Properties of Foamed Mortar Prepared with Granulated Blast-Furnace Slag

Abstract

:1. Introduction

2. Experimental Work

2.1. Materials

| Chemical Constituents(%) | Cement | Slag |

|---|---|---|

| SiO2 | 21.1 | 32.5 |

| Al2O3 | 5.2 | 13.8 |

| Fe2O3 | 3.1 | 0.2 |

| CaO | 64.4 | 42.9 |

| MgO | 1.1 | 5.8 |

| SO3 | 2.5 | - |

| Na2O | 0.2 | - |

| K2O | 0.6 | - |

| P2O2 | <0.9 | - |

| Carbon content | - | - |

| Physical Properties | - | - |

| Specific gravity | 3.2 | 2.9 |

| Fineness (% passing 45 μm) | 93.0 | 100 |

2.2. Mix Compositions

2.3. Specimens Preparation

| Series 1: Initial laboratory trials | ||||||

| Mix details | c/s (in kg/m3) | Cement: slag (in kg/m3) | * Foam volume (L/m3) | w/c | Curing condition | Examine properties |

| ILT-0.54 | 1 (500:500) | 1:0 (500:0) | 550 | 0.54 | Water | 1. Fresh state properties (table flow spread and self-compacting slump spread) 2. Compressive strength |

| ILT-0.56 | 523 | 0.56 | ||||

| ILT-0.58 | 502 | 0.58 | ||||

| ILT-0.60 | 480 | 0.60 | ||||

| ILT-0.62 | 465 | 0.62 | ||||

| ILT-0.64 | 448 | 0.64 | ||||

| Series 2: Investigation on the effect of slag and curing conditions | ||||||

| Mix details | c/s (in kg/m3) | Cement: slag (in kg/m3) | Foam volume (L/m3) | w/c | Curing condition | Examine properties |

| CFM-A | 1 (500:500) | 1:0 (500:0) | 518 | 0.56 | 28 Air | 1. Compressive strength 2. Ultrasonic pulse velocity 3. Thermal conductivity |

| CFM-NW | 7 Water + 21 Air | |||||

| CFM-W+A | 28 NW | |||||

| CFM-W+NW | 7 Water + 21 NW | |||||

| SFM-A | 0.5:0.5 (250:250) | 512 | 28 Air | |||

| SFM-NW | 7 Water + 21 Air | |||||

| SFM-W+A | 28 NW | |||||

| SFM-W+NW | 7 Water + 21 NW | |||||

- (i)

- Twenty eight days of air curing in the laboratory with the constant range 30 °C ± 2 °C and an average relative humidity of 65%.

- (ii)

- Seven days of initial water curing at a constant temperature of 26 °C ± 2 °C plus 21 days of air curing.

- (iii)

- Twenty eight days of natural weathering outside the laboratory with the temperature ranging from 26 °C to 36 °C with relative humidity ranging from 65% to 90%.

- (iv)

- Seven days of initial water curing at a constant temperature of 26 °C ± 2 °C plus 21 days of natural weathering.

