Tailoring the Mechanical Properties of Al0.4CrFe2Ni2 Medium-Entropy Alloy via Thermomechanical Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Experimental Material

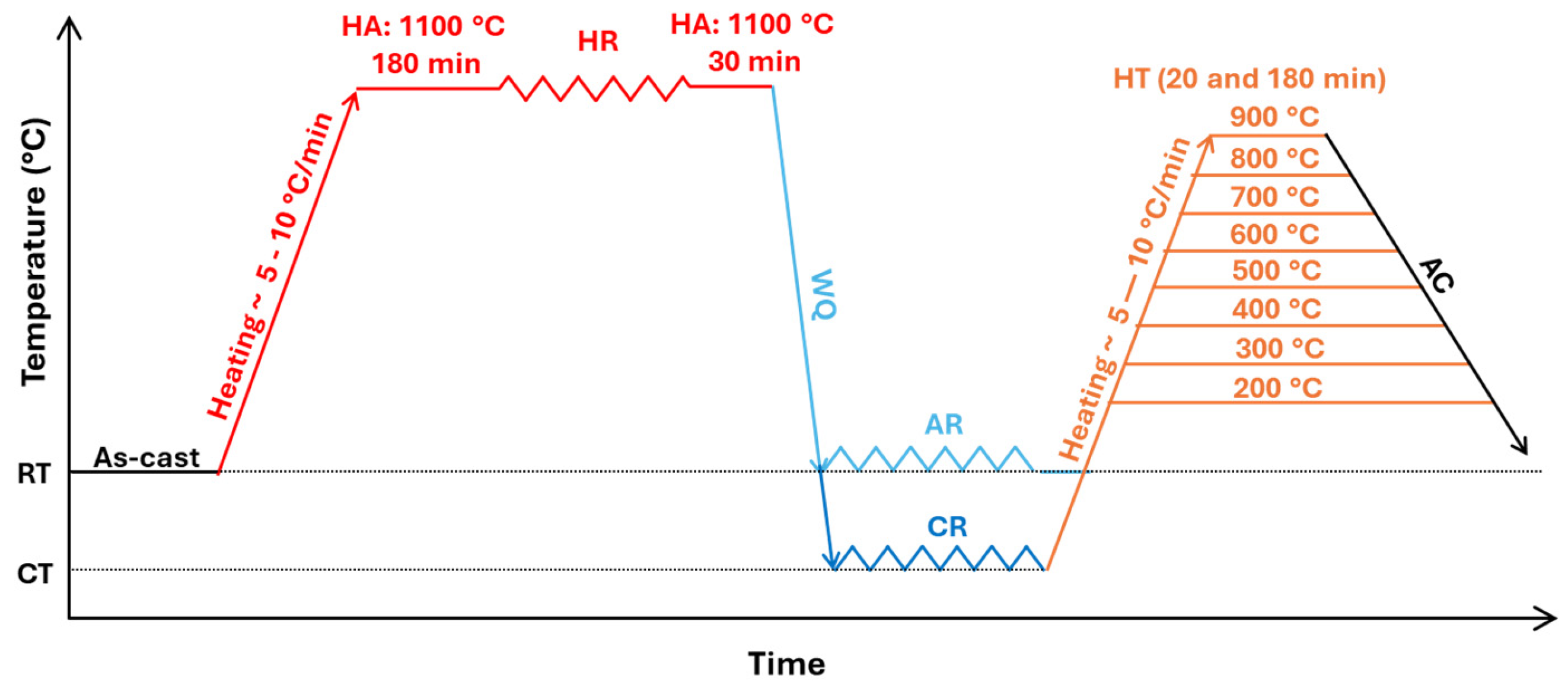

2.2. Thermomechanical Processing

2.3. Microstructure Characterization

2.4. Mechanical Testing

3. Results

