Improvement of Bearing Capacity in Recycled Aggregates Suitable for Use as Unbound Road Sub-Base

Abstract

:1. Introduction

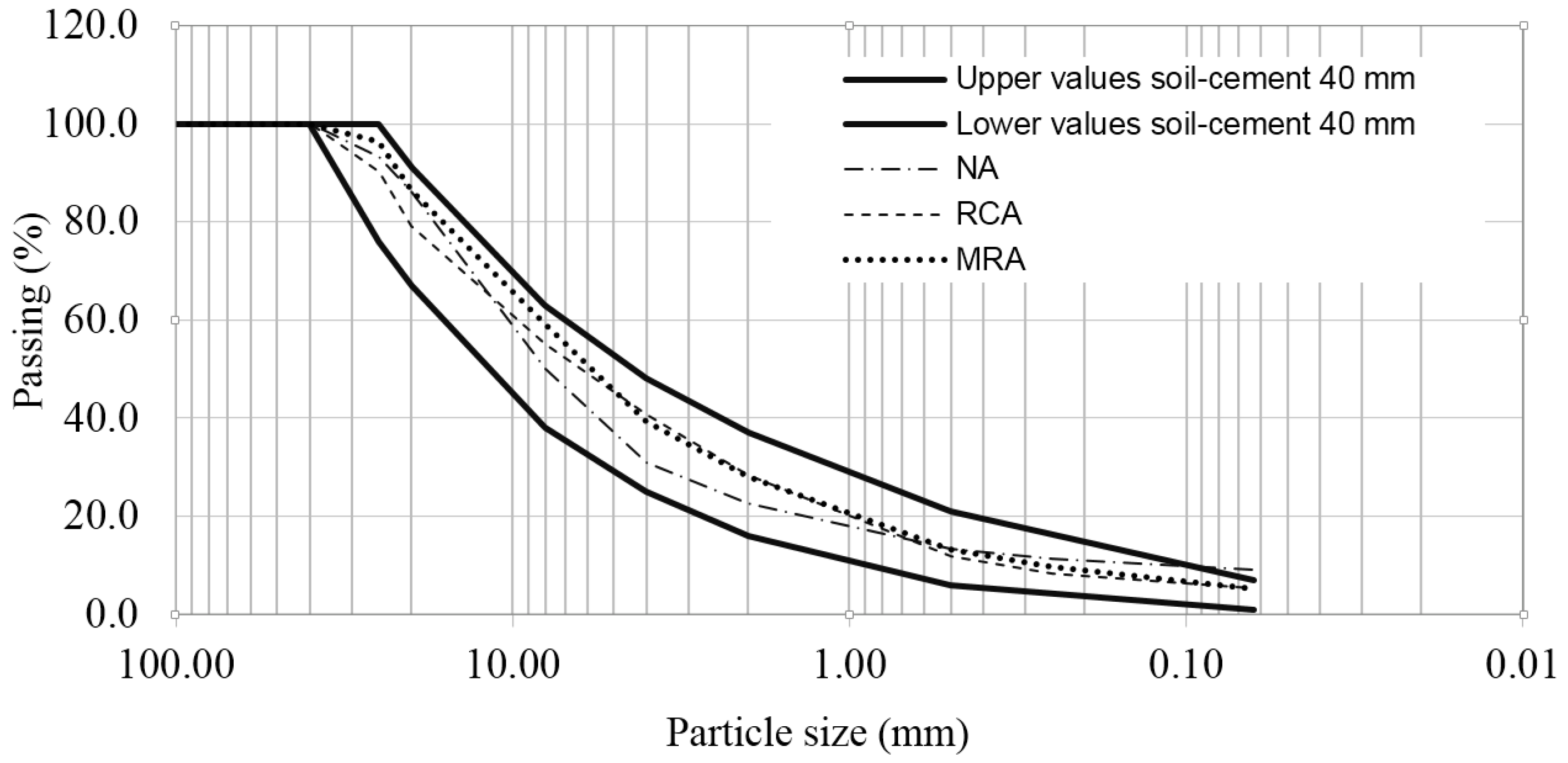

2. Materials

2.1. Natural Aggregates (NA)

| Properties | NA | RCA | MRA | Standard Established Limits |

|---|---|---|---|---|

| Density SSD (Mmg/m3) (0.063–4) (UNE-EN 1097-6:2001) | 2.77 | 2.68 | 2.54 | – |

| Density SSD (Mmg/m3) (4–31.5) (UNE-EN 1097-6:2001) | 2.76 | 2.63 | 2.47 | – |

| Water absorption (%) (0.063–4) (UNE-EN 1097-6:2001) | 1.96 | 2.45 | 5.83 | – |

| Water absorption (%) (4–31.5) (UNE-EN 1097-6:2001) | 0.54 | 2.37 | 5.01 | – |

| Nominal size (mm) | 25 | 25 | 25 | – |

| Sand Equivalent (UNE EN 933-8:2000) | 38 | 52 | 46 | T3 to T4: SE > 35 |

| L.A. abrasion value (%) (UNE EN 1097-2:1999) | 24.00 | 32.92 | 36.40 | T3 to T4: <35% * |

| Flakiness index (UNE EN 933-3:1997) | 13 | 5 | 13 | <35% |

| Acid-soluble sulphate (%SO3) (UNE 1744-1:1999) | 0.05 | 0.53 | 0.70 | 0.5%(c); <1%(d) |

