Fiber-Embedded Metallic Materials: From Sensing towards Nervous Behavior

Abstract

:1. Introduction

2. Embeddable Fibers

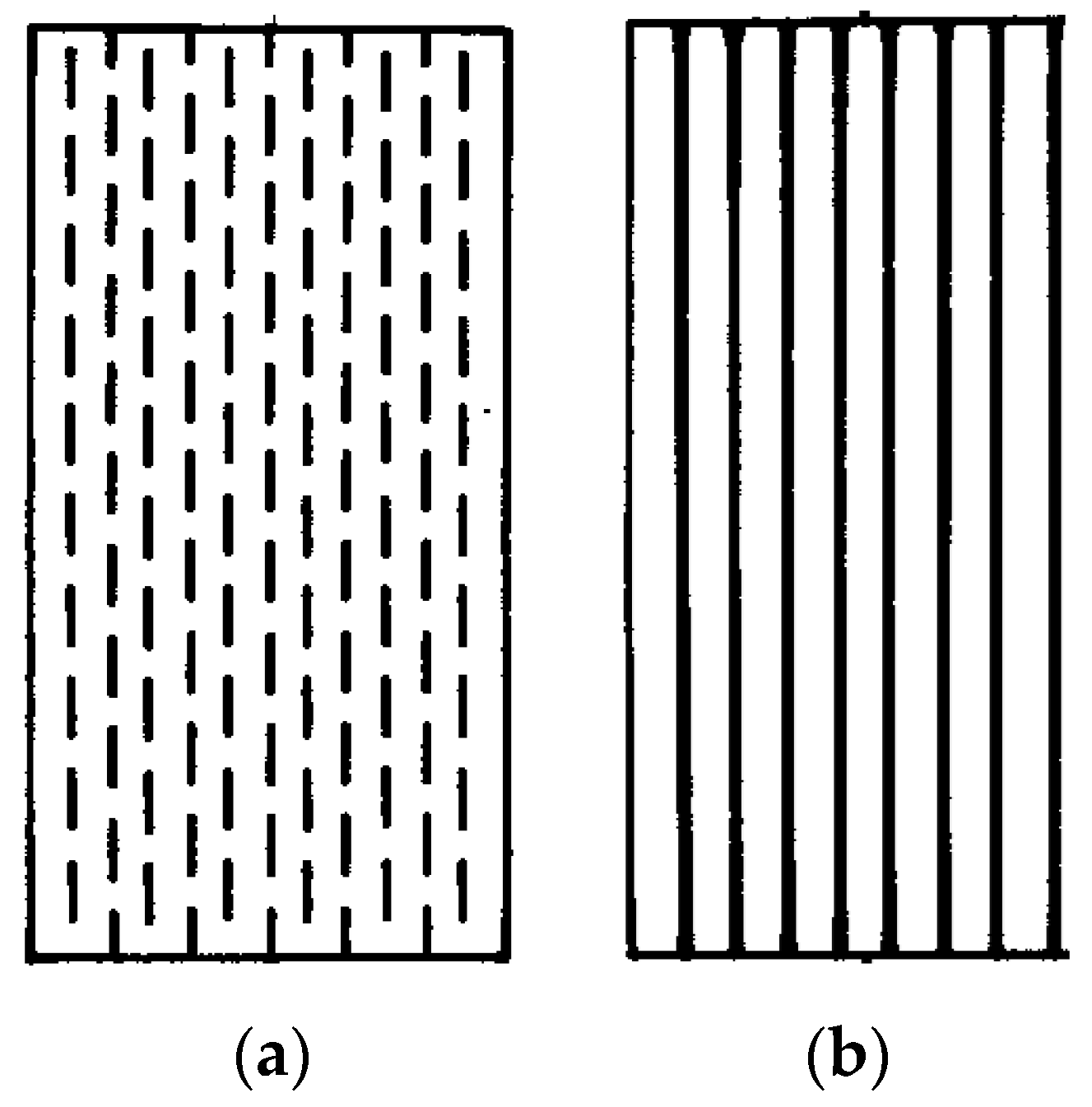

2.1. Conventional Fibers

2.2. Smart Fibers

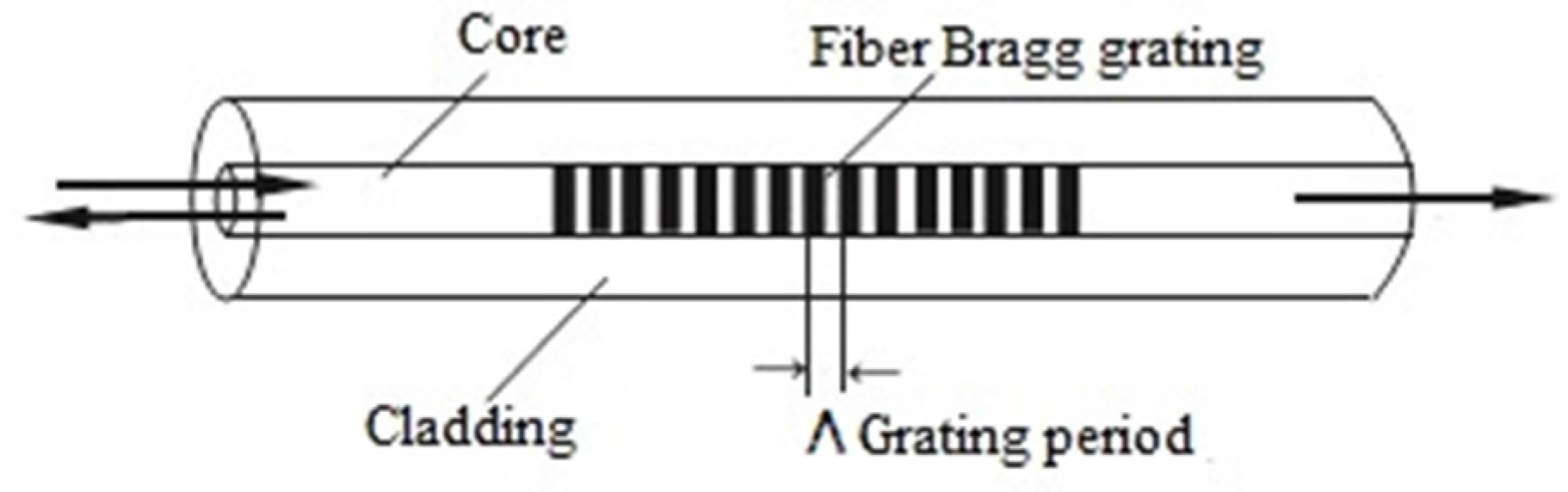

2.3. Optical Fibers

3. Embedding Processes

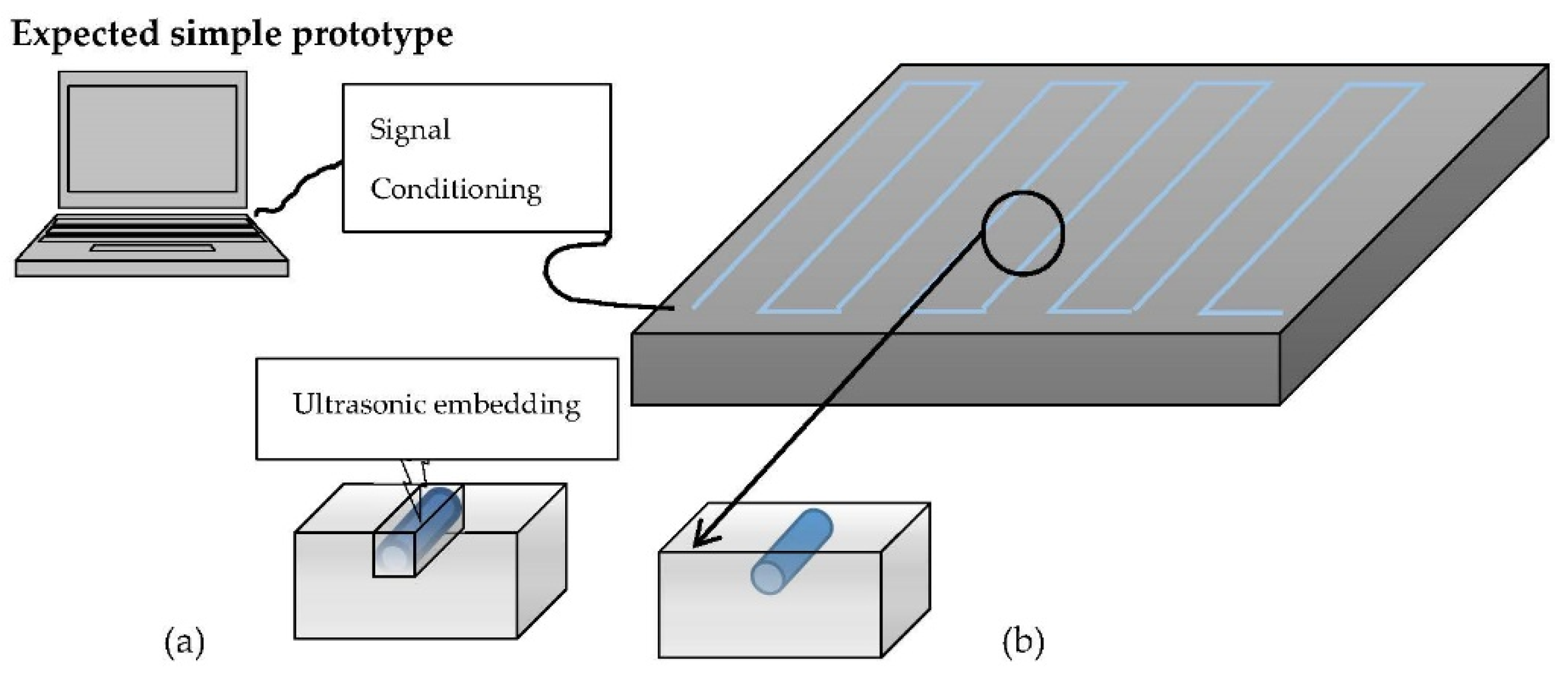

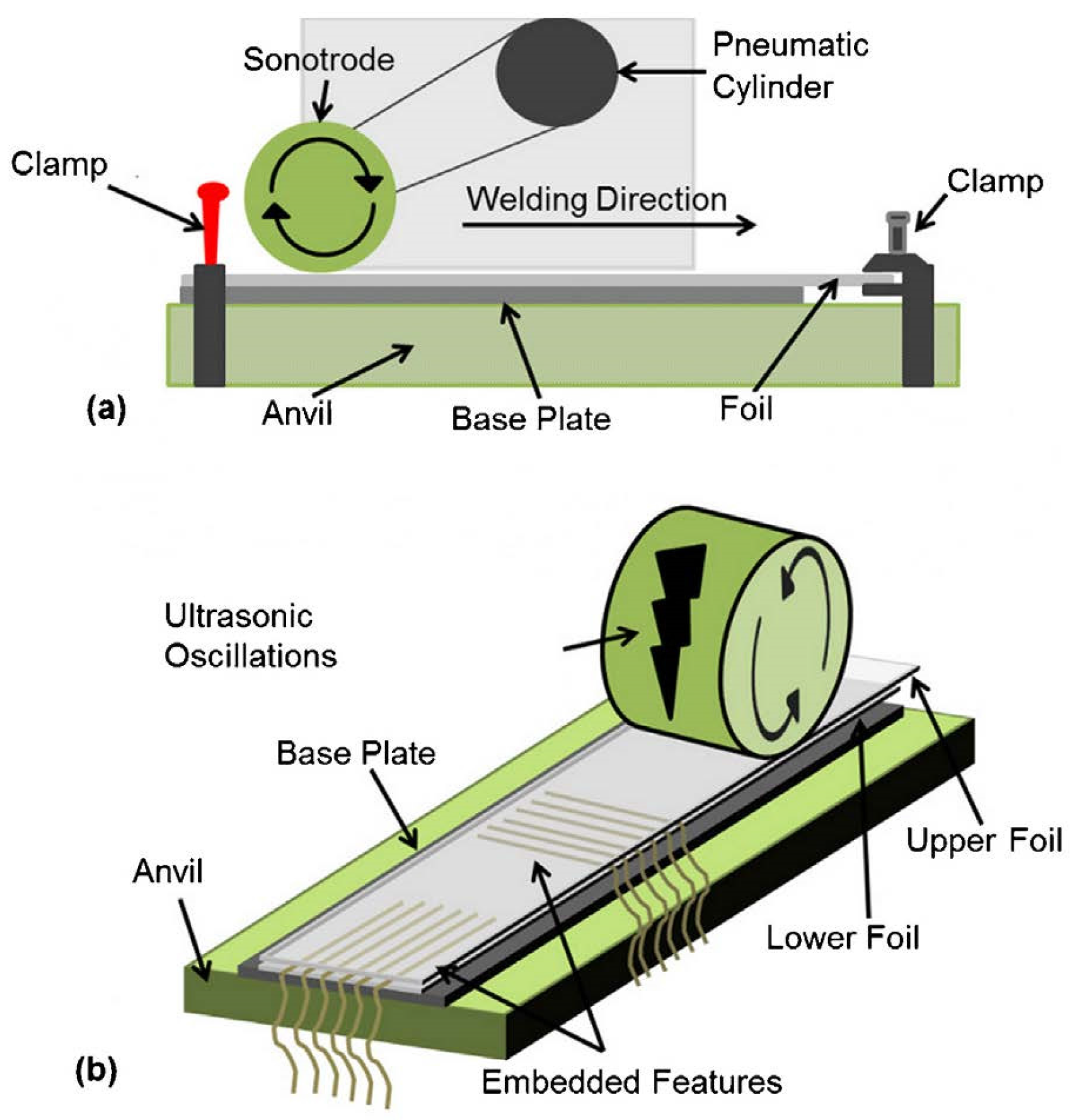

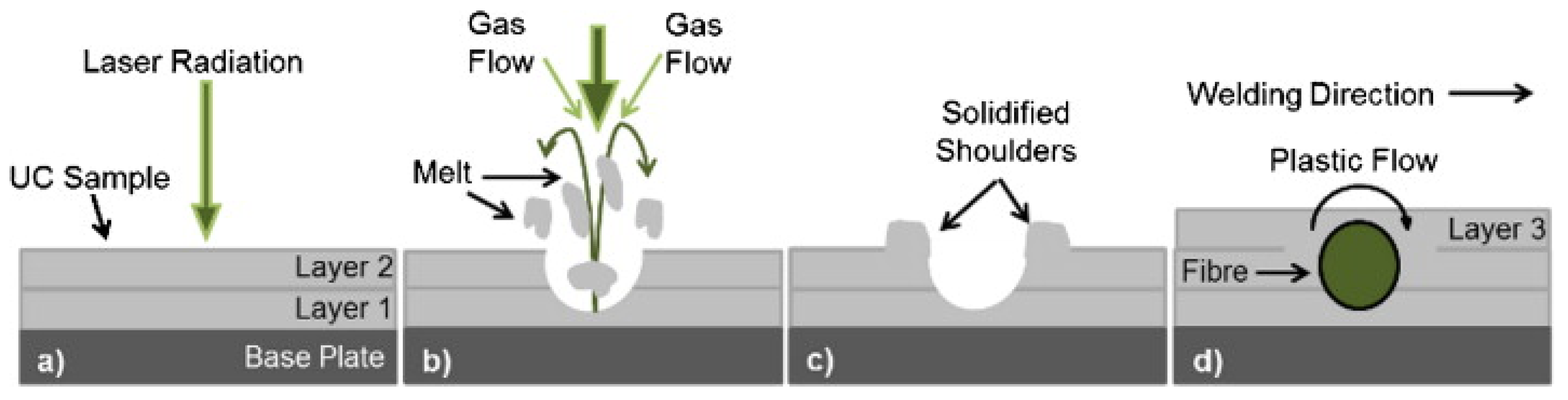

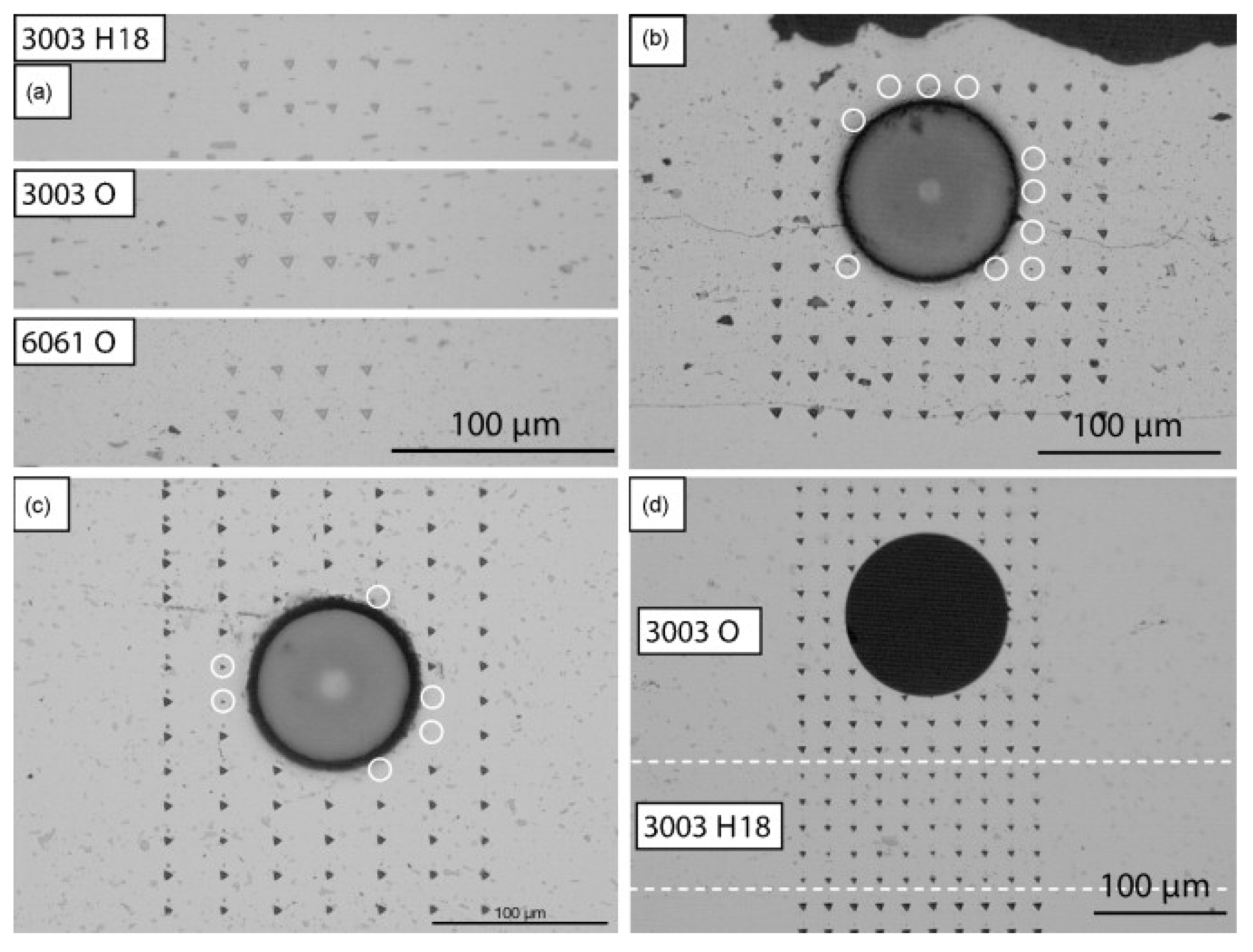

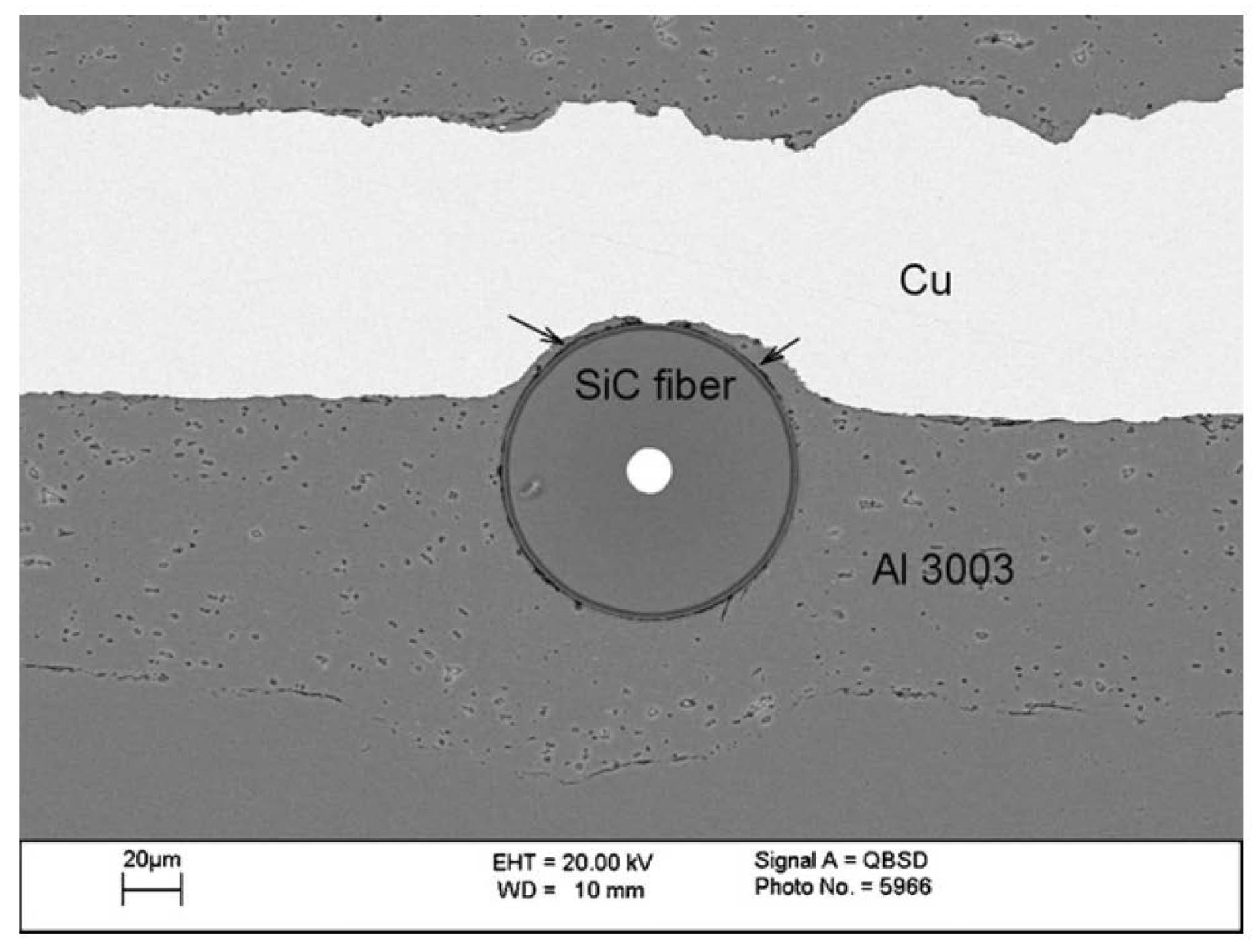

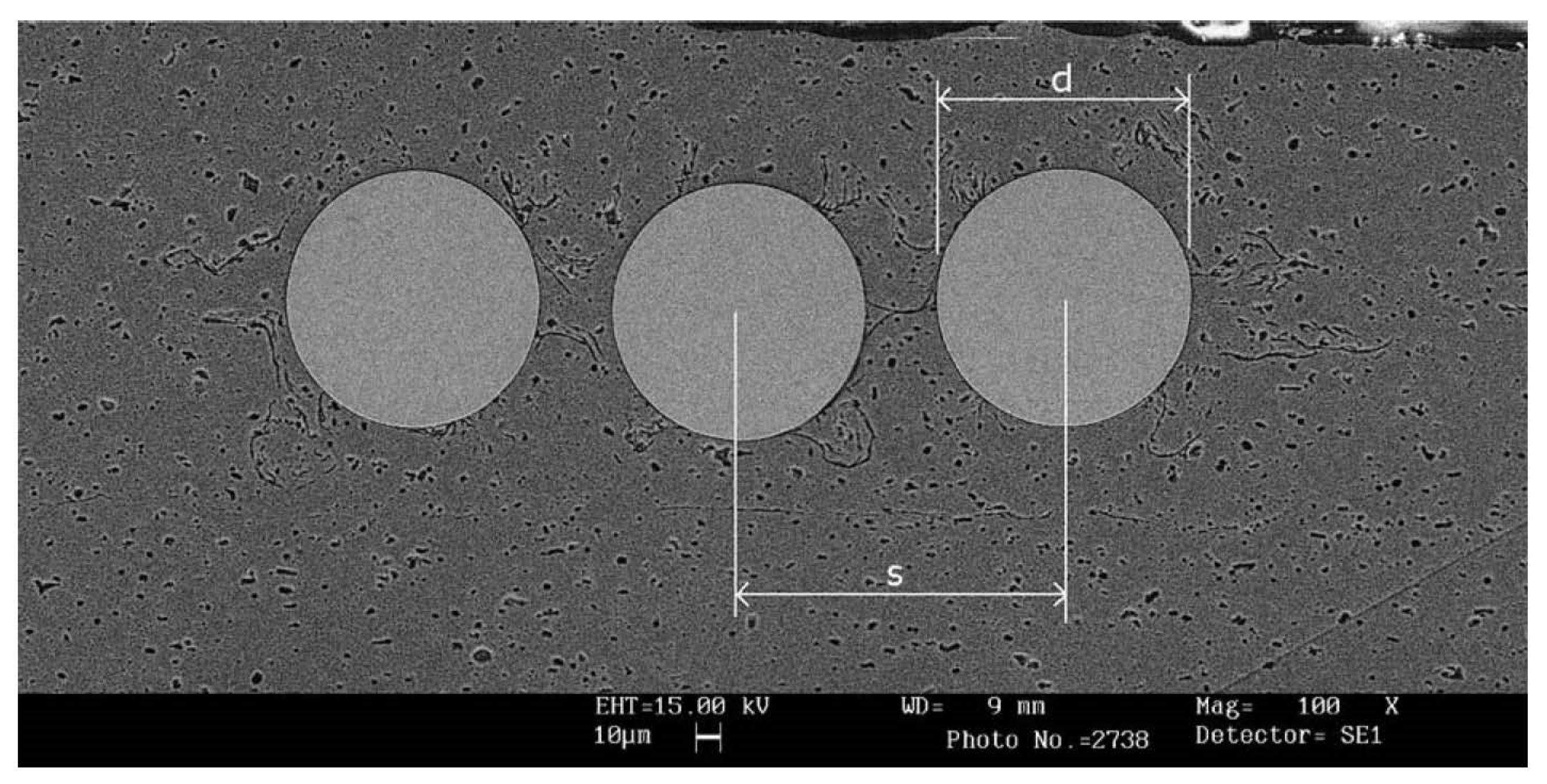

