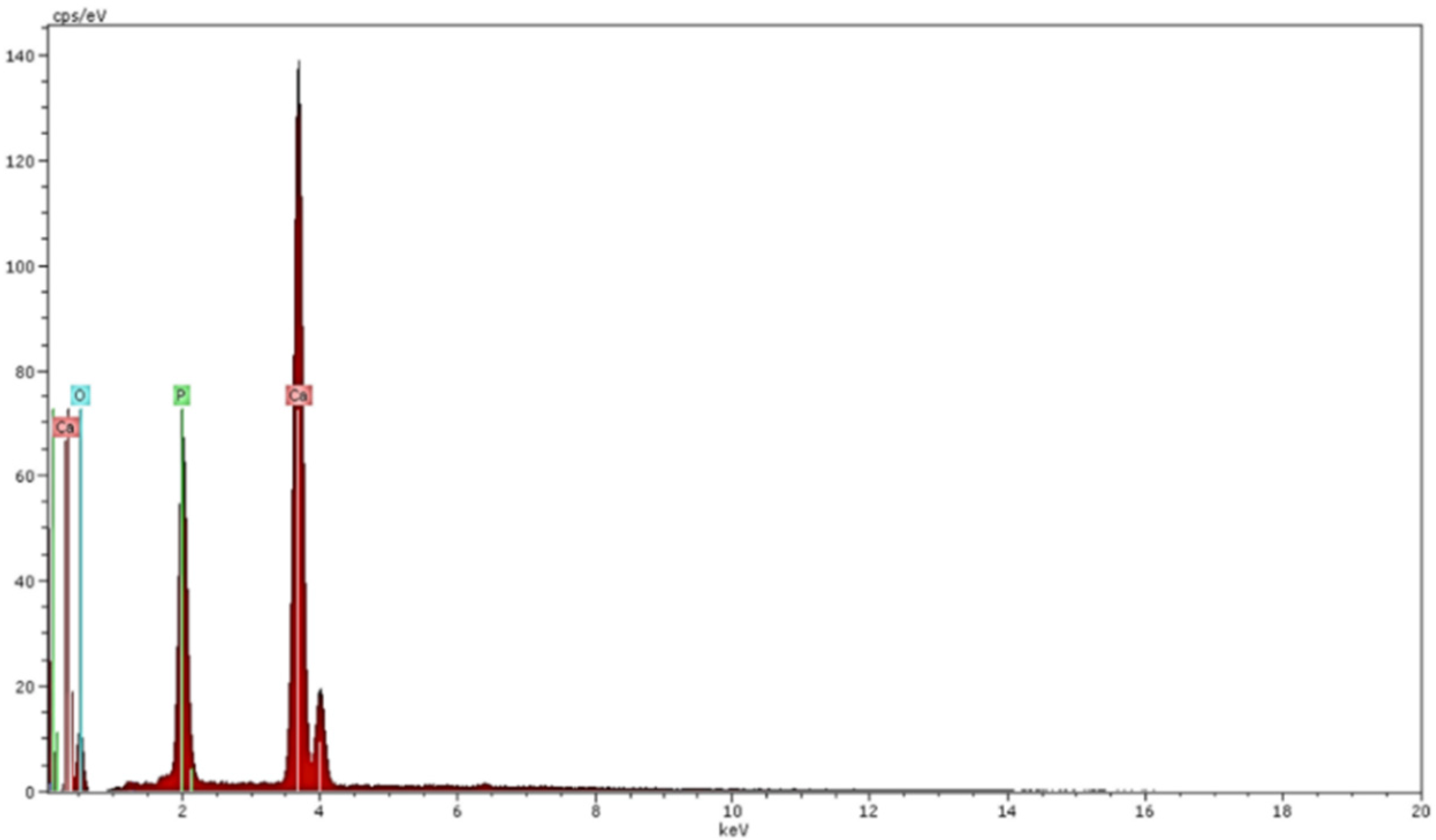

2.2. Coating Characterisations

2.3. Wear Assessments

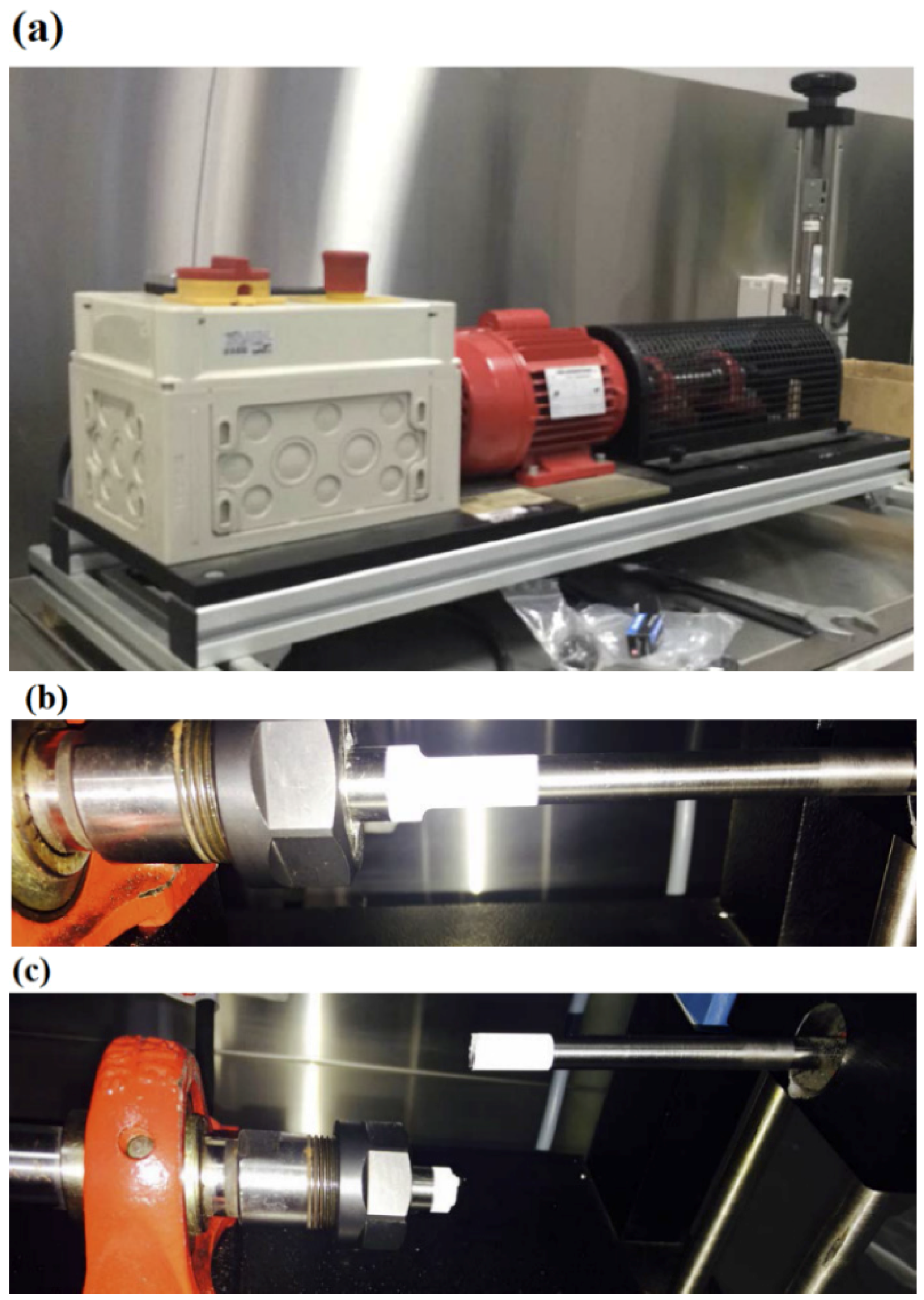

2.4. Fatigue Tests

3. Results and Discussion

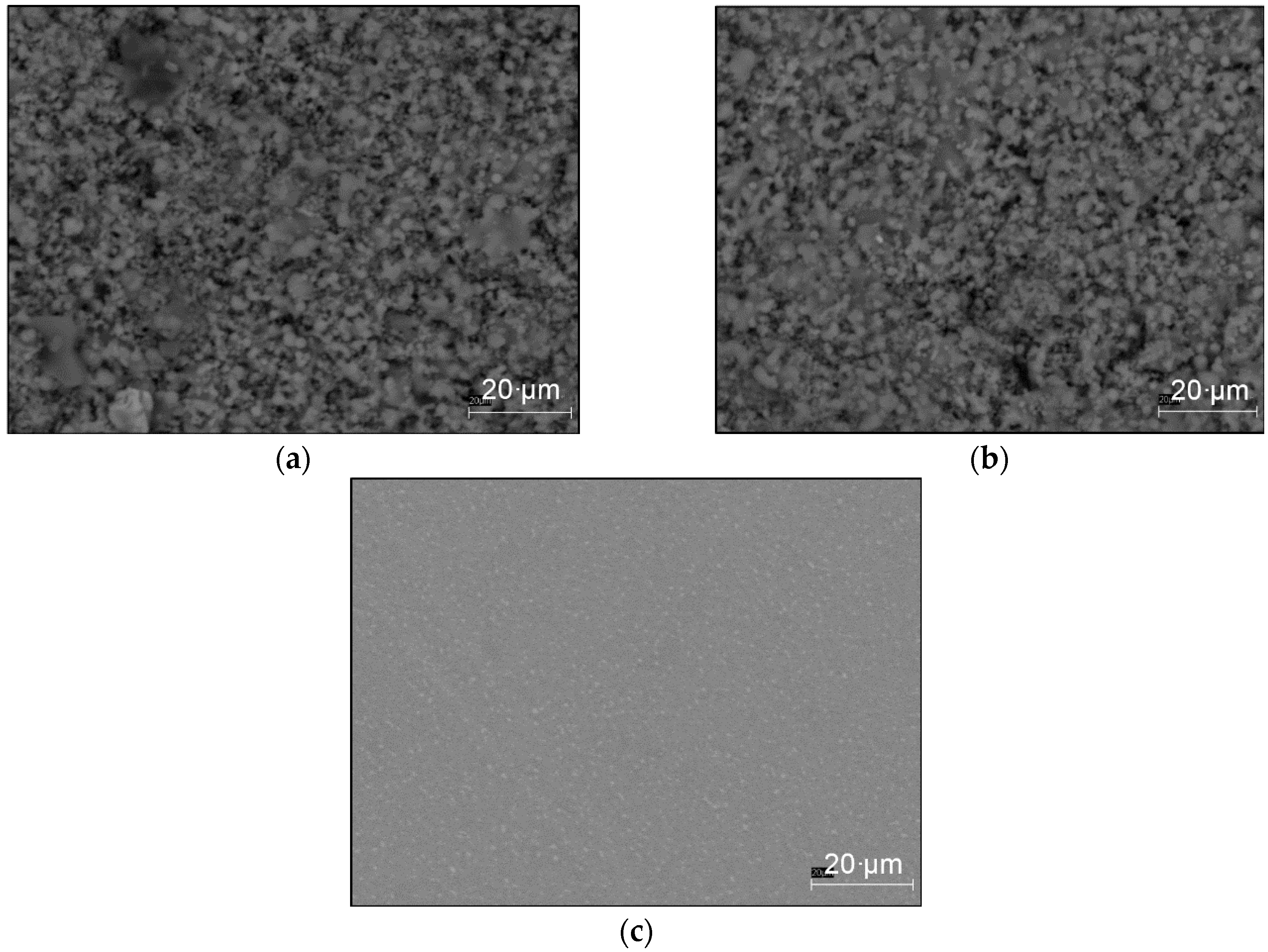

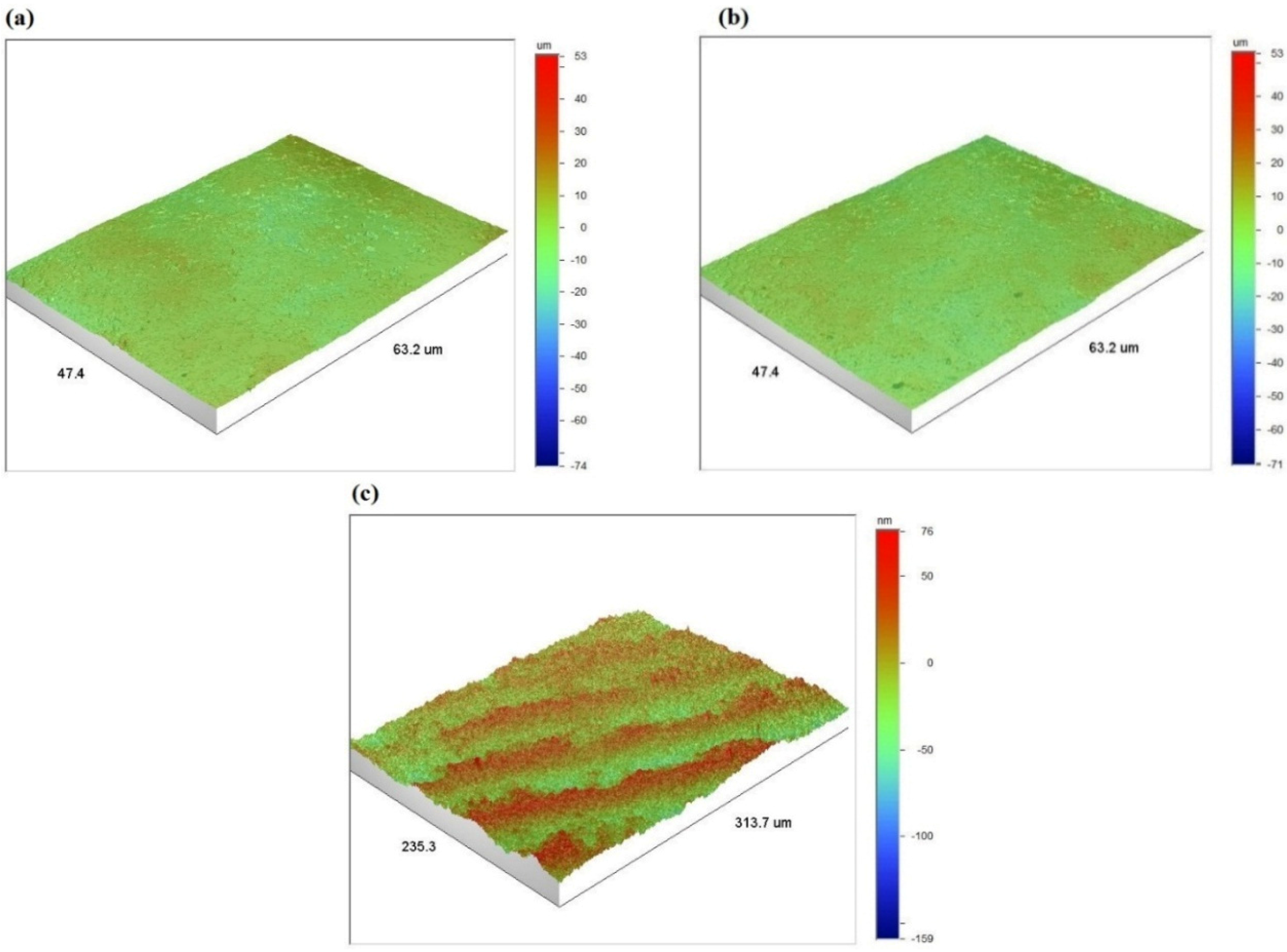

3.1. Coating Characteristics

| Tested Areas | 10 µm Coated Sample (µm) | 50 µm Coated Sample (µm) | Uncoated Sample (nm) |