2.4. Testing Methods

2.4.1. Fresh State Properties

2.4.2. Compressive Strength

2.4.3. Ultrasonic Pulse Velocity

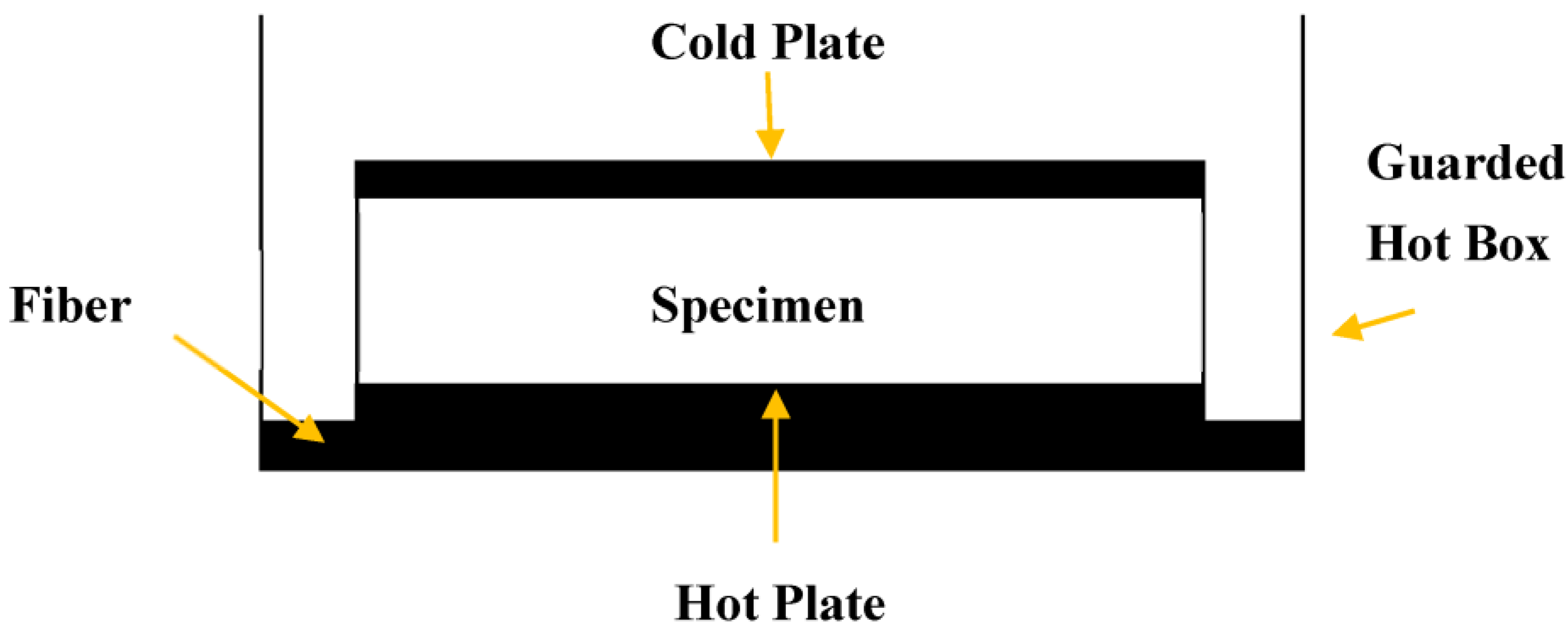

2.4.4. Thermal Conductivity

3. Results and Discussion

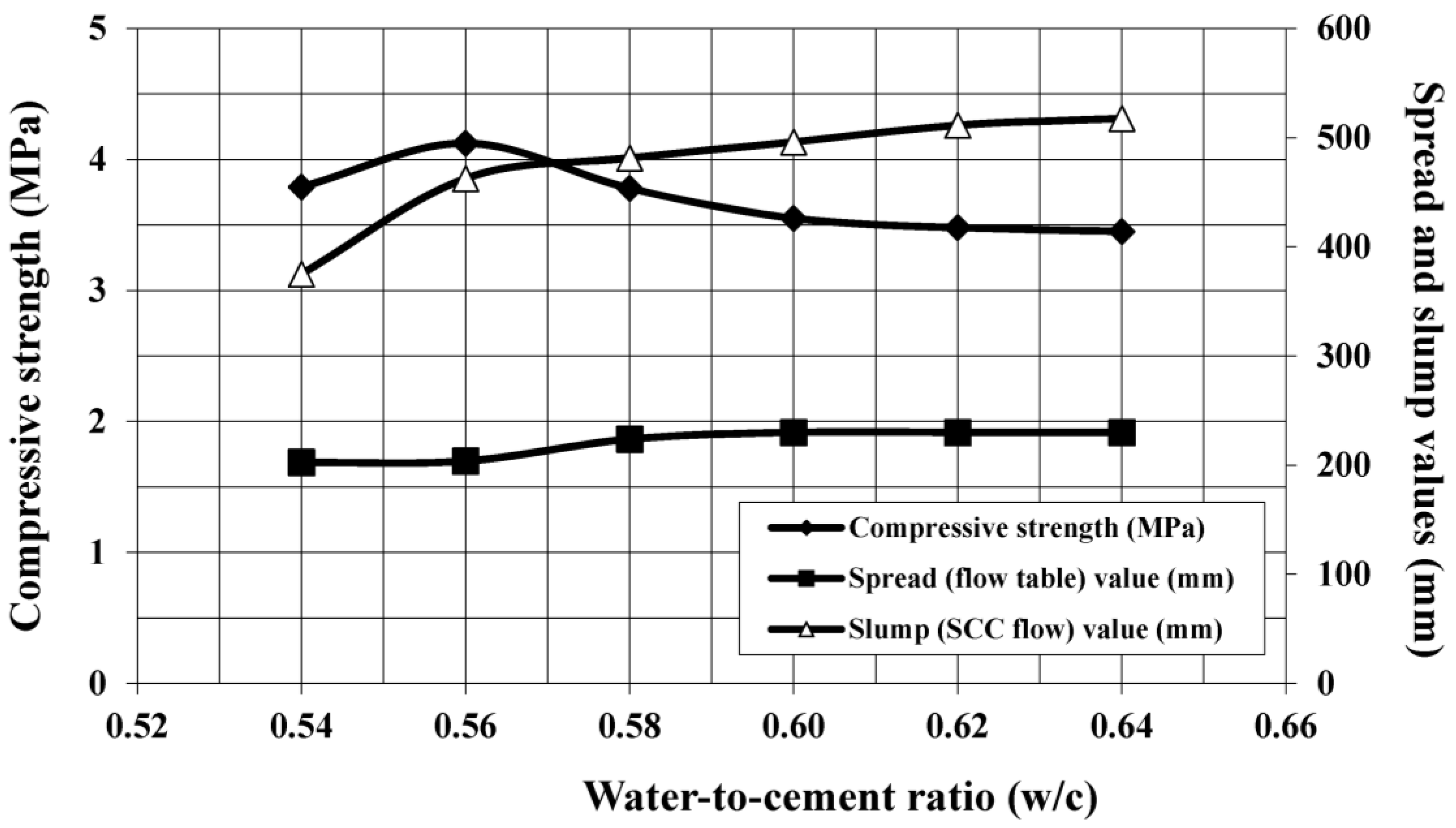

