Electroconductive Composites from Polystyrene Block Copolymers and Cu–Alumina Filler

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Conductive Filler

2.2.1. Pretreatment of Al2O3

2.2.2. Cu Coating on Pretreated Al2O3

2.3. Synthesis of Conductive Composites

2.4. Instrumentation and Characterization

2.4.1. X-ray Diffraction (XRD) Analysis

2.4.2. Morphological Analysis

2.4.3. Energy Dispersive Spectrometry (EDS) Analysis

2.4.4. Analysis of Surface/Volume Resistivity and Electrical Conductivity

2.4.5. Analysis of Mechanical Properties

2.4.6. Analysis of Thermal Properties

3. Results and Discussion

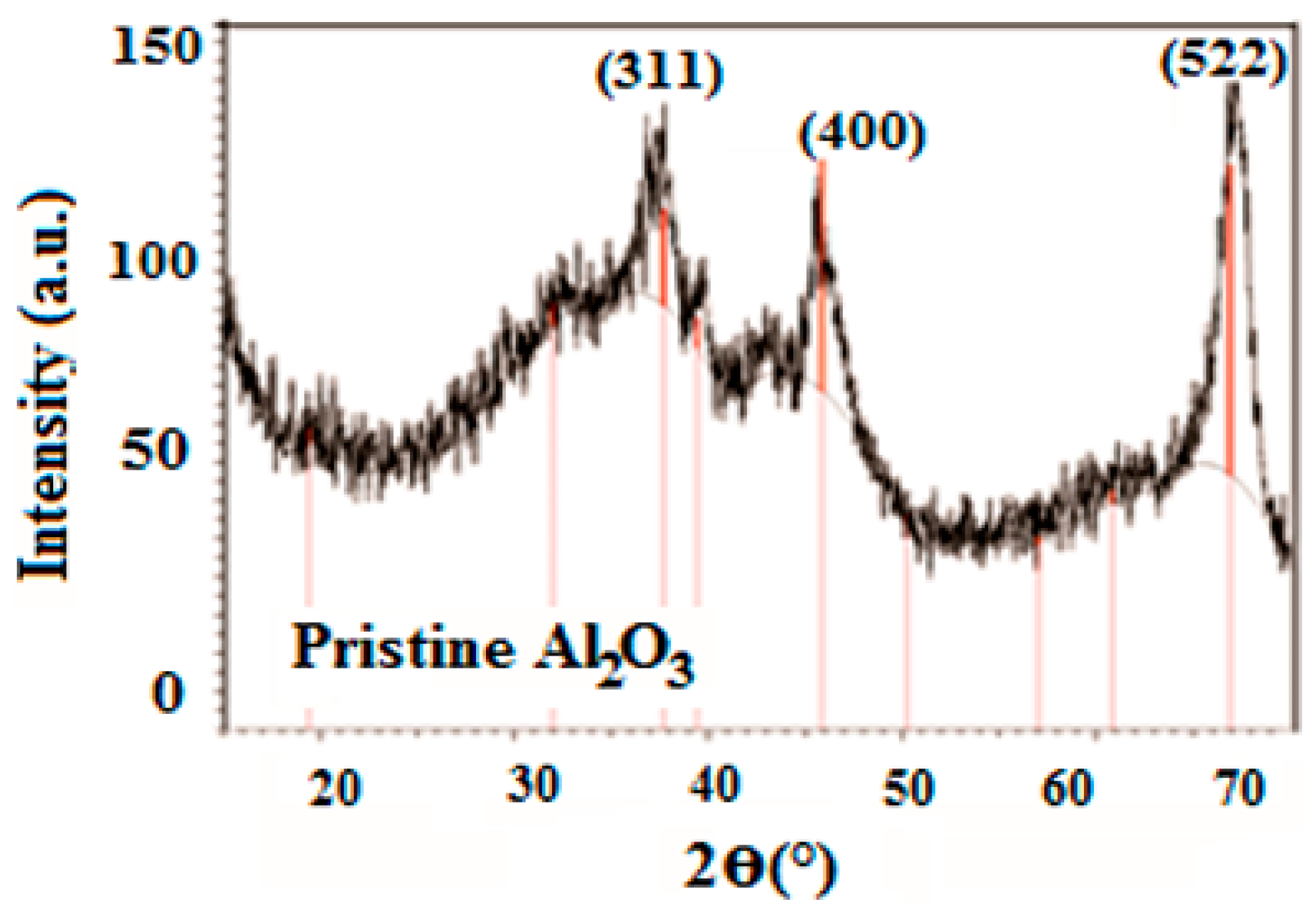

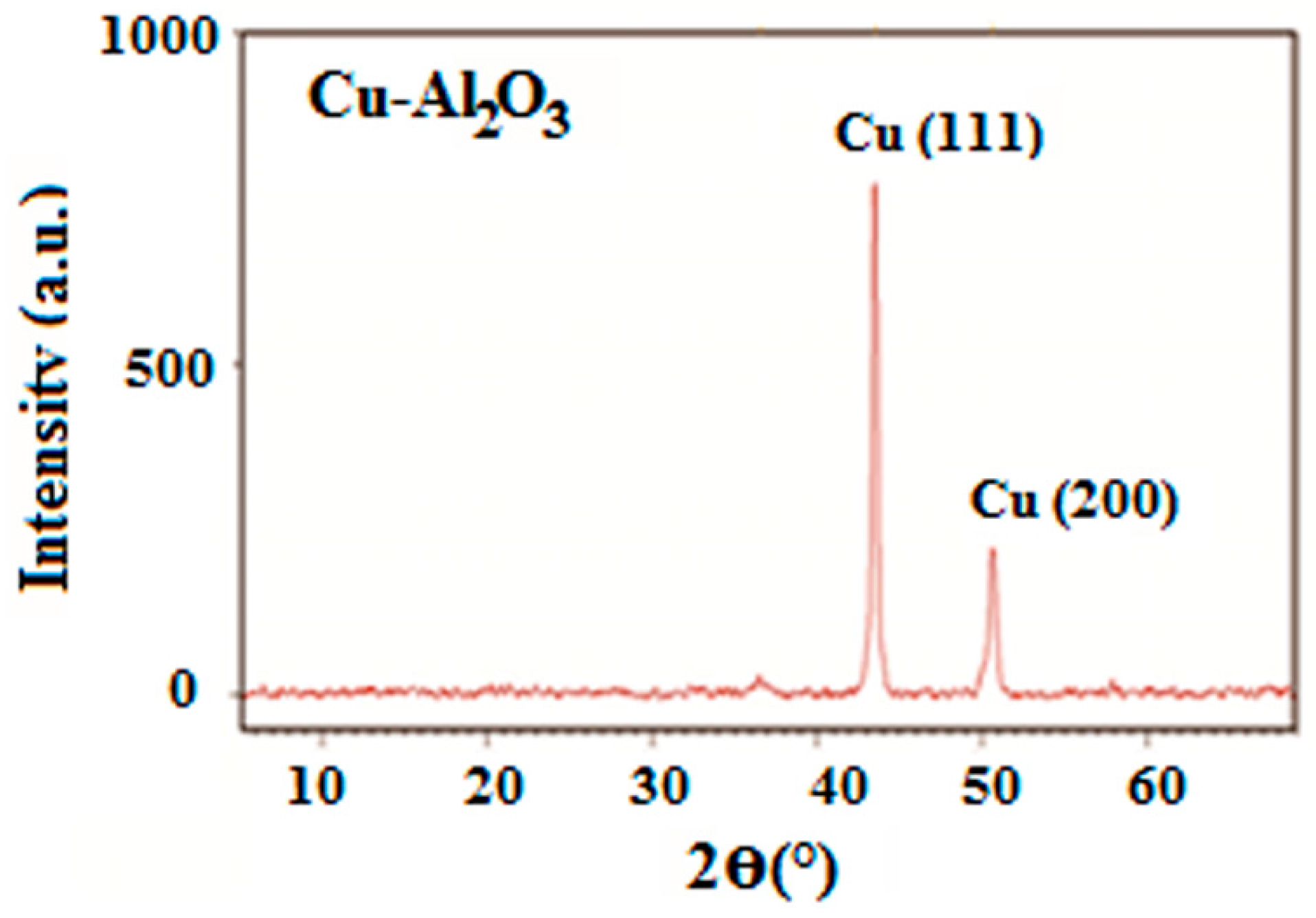

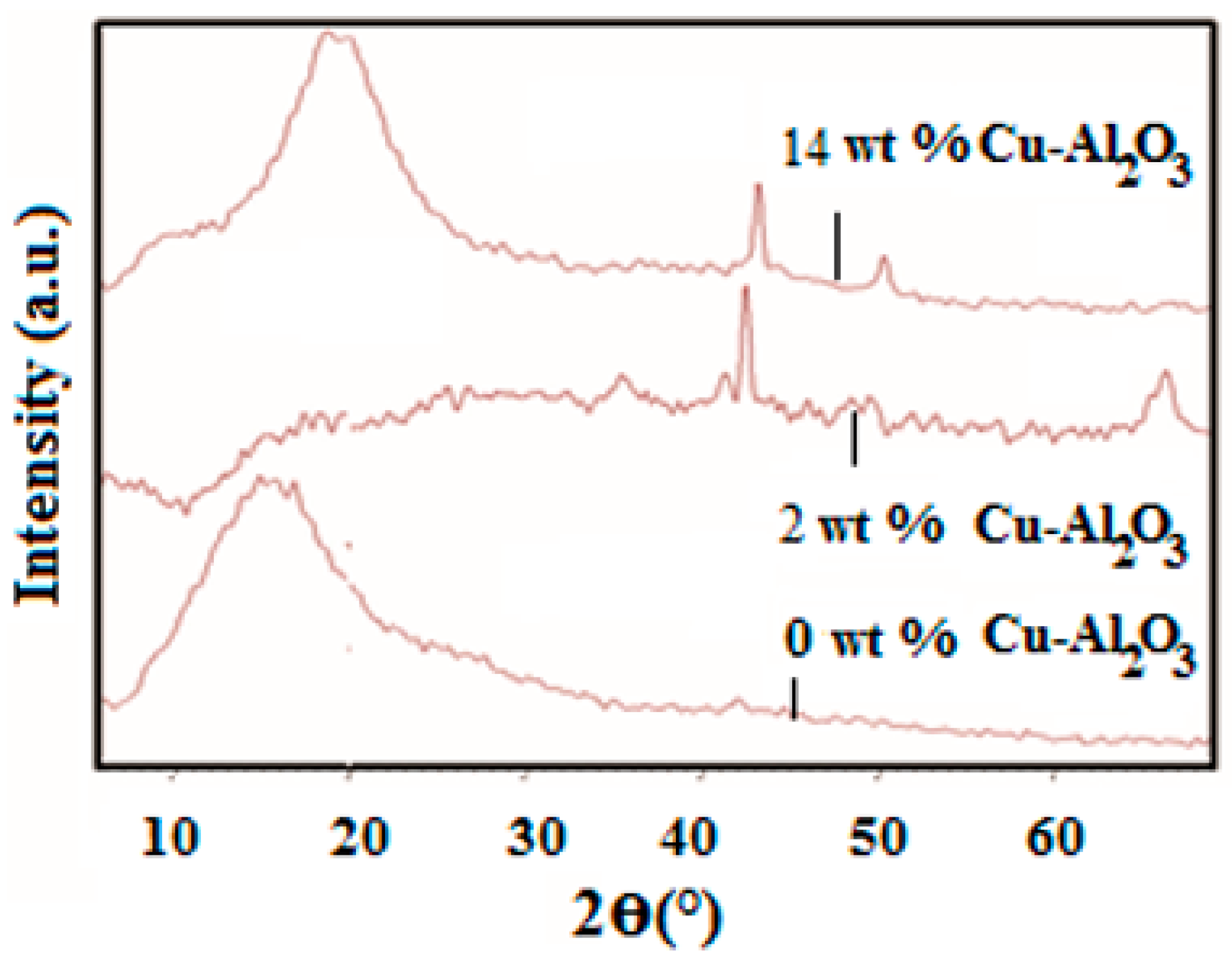

3.1. XRD Analysis of Pristine and Cu-Coated Al2O3 Powder and Composite Films

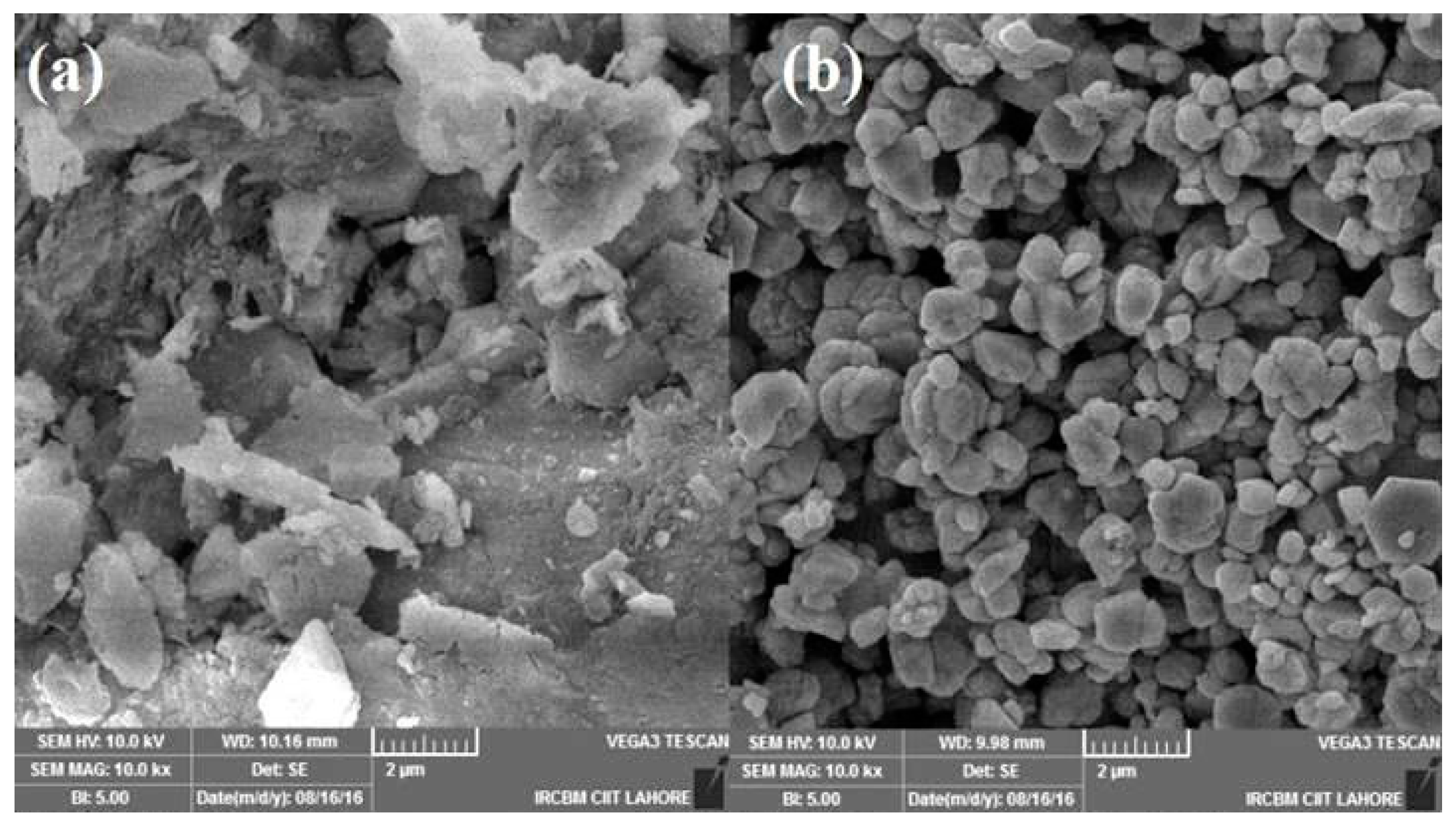

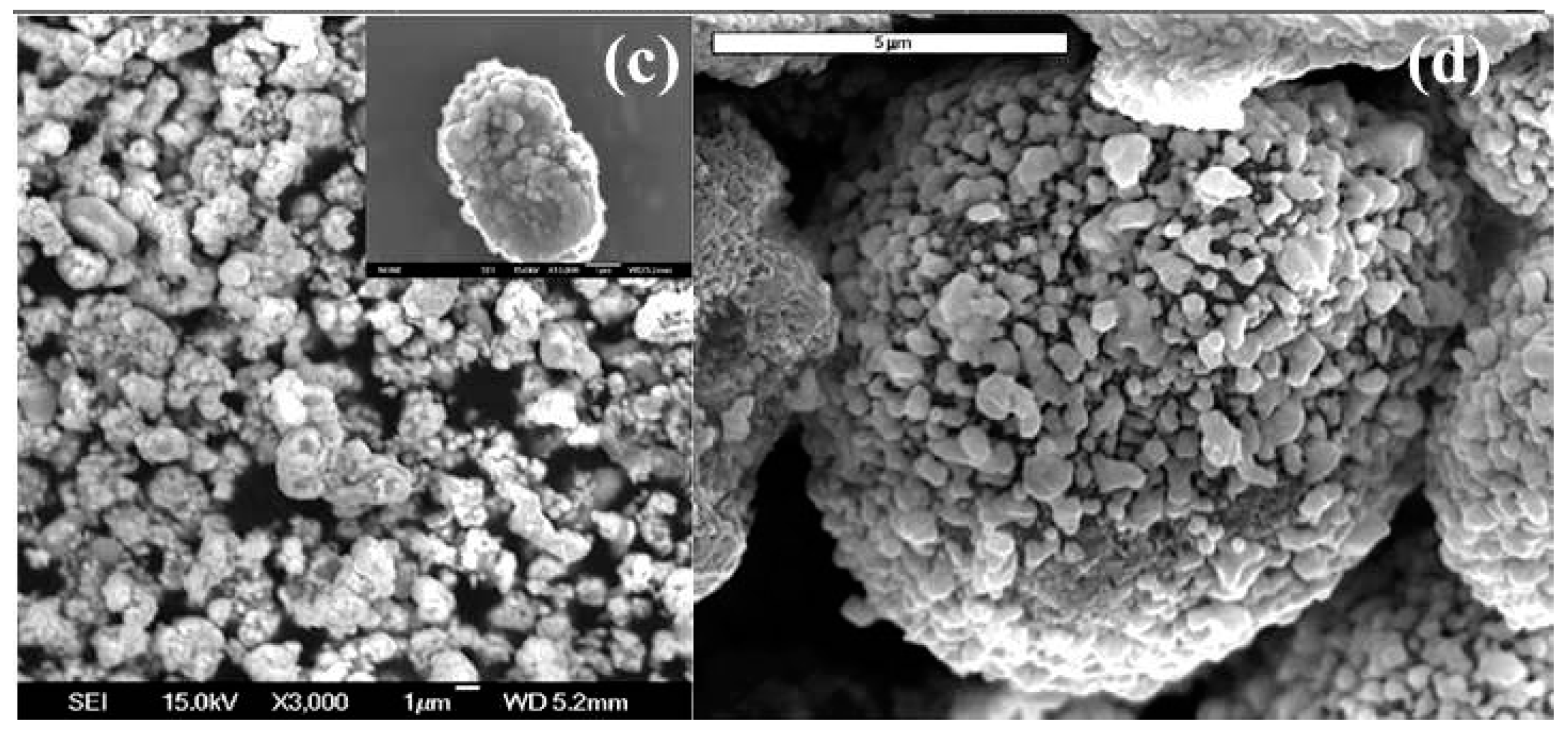

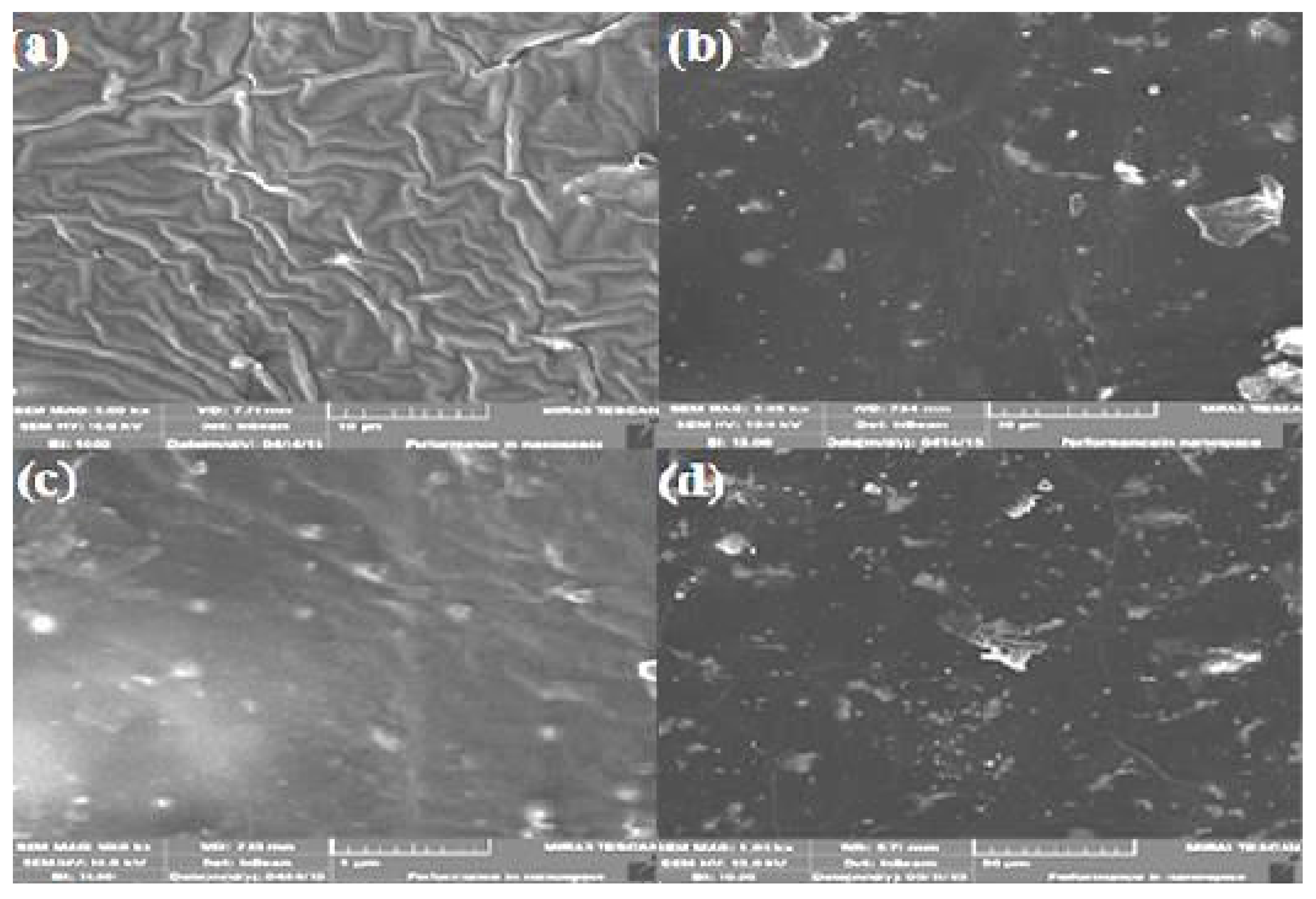

