Residual Stress Analysis Based on Acoustic and Optical Methods

Abstract

:1. Introduction

2. Experimental

2.1. Principle of Operation

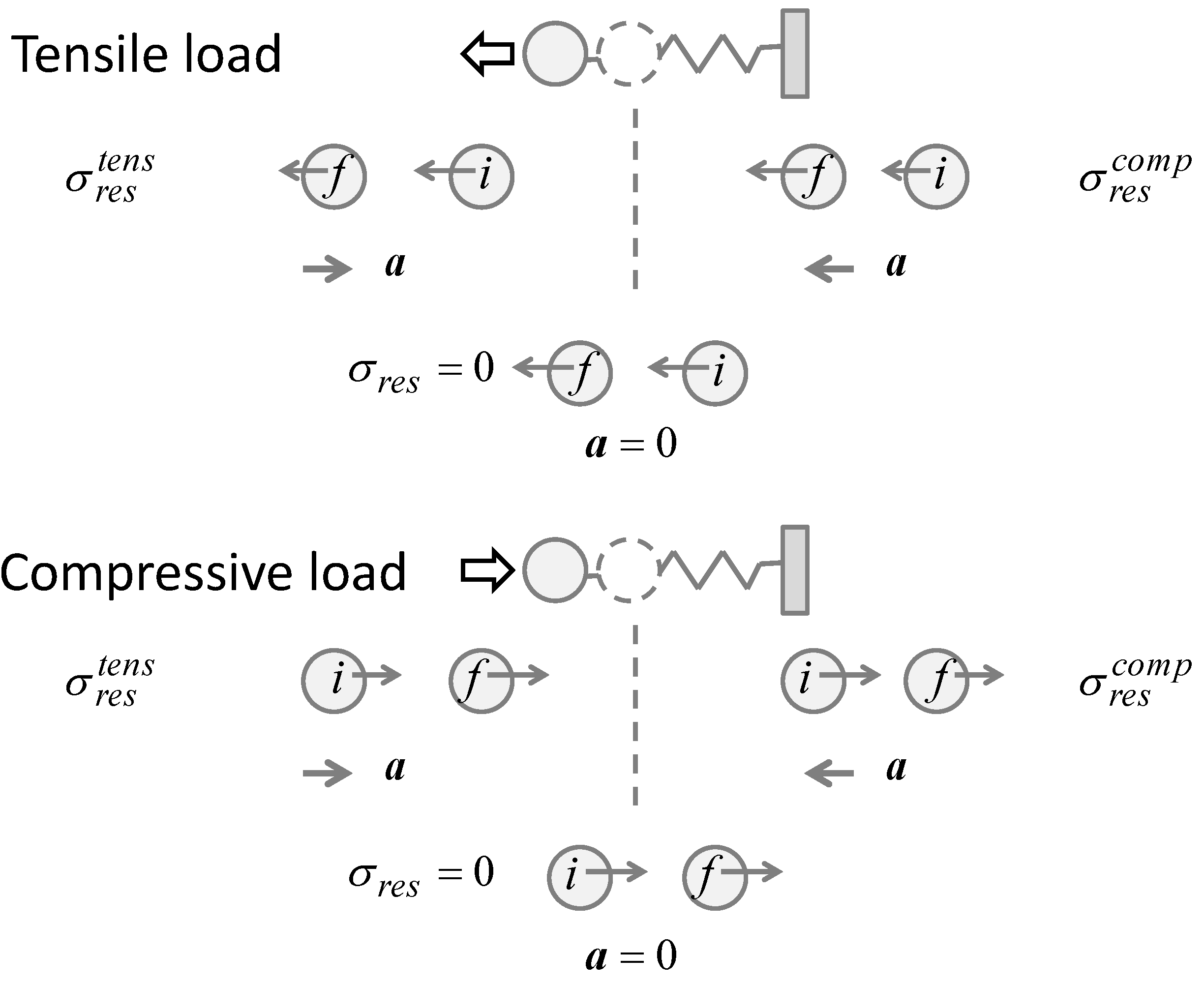

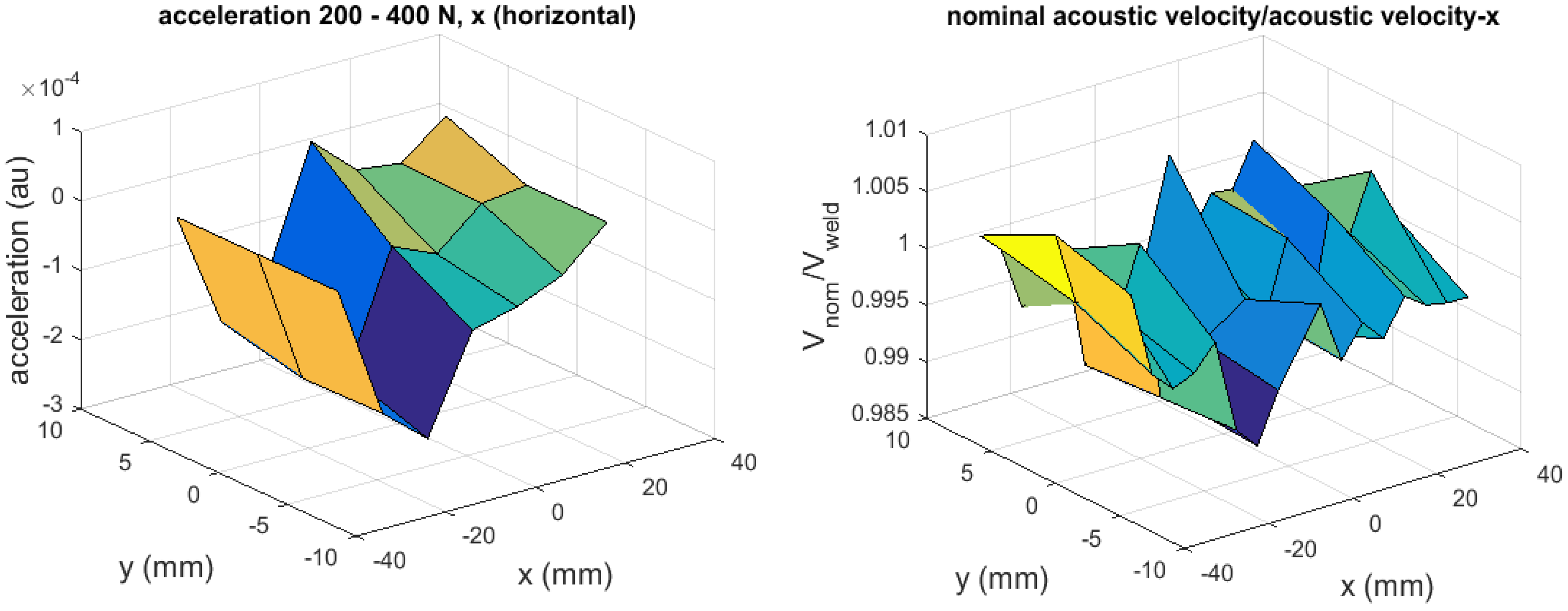

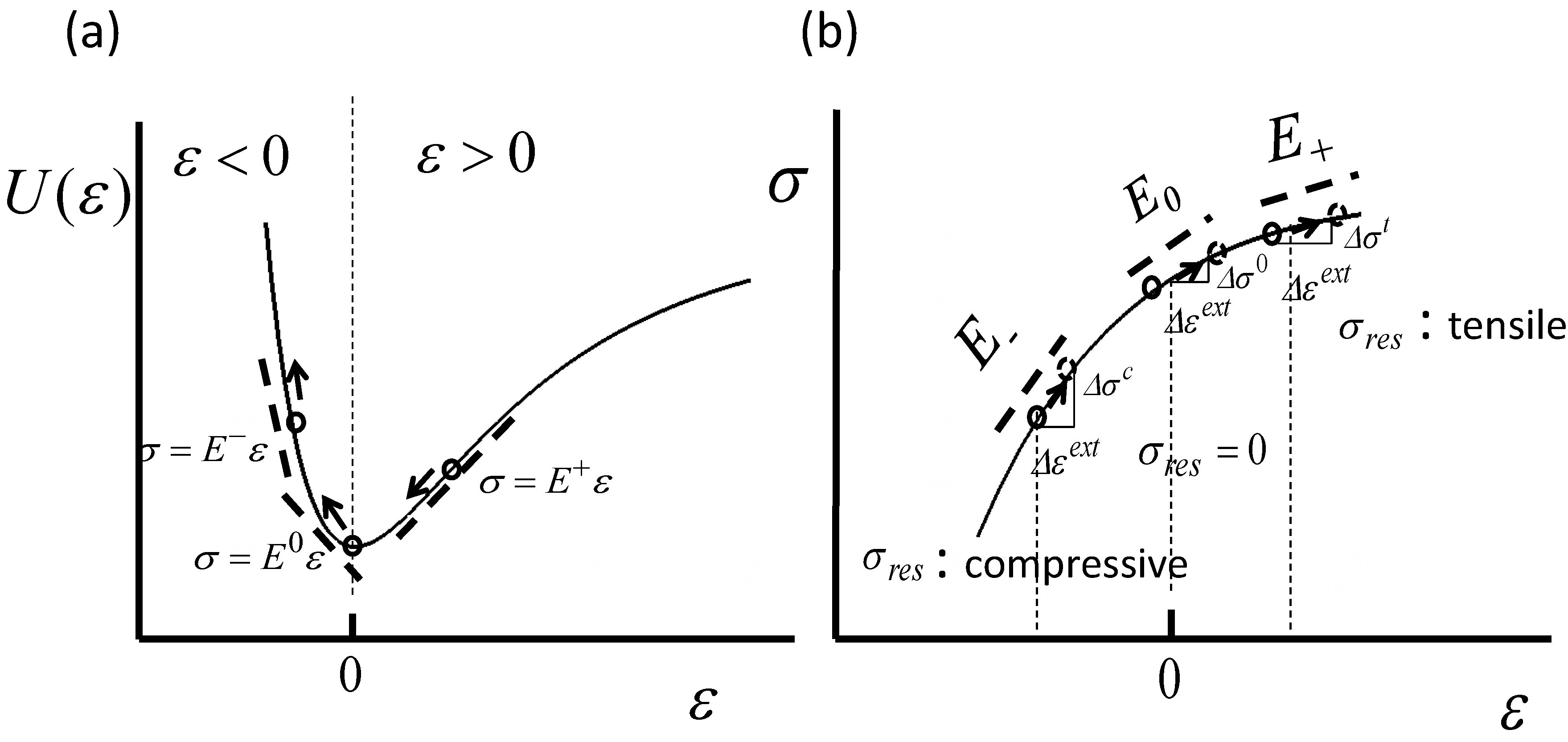

2.1.1. Acoustoelasticity

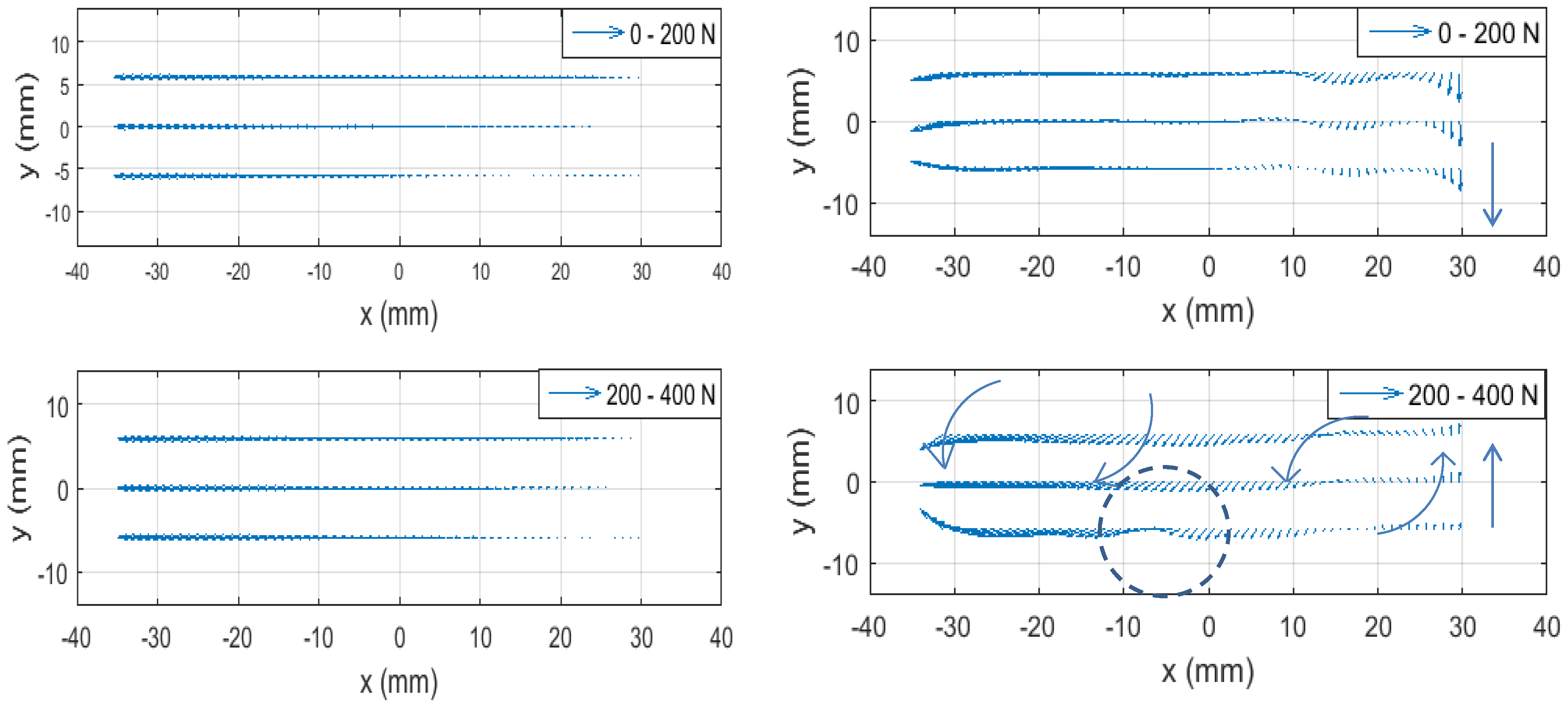

2.1.2. Dynamic Analysis with Electronic Speckle-Pattern Interferometry (ESPI)

| External Force | σres: Tensile | σres: Compressive | ||||

|---|---|---|---|---|---|---|

2.2. Experimental Procedures

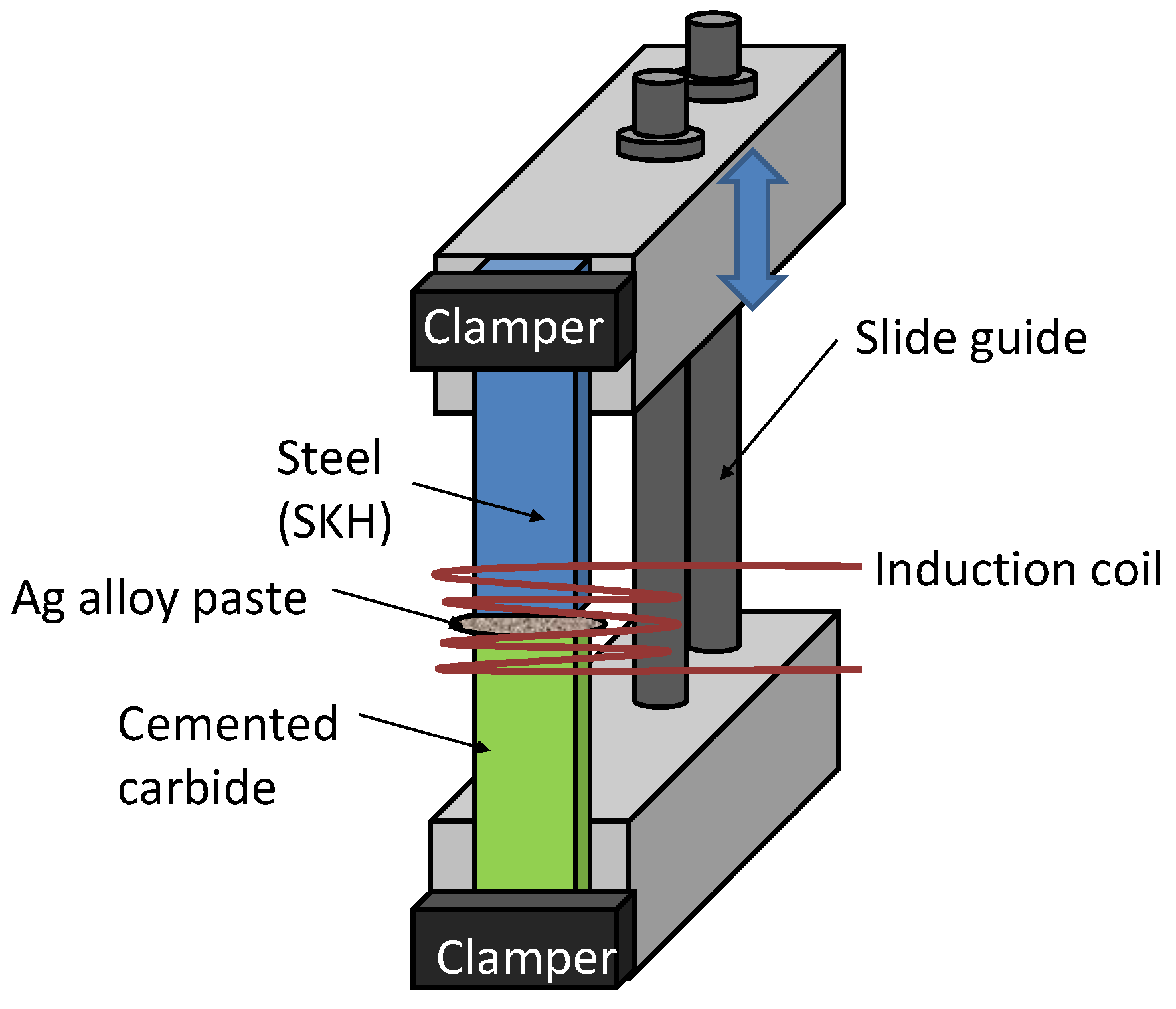

2.2.1. Specimen Preparation

| Material | Eelas (GPa) | α (10-6· K-1) | κ (Wm-1K-1) | σyield (GPa) |

|---|---|---|---|---|

| skh 51 | 219 | 11.9 | 23.0 | 2.38 |

| cc | 580 | 5.3 | 67.0 | 1.5 * |

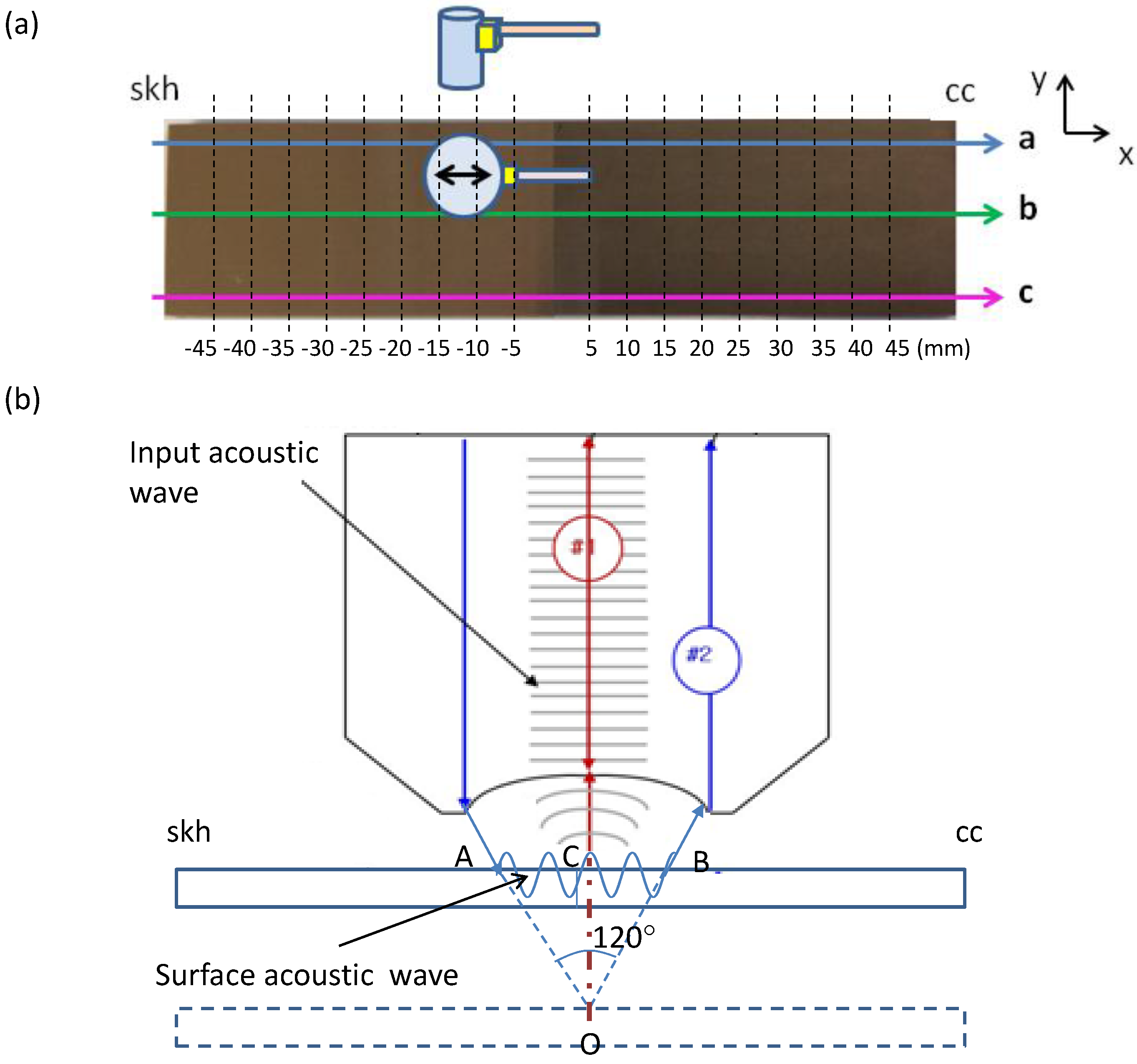

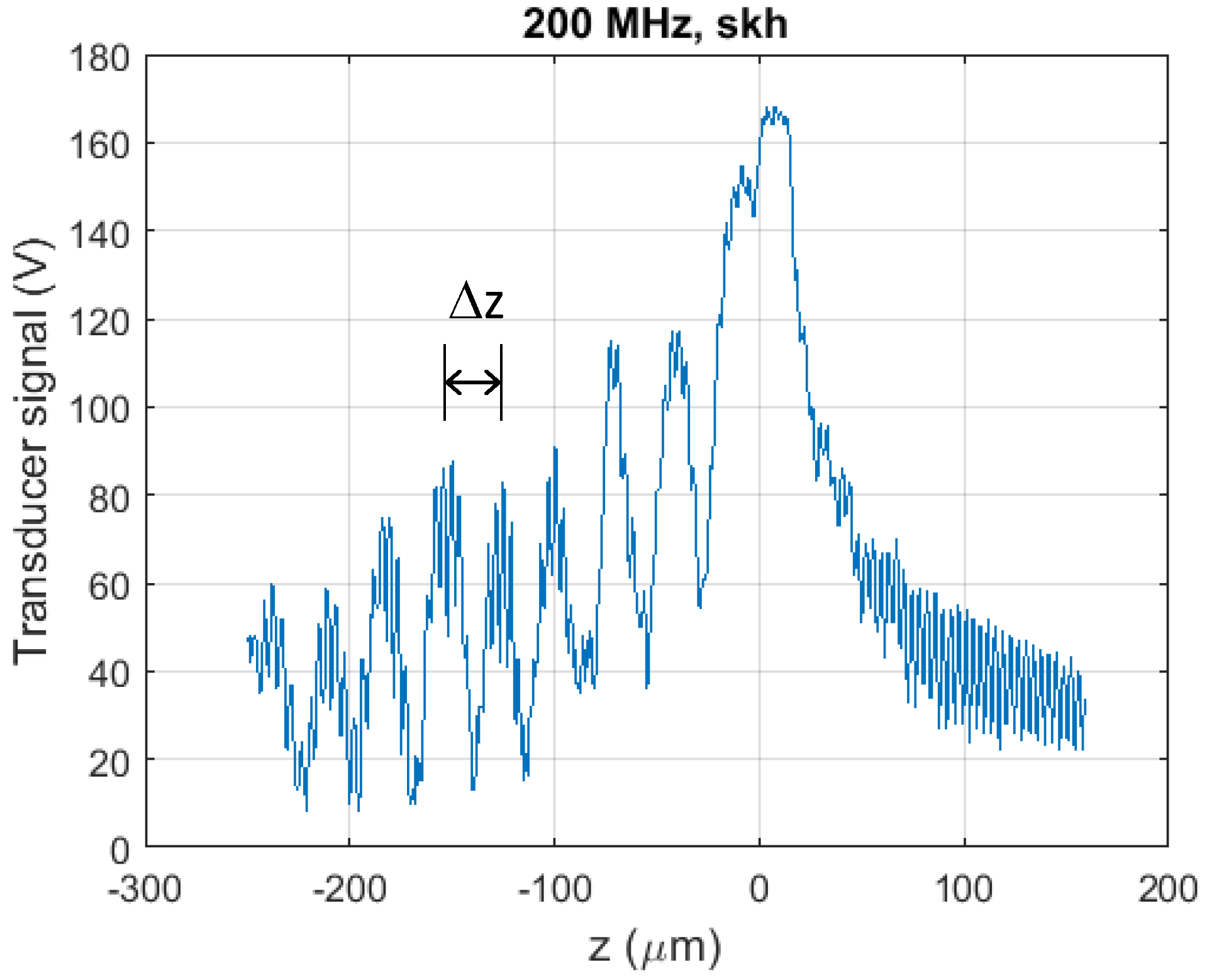

2.2.2. Acoustic Measurement

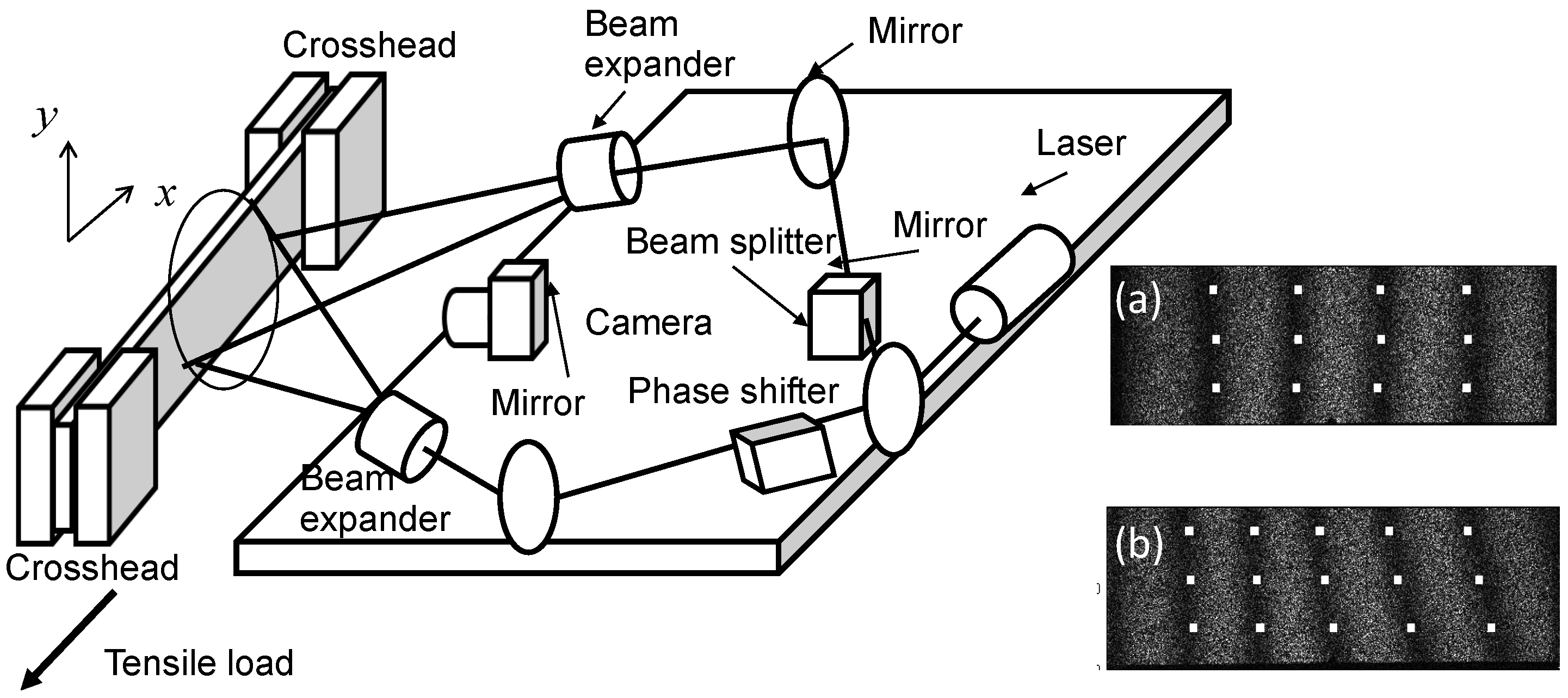

2.2.3. Displacement Measurement with ESPI