3.1. Initial Trial (Series 1)

3.2. Foamed Mortar with 0.56 w/c (Series 2)

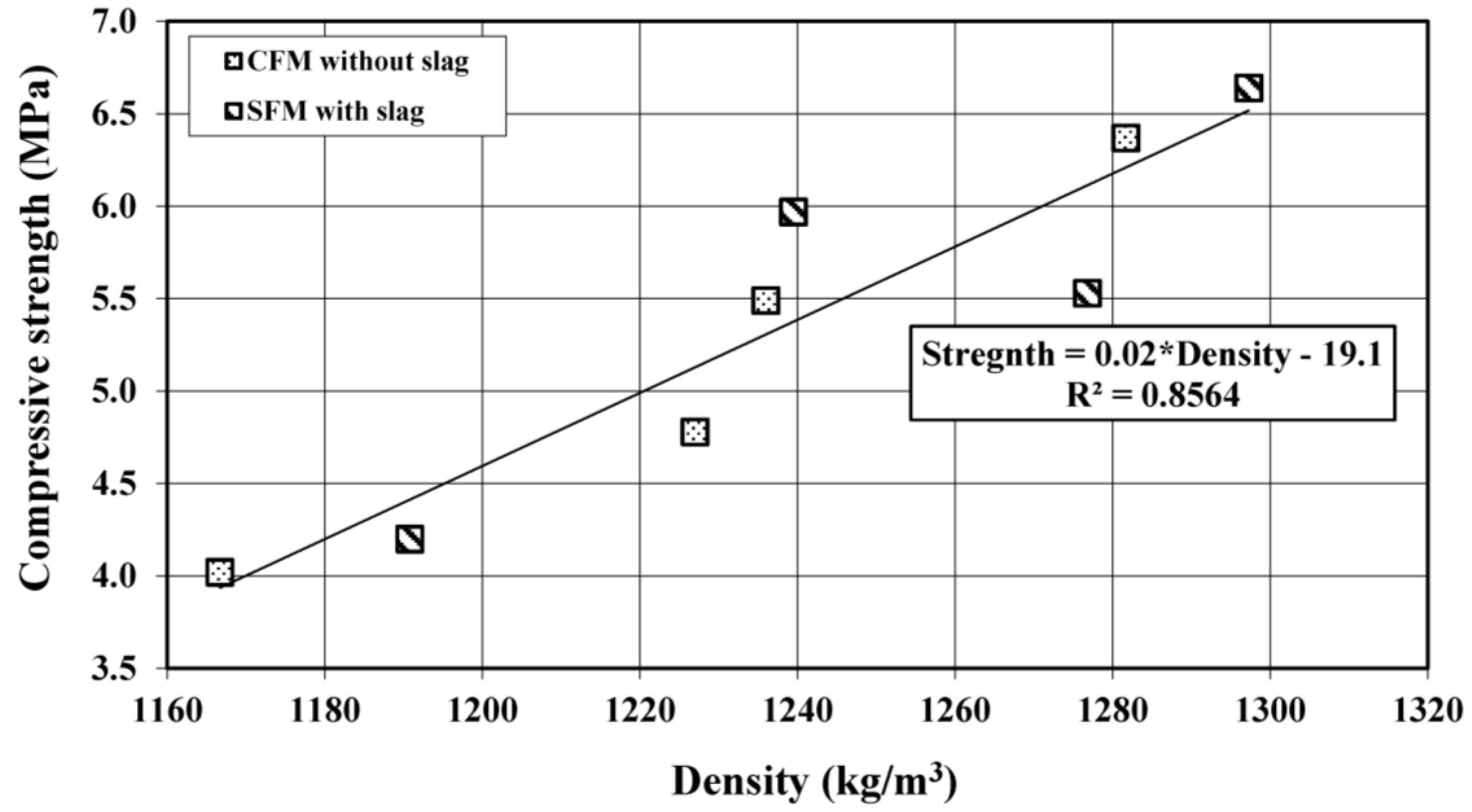

3.2.1. Compressive Strength

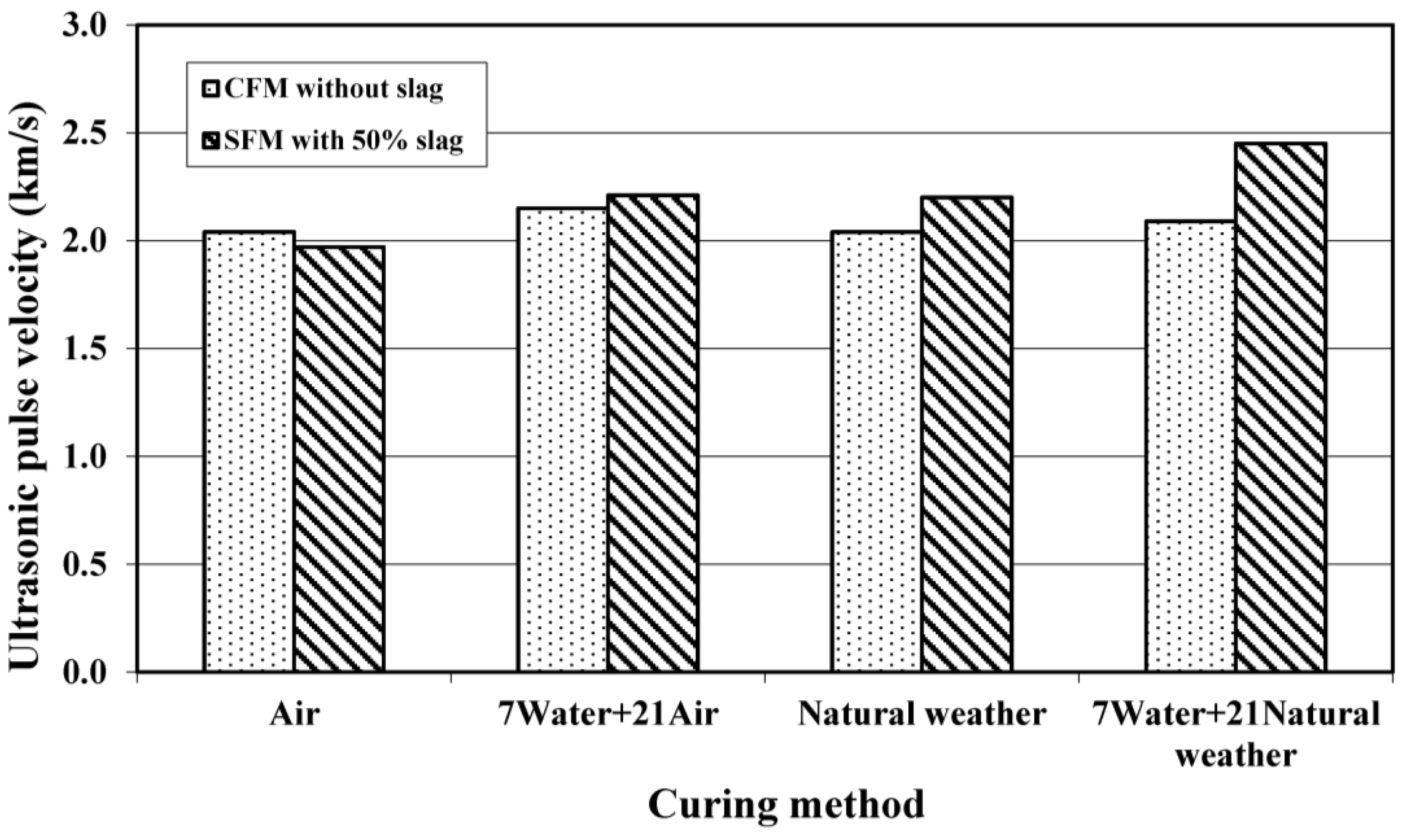

3.2.2. Ultrasonic Pulse Velocity

3.2.3. Thermal Conductivity

3.3. Further Discussion on the Effects of Curing Conditions

4. Conclusions

- The flowability of foamed mortar increased with increasing w/c ratio. However, a w/c ratio of 0.56 provided the highest compressive strength within the tested w/c ratios, ranging from 0.54 to 0.64.

