Damping Characteristics of Ti50Ni50−xCux (x = 0~30 at.%) Shape Memory Alloys at a Low Frequency

Abstract

:1. Introduction

2. Results and Discussion

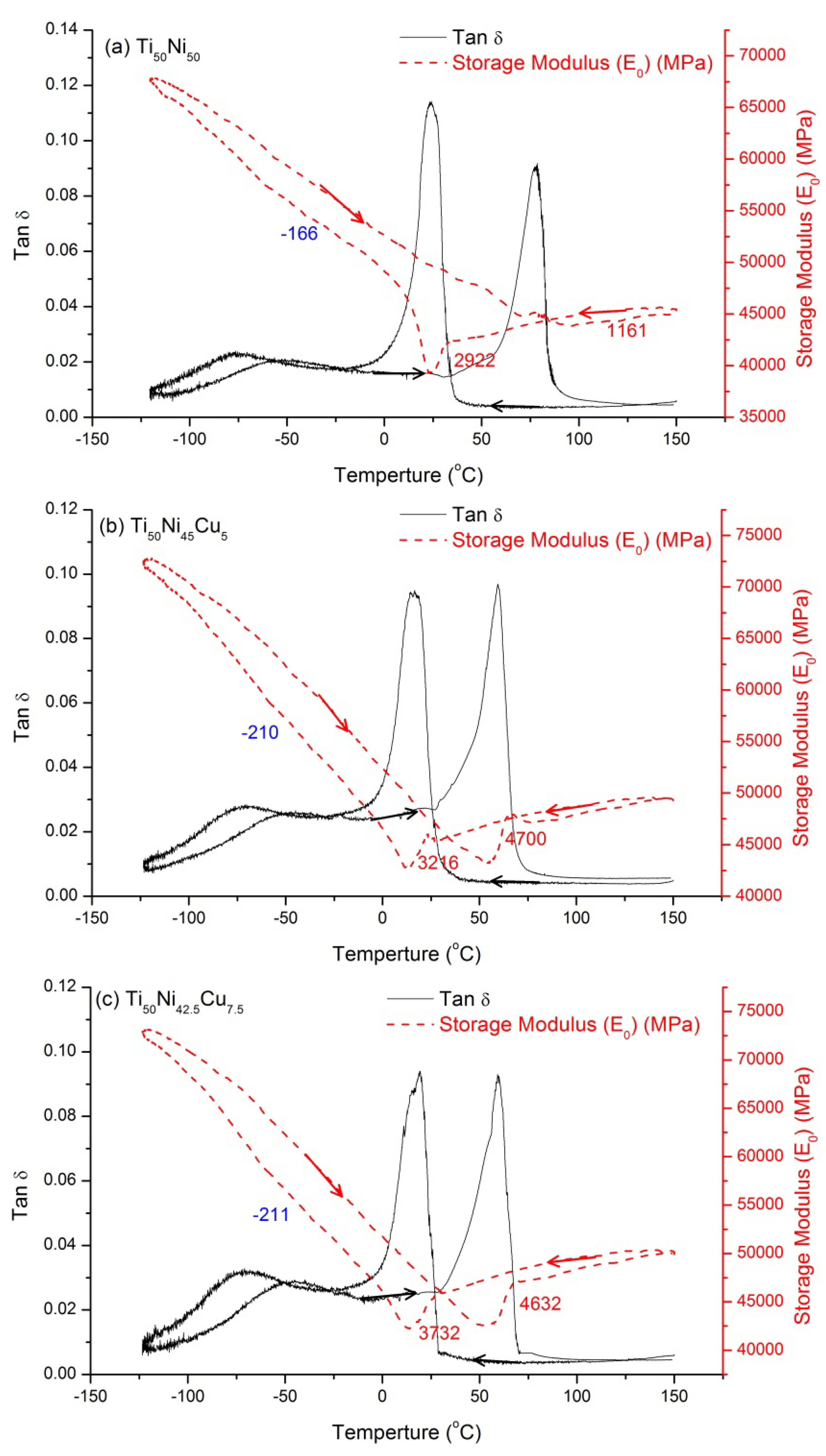

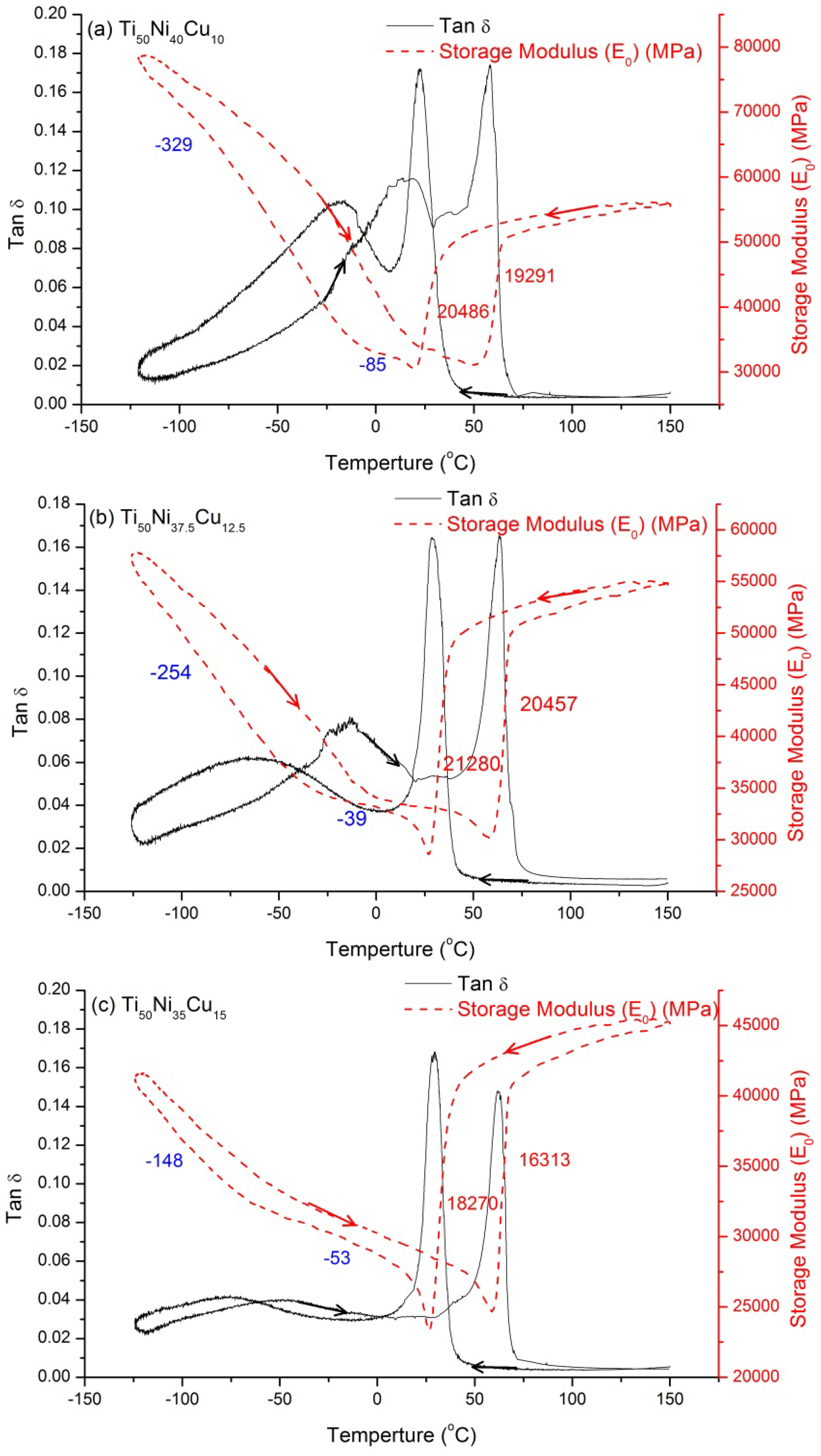

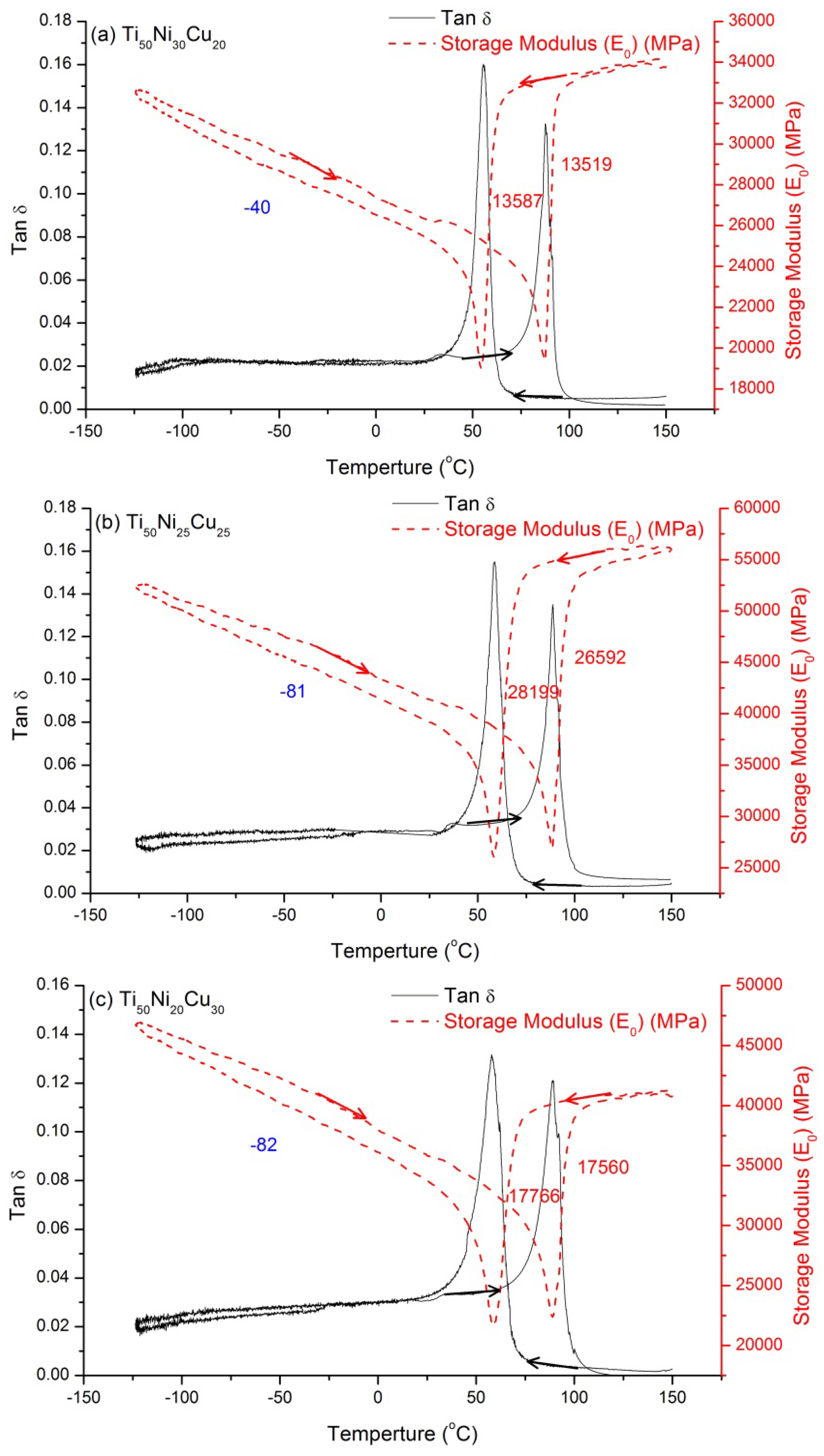