- Step 1: Using a digital camera, take an interferometric image of the specimen with the phase shifter at the base position and the two interferometric beams on top of each other on the specimen surface. Store the image data in computer memory (called the base image). Use this procedure for the first pair of the interferometric beams sensitive to the in-plane displacement component parallel to the tensile axis or the x-component (the x interferometer). Repeat the procedure for the second pair sensitive to the in-plane displacement perpendicular to the tensile axis and parallel to the braze line or the y-component (the y interferometer).

- Step 2: Similarly to Step 1, take another interferometric image with the phase shifter at the turned position. Store the resultant image in computer memory (called the turned image). Take this procedure for the x interferometer first and repeat it for the y interferometer.

- Step 3: Engage the tensile machine to apply a tensile load to the specimen. When the applied load reaches a preset value, take an interferometric image with the phase shifter at the turned position. Store the resultant image (called the deformed image) in computer memory. Use this procedure for the x and y interferometers respectively. Repeat the same procedure of taking a pair of x and y interferometric images at N more preset loads (at least one more load). While taking the pairs of images at preset loads, keep running the tensile machine with the same cross-head speed.

- Step 4: Subtract the base image from the turned image on a pixel-by-pixel basis. Save the resultant subtracted image in computer memory. This subtracted image consists of mutually parallel equidistant dark fringes (stripes) referred to as the carrier fringe pattern. Figure 4a shows a sample carrier fringe pattern for the x interferometer. The fringes are equidistant and parallel because the artificial phase is a linear function of x and independent of y.

- Step 5: Subtract the base image from the deformed image on a pixel-by-pixel basis. Save the resultant subtracted image in computer memory. This subtracted image contains the phase information associated with both the artificial phase and the phase change due to the deformation caused by the tensile load, . The image is called the overall fringe pattern. Figure 4b shows a sample overall fringe pattern for the x interferometer. Use this procedure N times, for each deformed image taken at the corresponding preset load.