3.1. Microstructural and Mechanical Properties During Thermomechanical Processing

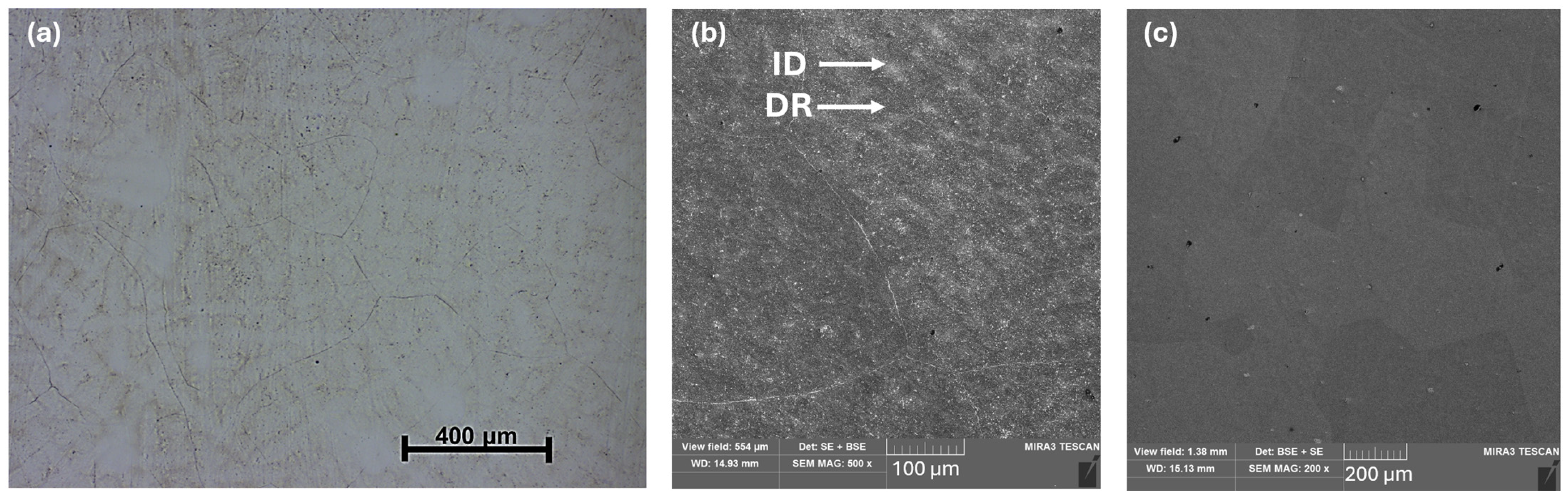

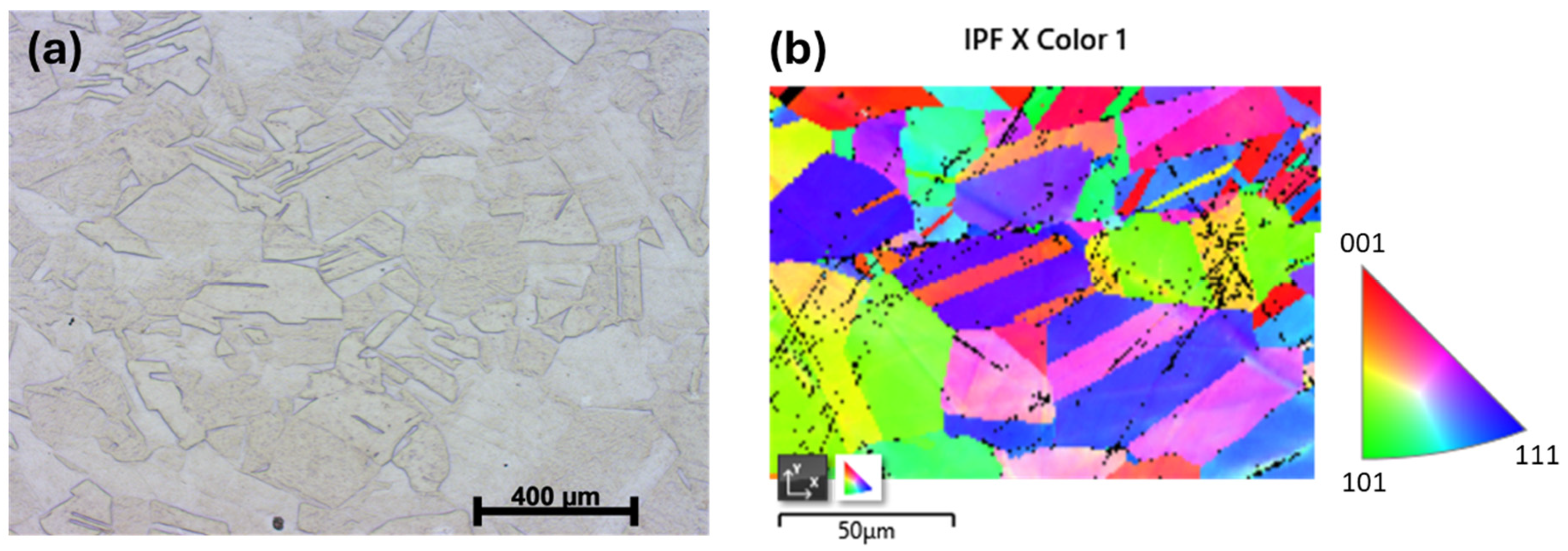

3.1.1. Initial Alloy Microstructure

