3.1. Aspherical Lens

We used the internal optical human eye model in CODE V, which was proposed by Liou and Brennan in 1997. However, this model is mainly based on the nonspherical development; therefore, for designing an IOL, changing its aspherical curvature and thickness was essential.

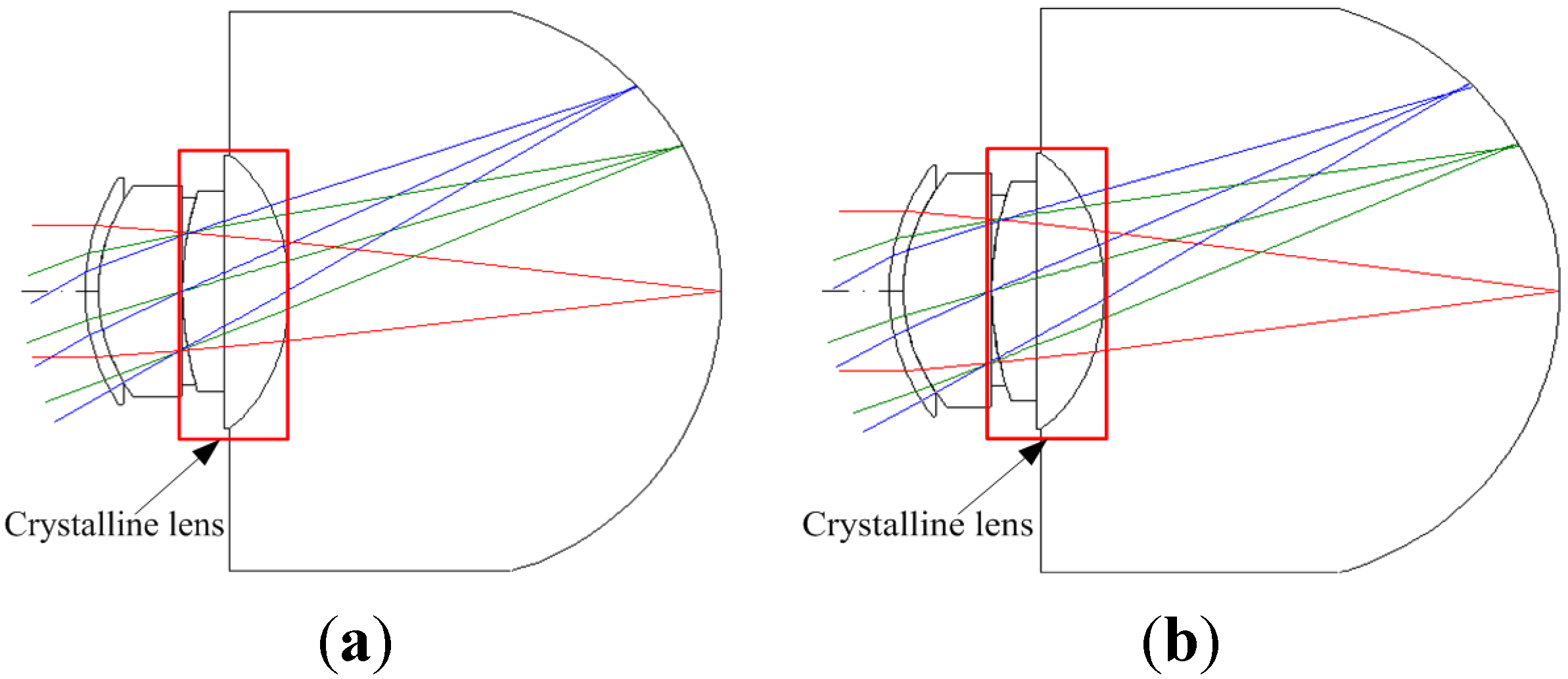

Table 1 lists the initial specifications of the crystalline lens of the human eye in the IOL design. The human eye crystalline lens two-dimensional (2D) layout is show in

Figure 1.

Table 1.

Initial specifications of the crystalline lens of the human eye.

Table 1.

Initial specifications of the crystalline lens of the human eye.

| Initial Conditions of Design |

|---|

| Anterior radius of the crystalline lens | 0 mm |

| Posterior radius of the crystalline lens | 0.0806 mm |

| Anterior thickness of the crystalline lens | 1.59 mm |

| Posterior thickness of the crystalline lens | 2.43 mm |

Figure 1.

Two-dimensional (2D) layout diagram of the initial crystalline lens [

17]. (

a) 5 mm; (

b) 6 mm.

Figure 1.

Two-dimensional (2D) layout diagram of the initial crystalline lens [

17]. (

a) 5 mm; (

b) 6 mm.

The effect of higher-order aberrations such as spherical aberration (SA) and tangential coma (TCO) on human vision depends mainly on the size of the pupil. Usually, it is about 5–6 mm around the pupil size of the human eye. Pupil size is larger at night than during the day because of more nearly the amount of incident light is needed in the dark environment. Large pupil size induces large amount of incident light into eye, it will therefore produce glare effect and enlarge spot size. The research currently takes the entrance pupil of 5 mm and 6 mm to analyze the effects in different pupil sizes of human eye.

The spot size is the root mean square (RMS) radius of the faculae’s radial dimension. By first obtaining the square distance between each light ray and the reference point, the mean value of all light rays can be obtained. Finally, the RMS is calculated as the distance between the section (

) and the reference point (

) of each critical light ray on the image plane. The formula for calculating the RMS is as follows:

In the formula,

n is the total number of light rays. A higher number of light rays results in a more accurate RMS radius. If all faculae are situated within the airy disk, the light energy is more centralized, and this optical system is close to the diffraction limit.

Table 2 presents the third-order aberrations and RMS of the initial human eye model.

Table 2.

Third-order aberrations in the initial human eye model. SA: spherical aberration; TCO: tangential coma; RMS: root mean square.

Table 2.

Third-order aberrations in the initial human eye model. SA: spherical aberration; TCO: tangential coma; RMS: root mean square.