2.1. Tan δ Value versus Temperature (T)

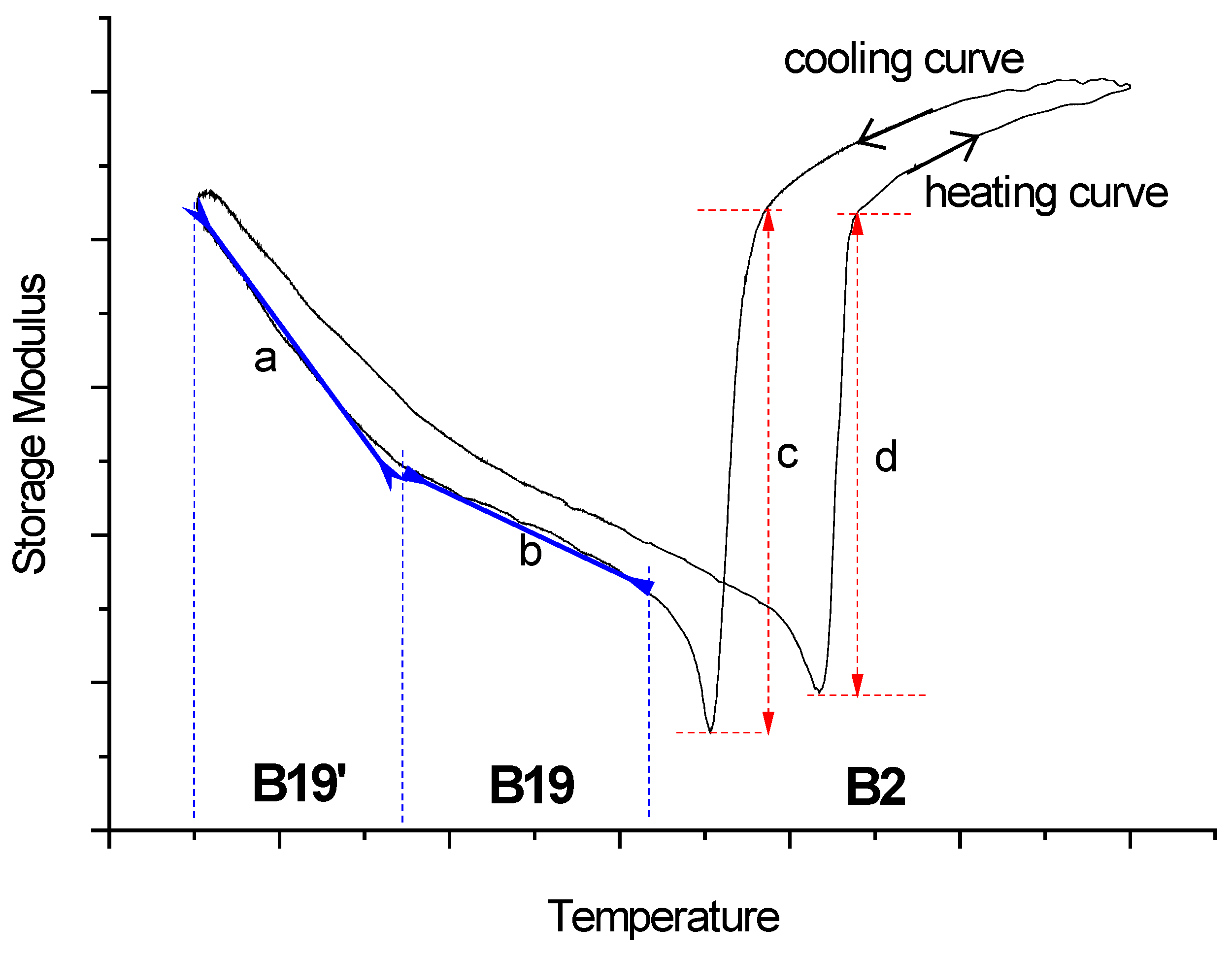

2.2. Storage Modulus Value (E0) versus Temperature (T)

| Ti50Ni50−xCux, x (at.%) | Transformation Sequences | E0 softening (MPa) | E0 hardening (MPa) | Slope of B19 (MPa/°C) | Slope of B19’ (MPa/°C) |