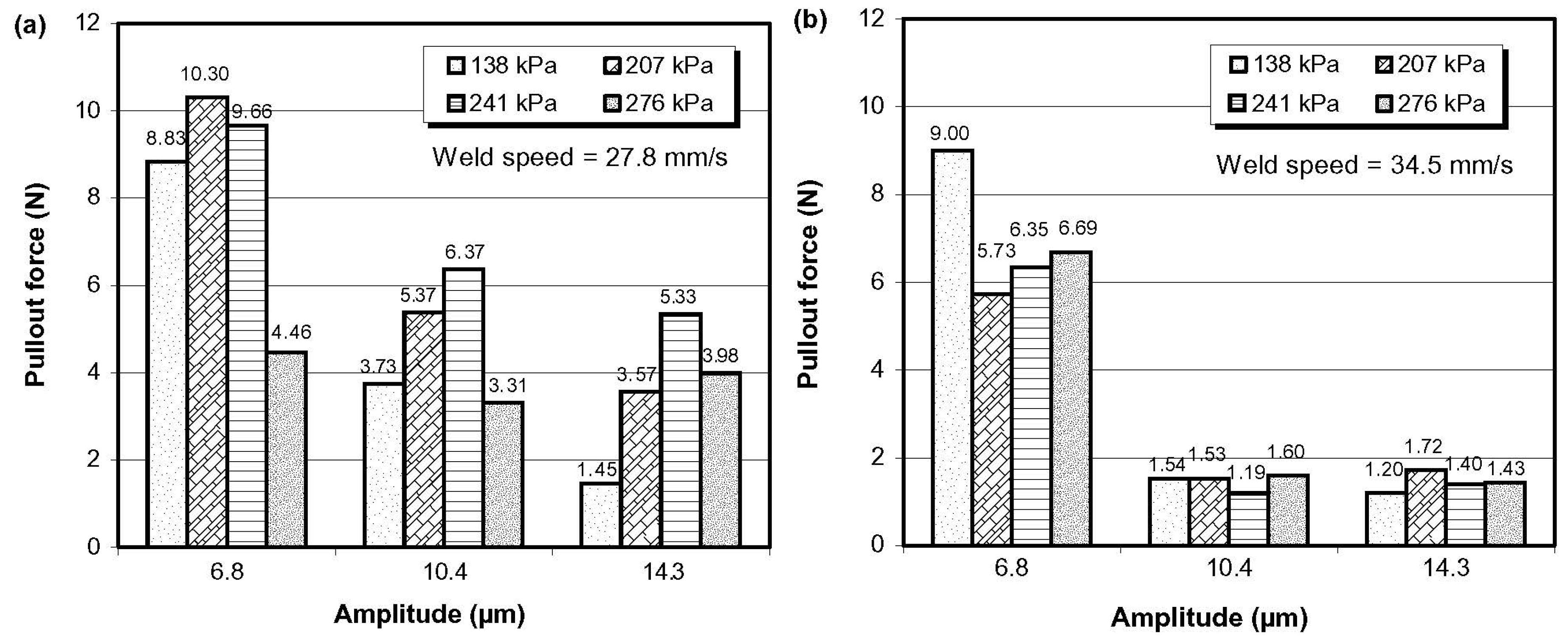

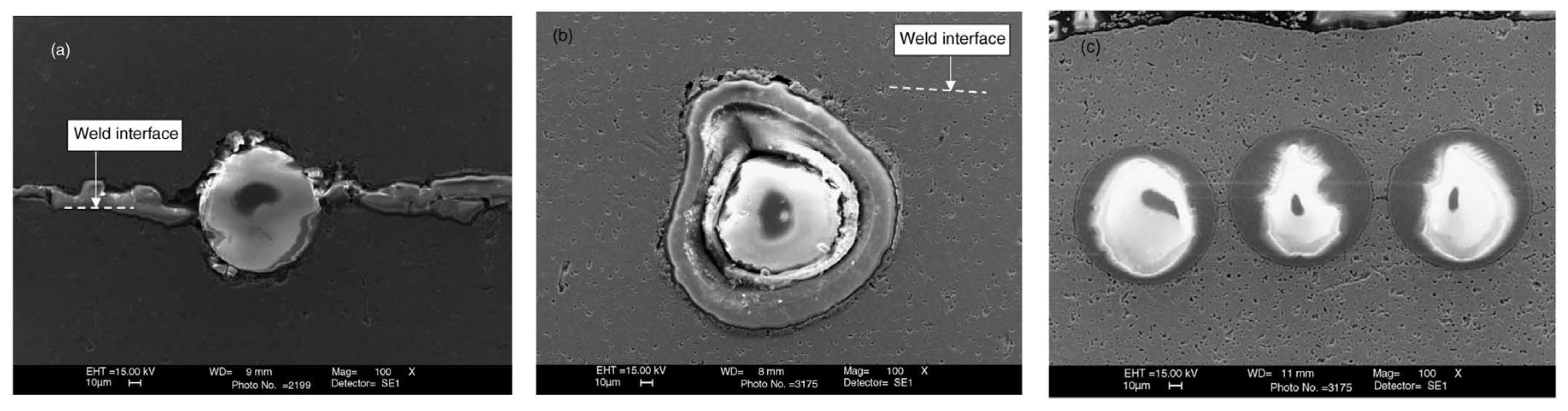

3.1. Ultrasonic Consolidation

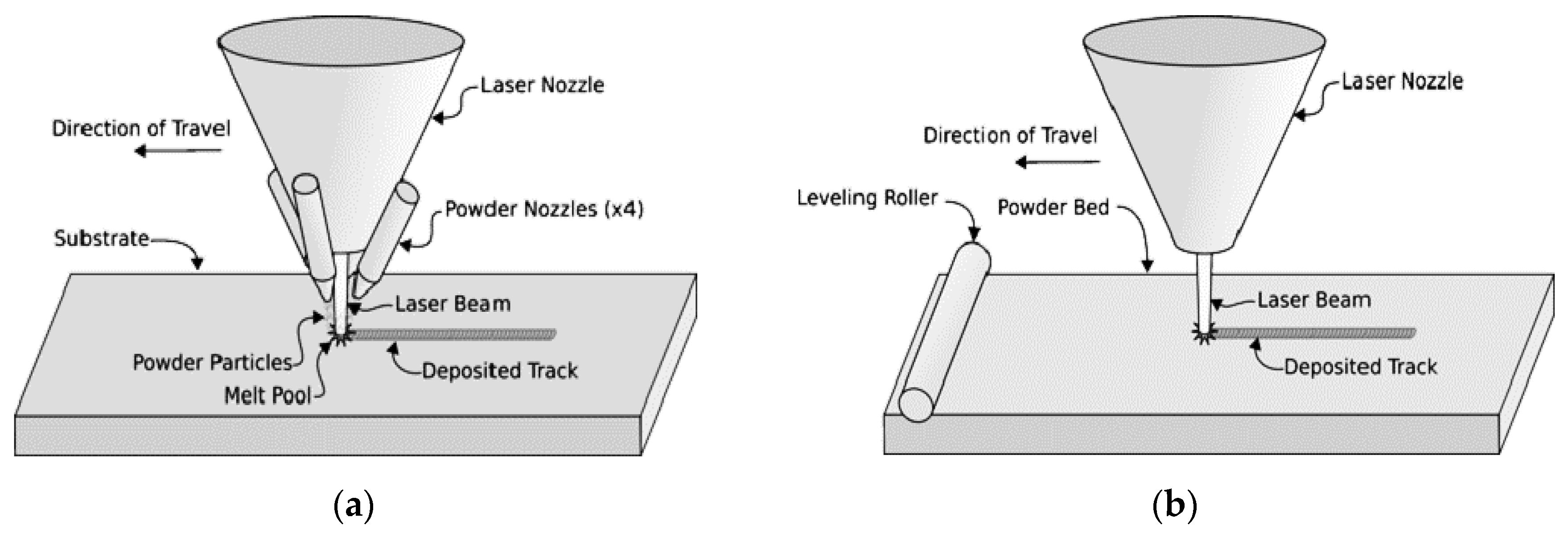

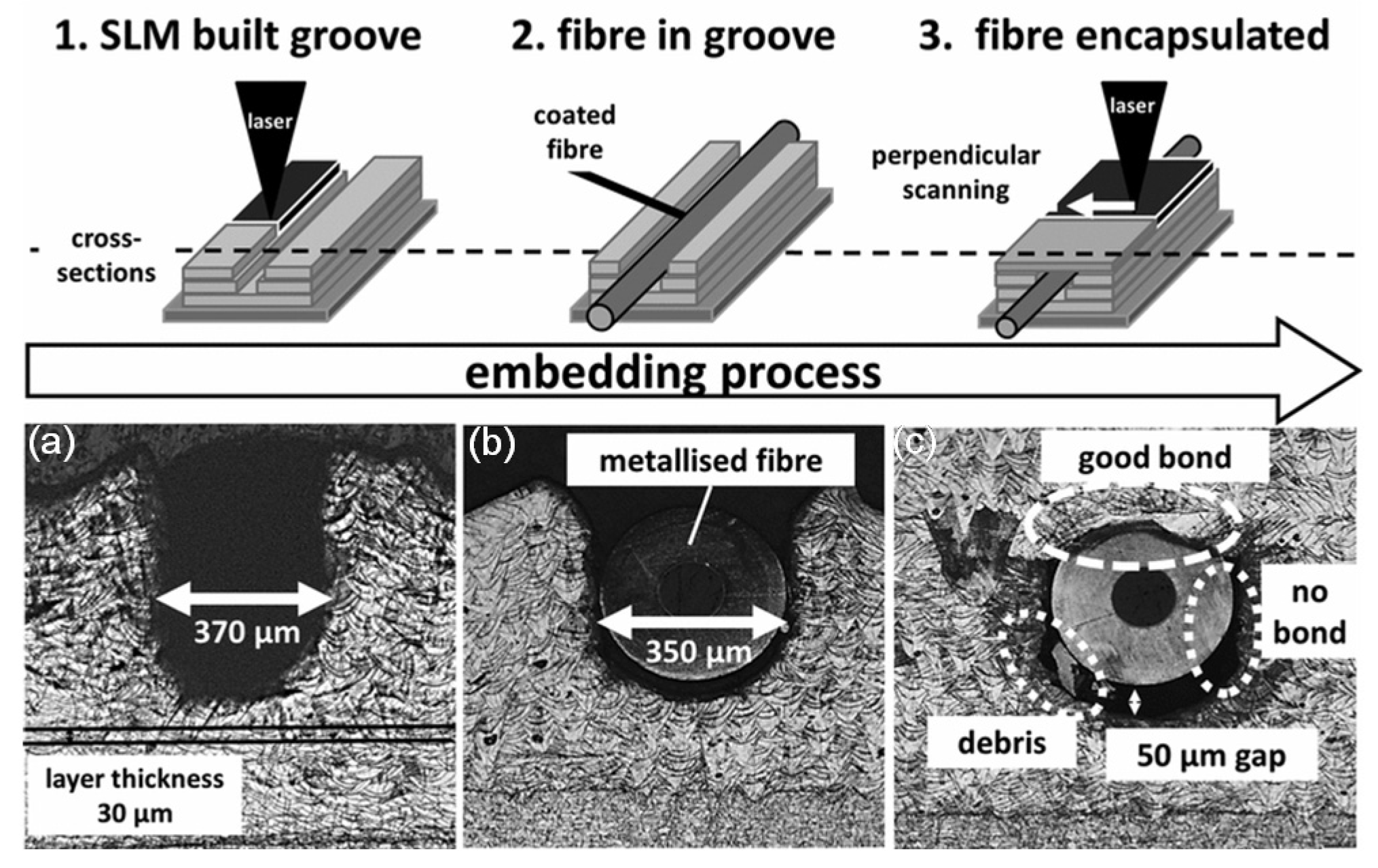

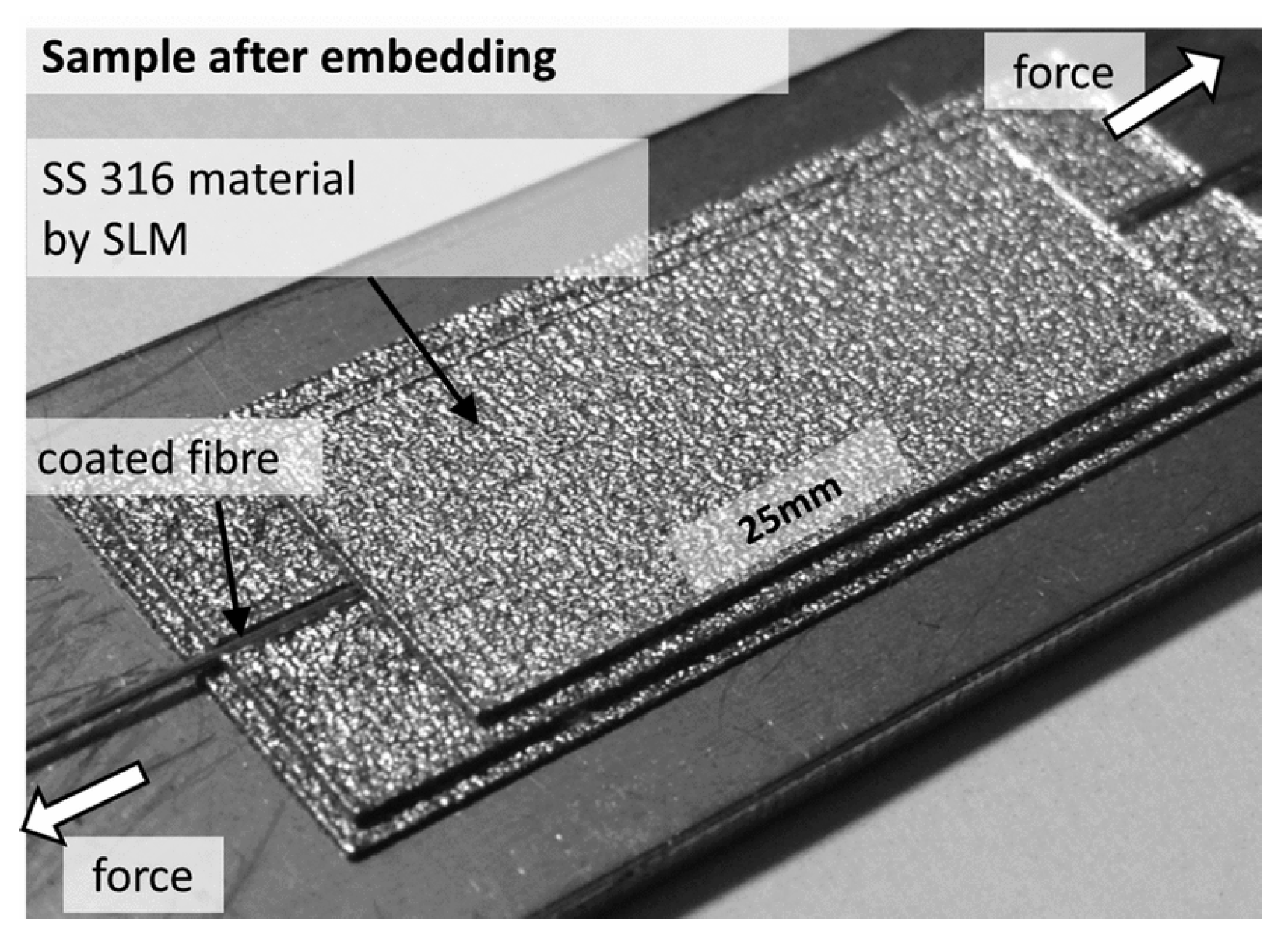

3.2. Laser Based Layered Manufacturing

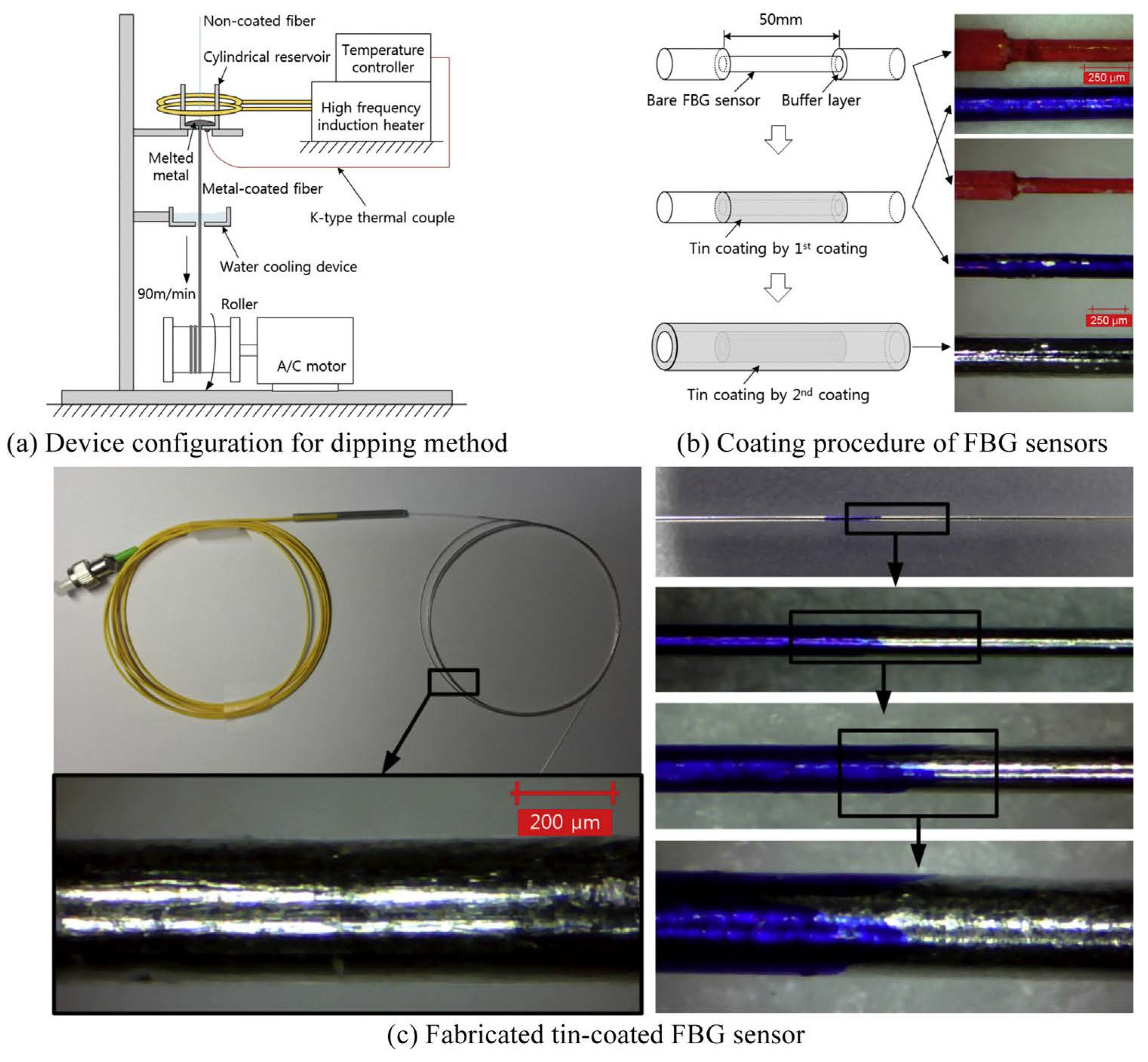

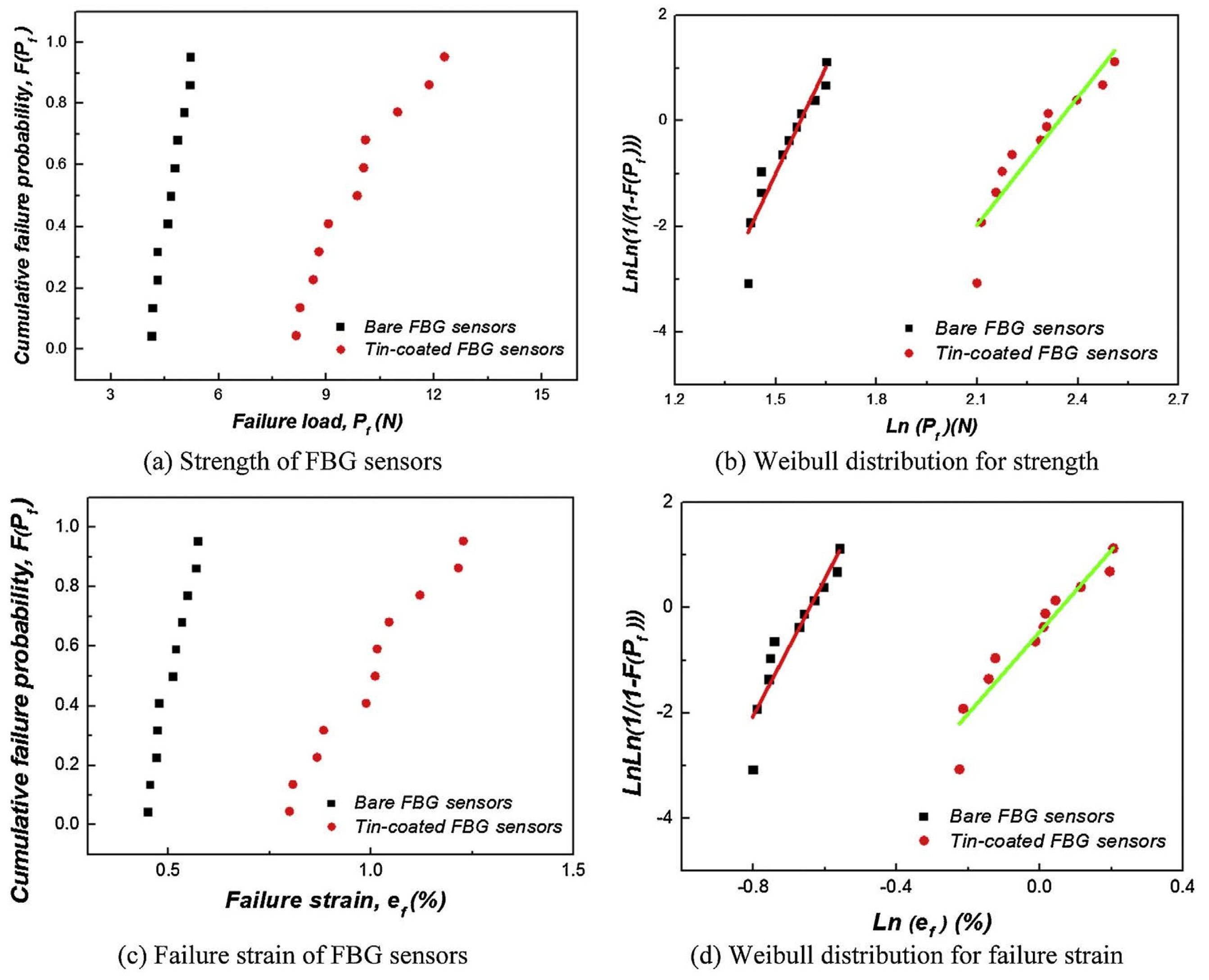

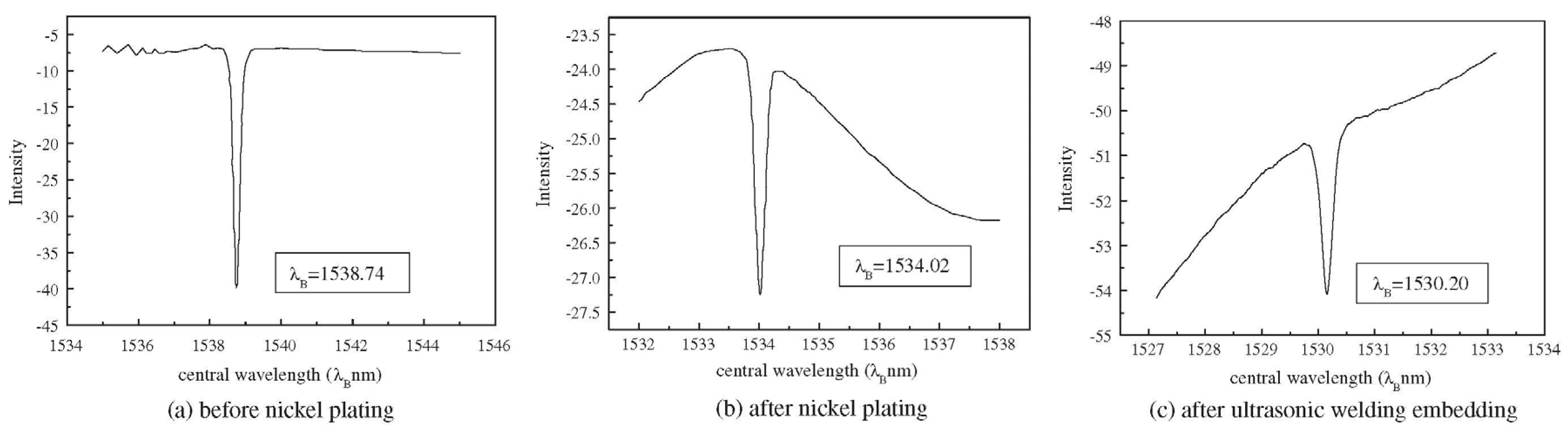

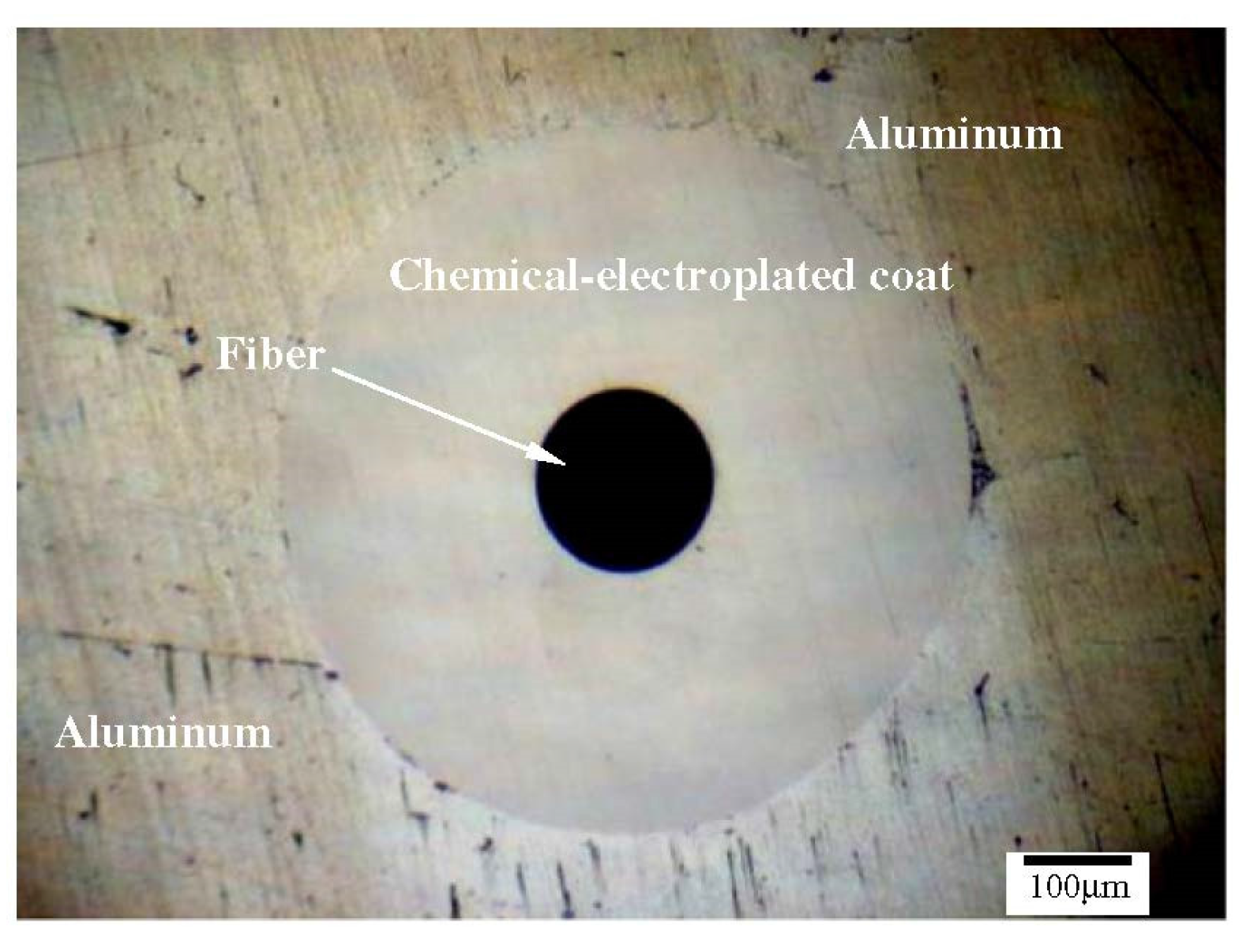

3.3. Pre-Embedding Processes

4. Materials Behavior

4.1. Strengthening Behavior