| | Aberration | SA | TCO | RMS |

|---|

| Pupil Size | |

|---|

| 5 mm | −0.016148 | −0.033068 | 0.005315 |

| 6 mm | −0.027904 | −0.047618 | 0.01264 |

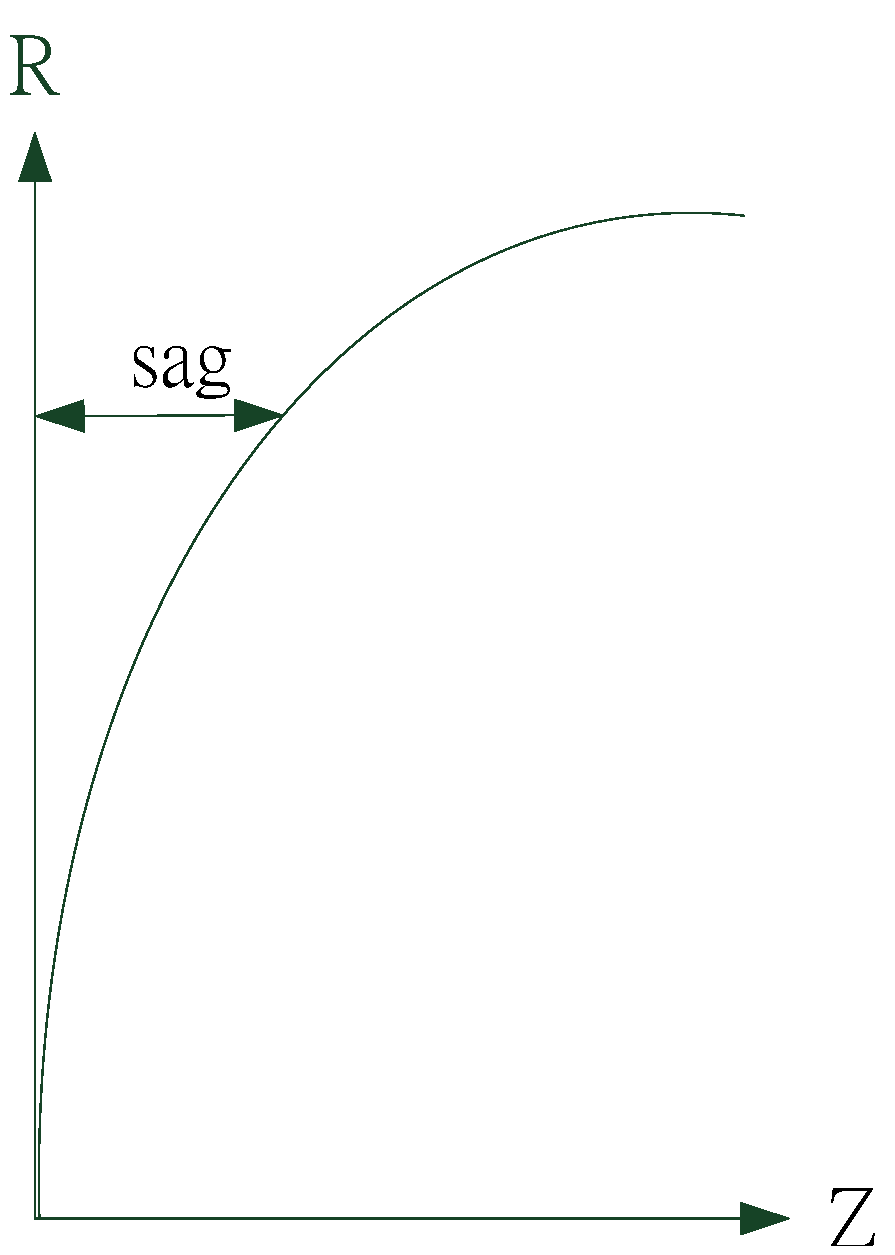

In this study, in the aspherical mathematical description, we neglected the higher-order aspherical coefficients; the formula can be written in the conic form presented in Equation (2). Thus, learned addition aspherical coefficient, which can change the radius of curvature and obtain the results of aspherical patterns. In this program, we modified the curvature of the lens to improve human eye lesions.

Here, Z represents lens sag (i.e., the rotational symmetry axis of aspherical), R is the radius of curvature of the vertex, X denotes the rotational symmetry axis of aspherical, and K represents the conic coefficient.

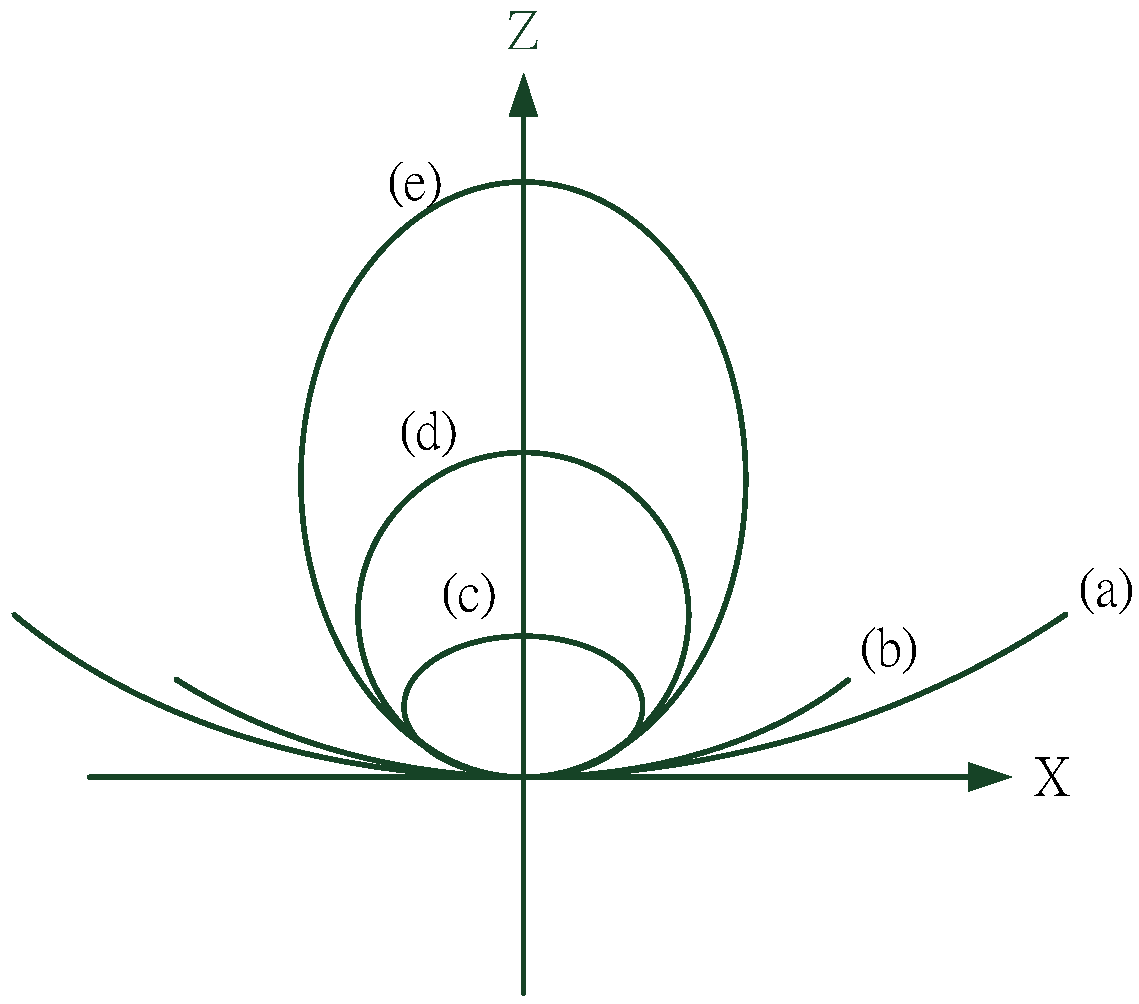

Figure 2 shows a schematic of the aspherical, and

Figure 3 presents a schematic of the conic section.

Figure 2.

Schematic of aspherical.

Figure 2.

Schematic of aspherical.

Figure 3.

Conic curve. (a) K < −1; (b) K = 1; (c) K > 1; (d) K = 0; (e) −1 < K < 0.

Figure 3.

Conic curve. (a) K < −1; (b) K = 1; (c) K > 1; (d) K = 0; (e) −1 < K < 0.

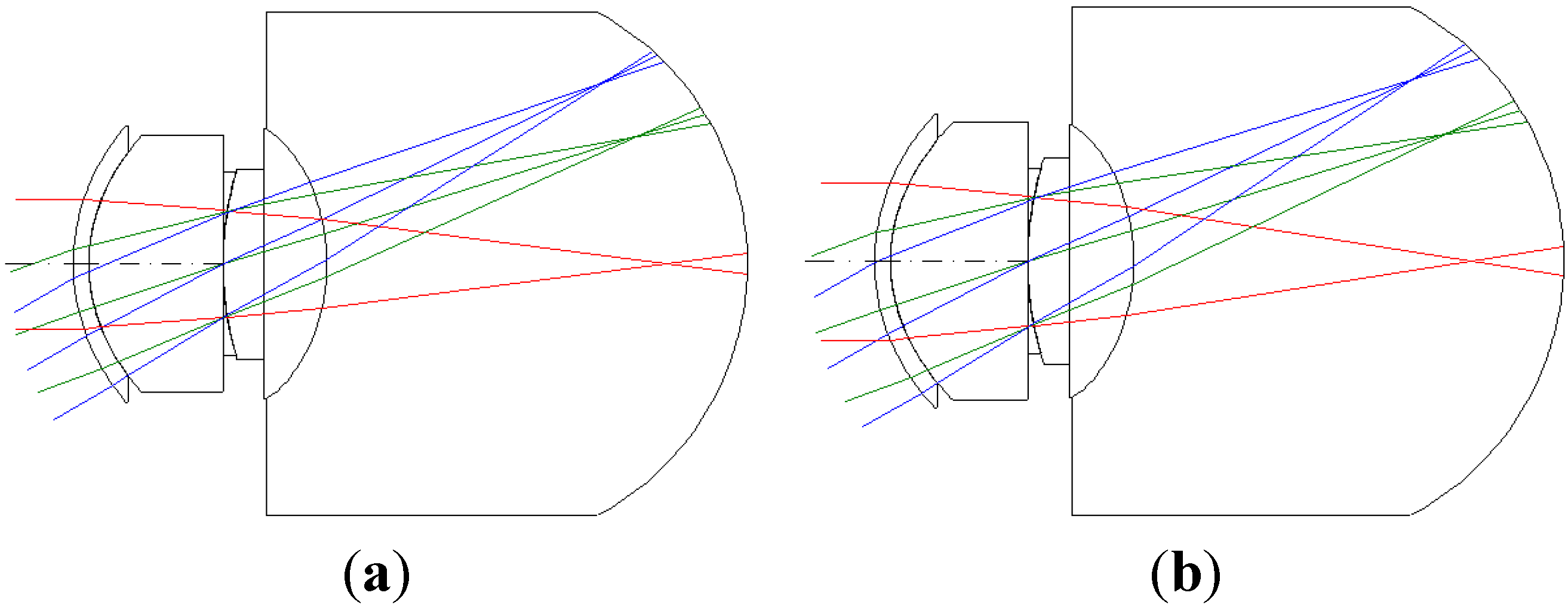

We chose polymethyl methacrylate as the IOL material. This study is expected to assist optical designers in further optimizing the IOL (in this study, myopia is 550 degrees myopia and 175 degrees astigmatism) after normal optimization by using current optical design software for achieving the theoretical maximum performance. For optical design purposes, we mainly calculated the parameters of the myopic and astigmatic states by first calculating the corneal lens and then the lens of the humor, as shown in

Figure 4.

