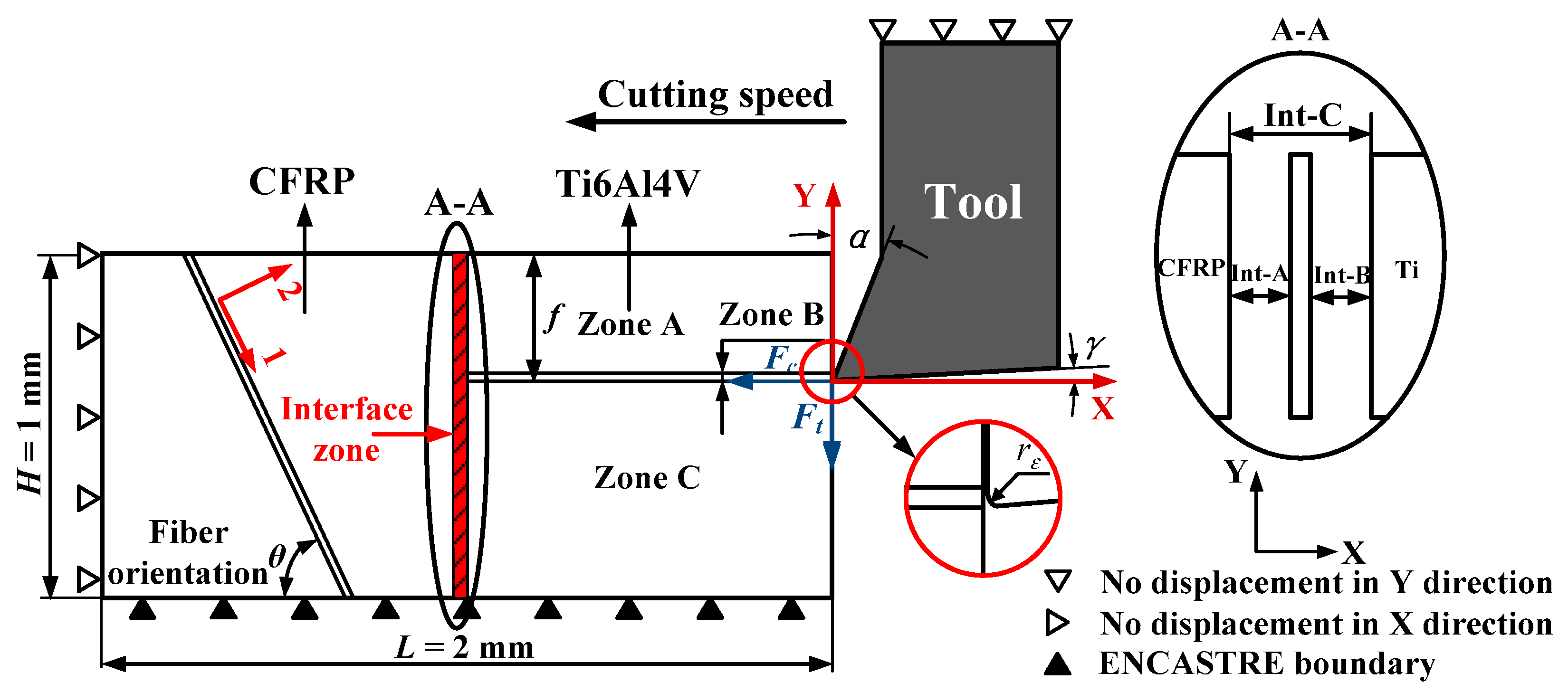

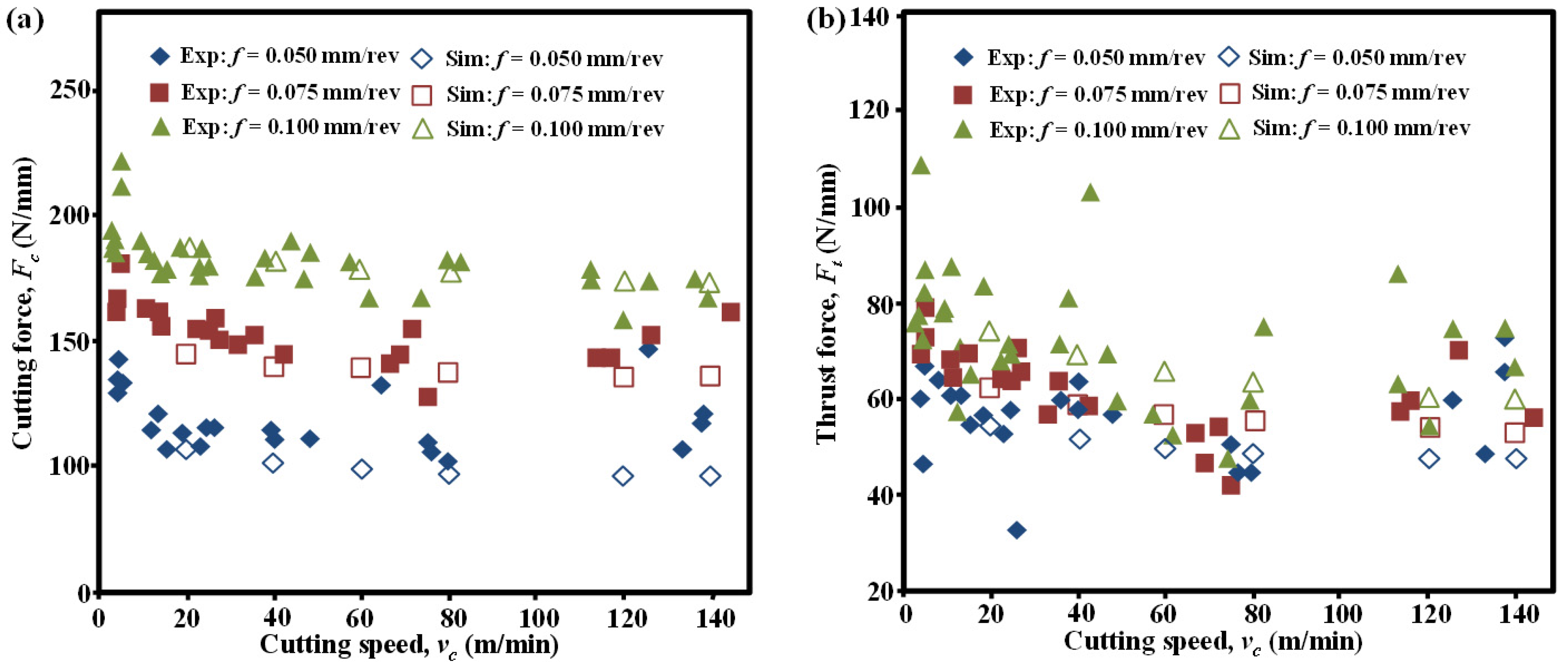

In this Section, numerical analyses concerning hybrid CFRP/Ti cutting are presented with the aim of better machining comprehension. Since Ti phase cutting and CFRP phase cutting require different optimal cutting parameters (vc and f), the cutting conditions used in the FE simulations were selected based on the compromise selection of the optimal parametric range for both the two phases of machining. Special focus was made on the analyses of the cutting process, interface damage formation, and parametric effects on fiber/matrix damage extent.