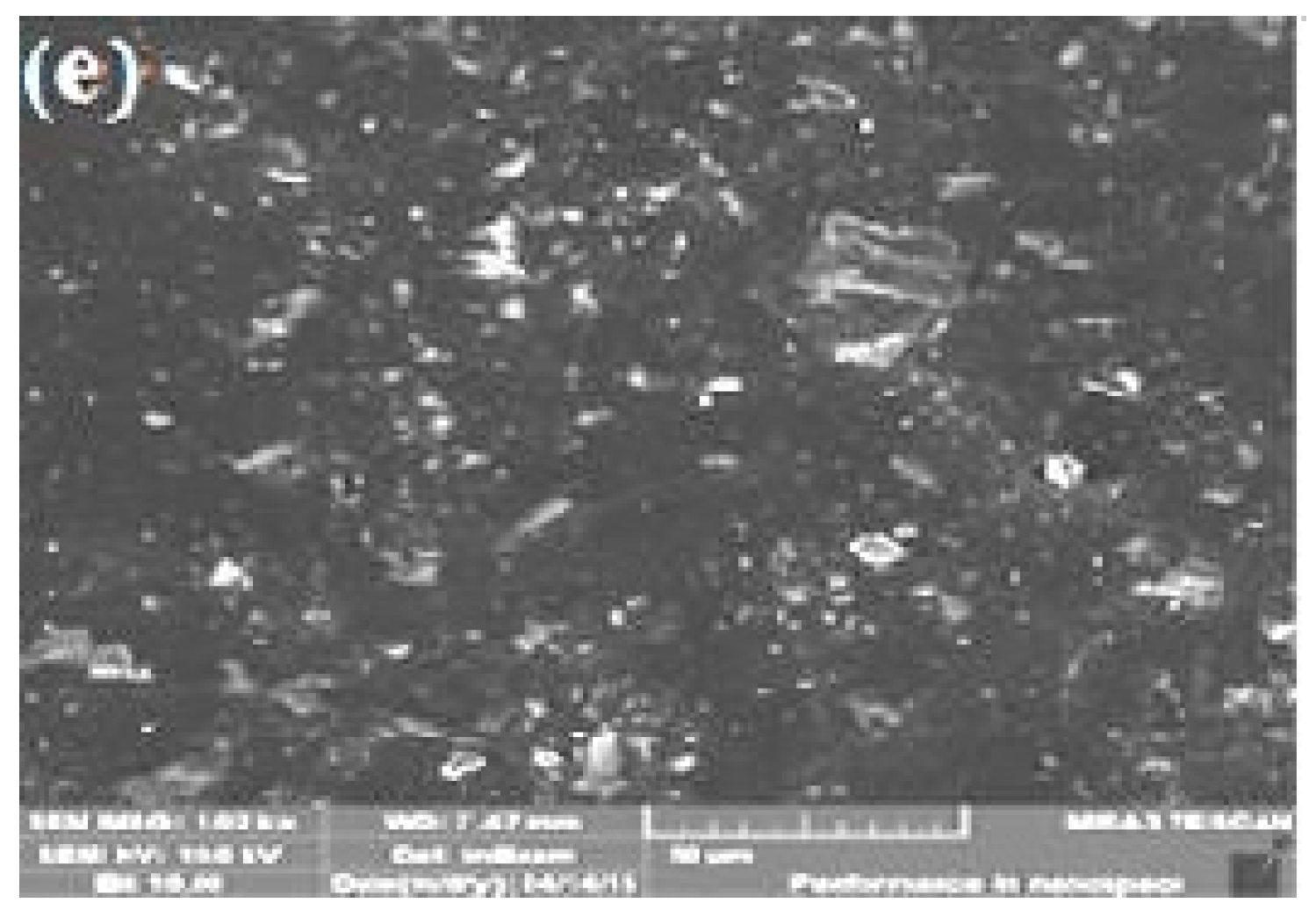

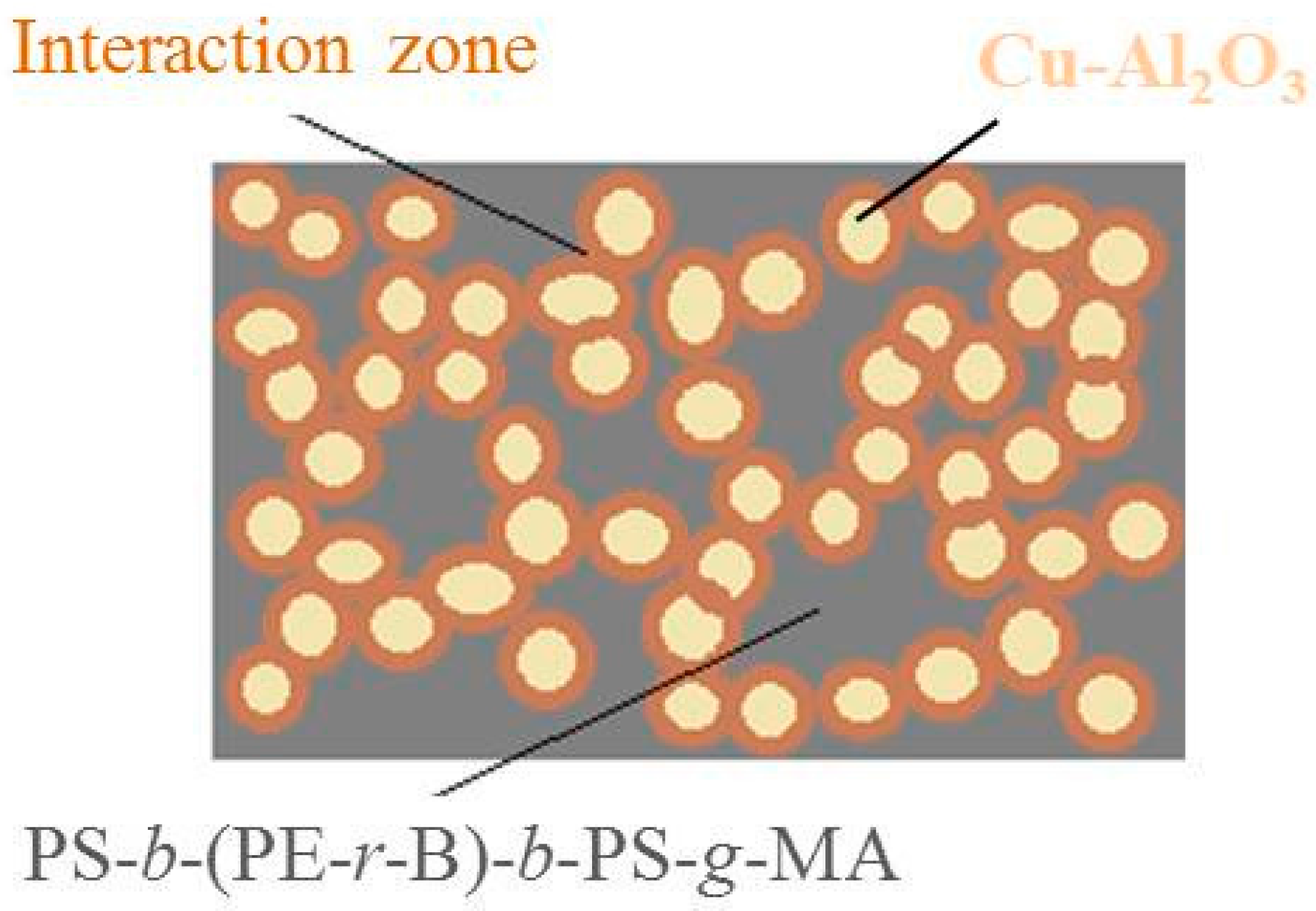

3.2. Morphological Study of Cu–Al2O3 Filler and Block Copolymer Composites

3.3. EDS Analysis of Cu–Al2O3 Filler and Block Copolymer Composites

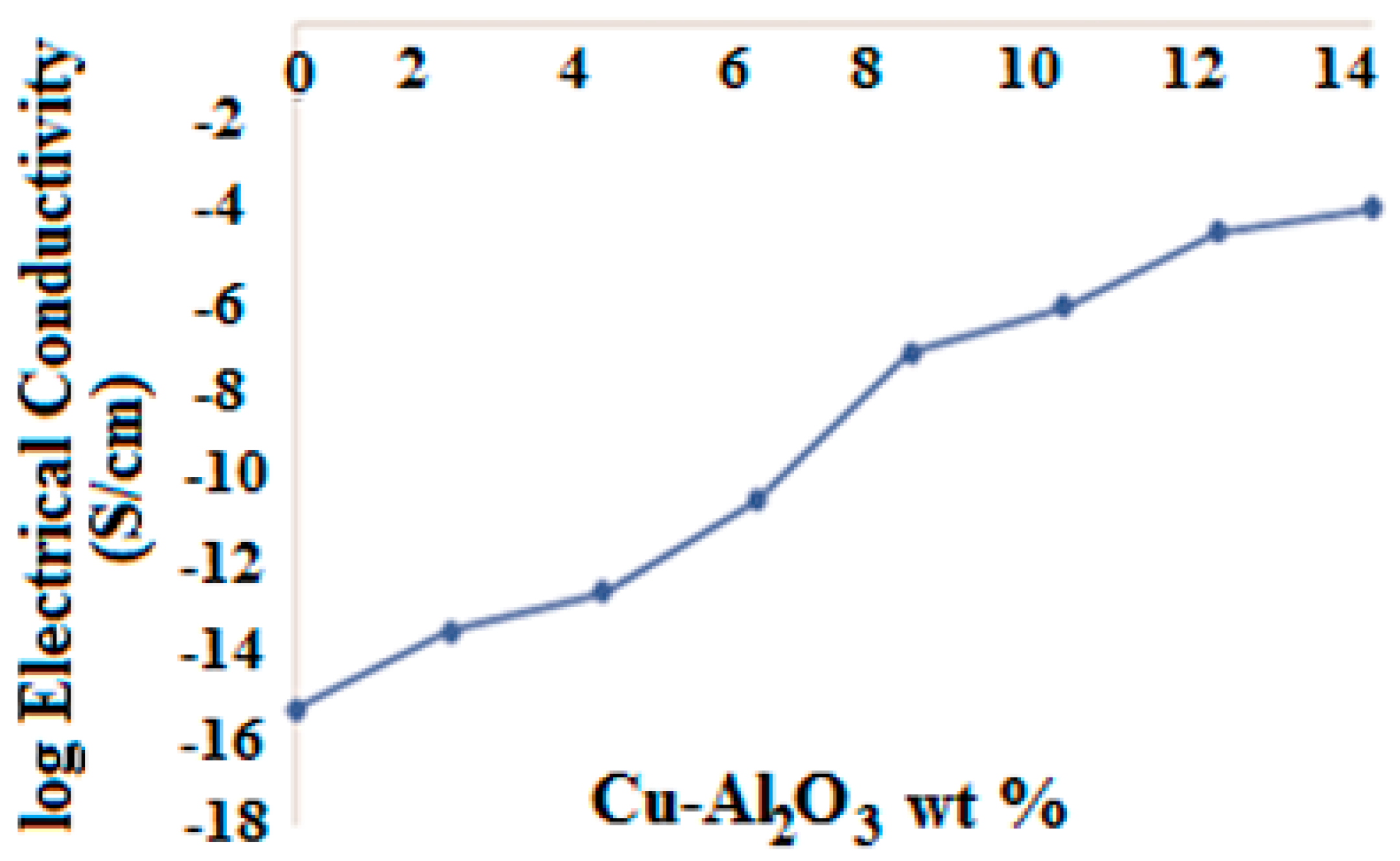

3.4. Surface/Volume Resistivity and Electrical Conductivity of Block Copolymer Composites

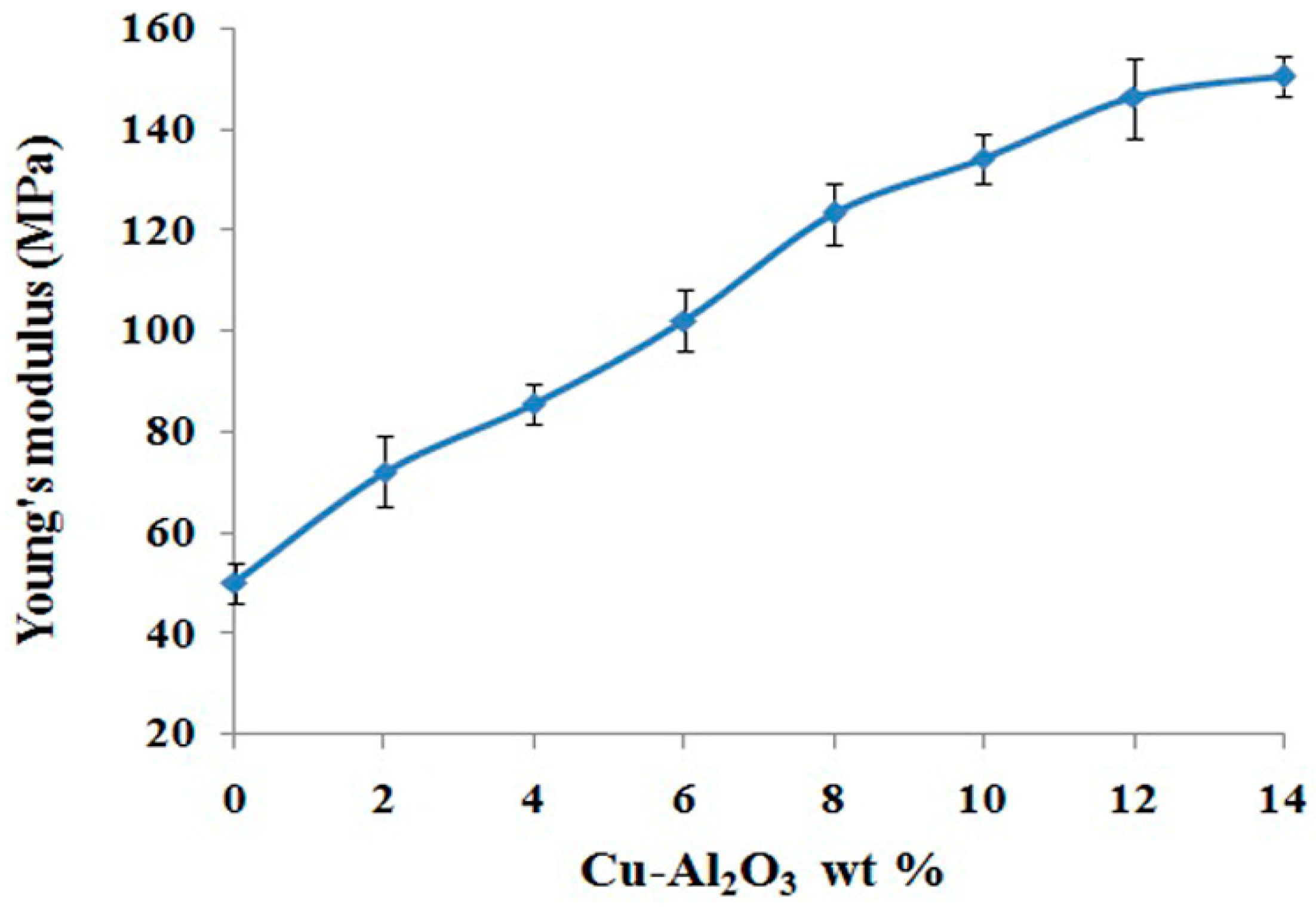

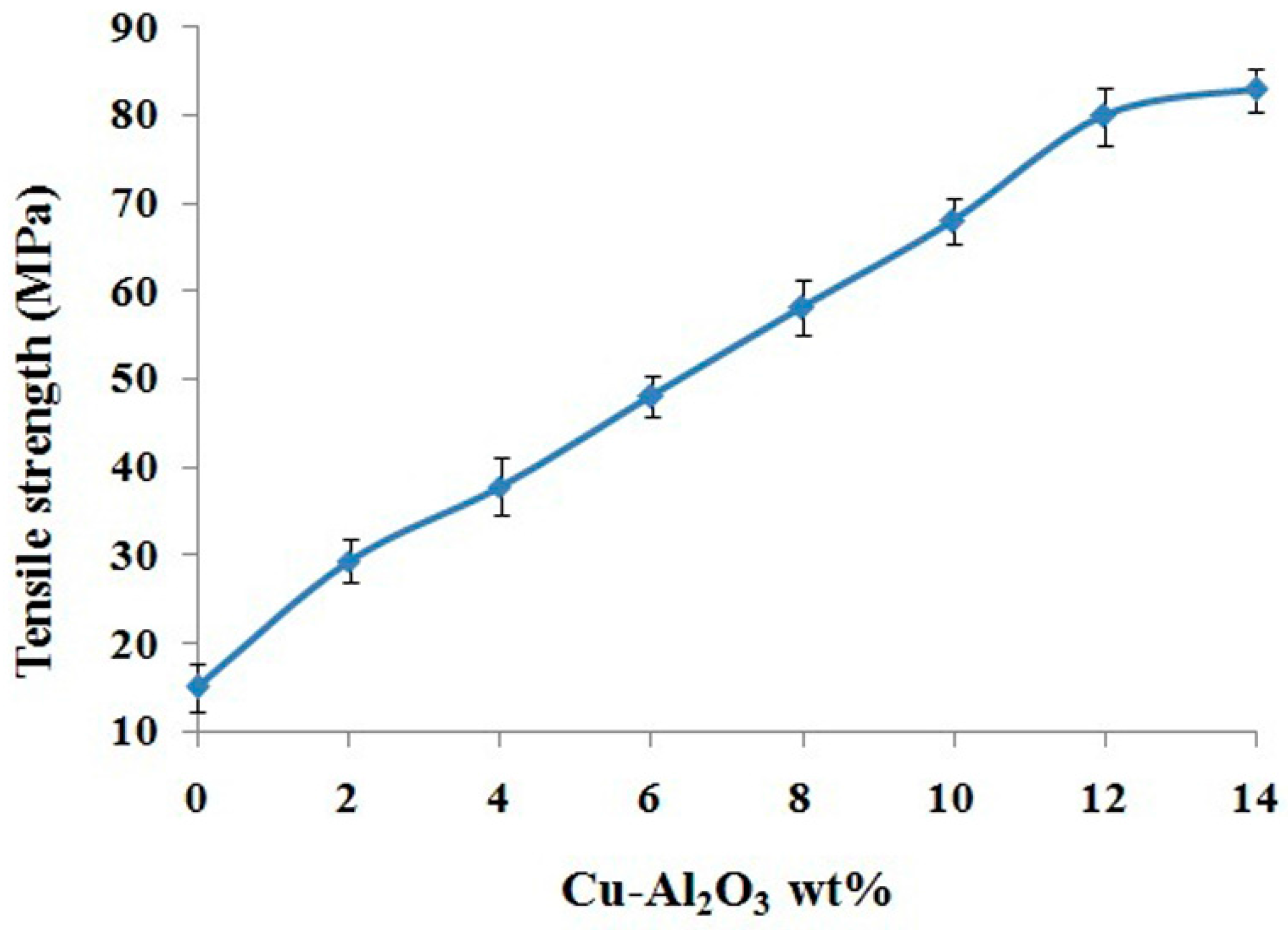

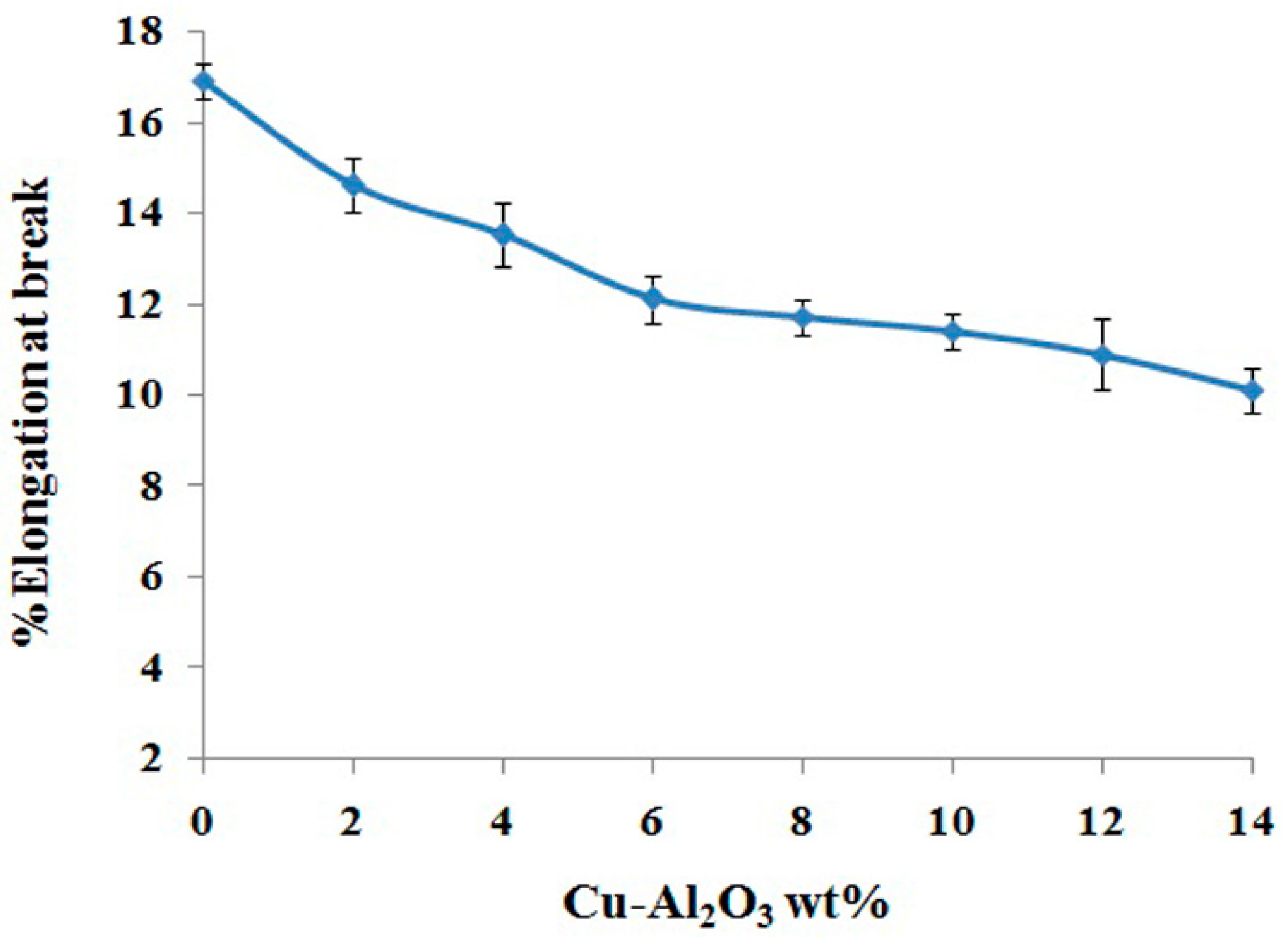