Figure 4.

The 2D layout illustrating 550 degrees myopia and 175 degrees astigmatism. (a) 5 mm; (b) 6 mm.

Figure 4.

The 2D layout illustrating 550 degrees myopia and 175 degrees astigmatism. (a) 5 mm; (b) 6 mm.

The myopic and astigmatic effects are calculated using Equations (3) and (4) [

18]:

where

M and

N are parameters related to myopia and astigmatism, respectively. We then calculated the design parameters of the corneal surface and the surface of the humor to express the states of myopia and astigmatism.

Table 3 reports the third-order aberrations of an imperfect human eye with myopia and astigmatism.

Table 3.

Third-order aberrations for 550 degrees myopia and 175 degrees astigmatism.

Table 3.

Third-order aberrations for 550 degrees myopia and 175 degrees astigmatism.

| | Aberration | SA | TCO | RMS |

|---|

| Pupil Size | |

|---|

| 5 mm | −0.073302 | −0.052464 | 0.537989 |

| 6 mm | −0.126666 | −0.075548 | 0.698584 |

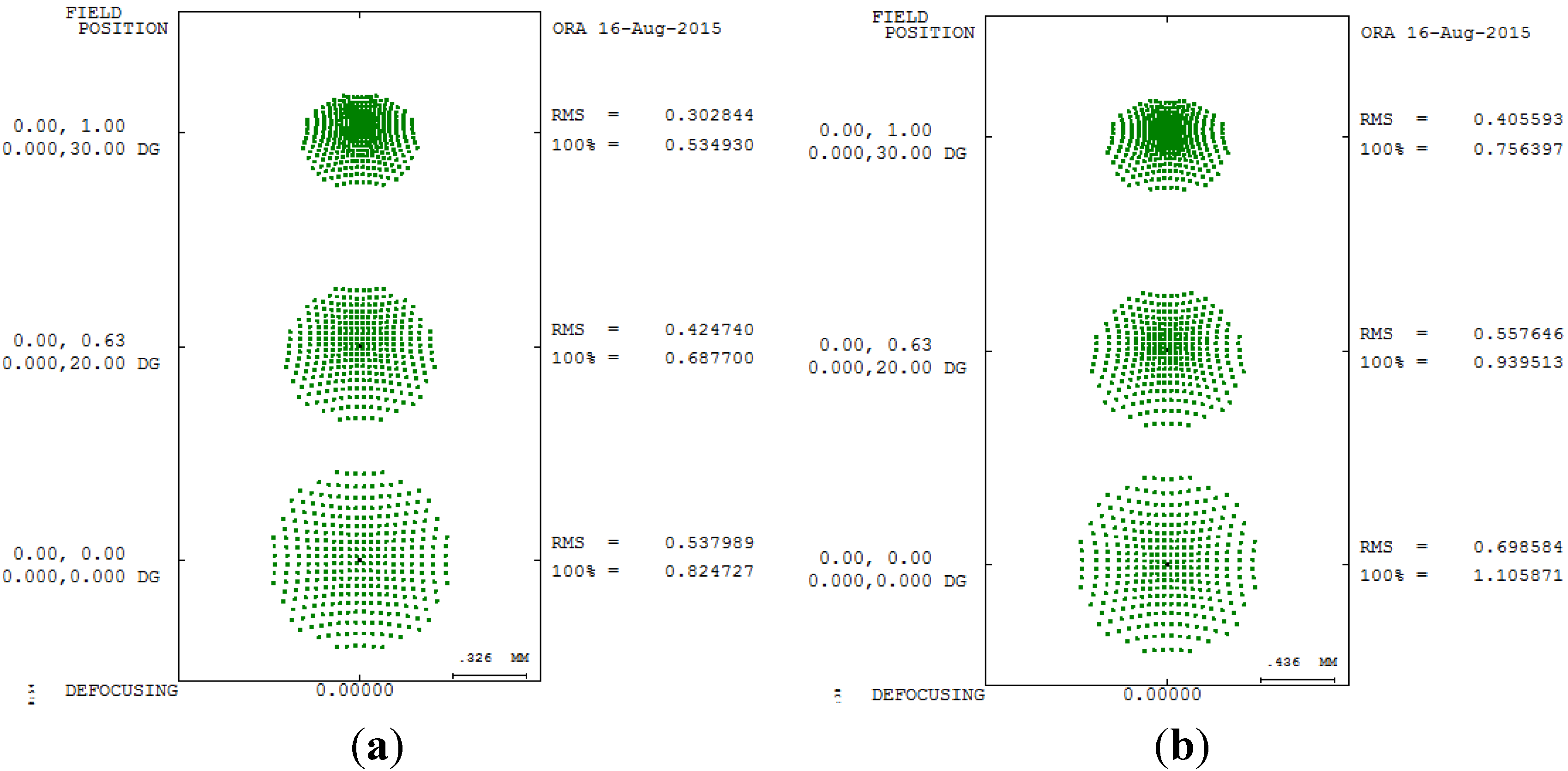

The distribution of energy can be determined through spot size analysis of the focus point, and the spot size is mainly determined using the radial root mean square.

Figure 5 shows the spot size analysis of 550 degrees myopia and 175 degrees astigmatism in different pupil sizes.

Figure 5.

Spot size diagram of 550 degrees myopia and 175 degrees astigmatism. (a) 5 mm; (b) 6 mm.

Figure 5.

Spot size diagram of 550 degrees myopia and 175 degrees astigmatism. (a) 5 mm; (b) 6 mm.