|---|---|---|---|

| Area 1 | Ra = 2.46 Rq = 3.15 Rmax = 12.4 | Ra = 2.60 Rq = 3.19 Rmax = 13.00 | Ra = 19.18 Rq = 23.39 Rmax = 10.10 |

| Area 2 | Ra = 2.47 Rq = 3.16 Rmax = 12.20 | Ra = 3.14 Rq = 3.84 Rmax = 13.00 | Ra = 13.99 Rq = 17.79 Rmax = 9.20 |

| Area 3 | Ra = 2.90 Rq = 3.68 Rmax = 14.30 | Ra = 2.42 Rq = 3.04 Rmax = 11.62 | Ra = 16.82 Rq = 22.15 Rmax = 8.76 |

| Area 4 | Ra = 2.21 Rq = 2.90 Rmax = 13.50 | Ra = 2.67 Rq = 3.40 Rmax = 12.80 | Ra = 13.11 Rq = 16.61 Rmax = 8.72 |

| Area 5 | Ra = 2.97 Rq = 3.78 Rmax = 13.90 | Ra = 2.47 Rq = 3.02 Rmax = 11.00 | Ra = 14.35 Rq = 18.13 Rmax = 9.14 |

| Average | Ra = 2.60 Rq = 3.33 Rmax = 13.26 | Ra = 2.66 Rq = 3.30 Rmax = 12.28 | Ra = 15.49 Rq = 19.61 Rmax = 9.18 |