|---|---|---|---|---|---|

| 0 | B2↔B19’ | 2922 | 1161 | N/A | −166 |

| 5 | 3216 | 4700 | N/A | −210 | |

| 7.5 | 3732 | 4632 | N/A | −211 | |

| 10 | B2↔B19↔B19’ | 20,486 | 19,291 | −85 | −329 |

| 12.5 | 21,280 | 20,457 | −39 | −254 | |

| 15 | 18,270 | 16,316 | −53 | −148 | |

| 20 | B2↔B19 | 13,587 | 13,519 | −40 | N/A |

| 25 | 28,199 | 26,592 | −81 | N/A | |

| 30 | 17,766 | 17,560 | −82 | N/A |

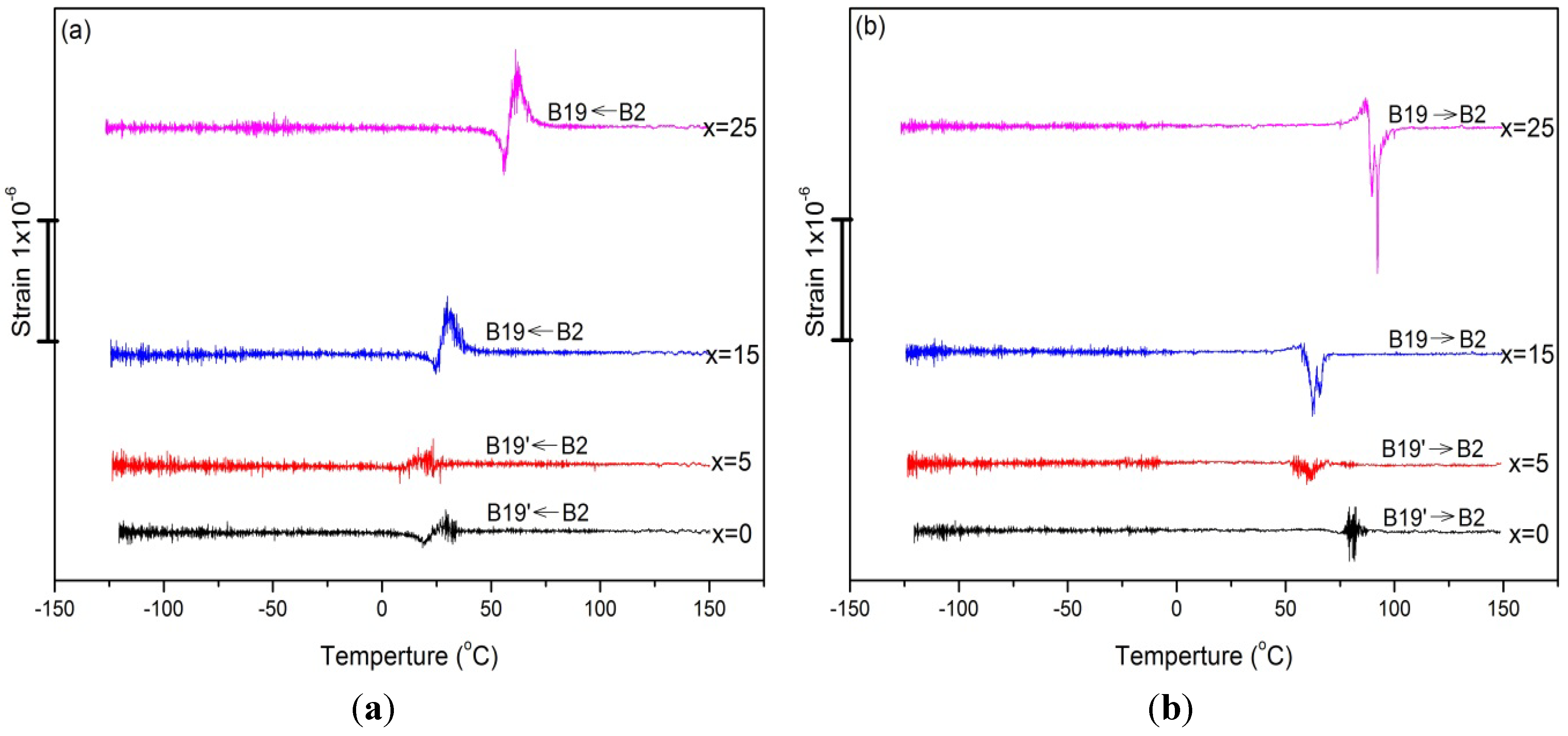

2.3. Strain Variation vs. Temperature (T)