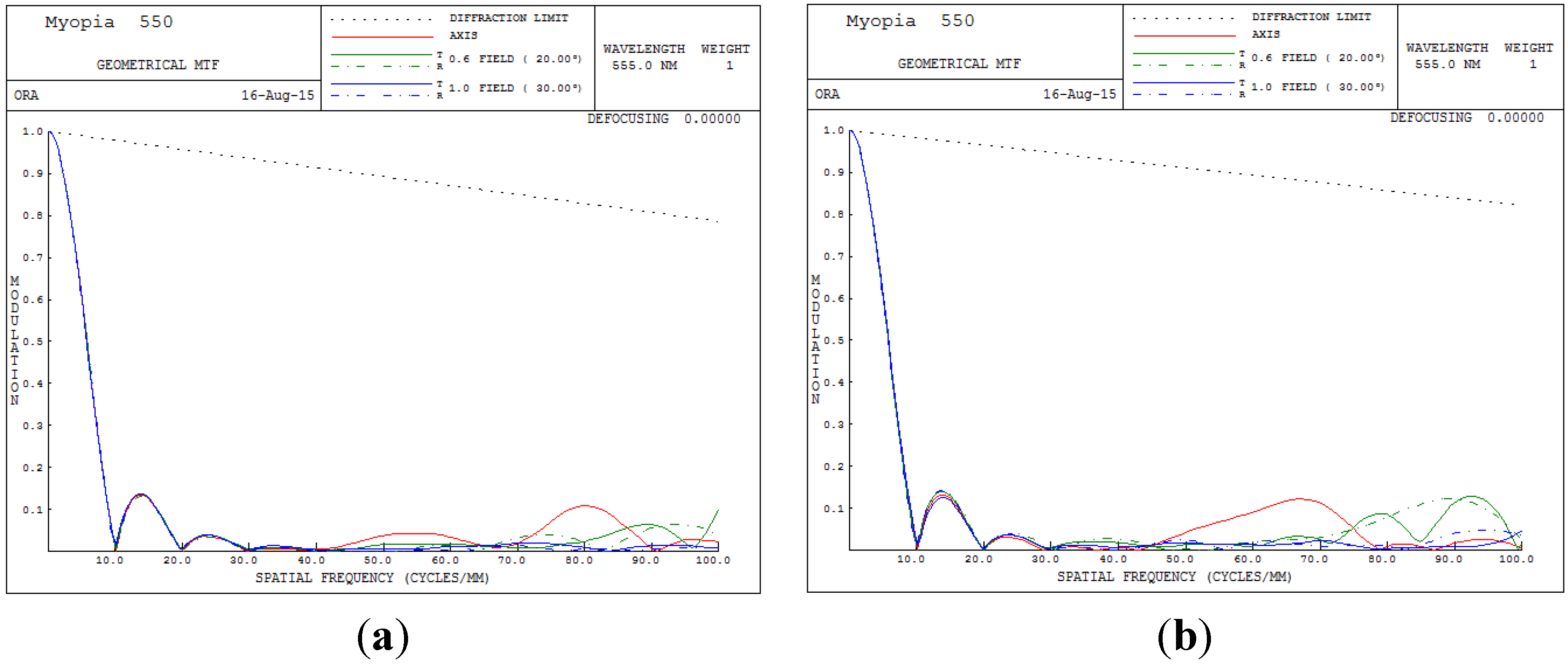

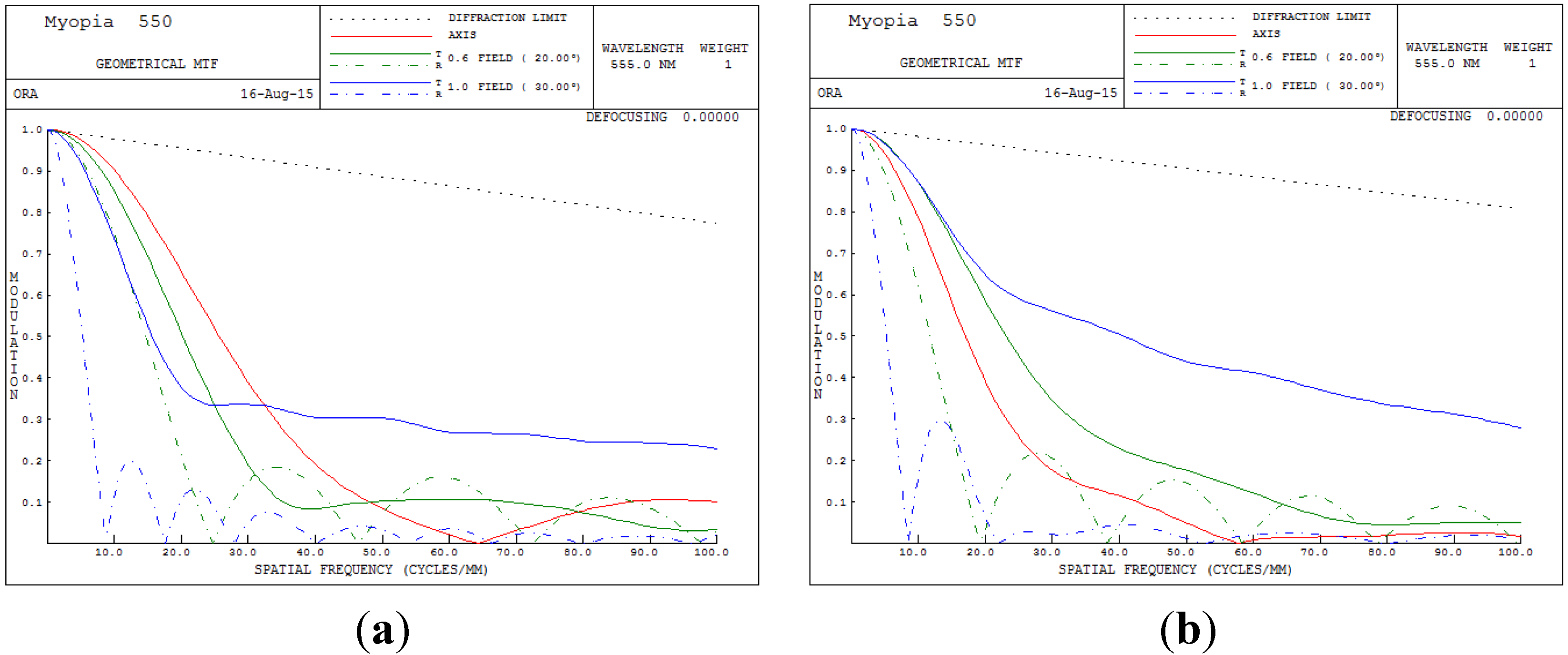

The overall clarity of images in the optical system can be judged from the MTF performance. The higher the MTF value for all spatial frequencies, the higher is the achievable image performance.

Figure 6 presents the MTF plot for the human eye conditions of 550 degrees myopia and 175 degrees astigmatism. In

Figure 6, the image quality clearly becomes unacceptable when the spatial frequency exceeds 8 cycles/mm.

The lens parameters of

Figure 4 after CODE V and GA optimizations are listed in

Table 4,

Table 5,

Table 6 and

Table 7 for different pupil sizes, respectively. The surface numbers listed in

Table 4,

Table 5,

Table 6 and

Table 7 are according to 2D layout of

Figure 4. The surface number (surface #) listed in

Table 4,

Table 5,

Table 6 and

Table 7 are according to 2D layout of

Figure 4 of each lens location from left to right, for example, the surface #Object is the object plane of

Figure 4, the surface #1 is the first lens of

Figure 4, the surface #2 is the second lens of

Figure 4, the surface #Stop is the third lens of

Figure 4, the surface #4 is the fourth lens of

Figure 4,

etc. and the surface #Image is the last lens of

Figure 4.

Figure 6.

Modulation transfer function (MTF) plot for 550 degrees myopia and 175 degrees astigmatism. (a) 5 mm; (b) 6 mm.

Figure 6.

Modulation transfer function (MTF) plot for 550 degrees myopia and 175 degrees astigmatism. (a) 5 mm; (b) 6 mm.

Table 4.

The lens parameter after CODE V optimization for pupil size 5 mm.

Table 4.

The lens parameter after CODE V optimization for pupil size 5 mm.

| Surface# | Surface Type | Y Radius | Thickness | Glass | Refract Mode | Y Semi-Aperture |

|---|

| #Object | Sphere | 0 | Infinity | - | Refract | - |

| #1 | Conic | 0.1287 | 0.6 | “cornea” | Refract | 4.6712 |

| #2 | Conic | 0.1563 | 5.195 | “humor” | Refract | 4.3066 |

| #Stop | Sphere | 0 | 0 | “humor” | Refract | 3 |

| #4 | Conic | 0.0707 | 0.0915 | ACRYLIC_SPECIAL | Refract | 2.0413 |

| #5 | Sphere | 0 | 1.2623 | ACRYLIC_SPECIAL | Refract | 2.2640 |

| #6 | Conic | −0.0853 | 16.27 | “humor” | Refract | 2.6105 |

| #Image | Sphere | −0.0909 | 0 | “humor” | Refract | 7.7009 |

Table 5.

The lens parameter after proposed genetic algorithm (GA) optimization for pupil size 5 mm.

Table 5.

The lens parameter after proposed genetic algorithm (GA) optimization for pupil size 5 mm.

| Surface# | Surface Type | Y Radius | Thickness | Glass | Refract Mode | Y Semi-Aperture |

|---|

| #Object | Sphere | 0 | Infinity | - | Refract | - |

| #1 | Conic | 0.1287 | 0.6 | “cornea” | Refract | 4.6712 |

| #2 | Conic | 0.1563 | 5.195 | “humor” | Refract | 4.3066 |

| #Stop | Sphere | 0 | 0 | “humor” | Refract | 3 |

| #4 | Conic | 0.0755 | 0.9283 | ACRYLIC_SPECIAL | Refract | 2.0408 |

| #5 | Sphere | 0 | 1.0016 | ACRYLIC_SPECIAL | Refract | 2.2688 |

| #6 | Conic | −0.0849 | 16.27 | “humor” | Refract | 2.5282 |

| #Image | Sphere | −0.0909 | 0 | “humor” | Refract | 7.6499 |

Table 6.