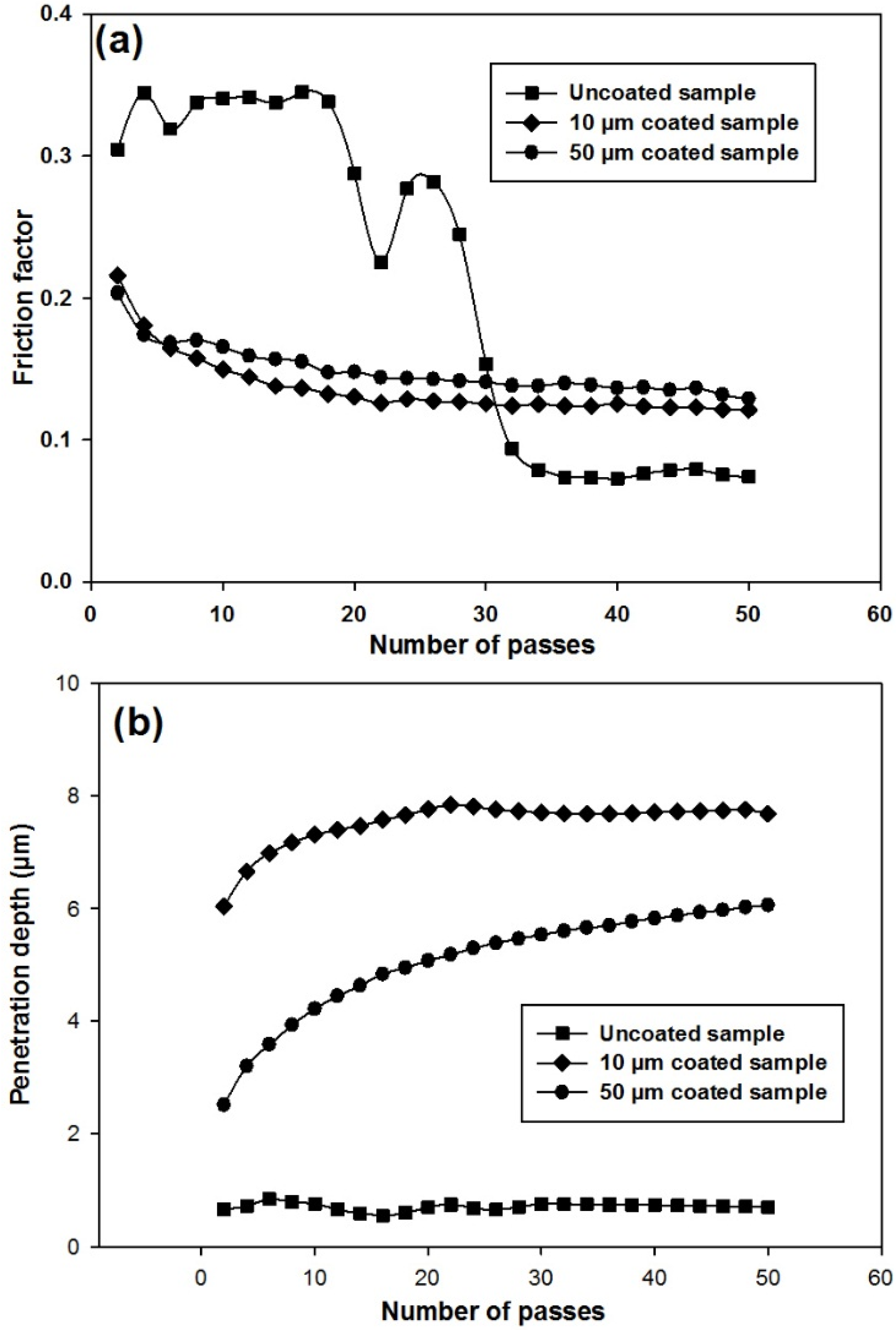

3.2. Wear Resistance Results

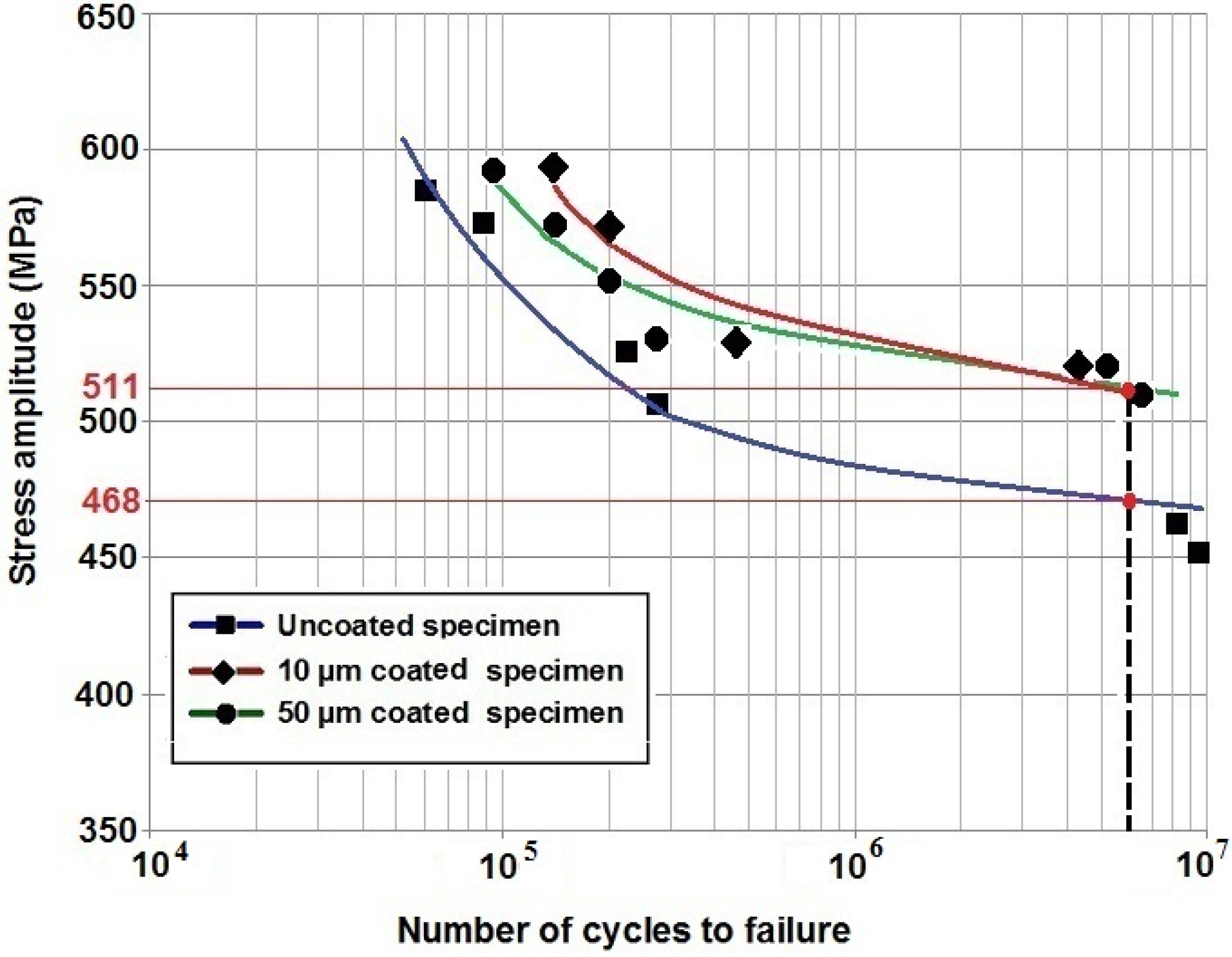

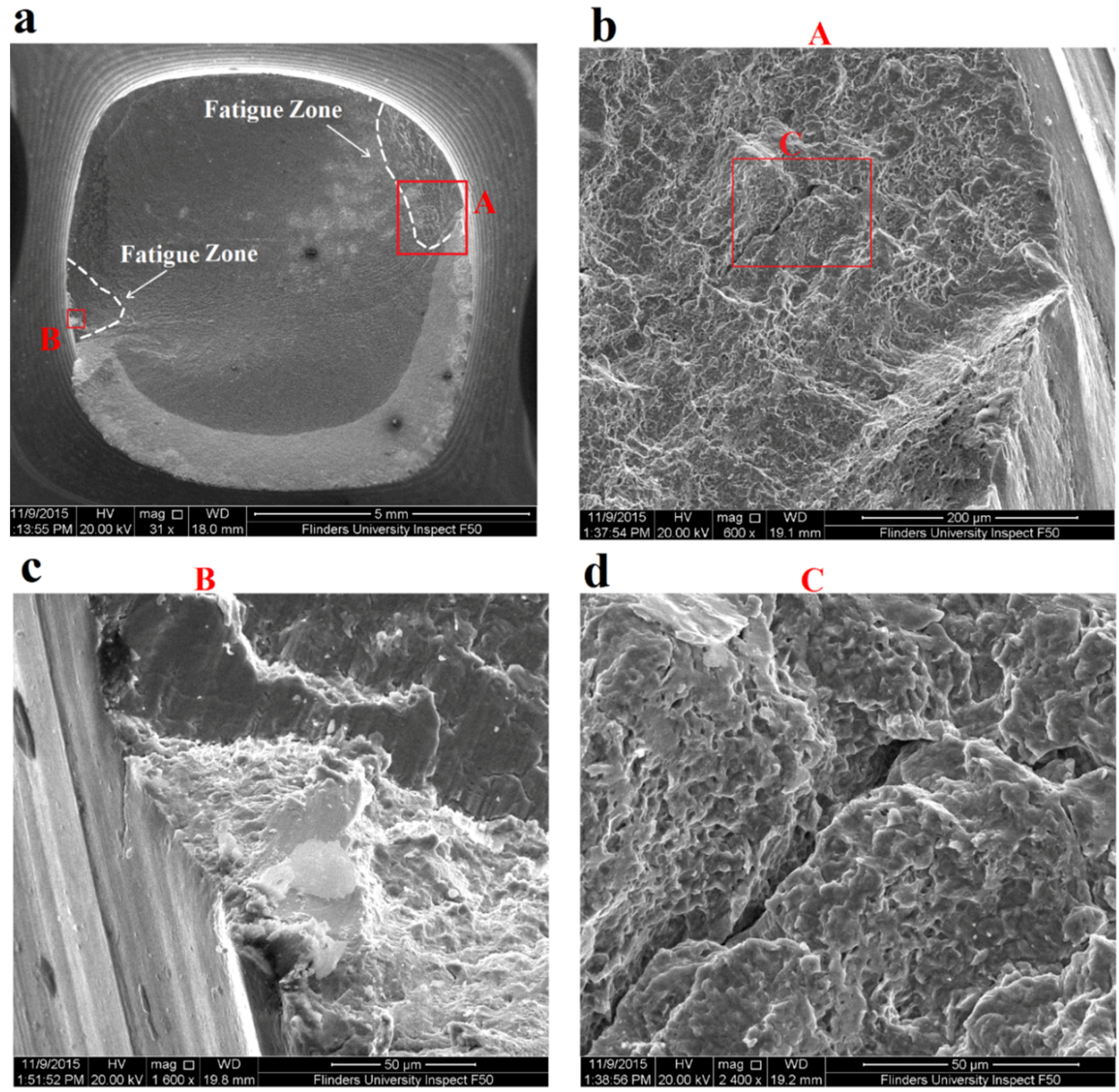

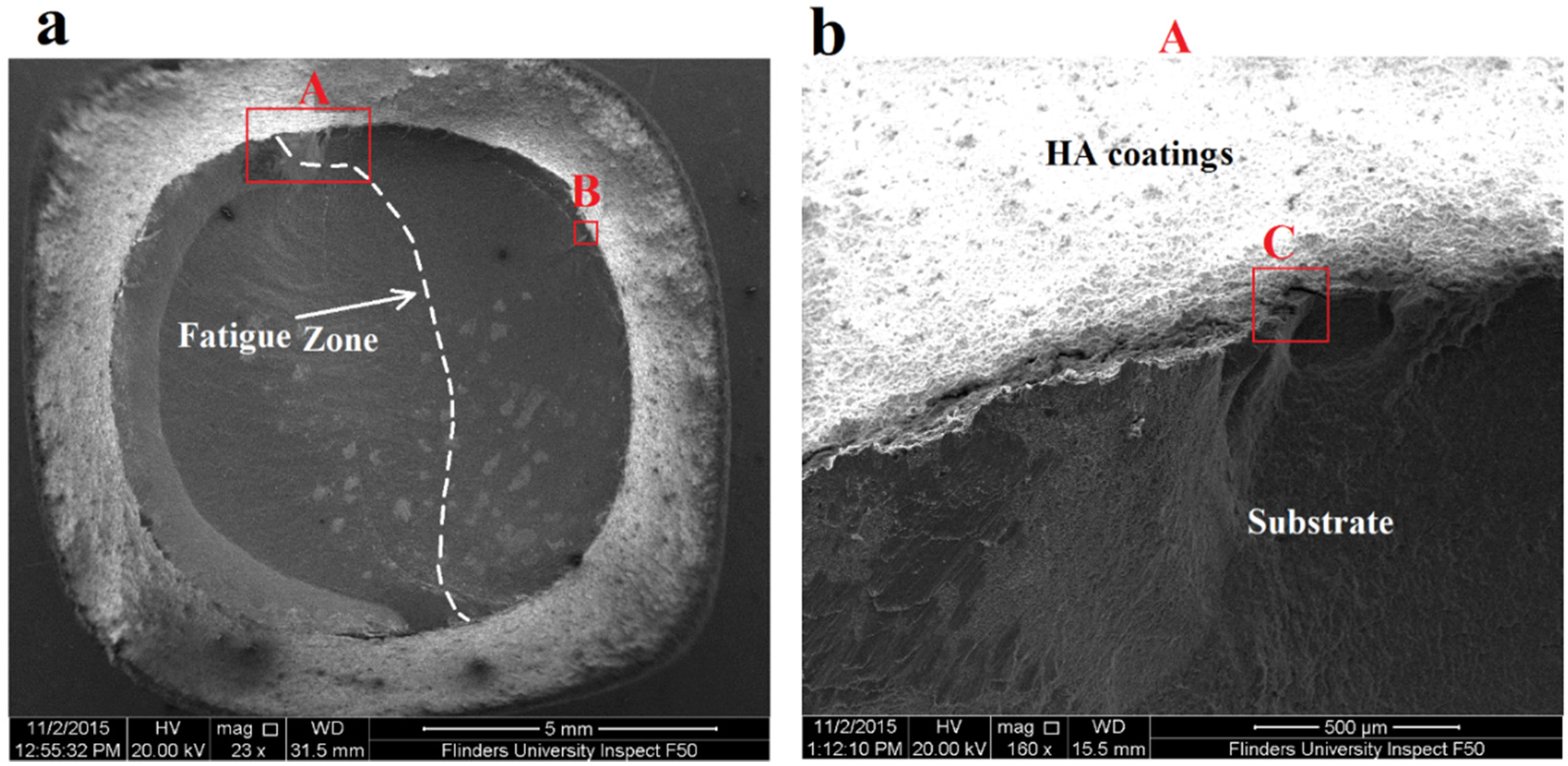

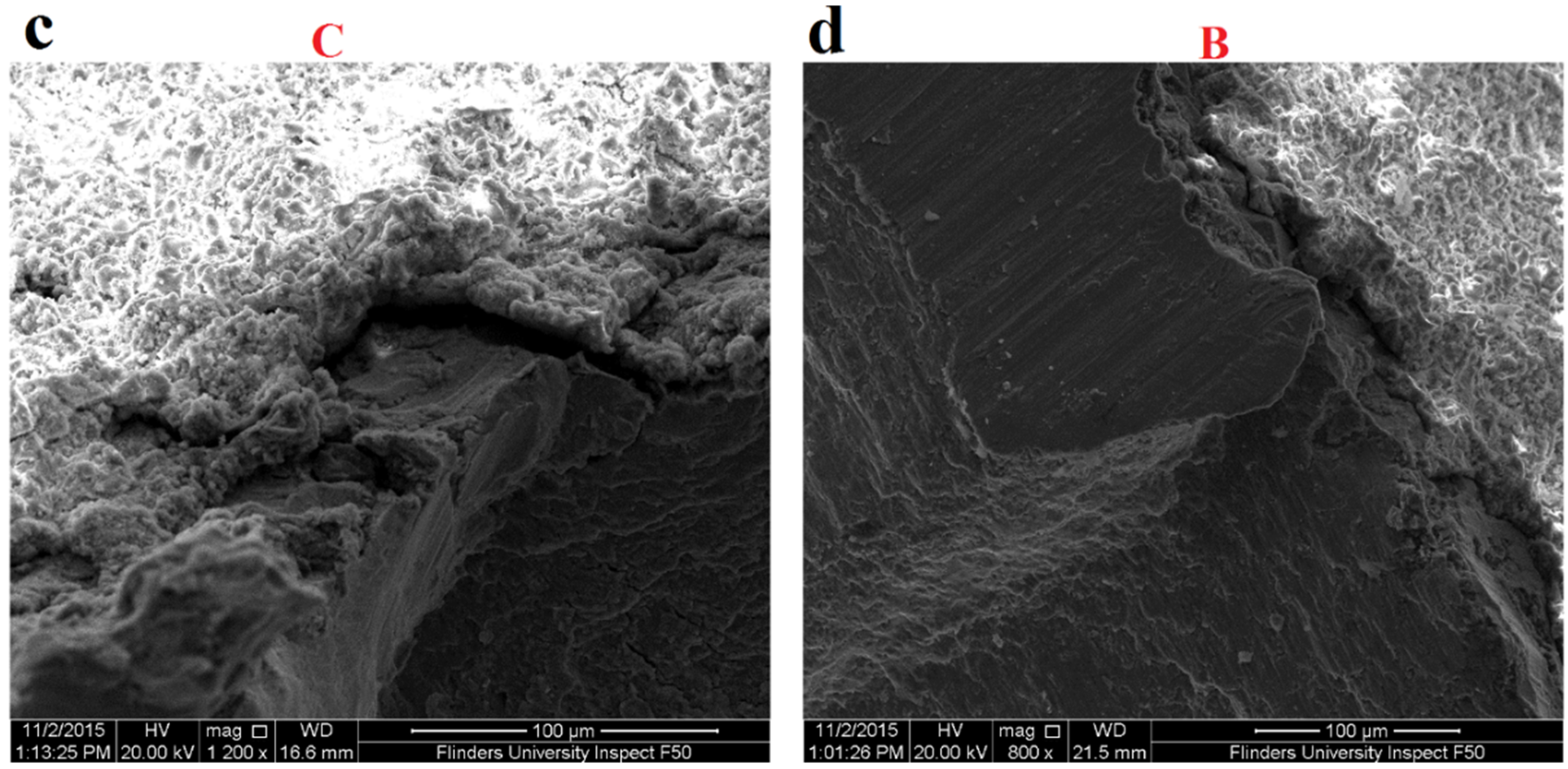

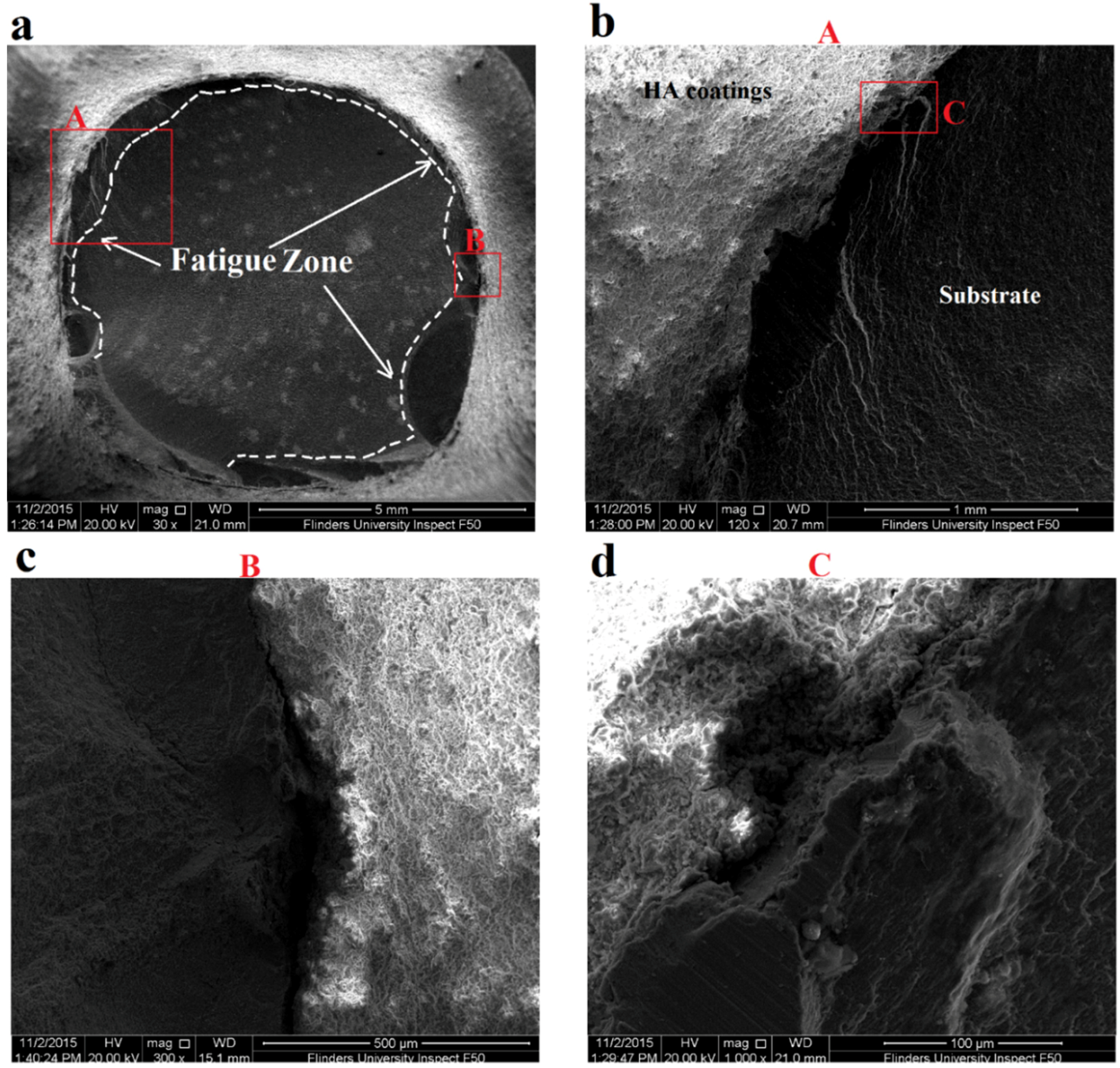

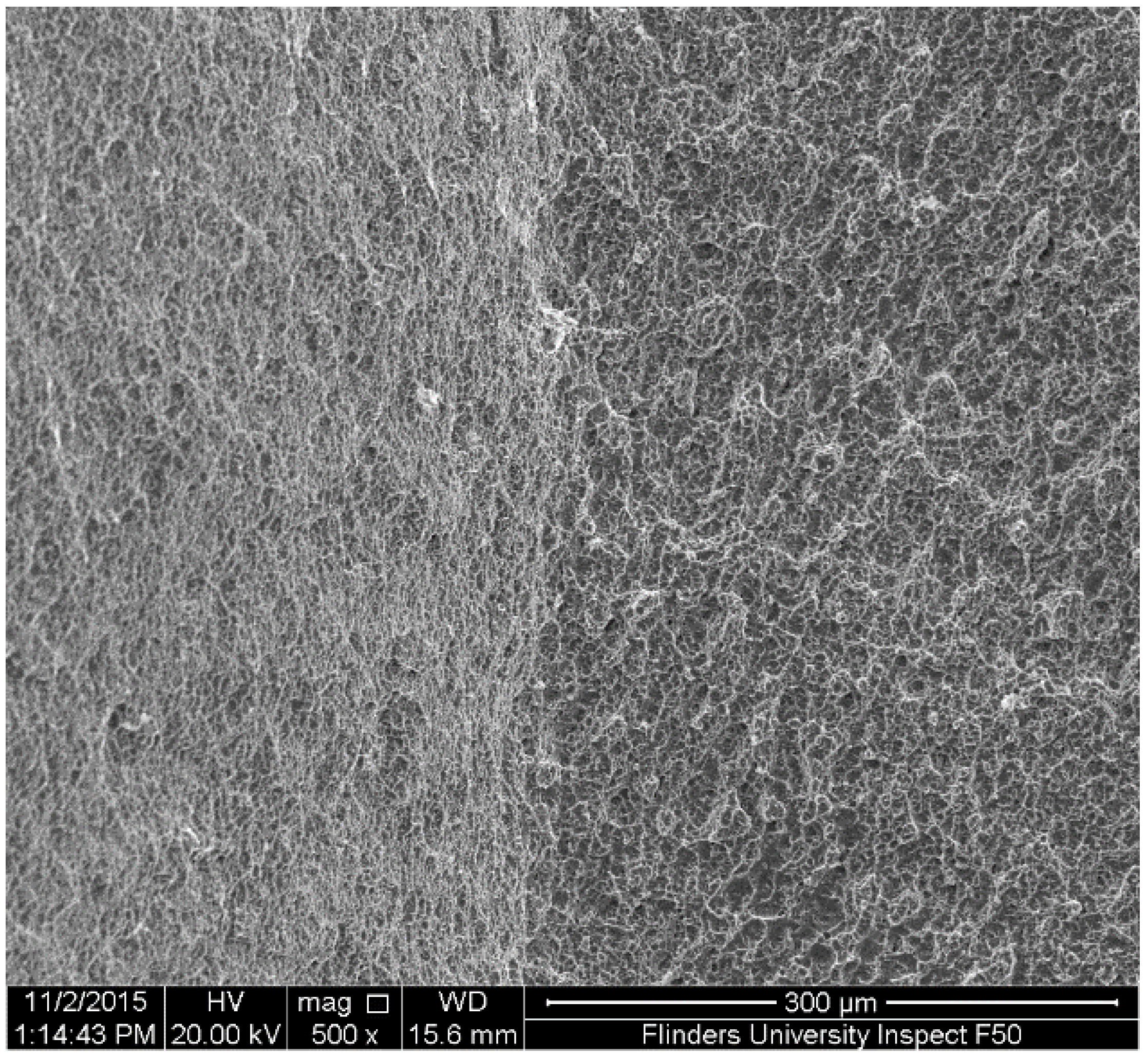

3.3. Fatigue Test Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Niinomi, M. Metallic biomaterials. J. Artif. Organs 2008, 11, 105–110. [Google Scholar] [CrossRef] [PubMed]

- Navarro, M.; Michiardi, A.; Castaño, O.; Planell, J. Biomaterials in orthopaedics. J. R. Soc. Interface 2008, 5, 1137–1158. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zreiqat, H. Functional coatings or films for hard-tissue applications. Materials 2010, 3, 3994–4050. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New developments of ti-based alloys for biomedical applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Temenoff, J.; Mikos, A.G. Biomaterials: The Intersection of Biology and Materials Science, 1st ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2008; pp. 235–258. [Google Scholar]

- Hussenbocus, S.; Kosuge, D.; Solomon, L.B.; Howie, D.W.; Oskouei, R.H. Head-neck taper corrosion in hip arthroplasty. BioMed Res. Int. 2015, 2015. [Google Scholar] [CrossRef] [PubMed]

- Hanawa, T. Recent development of new alloys for biomedical use. Mater. Sci. Forum 2006, 512, 243–248. [Google Scholar] [CrossRef]