3.5. Mechanical Properties of Cu–Al2O3/PS-b-(PE-r-B)-b-PS-g-MA Composites

3.5.1. Young’s Modulus

3.5.2. Tensile Strength

3.5.3. Elongation at Break

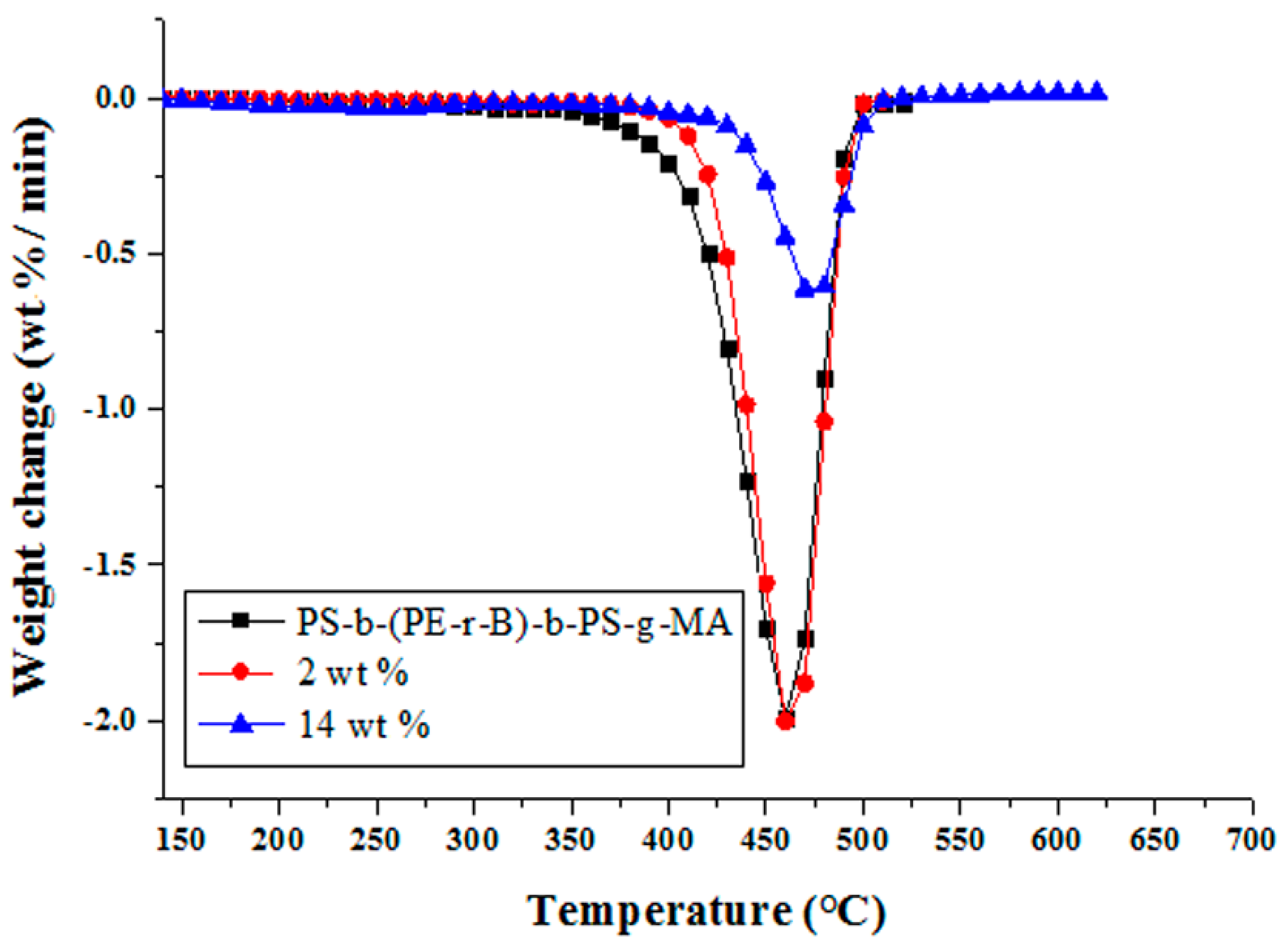

3.6. Thermal Characteristics of Block Copolymer Composites

3.6.1. Thermogravimetric Analysis (TGA)

3.6.2. Differential Scanning Calorimetry (DSC)

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rimdusit, S.; Jubsilp, C.; Tiptipakorn, S. Alloys and Composites of Polybenzoxazines: Properties and Applications; Springer: Singapore, 2013; pp. 139–141. [Google Scholar]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Shacham-Diamand, Y.; Osaka, T.; Okinaka, Y.; Sugiyama, A.; Dubin, V. 30 years of electroless plating for semiconductor and polymer micro-systems. Microelectron. Eng. 2015, 132, 35–45. [Google Scholar] [CrossRef]

- Sudagar, J.; Lian, J.; Sha, W. Electroless nickel alloy composite and nano coatings—A critical review. J. Alloys Compd. 2013, 571, 183–204. [Google Scholar] [CrossRef]

- Agarwala, R.C.; Agarwala, V. Electroless alloy composite coatings: A review. Sadhana 2003, 28, 475–493. [Google Scholar] [CrossRef]

- Zhai, T.; Ding, C.; Lu, L.; Zhang, C. Autocatalytic deposition of copper coating on poly (ether ether ketone)/multiwalled carbon nanotubes composites via a palladium-free and simplified electroless process. Mater. Lett. 2015, 147, 46–49. [Google Scholar] [CrossRef]