| Organic matter (%) (UNE 103204:1993) | 0 | 0.75 | 0.43 | <1% |

2.2. Recycled Aggregates (RA): Recycled Concrete Aggregates (RCA) and Mixed Recycled Aggregates (MRA)

| Properties | RCA | MRA |

|---|---|---|

| Ra (%) (Asphalt) | 8.9 | 8.1 |

| Rb (%) (Ceramics) | 0.3 | 23.7 |

| Rc (%) (Concrete and mortar a) | 42.1 | 31.5 |

| Ru (Unbound aggregates b) | 48.5 | 36.5 |

| X1 (%) (Natural soil) | 0 | 0 |

| X2 (%) (Others) | <0.1 | <0.1 |

| X3 (%) (Gypsum) | <0.1 | <0.1 |

3. Experimental Tests

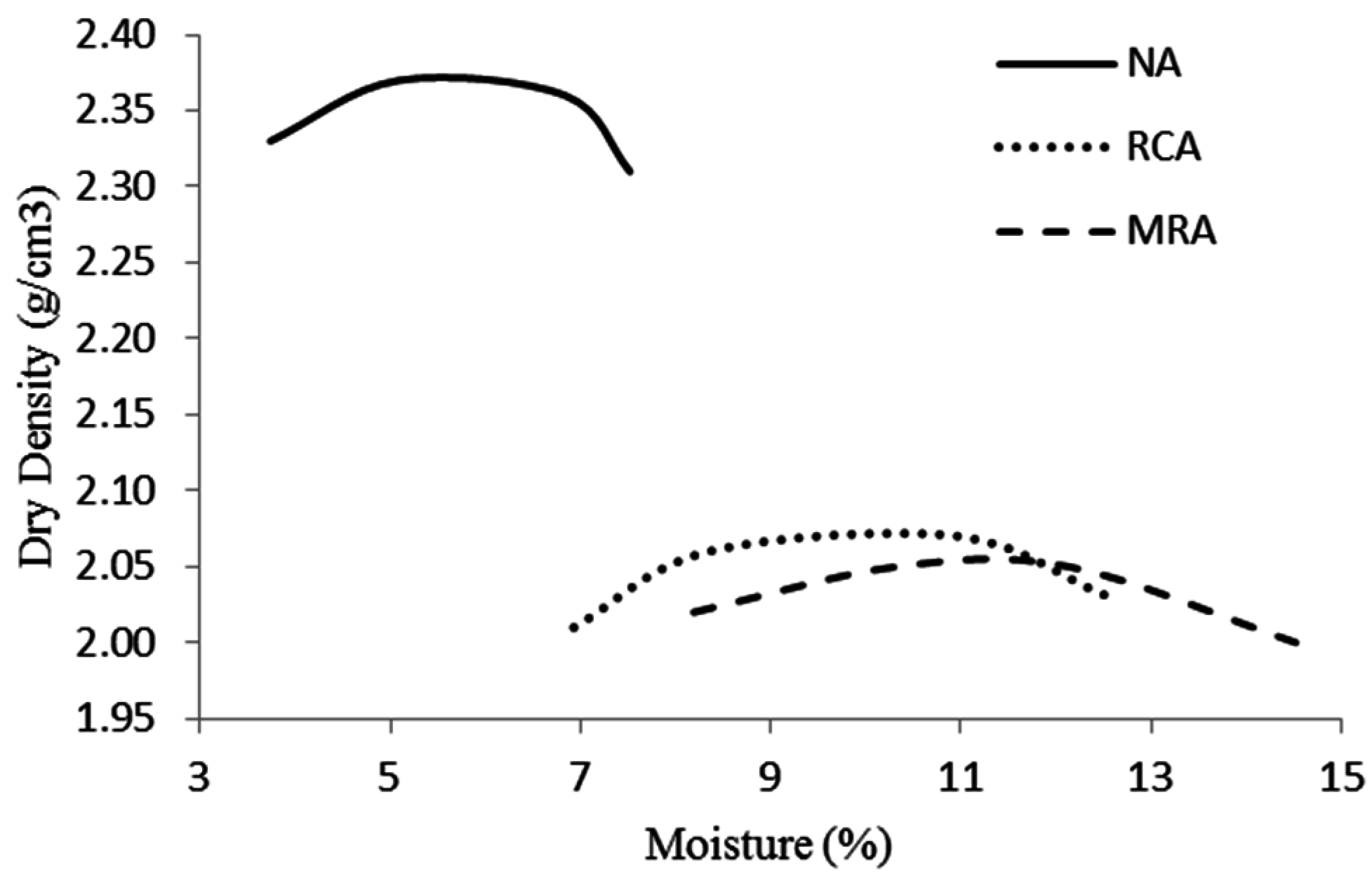

3.1. Modified Proctor Test

3.2. California Bearing Ratio (CBR) Standard Test

3.3. Accelerated Swelling Test for Soil Treated by Lime and/or Hydraulic Binder According to UNE-EN-13286-49

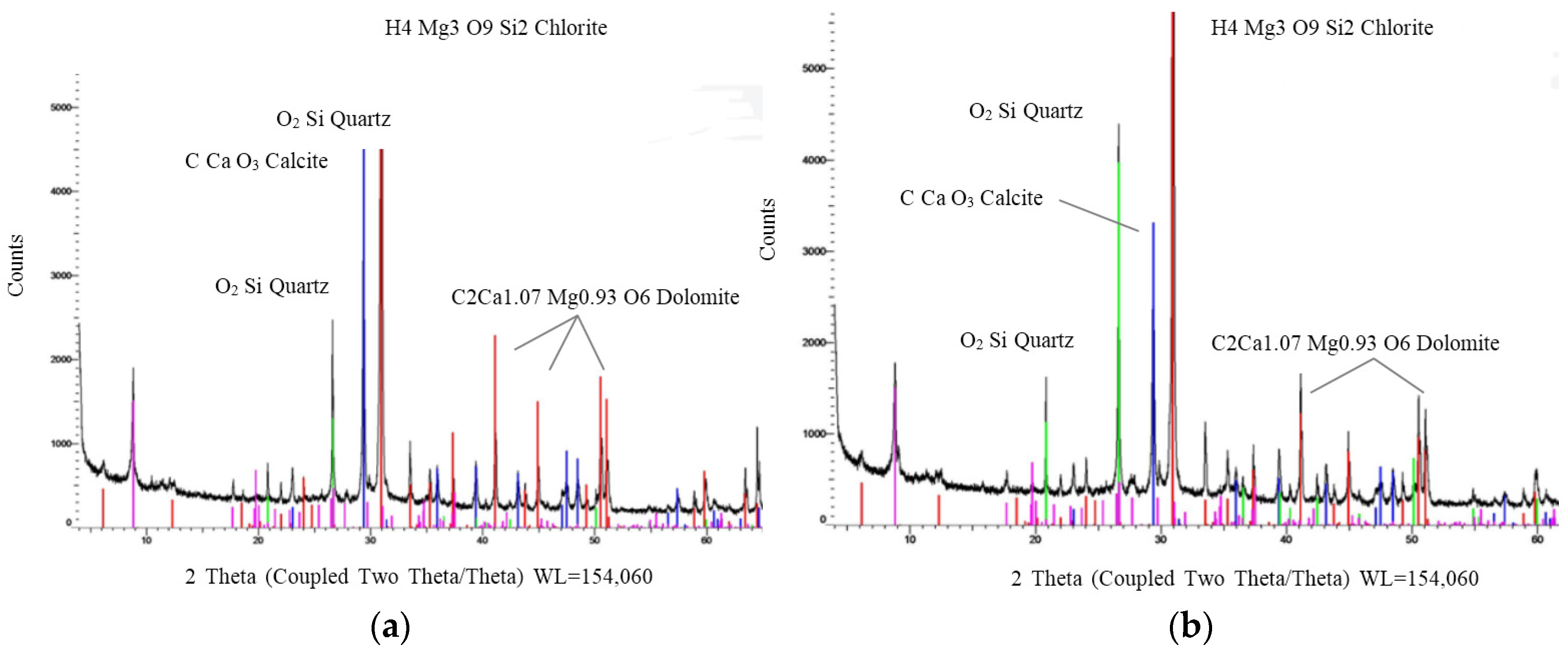

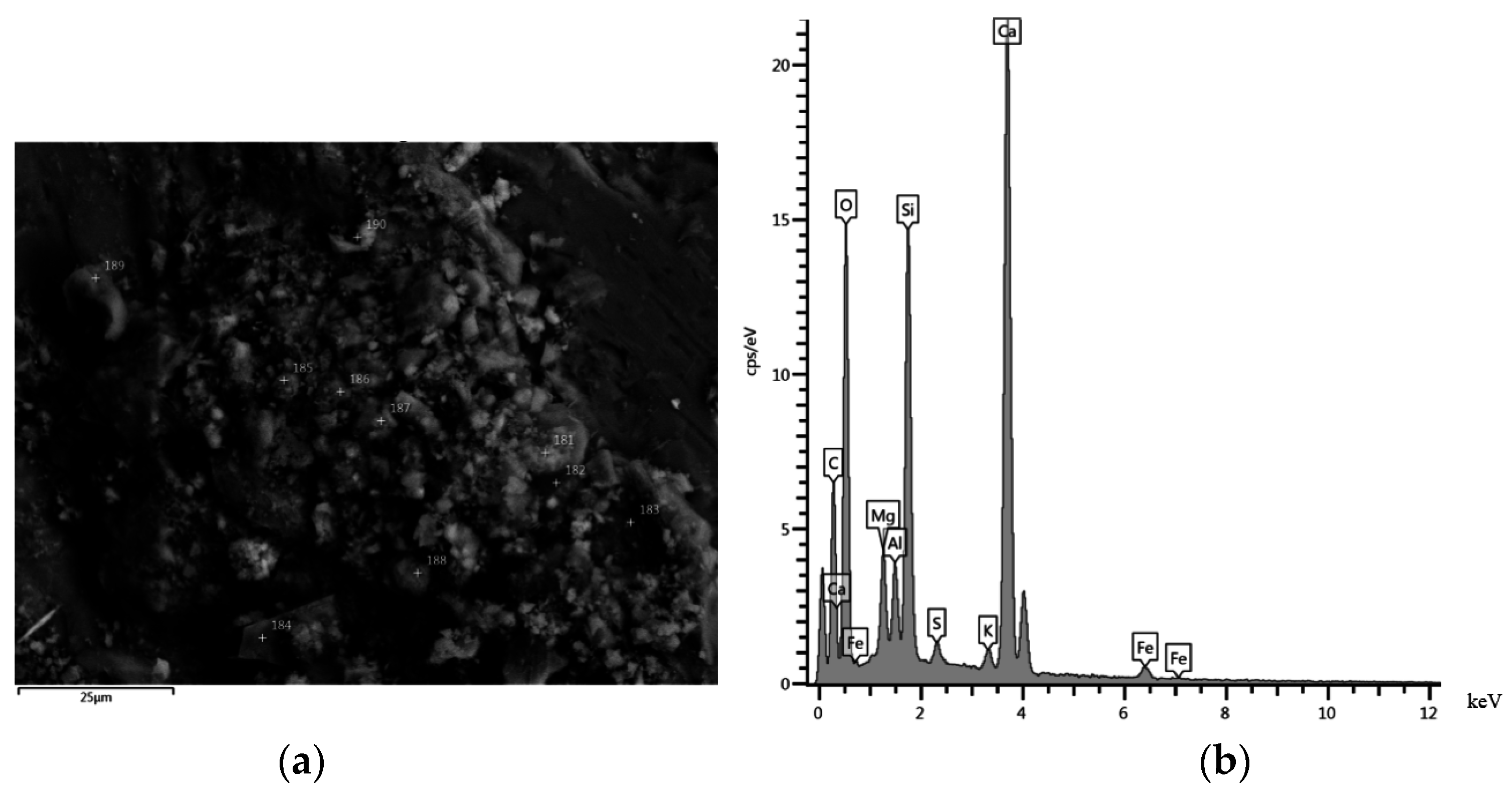