4.1. Cutting Process Investigation

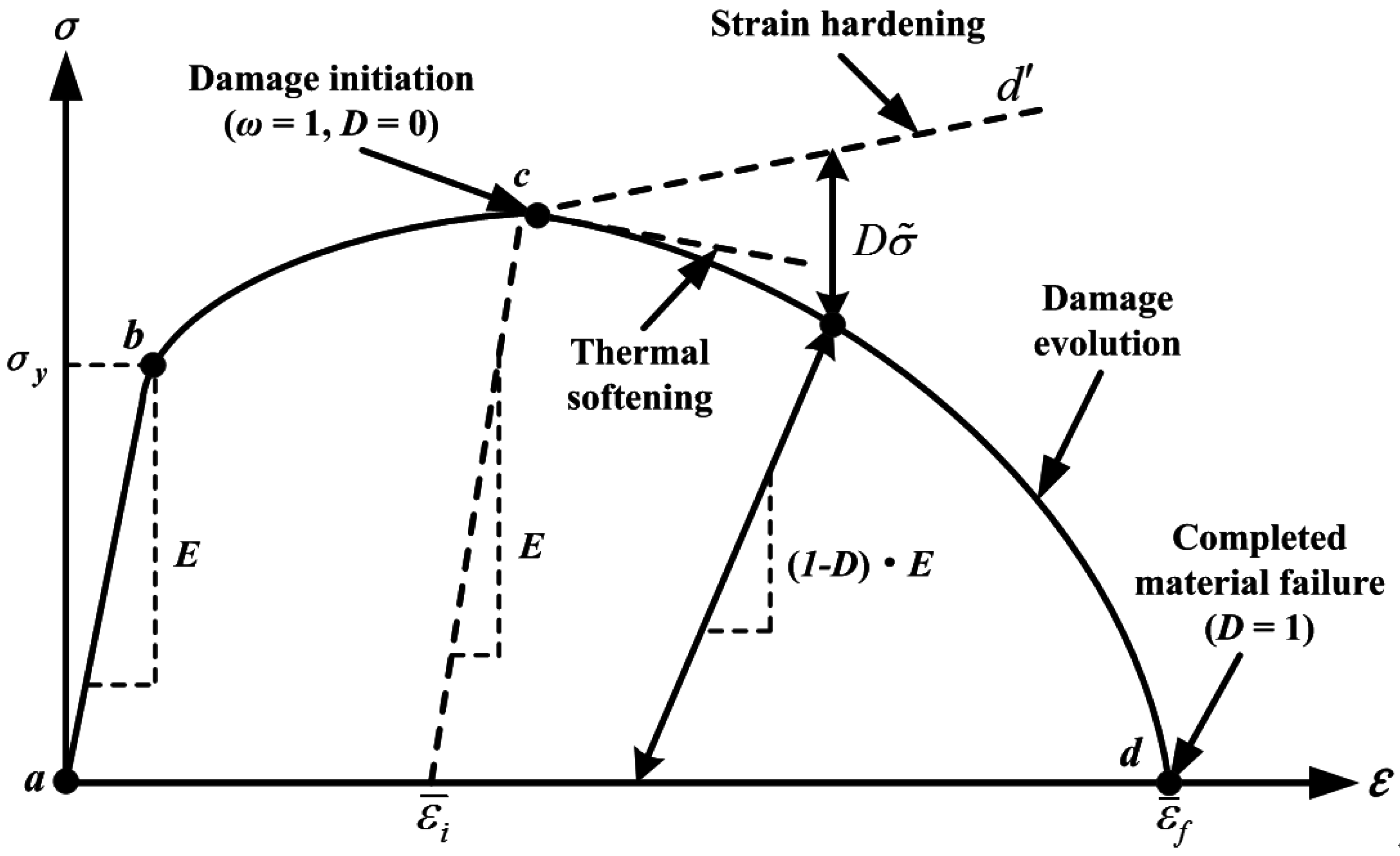

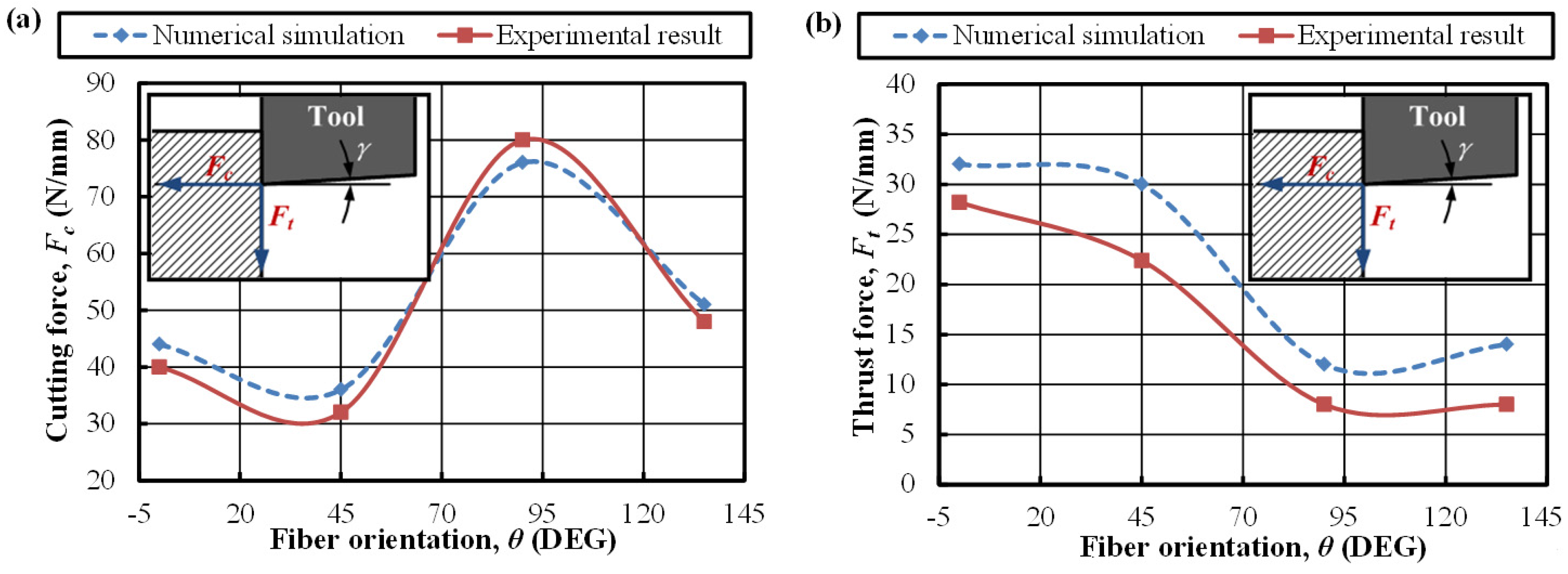

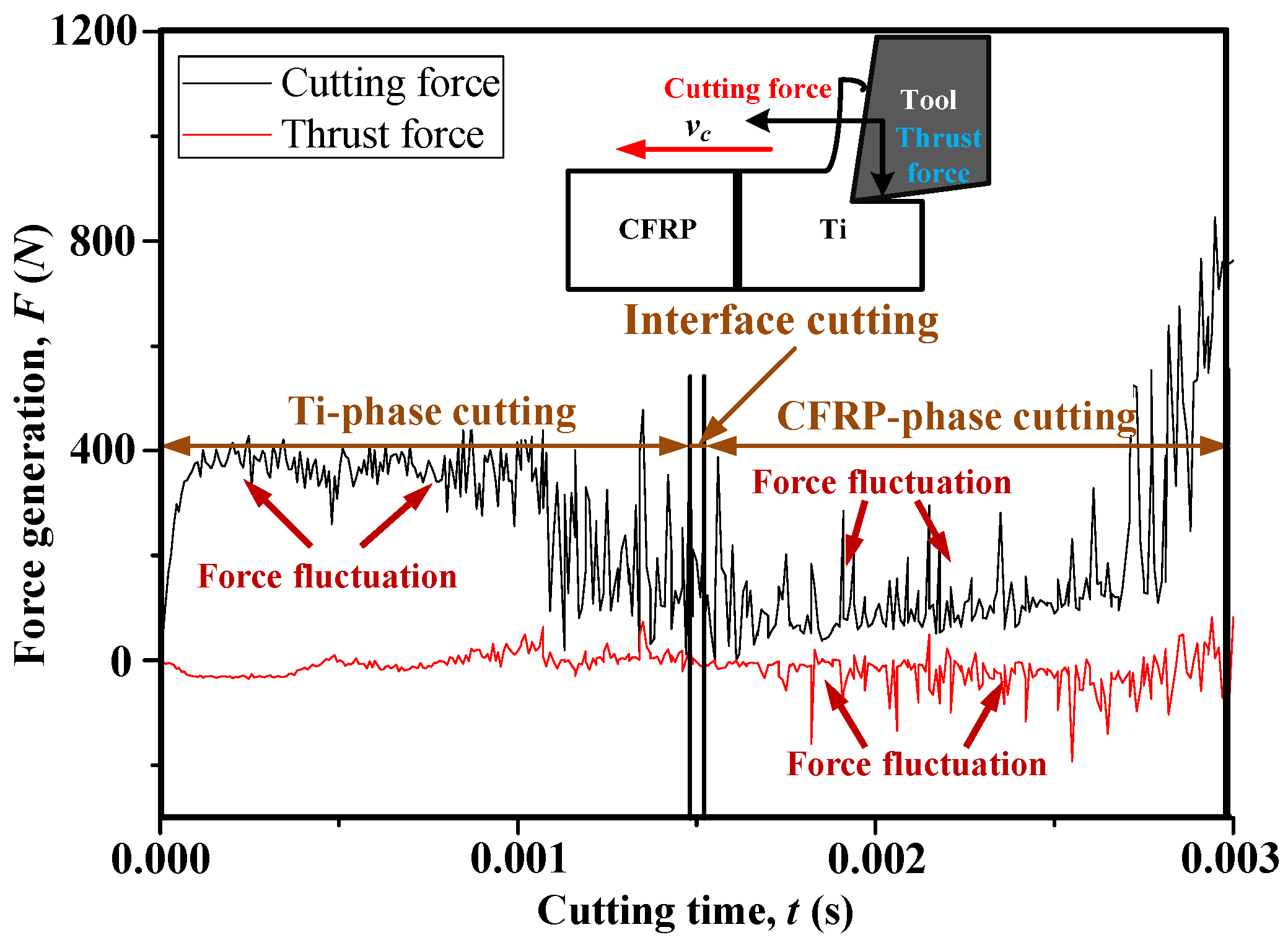

The cutting process of hybrid CFRP/Ti exhibits quite differently from the single-composite and single-metal cutting cases due to the multi-tool-work interaction domains. The disparate natures of each constituent make the chip separation modes more interrelated and coupled governing the bi-material interface consumption (BIC) [

37,

38]. The interface cutting commonly experienced changeable chip-separation modes and severe transitions of thermo/mechanical responses (e.g., force generation, cutting temperature, strain/stress flow). To reveal the key phenomena controlling CFRP/Ti cutting, the evolution of force generation

versus cutting time and also the chip formation progression under fixed cutting conditions of

vc = 40 m/min,

f = 0.2 mm/rev and θ = 0° are presented in

Figure 6 and

Figure 7, respectively. The force generations in CFRP/Ti cutting were split into two components,

i.e., the cutting-force component (

Fc) and the thrust-force component (

Ft), which signify the tribological interactions between tool rake and chip surfaces, together with tool flank and machined surfaces, respectively. It was noticeable that typically three cutting stages referring to the Ti-phase cutting, interface cutting, and CFRP-phase cutting could be seen from the force signal variation and the chip-morphology evolution.

Figure 6.

Evolution of the force generation versus cutting time when cutting hybrid CFRP/Ti composite (vc = 40 m/min, f = 0.2 mm/rev and θ = 0°).

Figure 6.

Evolution of the force generation versus cutting time when cutting hybrid CFRP/Ti composite (vc = 40 m/min, f = 0.2 mm/rev and θ = 0°).

