Evaluation of Superficial and Dimensional Quality Features in Metallic Micro-Channels Manufactured by Micro-End-Milling

Abstract

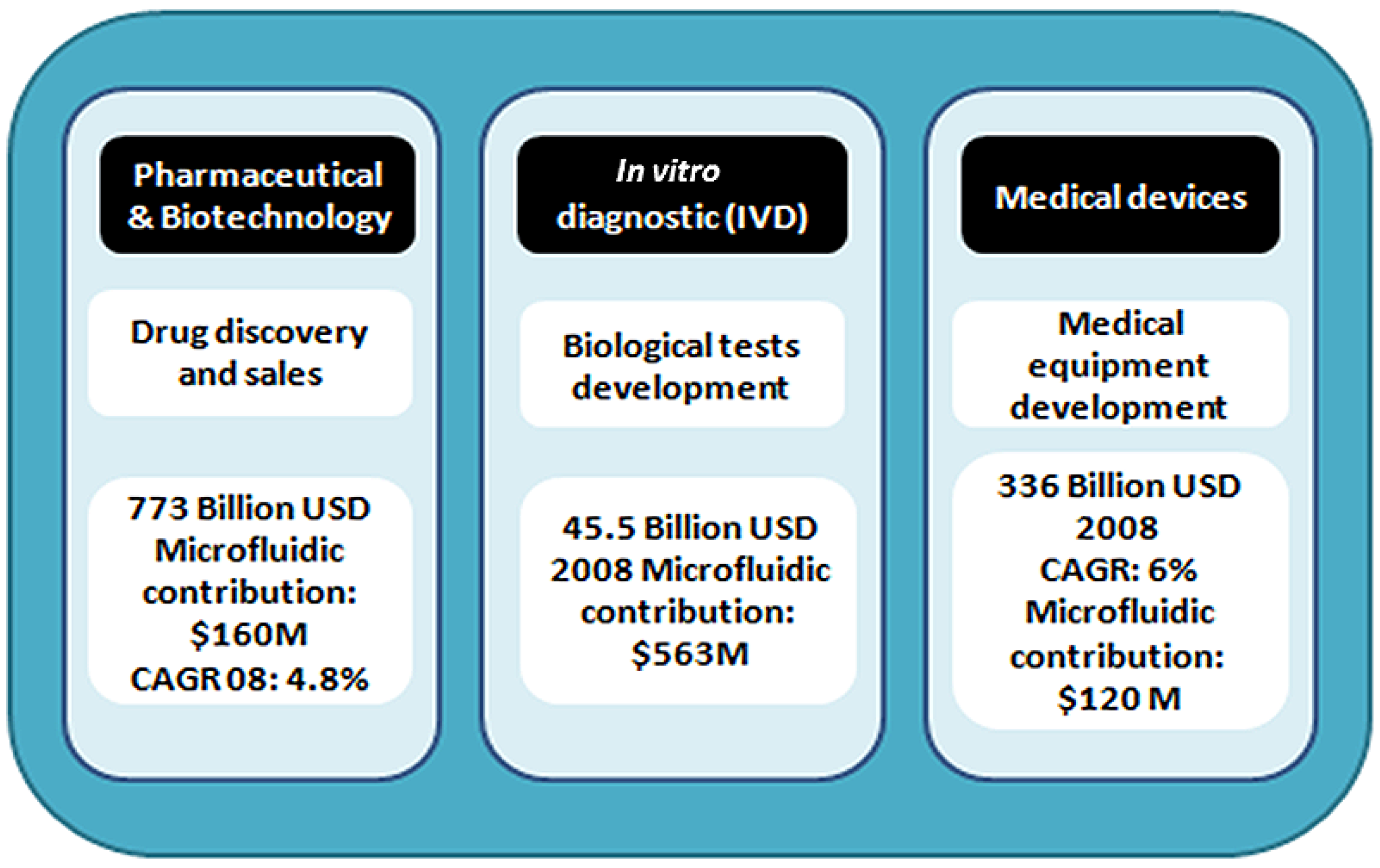

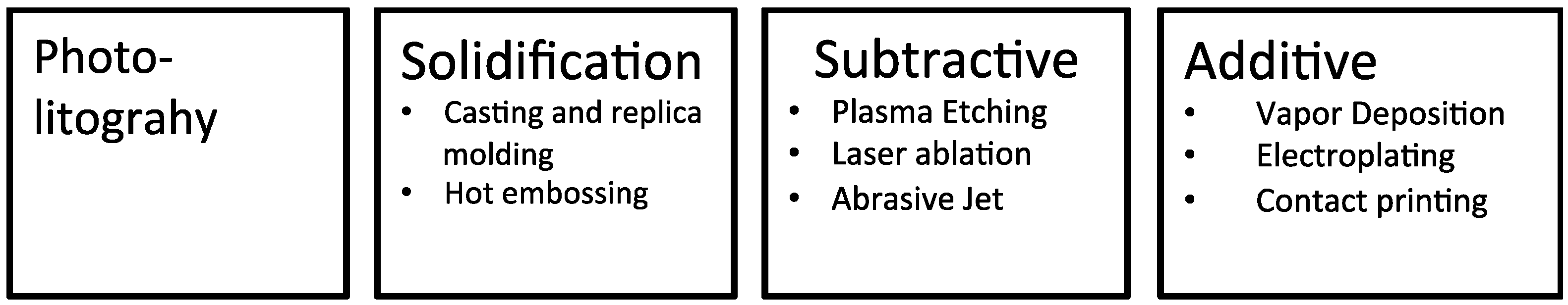

:1. Introduction

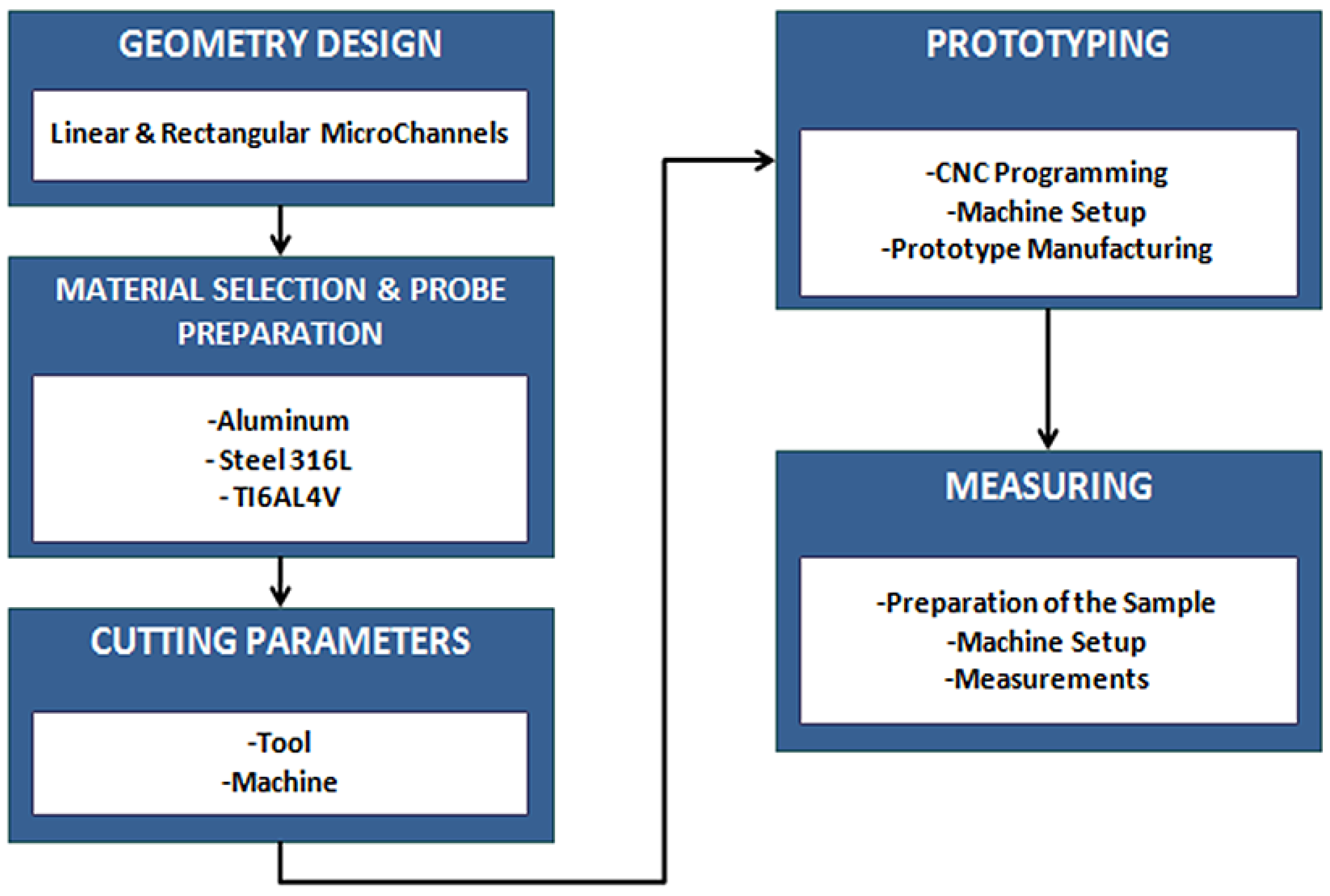

2. Experimental Section

2.1. Micro-Channel Design

2.2. Experimental Plan

| Variable Factor | Aluminum | Titanium/Steel | ||

|---|---|---|---|---|

| L1 | L2 | L1 | L2 | |

| Spindle speed [S], min−1 | 10,000 | 12,000 | 10,000 | 12,000 |

| Depth of cut per pass [ap] µm | 2 | 10 | 2 | 10 |

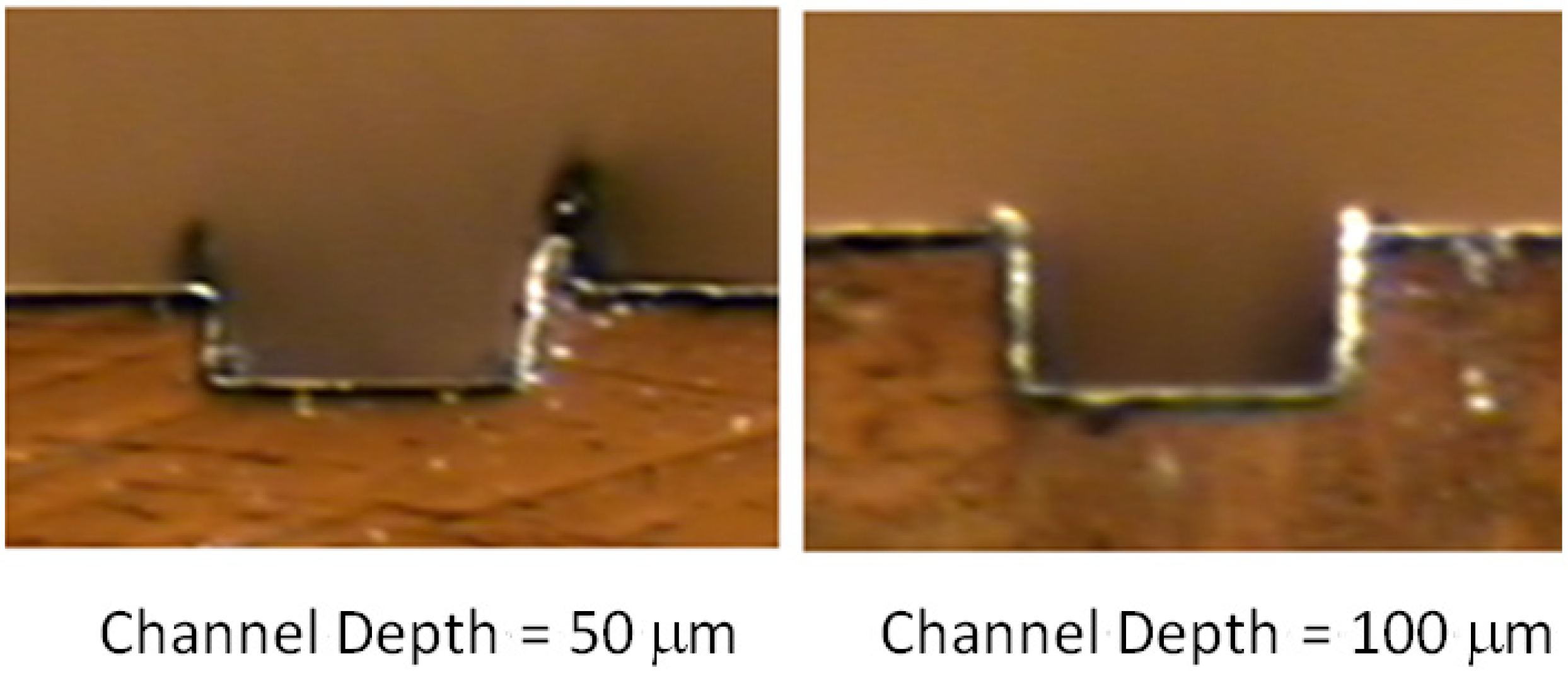

| Channel depth [d], µm | 50 | 100 | 50 | 100 |

| Feed per tooth [fz], µm/fz | 1.25 | 1.90 | 0.625 | 1.25 |

| Coolant | Dry | Wet | Dry | Wet |

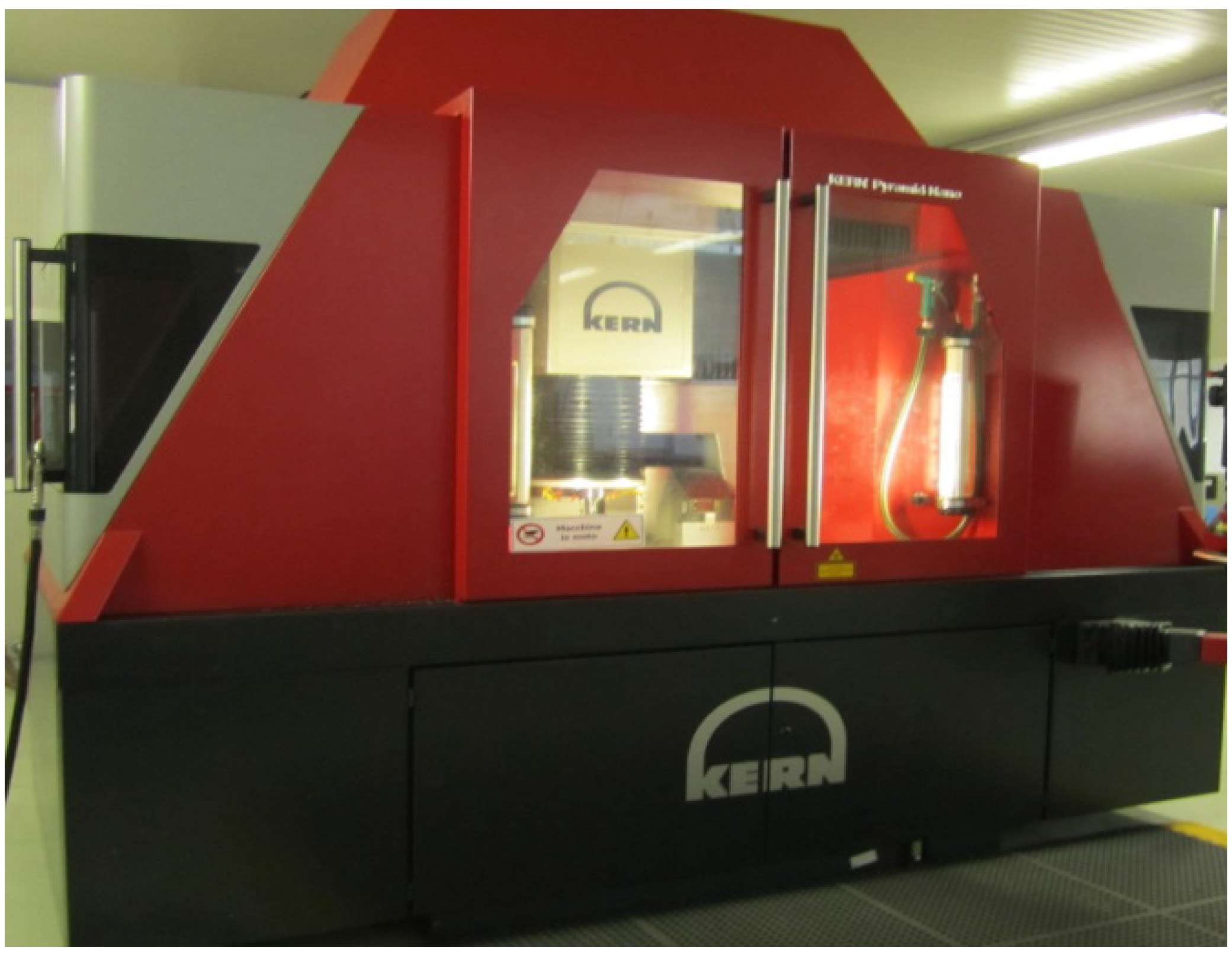

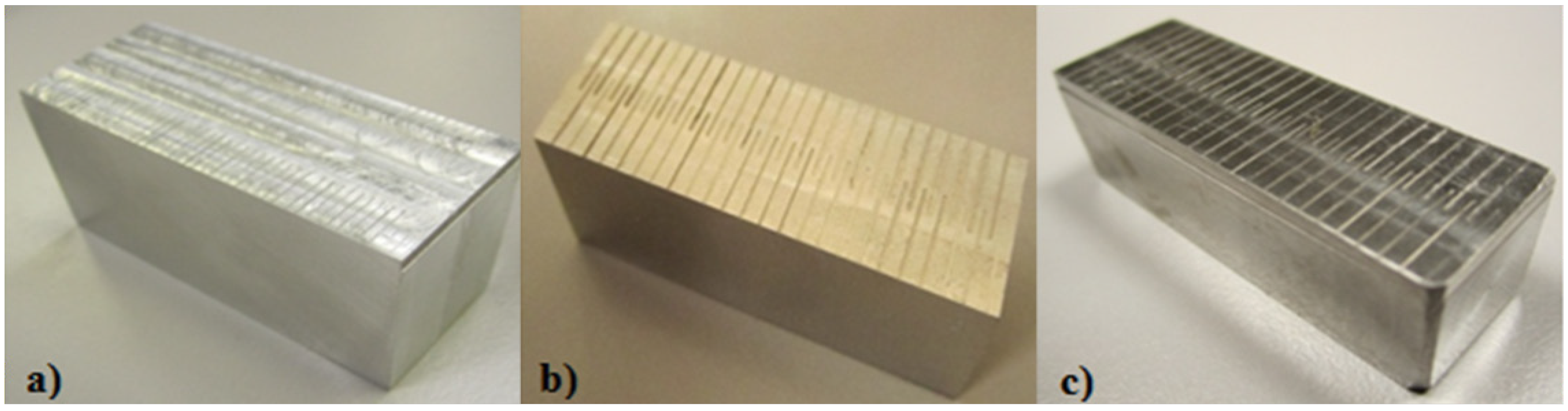

2.3. Equipment and Material