- Farhoudi, H.; Oskouei, R.H.; Jones, C.F.; Taylor, M. A novel analytical approach for determining the frictional moments and torques acting on modular femoral components in total hip replacements. J. Biomech. 2015, 48, 976–983. [Google Scholar] [CrossRef] [PubMed]

- Oskouei, R.H.; Ibrahim, R.N. Improving fretting fatigue behaviour of Al 7075-T6 bolted plates using electroless Ni–P coatings. Int. J. Fatigue 2012, 44, 157–167. [Google Scholar] [CrossRef]

- Mohseni, E.; Zalnezhad, E.; Bushroa, A.R. Comparative investigation on the adhesion of hydroxyapatite coating on Ti-6Al-4V implant: A review paper. Int. J. Adhes. Adhes. 2014, 48, 238–257. [Google Scholar] [CrossRef]

- Zalnezhad, E.; Baradaran, S.; Bushroa, A.R.; Sarhan, A.D. Mechanical property enhancement of Ti-6Al-4V by multilayer thin solid film Ti/TiO2 nanotubular array coating for biomedical application. Metall. Mater. Trans. A 2014, 45, 785–797. [Google Scholar] [CrossRef]

- Oskouei, R.H.; Sushimatha, K. Parylene coatings in medical devices and implants: A review. Univers. J. Biomed. Eng. 2015, 3, 9–14. [Google Scholar]

- Tadic, D.; Peters, F.; Epple, M. Continuous synthesis of amorphous carbonated apatites. Biomaterials 2002, 23, 2553–2559. [Google Scholar] [CrossRef]

- Ahmad Ramli, R.; Adnan, R.; Abu Bakr, M.; Massudi, S. Synthesis and characterisation of pure nanoporous hydroxyapatite. J. Phys. Sci. 2011, 22, 25–37. [Google Scholar]

- Faig-Martí, J.; Gil-Mur, F.J. Hydroxyapatite coatings in prosthetic joints. Rev. Esp. Cir. Ortop. Traumatol. Engl. Ed. 2008, 52, 113–120. [Google Scholar] [CrossRef]

- Kuroda, K.; Okido, M. Hydroxyapatite coating of titanium implants using hydroprocessing and evaluation of their osteoconductivity. Bioinorg. Chem. Appl. 2012, 2012. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Shi, B.; Fairchild, A.; Cale, T. Applications of plasma coatings in artificial joints: An overview. Vacuum 2004, 73, 317–326. [Google Scholar] [CrossRef]

- Holmes, R.; Bucholz, R.W.; Mooney, V. Porous hydroxyapatite as a bone-graft substitute in metaphyseal defects. A histometric study. J. Bone Jt. Surg. Br. Vol. 1986, 68, 904–911. [Google Scholar]

- Cook, S.D.; Kay, J.F.; Thomas, K.A.; Jarcho, M. Interface mechanics and histology of titanium and hydroxylapatite-coated titanium for dental implant applications. Int. J. Oral Maxillofac. Implants 1987, 2, 15–22. [Google Scholar] [PubMed]

- Ozawa, S.; Kasugai, S. Evaluation of implant materials (hydroxyapatite, glass-ceramics, titanium) in rat bone marrow stromal cell culture. Biomaterials 1996, 17, 23–29. [Google Scholar] [CrossRef]

- Morks, M.F.; Kobayashi, A.; Fahim, N.F. Abrasive wear behavior of sprayed hydroxyapitite coatings by gas tunnel type plasma spraying. Wear 2007, 262, 204–209. [Google Scholar] [CrossRef]

- Metikoš-Huković, M.; Tkalčec, E.; Kwokal, A.; Piljac, J. An in vitro study of ti and ti-alloys coated with sol–gel derived hydroxyapatite coatings. Surf. Coat. Technol. 2003, 165, 40–50. [Google Scholar] [CrossRef]

- Balani, K.; Anderson, R.; Laha, T.; Andara, M.; Tercero, J.; Crumpler, E.; Agarwal, A. Plasma-sprayed carbon nanotube reinforced hydroxyapatite coatings and their interaction with human osteoblasts in vitro. Biomaterials 2007, 28, 618–624. [Google Scholar] [CrossRef] [PubMed]

- Apachitei, I.; Lonyuk, B.; Fratila-Apachitei, L.E.; Zhou, J.; Duszczyk, J. Fatigue response of porous coated titanium biomedical alloys. Scr. Mater. 2009, 61, 113–116. [Google Scholar] [CrossRef]

- Vadiraj, A.; Kamaraj, M. Fretting fatigue studies of titanium nitride-coated biomedical titanium alloys. J. Mater. Eng. Perform. 2006, 15, 553–557. [Google Scholar] [CrossRef]

- Lynn, A.K.; DuQuesnay, D.L. Hydroxyapatite-coated Ti-6Al-4V: Part 1: The effect of coating thickness on mechanical fatigue behaviour. Biomaterials 2002, 23, 1937–1946. [Google Scholar] [CrossRef]

- Lynn, A.K.; DuQuesnay, D.L. Hydroxyapatite-coated Ti-6Al-4V: Part 2: The effects of post-deposition heat treatment at low temperatures. Biomaterials 2002, 23, 1947–1953. [Google Scholar] [CrossRef]

- Standard Practice for Surface Preparation and Marking of Metallic Surgical Implants; ASTM F86-04; ASTM International: West Conshohocken, PA, USA, 2004.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oskouei, R.H.; Fallahnezhad, K.; Kuppusami, S. An Investigation on the Wear Resistance and Fatigue Behaviour of Ti-6Al-4V Notched Members Coated with Hydroxyapatite Coatings. Materials 2016, 9, 111. https://doi.org/10.3390/ma9020111

Oskouei RH, Fallahnezhad K, Kuppusami S. An Investigation on the Wear Resistance and Fatigue Behaviour of Ti-6Al-4V Notched Members Coated with Hydroxyapatite Coatings. Materials. 2016; 9(2):111. https://doi.org/10.3390/ma9020111

Chicago/Turabian StyleOskouei, Reza H, Khosro Fallahnezhad, and Sushmitha Kuppusami. 2016. "An Investigation on the Wear Resistance and Fatigue Behaviour of Ti-6Al-4V Notched Members Coated with Hydroxyapatite Coatings" Materials 9, no. 2: 111. https://doi.org/10.3390/ma9020111

APA StyleOskouei, R. H., Fallahnezhad, K., & Kuppusami, S. (2016). An Investigation on the Wear Resistance and Fatigue Behaviour of Ti-6Al-4V Notched Members Coated with Hydroxyapatite Coatings. Materials, 9(2), 111. https://doi.org/10.3390/ma9020111