Evaluation of Subsequent Heat Treatment Routes for Near-β Forged TA15 Ti-Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starting Materials

2.2. Experimental Procedure

3. Results and Discussion

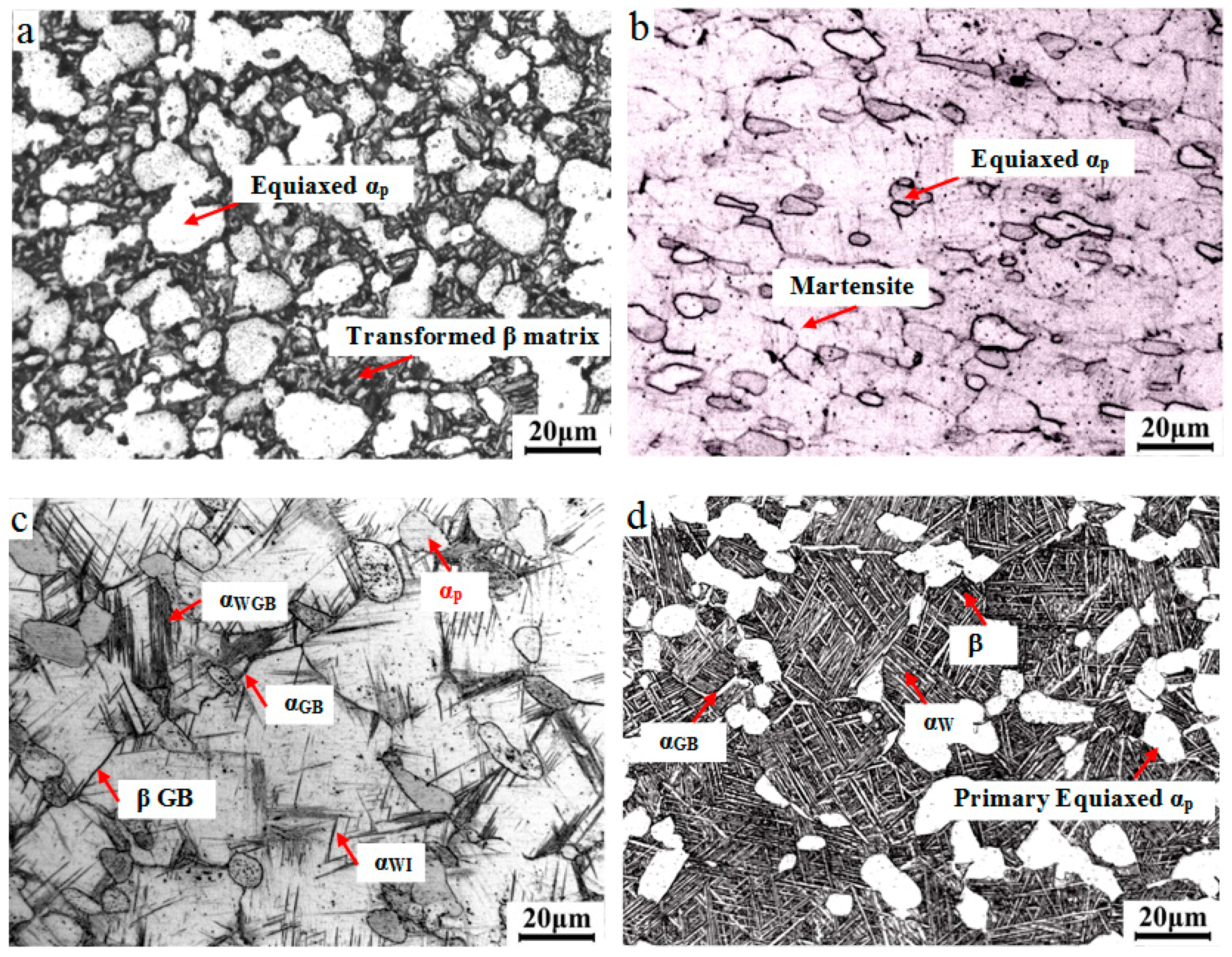

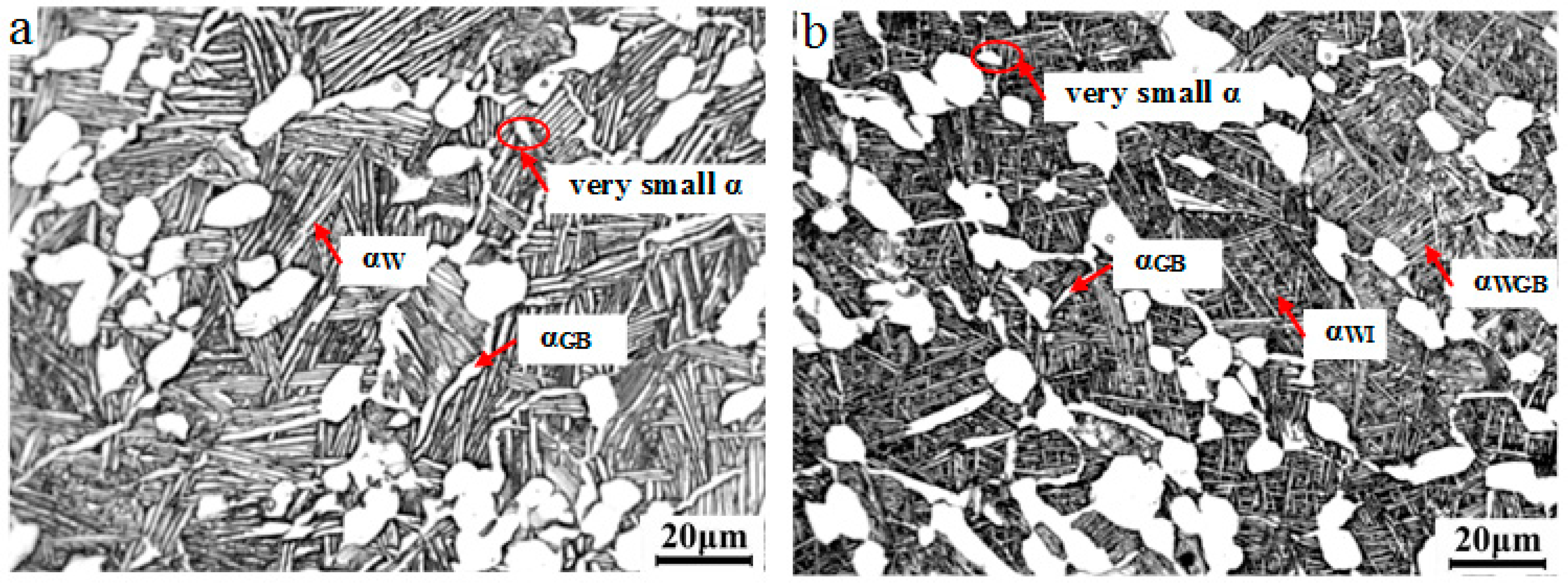

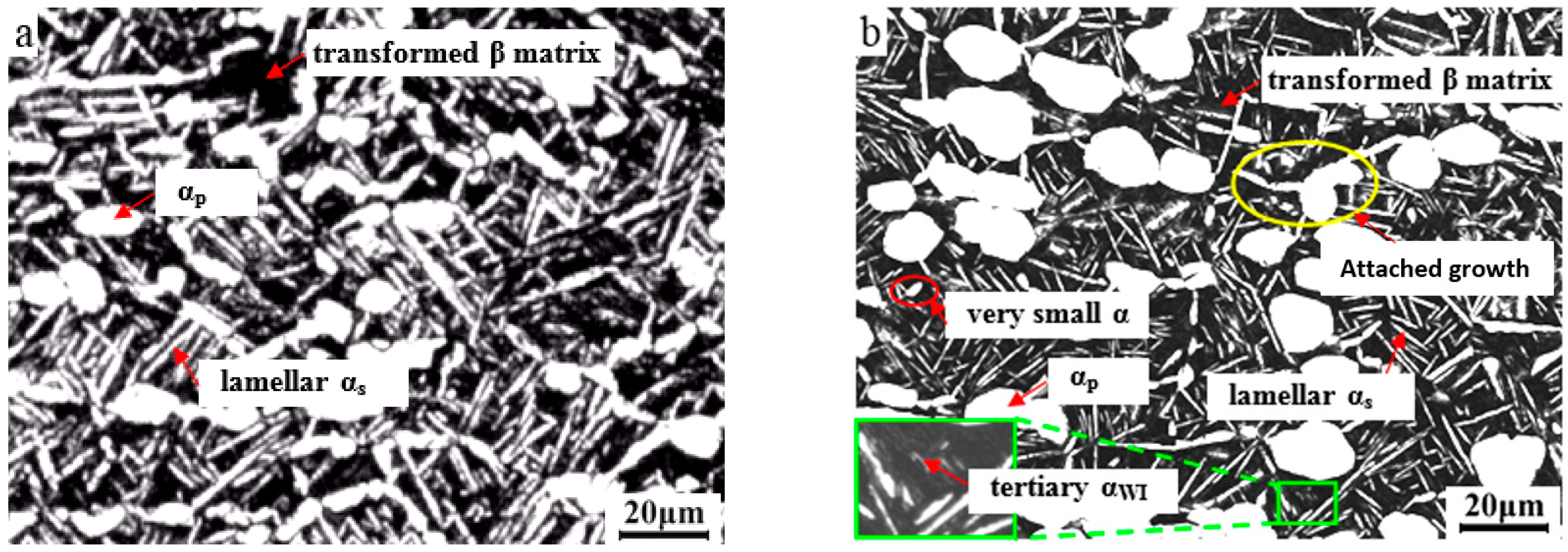

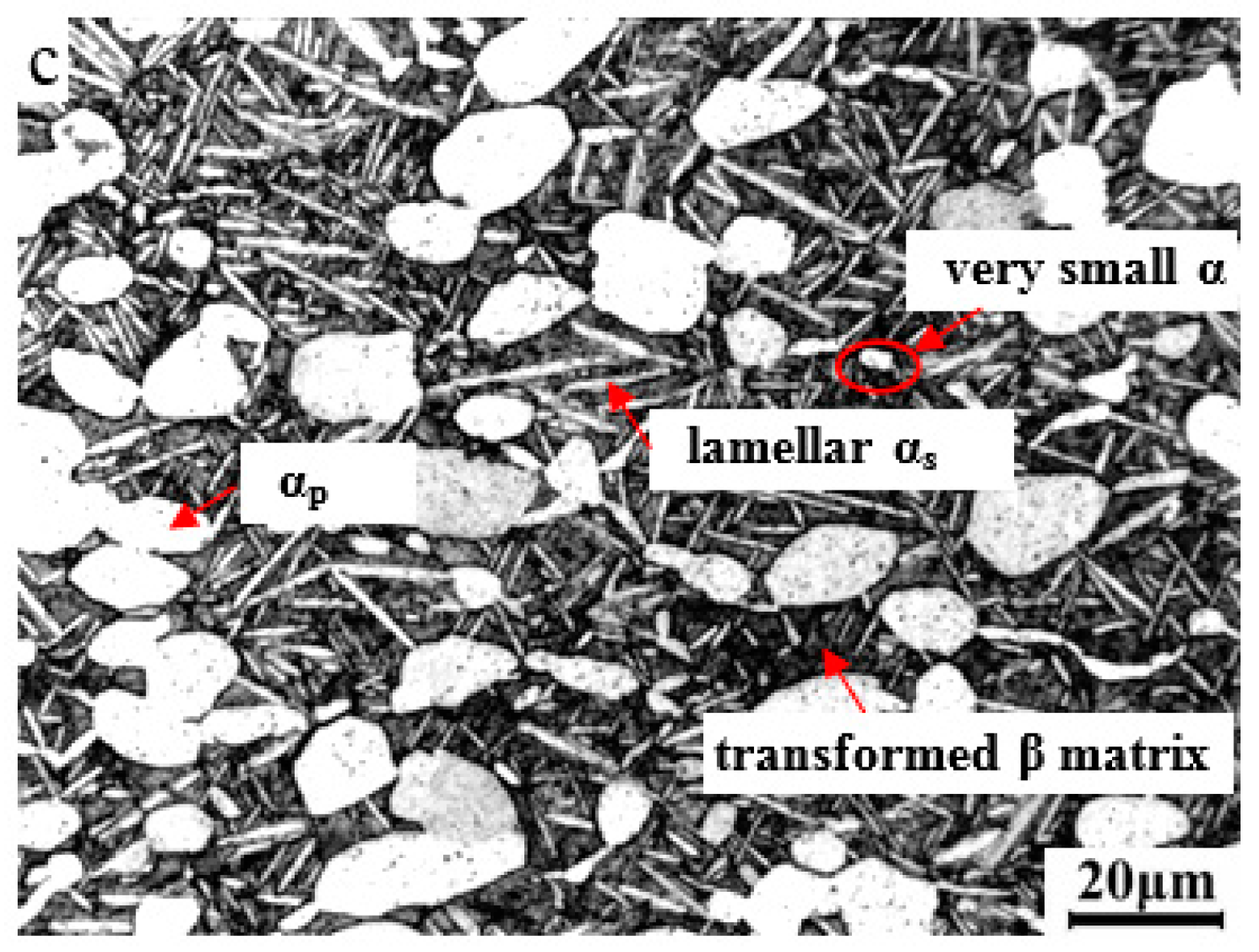

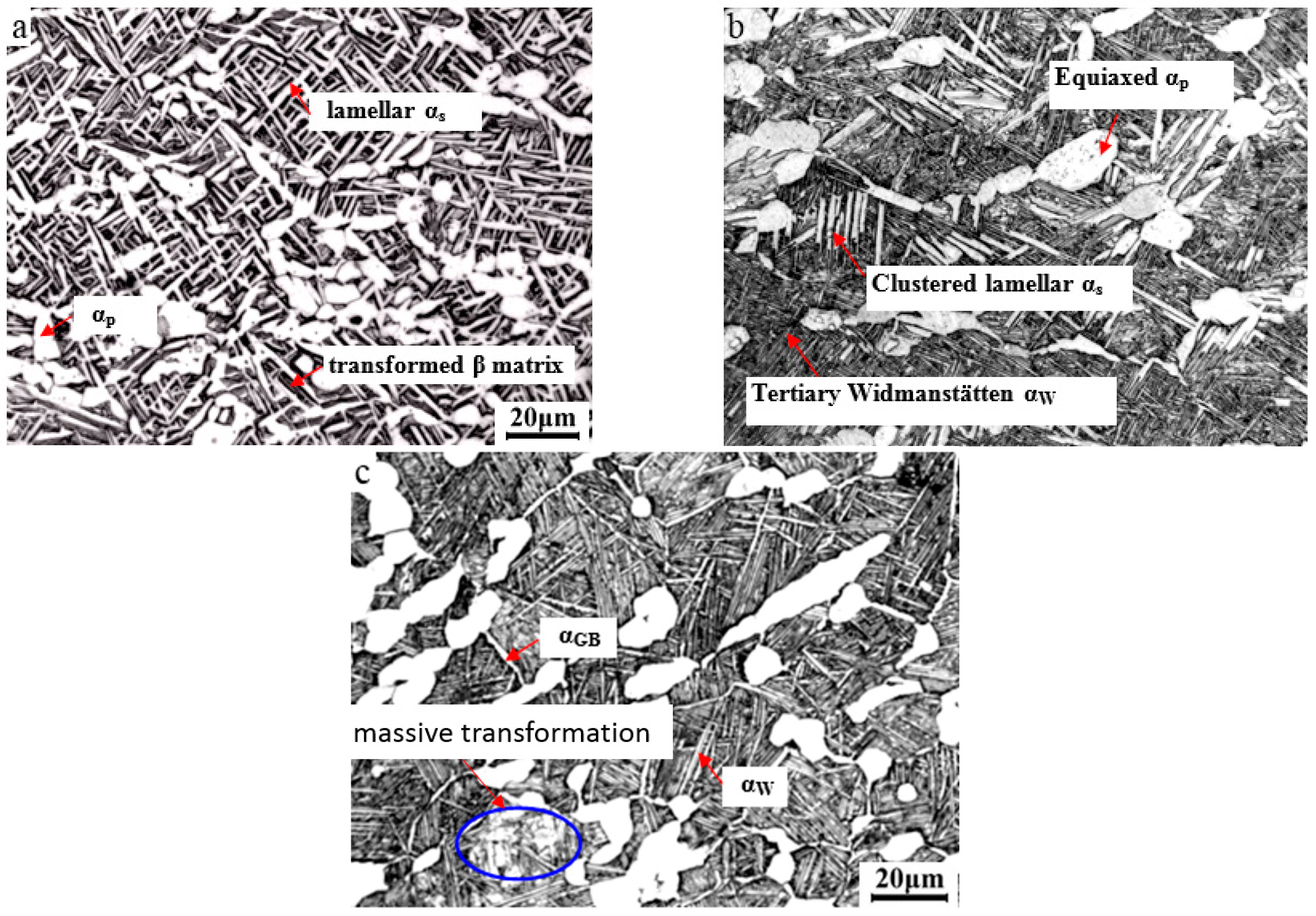

3.1. Microstructural Evolution of Near β-forged TA15 Alloy under Different Heat Treatment Routes

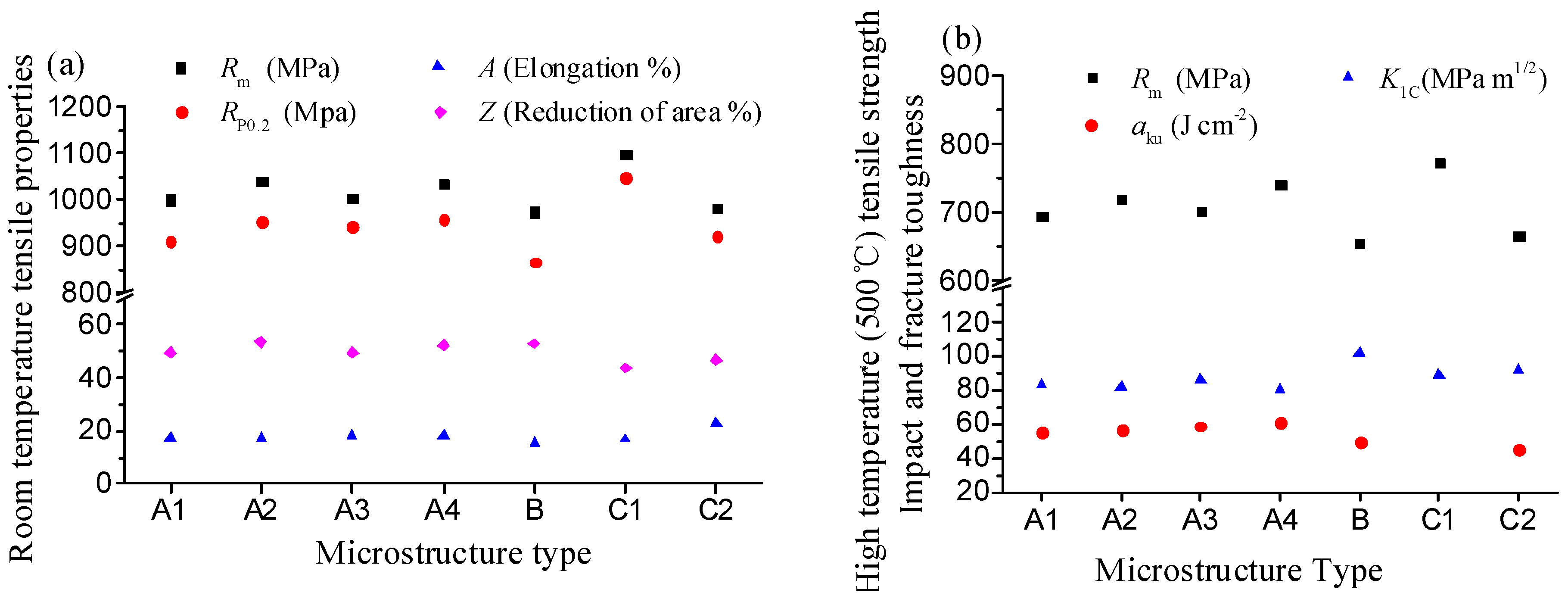