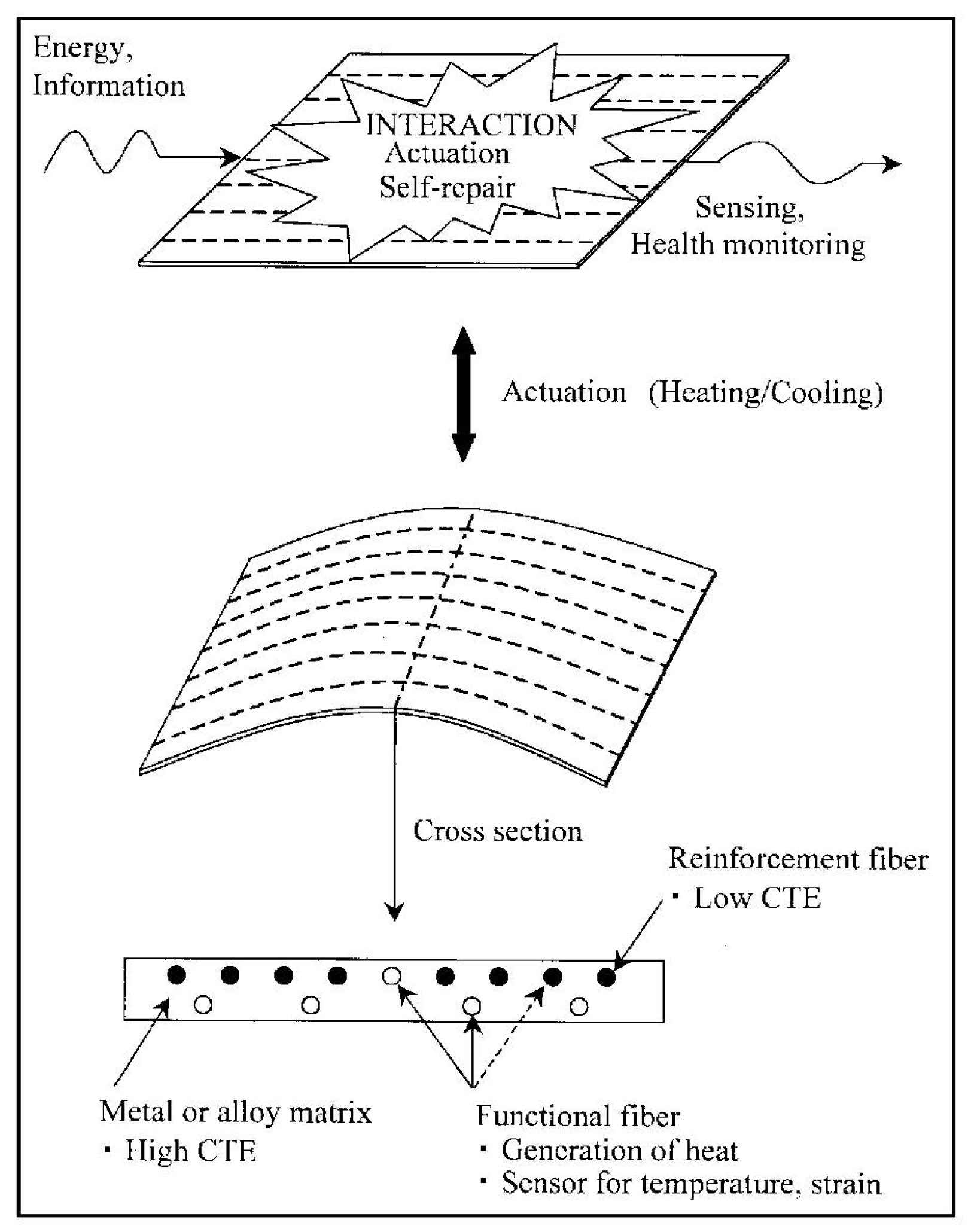

4.2. Smart Behavior

| Matrix | Reinforcement (vol %) | Fabrication Method | Temperature/Pressure | Interface | Ref. |

|---|---|---|---|---|---|

| 1100Al | NiTif (4–9) | Pressure casting | 970 K/65 MPa | 4 μm layer | [58,59] |

| 1100Al | NiTif (3) | Hot pressing | 843 K/200 MPa cool pressure | Unknown | [60] |

| AC4AAl | NiTiw (2–4) | Squeeze casting | 1,023 K/75 MPa | 1.1 μm layer | [61] |

| 1060Al | NiTif (20, 30) | Pressure infiltration process | 973 K/30 MPa | Three layers Al3Ti, Al3Ni | [62] |