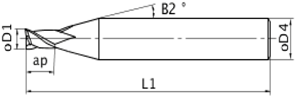

| Mitsubishi© MS2SSD0020 |  |

|---|---|

| Material/coating: | Solid carbide/CRN |

| Number of flutes (z): | 2 |

| Cutting diameter (D1) [mm] | 0.2 |

| M ax. cutting edge diameter tolerance | 0 |

| Min. cutting edge diameter tolerance | −0.02 |

| Shank diameter (D4) [mm] | 4 |

| Overall length (L1) [mm] | 40 |

| Length of cut (ap) [mm] | 0.3 |

| Tool interference corner (B2) [°] | 15 |

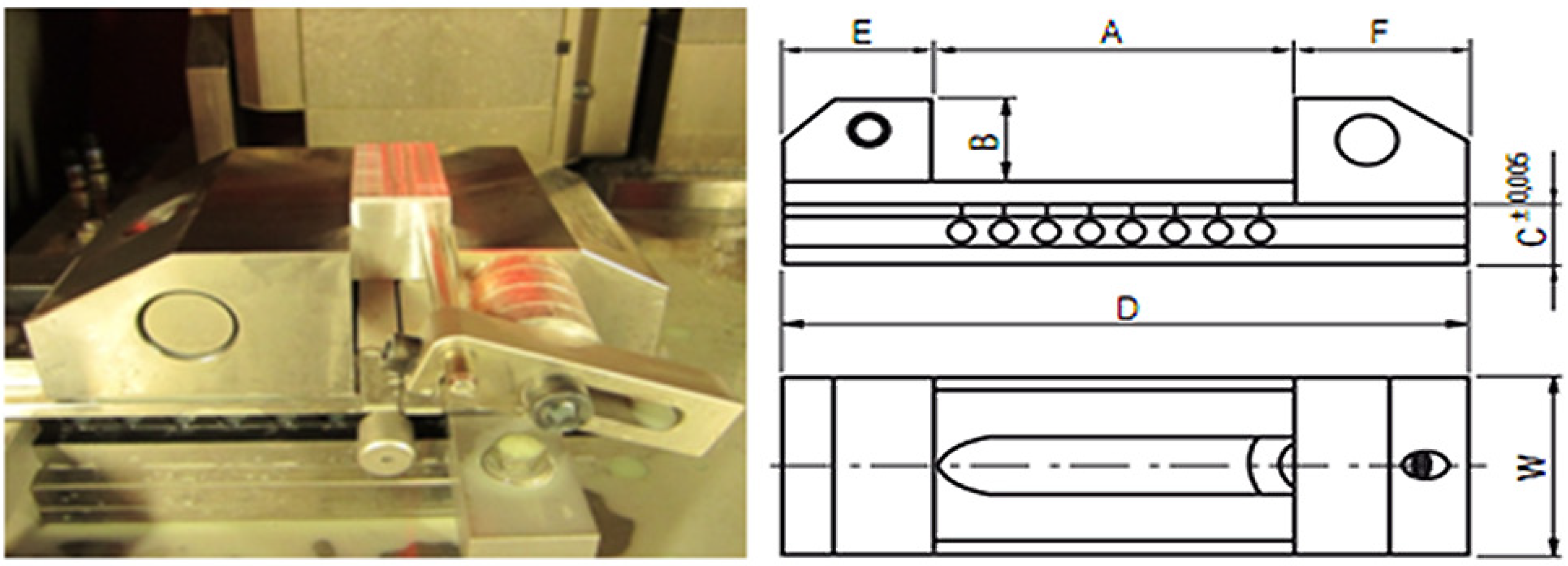

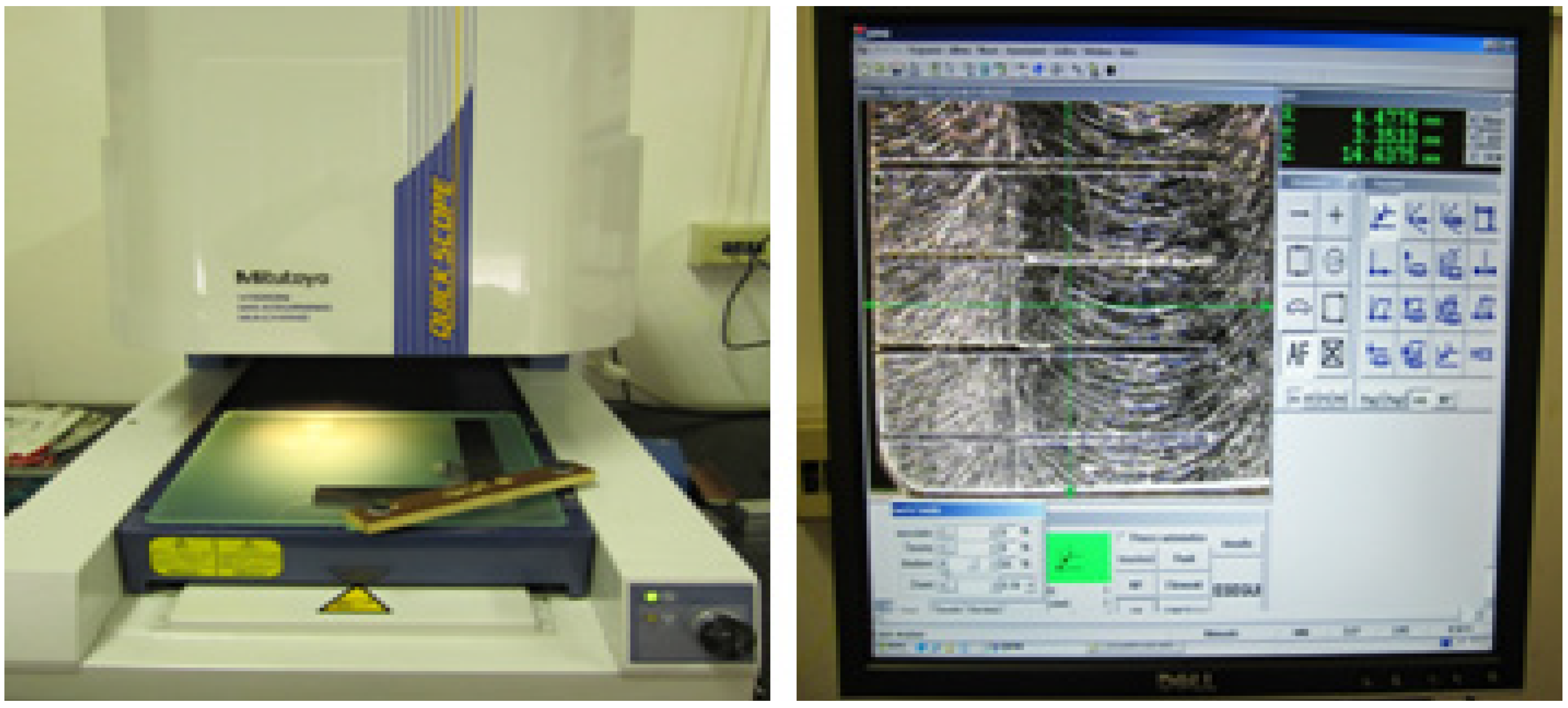

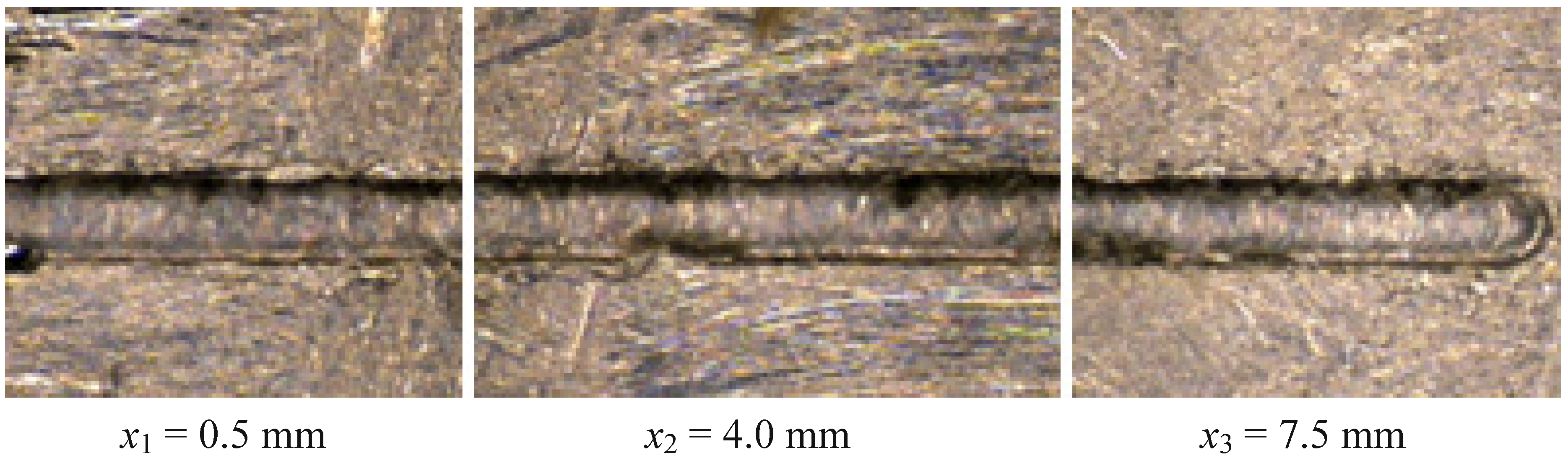

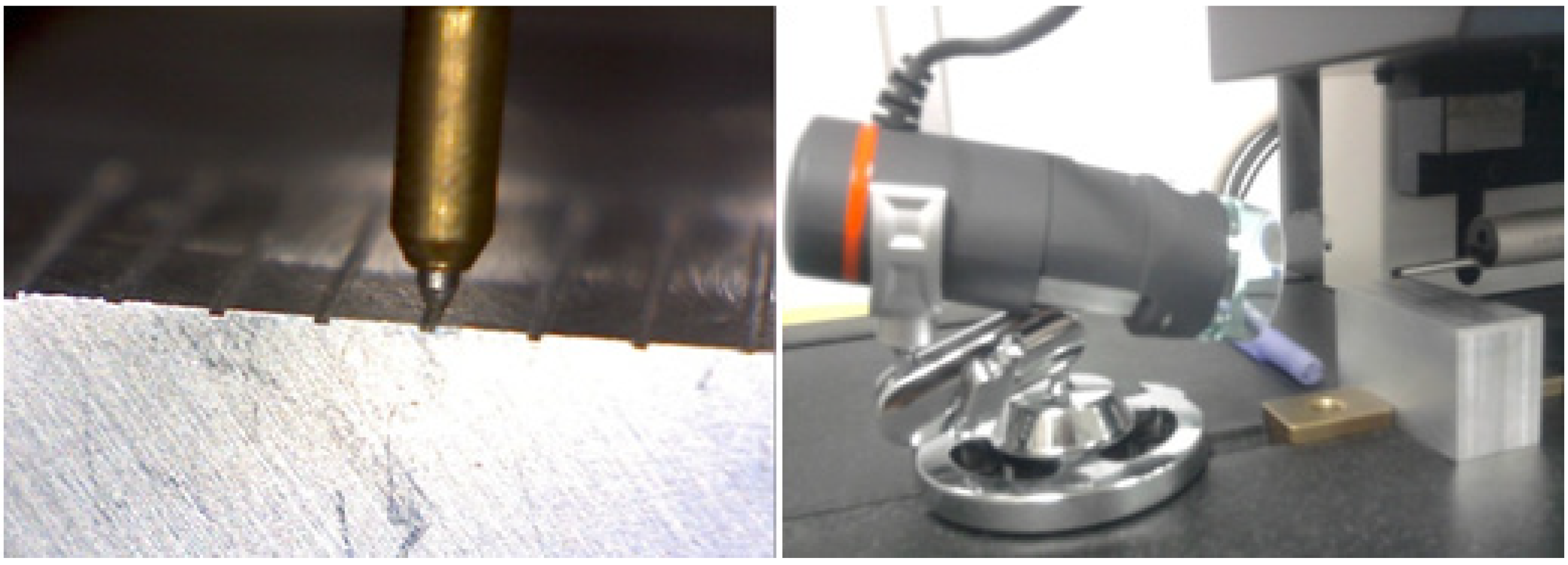

2.4. Metrology and Sample Preparation

| Response Variable | Measurement Type | Evaluation |

|---|---|---|

| Burr formation | Qualitative | Rating 1–5 |

| Shape | Qualitative | Profile |

| Dimension | Quantitative | Width size [μm] |