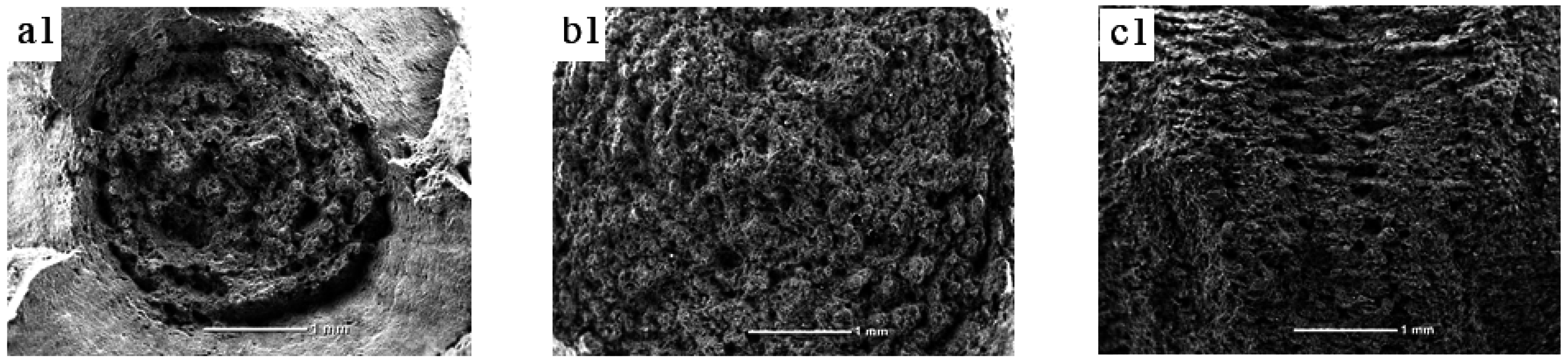

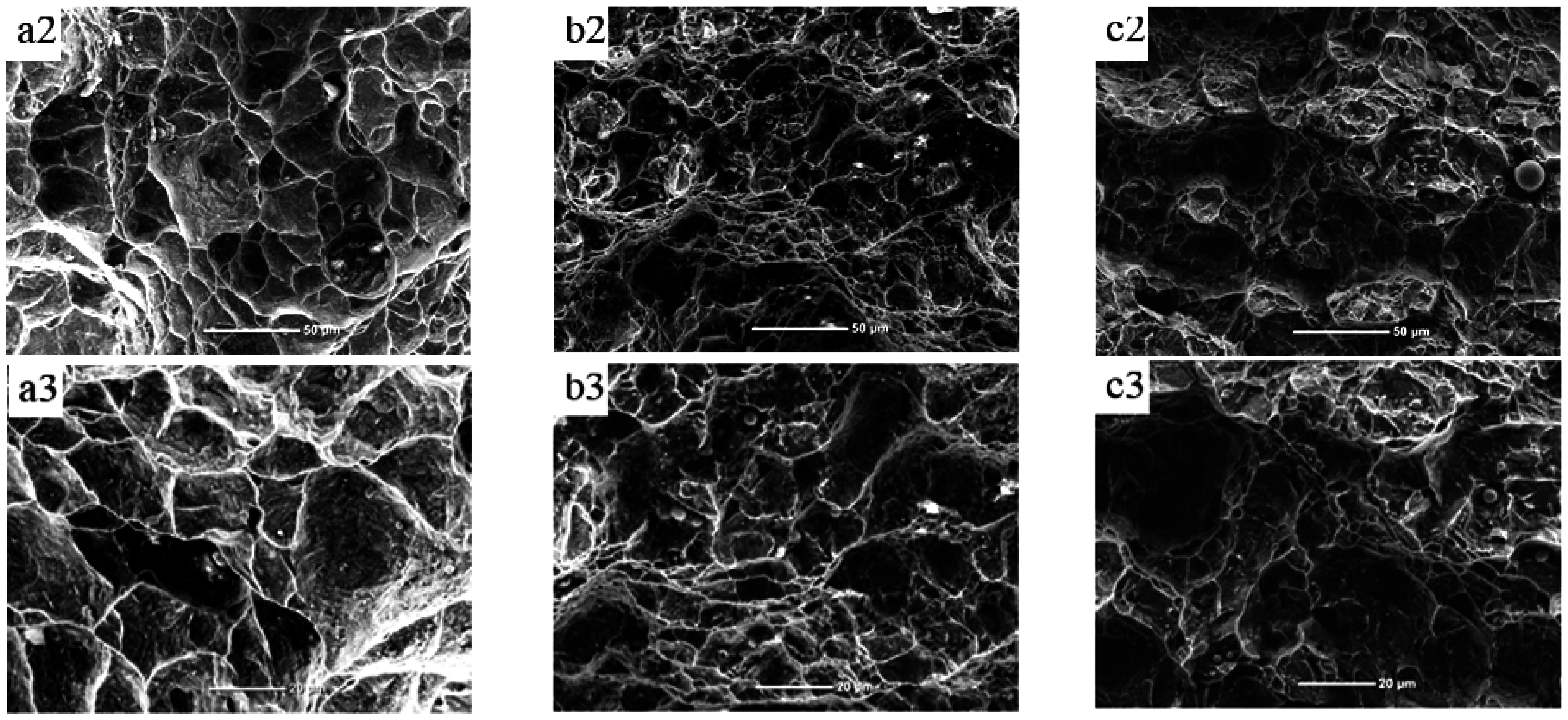

3.2. Microstructural Characteristics and Mechanical Properties

3.3. Evaluation of Heat Treatment Routes for Near-Forged TA15 Alloy

4. Conclusions

- (1)

- Bimodal microstructure, possessing moderate low and high temperature tensile properties, fracture and impact toughness, was obtained through near-β forging combined with low-temperature annealing (830 °C/1 h/AC) or near-β toughening and strengthening treatment (970 °C/1.5 h/WQ + 850 °C/1.5 h/AC). Air