Effect of Pre-Oxidation Treatment of Nano-SiC Particulates on Microstructure and Mechanical Properties of SiC/Mg-8Al-1Sn Composites Fabricated by Powder Metallurgy Combined with Hot Extrusion

Abstract

:1. Introduction

2. Experimental Section

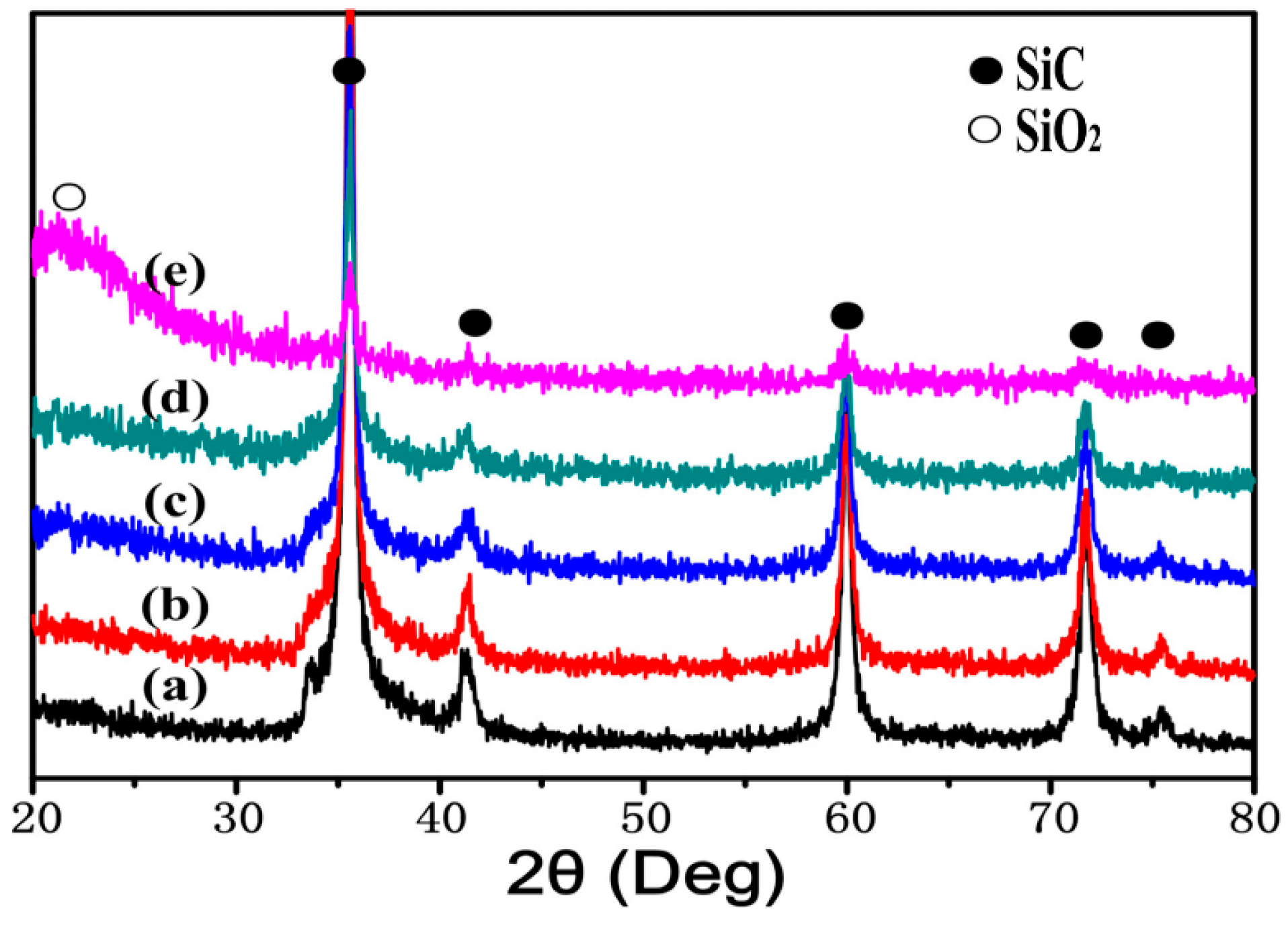

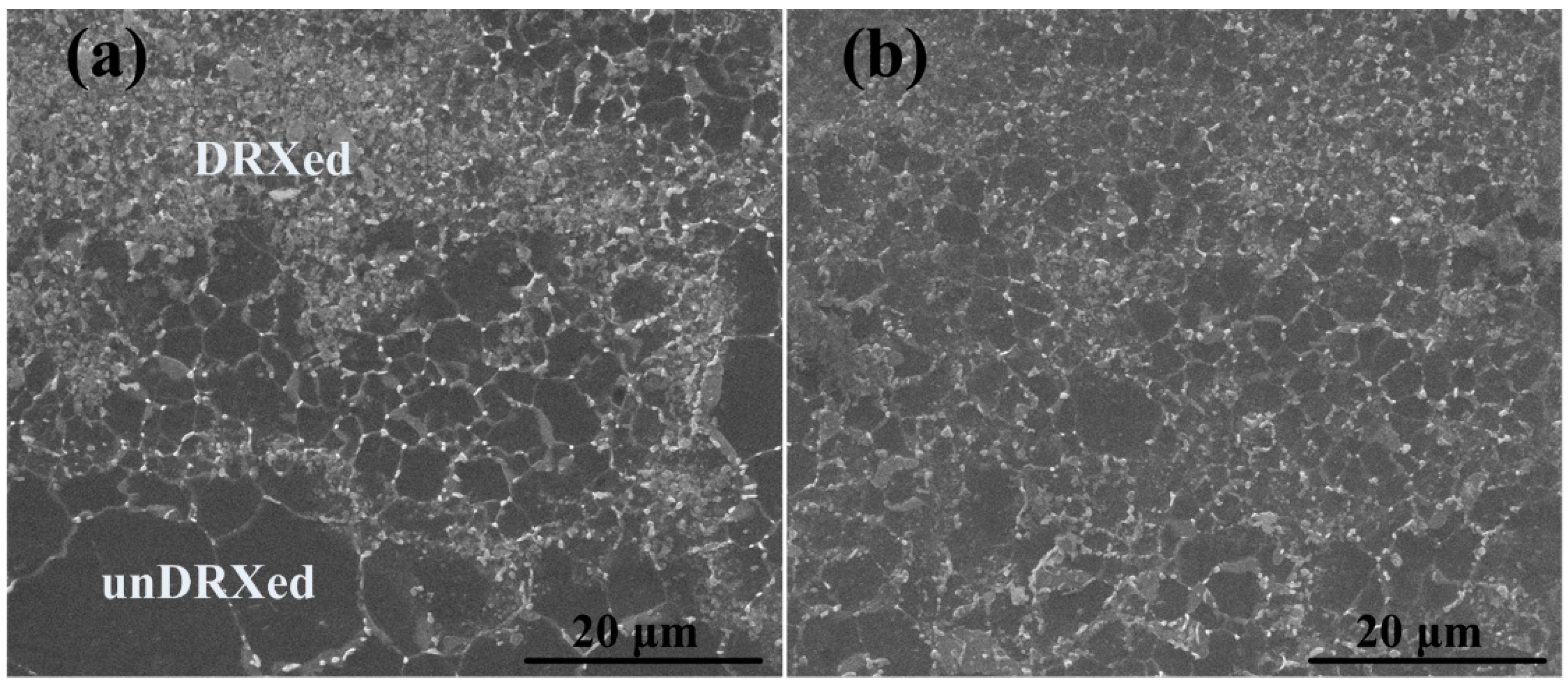

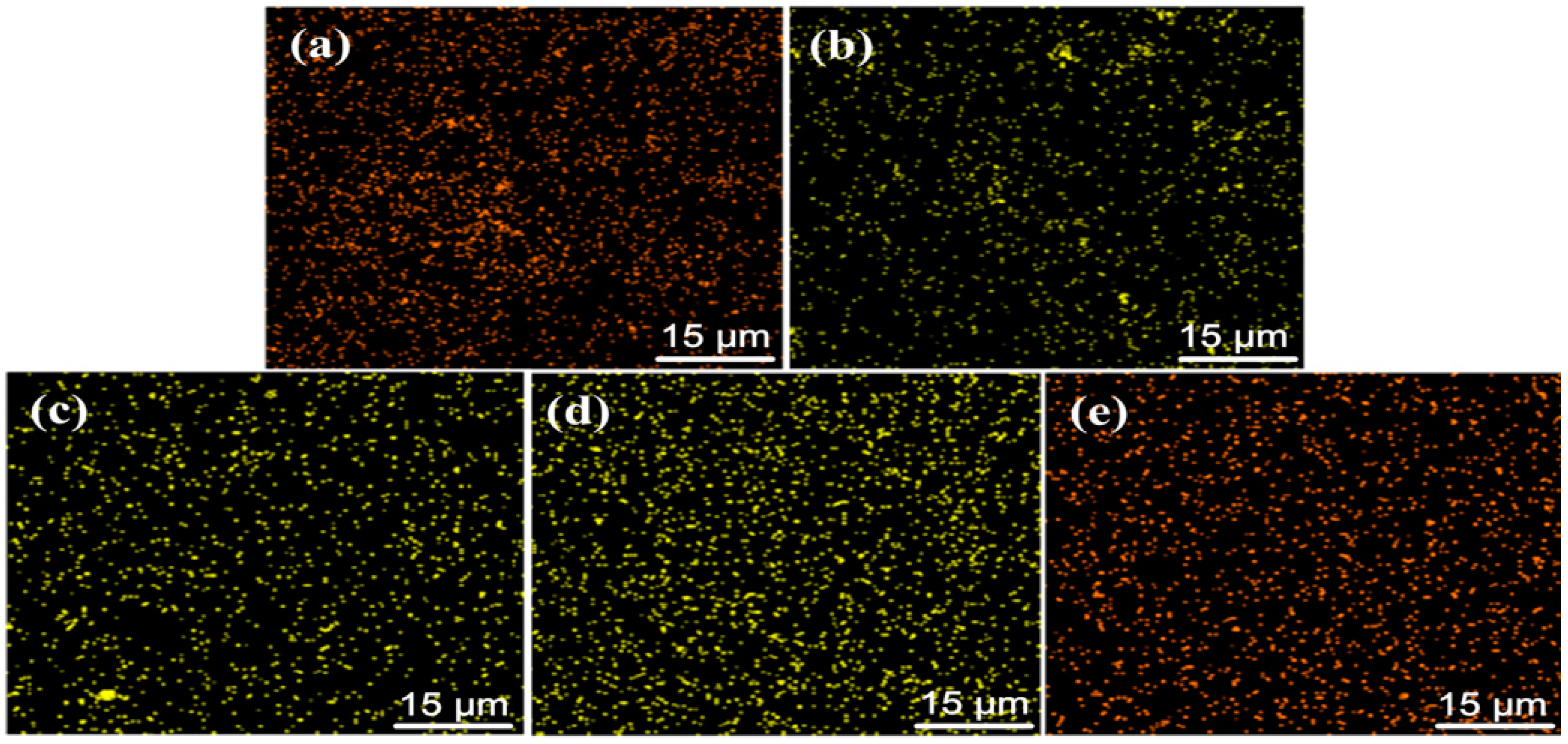

