Strain Rate Behavior in Tension of Reinforcing Steels HPB235, HRB335, HRB400, and HRB500

Abstract

:1. Introduction

- An increase in yield strengths and ultimate strengths have been confirmed;

- Yield strength is more strain rate-sensitive than ultimate strength;

- Steels with relatively low strengths are susceptible to strain rates compared to those with relatively high strengths;

- No changes have been found in the elastic modulus;

- The magnitude of the strain rate effect is different for various types of steel materials;

- The variation tendency of plateau lengths (only for hot rolled rebars) and ultimate strains under high strain rates are inconsistent based on different test sources.

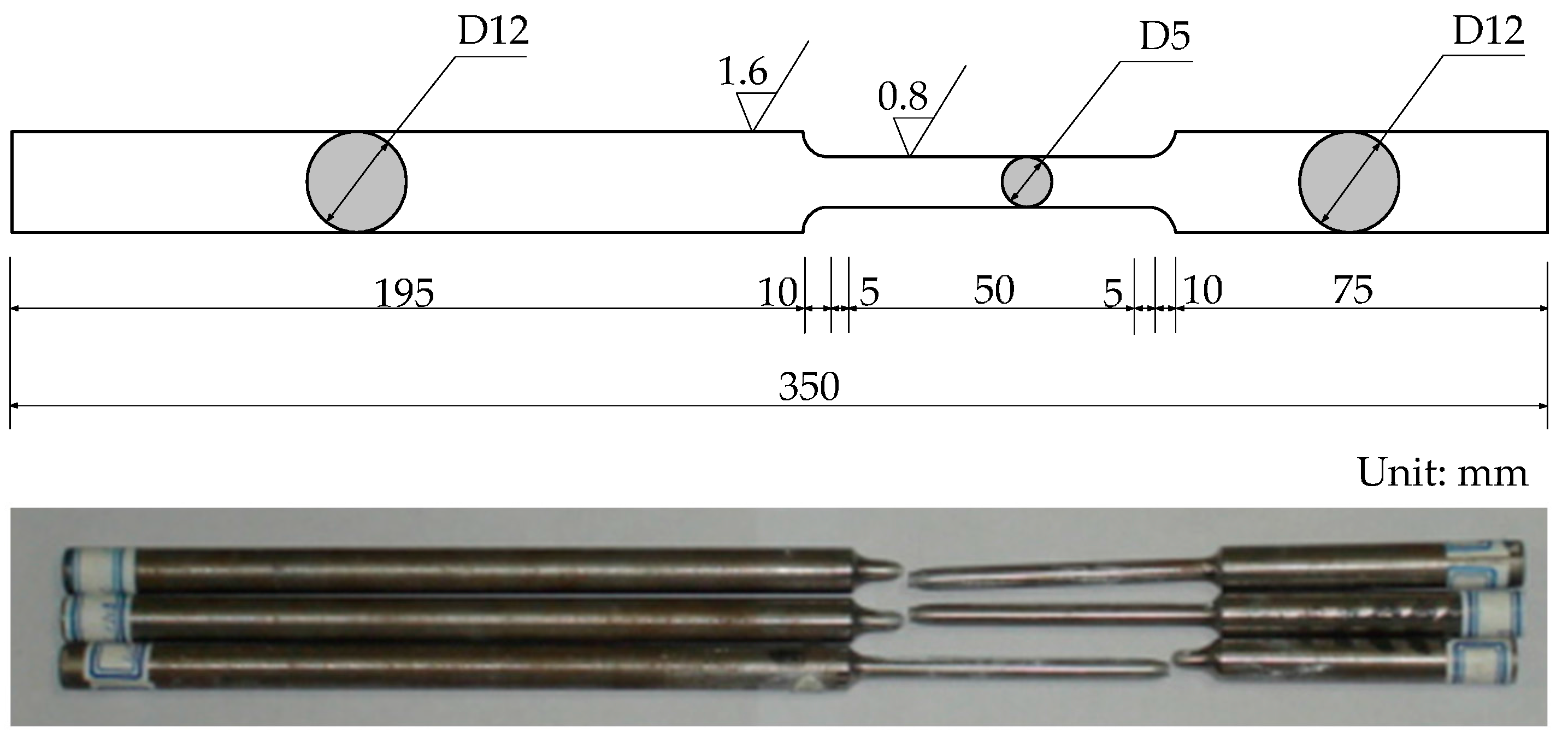

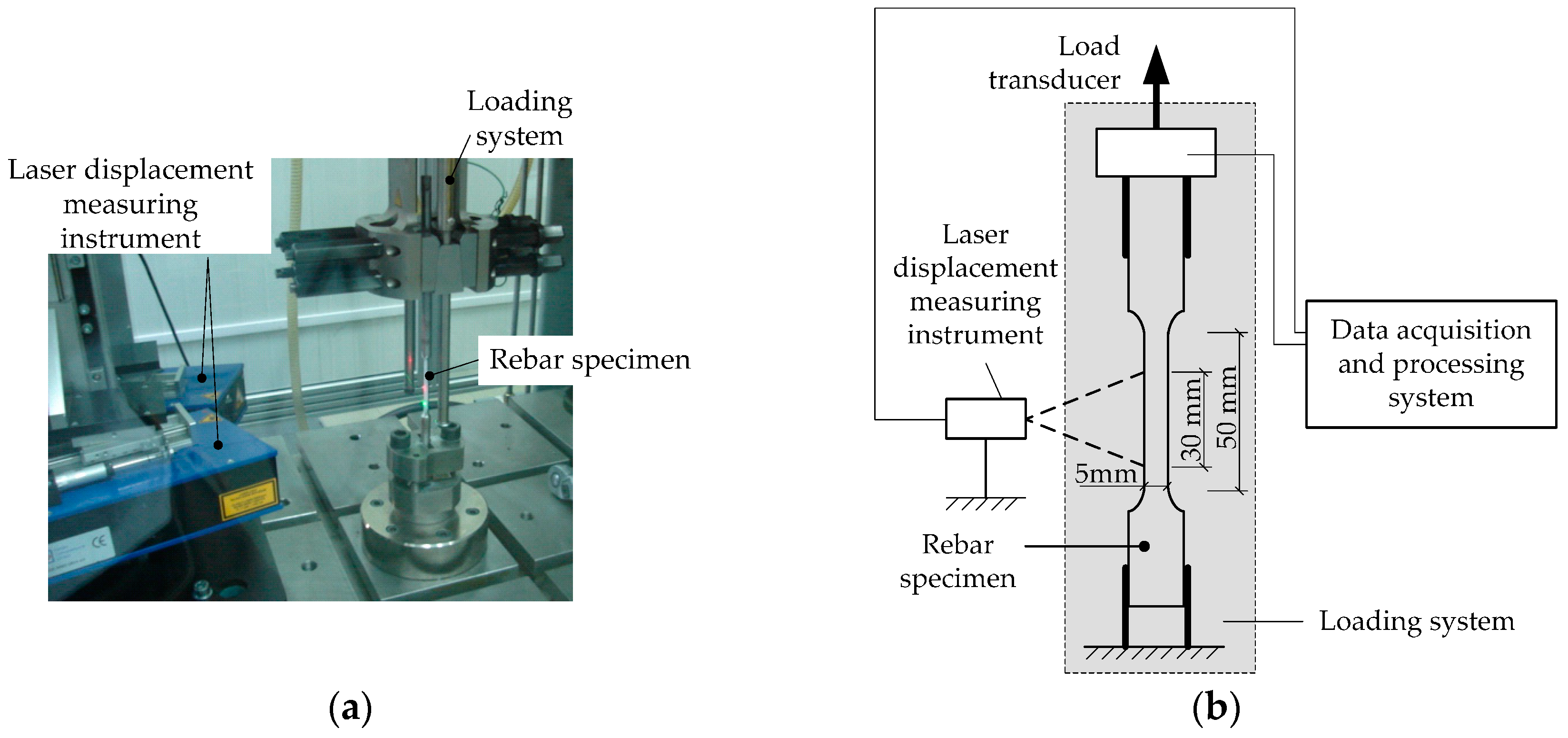