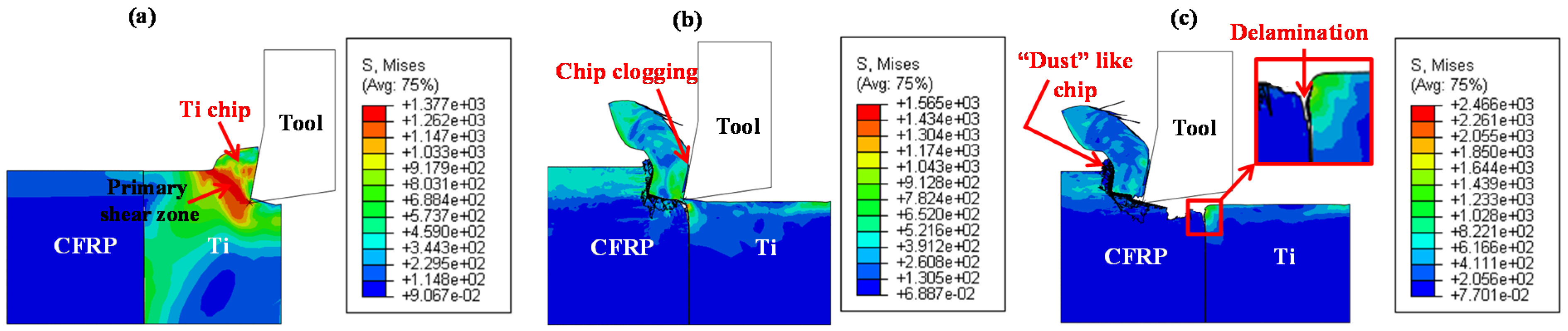

Figure 7.

Chip-morphology evolution during CFRP/Ti cutting: (a) Ti-phase cutting; (b) interface cutting; (c) CFRP-phase cutting (vc = 40 m/min, f = 0.2 mm/rev and θ = 0°) (Note: the symbol “S” in the figure represents the von Mises stress and the unit is MPa).

Figure 7.

Chip-morphology evolution during CFRP/Ti cutting: (a) Ti-phase cutting; (b) interface cutting; (c) CFRP-phase cutting (vc = 40 m/min, f = 0.2 mm/rev and θ = 0°) (Note: the symbol “S” in the figure represents the von Mises stress and the unit is MPa).

As depicted in

Figure 6 and

Figure 7, when the tool edges initially cut into the Ti phase, material separation occurred through the elastic-plastic deformation mode that controlled the tool-Ti interaction area. The shearing actions arising from the thermo-mechanical coupling effects produced “continuous” chip morphology that flowed on the tool rake face. It should be noted that the Ti-chip morphology exhibited strong sensitivity to the input parameters (cutting parameters and tool geometries) during machining. Since very low cutting speed and positive tool rake angle were used in the current simulation case, the resected chip shape exhibited a more “continuous” rather than a “serrated” appearance. Under the fixed cutting conditions, the machining operation gradually achieved a steady state for which the forces generation approximately attained a stable variation condition. Besides, despite reaching a steady cutting process, high-frequency force fluctuation was also pronounced in Ti-phase cutting as described in

Figure 6. The force-generation usually signifies the mechanical-energy consumption of tool-work interactions in cutting and presents a close relation with the inherent properties of the studied workpiece. Since the Ti alloy exhibited ductile behavior and low thermal conductivity, the chip separation typically involved serious thermo-plastic instability and shear localization in the primary cutting zone. Such a phenomenon would promote the quick occurrence of crack initiation and progression dominating the active cutting zones and result in the instability of the tool-work interaction controlling the chip removal process, as reflected in the cyclic force fluctuations. In addition, when the cutting time (

t) approximately exceeded 1.0 ms, the cutting-force component was observed to suffer a gradual reduction. The physical phenomenon could be explained by the decreased uncut Ti-chip thickness contributing to the reduction of force resistance when the tool tended to finalize the Ti-phase cutting. With tool advancement, especially when the cutting edges cut into the interface region, the previously-resected Ti chip adhered on the tool rake face and replaced the tool edges for further chip separation. Due to the transition from tool-Ti interaction to tool-CFRP interaction, the cutting force magnitudes underwent quick drop throughout the interface cutting. In such circumstances, the chip separation mode shifted gradually from plastic-defamation into brittle-fracture, which inevitably resulted in the serious transfer of mechanical/physical loads exerted on the tool-work system. The harsh cutting conditions dominating the CFRP/Ti interface cutting was the key contributor promoting the severe damage formation in the bi-material interface.

With further cutting progression, the tool tip cut across the interface region completely and induced a large extent of delamination damage focused on the interface area as shown in the magnified view of

Figure 7c. When the tool penetrated into the CFRP phase, material removal took place through successive ruptures aided by the diverse nature and uneven load sharing among the fiber/matrix systems. Since brittle fracture operated as the predominant cutting mode, the resected chip morphology was produced in the form of “discontinuous” shape (especially “dust” like appearance), as illustrated in

Figure 7c. Concerning force generation, both the cutting force and thrust force signals were predicted to undergo severe fluctuation and high-frequency variation. However, the mechanisms governing the physical phenomena were disparate. For the cutting force variation, it was induced due to the crack initiation and evolution governing the chip separation process. In contrast, the thrust force fluctuation was mainly attributed to the intense bouncing-back effects on the tool flank surface arising from released carbon fibers in the machined surface [

39].

Moreover, when the cutting tool approached the finish of the cutting process, a significant increase of cutting force generation became pronounced as portrayed in

Figure 6. This abnormal phenomenon could be explained as follows. When the tool cuts into the CFRP phase, the Ti chip adhered on the tool rake face and replaced the cutting edges for further chip separation. In addition, the produced “dust” like composite chips also caused serious clogging on the head of the Ti chip. Due to these phenomena, the accumulated chip volume inevitably led to a dramatic rise of the cutting resistance, and hence the higher cutting force generation.