| Roughness | Quantitative | Ra [μm] |

| Material | SiC Grain Size | Cloth Size [μm] |

|---|---|---|

| Aluminum alloy | 80-220-500-800-1200 | 1 |

| Stainless steel 316L | 80-120-220-320-500-800-1000 | 1–3 |

| Ti6Al4V | 320-500-800 | 1 |

2.5. Statistical Analysis

2.6. Measurement Systems Validation

3. Results

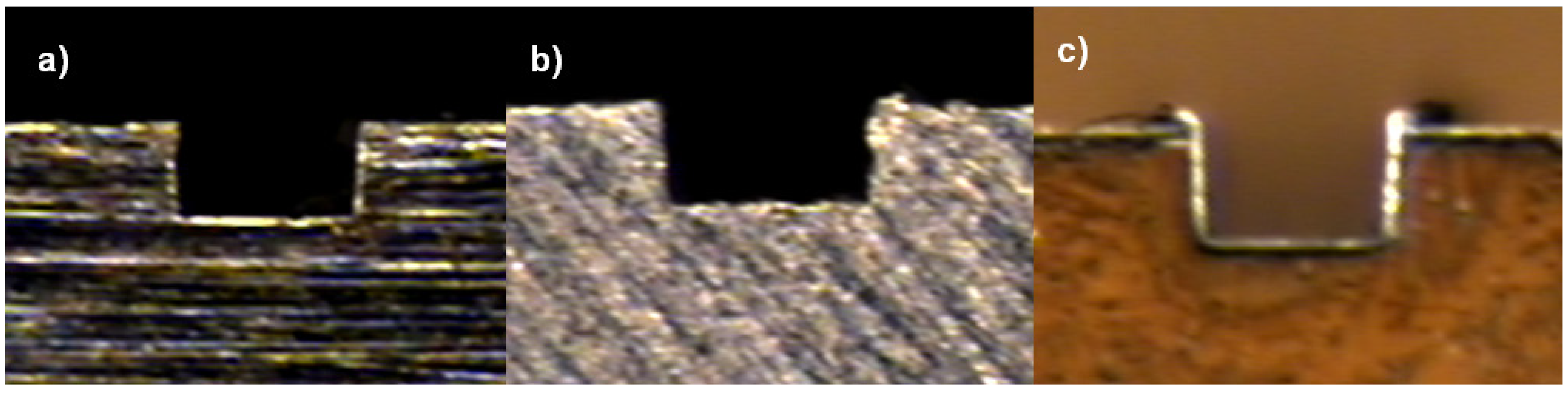

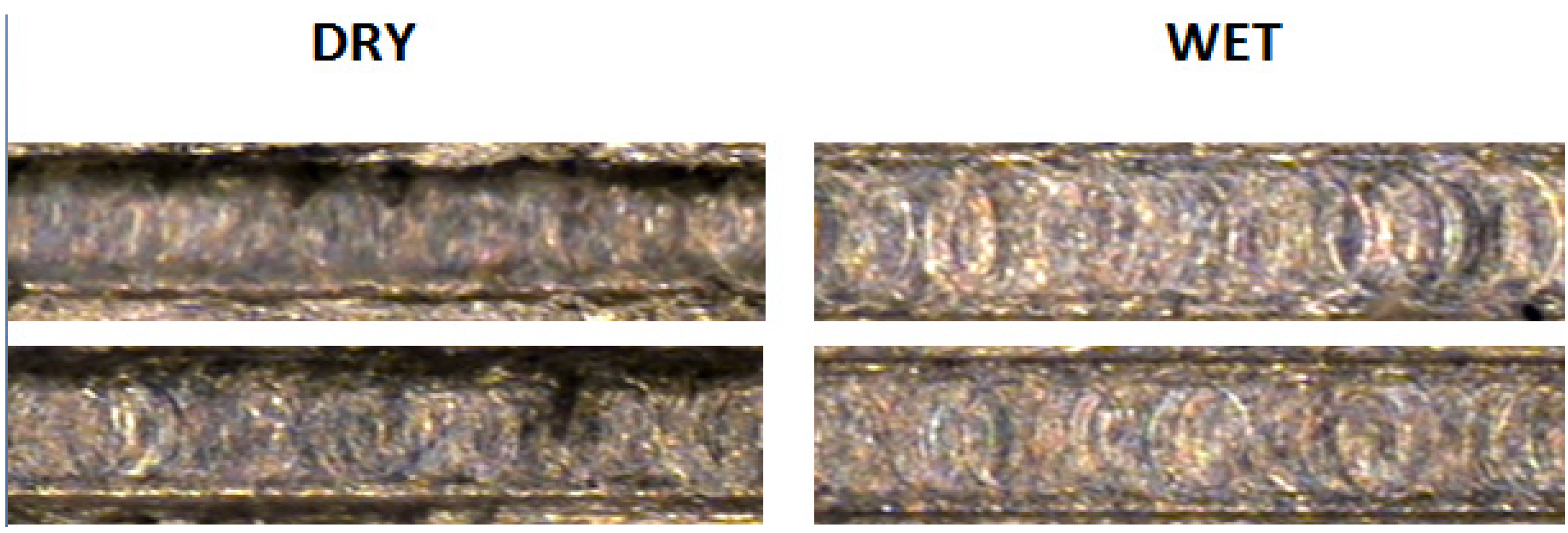

3.1. Aluminum Alloy

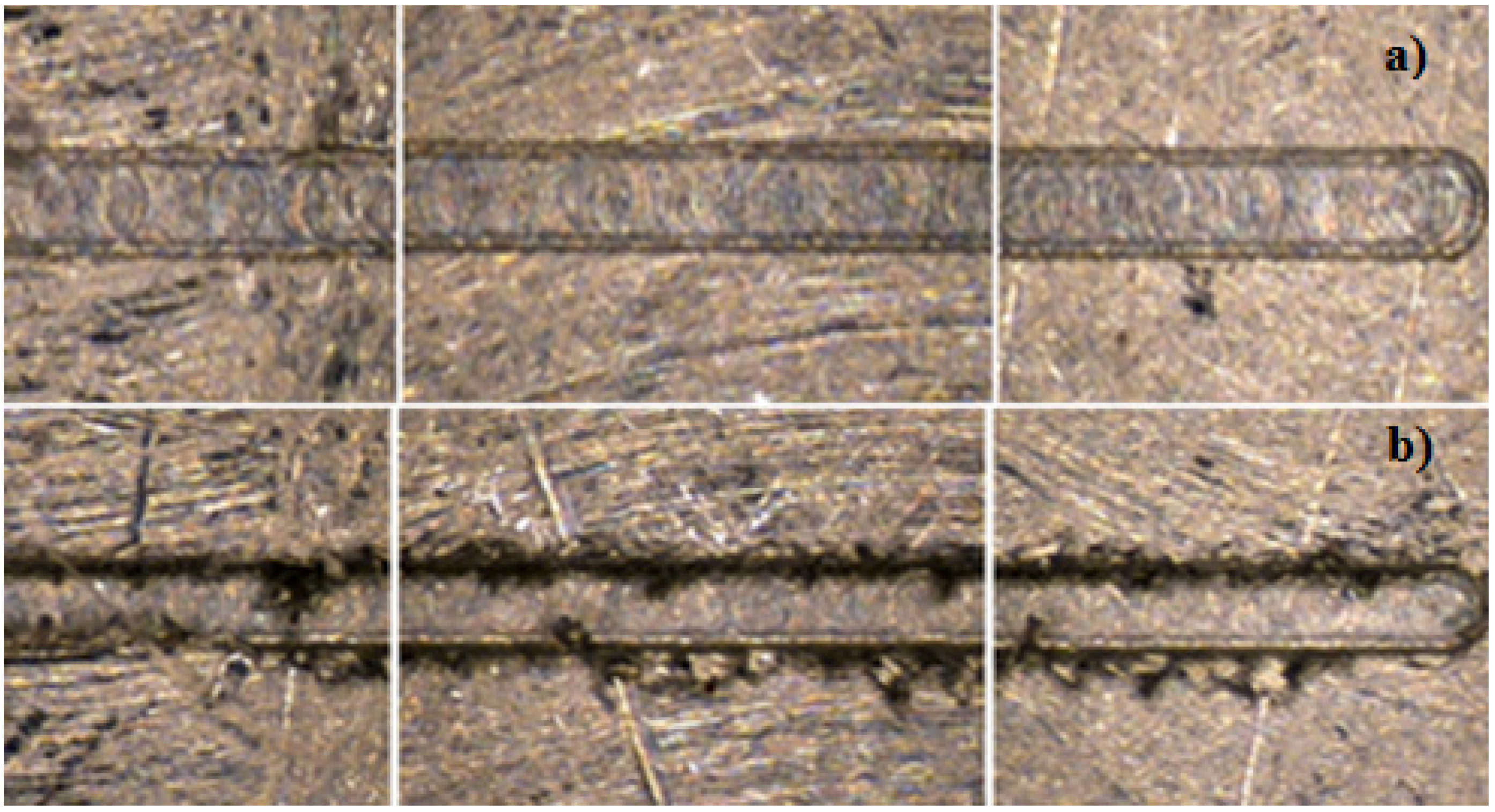

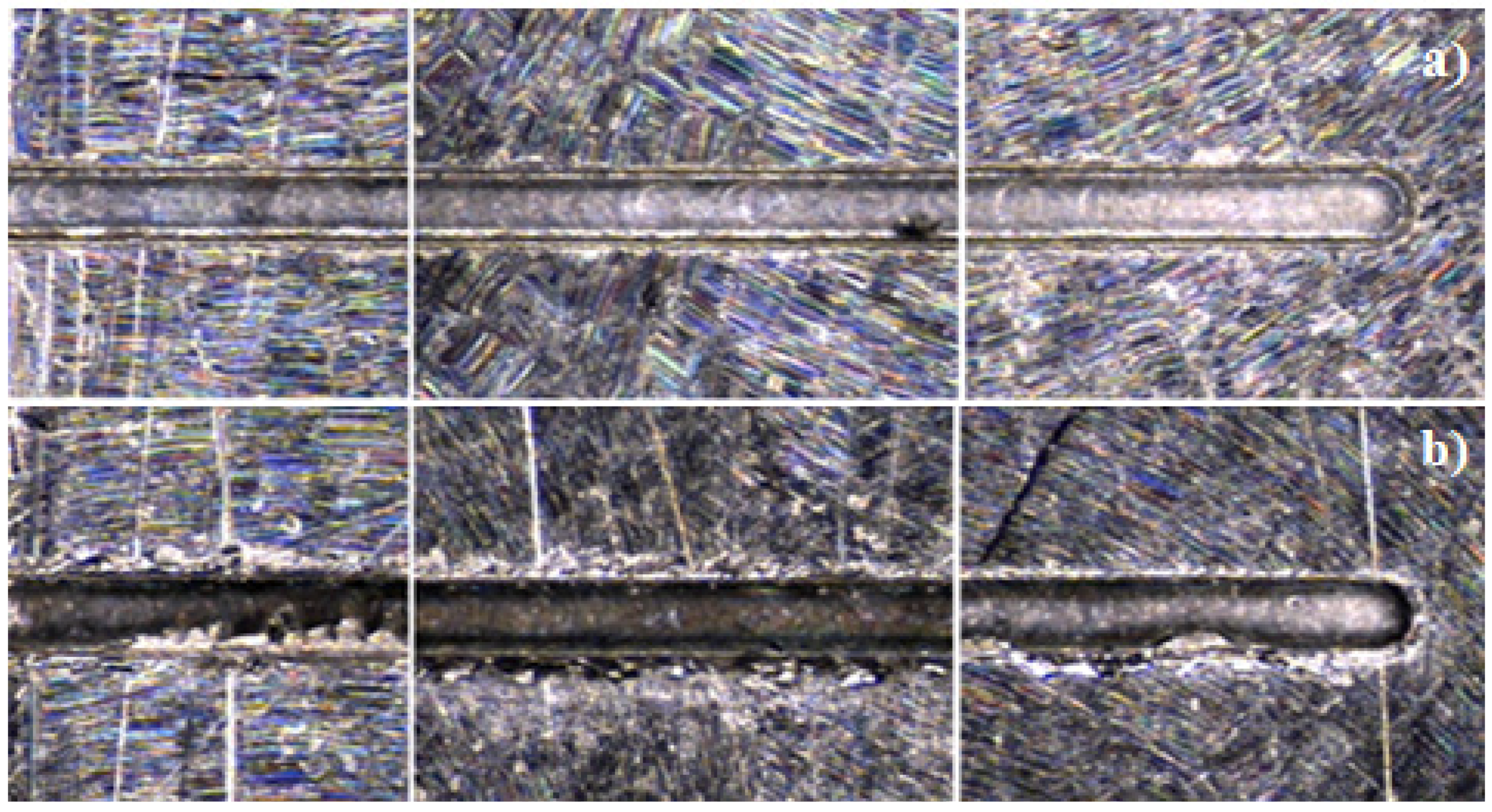

3.2. Austenitic Stainless Steel (AISI 316L)

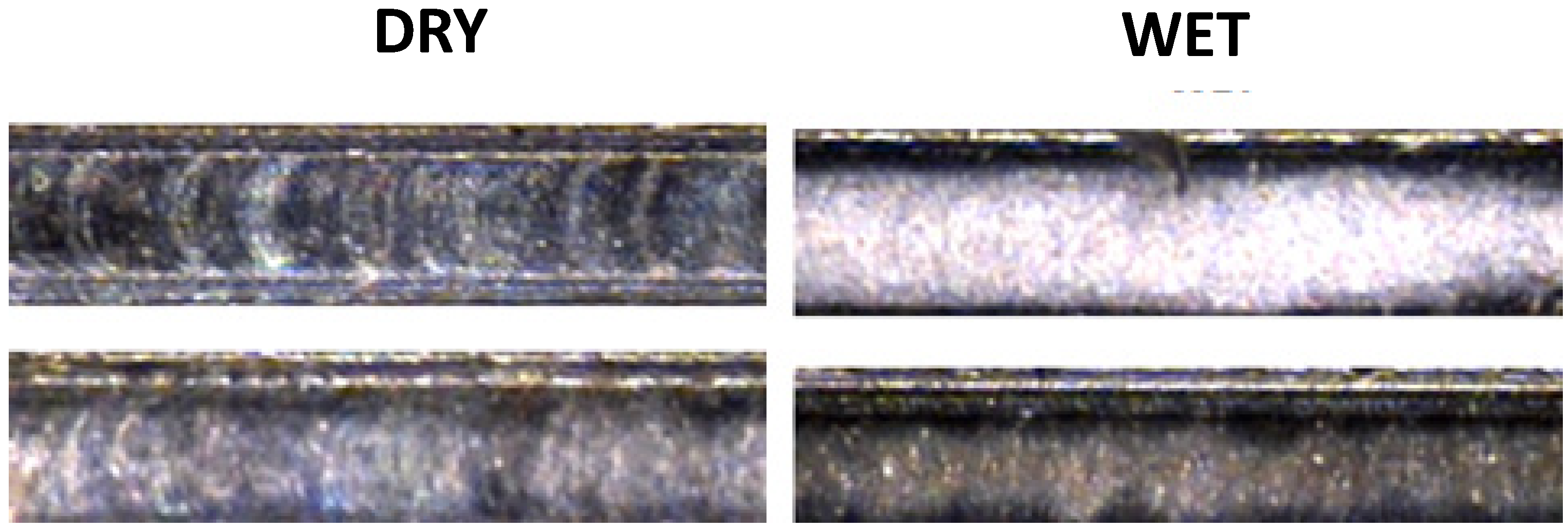

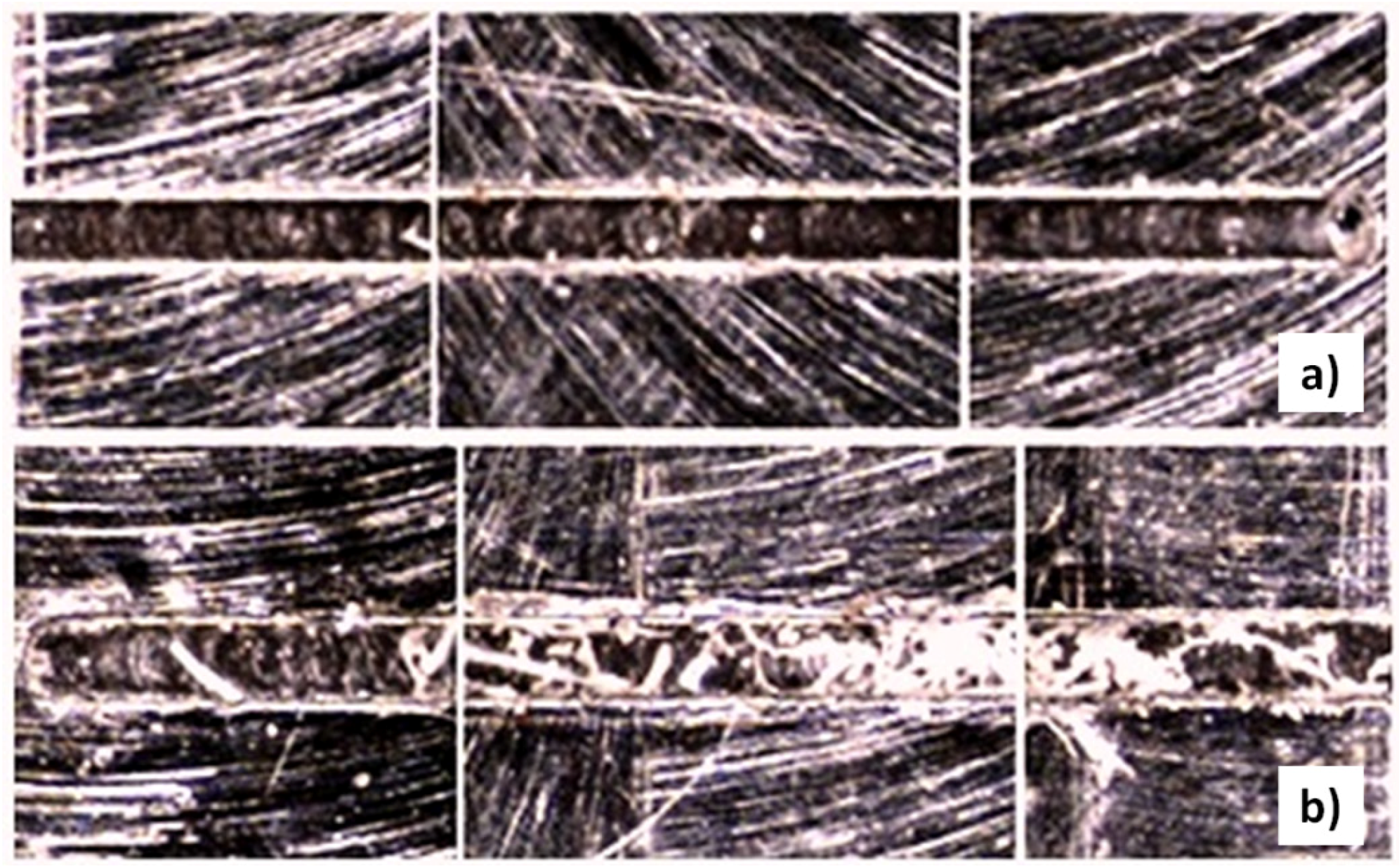

3.3. Titanium Alloy Ti6Al4V

4. Discussion

- (1)

- In the review presented by Camara et al. [21], discussions regarding tool geometry, tool materials, cutting parameters and other factors over burr formation and surface roughness in micro-machining