- Step 6: Assign an integer representing the fringe order to each of the fringes of the carrier fringe pattern and the overall fringe patterns, respectively (Here the fringe order is defined as follows. In accordance with the electronic speckle interferometry, each dark fringe represents the contour of a constant displacement that corresponds to the phase difference of where n is an integer. Depending on the angle of incidence of the interferometric beams and other geometric factors, corresponds to the unit displacement where ξ denotes the displacement vector and is the coordinate variable that the pair of the interferometric beams is sensitive to. Assign to the dark fringe corresponding to zero displacement. Subsequently, assign or to the fringe next to the fringe corresponding to . Here if the next fringe corresponds displacement of , assign and if it corresponds to , assign . Similarly, assign a signed integer to the next dark fringe one by one as corresponds to (Figure 4).) Once all the fringes are assigned with an order, draw grid lines parallel to the x-axis at through . For each grid line, find the coordinate points where each fringe crosses the grid line. This yields a vector where is the x coordinate at which the grid line crosses the fringe. After all the grid lines are processed, generate a table containing the coordinate points where grid lines cross all the fringes. Here the vector for the grid line at constitutes the row of the table. The resultant table is called the fringe order table. Generate a fringe order table for the respective components of the in-plane displacement vector, and .

- Step 7: Once a fringe order table is generated, replace the fringe order with corresponding displacement vector component according to the relation . Subsequently, for each row interpolate the vector with respect to the discrete values of from the lowest to highest values of n for the row. Here, is the unit displacement corresponding to one fringe interval (the displacement that causes the optical phase change of ). Iteration of this procedure for all the rows yields a map of that provides the displacement component for all the grid points.