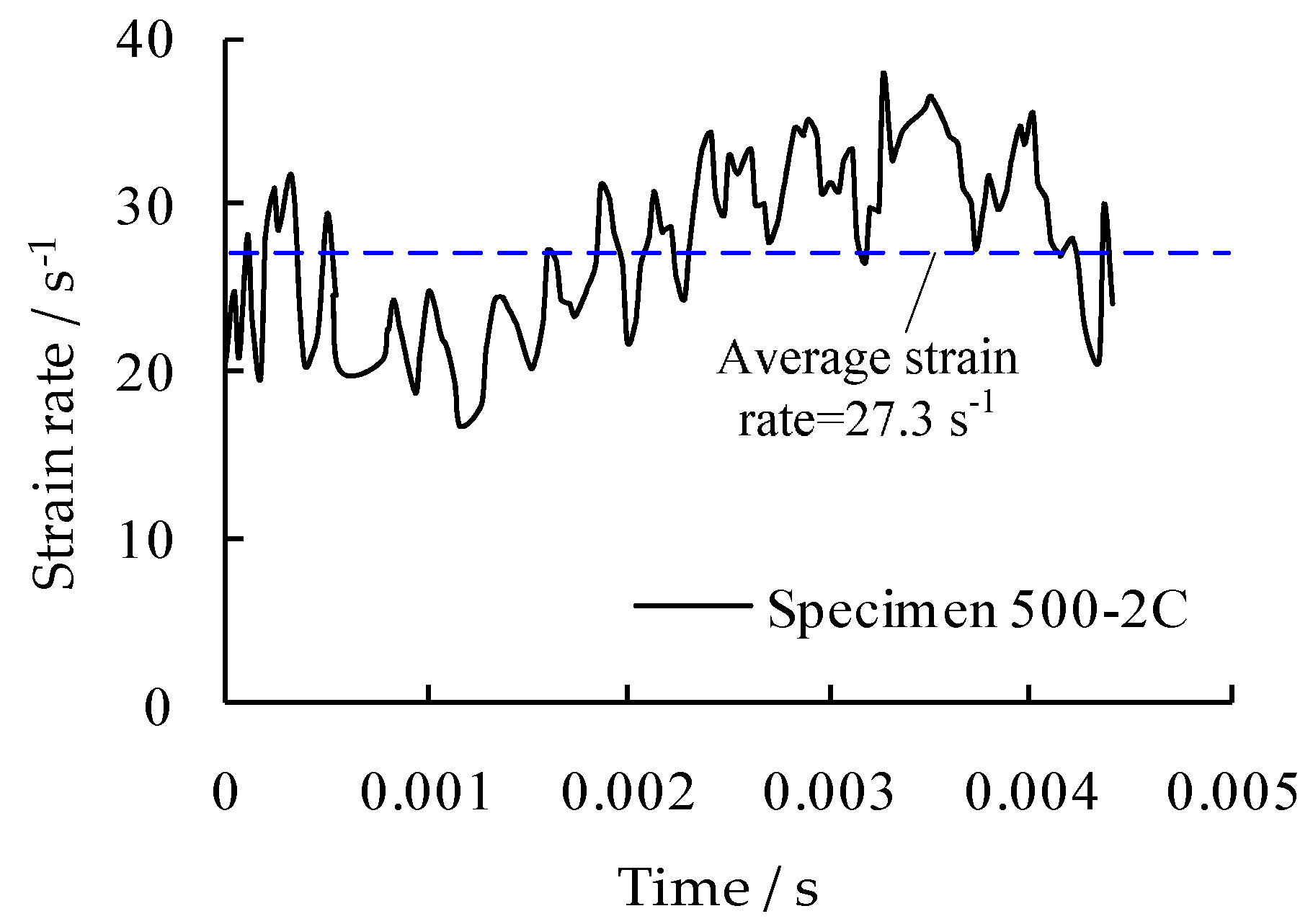

2. Experimental Procedure

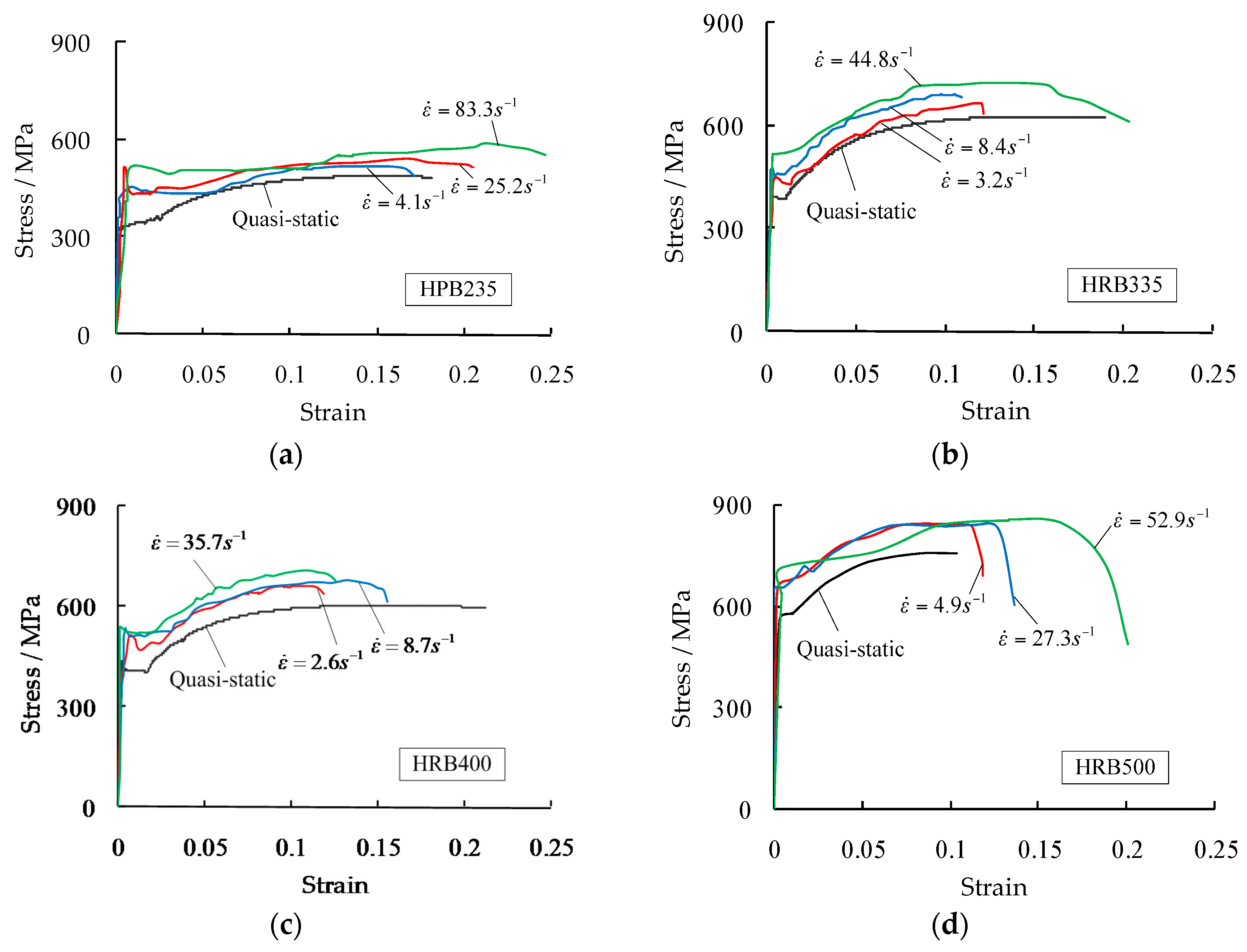

3. Test Results and Discussion

- The yield strengths and ultimate strengths increase with the increase in strain rates in the ranges from 13% to 41% and from 9% to 19%, respectively;

- The increased magnitudes of the yield strengths are greater than those of the ultimate strengths;