cooling after near-β forging resulted in thicker (0.75 μm) clustered αW, while water quenching led to thin (0.45 μm) interlaced αW.

- (2)

- After near-β forging (AC + WQ) combined with solution + aging (930 °C/1 h/AC + 550 °C/5 h/AC) or high-temperature annealing (930 °C/1 h/AC), a quasi tri-modal microstructure with low room and high temperature tensile strength and impact toughness but high fracture toughness was obtained.

- (3)

- A tri-modal microstructure was obtained after near-β forging (WQ) and solution + aging (930 °C/1 h/AC + 550 °C/5 h/AC), or after near-β forging (WQ) and toughening + strengthening (950 °C/100 min/WQ + 800 °C/8 h/AC), consisting of small equiaxed αp (6.20–6.40 μm) and thick lamellar αs (1.20–1.35 μm), possessing good comprehensive performance matching.

- (4)

- For near-β forged TA15 alloy, when moderate mechanical properties were required, water quenching after near-β forging and subsequent low-temperature annealing were recommended; when excellent comprehensive performance was needed, solution and aging treatment was recommended; and when high fracture toughness was considered, high-temperature annealing treatment was recommended.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shen, G.; Furrer, D. Manufacturing of Aerospace Forgings. J. Mater. Process. Technol. 2000, 98, 189–194. [Google Scholar] [CrossRef]

- Sun, Z.C.; Yang, H. Microstructure and mechanical properties of TA15 titanium alloy under multi-step local loading forming. Mater. Sci. Eng. A 2009, 523, 184–192. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zeng, W.D.; Yu, H.Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components. Mater. Sci. Eng. A 2005, 393, 204–212. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Viswanathan, G.B.; Denkenberger, R.; Hamish, D.F.; Fraser, L. The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy. Acta Mater. 2003, 51, 4679–4691. [Google Scholar] [CrossRef]

- Collins, P.C.; Koduri, S.; Welk, B.; Tiley, J.; Fraser, H.L. Neural networks relating alloy composition, microstructure, and tensile properties of α/β-processed TIMETAL 6-4. Metall. Mater. Trans. A 2013, 44, 1441–1453. [Google Scholar] [CrossRef]