3.1.2. Microstructure Evolution During Hot Rolling

3.1.3. Microstructural Evolution During Rolling at Ambient Temperature Rolling

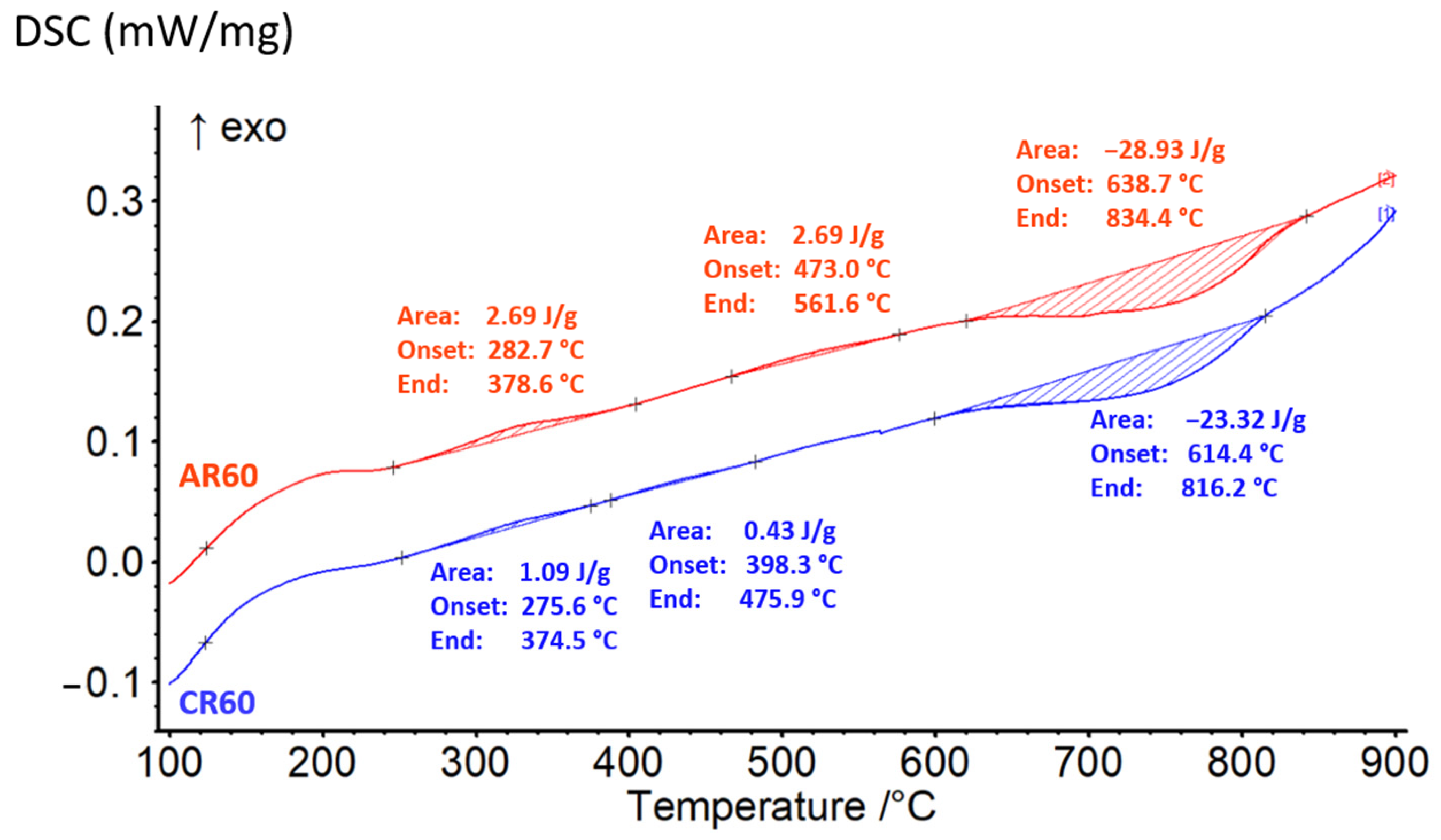