3.4. X-ray Diffraction (XRD) and Scanning Electron Microscopy (SEM)

4. Results and Discussion

4.1. Modified Proctor Test

| Blend | Optimum Moisture Content (%) | Maximum Dry Density (g/cm3) |

|---|---|---|

| NA | 5.96 | 2.38 |

| RCA | 10.18 | 2.08 |

| MRA | 11.20 | 2.02 |

4.2. California Bearing Ratio (CBR) Standard Test

4.3. Accelerated Swelling Test

| Blends | Initial Density (g/m3) | Compressive Strength (MPa) | Swelling after 7 Days of Soaking (%) |

|---|---|---|---|

| NA | 2.37 | 0.04 | 2.60 |

| RCA | 2.16 | 0.55 | 2.30 |

| MRA | 2.14 | 1.15 | 4.00 |

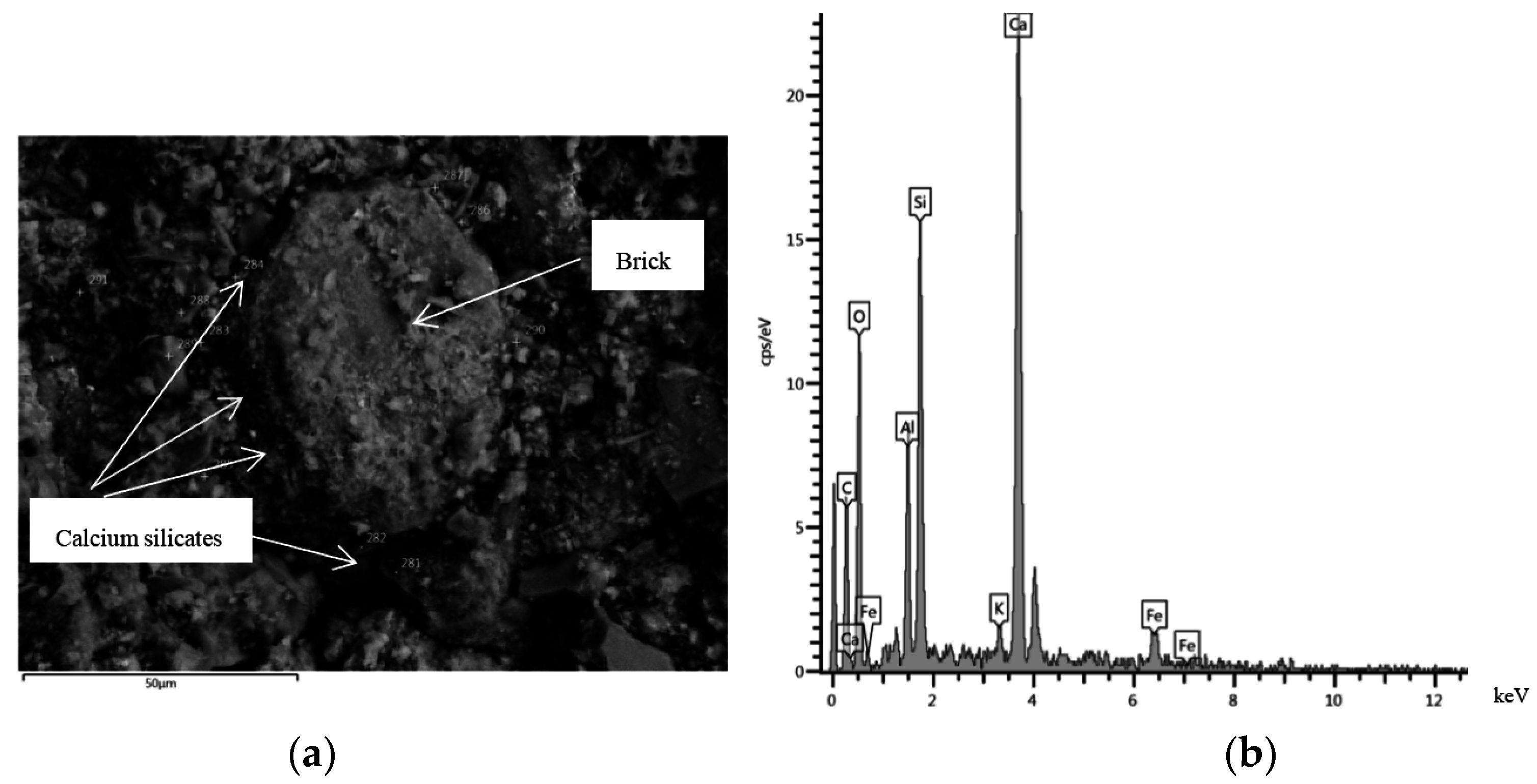

4.4. SEM and Diffraction Analyses of the Blended Mixtures

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leite, F.D.C.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–130. [Google Scholar] [CrossRef]