of metallic materials are extensive, but there is scarce evidence of work regarding these effects and channel profiles in different metallic materials. The present work can contribute to a deeper understanding of the integrated effect of burr/surface roughness/geometry.

- (2)

- All the materials’ top burr formation was affected by the depth of cut per pass. Lekkala et al. [24] realized a similar experiment on Al alloy and stainless steel in which the ANOVA analysis also showed the same trend on the significant influence of ap on burr formation, proposing vibrations as the possible explanation. In contrast, in his study, stainless steel burrs appeared in larger amount than for aluminum. In the case of Ti6Al4V, the burr formation was minimized by a lower ap (2 μm), contrasting a study of Schueler [25] in which by applying the same ap, massive burr formations occurred. The literature assures us that as the depth of the cut increases, the tool is pushed further beneath the surface of the work material; this would in turn impress the grooves on the surface being machined, because of the increased cutting load. Bisacco et al. [2] highlighted the ploughing phenomenon that could explain the behavior of titanium alloy versus burr formation, where a plastic deformation occurred when the depth of the cut was lower than a critical chip thickness. Kim et al. [26] classified the deformation into two types, the forced deflection of the tool and the elasto-plastic deformation of the workpiece material. The burr formation in all materials can also be explained by the tool wear, which is one of the most important aspects of machining. As in Lee et al. and Schmidt [27,28], the burr size in stainless steel was related to the amount of tool wear. If a built-up edge is encountered on the tool, the tool can continue to cut for a long time without wear, but this affects the channel dimensions.

- (3)

- In Ti6Al4V, the roughness was minimized by a lower ap (2 μm) and high feed rates (25 and 30 mm/min); this can explain that with a cutting depth so small and a high load, the cutting of the material does not exist any longer, but only plastic deformation and ploughing of the material. These results are supported by studies conducted by Yang and Chen [29], in which an increase on the depth of the cut that worsens surface roughness was encountered; these were also similar to Ginta et al. [30], which varied the cutting conditions in the same Ti alloy (Ti6Al4V). Korkut and Donertas [31] even stated a linear model, where the increase on the depth of cut increased the surface roughness.