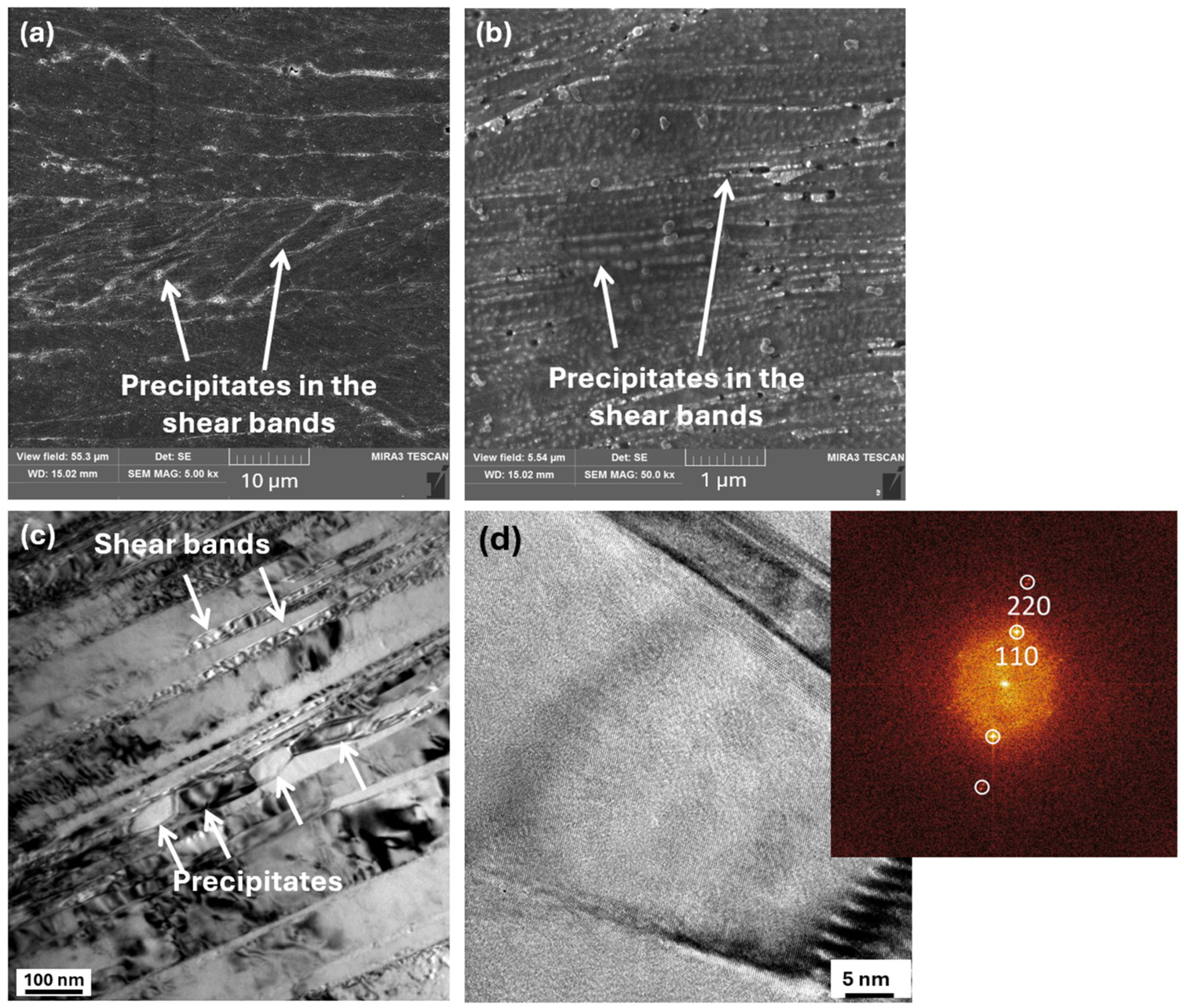

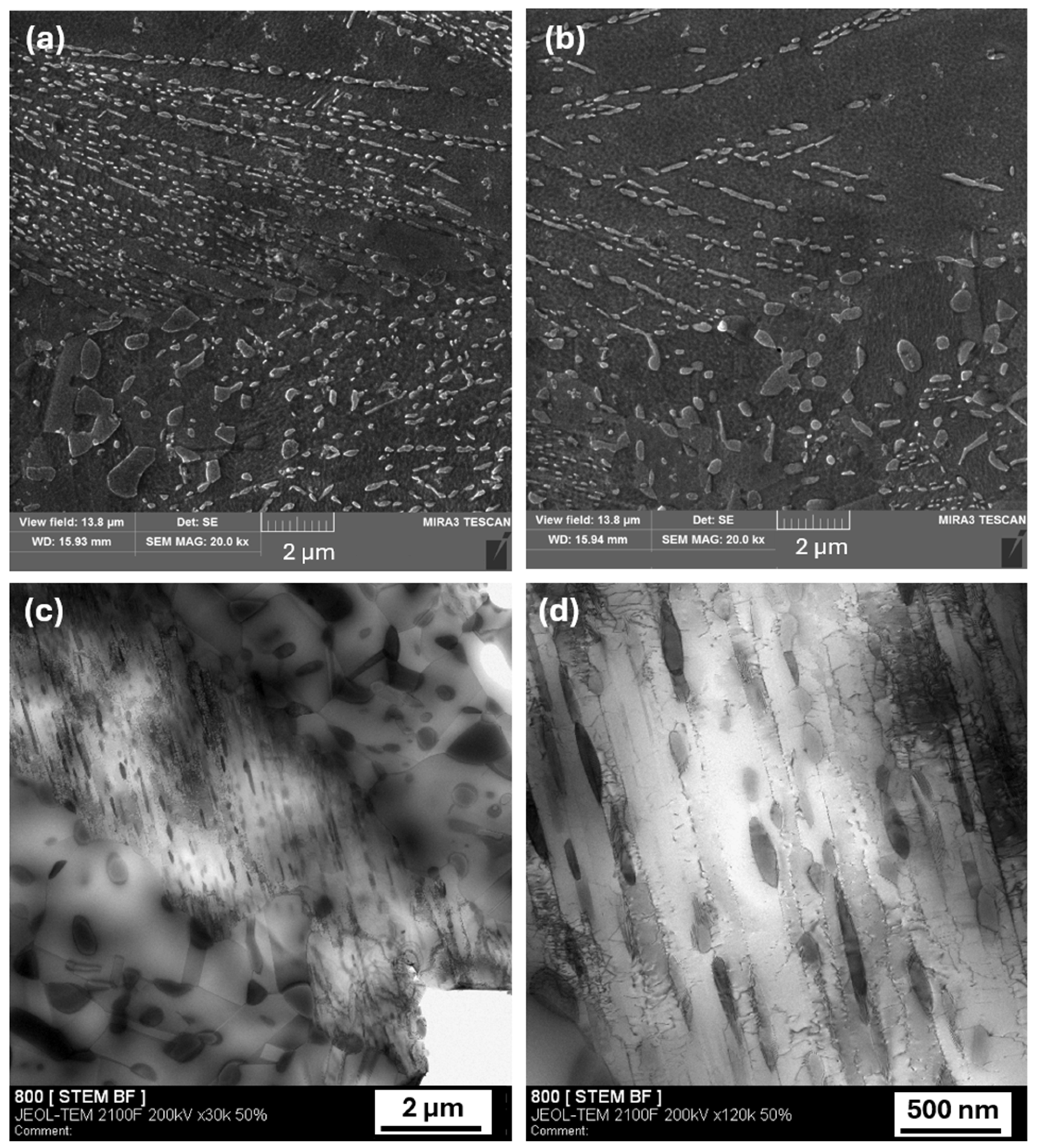

3.1.4. Microstructural Evolution During Cryogenic Rolling