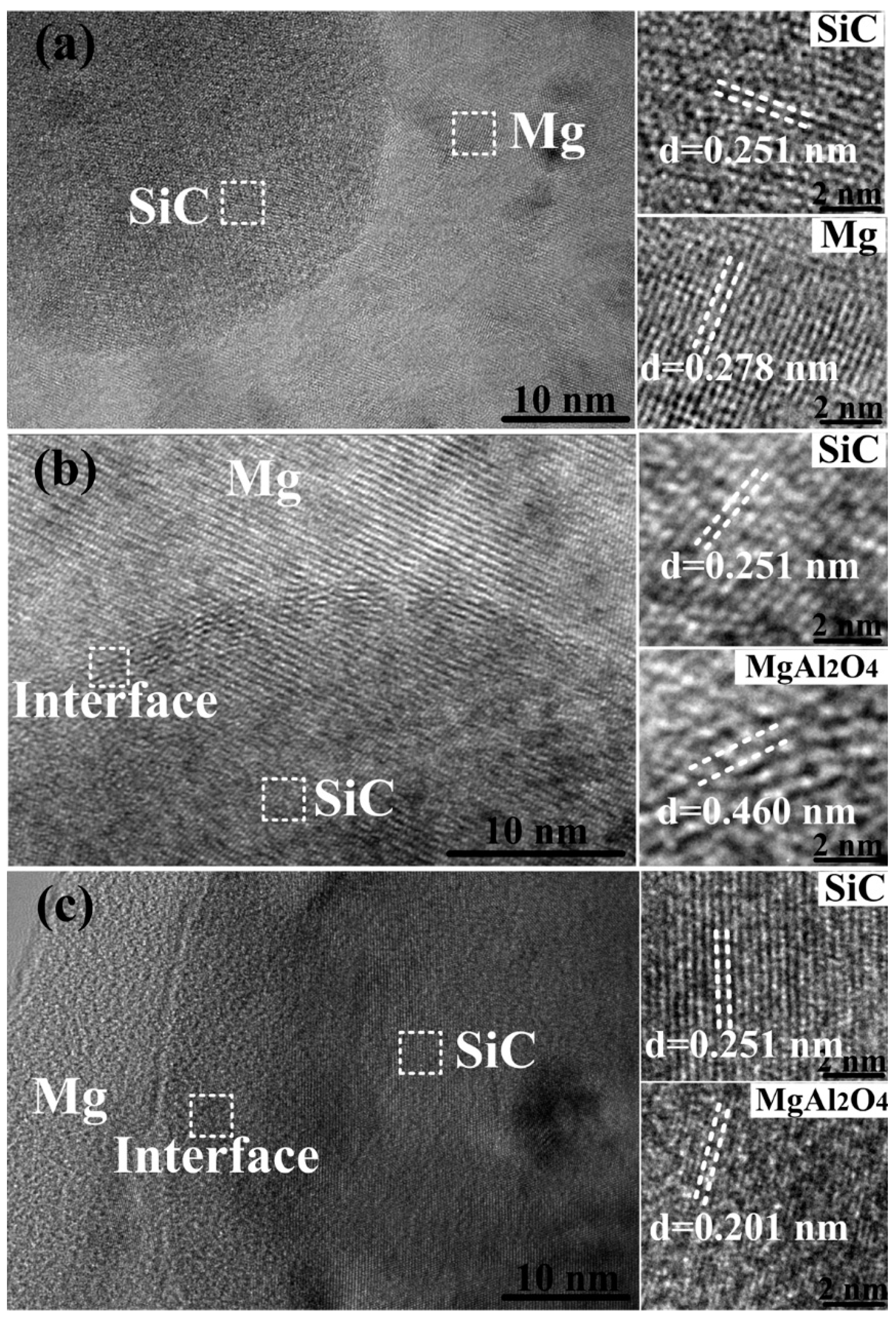

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ayman, E.; Junko, U.; Katsuyoshi, K. Application of rapid solidification powder metallurgy to the fabrication of high-strength, high-ductility Mg-Al-Zn-Ca-La alloy through hot extrusion. Acta Mater. 2011, 59, 273–282. [Google Scholar] [CrossRef]