- Barbudo, A.; Agrela, F.; Ayuso, J.; Jiménez, J.R.; Poon, C.S. Statistical analysis of recycled aggregates derived from different sources for sub-base applications. Constr. Build. Mater. 2012, 28, 129–138. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled aggregate on strength properties of Concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Rao, M.C.; Bhattacharyya, S.K.; Barai, S.V. Influence of field recycled coarse aggregate on properties of concrete. Mater. Struct. 2011, 44, 205–220. [Google Scholar]

- Jiménez, J.R.; Ayuso, J.; Galvín, A.P.; López, M.; Agrela, F. Use of mixed recycled aggregates with a low embodied energy from non-selected CDW in unpaved rural roads. Constr. Build. Mater. 2012, 34, 34–43. [Google Scholar] [CrossRef]

- Xuan, D.X.; Houben, L.J.M.; Molenaar, A.A.A.; Shui, Z.H. Mechanical properties of cement-treated aggregate material—A review. Mater. Des. 2012, 33, 496–502. [Google Scholar] [CrossRef]

- Perez, P.; Agrela, F.; Herrador, R.; Ordoñez, J. Application of cement-treated recycled materials in the construction of a section of road in Malaga, Spain. Constr. Build. Mater. 2013, 44, 593–599. [Google Scholar] [CrossRef]

- Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Binici, H. Effect of crushed ceramic and basaltic pumice as fine aggregates on concrete mortars properties. Constr. Build. Mater. 2007, 21, 1191–1197. [Google Scholar] [CrossRef]

- Agrela, F.; Cabrera, M.; Galvín, A.P.; Barbudo, A.; Ramirez, A. Influence of the sulphate content of recycled aggregates on the properties of cement-treated granular materials using Sulphate-Resistant Portland Cement. Constr. Build. Mater. 2014, 68, 127–134. [Google Scholar] [CrossRef]

- Mas, B.; Cladera, A.; del Olmo, T.; Pitarch, F. Influence of the amount of mixed recycled aggregates on the properties of concrete for non-structural use. Constr. Build. Mater. 2012, 27, 612–622. [Google Scholar] [CrossRef]

- Molenaar, A.A.A.; van Niekerk, A.A. Effects of gradation, composition, and degree of compaction on the mechanical characteristics of recycled unbound materials. Transp. Res. Record 2002, 1787, 73–82. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Azam, A.M.; Cameron, D.A. Geotechnical properties of blends of recycled clay masonry and recycled concrete aggregates in unbound pavement construction. J. Mater. Civil Eng. 2013, 25, 788–798. [Google Scholar] [CrossRef]

- Herrador, R.; Pérez, P.; Garach, L.; Ordóñez, J. Use of recycled construction and demolition waste aggregate for road course surfacing. J. Transp. Eng. 2012, 138, 182–190. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Agrela, F.; Ayuso, J.; López, M. A comparative study of recycled aggregates from concrete and mixed debris as material for unbound road sub-base. Mater. Constr. 2011, 61, 289–302. [Google Scholar] [CrossRef]

- Agrela, F.; Barbudo, A.; Ramírez, A.; Ayuso, J.; Carvajal, M.D.; Jiménez, J.R. Construction of road sections using mixed recycled aggregates treated with cement in Málaga, Spain. Resour. Conserv. Recycl. 2012, 58, 98–106. [Google Scholar] [CrossRef]

- Arm, M. Self-cementing properties of crushed demolished concrete in unbound layers: Results from triaxial tests and field tests. Waste Manag. 2001, 21, 235–239. [Google Scholar] [CrossRef]

- Poon, C.-S.; Qiao, X.C.; Chan, D. The cause and influence of self-cementing properties of fine recycled concrete aggregates on the properties of unbound sub-base. Waste Manag. 2006, 26, 1166–1172. [Google Scholar] [CrossRef] [PubMed]

- Vegas, I.; Ibañez, J.A.; Lisbona, A.; Sáez de Cortazar, A.; Frías, M. Pre-normative research on the use of mixed recycled aggregates in unbound road sections. Constr. Build. Mater. 2011, 25, 2674–2682. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- UNE-EN 933–1: 2006. Test for Geometrical Properties of Aggregates. Part 1. Determination of Particle Size Distribution. Sieving Method; The European Committee for Standardization (CEN): Brussels, Belgium, 2006.