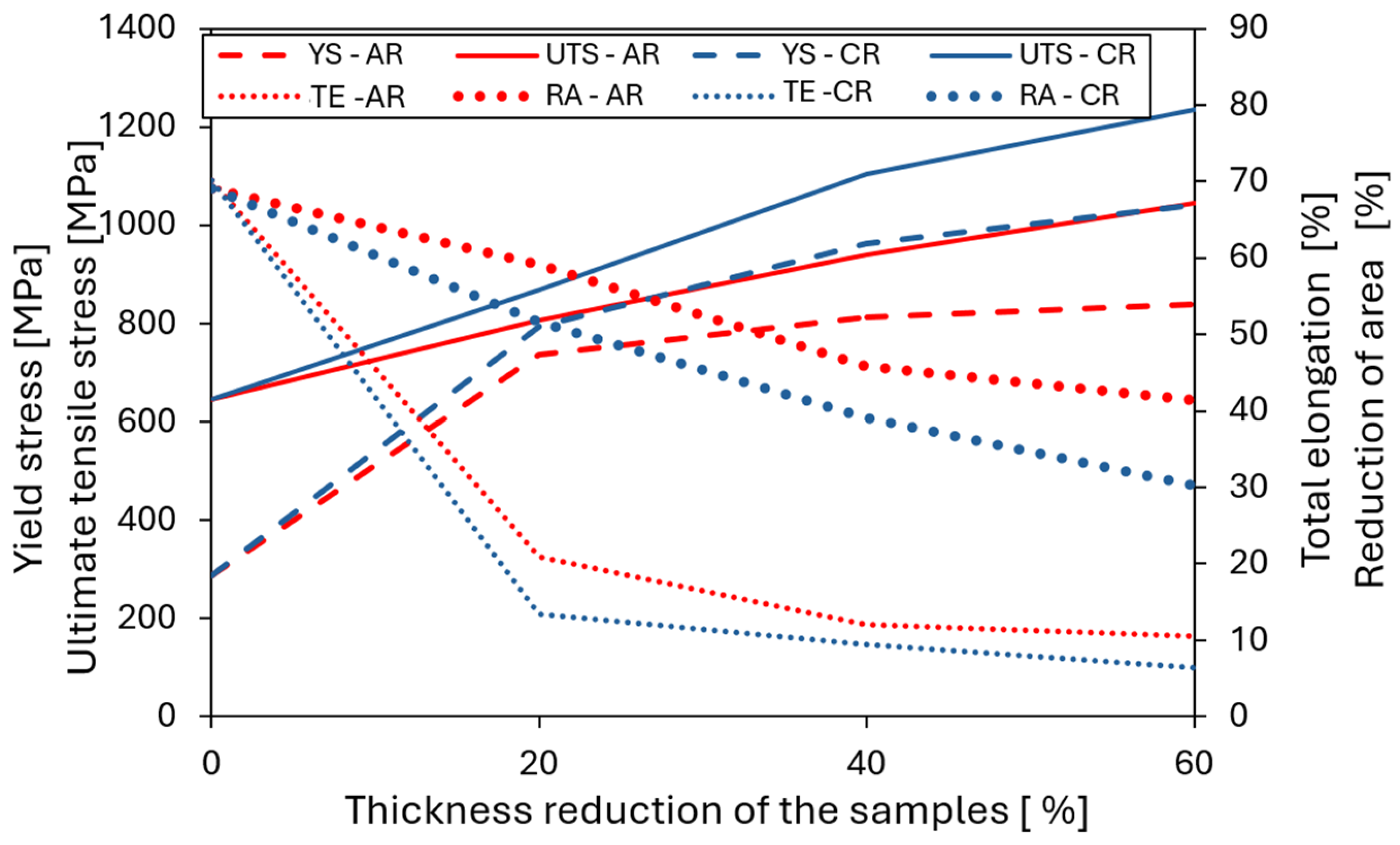

3.2. Mechanical Properties After Homogenization of the As-Cast State and After Alloy Strengthening by Rolling Under Ambient and Cryogenic Conditions