- Shahzad, M.; Waqas, H.; Rafi-ud-din; Qureshi, A.H.; Wagner, L. The roles of Zn distribution and eutectic particles on microstructure development during extrusion and anisotropic mechanical properties in a Mg-Zn-Zr alloy. Mater. Sci. Eng. A 2015, 620, 50–57. [Google Scholar] [CrossRef]

- Chai, F.; Zhang, D.T.; Li, Y.Y. Effect of Thermal History on Microstructures and Mechanical Properties of AZ31 Magnesium Alloy Prepared by Friction Stir Processing. Materials 2014, 7, 1573–1589. [Google Scholar] [CrossRef]

- Tanhaee, Z.; Mahmudi, R. The microstructure and creep characteristics of cast Mg-3Si and Mg-3Si-1Gd alloys. Mater. Sci. Eng. A 2016, 673, 148–157. [Google Scholar] [CrossRef]

- Liu, L.M.; Ren, D.X.; Liu, F. A Review of Dissimilar Welding Techniques for Magnesium Alloys to Aluminum Alloys. Materials 2014, 7, 3735–3757. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Zhu, Y.M.; Xu, S.W.; Bian, M.Z.; Davies, C.H.J.; Birbilis, N.; Nie, J.F. Texture evolution during static recrystallization of cold-rolled magnesium alloys. Acta Mater. 2016, 105, 479–494. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Yoon, E.Y.; Chae, H.J.; Kim, T.S.; Lee, J.W.; Kim, H.S. Microstructure and mechanical properties of a Mg-Zn-Y alloy produced by a powder metallurgy route. J. Alloys Compd. 2014, 586, s95–s100. [Google Scholar] [CrossRef]

- Wang, H.Y.; Jiang, Q.C.; Li, X.L.; Wang, J.G.; Guan, Q.F.; Liang, H.Q. In situ synthesis of TiC from nanopowders in a molten magnesium alloy. Mater. Res. Bull. 2013, 38, 1387–1392. [Google Scholar] [CrossRef]

- Ferreira, S.C.; Conde, A.; Arenas, M.A.; Rocha, L.A.; Velhinho, A. Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy. Materials 2014, 7, 8151–8167. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Mechanical properties and microstructure of SiC-reinforced Mg-(2,4)Al-1Si nanocomposites fabricated by ultrasonic cavitation based solidification processing. Mater. Sci. Eng. A 2008, 486, 357–362. [Google Scholar] [CrossRef]

- Labib, F.; Mahmudi, R.; Ghasemi, H.M. Impression creep behavior of extruded Mg-SiCp composites. Mater. Sci. Eng. A 2015, 640, 91–97. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Sabat, R.K.; Jayalakshmi, S.; Suwas, S.; Gupta, M. Effect of hybridizing micron-sized Ti with nano-sized SiC on the microstructural evolution and mechanical response of Mg-5.6Ti composite. J. Alloys Compd. 2013, 575, 207–217. [Google Scholar] [CrossRef]

- Matin, A.; Saniee, F.F.; Abedi, H.R. Microstructure and mechanical properties of Mg/SiC and AZ80/SiC nano-composites fabricated through stir casting method. Mater. Sci. Eng. A 2015, 625, 81–88. [Google Scholar] [CrossRef]

- Mo, W.F.; Zhang, L.; Wu, G.H.; Zhang, Y.; Liu, W.C.; Wang, C.L. Effects of processing parameters on microstructure and mechanical properties of squeeze-cast Mg-12Zn-4Al-0.5Ca alloy. Mater. Des. 2014, 63, 729–737. [Google Scholar] [CrossRef]

- Kwak, T.Y.; Kim, W.J. Hot compression behavior of the 1 wt % calcium containing Mg-8Al-0.5Zn (AZ80) alloy fabricated using electromagnetic casting technology. Mater. Sci. Eng. A 2014, 615, 222–230. [Google Scholar] [CrossRef]