| 6061Al | NiTif (19.5) | Vacuum hot pressing | 813–823 K/2,000 kgf | Unknown | [63,64] |

| 6082Al | NiTif (~20) | Hot pressing | 806–833 K/25 MPa | Unknown | [65,66,67,68,69,70,71] |

| 6061Al | NiTif (2.7–5.3) | Vacuum hot pressing | 813–823 K/7–54 MPa | Al3Ti, Al3Ni | [72,73] |

| 6061Al | NiTif (3.2–7.0) | Hot-press method | 803–833 K/40–60 MPa | 400 μm layer, TixAly | [74,75,76] |

| 2024Al | |||||

| Pure Al | NiTif (6, 20) | Vacuum hot pressed | 873 K | Unknown | [77,78,79,80] |

| 3003-H18 | NiTif NiTi ribbon (5, 15, 20) | Ultrasonic consolidation | <573 K/<300 kPa | No | [7,8,81,82,83] |

| 6061Al | NiTi (20) | Spark plasma sintering | 633–873 K | Ni3Ti, Ti2Ni, Al3Ni | [84] |

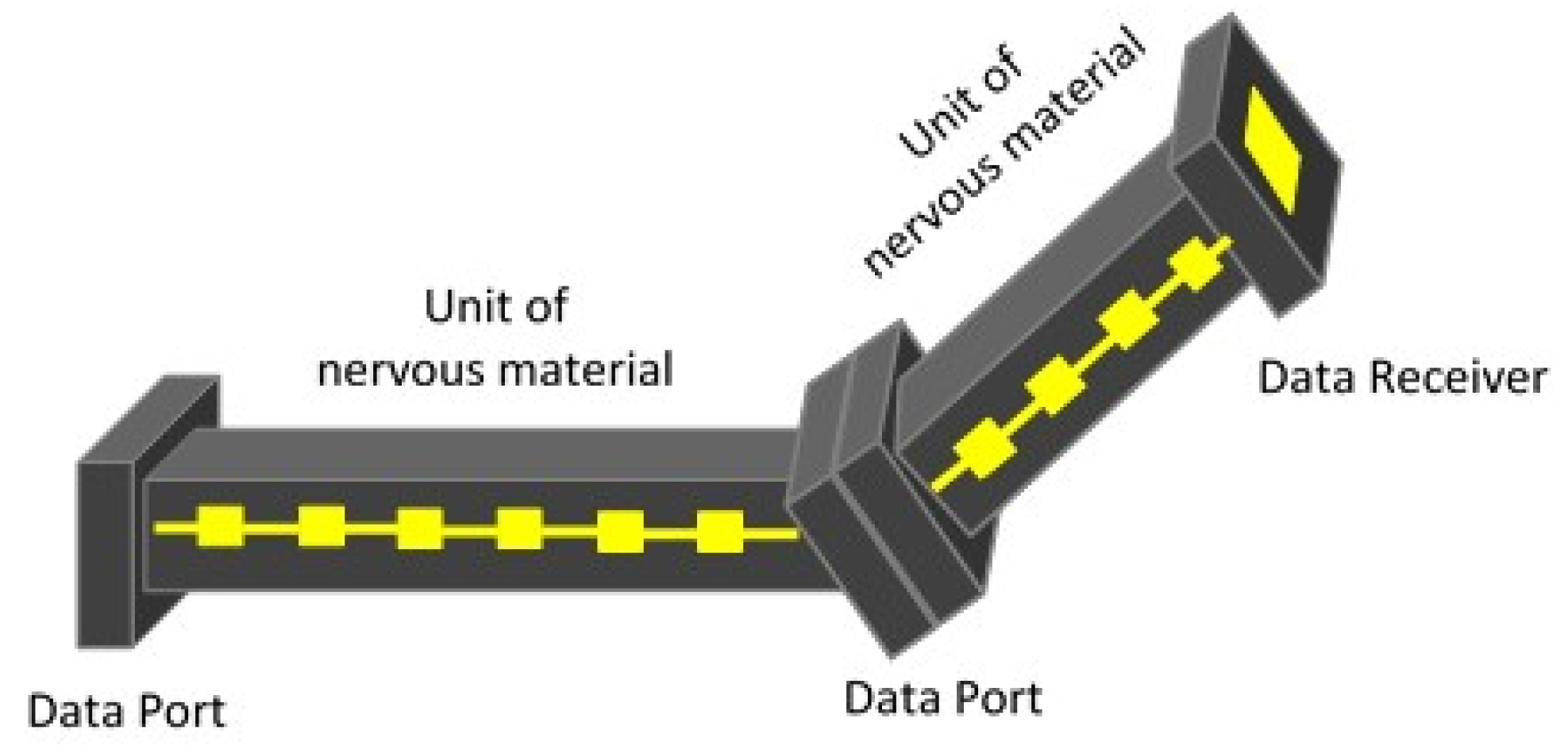

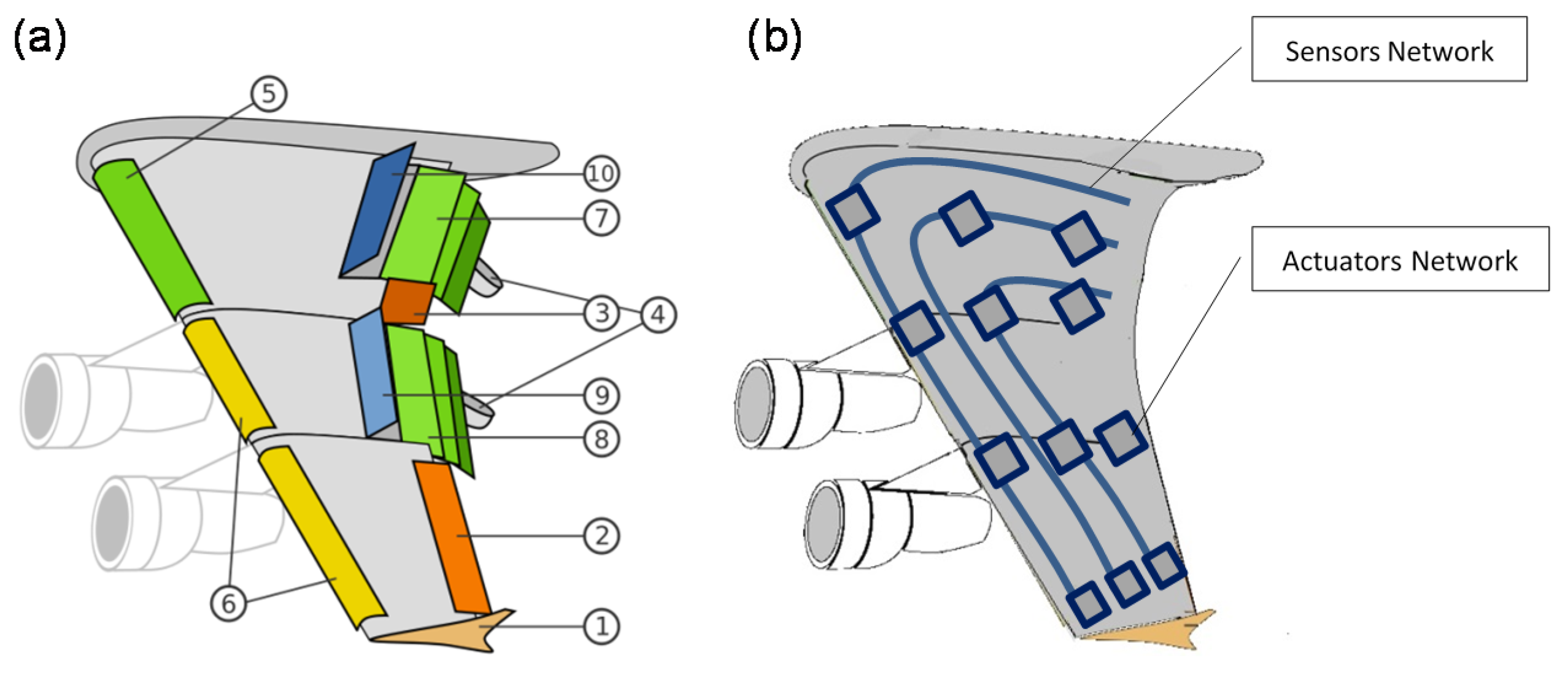

4.3. Nervous Behavior

5. Current Challenges

6. Future Directions and Applications

7. Conclusions

- Smart fibers were successfully embedded in metals, using a wide range of techniques, to create smart materials but at subsurface level only.

- Ultrasonic consolidation and laser-based layered manufacturing processes remain the most suitable techniques to embed optical fibers in metals. Some laboratory tested examples proved to be successful.

- Pre-embedding treatments might contribute to the protection and facilitate the embedding of optical fibers without much damage of the fibers.

- The embedding process of optical fibers in metals is in its infancy; and it is believed to be a cutting-edge research topic when considering most aspects securing in-depth and volumetric embedding of lengthy fiber optics.