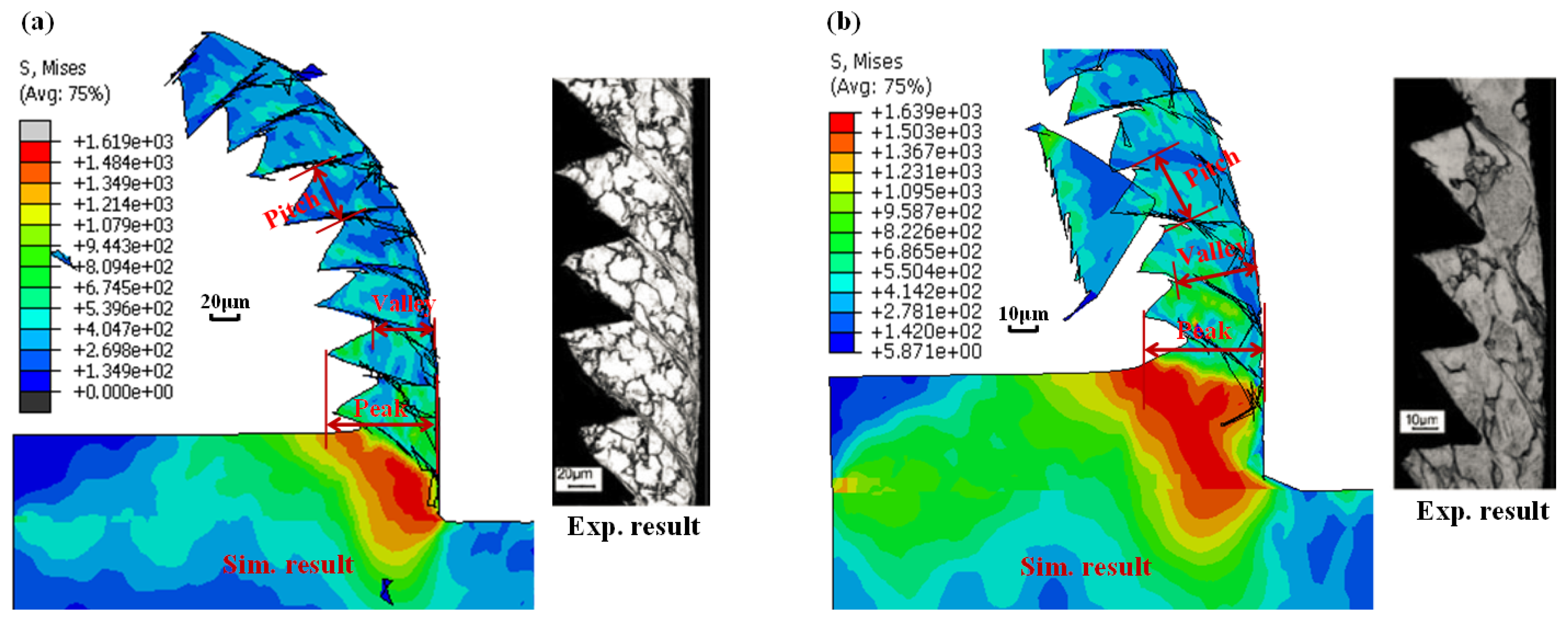

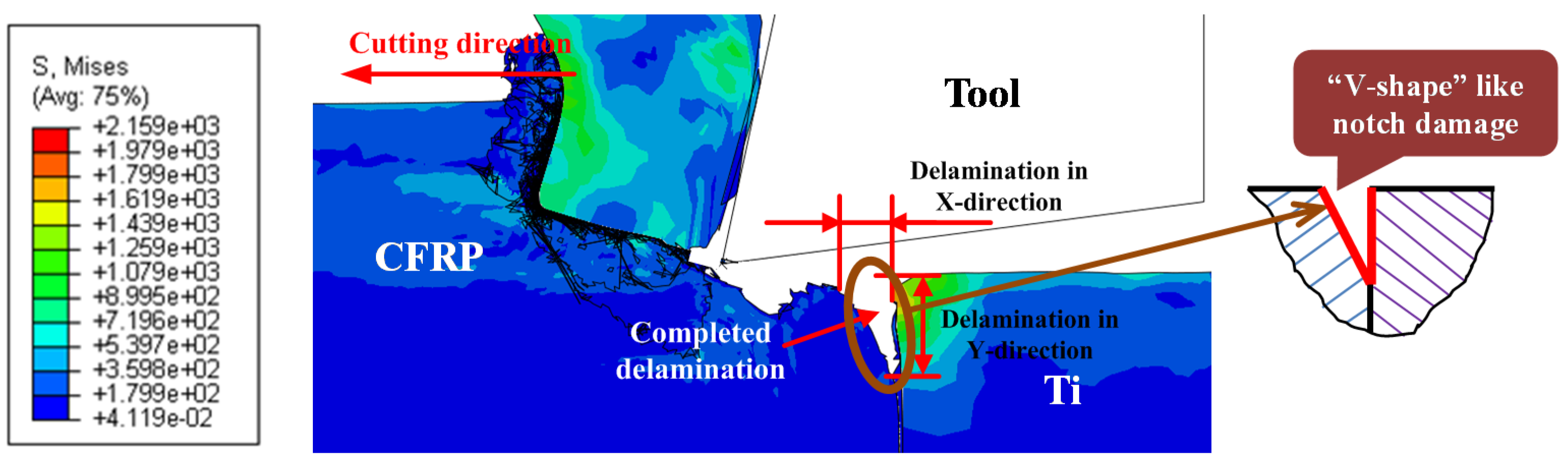

4.2. Inspection of Interface Damage Formation

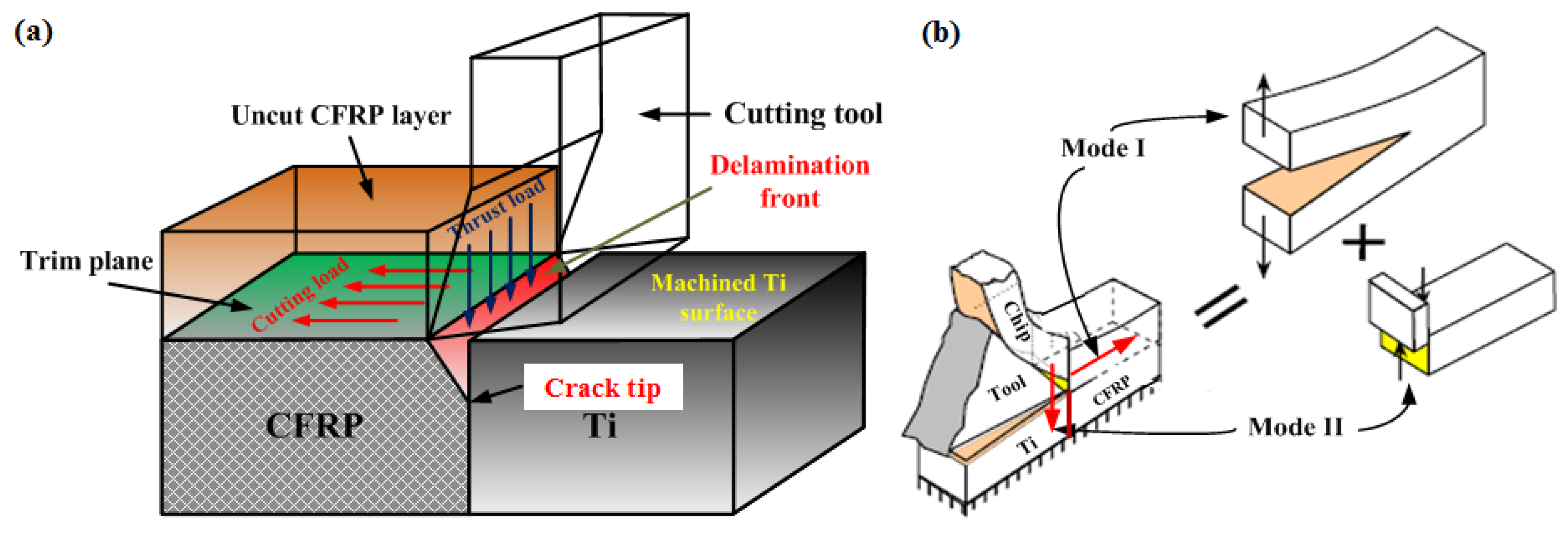

In CFRP/Ti cutting, the bi-material interface consumption (BIC) signifies the tremendous mechanical/thermal energy transfer arising from disparate phase cutting, the interrelated chip separation modes, and mixed machining responses controlling the hybrid cutting process. BIC plays a significant role in affecting the final surface quality and subsurface damage formation. The interface cutting can be identified as the weakest region vulnerable to serious damage formation.

Figure 8 presents the FE observation of interface damage morphology with OC of CFRP/Ti composite under the cutting conditions of

vc = 40 m/min,

f = 0.2 mm/rev and θ = 0°. It was noticeable that the key characteristic of the interface damage was a “V-shape” like notch damage focused on the CFRP-Ti contact boundary. A large extent of delamination damage became pronounced in both tool-cutting direction (

X-direction) and through-thickness direction (

Y-direction) as depicted in

Figure 8. However, the key manifestation was the severe tearing in the CFRP-phase boundary deviating far from the Ti-phase boundary. The physical phenomena demonstrated that the crack trajectory would experience a quick damage evolution concerning the tool cutting direction during the machining process. The key mechanisms controlling the crack trajectory and evolution in the bi-material interface were strongly influenced by two important factors. The first was the relative fracture toughness arising from the stacked constituents of the bi-material system. It is believed that the crack path prefers to take place nearer the more brittle constituent characterized by lower fracture toughness since it needs less energy to open and propagate the crack damage. In such a case, the preferred crack path occurring in the CFRP/Ti interface should exhibit more closely to the CFRP-phase boundary due to its relatively lower fracture toughness as compared to its counterpart. Another factor was the specific fracture mode encountered along the bi-material interface.

Figure 9 shows the schematization of the crack path and fracture modes I and II in cutting. It could be seen that when the tool edges completely passed through the Ti-phase boundary, the load path exerting on the bi-material system was uniquely applied on the uncut CFRP and interface layers while the machined Ti-phase surface was deprived of load occupation. As such, the cutting load parallel to the tool cutting direction together with the thrust load perpendicular to the cutting direction would produce mixed damage modes (fracture modes I and II) on the interface region. Consequently, it resulted in a sole path evolution of crack trajectory approaching the cutting direction. This phenomenon inevitably gave rise to the so-called “delamination” damage.

Figure 8.

FE observation of interface damage when cutting hybrid CFRP/Ti composite (vc = 40 m/min, f = 0.2 mm/rev and θ = 0°) (Note: the symbol “S” in the figure represents the von Mises stress and the unit is MPa).

Figure 8.

FE observation of interface damage when cutting hybrid CFRP/Ti composite (vc = 40 m/min, f = 0.2 mm/rev and θ = 0°) (Note: the symbol “S” in the figure represents the von Mises stress and the unit is MPa).

Figure 9.

Scheme of (a) crack path in interface region and (b) fracture modes I and II in cutting.

Figure 9.

Scheme of (a) crack path in interface region and (b) fracture modes I and II in cutting.

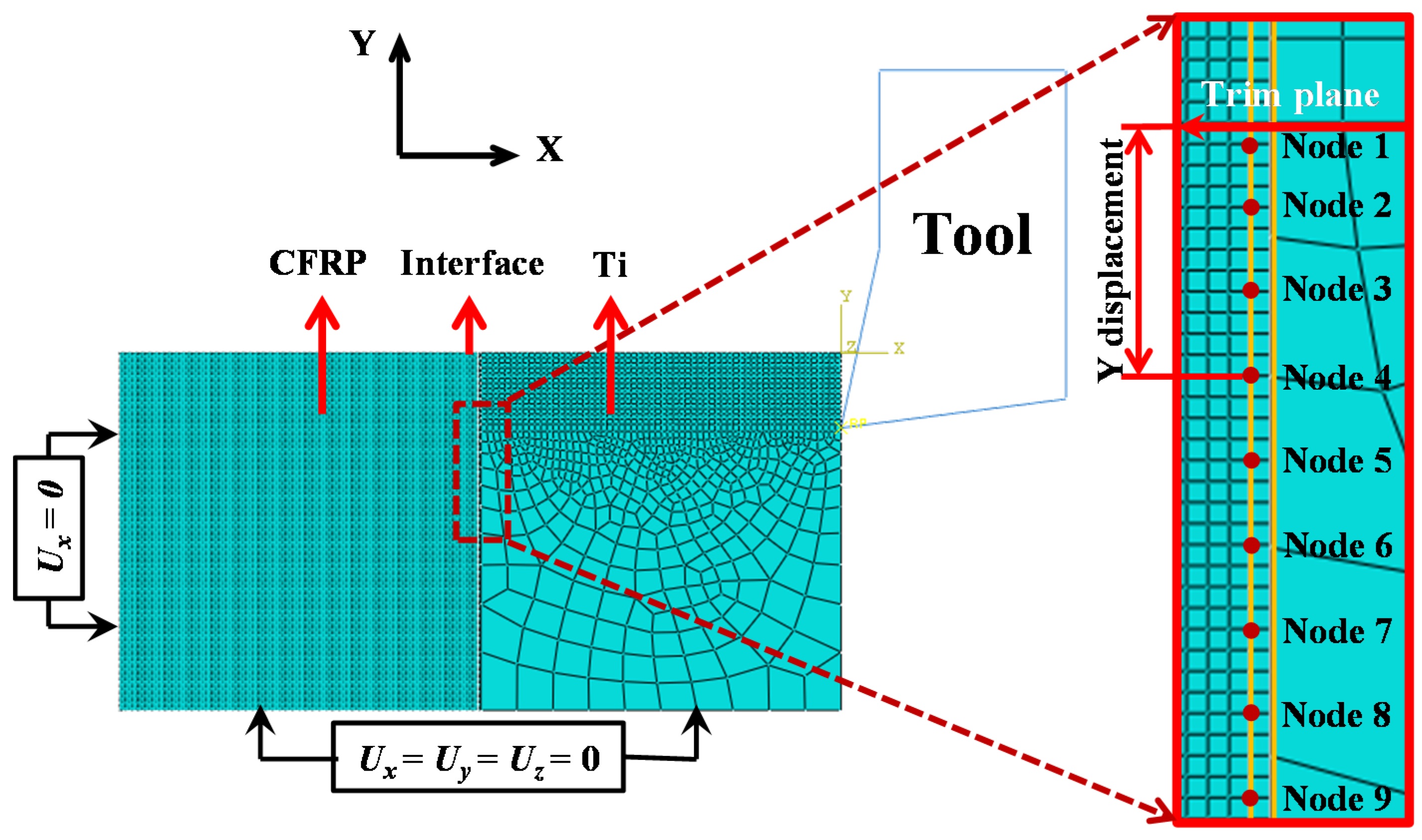

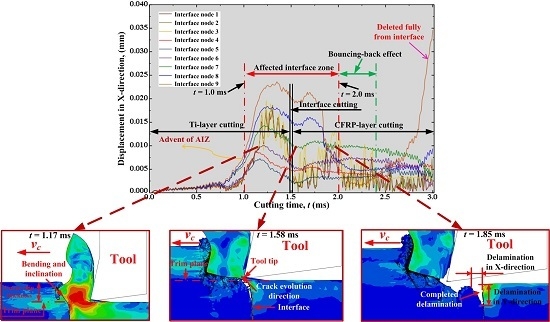

To specify the dynamic process of delamination formation and also the affected interface zone (AIZ), nine interface nodes beneath the trimmed plane were selected to characterize their

X-direction displacement

versus cutting time (

t) as shown in

Figure 10.