- Kursun, C.; Gogebakan, M. Characterization of nanostructured Mg-Cu-Ni powders prepared by mechanical alloying. J. Alloys Compd. 2015, 619, 138–144. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M. Room temperature mechanical properties of Mg-Cu-Al alloys synthesized using powder metallurgy method. Mater. Sci. Eng. A 2015, 644, 129–136. [Google Scholar] [CrossRef]

- Watanabe, H.; Mukai, T.; Mabuchi, M.; Higashi, K. Superplastic deformation mechanism in powder metallurgy magnesium alloys and composites. Acta Mater. 2001, 49, 2027–2037. [Google Scholar] [CrossRef]

- Chen, Z.N.; Kang, H.J.; Fan, G.H.; Li, J.H.; Lu, Y.P.; Jie, J.C.; Zhang, Y.B.; Li, T.J.; Jian, X.G.; Wang, T.M. Grain refinement of hypoeutectic Al-Si alloys with B. Acta Mater. 2016, 120, 168–178. [Google Scholar] [CrossRef]

- Kim, B.; Do, J.; Lee, S.; Park, I. In situ fracture observation and fracture toughness analysis of squeeze cast AZ51-xSn magnesium alloys. Mater. Sci. Eng. A 2010, 527, 6745–6757. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Y.A.; Gao, J.J. Comparative study regarding the effect of Al, Zn, and Gd on the microstructure and mechanical properties of Mg alloy Mg-Sn-Li. Mater. Des. 2016, 105, 34–40. [Google Scholar] [CrossRef]

- Park, S.H.; Jung, J.G.; Yoon, J.H.; You, B.S. Influence of Sn addition on the microstructure and mechanical properties of extruded Mg-8Al-2Zn alloy. Mater. Sci. Eng. A 2015, 626, 128–135. [Google Scholar] [CrossRef]

- Yu, L.; Cao, J.H.; Cheng, Y.L. An improvement of the wear and corrosion resistances of AZ31 magnesium alloy by plasma electrolytic oxidation in a silicate-hexametaphosphate electrolyte with the suspension of SiC nanoparticles. Surf. Coat. Technol. 2015, 276, 266–278. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.S.; Asif, M.; Tang, A. Powder metallurgy of Mg-1%Al-1%Sn alloy reinforced with low content of graphene nanoplatelets (GNPs). J. Ind. Eng. Chem. 2014, 20, 4250–4255. [Google Scholar] [CrossRef]

- Esmaily, M.; Blucher, D.B.; Svensson, J.E.; Halvarsson, M.; Johansson, L.G. New insights into the corrosion of magnesium alloys-The role of aluminum. Scr. Mater. 2016, 115, 91–95. [Google Scholar] [CrossRef]

- Sritharan, T.; Chan, L.S.; Tan, L.K.; Hung, N.P. A feature of the reaction between Al and SiC particles in an MMC. Mater. Charact. 2001, 47, 75–77. [Google Scholar] [CrossRef]

- Shi, Z.; Ochiai, S.; Gu, M.; Hojo, M.; Lee, J.C. The formation and thermostability of MgO and MgAl2O4 nanoparticles in oxidized SiC particle-reinforced Al-Mg composites. Appl. Phys. A 2002, 74, 97–104. [Google Scholar] [CrossRef]

- Shi, Z.L.; Yang, J.M.; Lee, J.C.; Zhang, D.; Lee, H.I.; Wu, R.J. The interfacial characterization of oxidized SiC(p)/2014 Al composites. Mater. Sci. Eng. A 2001, 303, 46–53. [Google Scholar] [CrossRef]

- Luo, Z.P.; Song, Y.G.; Zhang, S.Q. A TEM study of the microstructure of SiCp/Al composite prepared by pressureless infiltration method. Scr. Mater. 2001, 45, 1183–1189. [Google Scholar] [CrossRef]

- Gu, M.Y.; Jin, Y.P.; Mei, Z.; Wu, Z.G.; Wu, R.J. Effects of reinforcement oxidation on the mechanical properties of SiC particulate reinforced aluminum composites. Mater. Sci. Eng. A 1998, 252, 188–198. [Google Scholar] [CrossRef]