2.4. The Damping Properties Exhibited in B2↔B19 and B2↔B19’ Transformations

2.5. The Relaxation Peak in DMA Curves

2.5.1. The Appearance of the Relaxation Peak

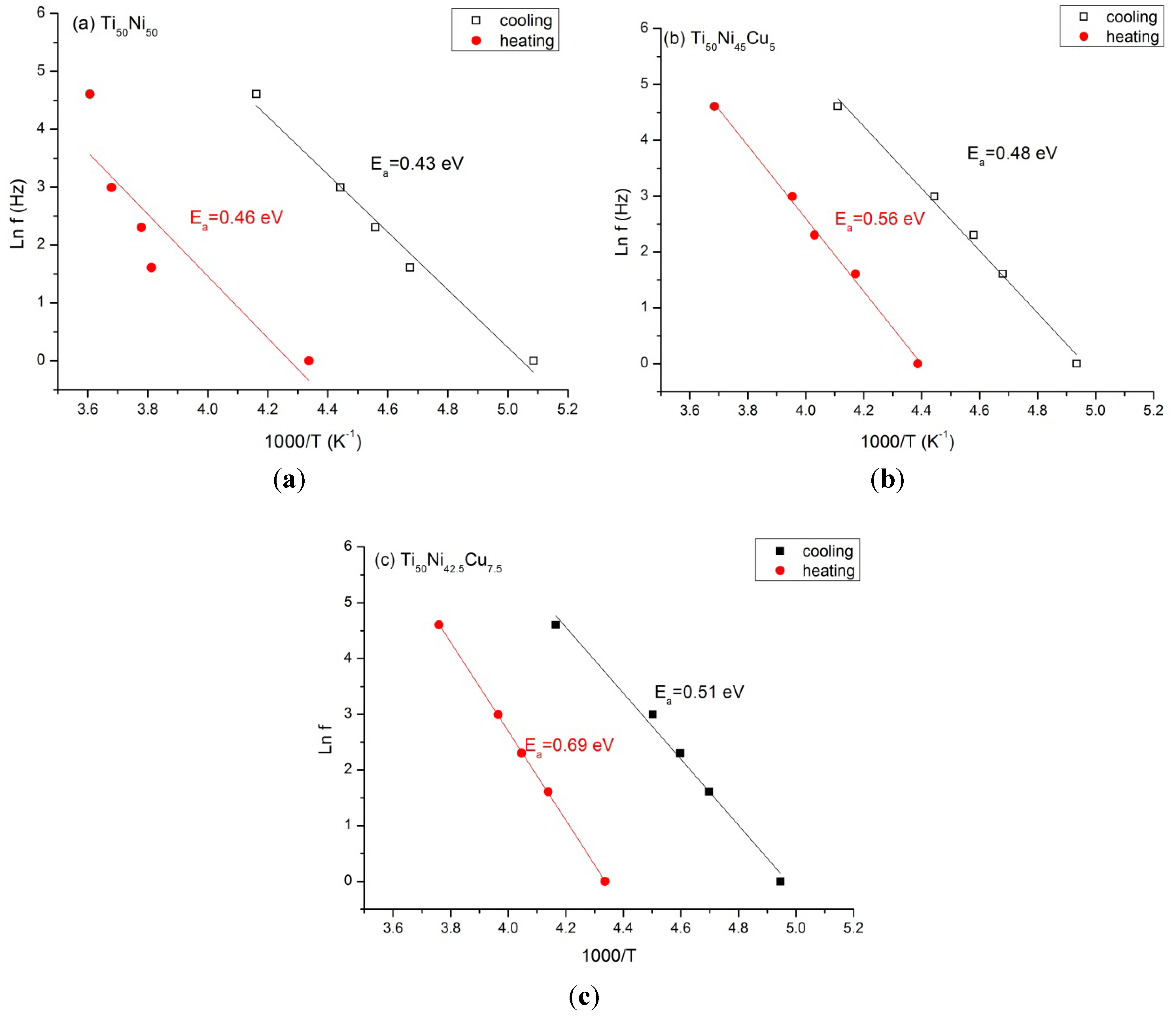

2.5.2. The Activation Energy (Ea) of the Relaxation Peak

| Ti50Ni50−xCux, x (at.%) | 0 a | 5 a | 7.5 a | 15 b | 16 c | 20 c | 25 b |

|---|---|---|---|---|---|---|---|

| In cooling | 0.43 eV | 0.48 eV | 0.51 eV | N/A | 0.76 eV | 0.67 eV | N/A |

| In heating | 0.46 eV | 0.56 eV | 0.69 eV | 0.68 eV | 0.71 eV | 0.64 eV | 0.61 eV |