- Peters, M.; Hemptenmacher, J.; Kumpert, J.; Leyens, C.; Peters, M. Titanium and Titanium Alloys, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2003; pp. 153–180. [Google Scholar]

- Mishra, H.; Ghosal, P.; Nandy, T.K.; Sagar, P.K. Influence of Fe and Ni on creep of near α-Ti alloy IMI834. Mater. Sci. Eng. A 2005, 399, 222–231. [Google Scholar] [CrossRef]

- Whittaker, R.; Fox, K.; Walker, A. Texture variations in titanium alloys for aeroengine applications. Mater. Sci. Technol. 2010, 26, 676–684. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Sharma, H.; Bohemen, S.M.S.; Petrov, R.H.; Sietsma, J. Three-dimensional analysis of microstructures in titanium. Acta Mater. 2010, 58, 2399–2407. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, F.; Huang, A.J.; Li, G.P. Evolution of microstructure of full lamellar titanium alloy BT18Y solutionized at α + β phase field. Acta Metall. Sin. 2005, 41, 713–720. [Google Scholar]

- Wang, Y.; Ma, N.; Chen, Q.; Zhang, F.; Chen, S.L.; Chang, Y.A. Predicting phase equilibrium, phase transformation, and microstructure evolution in titanium alloys. JOM 2005, 57, 32–39. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S.L. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Shi, R.; Dixit, V.; Viswanathan, G.B.; Fraser, H.L.; Wang, Y. Experimental assessment of variant selection rules for grain boundary α in titanium alloys. Acta Mater. 2016, 102, 197–211. [Google Scholar] [CrossRef]

- Zhang, W.F.; Wang, Y.H.; Ma, J.M. Heat treatment strengthening and its mechanism of large forging for TA15 titanium alloy. Chin. J. Rare Met. 2010, 34, 1–5. (In Chinese) [Google Scholar]

- Fan, X.G.; Yang, H.; Yan, S.L.; Gao, P.F.; Zhou, J.H. Mechanism and kinetics of static globularization in TA15 titanium alloy with transformed structure. J. Alloys Compd. 2012, 533, 1–8. [Google Scholar] [CrossRef]

- Xu, J.W.; Zeng, W.D.; Jia, Z.Q.; Sun, X.; Zhou, J.H. Microstructure coarsening behavior of Ti-17 alloy with equiaxed alpha during heat treatment. J. Alloys Compd. 2015, 618, 343–348. [Google Scholar] [CrossRef]

- Li, S.K.; Xiong, B.Q.; Hui, S.X. Effects of cooling rate on the fracture properties of TA15 ELI alloy plates. Rare Met. 2007, 26, 33–38. [Google Scholar]

- Semiatin, S.L.; Knidley, S.L.; Fagin, P.N.; Zhang, F.; Barker, D.R. Microstructure evolution during alpha-beta heat treatment of Ti-6Al-4V. Mater. Sci. Eng. A 2003, 34, 2377–2386. [Google Scholar] [CrossRef]

- Sun, Z.C.; Guo, S.S.; Yang, H. Nucleation and growth mechanism of α-lamellae of Ti alloy TA15 cooling from an α + β phase field. Acta Mater. 2013, 61, 2057–2064. [Google Scholar] [CrossRef]

- Zhu, S.; Yang, H.; Guo, L.G.; Fan, X.G. Effect of cooling rate on microstructure evolution during α/β heat treatment of TA15 titanium alloy. Mater. Charact. 2012, 70, 101–110. [Google Scholar] [CrossRef]

- Zhu, J.C.; Wang, Y.; Lai, Z.H.; Han, L.; Liu, Y. A Heat Treatment Process for Obtaining Tri-Modal Microstructure in Two-Phase Titanium Alloy. Chinese Invention Patent 200910073419.9, 2 June 2010. [Google Scholar]

- Zhu, J.C.; He, D.; Yang, X.W.; Liu, Y. EBSD study on dual heat treatment and microstructure evolution of TA15 titanium alloy. Rare Met. Mater. Eng. 2013, 42, 382–386. (In Chinese) [Google Scholar]

- Sun, Z.C.; Wang, X.Q.; Zhang, J.; Yang, H. Prediction and control of equiaxed α in near-β forging of TA15 Ti-alloy based on BP neural network: For purpose of tri-modal microstructure. Mater. Sci. Eng. A 2014, 591, 18–25. [Google Scholar] [CrossRef]

- Sun, Z.C.; Mao, X.J.; Wu, H.L.; Yang, H.; Li, J.J. Tri-modal microstructure and performance of TA15 Ti-alloy under near-β forging and given subsequent solution and aging treatment. Mater. Sci. Eng. A 2016, 654, 113–123. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Dutta, B. Influence of prior deformation rate on the mechanism of β→α + β transformation in Ti-6Al-4V. Scr. Mater. 2002, 9, 673–678. [Google Scholar] [CrossRef]