- Reddy, E.L.; Lee, H.C.; Kim, D.H. Steam reforming of methanol over structured catalysts prepared by electroless deposition of Cu and Zn on anodically oxidized alumina. Int. J. Hydrogen Energy 2015, 40, 2509–2517. [Google Scholar] [CrossRef]

- Moon, J.H.; Kim, K.H.; Choi, H.W.; Lee, S.W.; Park, S.J. Electroless silver coating of rod-like glass particles. Ultramicroscopy 2008, 108, 1307–1310. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Liu, J.; Wang, L.; Zhao, F. Development of electrochemical DNA biosensor based on gold nanoparticle modified electrode by electroless deposition. Bioelectrochemistry 2010, 79, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Kretz, F.; Gacsi, Z.; Kovacs, J.; Pieczonka, T. The electroless deposition of nickel on SiC particles for aluminum matrix composites. Surf. Coat. Technol. 2004, 180, 575–579. [Google Scholar] [CrossRef]

- Kuester, S.; Merlini, C.; Barra, G.M.; Ferreira, J.C.; Lucas, A.; de Souza, A.C.; Soares, B.G. Processing and characterization of conductive composites based on poly (styrene-b-ethylene-ran-butylene-b-styrene)(SEBS) and carbon additives: A comparative study of expanded graphite and carbon black. Compos. Part B 2016, 84, 236–247. [Google Scholar] [CrossRef]

- Sarı, A.; Alkan, C.; Karaipekli, A.; Onal, A. Preparation, characterization and thermal properties of styrene maleic anhydride copolymer (SMA)/fatty acid composites as form stable phase change materials. Energy Convers. Manag. 2008, 49, 373–380. [Google Scholar] [CrossRef]

- Araby, S.; Meng, Q.; Zhang, L.; Kang, H.; Majewski, P.; Tang, Y. Electrically and thermally conductive elastomer/graphene nanocomposites by solution mixing. J. Polym. 2014, 55, 201–210. [Google Scholar] [CrossRef]

- Tian, Q.H.; Guo, X.Y. Simulation of electromagnetic-flow fields in Mg melt under pulsed magnetic field. Trans. Nonferrous Met. Soc. China 2010, 20, 283–287. [Google Scholar] [CrossRef]

- Standard Test Methods for DC Resistance or Conductance of Insulating Materials; ASTM D257-07; ASTM International: West Conshohocken, PA, USA, 2007.

- Standard Test Method for Tensile Properties of Plastics; ASTM D638-02; ASTM International: West Conshohocken, PA, USA, 2002.

- Standard Test Method for Tensile Properties of Plastics; ASTM D638-03; ASTM International: West Conshohocken, PA, USA, 2003.

- Ma, H.; Liu, Z.; Wu, L.; Wang, Y.; Wang, X. Study of a pre-treatment process for electroless copper plating on ceramics. Thin Solid Films 2011, 519, 7860–7863. [Google Scholar] [CrossRef]

- Mondin, G.; Lohe, M.R.; Wisser, F.M.; Grothe, J.; Mohamed-Noriega, N.; Leifert, A.; Dorfler, S.; Bachmatiuk, A.; Rummelib, M.H.; Kaskel, S. Electroless copper deposition on (3-mercaptopropyl) triethoxysilane-coated silica and alumina nanoparticles. Electrochim. Acta 2013, 114, 521–526. [Google Scholar] [CrossRef]

- Reddy, K.R.; Sin, B.C.; Yoo, C.H.; Park, W.; Ryu, K.S.; Lee, J.S.; Shon, D.; Lee, Y. A new one-step synthesis method for coating multi-walled carbon nanotubes with cuprous oxide nanoparticles. Scr. Mater. 2008, 58, 1010–1013. [Google Scholar] [CrossRef]

- Chang, H.F.; Saleque, M.A.; Hsu, W.S.; Lin, W.H. Characterization and dehydrogenation activity of CuAl2O3 catalysts prepared by electroless plating technique. J. Mol. Catal. A Chem. 1996, 109, 249–260. [Google Scholar] [CrossRef]

- Sharma, R.; Agarwala, R.C.; Agarwala, V. Development of copper coatings on ceramic powder by electroless technique. Appl. Surf. Sci. 2006, 252, 8487–8493. [Google Scholar] [CrossRef]

- Leon, C.A.; Rodriguez-Ortiz, G.; Nanko, M.; Aguilar, E.A. Pulsed electric current sintering of Cu matrix composites reinforced with plain and coated alumina powders. Powder Technol. 2014, 252, 1–7. [Google Scholar] [CrossRef]

- Silvain, J.F.; Bobet, J.L.; Heintz, J.M. Electroless deposition of copper onto alumina sub-micronic powders and sintering. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1387–1390. [Google Scholar] [CrossRef]

- Wang, H.; Jia, J.; Song, H.; Hu, X.; Sun, H.; Yang, D. The preparation of Cu-coated Al2O3 composite powders by electroless plating. Ceram. Int. 2011, 37, 2181–2184. [Google Scholar] [CrossRef]

- Krupa, I.; Miková, G.; Novák, I.; Janigová, I.; Nógellova, Z.; Lednický, F.; Prokes, J. Electrically conductive composites of polyethylene filled with polyamide particles coated with silver. Eur. Polym. J. 2007, 43, 2401–2413. [Google Scholar] [CrossRef]

- Goyal, R.K.; Tiwari, A.N.; Mulik, U.P.; Negi, Y.S. Novel high performance Al2O3/poly (ether ether ketone) nanocomposites for electronics applications. Compos. Sci. Technol. 2007, 67, 1802–1812. [Google Scholar] [CrossRef]

- Choi, S.; Kim, K.; Nam, J.; Shim, S.E. Synthesis of silica-coated graphite by enolization of polyvinylpyrrolidone and its thermal and electrical conductivity in polymer composites. Carbon 2013, 60, 254–265. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Saadeh, W.H.; Sundararaj, U. EMI shielding effectiveness of carbon based nanostructured polymeric materials: A comparative study. Carbon 2013, 60, 146–156. [Google Scholar] [CrossRef]

- Chu, B.; Zhou, X.; Ren, K.; Neese, B.; Lin, M.; Wang, Q.; Bauer, F.; Zhang, Q.M. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef] [PubMed]

- Rahaman, M.; Chaki, T.K.; Khastgir, D. Development of high performance EMI shielding material from EVA, NBR, and their blends: effect of carbon black structure. J. Mater. Sci. 2011, 46, 3989–3999. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yuan, J.K.; Zha, J.W.; Zhou, T.; Li, S.T.; Hu, G.H. Fundamentals, processes and applications of high-permittivity polymer–matrix composites. Prog. Mater. Sci. 2012, 57, 660–723. [Google Scholar] [CrossRef]

- Xu, S.; Rezvanian, O.; Peters, K.; Zikry, M.A. The viability and limitations of percolation theory in modeling the electrical behavior of carbon nanotube–polymer composites. Nanotechnology 2013, 24, 155706. [Google Scholar] [CrossRef] [PubMed]

- Pang, H.; Xu, L.; Yan, D.X.; Li, Z.M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Deng, H.; Lin, L.; Ji, M.; Zhang, S.; Yang, M.; Fu, Q. Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials. Prog. Polym. Sci. 2014, 39, 627–655. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, H.B.; Hong, S.; Jiang, Z.G.; Gui, C.; Li, X.; Yu, Z.Z. Simultaneous improvement in both electrical conductivity and toughness of polyamide 6 nanocomposites filled with elastomer and carbon black particles. Ind. Eng. Chem. Res. 2014, 53, 2270–2276. [Google Scholar] [CrossRef]

- Arjmand, M.; Mahmoodi, M.; Gelves, G.A.; Park, S.; Sundararaj, U. Electrical and electromagnetic interference shielding properties of flow-induced oriented carbon nanotubes in polycarbonate. Carbon 2011, 49, 3430–3440. [Google Scholar] [CrossRef]

- Zheng, W.; Wong, S.C. Electrical conductivity and dielectric properties of PMMA/expanded graphite composites. Compos. Sci. Technol. 2003, 63, 225–235. [Google Scholar] [CrossRef]

- Wei, Y.F.; Li, Z.Q. Measurement of specific contact resistivity using scanning voltage probes. Appl. Phys. Lett. 2013, 102, 131605. [Google Scholar]

- Al-Saleh, M.H. Influence of conductive network structure on the EMI shielding and electrical percolation of carbon nanotube/polymer nanocomposites. Synth. Met. 2015, 205, 78–84. [Google Scholar] [CrossRef]

- Nadeem, Q.; Rizwan, M.; Gill, R.; Rafique, M.; Shahid, M. Fabrication of alumina based electrically conductive polymer composites. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, D.H.; Raghu, A.V.; Reddy, K.R.; Lee, H.I.; Yoon, K.S.; Jeong, H.M.; Kim, B.K. Properties of graphene/waterborne polyurethane nanocomposites cast from colloidal dispersion mixtures. J. Macromol. Sci. Part B Phys. 2012, 51, 197–207. [Google Scholar] [CrossRef]