- The rebar grades with relatively low strengths (e.g., HPB235) are more susceptible to strain rates than the rebar grades with relatively high strengths (e.g., HRB500);

- Elastic moduli are independent of strain rates;

- No statistical tendency was found for the plateau lengths;

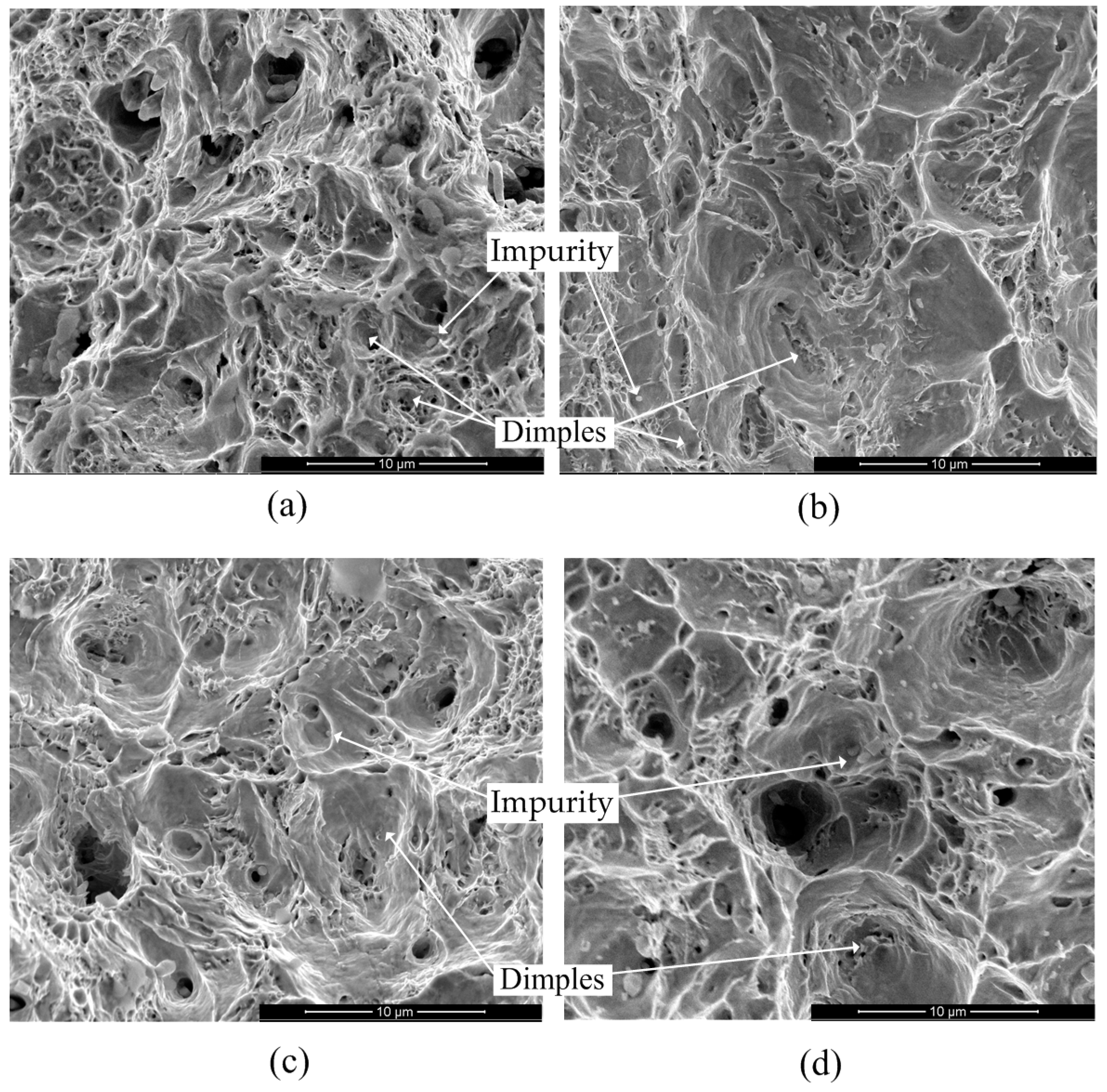

- No statistical tendency was found for the ultimate strains and all the rebars failed in a ductile manner.