- Bahrami, A.; Pech-Canul, M.I.; Gutiérrez, C.A.; Soltani, N. Wetting and reaction characteristics of crystalline and amorphous SiO2 derived rice-husk ash and SiO2/SiC substrates with Al-Si-Mg alloys. Appl. Surf. Sci. 2015, 357, 1104–1113. [Google Scholar] [CrossRef]

- Li, B.; Luo, B.H.; He, K.J.; Zeng, L.Z.; Fan, W.L.; Bai, Z.H. Effect of aging on interface characteristics of Al-Mg-Si/SiC composites. J. Alloys Compd. 2015, 649, 495–499. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Wang, X.J.; Gong, W.X.; Wu, K.; Wang, F.H. Effect of SiC particles on microarc oxidation process of magnesium matrix composites. Appl. Surf. Sci. 2013, 283, 906–913. [Google Scholar] [CrossRef]

- Yang, Y.W.; Wu, P.; Wang, Q.Y.; Wu, H.; Liu, Y.; Deng, Y.W.; Zhou, Y.Z.; Shuai, C.J. The Enhancement of Mg Corrosion Resistance by Alloying Mn and Laser-Melting. Materials 2016, 9, 216. [Google Scholar] [CrossRef]

- Munitz, A.; Metzger, M.; Mehrabian, R. The interface phase in Al-Mg/Al2O3 composites. Metall. Mater. Trans. A 1979, 10, 1491–1497. [Google Scholar] [CrossRef]

- Luo, Z.P. Crystallography of SiC/MgAl2O4/Al interfaces in a pre-oxidized SiC reinforced SiC/Al composite. Acta Mater. 2006, 54, 47–58. [Google Scholar] [CrossRef]