Table 8 summarizes the depth beneath the trim plane of the selected interface nodes. The AIZ studied here was devoted to clarifying the actual cutting time that influenced the interface damage formation during the orthogonal cutting process.

Figure 10.

Scheme of selected interface nodes in the CFRP/Ti model.

Figure 10.

Scheme of selected interface nodes in the CFRP/Ti model.

Table 8.

Y-displacement from the trim plane of selected nodes in the interface zone.

Table 8.

Y-displacement from the trim plane of selected nodes in the interface zone.

| Number of Node | Depth beneath the Trim Plane (μm) | Number of Node | Depth beneath the Trim Plane (μm) |

|---|

| 1 | 5 | 2 | 20 |

| 3 | 40 | 4 | 60 |

| 5 | 80 | 6 | 100 |

| 7 | 120 | 8 | 140 |

| 9 | 160 | - |

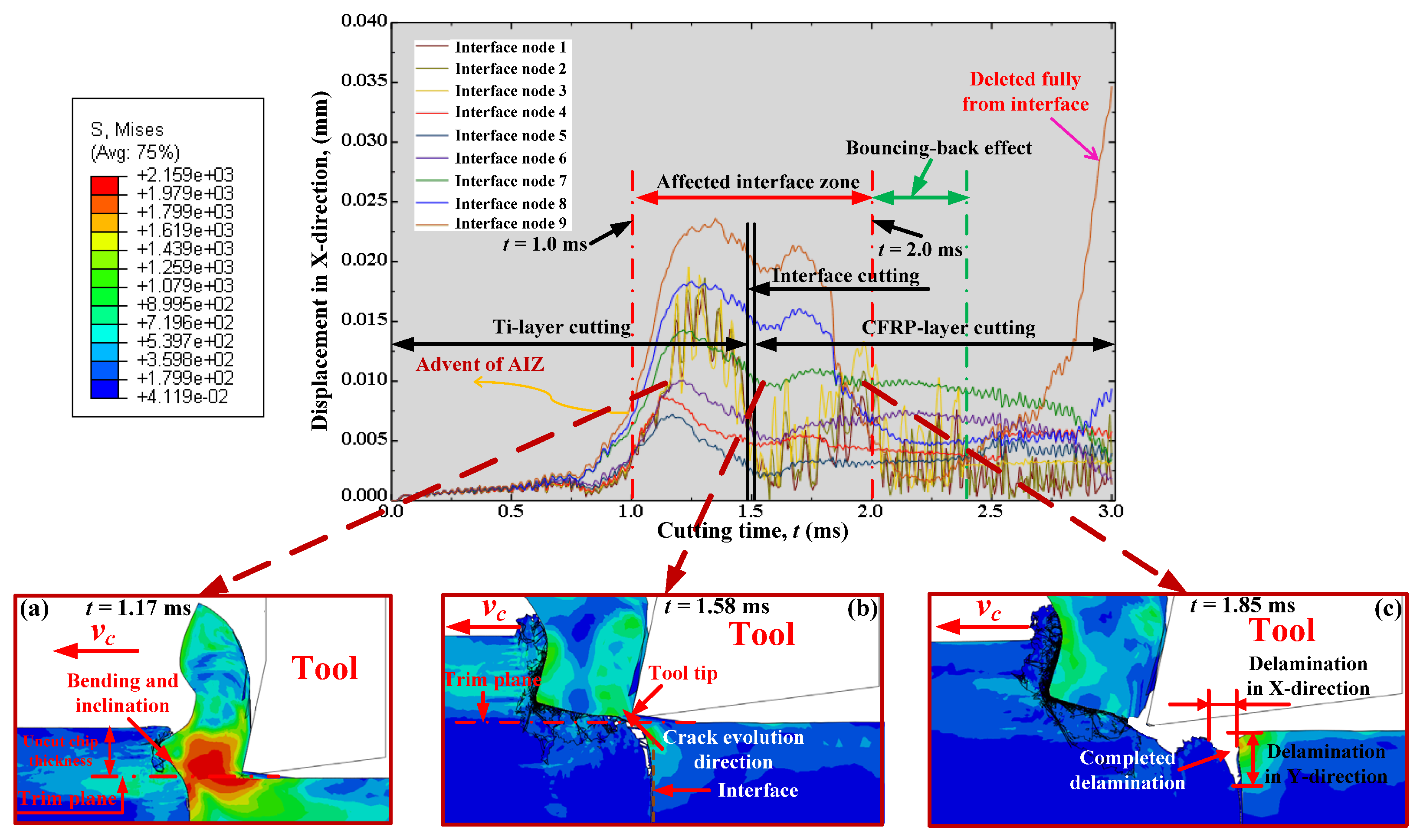

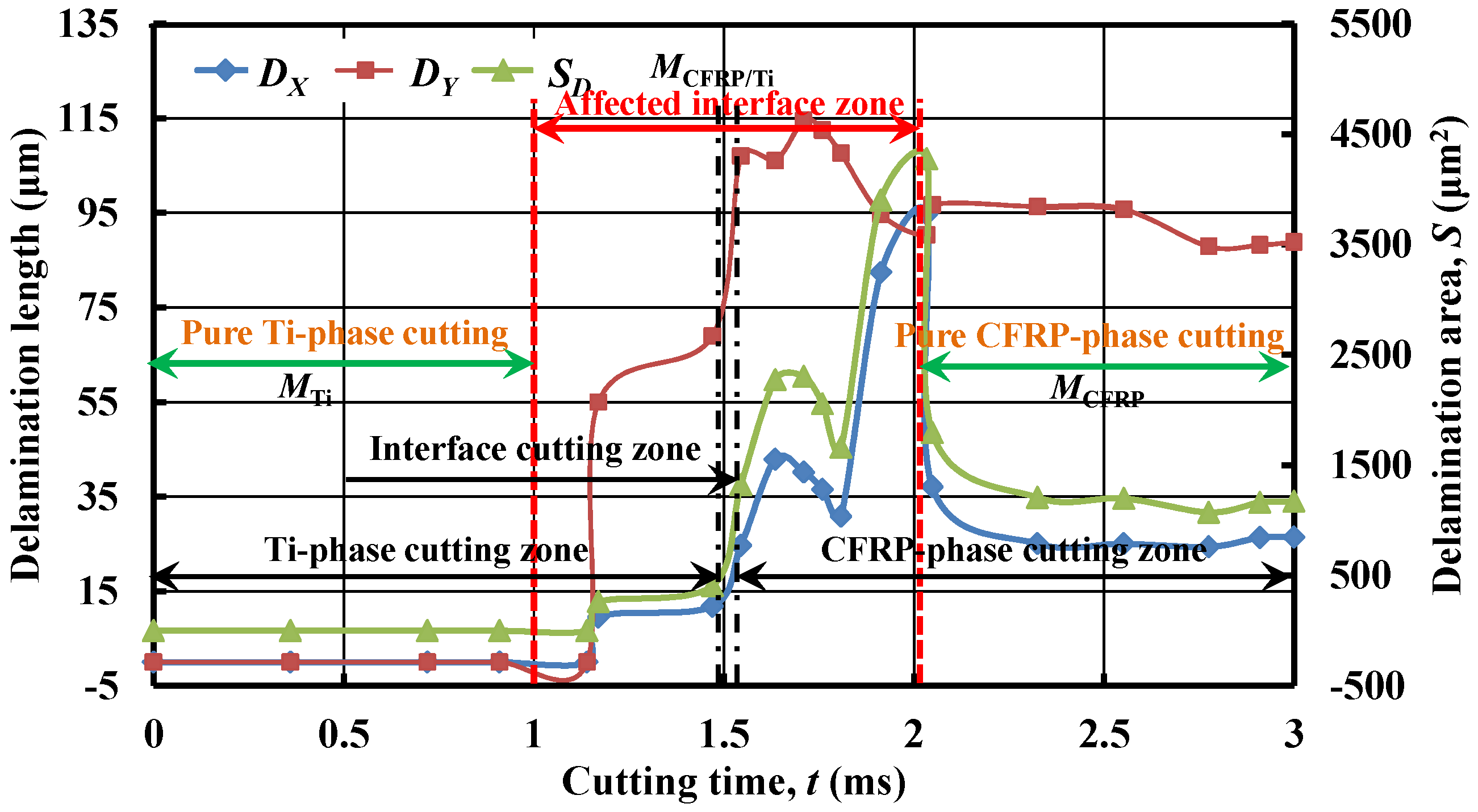

Figure 11 then illustrates the

X displacement evolution of the selected interface nodes with respect to the cutting time (

t) under the fixed cutting conditions of

vc = 40 m/min,

f = 0.2 mm/rev, and θ = 0°. It was apparent that the

X displacements of the selected interface nodes generally underwent three variation stages, i.e., the initial variation stage, rapid variation stage, and steady variation stage during the total cutting duration (

t = 3.0 ms). At the beginning of cutting, all the selected interface nodes were predicted to suffer slow-rate displacement variation, which indicated that the chip removal process initially exhibited slight/minor effects on the interface region. However, with the cutting progression, the machining operation gradually exerted significant influences on the output responses of the interface region with evidence that all the selected interface nodes began to experience high-extent displacement fluctuations and quickly enter into the rapid variation stage. The physical phenomena were predicted to take place in the Ti-phase cutting period approximately at a cutting time of 1.0 ms. Such evidence signified the advent of the affected interface zone (AIZ) prior to the interface-cutting period as illustrated in