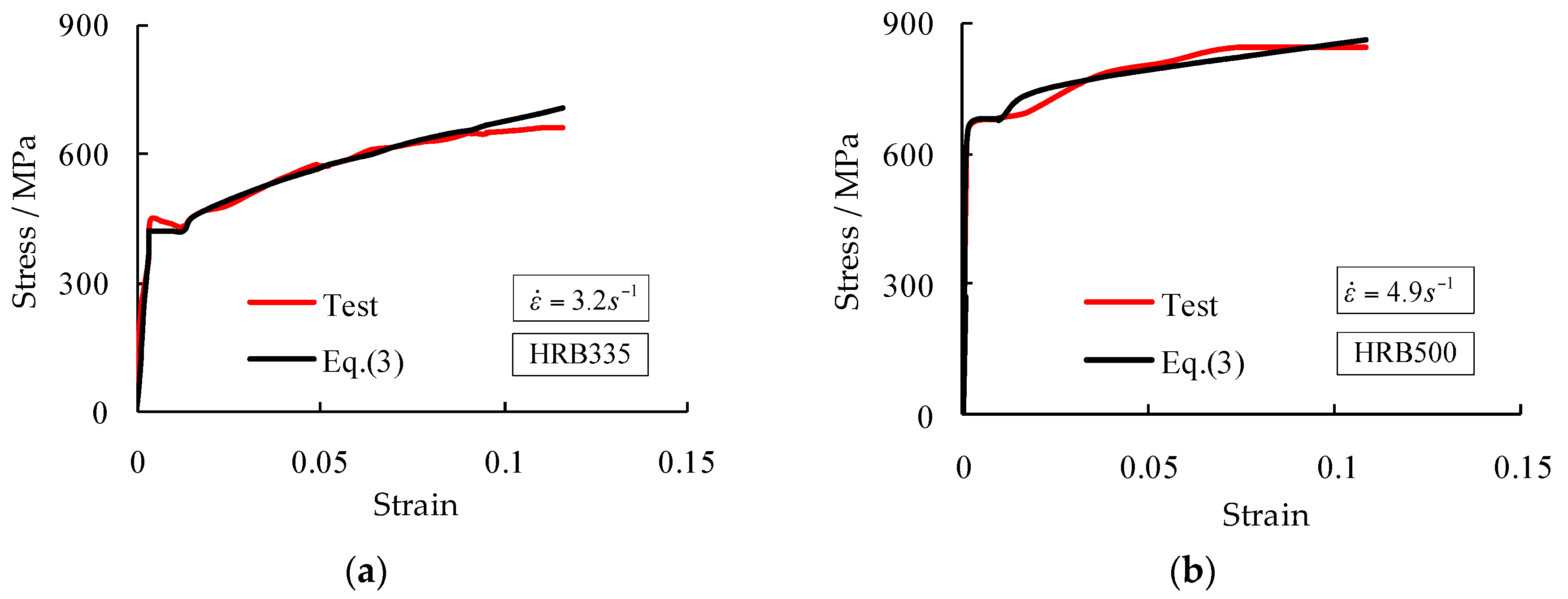

4. Constitutive Models

4.1. DIF Formulations

4.2. Johnson–Cook Model

4.3. Comparison with Existing Formulations

5. Conclusions

- (1)

- Significant strain rate effect was observed for the four rebar grades. Their yield strengths increased from 13% to 41% and their ultimate strengths improved from 9% to 19% in the strain rate range in the testing.

- (2)

- The strain rate behavior of the four rebar grades could be appropriately predicted using the parameters in the model based on the DIFs of strengths and the JC model for strain rates less than 75 s−1.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hao, H.; Hao, Y.F.; Li, J.; Chen, W.S. Review of the current practices in blast-resistant analysis and design of concrete structures. Adv. Struct. Eng. 2016, 19, 1193–1223. [Google Scholar]

- Mainstone, R.J. Properties of materials at high rates of straining or loading. Mater. Constr. 1975, 8, 102–116. [Google Scholar] [CrossRef]

- López Campos, J.Á.; Segade Robleda, A.; Vilán Vilán, J.A.; García Nieto, P.J.; Blanco Cordero, J. Study of a steel’s energy absorption system for heavy quadricycles and nonlinear explicit dynamic analysis of its behavior under impact by FEM. Materials 2015, 8, 6893–6908. [Google Scholar] [CrossRef]

- Hu, D.Y.; Meng, K.P.; Jiang, H.L.; Xu, J.; Liu, R.R. Strain rate dependent constitutive behavior investigation of AerMet 100 steel. Mater. Des. 2015, 87, 759–772. [Google Scholar] [CrossRef]