- Successful embedding of optical fibers and actuators array in metals without disruption would pave the way for further development of “nervous” materials.

- There is a potential to modify and upgrade embedding techniques, used for embedding smart fibers, and to extend their use for the development of nervous materials if the discussed challenges are addressed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Seshan, S.; Guruprasad, A.; Prabha, M.; Sudhakar, A. Fibre-reinforced metal matrix composites—A review. J. Indian Inst. Sci. 1996, 76, 1–14. [Google Scholar]

- Yang, Y. Fabrication of Long-Fiber-Reinforced Metal Matrix Composites Using Ultrasonic Consolidation. Ph.D. Thesis, Mechanical Engineering, Utah State University, Logan, UT, USA, December 2008. [Google Scholar]

- Taya, M.; Arenault, R.J. Metal Matrix Composites: Thermomechanical Behavior; Pergamon Press: Oxford, UK, 1989. [Google Scholar]

- Schwartz, M. Composite Materials Handbook; McGraw-Hill, Inc.: New York, NY, USA, 1992. [Google Scholar]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar]

- Li, X. Embedded Sensors in Layered Manufacturing. Ph.D. Thesis, Department of Mechanical Engineering, Stanford University, Stanford, CA, USA, June 2001. [Google Scholar]

- Kong, C.Y.; Soar, R.C.; Dickens, P.M. Ultrasonic consolidation for embedding SMA fibres within aluminium matrices. Compos. Struct. 2004, 66, 421–427. [Google Scholar] [CrossRef]

- Kong, C.Y.; Soar, R.C. Fabrication of metal-matrix composites and adaptive composites using ultrasonic consolidation process. Mater. Sci. Eng. A 2005, 412, 12–18. [Google Scholar] [CrossRef]

- Mou, C.; Saffari, P.; Li, D.; Zhou, K.; Zhang, L. Rupert soar and ian bennion, smart structure sensors based on embedded fibre Bragg grating arrays in aluminium alloy matrix by ultrasonic consolidation. Meas. Sci. Technol. 2009, 20. [Google Scholar] [CrossRef]

- Alemohammad, H.; Toyserkani, E. Metal embedded optical fiber sensors: Laser-based layered manufacturing procedures. J. Manuf. Sci. Eng. 2011, 133. [Google Scholar] [CrossRef]

- Zhang, X. Sensitivity Alteration of Fiber Bragg Grating Sensors through On-Fiber Metallic Coatings Produced by a Combined Laser-Assisted Maskless Microdeposition and Electroless Plating Process; Master of Applied Science in Mechanical Engineering, University of Waterloo: Waterloo, ON, Canada, 2013. [Google Scholar]

- Ni, D.R.; Ma, Z.Y. Shape memory alloy-reinforced metal-matrix composites: A review. Acta Metall. Sin. 2014, 27, 739–761. [Google Scholar] [CrossRef]

- Hotate, K. Fiber optic nerve systems for smart materials and smart structures. In Proceedings of the International Topical Meeting on Microwave Photonics, 2008. Jointly Held with the 2008 Asia-Pacific Microwave Photonics Conference, Mwp/Apmp 2008, Gold Coast, Australia, 9 September–3 October 2008; pp. 31–34.

- Measures, R.M. Smart structures with nerves of glass. Prog. Aerosp. Sci. 1989, 26, 289–351. [Google Scholar] [CrossRef]

- Mekid, S.; Kwon, O. Nervous materials: A new approach of using advanced materials for better control, reliability and safety of structures. Sci. Adv. Mater. 2009, 1, 276–285. [Google Scholar] [CrossRef]

- Mekid, S.; Saheb, N.; Khan, S.M.A.; Qureshi, K.K. Towards sensor array materials: Can failure be delayed? Sci. Technol. Adv. Mater. 2015, 16. [Google Scholar] [CrossRef]

- Christopoulos, A.; Hristoforou, E.; Koulalis, I.; Tsamasphyros, G. Inductive strain sensing using magnetostrictive wires embedded in carbon fibre laminates. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of recent developments. Assem. Autom. 2012, 32, 3–7. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of capabilities and applications. Assem. Autom. 2014, 34, 16–22. [Google Scholar] [CrossRef]

- Jin, N.; Yang, Y.; Luo, X.; Li, J.; Huang, B.; Liu, S.; Xiao, Z. Theoretical calculations on the adhesion, stability, electronic structure and bonding of SiC/W interface. Appl. Surf. Sci. 2014, 314, 896–905. [Google Scholar] [CrossRef]

- Yang, Y.Q.; Zhu, Y.; Chen, Y.; Zhang, Q.G.; Zhang, J.M. Processing and property of SiC fiber reinforced Ti-matrix composite. Rare Met. Mater. Eng. 2002, 31, 201–204. [Google Scholar]

- Bansal, N.P. CVD SiC fiber-reinforced barium aluminosilicate glass-ceramic matrix composites. Mater. Sci. Eng. A 1996, 220, 129–139. [Google Scholar] [CrossRef]

- Luo, X.; Yang, Y.Q.; Liu, C.X.; Ma, Z.J.; Yuan, M.N.; Chen, Y. The fabrication and property of SiC fiber reinforced copper matrix composites. Mater. Sci. Eng. A 2007, 459, 244–250. [Google Scholar] [CrossRef]

- Baimpas, N.; Lunt, A.J.G.; Dolbnya, I.P.; Dluhos, J.; Korsunsky, A.M. Nano-scale mapping of lattice strain and orientation inside carbon core SiC fibres by synchrotron X-ray diffraction. Carbon 2014, 79, 85–92. [Google Scholar] [CrossRef]

- Kaya, F.; Bowen, P. Effect of increased interfacial strength on the fatigue crack growth resistance and crack opening displacement of β Ti21S/SCS 6 composites. Mater. Sci. Eng. A 2008, 476, 301–307. [Google Scholar] [CrossRef]

- Lagoudas, D.C. Shape Memory Alloys: Modeling and Engineering Applications; Springer: Berlin, Germany, 2008. [Google Scholar]

- Damanpack, A.R.; Aghdam, M.M.; Shakeri, M. Micro-mechanics of composite with SMA fibers embedded in metallic/polymeric matrix under off-axial loadings. Eur. J. Mech. 2015, 49, 467–480. [Google Scholar] [CrossRef]

- Furuya, Y.; Sasaki, A.; Taya, M. Enhanced mechanical properties of TiNi shape memory fiber/Al matrix composite. Mater. Trans. 1993, 34, 224–227. [Google Scholar] [CrossRef]

- Keiser, G. Optical Fiber Communications; McGraw-Hill International Editions: Singapore, 2000. [Google Scholar]

- Yu, F.T.S.; Yin, S.; Yu, Y.T.S. Fiber Optic Sensors, 3rd ed.; Marcel Dekker: New York, NY, USA, 2002. [Google Scholar]

- Othonos, A.; Kalli, K. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House: New York, NY, USA, 1999. [Google Scholar]

- Kersey, A.; Davis, M.A.; Patrick, H.J.; Leblanc, M. Fiber grating sensors. J. Light. Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Fernando, G.F. Fibre optic sensor systems for monitoring composite structures. Reinf. Plast. 2005, 49, 41–49. [Google Scholar] [CrossRef]

- Mekid, S. Structural Material with Embedded Sensors. U.S. Patent 8,705,019, 22 April 2014. [Google Scholar]

- Minakuchi, S.; Takeda, N. Recent advancement in optical fiber sensing for aerospace composite structures. Photonic Sens. 2013, 3, 345–354. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fibre bragg gratings: Criticism and opportunities for research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [PubMed]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef] [PubMed]

- Kong, C.Y.; Soar, R. Method for embedding optical fibers in an aluminum matrix by ultrasonic consolidation. Appl. Opt. 2005, 44, 6325–6333. [Google Scholar] [CrossRef] [PubMed]

- Maier, R.R.J.; MacPherson, W.N.; Barton, J.S.; Carne, M.; Swan, M.; Sharma, J.N.; Futter, S.K.; Knox, D.A.; Jones, B.J.S.; McCulloch, S. Embedded fiber optic sensors within additive layer manufactured components. IEEE Sens. J. 2013, 13, 969–979. [Google Scholar] [CrossRef]

- Masurtschak, S.; Friel, R.J.; Gillner, A.; Ryll, J.; Harris, R.A. Fiber laser induced surface modification/manipulation of an ultrasonically consolidated metal matrix. J. Mater. Procss. Technol. 2013, 213, 1792–1800. [Google Scholar] [CrossRef] [Green Version]

- White, D. Ultrasonic Object Consolidation. U.S. Patent 6,519,500, 11 February 2003. [Google Scholar]

- White, D. Ultrasonic consolidation of aluminium tooling. Adv. Mater. Process. 2003, 161, 64–65. [Google Scholar]

- Kong, C.Y. Investigation of Ultrasonic Consolidation for Embedding Active/Passive Fibres in Aluminium Matrices. Ph.D. Thesis, Wolfson School of Mechanical and Manufacturing Engineering, Loughborough University, UK, 2005. [Google Scholar]

- Yang, Y.; Ram, G.D.J.; Stucker, B.E. An experimental determination of optimum processing parameters for Al/SiC metal matrix composites made using ultrasonic consolidation. J. Eng. Mater. Technol. 2007, 129, 538–549. [Google Scholar] [CrossRef]

- Kelly, G.S.; Scott Just, M., Jr.; Advani, S.G.; Gillespie, J.W., Jr. Energy and bond strength development during ultrasonic consolidation. J. Mater. Process. Technol. 2014, 214, 1665–1672. [Google Scholar] [CrossRef]

- Friel, R.J.; Harris, R.A. Ultrasonic additive manufacturing A hybrid production process for novel functional products. Procedia CIRP 2013, 6, 35–40. [Google Scholar] [CrossRef]

- Kong, C.Y.; Soar, R.C.; Dickens, P.M. Characterisation of aluminium alloy 6061 for the ultrasonic consolidation process. Mater. Sci. Eng. A 2003, 363, 99–106. [Google Scholar] [CrossRef]

- Li, X.; Prinz, F. Metal embedded fiber Bragg grating sensors in layered manufacturing. J. Manuf. Sci. Eng. 2003, 125, 577–585. [Google Scholar] [CrossRef]

- Ruan, J.; Sparks, T.E.; Fan, Z.; Stroble, J.K.; Panackal, A.; Liou, F. A Review of Layer Based Manufacturing Processes for Metals. 2006. Available online: http://edge.rit.edu/content/P10551/public/SFF/SFF%202006%20Proceedings/Manuscripts/22-Ruan.pdf (accessed on 19 November 2015).

- Kim, S.W.; Jeong, M.S.; Lee, I.; Kwon, I.B. Static mechanical characteristics of tin-coated fiber Bragg grating sensors. Sens. Actuators A 2014, 214, 156–162. [Google Scholar] [CrossRef]

- Li, D.; Soar, R.C. Plastic flow and work hardening of Al alloy matrices during ultrasonic consolidation fibre embedding process. Mater. Sci. Eng. A 2008, 498, 421–429. [Google Scholar] [CrossRef]

- Li, D.; Soar, R.C. Characterization of process for embedding SiC fibers in Al 6061 O matrix through ultrasonic consolidation. J. Eng. Mater. Technol. 2009, 131. [Google Scholar] [CrossRef]

- Yang, Y.; Ram, G.D.J.; Stucker, B.E. Bond formation and fiber embedment during ultrasonic consolidation. J. Mater. Process. Technol. 2009, 209, 4915–4924. [Google Scholar] [CrossRef]

- Yang, Y.; Stucker, B.E.; Ram, G.D.J. Mechanical properties and microstructures of SiC fiber-reinforced metal matrix composites made using ultrasonic consolidation. J. Compos. Mater. 2010, 44, 3179–3194. [Google Scholar] [CrossRef]

- Zhu, Z.; Wynne, B.P.; Ghassemieh, E. Microstrcutural evolution of SiC fibre embedded AA6061 matrix induced by ultrasonic consolidation. MRS Proc. 2008, 1075. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Asanuma, H. The development of metal-based smart composites. JOM 2000, 52, 21–25. [Google Scholar] [CrossRef]

- Michaud, V. Can shape memory alloy composites be smart? Scr. Mater. 2004, 50, 249–253. [Google Scholar] [CrossRef]

- Taya, M.; Furuya, Y.; Yamada, Y.; Watanabe, R.; Shibata, S.; Mori, T. Strengthening mechanisms of TiNi shape memory fiber/Al matrix composite. In Proceedings of the North American Conference on Smart Structures and Materials, Albuquerque, NM, USA, 1–4 February 1993.