The lens parameter after CODE V optimization for pupil size 6 mm.

Table 6.

The lens parameter after CODE V optimization for pupil size 6 mm.

| Surface# | Surface Type | Y Radius | Thickness | Glass | Refract Mode | Y Semi-Aperture |

|---|

| #Object | Sphere | 0 | Infinity | - | Refract | - |

| #1 | Conic | 0.1287 | 0.6 | “cornea” | Refract | 4.6712 |

| #2 | Conic | 0.1563 | 5.195 | “humor” | Refract | 4.3066 |

| #Stop | Sphere | 0 | 0 | “humor” | Refract | 3 |

| #4 | Conic | 0.0819 | 0.9763 | ACRYLIC_SPECIAL | Refract | 2.0413 |

| #5 | Sphere | 0 | 1.2627 | ACRYLIC_SPECIAL | Refract | 2.2640 |

| #6 | Conic | −0.0702 | 16.27 | “humor” | Refract | 2.6105 |

| #Image | Sphere | −0.0909 | 0 | “humor” | Refract | 7.7009 |

Table 7.

The lens parameter after proposed GA optimization for pupil size 6 mm.

Table 7.

The lens parameter after proposed GA optimization for pupil size 6 mm.

| Surface# | Surface Type | Y Radius | Thickness | Glass | Refract Mode | Y Semi-Aperture |

|---|

| #Object | Sphere | 0 | Infinity | - | Refract | - |

| #1 | Conic | 0.1287 | 0.6 | “cornea” | Refract | 4.6712 |

| #2 | Conic | 0.1563 | 5.195 | “humor” | Refract | 4.3066 |

| #Stop | Sphere | 0 | 0 | “humor” | Refract | 3 |

| #4 | Conic | 0.0791 | 1.1739 | ACRYLIC_SPECIAL | Refract | 2.0408 |

| #5 | Sphere | 0 | 1.1021 | ACRYLIC_SPECIAL | Refract | 2.2688 |

| #6 | Conic | −0.0723 | 16.27 | “humor” | Refract | 2.5282 |

| #Image | Sphere | −0.0909 | 0 | “humor” | Refract | 7.6499 |

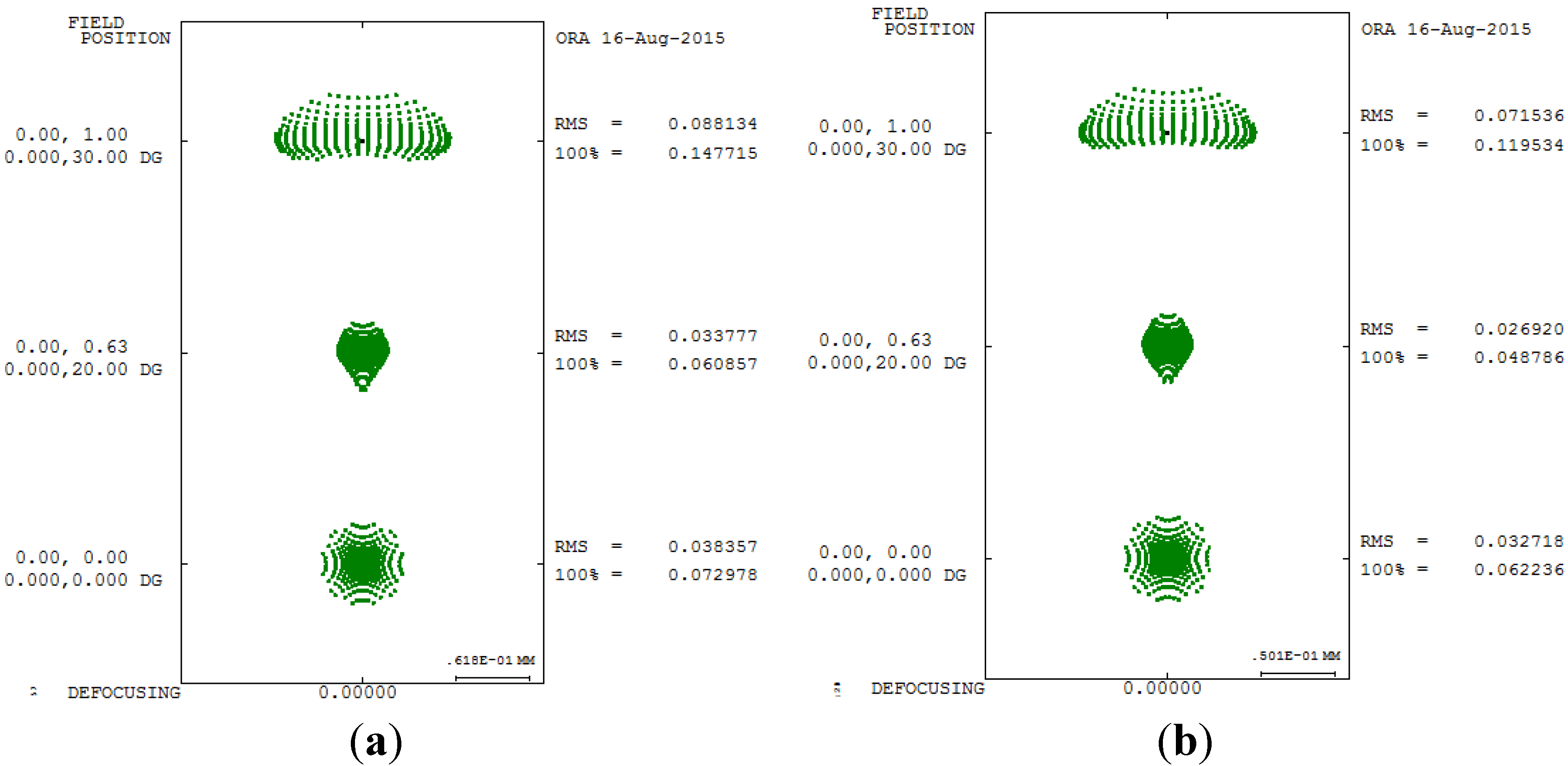

The third-order aberration results after correcting the 550 degrees myopia and 175 degrees astigmatism by using the built-in optimization method in CODE V is reported in

Table 8.