- (4)

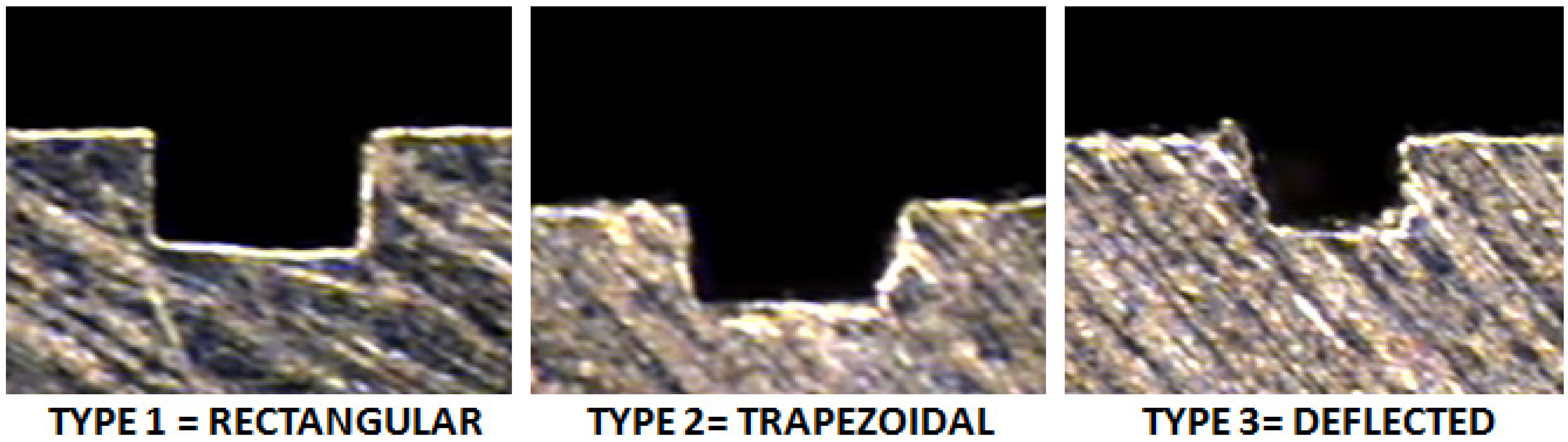

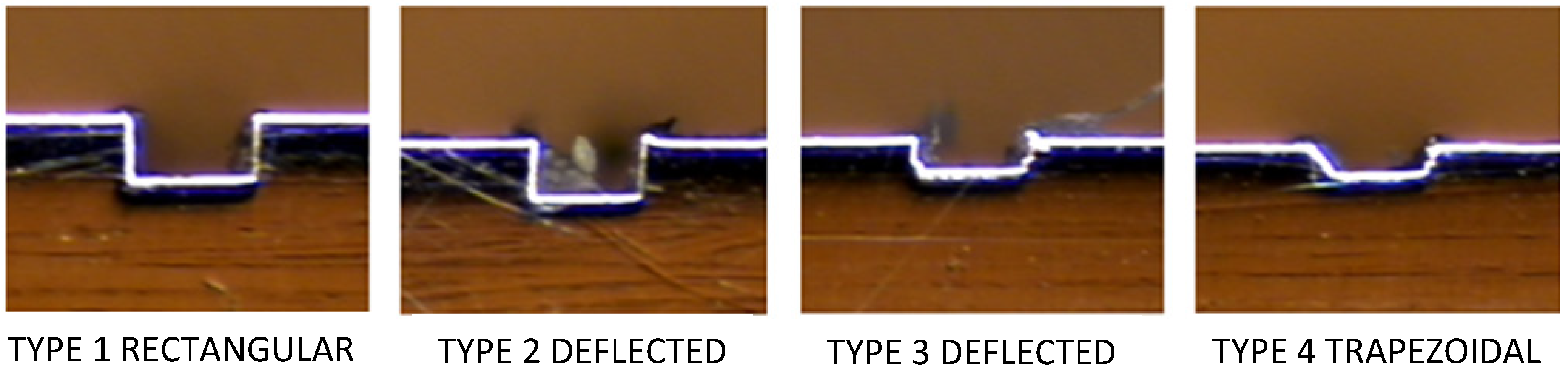

- Run out was another issue with great impact in micro-machining. Due to the lower strength in the micro-tool, run out causes less stiffness and more vibrations than conventional processes, generating higher roughness or deflection of the tool. The deviation of the desired shape of the profiles can be due to this phenomenon creating a tool deflection, greatly affecting the chip formation and accuracy.

- (5)

- According to Dornfeld [27], a typical flood of coolant is generally not suitable for micro-machining, because, first, the flow pressure may influence the cutting tool behavior and the removal of excess working fluid after micro-machining is challenging. However, in the present experiments, the presence of coolant was strongly proposed to minimize the roughness, as clearly seen in all three materials. Muthukrishnan et al. [32] show the influence of coolant in micro-milling of Ti6Al4V. Their results validated the present results, showing better roughness in wet machining, as coolant prevents the formation of a built up edge, which damages the surface.

5. Conclusions

- (1)

- In general, a better surface quality in terms of burr formation and roughness was obtained in AISI 316L, although Ti6Al4V had the best behavior in forming the desired rectangular profile. The application of coolant was critical to get better quality superficial features, which avoided built up edge formation and heating of the material.

- (2)

- In all three workpieces, burr formation can be controlled by a low depth of cut per pass. A low ap (2 μm) minimizes burr formation in all materials, and it also influences accuracy in the dimensional measurements.

- (3)

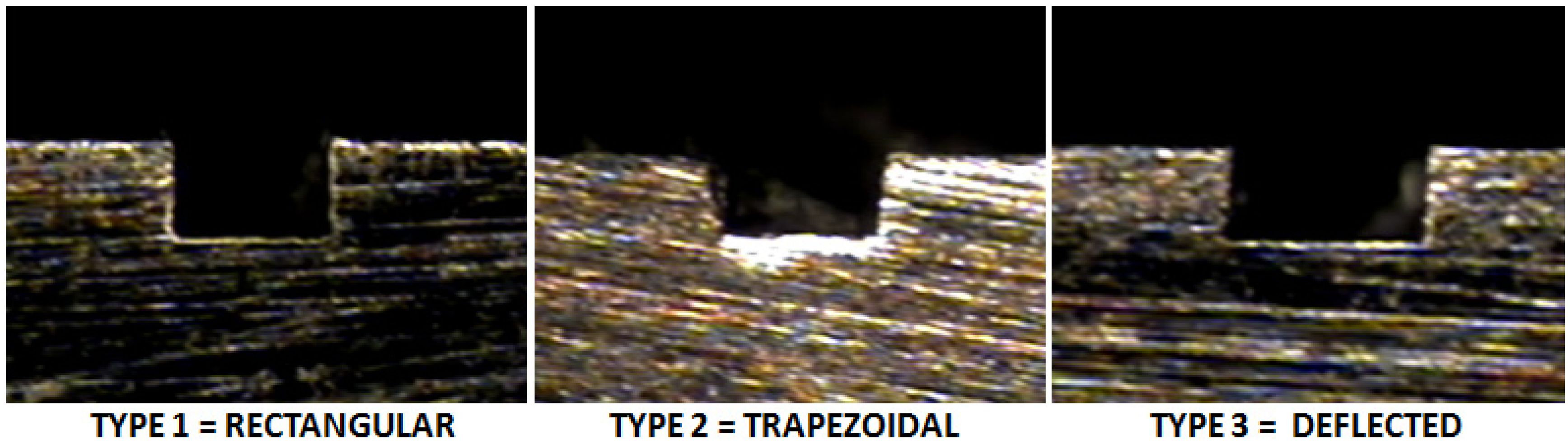

- The deviated shapes encountered were trapezoidal, regular and deflected. These profiles can be explained by the possible run out of the tool, tool wear and the built up edge.

- (4)

- There is a general affinity in the machining process of developing V-shaped microchannels. Further research is needed for a better understanding of the behavior of the tool deflection in the three different materials, since this deviation affects heat and fluid flow.

- (5)

- The critical phenomena encountered, like run-out, the ploughing effect, minimum chip thickness and tool wear, explained the deviations in the form, dimensions and surface quality, which can be minimized with a proper calibration of cutting conditions, mostly the depth of the cut, according to the findings of this work.

Acknowledgments

References

- de Chiffre, L.; Kunzmann, H.; Peggs, G.N.; Lucca, D.A. Surfaces in precision engineering, microengineering and nanotechnology. CIRP Ann. Manuf. Technol. 2003, 52, 561–577. [Google Scholar]

- Alting, L.; Kimura, F.; Hansen, H.N.; Bissacco, G. Micro engineering. CIRP Ann. Manuf. Technol. 2003, 52, 635–657. [Google Scholar] [CrossRef]

- Dornfeld, D.; Min, S.; Takeuchi, Y. Recent advances in mechanical micromachining. CIRP Ann. Manuf. Technol. 2006, 55, 745–768. [Google Scholar] [CrossRef]

- Dhanorker, A.; Özel, T. An experimental and modeling study on meso/micro end milling process. In Proceedings of 2006 ASME International Conference on Manufacturing Science and Engineering, Ypsilanti, MI, USA, 8–11 October 2006.