- The use of 50% slag as cement replacement in foamed mortar improved the compressive strength and ultrasonic pulse velocity as well as thermal insulation properties. The relationship between the 28-day compressive strength and density yielded under different curing conditions of foamed mortars are proposed that can be used to predict strength within the tested density range.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ramamurthy, K.; Nambiar, E.K.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of high fly ash content on the compressive strength of foamed concrete. Cem. Concr. Res. 2001, 31, 105–112. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Preliminary views on the potential of foamed concrete as a structural material. Mag. Concr. Res. 2005, 57, 21–31. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. Ash content for optimum strength of foamed concrete. Cem. Concr. Res. 2002, 32, 241–246. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Influence of filler type on the properties of foam concrete. Cem. Concr. Res. 2006, 28, 475–480. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Heat of hydration in foamed concrete: Effect of mix constituents and plastic density. Cem. Concr. Res. 2006, 36, 1032–1041. [Google Scholar] [CrossRef]

- Yang, K.-H.; Lee, K.-H.; Song, J.-K.; Gong, M.-H. Properties and sustainability of alkali-activated slag foamed concrete. J. Clean. Produc. 2014, 68, 226–233. [Google Scholar] [CrossRef]

- Gesoglu, M.; Ozbay, E. Effects of mineral admixtures on fresh and hardened properties of self-compacting concrete: Binary, ternary and quaternary systems. Mater. Struct. 2007, 40, 923–937. [Google Scholar] [CrossRef]

- Standard Specification of Portland Cement; American Society of Testing and Materials: Washington, DC, USA, 2007; ASTM C150.

- Standard Test Method for Flow of Hydraulic Cement Mortar; American Society of Testing and Materials: Washington, DC, USA, 2007; ASTM C1437.

- Standard Test Method for Slump Flow of Self Consolidating Concrete; American Society of Testing and Materials: Washington, DC, USA, 2005; ASTM C1611.

- Methods of Testing Mortars, Screeds and Plasters; British Standards Institutions: London, UK, 1980; BS 4551.

- Testing Concrete: Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete; British Standards Institutions: London, UK, 1980; BS1881-203.

- Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods: Dry and Moist Product of Medium and Low Thermal Resistance; British Standards Institutions: London, UK, 2001; BS EN 12664.

- Durack, J.M.; Weiqing, L. The properties of foamed air cured fly ash based concrete for masonry production. In Proceedings of the 5th Australasian Masonry Conference, Gladstone, Queensland, Australia, 1–3 July 1998; pp. 129–138.

- Lim, S.K.; Hussin, M.W.; Zakaria, F.; Ling, T.C. GGBFS as potential filler in polyester grout: Flexural strength and toughness. Constr. Build. Mater. 2009, 23, 2007–2015. [Google Scholar] [CrossRef]

- Lim, S.K.; Ling, T.C.; Hussin, M.W. Ground-granulated blast-furnace slag as potential filler in polyester grout: Compressive strength development. ACI Mater. J. 2011, 108, 120–127. [Google Scholar]

- Standard Specification for Nonloadbearing Concrete Masonry Units; American Society of Testing and Materials: Washington, DC, USA, 2006; ASTM C129.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Lim, S.-K.; Tan, C.-S.; Li, B.; Ling, T.-C.; Huang, R.; Wang, Q. Properties of Foamed Mortar Prepared with Granulated Blast-Furnace Slag. Materials 2015, 8, 462-473. https://doi.org/10.3390/ma8020462

Zhao X, Lim S-K, Tan C-S, Li B, Ling T-C, Huang R, Wang Q. Properties of Foamed Mortar Prepared with Granulated Blast-Furnace Slag. Materials. 2015; 8(2):462-473. https://doi.org/10.3390/ma8020462

Chicago/Turabian StyleZhao, Xiao, Siong-Kang Lim, Cher-Siang Tan, Bo Li, Tung-Chai Ling, Runqiu Huang, and Qingyuan Wang. 2015. "Properties of Foamed Mortar Prepared with Granulated Blast-Furnace Slag" Materials 8, no. 2: 462-473. https://doi.org/10.3390/ma8020462

APA StyleZhao, X., Lim, S.-K., Tan, C.-S., Li, B., Ling, T.-C., Huang, R., & Wang, Q. (2015). Properties of Foamed Mortar Prepared with Granulated Blast-Furnace Slag. Materials, 8(2), 462-473. https://doi.org/10.3390/ma8020462