Figure 11. The occurrence of AIZ commonly implied that the CFRP/Ti interface had suffered dramatic influences arising from the Ti-chip removal process. As depicted in

Figure 11a, the produced Ti chip caused severe bending and inclination effects on the interface zone and also the uncut CFRP-chip layer. The pronounced displacement variation in AIZ strongly demonstrated the appearance of serious detaching and separation concerning the interface zone. In addition, the interface nodes located near the trim plane typically underwent larger

X displacement compared to their counterparts far away from the trim plane. The reason might be due to the different levels of influences arising from tool-work interactions. When the cutting time approximately reached 2.0 ms, the

X displacements of the selected interface nodes gradually achieved the steady variation state, indicating the diminishing trend of the cutting influences on the interface region. For instance, as shown in

Figure 11c, both the deamination lengths in

X and

Y directions reached their stable values. In such a case, the AIZ could be defined probably at a duration of

t [1.0, 2.0 ms]. With regard to the severe displacement fluctuation occurring in the steady variation state, the reason might be induced as being due to the bouncing-back effects from adjacent CFRP elements still affected by the local cutting operation. At the end of the cutting process, all the selected interface nodes approached attainment of constant displacements in the

X direction except the interface node 1. The dramatic displacement increase of interface node 1 demonstrated that the node had been deleted completely from the interface zone.

Figure 11.

Displacement in X-direction of selected interface nodes versus cutting time (t): (a) cutting process at t = 1.17 ms; (b) cutting process at t = 1.58 ms and (c) cutting process at t = 1.85 ms.

Figure 11.

Displacement in X-direction of selected interface nodes versus cutting time (t): (a) cutting process at t = 1.17 ms; (b) cutting process at t = 1.58 ms and (c) cutting process at t = 1.85 ms.

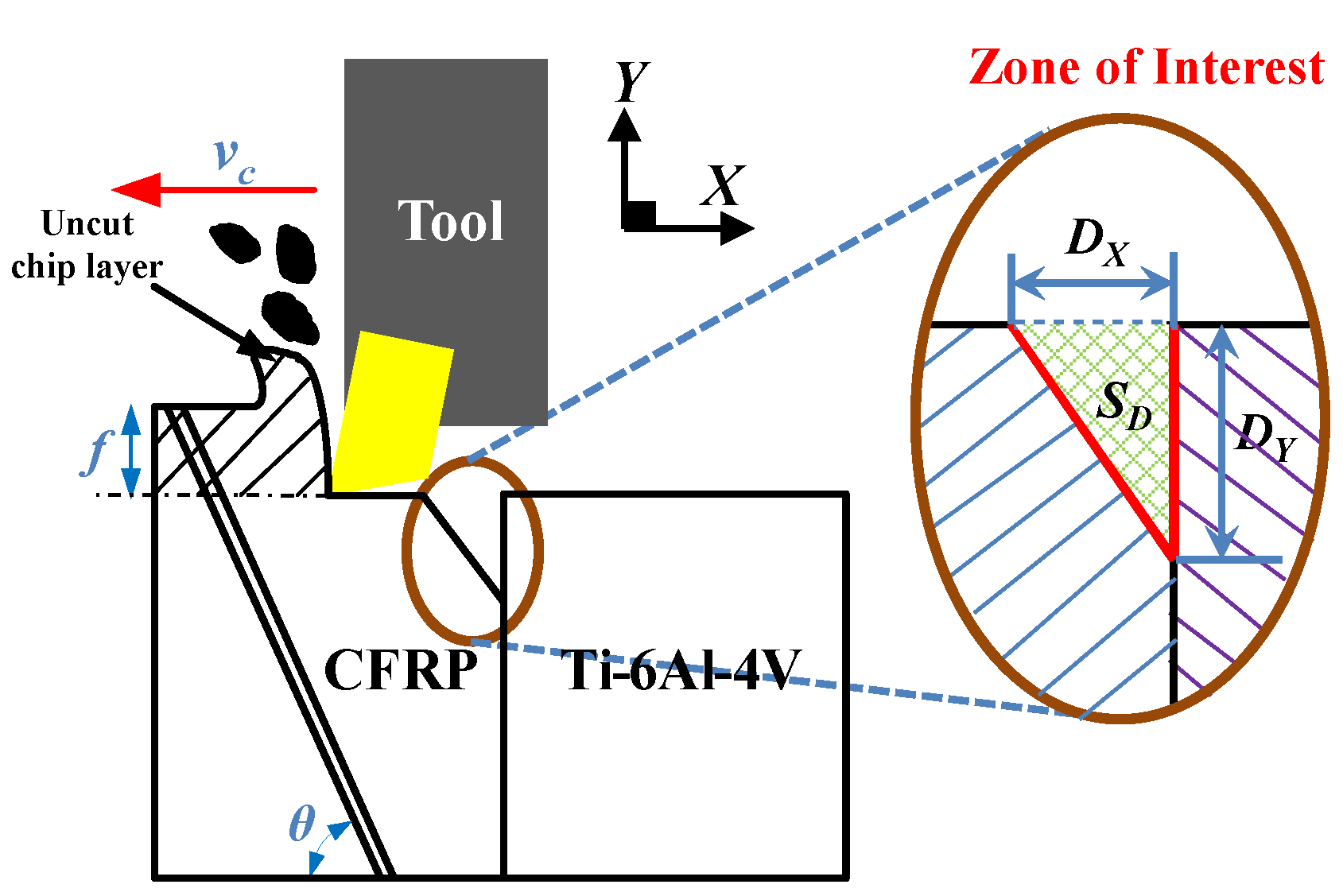

To quantify the delamination extent occurring in the interface zone, three indicators,

i.e.,

DX,

DY, and

SD were introduced for evaluation in this study, where

DX signified the delamination length in the tool-cutting direction (

X-direction),

DY denoted the delamination length in the through-thickness direction (

Y-direction) and

SD implied the delamination area of the damage zone as shown schematically in

Figure 12. The delamination area (

SD) was defined as illustrated in Equation (13).

Figure 12.

Scheme of delamination damage evaluation in CFRP/Ti cutting.

Figure 12.

Scheme of delamination damage evaluation in CFRP/Ti cutting.

Figure 13 presents the evolution of interface delamination damage

versus cutting time (

t). The results confirmed that all the delamination indicators (

DX,

DY and

SD) exhibited similar evolution trends as the

X displacements of the selected interface nodes

versus cutting time (

t) in

Figure 11. The comparison mutually demonstrated the reliability of the two numerical observations. Moreover, as depicted in

Figure 13, from the geometrical consideration, the entire hybrid CFRP/Ti cutting can be divided into three stages referring to (

i) Ti-phase cutting, (

ii) interface cutting, and (

iii) CFRP-phase cutting in terms of their respective cutting lengths. However, such a category actually couldn’t reflect the real machining behavior of the bi-material system due to ignorance of the interactive cutting influences arising from each-phase cutting. In reality, the entire hybrid cutting process could be divided into three basic zones based on the interactive influences of each phase machining.

Figure 13.

Evolution of delamination damage (DX, DY and SD) as function of cutting time (t).

Figure 13.

Evolution of delamination damage (DX, DY and SD) as function of cutting time (t).

(i) Pure Ti-phase cutting t [0, 1.0 ms] signifies the cutting period concerning the absolute Ti-phase machining with minimum influence affecting the CFRP/Ti interface and the CFRP zone. Such a zone represents the machinability of the single Ti-alloy phase (MTi).

(ii) AIZ cutting t [1.0, 2.0 ms] denotes the cutting duration concerning the machining variation of the bi-material interface arising from Ti-phase cutting and CFRP-phase cutting. Moreover, the AIZ cutting zone in reality represents the real machinability of the stacked CFRP/Ti material (MCFRP/Ti).

(iii) Pure CFRP-phase cutting t [2.0, 3.0 ms] implies the cutting time concerning the absolute CFRP-phase machining and reflects the machinability of the standard CFRP phase (MCFRP).

During the pure Ti-phase cutting zone, all DX, DY and SD nearly remained constant values (probably zero values), indicating that no delamination occurred in the interface zone. With the continuation of the cutting process, especially when t reached the AIZ, the three delamination indicators totally suffered a dramatic increase with elevated cutting time. Such a phenomenon signified that the delamination damage was principally formed at the AIZ cutting period. Besides, the subsequent reduction of the delamination indicators in the AIZ might be caused by the bouncing-back effects from adjacent CFRP elements affected by the cutting operation. Moreover, with further increased t, especially in the pure CFRP-phase cutting zone, DX, DY and SD gradually reached their steady values, which meant that the later cutting process (post CFRP-phase cutting) generated less effect on the interface delamination formation.