3. Experimental Procedures

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Otsuka, K.; Shimizu, K. Pseudoelasticity and shape memory effects in alloys. Int. Met. Rev. 1986, 31, 93–114. [Google Scholar] [CrossRef]

- Miyazaki, S.; Otsuka, K. Development of shape memory alloys. ISIJ Int. 1989, 29, 353–377. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1998; pp. 1–96. [Google Scholar]

- Otsuka, K.; Kakeshita, T. Science and technology of shape-memory alloys: New developments. MRS Bull. 2002, 27, 91–100. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Damping capacity of thermoelastic martensite in shape memory alloys. J. Alloys Compd. 2003, 355, 58–64. [Google Scholar] [CrossRef]

- Otsuka, K.; Xu, Y.; Ren, X. Ti-Ni-based shape memory alloys as smart materials. Mater. Sci. Forum 2003, 426–432, 251–258. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Fan, G.; Zhou, Y.; Otsuka, K.; Ren, X.; Nakamura, K.; Ohba, T.; Suzuki, T.; Yoshida, I.; Yin, F. Effects of frequency, composition, hydrogen and twin boundary density on the internal friction of Ti50Ni50−xCux shape memory alloys. Acta Mater. 2006, 54, 5221–5229. [Google Scholar] [CrossRef]

- Nam, T.H.; Saburi, T.; Shimizu, K. Cu-Content dependence of shape memory characteristics in Ti-Ni-Cu alloys. Mater. Trans. 1990, 31, 959–967. [Google Scholar] [CrossRef]

- Nam, T.H.; Saburi, T.; Shimizu, K. Effect of thermo-mechanical treatment on shape memory characteristics in a Ti-40Ni-10Cu (at.%) alloy. Mater. Trans. 1991, 32, 814–820. [Google Scholar] [CrossRef]

- Ramachandran, B.; Tang, R.C.; Chang, P.C.; Kuo, Y.K.; Chien, C.; Wu, S.K. Cu-substitution effect on thermoelectric properties of the TiNi-based shape memory alloys. J. Appl. Phys. 2013, 113, 203702–203707. [Google Scholar]

- Chang, S.H.; Hsiao, S.H. Inherent internal friction of Ti50Ni50−xCux shape memory alloys measured under isothermal conditions. J. Alloys Compd. 2014, 586, 69–73. [Google Scholar] [CrossRef]

- Teng, Y.; Zhu, S.; Wang, F.; Wu, W. Electronic structures and shape-memory behavior of Ti50Ni50−xCux (x = 0, 6.25, 12.5, 18.75 and 25.0 at.%) by density functional theory. Phys. B 2007, 393, 18–23. [Google Scholar] [CrossRef]

- Chang, S.H.; Wu, S.K. Textures in cold-rolled and annealed Ti50Ni50 shape memory alloy. Scripta Mater. 2004, 50, 937–941. [Google Scholar] [CrossRef]

- San, J.; Nó, M.L. Damping behavior during martensitic transformation in shape memory alloys. J. Alloys Compd. 2003, 355, 65–71. [Google Scholar]

- Chen, Y.; Jiang, H.C.; Liu, S.W.; Rong, L.J.; Zhao, X.Q. Damping capacity of TiNi-based shape memory alloys. J. Alloys Compd. 2009, 482, 151–154. [Google Scholar] [CrossRef]

- Chien, C.; Wu, S.K. Damping capacities of Ti50Ni50−xCux shape memory alloys measured under temperature, strain, and frequency sweeps. In Proceedings of International Conference on Electronic Materials, Taipei, Taiwan, 10–14 June 2014.