- Choi, J.Y.; Lee, J.; Lee, K.; Koh, J.Y.; Cho, J.H.; Han, H.N.; Park, K.T. Effects of the strain rate on the tensile properties of a TRIP-aided duplex stainless steel. Mater. Sci. Eng. A 2016, 666, 280–287. [Google Scholar] [CrossRef]

- Brandes, K.; Limberger, E.; Herter, J.; Berner, K. Kinetische Grenztragfähigkeit von Stoßartig Belasteten Stahlbetonbauteilen. Zugversuche an Betonstahl mit Erhöhter Dehngeschwindigkeit; Research Report 129; Bundesanstalt für Materialprüfung: Berlin, Germany, 1986. [Google Scholar]

- Cadoni, E.; Dotta, M.; Forni, D.; Tesio, N.; Albertini, C. Mechanical behaviour of quenched and self-tempered reinforcing steel in tension under high strain rate. Mater. Des. 2013, 49, 657–666. [Google Scholar] [CrossRef]

- Cadoni, E.; Fenu, L.; Forni, D. Strain rate behaviour in tension of austenitic stainless steel used for reinforcing bars. Constr. Build. Mater. 2012, 35, 399–407. [Google Scholar] [CrossRef]

- Forni, D.; Chiaia, B.; Cadoni, E. Strain rate behaviour in tension of S355 steel: Base for progressive collapse analysis. Eng. Struct. 2016, 119, 164–173. [Google Scholar] [CrossRef]

- Rohr, I.; Nahme, H.; Thoma, K. Material characterization and constitutive modeling of ductile high strength steel for a wide rang of strain rates. Int. J. Impact Eng. 2005, 31, 401–433. [Google Scholar] [CrossRef]

- Eibl, J. Concrete Structures under Impact and Impulsive Loading; CEB-Bulletin d’Information, No. 187; Comite Euro-International du Beton: Dubrovnik, Croatia, 1988; pp. 1–183. [Google Scholar]

- Malvar, L.J. Review of static and dynamic properties of steel reinforcing bars. ACI Mater. 1998, 95, 609–616. [Google Scholar]

- Cadoni, E.; Dotta, M.; Forni, D.; Tesio, N. High strain rate behaviour in tension of steel B500A reinforcing bar. Mater. Struct. 2015, 48, 1803–1813. [Google Scholar] [CrossRef]

- Xu, K.; Lu, Y. Numerical simulation study of spallation in reinforced concrete plates subjected to blast loading. Comput. Struct. 2006, 84, 431–438. [Google Scholar] [CrossRef]

- Shi, Y.; Hao, H.; Li, Z.X. Numerical derivation of pressure–impulse diagrams for prediction of RC column damage to blast loads. Int. J. Impact Eng. 2008, 35, 1213–1227. [Google Scholar] [CrossRef]

- GB/T228-2002. Metallic Materials—Tensile Testing at Ambient Temperature; Standards Press of China: Beijing, China, 2002. [Google Scholar]

- Johnson, G.; Cook, W. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Williams, G.D.; Williamson, E.B. Response of reinforced concrete bridge columns subjected to blast loads. J. Struct. Eng. 2011, 137, 903–913. [Google Scholar] [CrossRef]

| Rebar Grade | C | S | Mn | Si | P | Cr | V | Mo | Cu | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| HPB235 | 0.15 | 0.025 | 0.53 | 0.16 | 0.029 | - | - | - | - | - |

| HRB335 | 0.20 | 0.026 | 1.41 | 0.50 | 0.028 | 0.090 | <0.02 | <0.02 | 0.088 | 0.022 |

| HRB400 | 0.22 | 0.027 | 1.38 | 0.52 | 0.023 | 0.031 | <0.02 | <0.02 | <0.02 | <0.02 |

| HRB500 | 0.25 | 0.28 | 1.43 | 0.03 | 0.02 | 0.07 | <0.01 | 0.10 | 0.02 | 0.02 |

| Rebar Grade | Group | Specimen No. | (1/s) | fy (Mpa) | DIF of fy | fu (Mpa) | DIF of fu | Ultimate Strain # |