- Furuya, Y. Design and Material Evaluation of Shape Memory Composites. J. Intell. Mater. Syst. Struct. 1996, 7, 321–330. [Google Scholar] [CrossRef]

- Han, C.; Choi, I.; Cho, K.; Park, I. Fabrication and characterization of AI/TINI shape memory composites. Met. Mater. 2000, 6, 169–175. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Q.; Wu, G.H.; Liu, Y.; Li, D.G. Effect of pre-oxidation of TiNi fibers on the interfacial and mechanical property of TiNif/Al composite. Mater. Sci. Eng. A 2014, 597, 20–28. [Google Scholar] [CrossRef]

- Armstrong, W.D.; Kino, H. Martensitic Transformations in a NiTi Fiber Reinforced 6061 Aluminum Matrix Composite. J. Intell. Mater. Syst. Struct. 1995, 6, 809–816. [Google Scholar] [CrossRef]

- Armstrong, W.D.; Kino, H. Shape recovery transformation in a NiTi fiber reinforced metal matrix composite. In Proceedings of US-Japan Workshop on Smart Materials and Structures, Seattle, WA, USA, 3–4 December 1997; pp. 83–90.

- Armstrong, W.D.; Lorentzen, T. Fiber phase transformation and matrix plastic flow in a room temperature tensile strained NiTi shape memory alloy fiber reinforced 6082 aluminum matrix composite. Scr. Mater. 1997, 36, 1037–1043. [Google Scholar] [CrossRef]

- Armstrong, W.D.; Lorentzen, T.; BrØndsted, P.; Larsen, P.H. An experimental and modeling investigation of the external strain, internal stress and fiber phase transformation behavior of a NiTi actuated aluminum metal matrix composite. Acta Mater. 1998, 46, 3455–3466. [Google Scholar] [CrossRef]

- Armstrong, W.D.; Lorentzen, T. Thermal deformation behavior of a NiTi actuated aluminum metal-matrix composite. In Proceedings of the Smart Structures and Materials 1999 Conference, Newport Beach, CA, USA, 1–4 March 1999.

- Armstrong, W.D.; Reinhall, P.G. High-passive structural damping in a NiTi shape memory alloy fiber aluminum metal matrix composite. In Proceedings of the Smart Structures and Materials 2000 Conference, Newport Beach, CA, USA, 5–9 March 2000.

- Armstrong, W.D.; Lorentzen, T. Large self-thermal-plastic deformation in a NiTi shape-memory alloy fiber-actuated aluminum metal-matrix composite. Metall. Mater. Trans. A 2002, 33, 3535–3540. [Google Scholar] [CrossRef]

- Bannuru, T.; Armstrong, W.D. Observed dependencies of the large thermal-compressive response of a NiTi shape-memory alloy fiber aluminum metal matrix composite on maximum tensile strain imposed during a preceding room-temperature tensile process. Metall. Mater. Trans. A 2004, 35, 1403–1406. [Google Scholar] [CrossRef]

- Armstrong, W.D.; Bannuru, T. Observed dependencies of the large thermal-compressive response of a NiTi shape-memory alloy fiber aluminum metal matrix composite. In Proceedings of the Smart Structures and Materials 2005 Conference, San Diego, CA, USA, 7–10 March 2005.

- Hamada, K.; Lee, J.H.; Mizuuchi, K.; Taya, M.; Inoue, K. Thermomechanical behavior of TiNi shape memory alloy fiber reinforced 6061 aluminum matrix composite. Metall. Mater. Trans. A 1998, 29, 1127–1135. [Google Scholar] [CrossRef]

- Mizuuchi, K.; Hamada, K.; Taya, M.; Inoue, K. Processing of NiTi SMA Fiber/6061 Al metal-matrix composite by vacuum hot pressing. In Proceedings of US-Japan Workshop on Smart Materials and Structures, Seattle, WA, USA, 3–4 December 1997; pp. 75–81.

- Park, Y.C.; Lee, G.C.; Furuya, Y. A study on the fabrication of TiNi/Al6061 shape memory composite material by hot-press method and its mechanical property. Mater. Trans. 2004, 45, 264–271. [Google Scholar] [CrossRef]

- Park, Y.C.; Kang, J.H.; Lee, J.K.; Lee, G.C.; Furuya, Y. Effect of cold rolling on fatigue crack propagation of TiNi/Al6061 shape memory composite. Smart Mater. Struct. 2007, 16, 982–988. [Google Scholar] [CrossRef]

- Park, Y.C.; Jo, Y.J.; Baek, S.H.; Furuya, Y. Fatigue design curve of a TiNi/Al shape memory alloy composite for aircraft stringer design. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- Cui, L.S.; Zheng, Y.J.; Zhu, D.; Yang, D.Z. The effects of thermal cycling on the reverse martensitic transformation of prestrained TiNi alloy fibers embedded in Al matrix. J. Mater. Sci. Lett. 2000, 19, 1115–1117. [Google Scholar] [CrossRef]

- Zheng, Y.J.; Cui, L.S.; Zhu, D.; Yang, D.Z. The constrained phase transformation of prestrained TiNi fibers embedded in metal matrix smart composite. Mater. Lett. 2000, 43, 91–96. [Google Scholar] [CrossRef]

- Zheng, Y.J.; Cui, L.S. Martensite fraction-temperature diagram of TiNi wires embedded in an aluminum matrix. Intermetallics 2004, 12, 1305–1309. [Google Scholar] [CrossRef]

- Zheng, Y.J.; Cui, L.S.; Li, Y.; Yang, D.Z. Separation of the martensite in TiNi fiber reinforced aluminum matrix composite. J. Mater. Sci. Technol. 2004, 20, 390–394. [Google Scholar]

- Hahnlen, R.; Dapino, M.J. Performance and modeling of active metal-matrix composites manufactured by ultrasonic additive manufacturing. In Proceedings of the Conference on Industrial and Commercial Applications of Smart Structures Technologies 2011, San Diego, CA, USA, 7–8 March 2011.

- Hahnlen, R.; Dapino, M.J. Stress-induced tuning of ultrasonic additive manufacturing Al-NiTi composites. In Proceedings of the Conference on Behavior and Mechanics of Multifunctional Materials and Composites, San Diego, CA, USA, 12–15 March 2012.

- Hahnlen, R.; Dapino, M.J. NiTi–Al interface strength in ultrasonic additive manufacturing composites. Compos. B 2014, 59, 101–108. [Google Scholar] [CrossRef]

- Mizuuchi, K.; Inoue, K.; Hamada, K.; Sugioka, M.; Itami, M.; Okanda, Y.; Kawahara, M. Processing and properties of TiNi shape memory fiber-reinforced 6061 aluminum matrix composite made by spark plasma sintering. In Proceedings of the 5th European Conference on Smart Structures and Materials, Glasgow, UK, 22–24 May 2000.

- Friel, R.J.; Harris, R.A. A nanometre-scale fibre-to-matrix inter face characterization of an ultrasonically consolidated metal matrix composite. J. Mater. 2010, 224, 31–40. [Google Scholar]

- Havermann, D.; Mathew, J.; MacPherson, W.N.; Maier, R.R.J.; Hand, D.P. Temperature and strain measurements with fibre Bragg gratings embedded in stainless steel 316. J. Lightwave Technol. 2015, 33, 2474–2479. [Google Scholar] [CrossRef]

- Maier, R.R.J.; Havermann, D.; Schneller, O.; Mathew, J.; Polyzos, D.; MacPherson, W.N.; Hand, D.P. Optical fibre sensing in metals by embedment in 3D printed metallic structures. In Proceedings of the 23rd International Conference on Optical Fibre Sensors, Santos Santander, Spain, 2 June 2014.

- Taylor, H.F.; Lee, C.E. Sensing applications of fiber fabry-perot interferometers embedded in composites and in metals. Exp. Smart Mater. Struct. ASME 1993, 181, 47–52. [Google Scholar]

- Lee, C.E.; Alcoz, J.J.; Gibler, W.; Atkins, R.A.; Taylor, H.F. Method for embedding optical fibers and optical fiber sensors in metal parts and structures. Fiber Opt. Smart Struct. Skins IV 1991, 1588. [Google Scholar] [CrossRef]

- Baldini, S.E.; Tubbs, D.J.; Stange, W.A. Embedding fiber optic sensors in titanium matrix composites. Fiber Opt Smart Struct. Skins III 1990, 1370. [Google Scholar] [CrossRef]

- Li, X.C.; Golnas, A.; Prinz, F. Shape deposition manufacturing of smart metallic structures with embedded sensors. Proc. SPIE Int. Soc. Opt. Eng. 2000, 3986, 160–171. [Google Scholar]

- Li, X.; Johnsen, J.; Groza, J.; Prinz, F. Processing and microstructures of fiber Bragg grating sensors embedded in stainless steel. Metall. Mater. Trans. A 2002, 33, 3019–3024. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Feng, Y.; Zhang, H. Ultrasonic embedding of nickel-coated fiber Bragg grating in aluminum and associated sensing characteristics. Opt. Fiber Technol. 2012, 18, 7–13. [Google Scholar] [CrossRef]

- Li, X.C.; Prinz, F.; Seim, J. Thermal behavior of a metal embedded fiber Bragg grating sensor. Smart Mater. Struct. 2001, 10, 575–579. [Google Scholar] [CrossRef]

- Havermann, D.; Mathew, J.; MacPherson, W.N.; Maier, R.R.J.; Hand, D.P. In-situ measurements with fibre Bragg gratings embedded in stainless steel. Proc. SPIE 2014, 9157. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Y.; Zhang, H.; Peng, G. Fiber Bragg grating sensor metallization and embedding into 42CrMo steel by soldering. Trans. China Weld. Inst. 2008, 29, 69–72. [Google Scholar]

- Li, Y.; Li, W.; Wang, F.; Liu, F. Embedding fiber sensor in 1100 Aluminium foil using ultrasonic welding method. Trans. China Weld. Inst. 2011, 32, 9–12. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saheb, N.; Mekid, S. Fiber-Embedded Metallic Materials: From Sensing towards Nervous Behavior. Materials 2015, 8, 7938-7961. https://doi.org/10.3390/ma8115435

Saheb N, Mekid S. Fiber-Embedded Metallic Materials: From Sensing towards Nervous Behavior. Materials. 2015; 8(11):7938-7961. https://doi.org/10.3390/ma8115435

Chicago/Turabian StyleSaheb, Nouari, and Samir Mekid. 2015. "Fiber-Embedded Metallic Materials: From Sensing towards Nervous Behavior" Materials 8, no. 11: 7938-7961. https://doi.org/10.3390/ma8115435

APA StyleSaheb, N., & Mekid, S. (2015). Fiber-Embedded Metallic Materials: From Sensing towards Nervous Behavior. Materials, 8(11), 7938-7961. https://doi.org/10.3390/ma8115435