- Lo, Y.C.; Wu, S.K.; Horng, H.E. A study of B2↔B19↔B19' two-stage martensitic transformation in a Ti50Ni40Cu10 alloy. Acta Metall. Mater. 1993, 41, 747–759. [Google Scholar] [CrossRef]

- Yoshida, I.; Monma, D.; Iino, K.; Otsuka, K.; Asai, M.; Tsuzuki, H. Damping properties of Ti50Ni50−xCux alloys utilizing martensitic transformation. J. Alloys Compd. 2003, 355, 79–84. [Google Scholar] [CrossRef]

- Lin, K.N.; Wu, S.K. Multi-stage transformation in annealed Ni-rich Ti49Ni41Cu10 shape memory alloy. Intermetallics 2010, 18, 87–91. [Google Scholar] [CrossRef]

- Nagasawa, A.; Nakanishi, N.; Enami, K. The nature of special-mode softening and the mechanism of martensitic phase transition in β-phase alloys. Philos. Mag. A 1981, 43, 1345–1357. [Google Scholar] [CrossRef]

- Ren, X.; Taniwaki, K.; Otsuka, K.; Suzuki, T.; Tanaka, K.; Chumlyakov, Y.I.; Ueki, T. Elastic constants of Ti50Ni30Cu20 alloy prior to martensitic transformation. Philos. Mag. A 1999, 79, 31–41. [Google Scholar]

- Chang, S.H.; Wu, S.K. Determining transformation temperatures of equiatomic TiNi shape memory alloy by dynamic mechanical analysis test. J. Alloys Compd. 2013, 577, S241–S244. [Google Scholar] [CrossRef]

- Jiang, H.J.; Ke, C.B.; Cao, S.S.; Ma, X.; Zhang, X.P. Phase transformation and damping behavior of lightweight porous TiNiCu alloys fabricated by powder metallurgy process. Trans. Nonferr. Met. Soc. China 2013, 23, 2029–2036. [Google Scholar] [CrossRef]

- Ueura, T.; Sakaguchi, T.; Igata, N.; Takeuchi, S. Internal friction of hydrogenated Ti (Ni, Cu) shape memory alloys. Key Eng. Mater. 2006, 319, 39–44. [Google Scholar] [CrossRef]

- Tadaki, T.; Wayman, C.M. Electron microscopy studies of martensitic transformations in Ti50Ni50−xCux alloys. Part I. Compositional dependence of one-third reflections from the matrix phase. Metallography 1982, 15, 233–245. [Google Scholar] [CrossRef]

- Tadaki, T.; Wayman, C.M. Electron microscopy studies of martensitic transformations in Ti50Ni50−xCux alloys. Part II. Morphology and crystal structure of martensites. Metallography 1982, 15, 247–258. [Google Scholar] [CrossRef]

- Moberly, W.; Proft, J.; Duerig, T. Twinless martensite in TiNiCu shape memory alloys. Mater. Sci. Forum 1990, 56–58, 605–610. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chien, C.; Wu, S.-K.; Chang, S.-H. Damping Characteristics of Ti50Ni50−xCux (x = 0~30 at.%) Shape Memory Alloys at a Low Frequency. Materials 2014, 7, 4574-4586. https://doi.org/10.3390/ma7064574

Chien C, Wu S-K, Chang S-H. Damping Characteristics of Ti50Ni50−xCux (x = 0~30 at.%) Shape Memory Alloys at a Low Frequency. Materials. 2014; 7(6):4574-4586. https://doi.org/10.3390/ma7064574

Chicago/Turabian StyleChien, Chen, Shyi-Kaan Wu, and Shih-Hang Chang. 2014. "Damping Characteristics of Ti50Ni50−xCux (x = 0~30 at.%) Shape Memory Alloys at a Low Frequency" Materials 7, no. 6: 4574-4586. https://doi.org/10.3390/ma7064574

APA StyleChien, C., Wu, S.-K., & Chang, S.-H. (2014). Damping Characteristics of Ti50Ni50−xCux (x = 0~30 at.%) Shape Memory Alloys at a Low Frequency. Materials, 7(6), 4574-4586. https://doi.org/10.3390/ma7064574