3. Results and Discussion

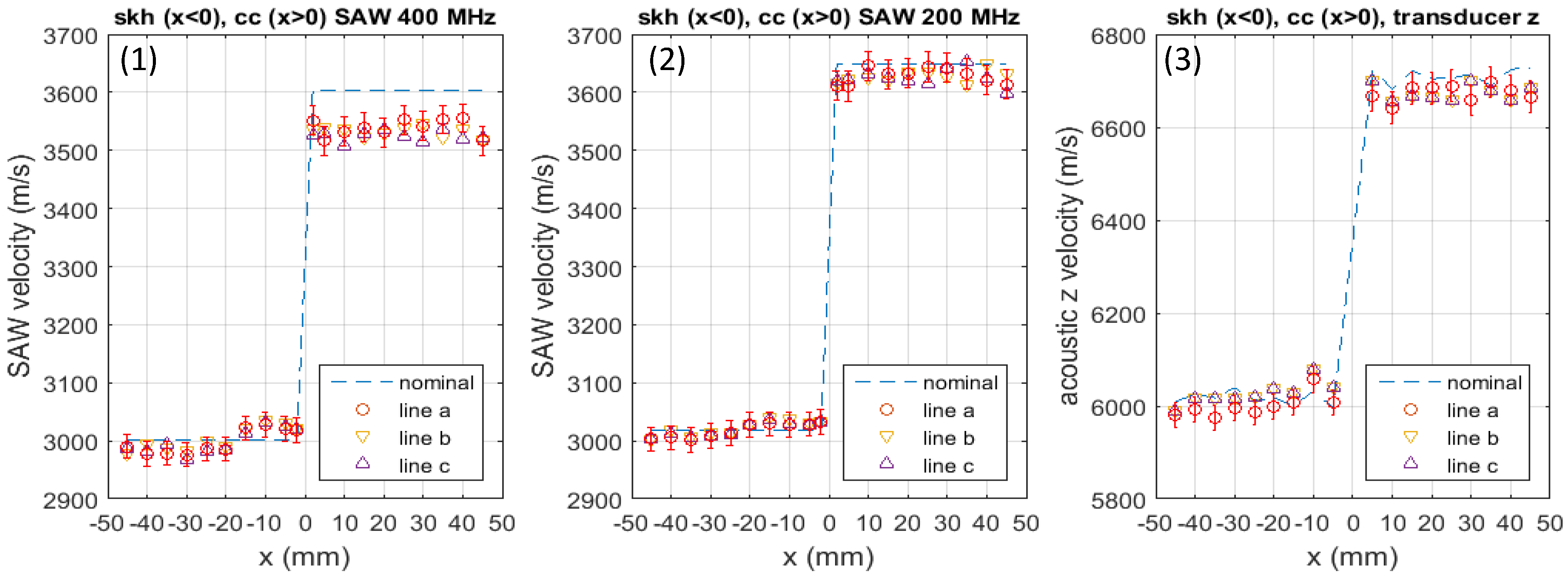

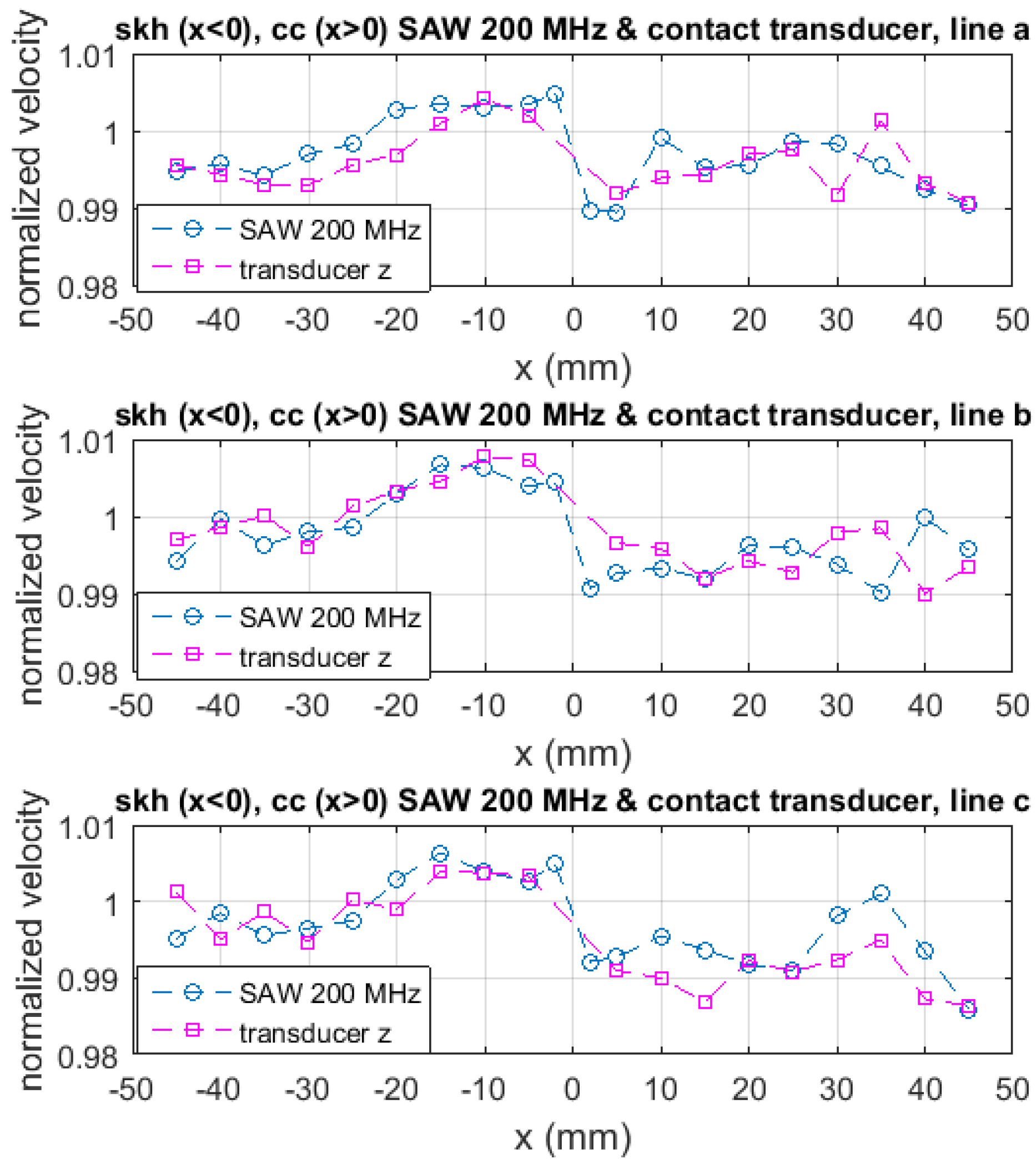

3.1. Acoustic Measurement

| Method | Error | Standard Deviation | ||

|---|---|---|---|---|

| skh 51 | cc | skh 51 | cc | |

| 400 MHz SAM | 0.7% | 0.7% | 0.34% | 1.2% |

| 200 MHz SAM | 0.5% | 0.5% | 0.15% | 0.4% |

| Contact transducer | 0.45% | 0.5% | 0.23% | 0.24% |

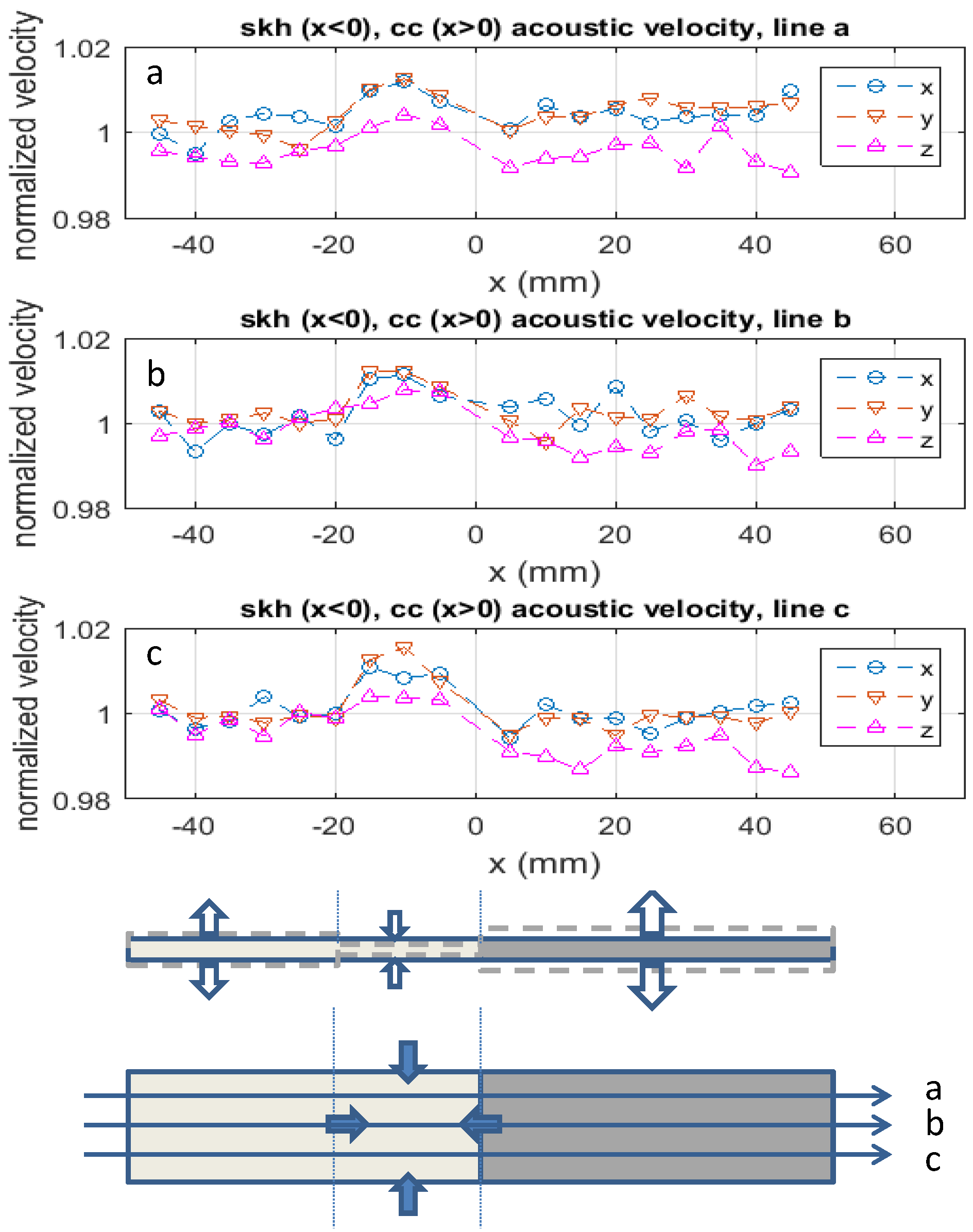

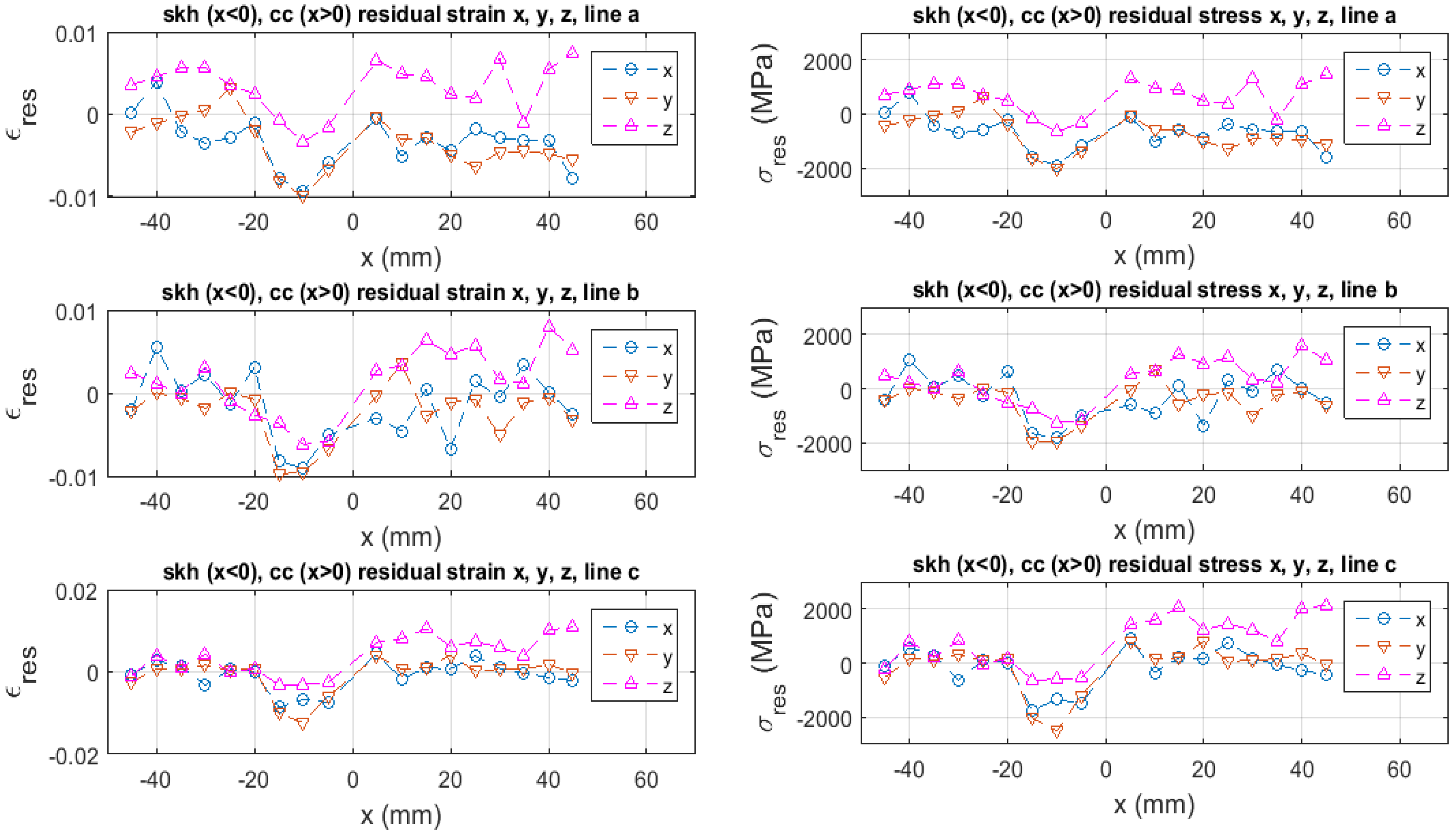

3.2. Residual Strain and Stress Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Acoustoelasticity

Appendix B. Curve

References

- Schajer, G.S. Practical Residual Stress Measurement Methods, 1st ed.; Wiley: Chichester, UK, 2013. [Google Scholar]

- Kandil, F.A.; Lord, J.D.; Fry, A.T.; Grant, P.V. A Review of Residual Stresses Measurement Methods—A Guide to Technique Selection; NFL Report MATC(A)O4; National Physical Laboratory: Teddington, UK, 2001. [Google Scholar]

- Schajer, G.S.; Yang, L. Residual-stress measurement in orthotropic materials using the hole-drilling method. Exp. Mech. 1994, 12, 324–333. [Google Scholar] [CrossRef]

- Eijpe, M.P.I.M.; Powell, P.C. Determination of residual shear stress in composites by a modified layer-removal method. J. Mater. Sci. 1998, 33, 2019–2026. [Google Scholar] [CrossRef]