- Spanish General Technical Specifications for Road Construction (PG3), 2004; Ministry of Development, Government of Spain: Madrid, Spain, 2004.

- UNE-EN 933–11: 2009. Tests for Geometrical Properties of Aggregates. Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; AENOR (The Spanish Association for Standardization and Certification): Madrid, Spain, 2009.

- Agrela, F.; Sánchez de Juan, M.; Ayuso, J.; Geraldes, V.L.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Odler, I.; Colan-Subauste, J. Investigations on cement expansion associated with ettringite formation. Cem. Concr. Res. 1999, 29, 731–735. [Google Scholar] [CrossRef]

- BS 8500–2:2002: Concrete-Complementary British Standard to BS EN 206–1. Part 2: Specification for Constituent Materials and Concrete; British Standards Institution: London, UK, 2002.

- Vegas, I.; Ibañez, J.A.; San José, J.T.; Urzelai, A. Construction demolition wastes, Waelzslag and MSWI bottom ash: A comparative technical analysis as material for road construction. Waste Manag. 2008, 28, 565–574. [Google Scholar] [CrossRef] [PubMed]

- UNE 103501:1994. Geotechnic. Compactation Test. Modified Proctor; AENOR: Madrid, Spain, 1994.

- Al-Amoudi, O.S.B.; Asi, I.M.; Al-Abdul Wahhab, H.I.; Khan, Z.A. Clegg hammer—California-bearing ratio correlations. J. Mater. Civil Eng. 2002, 14, 512–523. [Google Scholar] [CrossRef]

- UNE-EN-13286–49:2008. Accelerated Swelling Test for Soil Treated by Lime or Hydraulic Binder; AENOR: Madrid, Spain, 2008.

- Güneyisi, E.; Gesoğlu, M.; Algin, Z.; Yazici, H. Effect of surface treatment methods on the properties of self-compacting concrete with recycled aggregates. Constr. Build. Mater. 2014, 64, 172–183. [Google Scholar] [CrossRef]

- Shui, Z.; Xuan, D.; Wan, H.; Cao, B. Rehydration reactivity of recycled mortar from concrete waste experienced to thermal treatment. Constr. Build. Mater. 2008, 22, 1723–1729. [Google Scholar] [CrossRef]

- Salem, R.M.; Burdette, E.G. Role of chemical and mineral admixtures on physical properties and frost-resistance of recycled aggregate concrete. ACI Mater. J. 1998, 95, 558–563. [Google Scholar]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Etxeberria, M. Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete. Cem. Concr. Compos. 2011, 33, 286–291. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garach, L.; López, M.; Agrela, F.; Ordóñez, J.; Alegre, J.; Moya, J.A. Improvement of Bearing Capacity in Recycled Aggregates Suitable for Use as Unbound Road Sub-Base. Materials 2015, 8, 8804-8816. https://doi.org/10.3390/ma8125493

Garach L, López M, Agrela F, Ordóñez J, Alegre J, Moya JA. Improvement of Bearing Capacity in Recycled Aggregates Suitable for Use as Unbound Road Sub-Base. Materials. 2015; 8(12):8804-8816. https://doi.org/10.3390/ma8125493

Chicago/Turabian StyleGarach, Laura, Mónica López, Francisco Agrela, Javier Ordóñez, Javier Alegre, and José Antonio Moya. 2015. "Improvement of Bearing Capacity in Recycled Aggregates Suitable for Use as Unbound Road Sub-Base" Materials 8, no. 12: 8804-8816. https://doi.org/10.3390/ma8125493

APA StyleGarach, L., López, M., Agrela, F., Ordóñez, J., Alegre, J., & Moya, J. A. (2015). Improvement of Bearing Capacity in Recycled Aggregates Suitable for Use as Unbound Road Sub-Base. Materials, 8(12), 8804-8816. https://doi.org/10.3390/ma8125493