- Yu, W.X.; Li, M.Q.; Luo, J. Effect of deformation parameters on the precipitation mechanism of secondary α phase under high temperature isothermal compression of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2010, 527, 4210–4217. [Google Scholar] [CrossRef]

- Second Editing Office of China Standards Press. Test Methods for Mechanical Properties and Processing Performance of Metal; Second Editing Office of China Standards Press: Beijing, China, 2001. (In Chinese) [Google Scholar]

- Sun, Z.C.; Han, F.X.; Wu, H.L.; Yang, H. Tri-modal microstructure evolution of TA15 Ti-alloy under conventional forging combined with given subsequent heat treatment. J. Mater. Process. Technol. 2016, 229, 72–81. [Google Scholar] [CrossRef]

- Sun, Z.C.; Li, X.S.; Wu, H.L.; Yang, H. Morphology evolution and growth mechanism of the secondary Widmanstatten α phase in the TA15 Ti-alloy. Mater. Charact. 2016, 118, 167–174. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zeng, W.D.; Yu, H.Q. A new high-temperature deformation strengthening and toughening process for titanium alloys. Mater. Sci. Eng. A 1996, 221, 58–62. [Google Scholar] [CrossRef]

- Totten, G.E.; MacKenzie, D.S. Handbook of Aluminum: Vol. 1: Physical Metallurgy and Processes, 1st ed.; CRC Press: New York, NY, USA, 2003; pp. 317–323. [Google Scholar]

| Element | Al | Zr | Mo | V | Si | C | Fe | O | N | H | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal composition/(wt %) | 6.63–6.75 | 2.23–2.27 | 1.73–1.80 | 2.24–2.27 | <0.04 | <0.006 | 0.14 | 0.12 | <0.002 | 0.002 | Balance |

| No. | Forging Conditions | Cooling Mode | Heat Treatment Route | Heat Treatment Condition | Microstructural Type | Microstructural Characteristic |

|---|---|---|---|---|---|---|

| 1 | 970 °C/0.1 s−1/65% | WQ | - | - | - | - |

| 2 | 970 °C/0.1 s−1/65% | AC + WQ | - | - | - | - |

| 3 | 970 °C/0.1 s−1/65% | AC | - | - | Bimodal (A1) | Very thin interlaced αW, small αp |

| 4 | 970 °C/0.1 s−1/40% | AC | LTA | 830 °C/1 h/AC | Bimodal (A3) | Thick clustered αW, smaller αp |

| 5 | 970 °C/0.1 s−1/40% | WQ | LTA | 830 °C/1 h/AC | Bimodal (A4) | Thin interlaced αW, smaller αp |

| 6 | 970 °C/0.1 s−1/60% | AC + WQ | HTA | 930 °C/1 h/AC | Quasi tri-modal (B1) | Short and thick αs, large αp |

| 7 | 970 °C/0.1 s−1/65% | WQ | SA | 930 °C/1 h/AC + 550 °C/5 h/AC | Tri-modal (C1) | Long and very thick αs, small αp |

| 8 | 970 °C/0.1 s−1/60% | AC + WQ | SA | 930 °C/1 h/AC + 550 °C/5 h/AC | Quasi tri-modal (B2) | Short and thick αs, large αp |

| 9 | 970 °C/0.1 s−1/65% | WQ | TS | 950 °C/100 min/WQ + 800 °C/8 h/AC | Tri-modal (C2) | Short and thicker αs, smaller αp |

| 10 | 970 °C/0.1 s−1/60% | AC + WQ | TS | 950 °C/1 h/WQ + 800 °C/5 h/AC | Tri-modal (C3) | Short and thicker clustered αs, very large αp |

| 11 | 965 °C/0.1 s−1/65% | AC | NTS | 970 °C/1.5 h/WQ + 850 °C/1.5 h/AC | Bimodal (A2) | Thin and long clustered αW, moderate αp |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Wu, H.; Yang, H. Evaluation of Subsequent Heat Treatment Routes for Near-β Forged TA15 Ti-Alloy. Materials 2016, 9, 872. https://doi.org/10.3390/ma9110872

Sun Z, Wu H, Yang H. Evaluation of Subsequent Heat Treatment Routes for Near-β Forged TA15 Ti-Alloy. Materials. 2016; 9(11):872. https://doi.org/10.3390/ma9110872

Chicago/Turabian StyleSun, Zhichao, Huili Wu, and He Yang. 2016. "Evaluation of Subsequent Heat Treatment Routes for Near-β Forged TA15 Ti-Alloy" Materials 9, no. 11: 872. https://doi.org/10.3390/ma9110872

APA StyleSun, Z., Wu, H., & Yang, H. (2016). Evaluation of Subsequent Heat Treatment Routes for Near-β Forged TA15 Ti-Alloy. Materials, 9(11), 872. https://doi.org/10.3390/ma9110872