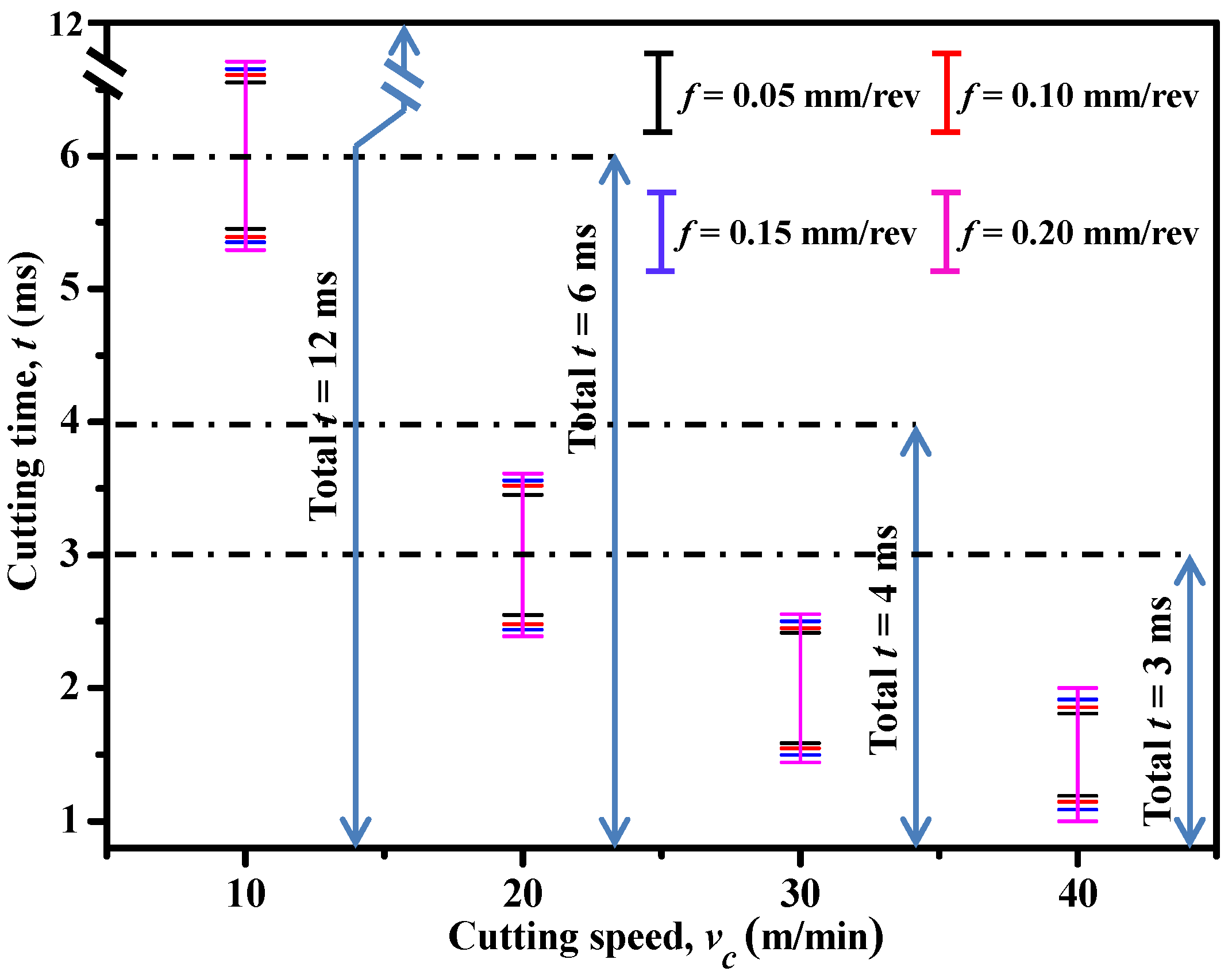

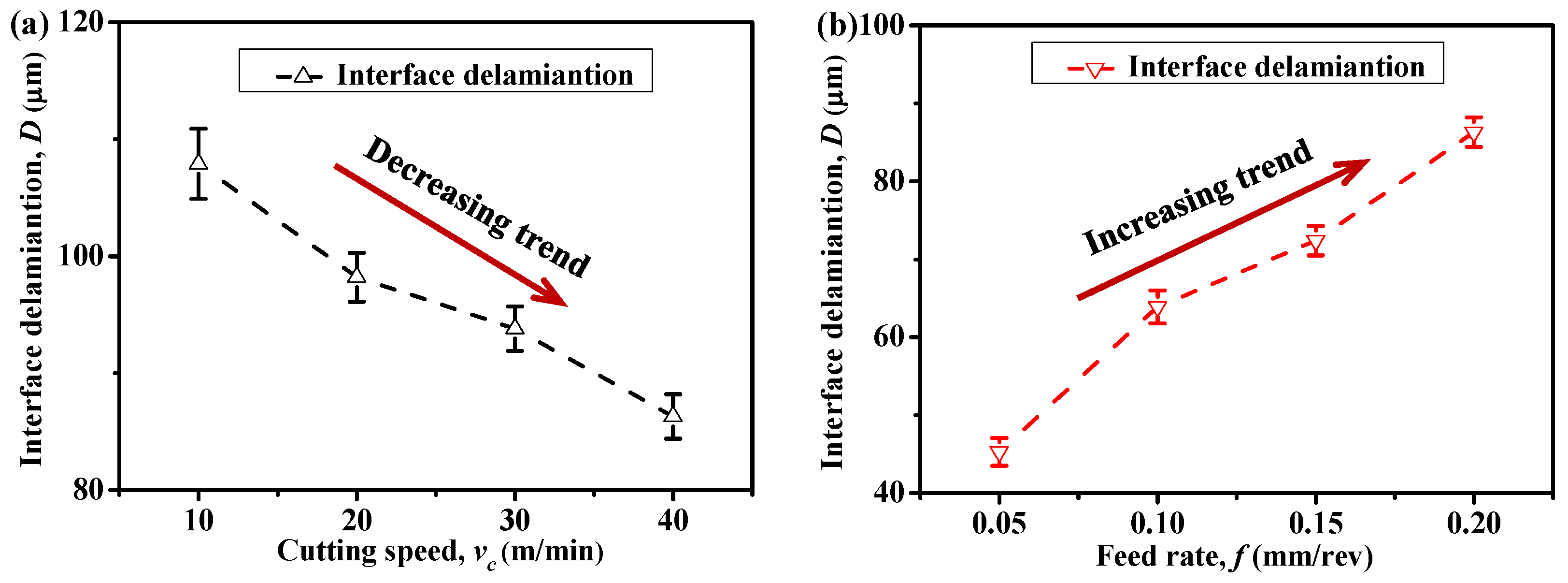

Moreover, to inspect the effects of input variables on the AIZ and also on the interface delamination extent, a parametric study was performed by considering various cutting speeds and feed rates.

Figure 14 and

Figure 15 present the acquired results. Note that in

Figure 14, the symbol “

I” indicates the cutting duration of AIZ and the interface delamination extent (

D) was measured based on the

DY length (delamination length in the through-thickness direction (

Y-direction)). As can be seen in

Figure 14, both

vc and

f were found to have significant effects on the AIZ cutting time. Specifically,

vc exhibited a negative impact on the AIZ cutting duration while the impact of

f was positive. A parametric combination of high

vc and low

f commonly resulted in the lowest AIZ cutting duration. Moreover, as is evident in

Figure 15, all the examined parametric variables showed pronounced influences on the interface delamination extent. The impact of

vc was found to be negative, i.e., an increase of

vc resulted in the reduction of

D, while the impact of

f was positive. The mechanisms controlling the variation phenomena could be associated with their specific influences on AIZ. This was because when

vc was elevated, typically a reduced cutting time of AIZ was achieved as illustrated in

Figure 14. As such, the decreased AIZ inevitably alleviated the damage extent of induced interface delamination. In contrast, an increase of

f usually led to an increased AIZ (as depicted in

Figure 14), and hence gave rise to a higher extent of interface delamination as shown in

Figure 15b. Therefore, from the above analyses, for minimizing the extent of interface delamination, a high cutting speed and a low feed rate are strongly preferred.

Figure 14.

Effects of cutting speed (vc) and feed rate (f) on cutting duration of AIZ (Note: “Ι” indicates the cutting duration of AIZ) (θ = 0°).

Figure 14.

Effects of cutting speed (vc) and feed rate (f) on cutting duration of AIZ (Note: “Ι” indicates the cutting duration of AIZ) (θ = 0°).

Figure 15.

Interface delamination extent (D) in function of: (a) cutting speed (vc) (f = 0.2 mm/rev and θ = 0°) and (b) feed rate (f) (vc = 40 m/min and θ = 0°).

Figure 15.

Interface delamination extent (D) in function of: (a) cutting speed (vc) (f = 0.2 mm/rev and θ = 0°) and (b) feed rate (f) (vc = 40 m/min and θ = 0°).