- Roberts, S.J.; McCartney, L.N.; Broughton, W.R. A novel method of determining stress distribution in plates using the incremental slitting technique. J. Strain Anal. Eng. Des. 2011, 46, 280–297. [Google Scholar] [CrossRef]

- Tebedge, N.; Alpsten, G.; Tall, L. Residual-stress measurement by the sectioning method. Exp. Mech. 1973, 13, 88–96. [Google Scholar] [CrossRef]

- Bate, S.K.; Green, D.; Buttle, D. A review of residual stress distributions in welded joints for the defect assessment of offshore structures. In Health Safety Exclusive—Offshore Technology Report; Her Majesty’s Stationery Office: Norwich, UK, 1997. [Google Scholar]

- Colegrove, P.; Ikeagu, C.; Thistlethwaite, A.; Williams, S.; Nagy, T.; Suder, W.; Steuwer, A.; Pirling, T. The welding process impact on residual stress and distortion. Sci. Technol. Weld. Join. 2009, 14, 717–725. [Google Scholar] [CrossRef]

- Drescher-Krasicka, E.; Willis, J.R. Mapping stress with ultrasound. Nature 1996, 384, 52–55. [Google Scholar] [CrossRef]

- Drescher-Krasicka, E.; Ostertag, C.P. Residual stress measurements in welded steel beam columns by scanning acoustic microscopy. J. Mater. Sci. 1999, 34, 4173–4179. [Google Scholar] [CrossRef]