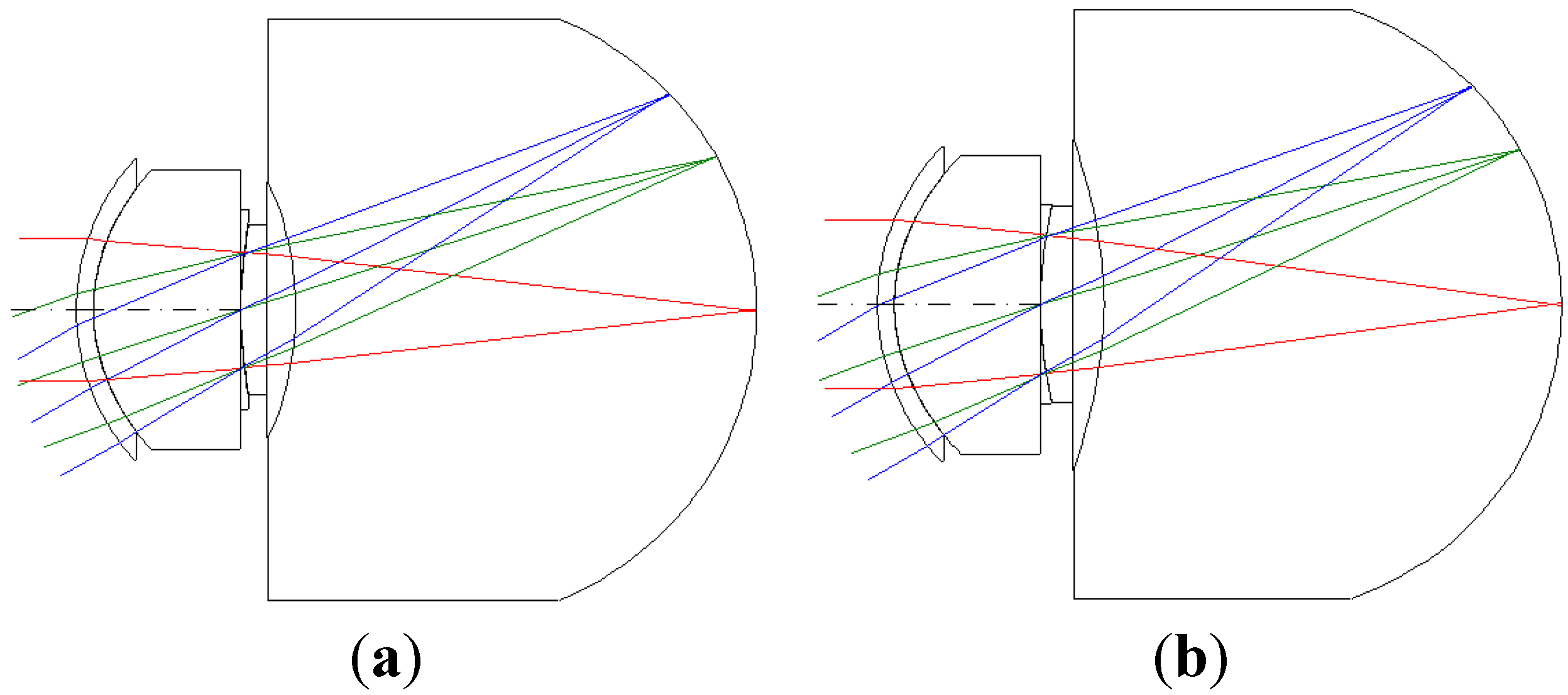

Figure 7 shows a 2D layout obtained after applying the built-in optimization method.

Figure 7 shows the imperfect focusing points on a retina.

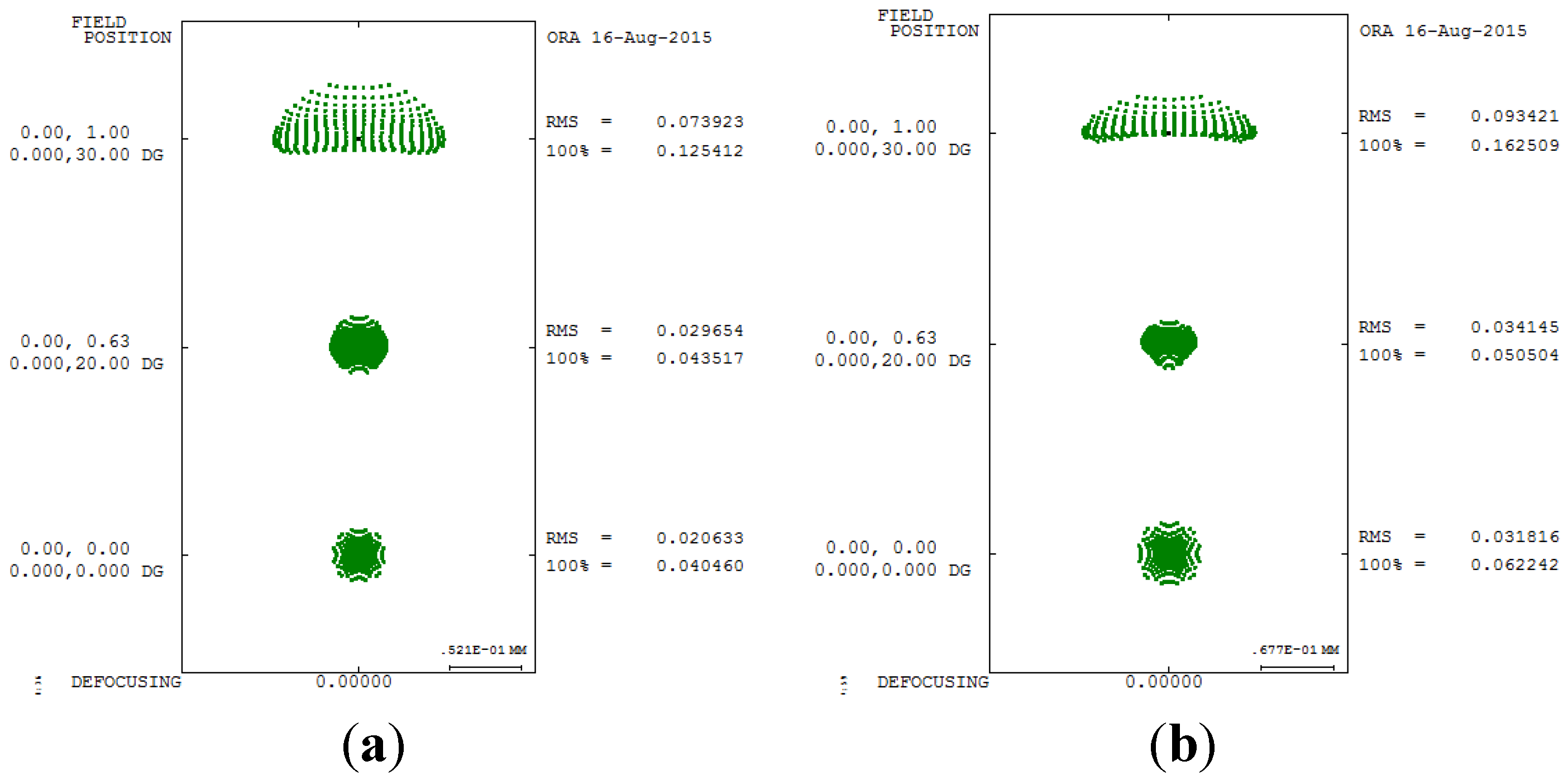

Figure 8 and

Figure 9 show the spot size diagram and MTF performance after applying the built-in optimization method, respectively. In

Figure 8, the spot size plot is denser than in

Figure 5 for the imperfect human eye state, implying that the built-in optimization method reduced aberrations. Moreover, the MTF values also increased as shown in

Figure 9, indicating clearer human eye vision.

Table 8.

Third-order aberrations after applying the built-in optimization method in CODE V.

Table 8.

Third-order aberrations after applying the built-in optimization method in CODE V.

| | Aberration | SA | TCO | RMS |

|---|

| Pupil Size | |

|---|

| 5 mm | 0.01 | −0.0162 | 0.032718 |

| 6 mm | 0.01 | −0.01781 | 0.038357 |

Figure 7.

The 2D layout after applying the built-in optimization method in CODE V. (a) 5 mm; (b) 6 mm.

Figure 7.

The 2D layout after applying the built-in optimization method in CODE V. (a) 5 mm; (b) 6 mm.

Figure 8.

Spot size diagram after applying the built-in optimization method in CODE V. (a) 5 mm; (b) 6 mm.

Figure 8.

Spot size diagram after applying the built-in optimization method in CODE V. (a) 5 mm; (b) 6 mm.