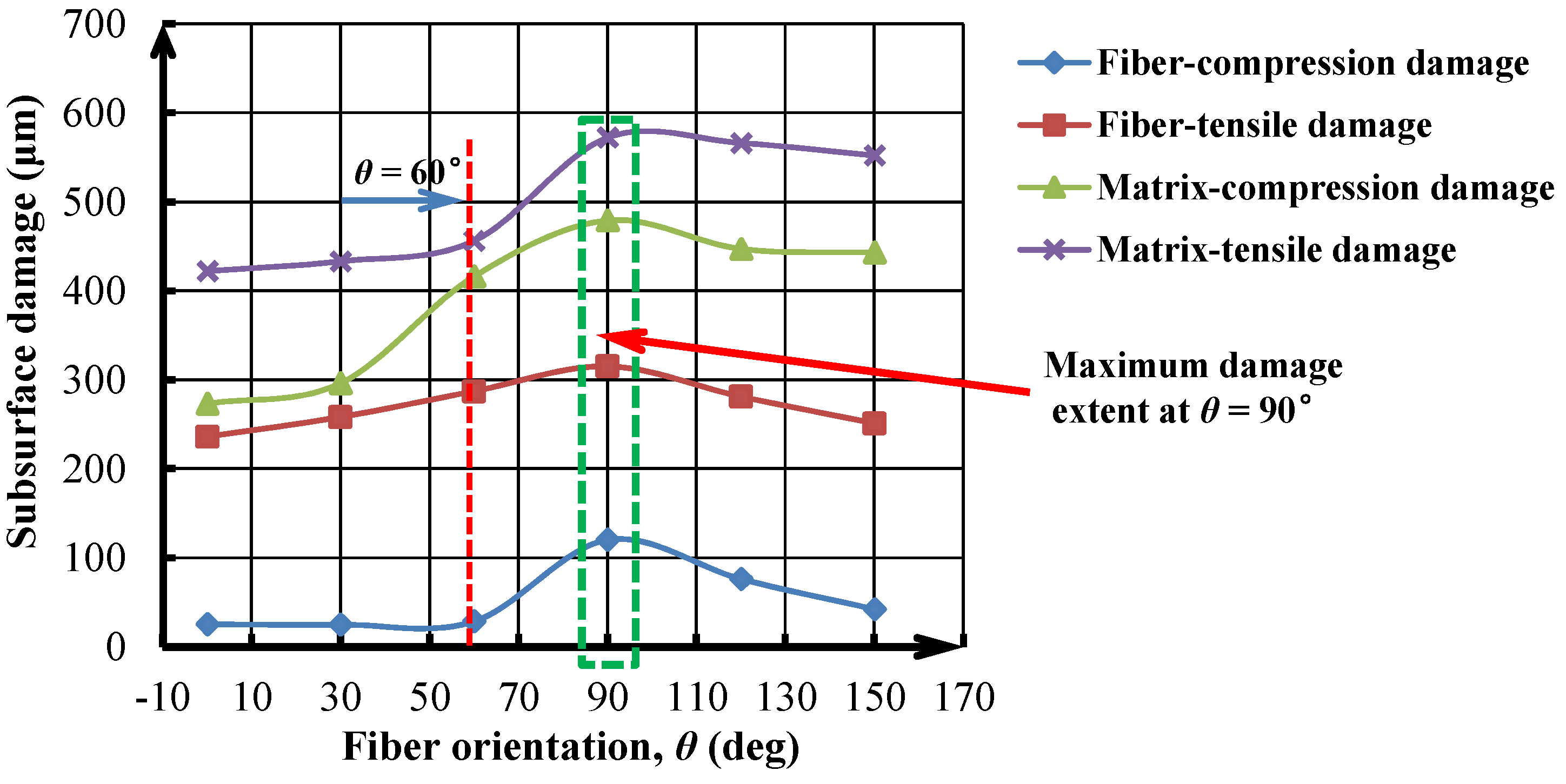

4.3. Subsurface Damage Study

Apart from the severe interface imperfection, the subsurface damage occurring in the composite phase is also a particular concern when machining hybrid CFRP/Ti composite. As discussed above, the composite-phase damage takes place following four types of fiber/matrix failure,

i.e., fiber compression damage, fiber tensile damage, matrix compression damage, and matrix tensile damage. To inspect the subsurface composite damage resulting from the hybrid cutting operation, a parametric analysis was performed. The fiber/matrix failure was measured as the largest distance from the machined CFRP surface to the deepest fully damaged area, as shown schematically in

Figure 16. The fiber/matrix failure extent was predicted and studied

versus the fiber orientation (θ) under the fixed cutting conditions of

vc = 40 m/min and

f = 0.2 mm/rev as depicted in

Figure 17. It was noticeable that the

θ exhibited significant influence on the evolution of the various types of fiber/matrix damage during the chip removal process. The subsurface damage extent increased with elevated θ, especially the elevation became pronounced when θ was above 60° as depicted in

Figure 17. All the damage types tended to reach their maximum extent at θ = 90°. With θ’s further increase, the subsurface damage appeared to suffer a slight decrease. Such findings of θ’s effect on composite damage agreed well with the observations of Arola

et al. [

17], and Wang and Zhang [

39] when cutting CFRP laminates. The mechanisms controlling the mentioned phenomena could be attributed to the change of failure modes from bending and crushing in case of θ = 0° to a fracture by compression and interfacial-shearing mode for positive fiber orientation (0° < θ ≤ 90°) [

40], which inevitably led to in-depth fiber/matrix damage. For θ above 90°, chip-separation modes were shifted to be dominated by pressing, inter-laminar shearing, matrix cracking, and fiber/matrix interface debonding. This situation would result in less energy-consumption for chip separation and lower cutting resistance for machining. As a result, less extent of damage formation was promoted.

Figure 16.

Scheme of damage measurement in the CFRP phase (Note: HSNMCCRT represents the matrix-compression failure mode).

Figure 16.

Scheme of damage measurement in the CFRP phase (Note: HSNMCCRT represents the matrix-compression failure mode).

Figure 17.

Fiber/matrix damage extent versus fiber orientation (θ) (vc = 40 m/min and f = 0.2 mm/rev).

Figure 17.

Fiber/matrix damage extent versus fiber orientation (θ) (vc = 40 m/min and f = 0.2 mm/rev).

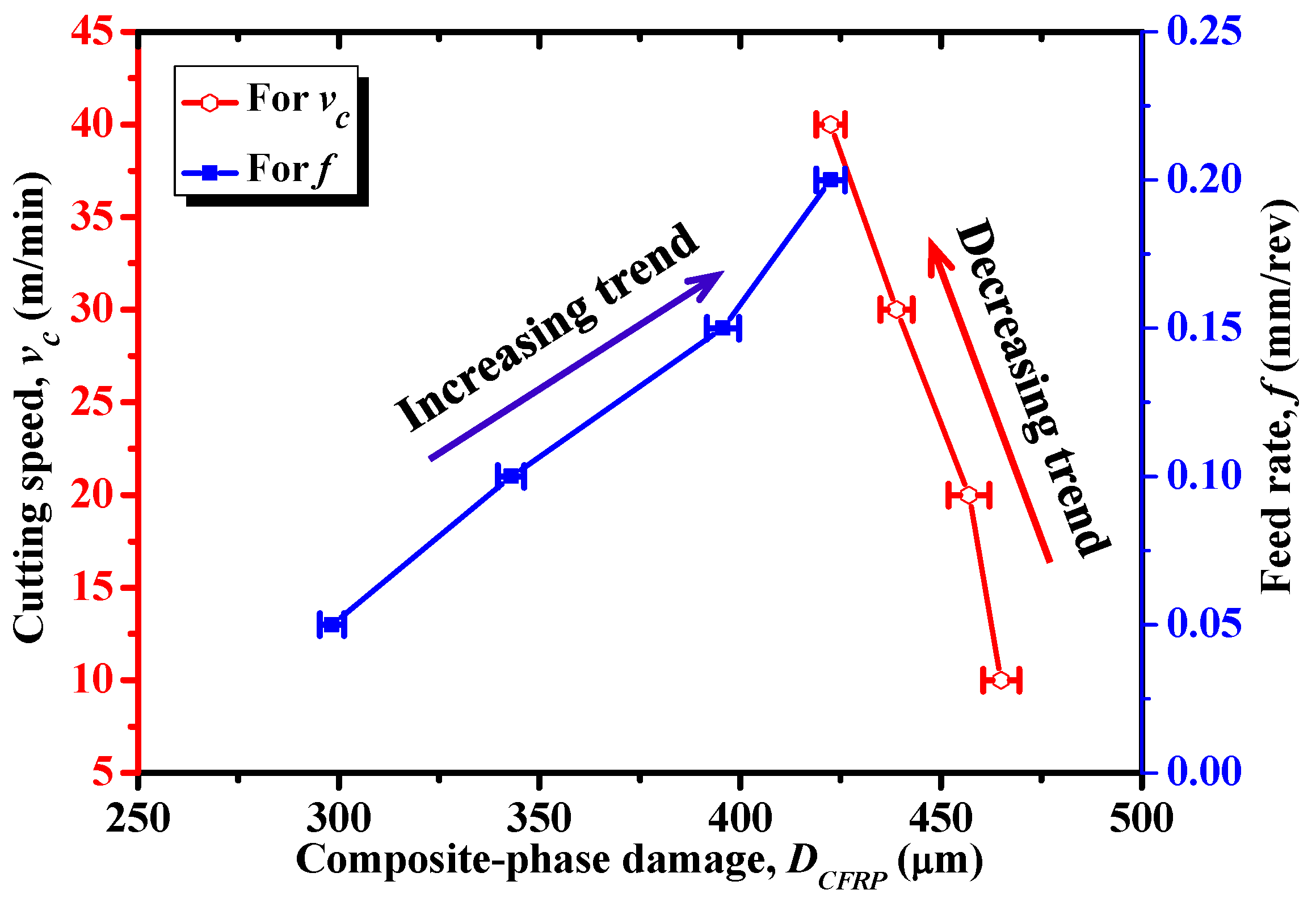

In addition,

Figure 18 also shows the parametric effects of

vc and

f on the cutting-induced composite-phase damage. Note that the composite-phase damage (

DCFRP) was evaluated based on the type of fiber/matrix failure that caused the largest extent of damage (e.g., as shown in

Figure 17, matrix-compression damage caused the maximum damage extent). Afterward,

DCFRP was measured as the largest distance from the machined CFRP surface to the deepest fully damaged area. Each measurement was repeated three times in order to ensure sufficient credibility for the acquired results. As shown in

Figure 18, it was noticeable that the

f had remarkable effects on the composite-phase damage in such a manner that a small increase of

f resulted in a dramatically elevated

DCFRP. In contrast, an increase of

vc typically led to a direct reduction of

DCFRP. The phenomena implied that the use of high-speed cutting (HSC) might benefit the reduction of composite-phase damage formation when machining hybrid CFRP/Ti composite. Therefore, based on the above analyses, the optimum cutting parameters for composite damage minimization should consist of small fiber orientation, high cutting speed, and low feed rate when machining this bi-material system.

Figure 18.

Effects of cutting speed (vc) and feed rate (f) on composite-phase damage extent (DCFRP) (θ = 0°).

Figure 18.

Effects of cutting speed (vc) and feed rate (f) on composite-phase damage extent (DCFRP) (θ = 0°).