|---|---|---|---|---|---|---|---|---|

| HPB235 | 235-0 | 235-0A | ≤0.0003 | 329.0 | - | 484.0 | - | 0.141 |

| 235-0B | ≤0.0003 | 326.0 | - | 479.0 | - | 0.161 | ||

| 235-0C | ≤0.0003 | 332.0 (329.0) * | - | 490.0 (484.0) | - | 0.156 (0.153) | ||

| 235-1 | 235-1A | 4.1 | 443.6 | 1.35 | 519.1 | 1.07 | 0.128 | |

| 235-1B | 7.1 | 401.7 | 1.22 | 541.8 | 1.12 | 0.257 | ||

| 235-1C | 8.2 (6.5) * | 417.1 (420.8) | 1.27 (1.28) | 556.0 (539.0) | 1.15 (1.11) | 0.205 (0.197) | ||

| 235-2 | 235-2A | 22.4 | 429.7 | 1.31 | 565.0 | 1.17 | 0.257 | |

| 235-2B | 15.4 | 432.6 | 1.32 | 540.8 | 1.12 | 0.167 | ||

| 235-2C | 25.2 (21.0) | 445.7 (436.0) | 1.36 (1.33) | 542.5 (549.4) | 1.12 (1.14) | 0.179 (0.201) | ||

| 235-3 | 235-3A | 68.4 | 443.9 | 1.35 | 564.1 | 1.17 | 0.235 | |

| 235-3B | 73.0 | 455.7 | 1.39 | 572.1 | 1.18 | 0.165 | ||

| 235-3C | 83.3 (74.9) | 495.1 (464.9) | 1.51 (1.41) | 588.6 (575.0) | 1.22 (1.19) | 0.213 (0.204) | ||

| HRB335 | 335-0 | 335-0A | ≤0.0003 | 387.0 | - | 626.0 | - | 0.154 |

| 335-0B | ≤0.0003 | 383.0 | - | 631.0 | - | 0.153 | ||

| 335-0C | ≤0.0003 | 390.0 (386.7) | - | 640.0 (632.3) | - | 0.152 (0.153) | ||

| 335-1 | 335-1A | 3.2 | 425.7 | 1.10 | 701.3 | 1.11 | 0.161 | |

| 335-1B | 2.3 | 460.5 | 1.19 | 696.8 | 1.10 | 0.102 | ||

| 335-1C | 3.2 (2.9) | 428.8 (438.3) | 1.11 (1.13) | 662.0 (686.7) | 1.05 (1.09) | 0.116 (0.126) | ||

| 335-2 | 335-2A | 7.6 | 454.6 | 1.18 | 680.0 | 1.08 | 0.085 | |

| 335-2B | 8.4 | 460.4 | 1.19 | 690.8 | 1.09 | 0.097 | ||

| 335-2C | 9.1 (8.4) | 469.4 (461.5) | 1.21 (1.19) | 704.2 (691.7) | 1.11 (1.09) | 0.120 (0.101) | ||

| 335-3 | 335-3A | 44.8 | 518.6 | 1.34 | 723.6 | 1.14 | 0.12 | |

| 335-3B | 39.0 | 534.6 | 1.38 | 699.5 | 1.11 | 0.118 | ||

| 335-3C | 30.6 (38.1) | 518.8 (524.0) | 1.34 (1.35) | 737.1 (720.1) | 1.17 (1.14) | 0.092 (0.110) | ||

| HRB400 | 400-0 | 400-0A | ≤0.0003 | 403.0 | - | 604.0 | - | 0.156 |

| 400-0B | ≤0.0003 | 406.0 | - | 603.0 | - | 0.158 | ||

| 400-0C | ≤0.0003 | 402.0 (404.0) | - | 602.0 (603.0) | - | 0.153 (0.156) | ||

| 400-1 | 400-1A | 2.6 | 473.0 | 1.17 | 662.9 | 1.10 | 0.107 | |

| 400-1B | 3.0 | 485.3 | 1.20 | 653.4 | 1.08 | 0.116 | ||

| 400-1C | 3.5 (3.0) | 492.2 (483.5) | 1.22 (1.20) | 635.9 (650.7) | 1.06 (1.08) | 0.130 (0.118) | ||

| 400-2 | 400-2A | 9.8 | 500.0 | 1.24 | 654.5 | 1.09 | 0.132 | |

| 400-2B | 9.5 | 498.1 | 1.23 | 654.1 | 1.09 | 0.126 | ||

| 400-2C | 8.7 (9.3) | 512.0 (503.3) | 1.27 (1.25) | 679.0 (662.5) | 1.13 (1.10) | 0.132 (0.130) | ||

| 400-3 | 400-3A | 49.9 | 520.0 | 1.29 | 689.6 | 1.14 | 0.118 | |

| 400-3B | 35.7 | 526.7 | 1.30 | 707.3 | 1.17 | 0.109 | ||

| 400-3C | 35.8 (40.5) | 517.0 (521.2) | 1.28 (1.29) | 694.4 (697.1) | 1.15 (1.16) | 0.117 (0.115) | ||

| HRB500 | 500-0 | 500-0A | ≤0.0003 | 594.7 | - | 779.6 | - | 0.096 |

| 500-0B | ≤0.0003 | 572.7 | - | 752.1 | - | 0.097 | ||

| 500-0C | ≤0.0003 | 579.9 (582.4) | - | 760.3 (764.0) | - | 0.093 (0.095) | ||

| 500-1 | 500-1A | 5.6 | 642.1 | 1.10 | 837.3 | 1.10 | 0.094 | |

| 500-1B | 4.9 | 676.2 | 1.16 | 839.0 | 1.10 | 0.102 | ||