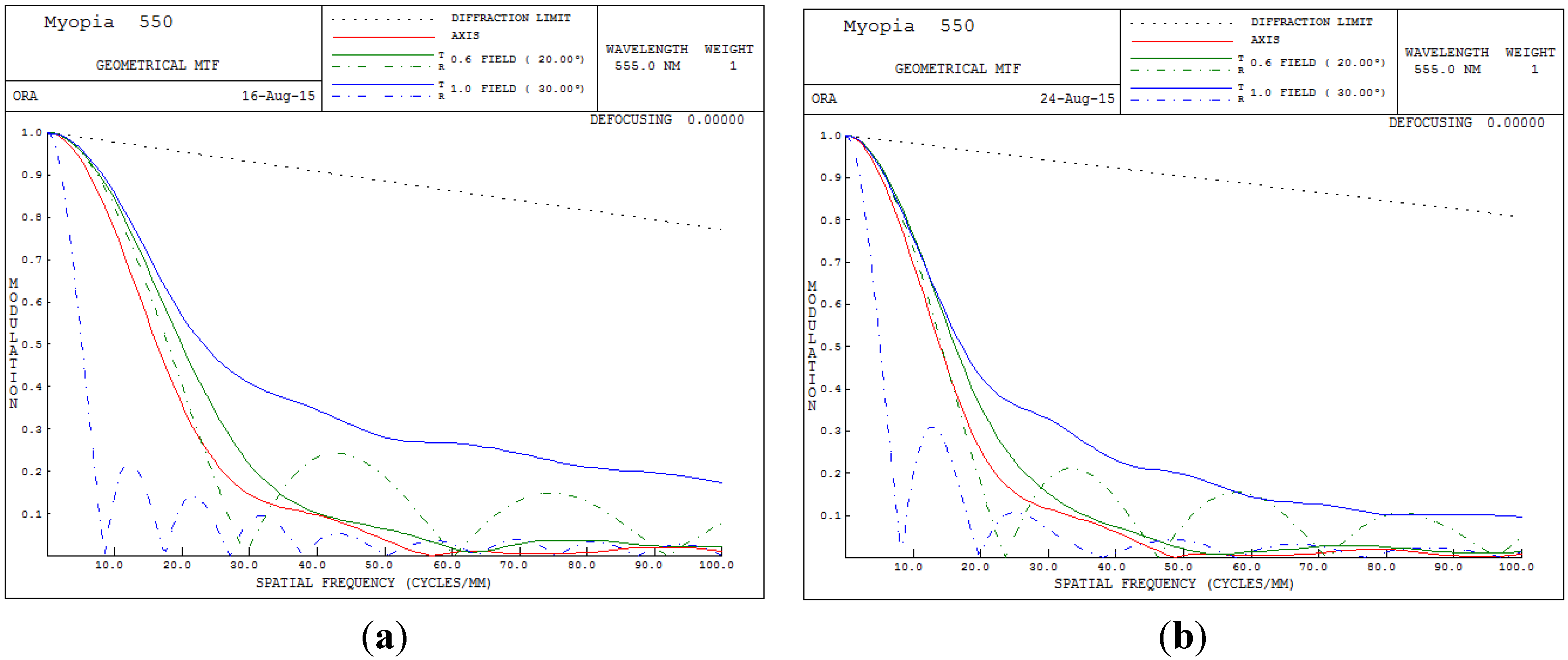

Figure 9.

MTF plot after applying the built-in optimization method in CODE V. (a) 5 mm; (b) 6 mm.

Figure 9.

MTF plot after applying the built-in optimization method in CODE V. (a) 5 mm; (b) 6 mm.

3.2. Principle of Genetic Algorithm

In

Table 3 and

Figure 9, we can see that the built-in optimization of SA yielded good results; however, the optimization method for the TCO, RMS and MTF do not perform very well. Hence, a GA was used to overcome this problem and achieve a balanced optimization for the TCO, RMS and MTF performance.

The concept of GA is derived from Darwin’s concept of evolution, that is, the theory of natural selection, which postulates survival of the fittest. The less fit are eliminated because the reproduction process, the resilience of individual organisms is relatively easy to find a good mate with each other to reproduce the next generation through after a long evolution, and finally will make the organism can adapt to the environment given to stable growth conditions. Some scholars have observed such changes in order to adapt to the environment and natural phenomena, simulate biological evolution between children raised on the best application engineering [

19,

20,

21].

The GA technique is applied to the optical design of the artificial IOL. The advantages of integrating the GA optimization process with the optical design are the obtention of the overall physical artificial crystal focusing function and higher flexibility. Use this way to match and change data, that achieving superior outcomes to those of the CODE V built-in function. Simulation results showed that not only was the state of the SA reduced but the TCO, MTF, and spot size also improved effectively, leading to the accurate focusing of light on the retina. However, the third-order aberration of SA worsens, because the optical design always involves a tradeoff between all aberrations. The IOL design mainly involves designing the curvature and thickness to improve the vision quality. Therefore, the chromosomes were the curvature and thickness, which randomly generated a new curvature and thickness gene according to the ethnic population. A calculated process used the fitness function to determine the good vision qualities for facilitating the subsequent crossover and mutation mechanisms. The fitness function used in the proposal is defined as:

where

and

are the weights,

pop_size is the population size and the roulette wheel method is applied to the selection operation. The whole area of the wheel is one. Each lens system based on the fitness probability is assigned an area in the wheel, that is:

where the

fitmax and

fitmin are the maximum and minimum values of

fin(

i).

According to Equation (6), the fitness probability of the lens system chosen to implement crossover operation is:

and:

the cumulative probability of the wheel is:

A random number α between 0 and 1 is generated for running the selection operation. We would select the genes of the ith lens system if

q(

i − 1) < α ≤

q(

i). Two genes parameters of lens systems are selected to implement the crossover operation. Let the two selected genes parameters be

X = (

x1,

x2,…,

x2) and

Y = (

y1,

y2,…,

y2). The offspring of these two parents is the sequence

Z = (

z1,

z2,…,

z2) and its crossover genes are defined by:

where β is a random number between 0 and 1. Following the selection and crossover operations, the better genes would be the ones that propagate the next generation lens system. However, the creatures in the real world evolve their genes to fit their environment better. A mutation probability

pm is defined and a random number between 0 and 1 is generated in the GA process. The mutation operation is implemented when α >

pm. The mutation operation used in the proposal is defined as:

where Δ is a constraint to prevent the result from being divergent. β is a random number between 0 and 1. The GA process is to implement the selection, crossover and mutation operations. The DLS method is added to the GA process to enhance the optimization result.

The merit function of current optical software focuses on reducing the image spot size, making high image resolution or an attractive MTF result. The other weightings from w1 to w2 are assigned the values all of 1. The population size, generation, crossover rate, and mutation rate are set to 100, 70, 0.8 and 0.2 respectively in running the optimization.

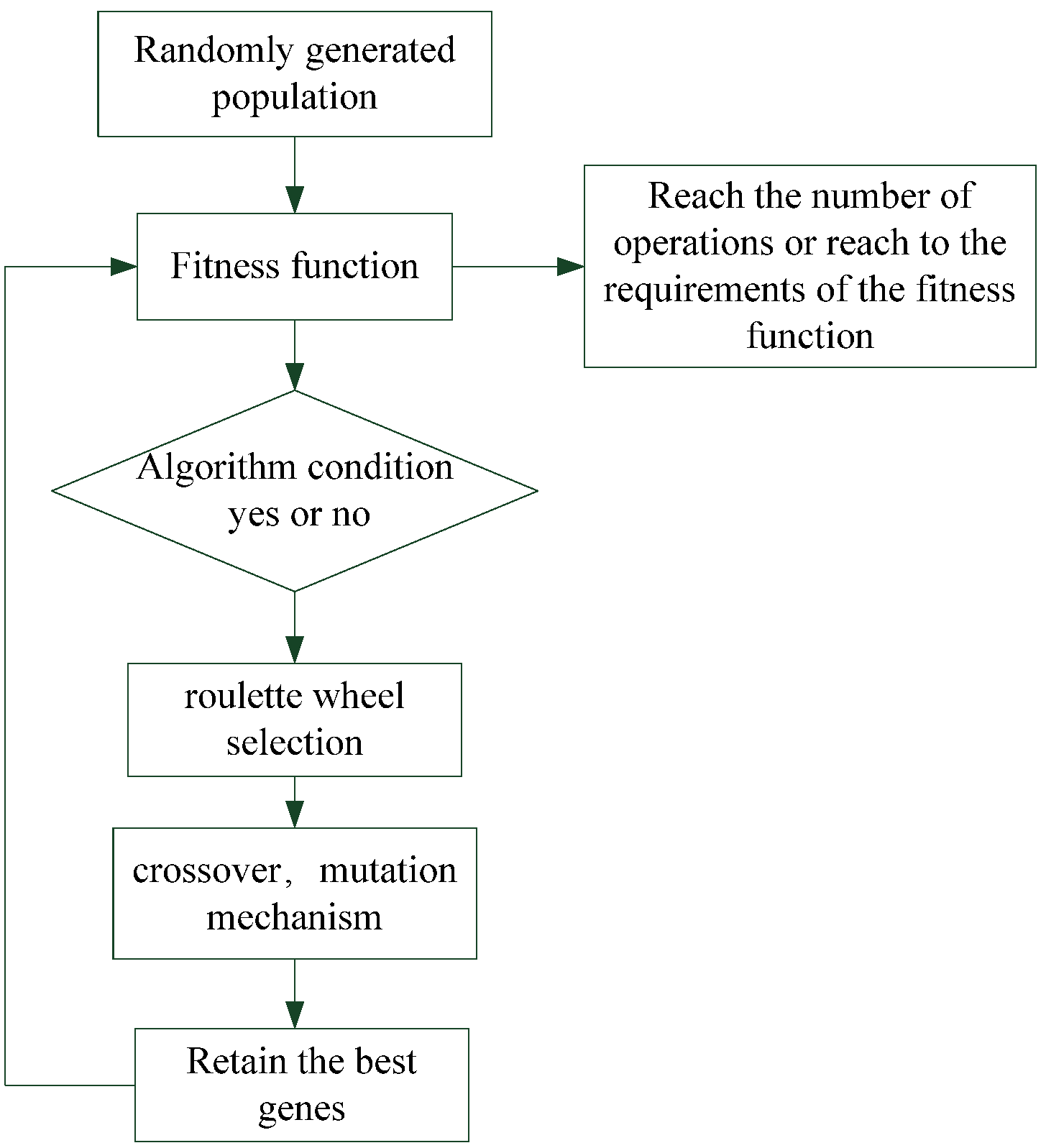

Finally, after crossover and mutation, the resulting chromosomes’ parameters are substituted into CODE V for designing an IOL. The flow chart of the GA is shown in

Figure 10.