- Zhoua, G.; Yao, S.C. Effect of surface roughness on laminar liquid flow in micro-channels. Appl. Therm. Eng. 2011, 31, 228–234. [Google Scholar] [CrossRef]

- Ribatski, G.; Wojtan, L.; Thome, J.R. An analysis of experimental data and prediction methods for two-phase frictional pressure drop and flowboiling heat transfer in micro-scale channels. Exp. Therm. Fluid Sci. 2006, 31, 1–19. [Google Scholar] [CrossRef]

- Tonkovich, A.L.; Fitzgerald, S.P.; Zilka, J.L.; LaMont, M.J.; Wang, Y.; Vander Wiel, D.P.; Wegeng, R.S. Microchannel chemical reactors for fuel processing applications. II. Compact fuel vaporization. In Microreaction Technology: Industrial Prospects; Springer: Berlin-Heidelberg, Germany, 2000; Volume 3, pp. 364–371. [Google Scholar]

- Wegeng, R.S.; Pederson, L.R.; TeGrotenhuis, W.E.; Whyatt, G.A. Compact fuel processors for fuel cell powered automobiles based on microchannel technology. Fuel Cells Bull. 2001, 3, 8–13. [Google Scholar] [CrossRef]

- Emerging Markets for Microfluidic Applications in Life Sciences and In-Vitro Diagnostics. Available online: http://mms10.mikrotechnik-dortmund.de/downloads/program/29.4._16.45_France_Breussin.pdf (accessed on 15 October 2011).

- Shen, S.; Xu, J.L.; Zhou, J.J.; Chen, Y. Flow and heat transfer in microchannels with rough wall surface. Energy Convers. Manag. 2006, 47, 1311–1325. [Google Scholar] [CrossRef]

- Khan, M.G.; Fartaj, A. A review on microchannel heat exchangers and potential applications. Int. J. Energy Res. 2010, 35, 553–582. [Google Scholar]

- Gunnasegaran, P. The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. Int. Commun. Heat Mass Transf. 2010, 37, 1078–1086. [Google Scholar] [CrossRef]

- Khadem, M.H. Numerical simulation of roughness effects on flow and heat transfer in microchannels at slip flow regime. Int. Commun. Heat Mass Transf. 2009, 36, 69–77. [Google Scholar] [CrossRef]

- Hetsroni, G.; Mosyak, A.; Pogrebnyak, E.; Yarin, L.P. Heat transfer in micro-channels: Comparison of experiments with theory and numerical results. Int. J. Heat Mass Transf. 2005, 48, 5580–5601. [Google Scholar] [CrossRef]

- Gamrat, G.; Favre-Marinet, M.; le Person, S. Modelling of roughness effects on heat transfer in thermally fully-developed laminar flows through microchannels. Int. J. Therm. Sci. 2009, 48, 2203–2214. [Google Scholar] [CrossRef]

- Taylor, J.B.; Carrano, A.L.; Kandlikar, S.G. Characterization of the effect of surface roughness and texture on fluid flow—Past, present, and future. Int. J. Therm. Sci. 2006, 45, 962–968. [Google Scholar] [CrossRef]

- Croce, G.; D’agaro, P.; Nonino, C. Three-dimensional roughness effect on microchannel heat transfer and pressure drop. Int. J. Heat Mass Transf. 2007, 50, 5249–5259. [Google Scholar] [CrossRef]

- Dehghandokhta, M.; Khanb, M.G.; Fartajb, A.; Sanayea, S. Numerical study of fluid flow and heat transfer in a multi-port serpentine meso-channel heat exchanger. Appl. Therm. Eng. 2011, 31, 1588–1599. [Google Scholar] [CrossRef]

- Lee, S.J.J.; Sundararajan, N. Microfabrication for Microfluidics; Artech House: Norwood, MA, USA, 2010; pp. 25–87. [Google Scholar]

- Cardoso, P.; Davim, J.P. A brief review on micromachining of materials. Rev. Adv. Mater. Sci. 2012, 30, 98–102. [Google Scholar]

- Câmara, M.A.; Campos Rubio, J.C.; Abrão, A.M.; Davim, J.P. State of the art on micromilling of materials: A review. J. Mater. Sci. Technol. 2012, 28, 673–685. [Google Scholar] [CrossRef]

- Jauregui, A.L.; Siller, H.R.; Rodriguez, C.A.; Zuñiga, A.E. Evaluation of micromechanical manufacturing processes for microfluidic devices. Int. J. Adv. Manuf. Technol. 2010, 48, 963–972. [Google Scholar] [CrossRef]

- Vazquez, E.; Rodríguez, C.A.; Zuñiga, A.E.; Ciurana, J. An experimental analysis of process parameters to manufacture metallic micro-channels by micro-milling. Int. J. Adv. Manuf. Technol. 2010, 51, 945–955. [Google Scholar] [CrossRef]

- Lekkala, R.; Bajpai, V.; Singh, R.K.; Joshi, S.S. Characterization and modeling of burr formation in micro-end milling. Precis. Eng. 2011, 35, 625–637. [Google Scholar] [CrossRef]

- Schueler, G.M.; Engmann, J.; Marx, T.; Haberland, R.; Aurich, J.C. Burr formation and surface characteristics in micro-end milling of titanium alloys. In Burrs—Analysis, Control and Removal, Proceedings of the CIRP International Conference on Burrs, Kaiserslautern, Germany, 2–3 April 2009; Aurich, J.C., Dornfeld, D., Eds.; Springer: Berlin-Heidelberg, Germany, 2010; pp. 12–13. [Google Scholar]

- Kim, C.J.; Mayor, J.R.; Ni, J. A static model of chip formation in microscale milling. ASME J. Manuf. Sci. Eng. 2004, 126, 710–718. [Google Scholar] [CrossRef]

- Lee, K.; Dornfeld, D.A. Micro-burr formation and minimization through process control. Precis. Eng. 2005, 29, 246–252. [Google Scholar] [CrossRef]

- Schmidt, J.; Tritschler, H. Micro cutting of steel. Microsyst. Technol. 2004, 10, 167–174. [Google Scholar] [CrossRef]

- Yang, J.L.; Chen, J.C. A systematic approach for identifying optimum surface roughness performance in end-milling operations. J. Ind. Technol. 2001, 17, 2–8. [Google Scholar]

- Ginta, T.L.; Amin, A.K.N.; Radzi, N.; Lajis, M.A. Development of surface roughness models in end-milling titanium alloy Ti-6Al-4V using uncoated tungsten carbide inserts. Eur. J. Sci. Res. 2009, 28, 542–551. [Google Scholar]

- Korkut, I.; Donertas, M.A. The influence of feed rate and cutting speed on the cutting forces, surface roughness and tool–chip contact length during face milling. J. Mater. Des. 2007, 28, 208–312. [Google Scholar] [CrossRef]

- Muthukrishnan, N.; Davim, P. Influence of coolant in machinability of titanium alloy (Ti-6Al-4V). J. Surf. Eng. Mater. Adv. Technol. 2011, 1, 9–14. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Monroy-Vázquez, K.P.; Attanasio, A.; Ceretti, E.; Siller, H.R.; Hendrichs-Troeglen, N.J.; Giardini, C. Evaluation of Superficial and Dimensional Quality Features in Metallic Micro-Channels Manufactured by Micro-End-Milling. Materials 2013, 6, 1434-1451. https://doi.org/10.3390/ma6041434

Monroy-Vázquez KP, Attanasio A, Ceretti E, Siller HR, Hendrichs-Troeglen NJ, Giardini C. Evaluation of Superficial and Dimensional Quality Features in Metallic Micro-Channels Manufactured by Micro-End-Milling. Materials. 2013; 6(4):1434-1451. https://doi.org/10.3390/ma6041434

Chicago/Turabian StyleMonroy-Vázquez, Karla P., Aldo Attanasio, Elisabetta Ceretti, Héctor R. Siller, Nicolás J. Hendrichs-Troeglen, and Claudio Giardini. 2013. "Evaluation of Superficial and Dimensional Quality Features in Metallic Micro-Channels Manufactured by Micro-End-Milling" Materials 6, no. 4: 1434-1451. https://doi.org/10.3390/ma6041434

APA StyleMonroy-Vázquez, K. P., Attanasio, A., Ceretti, E., Siller, H. R., Hendrichs-Troeglen, N. J., & Giardini, C. (2013). Evaluation of Superficial and Dimensional Quality Features in Metallic Micro-Channels Manufactured by Micro-End-Milling. Materials, 6(4), 1434-1451. https://doi.org/10.3390/ma6041434