| 500-1C | 5.2 (5.2) | 656.7 (658.3) | 1.13 (1.13) | 841.3 (839.2) | 1.10 (1.10) | 0.099 (0.098) | ||

| 500-2 | 500-2A | 23.8 | 698.7 | 1.20 | 865.9 | 1.13 | 0.113 | |

| 500-2B | 28.7 | 678.1 | 1.16 | 862.9 | 1.13 | 0.108 | ||

| 500-2C | 27.3 (26.6) | 707.0 (694.6) | 1.21 (1.19) | 843.4 (857.4) | 1.10 (1.12) | 0.114 (0.112) | ||

| 500-3 | 500-3A | 52.9 | 712.6 | 1.22 | 856.9 | 1.12 | 0.134 | |

| 500-3B | 59.0 | 718.3 | 1.23 | 859.2 | 1.12 | 0.145 | ||

| 500-3C | 50.7 (54.2) | 726.6 (719.2) | 1.25 (1.23) | 888.1 (868.1) | 1.16 (1.14) | 0.123 (0.134) |

| Rebar Grade | A (MPa) | B (MPa) | n | C |

|---|---|---|---|---|

| HPB235 | 377.7 | 160.8 | 0.3731 | 0.093 |

| HRB335 | 401.1 | 1167.7 | 0.6761 | 0.087 |

| HRB400 | 468.9 | 1201.8 | 0.7094 | 0.034 |

| HRB500 | 629.6 | 666.2 | 0.5976 | 0.030 |

| Rebar Grade | Average Strain Rate (s−1) | DIF of Strength | DIF | ||||

|---|---|---|---|---|---|---|---|

| Testing | Equations (1) and (2) | Equation (3) | Formulations in [11] | Malvar’s Formulations [12] | |||

| HPB235 | 6.5 | DIF of fy | 1.28 | 1.30 | 1.35 | - | 1.59 |

| DIF of fu | 1.11 | 1.13 | 1.13 | - | 1.14 | ||

| 21.0 | DIF of fy | 1.33 | 1.34 | 1.47 | - | - | |

| DIF of fu | 1.14 | 1.15 | 1.23 | - | - | ||

| 74.9 | DIF of fy | 1.41 | 1.38 | 1.61 | - | - | |

| DIF of fu | 1.19 | 1.16 | 1.35 | - | - | ||

| HRB335 | 2.9 | DIF of fy | 1.13 | 1.21 | 1.13 | - | 1.45 |

| DIF of fu | 1.09 | 1.09 | 1.19 | - | 1.11 | ||

| 8.4 | DIF of fy | 1.19 | 1.23 | 1.23 | - | 1.51 | |

| DIF of fu | 1.09 | 1.11 | 1.21 | - | 1.13 | ||

| 38.1 | DIF of fy | 1.36 | 1.27 | 1.37 | - | - | |

| DIF of fu | 1.14 | 1.12 | 1.38 | - | - | ||

| HRB400 | 3.0 | DIF of fy | 1.20 | 1.20 | 1.20 | 1.16 | 1.43 |

| DIF of fu | 1.08 | 1.10 | 1.26 | 1.13 | 1.12 | ||

| 9.3 | DIF of fy | 1.25 | 1.22 | 1.25 | 1.18 | 1.49 | |

| DIF of fu | 1.10 | 1.11 | 1.34 | 1.14 | 1.12 | ||

| 40.5 | DIF of fy | 1.29 | 1.25 | 1.31 | 1.20 | - | |

| DIF of fu | 1.16 | 1.13 | 1.36 | 1.16 | - | ||

| HRB500 | 5.2 | DIF of fy | 1.13 | 1.16 | 1.13 | - | 1.21 |

| DIF of fu | 1.10 | 1.10 | 1.09 | - | 1.07 | ||

| 26.6 | DIF of fy | 1.19 | 1.19 | 1.19 | - | - | |

| DIF of fu | 1.12 | 1.12 | 1.16 | - | - | ||

| 54.2 | DIF of fy | 1.23 | 1.20 | 1.21 | - | - | |

| DIF of fu | 1.14 | 1.12 | 1.22 | - | - | ||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, F.; Dong, Y.; Kuang, X.; Lu, L. Strain Rate Behavior in Tension of Reinforcing Steels HPB235, HRB335, HRB400, and HRB500. Materials 2016, 9, 1013. https://doi.org/10.3390/ma9121013

Lin F, Dong Y, Kuang X, Lu L. Strain Rate Behavior in Tension of Reinforcing Steels HPB235, HRB335, HRB400, and HRB500. Materials. 2016; 9(12):1013. https://doi.org/10.3390/ma9121013

Chicago/Turabian StyleLin, Feng, Yu Dong, Xinxin Kuang, and Le Lu. 2016. "Strain Rate Behavior in Tension of Reinforcing Steels HPB235, HRB335, HRB400, and HRB500" Materials 9, no. 12: 1013. https://doi.org/10.3390/ma9121013

APA StyleLin, F., Dong, Y., Kuang, X., & Lu, L. (2016). Strain Rate Behavior in Tension of Reinforcing Steels HPB235, HRB335, HRB400, and HRB500. Materials, 9(12), 1013. https://doi.org/10.3390/ma9121013