Figure 10.

Flowchart of the genetic algorithm (GA) used in the intraocular lens (IOL) design.

Figure 10.

Flowchart of the genetic algorithm (GA) used in the intraocular lens (IOL) design.

The 2D layout and third-order aberrations obtained after correcting the vision for 550 degrees myopia and 175 degrees astigmatism by using the proposed GA optimization method are as presented in

Figure 11 and

Table 9. Comparing the built-in optimization of CODE V (

Figure 7) and the proposed GA optimization method (

Figure 11), we can see that the proposed GA method provides a better focusing point on the retina.

Figure 11.

The 2D diagram after applying the GA optimization method. (a) 5 mm; (b) 6 mm.

Figure 11.

The 2D diagram after applying the GA optimization method. (a) 5 mm; (b) 6 mm.

Table 9.

Third-order aberrations after applying the GA optimization method.

Table 9.

Third-order aberrations after applying the GA optimization method.

| | Aberration | SA | TCO | RMS |

|---|

| Pupil Size | |

|---|

| 5 mm | 0.032994 | −0.011763 | 0.020633 |

| 6 mm | 0.014618 | −0.010201 | 0.031816 |

The improvement rate “

D” of the built-in optimization method and the proposed GA method can be calculated using:

where

Y is the third-order aberration value after applying the built-in optimization method, and

X is the third-order aberration after applying the proposed GA optimization method.

Table 10 and

Table 11 presents the improvement rate proposed GA method of third-order aberrations for the 550 degrees myopia and 175 degrees astigmatism states for different pupil sizes. A comparison of the spot diagrams in

Figure 8 and

Figure 12 shows a smaller spot size in the proposed GA method, implying that the proposed GA method yields better geometry for aberrations. A comparison of

Figure 9 and

Figure 13 shows higher MTF curves for the proposed GA method, confirming that a higher vision resolution can be achieved using the proposed GA optimization method.

Table 10.

Improvement rate of third-order aberrations after applying the proposed GA optimization method for pupil size 5 mm.

Table 10.

Improvement rate of third-order aberrations after applying the proposed GA optimization method for pupil size 5 mm.

| Quality Characteristics | SA | TCO |

|---|

| 550 degrees myopia and 175 degrees astigmatism condition | −0.073302 | −0.052464 |

| GA optimization | 0.032994 | −0.011763 |

| Difference values | 0.040308 | 0.040701 |

| Improvement rate (%) | 53.98% | 77.57% |

Table 11.

Improvement rate of third-order aberrations after applying the proposed GA optimization method for pupil size 6 mm.

Table 11.

Improvement rate of third-order aberrations after applying the proposed GA optimization method for pupil size 6 mm.

| Quality Characteristics | SA | TCO |

|---|

| 550 degrees myopia and 175 degrees astigmatism condition | −0.126666 | −0.075548 |

| GA optimization | 0.014618 | −0.010201 |

| Difference values | 0.112048 | 0.065347 |

| Improvement rate (%) | 88.45% | 86.49% |

Figure 12.

Spot size diagram after applying the GA optimization method. (a) 5 mm; (b) 6 mm.

Figure 12.

Spot size diagram after applying the GA optimization method. (a) 5 mm; (b) 6 mm.

Figure 13.

MTF plot obtained after applying the GA optimization method. (a) 5 mm; (b) 6 mm.

Figure 13.

MTF plot obtained after applying the GA optimization method. (a) 5 mm; (b) 6 mm.

Table 12 and

Table 13 list the improvement rates of the built-in and proposed optimization methods for 550 degrees myopia and 175 degrees astigmatism. Although the SA correction by the proposed optimization method is worse than that by the built-in optimization method, the crucial aberrations, TCO and RMS, in the human eye for pupil size 6 mm are improved by approximately 43% and 17%, respectively.

From optical design perspectives, MTF values represent the entire image contrast and sharpness and have a contrast range of 0 to 1. Generally, images cannot be analyzed after optical design when the MTF value is nearly 0. To determine the ideal image quality of the human eye vision, the MTF must be higher than 0.5 when the spatial frequency is 6, and the MTF must be approximately higher than 0.3 when the spatial frequency is 15.

Table 12.

Comparisons of third-order aberrations of the built-in and proposed optimization methods for 550 degrees myopia and 175 degrees astigmatism for pupil size 5 mm.

Table 12.

Comparisons of third-order aberrations of the built-in and proposed optimization methods for 550 degrees myopia and 175 degrees astigmatism for pupil size 5 mm.

| Quality Characteristics | SA | TCO | RMS |

|---|

| CODE V optimization | 0.01 | −0.016200 | 0.032718 |

| GA optimization | 0.032994 | −0.011763 | 0.020633 |

| Difference values | 0.022 | 0.004437 | 0.012 |

| Improvement rate (%) | −229% | 27.38% | 36.93% |

Table 13.

Comparisons of third-order aberrations of the CODE V built-in and proposed optimization methods for 550 degrees myopia and 175 degrees astigmatism for pupil size 6 mm.

Table 13.

Comparisons of third-order aberrations of the CODE V built-in and proposed optimization methods for 550 degrees myopia and 175 degrees astigmatism for pupil size 6 mm.

| Quality Characteristics | SA | TCO | RMS |

|---|

| CODE V optimization | 0.01 | −0.01781 | 0.038357 |

| GA optimization | 0.014618 | −0.010201 | 0.031816 |

| Difference values | 0.004618 | 0.007609 | 0.006541 |

| Improvement rate (%) | −46.18% | 42.72% | 17.05% |

Figure 6,

Figure 9 and

Figure 13 show MTF plots for the different myopic and astigmatic states for different pupil sizes.

Figure 6 plots the myopia and astigmatism conditions of the human eye, and the MTF values at different spatial frequencies do not exceed 0.1; hence, human vision becomes unacceptable.

Figure 9b shows the MTF plot after applying the built-in optimization method for pupil size 6 mm; the MTF value is 0.695 when the spatial frequency is 10. However, when the spatial frequency reaches 30, the MTF value rapidly drops below 0.115, implying that the image quality of the human eye worsens. In conclusion, the built-in method in CODE V is workable and satisfies all MTF conditions.

Figure 13b shows the MTF plot for the proposed GA optimization method for pupil size 6 mm; the proposed MTF values are 0.783 and 0.177 when the spatial frequencies are 10 and 30 cycles/degree, respectively, implying that the proposed GA design method is workable and really improves human vision.

Table 14 and

Table 15 show the MTF values and improvement rate for different simulation conditions and at spatial frequencies of 10, 20 and 30 lp/mm.

Table 14.

Modulation transfer function (MTF) values for pupil size 5 mm.

Table 14.

Modulation transfer function (MTF) values for pupil size 5 mm.

| Optimal State | 10 lp/mm | 20 lp/mm | 30 lp/mm |

|---|

| Myopic and astigmatism | 0.003 | 0.001 | 0 |

| Internal CODE V | 0.768 | 0.356 | 0.145 |

| GA | 0.901 | 0.657 | 0.389 |

| Improvement rate(%) | 14.76% | 45.81% | 62.72% |

Table 15.

MTF values for pupil size 6 mm.

Table 15.

MTF values for pupil size 6 mm.

| Optimal State | 10 lp/mm | 20 lp/mm | 30 lp/mm |

|---|

| Myopic and astigmatism | 0.005 | 0 | 0.007 |

| Internal CODE V | 0.695 | 0.253 | 0.115 |

| GA | 0.783 | 0.391 | 0.177 |

| Improvement rate(%) | 11.23% | 35.29% | 35.02% |