- Fitzpatrick, M.E.; Fry, A.T.; Holdway, P.; Kandil, F.A.; Shackleton, J.; Suominen, L. Determination of Residual Stresses by X-Ray Diffraction—Issue 2; Measurement Good Practice Guide No. 52; National Physical Laboratory: Teddington, UK, 2005. [Google Scholar]

- Fitzpatrick, M.E.; Lodini, A. Analysis of Residual Stress by Diffraction Using Neutron and Synchrotron Radiation; CRC Press: New York, NY, USA, 2003. [Google Scholar]

- Hughes, D.S.; Kelly, J.L. Second-order elastic deformation of solids. Phys. Rev. 1953, 92, 1145–1149. [Google Scholar] [CrossRef]

- Duquennoy, M.; Ouaftouh, M.; Ourak, M.; Jenot, F.; Xu, W.J. Theoretical and experimental determination of the natural and initial acoustoelastic coefficients. Rev. Prog. Quant. Nondestruct. Eval. 2002, 21, 1696–1702. [Google Scholar]

- Dorfi, H.R.; Busby, H.R.; Janssen, M. Ultrasonic stress measurements based on the generalized acoustic ratio technique. Int. J. Solids Struct. 1996, 33, 1157–1174. [Google Scholar] [CrossRef]

- Dequennoy, M.; Ouaftouh, M.; Ourak, M.; Jenot, F. Theoretical determination of Rayleigh wave acoustoelastic coefficients: Comparison with experimental values. Ultrasonics 2002, 39, 575–583. [Google Scholar] [CrossRef]

- Berruti, T.; Gola, M.M.; Briggs, G.D. Acoustoelastic measurements on aluminium alloy by means of a contact and a non-contact (LFB acoustic microscopy) technique. Acoust. Soc. Am. 1998, 103, 1370–1376. [Google Scholar] [CrossRef]

- Lee, Y.C.; Kuo, S.H. A new point contact surface acoustic wave transducer for measurement of acoustoelastic effect of polymethylmethacrylate. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2004, 51, 114–120. [Google Scholar] [PubMed]

- Vikram, C.S.; Pechersky, M.J.; Feng, C.; Engelhaupt, D. Residual-stress analysis by local laser heating and speckle-correlation interferometry. Exp. Tech. 2008, 20, 27–30. [Google Scholar] [CrossRef]

- Casavola, C.; Campanelli, S.L.; Pappalettere, C. Preliminary investigation on distribution of residual stress generated by the selective laser melting process. J. Strain Anal. Eng. Des. 2009, 44, 93–104. [Google Scholar] [CrossRef]

- Yoshida, S.; Sasaki, T.; Craft, S.; Usui, M.; Haase, J.; Becker, T.; Park, I.K. Stress Analysis on Welded Specimen with Multiple Methods. In Advancement of Optical Methods in Experimental Mechanics; Jin, H., Sciammarella, C., Yoshida, S., Lamberti, L., Eds.; Springer: New York, NY, USA, 2014; pp. 143–152. [Google Scholar]

- Yoshida, S.; Sasaki, T.; Usui, M.; Park, I.K. Analysis of near weld stress field based on strain measurement and physical mesomechanics. Phys. Mesomech. 2015, 18, 120–132. [Google Scholar]

- Yoshida, S. Deformation and Fracture of Solid-State Materials; Springer: New York, NY, USA, 2015. [Google Scholar]

- Atalar, A.; Quate, C.F.; Wickramasinghe, H.K. Phase imaging in reflection with the acoustic microscope. Appl. Phys. Lett. 1977, 31, 791–793. [Google Scholar] [CrossRef]

- Weglein, R.D.; Wilson, R.G. Characteristic material signatures by acoustic microscopy. Electron. Lett. 1978, 14, 352–354. [Google Scholar] [CrossRef]

- Atalar, A. A physical model for acoustic signatures. J. Appl. Phys. 1979, 50, 8237–8239. [Google Scholar] [CrossRef]

- Parmon, W.; Bertoni, H.L. Ray interpretation of the material signature in the acoustic microscope. Electron. Lett. 1979, 15, 684–686. [Google Scholar] [CrossRef]

- Kushibiki, J.; Chubachi, N. Material characterization by line-focus-beam acoustic microscope. IEEE Trans. Sonic Ultrason. 1985, SU-32, 189–212. [Google Scholar] [CrossRef]

- Zinin, P.V. Quantitative Acoustic Microscopy of Solids. In Handbook of Elastic Properties of Solids, Liquids, and Gases. Volume I: Dynamic Methods for Measuring the Elastic Properties of Solids; Levy, M., Bass, H., Stern, R., Keppens, V., Eds.; Academic Press: New York, NY, USA, 2001; pp. 187–226. [Google Scholar]

- Lemons, R.A.; Quate, C.F. Acoustic Microscopy. In Physical Acoustics; Mason, W.P., Thurston, R.N., Eds.; Academic Press: London, UK, 1979; pp. 1–92. [Google Scholar]

- Yoshida, S. Optical interferometric study on deformation and fracture based on physical mesomechanics. Phys. Mesomech. 1999, 2, 5–12. [Google Scholar]

- Sciammarella, C.A.; Sciammarella, F.M. Experimental Mechanics of Solids; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Wu, L. Development and Challenges of China High-Speed Steel Industry. In Advanced Steels: The Recent Scenario in Steel Science and Technology; Weng, Y., Dong, H., Gan, Y., Eds.; Springer: New York, NY, USA, 2011; p. 455. [Google Scholar]

- Grayeli, N.; Ilic, D.; Stanke, F.; Kino, G.S.; Shyne, J.C. Acoustic Measurement of Microstructures in Steels; E.L. Ginzton Laboratory Rep: La Jolla, CA, USA, 1979; pp. 429–434. [Google Scholar]

- Muir, D.D. One-Sided Ultrasonic Determination of Third Order Elastic Constants Using Angle-Beam Acoustoelasticity Measurements. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2009. [Google Scholar]

- Yoshida, S.; Siahaan, B.; Pardede, M.H.; Sijabat, N.; Simangunsong, H.; Simbolon, T.; Kusnowo, A. Observation of plastic deformation wave in a tensile-loaded aluminum-alloy. Phys. Lett. A 1999, 251, 54–60. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshida, S.; Sasaki, T.; Usui, M.; Sakamoto, S.; Gurney, D.; Park, I.-K. Residual Stress Analysis Based on Acoustic and Optical Methods. Materials 2016, 9, 112. https://doi.org/10.3390/ma9020112

Yoshida S, Sasaki T, Usui M, Sakamoto S, Gurney D, Park I-K. Residual Stress Analysis Based on Acoustic and Optical Methods. Materials. 2016; 9(2):112. https://doi.org/10.3390/ma9020112

Chicago/Turabian StyleYoshida, Sanichiro, Tomohiro Sasaki, Masaru Usui, Shuichi Sakamoto, David Gurney, and Ik-Keun Park. 2016. "Residual Stress Analysis Based on Acoustic and Optical Methods" Materials 9, no. 2: 112. https://doi.org/10.3390/ma9020112

APA StyleYoshida, S., Sasaki, T., Usui, M., Sakamoto, S., Gurney, D., & Park, I.-K. (2016). Residual Stress Analysis Based on Acoustic and Optical Methods. Materials, 9(2), 112. https://doi.org/10.3390/ma9020112