- Sau, K. Acetylene black filled Elastomeric conductive composites based on EPDM, NBR and Silicone rubber. History 2015, 15, 13–19. [Google Scholar]

- Sohi, N.J.S.; Rahaman, M.; Khastgir, D. Dielectric property and electromagnetic interference shielding effectiveness of ethylene vinyl acetate-based conductive composites: Effect of different type of carbon fillers. Polym. Compos. 2011, 32, 1148–1154. [Google Scholar] [CrossRef]

- Verma, P.; Saini, P.; Malik, R.S.; Choudhary, V. Excellent electromagnetic interference shielding and mechanical properties of high loading carbon-nanotubes/polymer composites designed using melt recirculation equipped twin-screw extruder. Carbon 2015, 89, 308–317. [Google Scholar] [CrossRef]

- Kwon, S.C.; Adachi, T.; Araki, W.; Yamaji, A. Effect of composing particles of two sizes on mechanical properties of spherical silica-particulate-reinforced epoxy composites. Compos. Part B Eng. 2008, 39, 740–746. [Google Scholar] [CrossRef]

- Fletcher, A.; Gupta, M.C. Mechanical properties of elastomer nanocomposites for electromagnetic interference shielding applications. J. Compos. Mater. 2014, 48, 1261–1276. [Google Scholar] [CrossRef]

- Bishay, I.K.; Abd-El-Messieh, S.L.; Mansour, S.H. Electrical, mechanical and thermal properties of polyvinyl chloride composites filled with aluminum powder. Mater. Des. 2011, 32, 62–68. [Google Scholar] [CrossRef]

- Gao, H.; Ji, B.; Jäger, I.L.; Arzt, E.; Fratzl, P. Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc. Natl. Acad. Sci. USA 2003, 100, 5597–5600. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.S.; Mariatti, M. Comparison on the properties of nickel-coated graphite (NCG) and graphite particles as conductive fillers in polypropylene (PP) composites. Polym. Plast. Technol. Eng. 2009, 48, 614–620. [Google Scholar] [CrossRef]

- Kuo, M.C.; Tsai, C.M.; Huang, J.C.; Chen, M. PEEK composites reinforced by nano-sized SiO2 and Al2O3 particulates. Mater. Chem. Phys. 2005, 90, 185–195. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, S.; Yang, H.; Wu, L. Structure and properties of polyurethane/nanosilica composites. J. Appl. Polym. Sci. 2005, 95, 1032–1039. [Google Scholar] [CrossRef]

- Renner, K.; Yang, M.S.; Móczó, J.; Choi, H.J.; Pukánszky, B. Analysis of the debonding process in polypropylene model composites. Eur. Polym. J. 2005, 41, 2520–2529. [Google Scholar] [CrossRef]

- Wang, K.; Wu, J.; Ye, L.; Zeng, H. Mechanical properties and toughening mechanisms of polypropylene/barium sulfate composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 1199–1205. [Google Scholar] [CrossRef]

- Zhang, Q.; Tian, M.; Wu, Y.; Lin, G.; Zhang, L. Effect of particle size on the properties of Mg(OH)2-filled rubber composites. J. Appl. Polym. Sci. 2004, 94, 2341–2346. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Zhou, W.; Qi, S.; Li, H.; Shao, S. Study on insulating thermal conductive BN/HDPE composites. Thermochim. Acta 2007, 452, 36–42. [Google Scholar] [CrossRef]

- Meincke, O.; Kaempfer, D.; Weickmann, H.; Friedrich, C.; Vathauer, M.; Warth, H. Mechanical properties and electrical conductivity of carbon-nanotube filled polyamide-6 and its blends with acrylonitrile/butadiene/styrene. Polymer 2004, 45, 739–748. [Google Scholar] [CrossRef]

- Shafiq, M.; Yasin, T.; Saeed, S. Synthesis and characterization of linear low-density polyethylene/sepiolite nanocomposites. J. Appl. Polym. Sci. 2012, 123, 1718–1723. [Google Scholar] [CrossRef]

- Vilaplana, F.; Ribes-Greus, A.; Karlsson, S. Analytical strategies for the quality assessment of recycled high-impact polystyrene: A combination of thermal analysis, vibrational spectroscopy, and chromatography. Anal. Chim. Acta 2007, 604, 18–28. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.G.; Kim, S.H.; Kang, H.C.; Park, S.H. Effect of TiO2 on PVDF/PMMA composite films prepared by thermal casting. Macromol. Res. 2013, 21, 349–355. [Google Scholar] [CrossRef]

- Xie, S.H.; Zhu, B.K.; Wei, X.Z.; Xu, Z.K.; Xu, Y.Y. Polyimide/BaTiO3 composites with controllable dielectric properties. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1152–1157. [Google Scholar] [CrossRef]

| Constituents of EL Bath | Chemicals | Amount (mmol) |

|---|---|---|

| Metal Salt | CuSO4·5H2O | 64 |

| Complexing Agent | KNaC4H4O6·4H2O | 106 |

| Na2EDTA | 54 | |

| NaOH | 350 | |

| Reducing Agent | HCHO | 170 |

| Stabilizer | CH4N2S | 0.013 |

| C2nH4n+2On+1 | 50 mL | |

| Conditions in EL bath | Temperature | 45–50 °C |

| Time | 30 min | |

| pH | 12.0–12.5 |

| Cu–Al2O3 (wt %) | Atomic wt % of Elements | |||

|---|---|---|---|---|

| C | O | Al | Cu | |

| 0 | 95.3 | 4.7 | – | – |

| 2 | 85.1 | 4.3 | 1.3 | 9.3 |

| 14 | 79.2 | 3.5 | 0.4 | 16.9 |

| Cu–Al2O3 (wt %) | Surface Resistivity (Ω/□) | Volume Resistivity (Ω·cm) | Electrical Conductivity (S/cm) |

|---|---|---|---|

| 0 | 2.3 × 1014 | 2.3 × 1015 | 4.35 × 10−16 |

| 2 | 4.2 × 1010 | 4.2 × 1013 | 2.38 × 10−14 |

| 4 | 5.8 × 109 | 5.8 × 1012 | 1.72 × 10−13 |

| 6 | 5.1 × 109 | 5.1 × 1010 | 1.96 × 10−11 |

| 8 | 2.3 × 108 | 2.3 × 107 | 4.35 × 10−8 |

| 10 | 2.1 × 108 | 2.1 × 106 | 4.76 × 10−7 |

| 12 | 1.3 × 108 | 4.5 × 104 | 2.22 × 10−5 |

| 14 | 4.0 × 104 | 1.3 × 104 | 7.69 × 10−5 |

| Composite Type | Tensile Strength (MPa) | Reference |

|---|---|---|

| PS-b-(PE-r-B)-b-PS-g-MA/Cu-Al2O3 | 82.9 | Present research |

| Polyethylene/Ag-coated polyamide | 2.7 | [26] |

| Waterborne polyurethane/graphene | 9.6 | [42] |

| Polyurethane/silica | 6.80 | [52] |

| Polypropylene/CaCO3 | 29.7 | [53] |

| Polypropylene/BaSO4 | 30.0 | [54] |

| Ethylene–propylene–diene monomer rubber/MgOH2 | 9.6 | [55] |

| Polypropylene/poly(methylmethacrylate) | 29.5 | [53] |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nadeem, Q.; Fatima, T.; Prinsen, P.; Ur Rehman, A.; Gill, R.; Mahmood, R.; Luque, R. Electroconductive Composites from Polystyrene Block Copolymers and Cu–Alumina Filler. Materials 2016, 9, 989. https://doi.org/10.3390/ma9120989

Nadeem Q, Fatima T, Prinsen P, Ur Rehman A, Gill R, Mahmood R, Luque R. Electroconductive Composites from Polystyrene Block Copolymers and Cu–Alumina Filler. Materials. 2016; 9(12):989. https://doi.org/10.3390/ma9120989

Chicago/Turabian StyleNadeem, QuratulAin, Tasneem Fatima, Pepijn Prinsen, Aziz Ur Rehman, Rohama Gill, Rashid Mahmood, and Rafael Luque. 2016. "Electroconductive Composites from Polystyrene Block Copolymers and Cu–Alumina Filler" Materials 9, no. 12: 989. https://doi.org/10.3390/ma9120989

APA StyleNadeem, Q., Fatima, T., Prinsen, P., Ur Rehman, A., Gill, R., Mahmood, R., & Luque, R. (2016). Electroconductive Composites from Polystyrene Block Copolymers and Cu–Alumina Filler. Materials, 9(12), 989. https://doi.org/10.3390/ma9120989