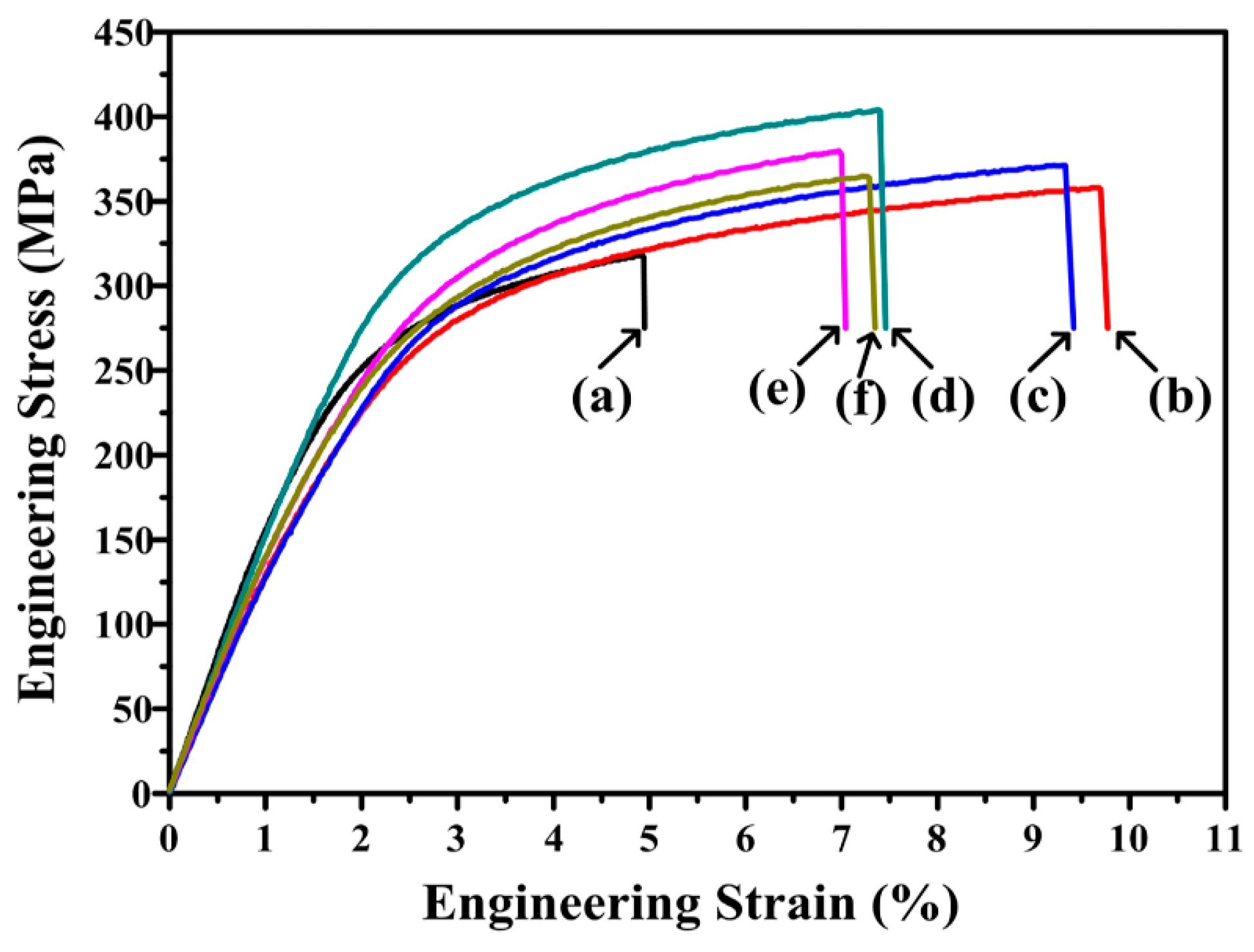

| Materials | YS/MPa | UTS/MPa | ε/% |

|---|---|---|---|

| AT81 | |||

| untreated | |||

| 973 K/2 h | |||

| 1073 K/2 h | |||

| 1173 K/2 h | |||

| 1273 K/2 h |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.-P.; Wang, Z.-G.; Zha, M.; Wang, C.; Yu, H.-C.; Wang, H.-Y.; Jiang, Q.-C. Effect of Pre-Oxidation Treatment of Nano-SiC Particulates on Microstructure and Mechanical Properties of SiC/Mg-8Al-1Sn Composites Fabricated by Powder Metallurgy Combined with Hot Extrusion. Materials 2016, 9, 964. https://doi.org/10.3390/ma9120964

Li C-P, Wang Z-G, Zha M, Wang C, Yu H-C, Wang H-Y, Jiang Q-C. Effect of Pre-Oxidation Treatment of Nano-SiC Particulates on Microstructure and Mechanical Properties of SiC/Mg-8Al-1Sn Composites Fabricated by Powder Metallurgy Combined with Hot Extrusion. Materials. 2016; 9(12):964. https://doi.org/10.3390/ma9120964

Chicago/Turabian StyleLi, Chuan-Peng, Zhi-Guo Wang, Min Zha, Cheng Wang, Hong-Chen Yu, Hui-Yuan Wang, and Qi-Chuan Jiang. 2016. "Effect of Pre-Oxidation Treatment of Nano-SiC Particulates on Microstructure and Mechanical Properties of SiC/Mg-8Al-1Sn Composites Fabricated by Powder Metallurgy Combined with Hot Extrusion" Materials 9, no. 12: 964. https://doi.org/10.3390/ma9120964

APA StyleLi, C.-P., Wang, Z.-G., Zha, M., Wang, C., Yu, H.-C., Wang, H.-Y., & Jiang, Q.-C. (2016). Effect of Pre-Oxidation Treatment of Nano-SiC Particulates on Microstructure and Mechanical Properties of SiC/Mg-8Al-1Sn Composites Fabricated by Powder Metallurgy Combined with Hot Extrusion. Materials, 9(12), 964. https://doi.org/10.3390/ma9120964