3.3. Influence of Post-Rolling Annealing on Microstructural Development and Mechanical Performance

4. Discussion

4.1. Homogenization of the As-Cast Microstructure of Al0.4CrFe2Ni2

4.2. Strengthening of the Alloy by Plastic Deformation

4.3. Precipitation Hardening of the Alloy and Its Thermal Stability

5. Conclusions

- The homogenization of the as-cast microstructure of the investigated MEA alloy through homogenization annealing followed by 80% hot rolling resulted in a chemically homogeneous, fine-grained polyhedral FCC microstructure with an increased fraction of annealing twins and a single-phase supersaturated solid solution, leading to a more stable plastic flow behavior of the material.

- The microstructural evolution during rolling under both temperature conditions (AR and CR) was predominantly governed by shear band formation; however, under cryogenic conditions (CR), a more pronounced deformation localization was observed, leading to the formation of deformation nanotwins and significantly enhanced strengthening. As a result, the CR60 condition achieved a yield strength of 1040 MPa and an ultimate tensile strength of 1235 MPa compared to 838 MPa (YS) and 1045 MPa (UTS) for the AR60 condition.

- Precipitation hardening of the alloy was achieved through the formation of B2 precipitates arranged in chain-like configurations along the shear bands, which significantly contributed to the enhancement of strength. The alloy processed under cryogenic conditions reached its maximum strengthening after annealing at 500 °C, exhibiting a yield strength of 1420 MPa and an ultimate tensile strength of 1465 MPa; this effect results from the synergistic contribution of a higher fraction of B2 precipitates and the presence of deformation nanotwins.

- The alloy exhibited good thermal stability up to 600 °C; however, upon exceeding this temperature and annealing at 800 °C, a pronounced deterioration of mechanical properties occurred, which was associated with partial recrystallization of the material.

- Overall, the investigated alloy offers a wide spectrum of tunable mechanical properties, which can be effectively tailored through appropriate combinations of thermomechanical processing routes, including rolling temperature, deformation degree, and subsequent heat treatment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, W.; Luo, X.; Ning, D.; Wang, M.; Yang, C.; Li, M.; Yang, Y.; Li, P.; Huang, B. Excellent Strength-Ductility Synergy Properties of Gradient Nano-Grained Structural CrCoNi Medium-Entropy Alloy. J. Mater. Sci. Technol. 2022, 112, 195–201. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable High-Entropy Dual-Phase Alloys Overcome the Strength–Ductility Trade-Off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Lee, W.; Oh, Y.; Jo, M.-G.; Han, H.N.; Kim, Y. Microstructures and Mechanical Properties of CrFeNi2Nbx Eutectic Multicomponent Alloys. J. Alloys Compd. 2021, 860, 158502. [Google Scholar] [CrossRef]

- Bała, P.; Górecki, K.; Dziurka, R.; Kozieł, T. The Effect of Al and Ti Additions on Solid Solution Strengthening and Precipitation Hardening in CoNiFe Medium-Entropy Alloys. Materials 2023, 16, 6297. [Google Scholar] [CrossRef]

- Wang, W.-R.; Wang, W.-L.; Wang, S.-C.; Tsai, Y.-C.; Lai, C.-H.; Yeh, J.-W. Effects of Al Addition on the Microstructure and Mechanical Property of AlxCoCrFeNi High-Entropy Alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Styles, M.; Zheng, Y.; Mishra, R.S.; Banerjee, R. Modifying Transformation Pathways in High Entropy Alloys or Complex Concentrated Alloys via Thermo-Mechanical Processing. Acta Mater. 2018, 153, 169–185. [Google Scholar] [CrossRef]

- Dasari, S.; Sarkar, A.; Sharma, A.; Gwalani, B.; Choudhuri, D.; Soni, V.; Manda, S.; Samajdar, I.; Banerjee, R. Recovery of Cold-Worked Al0.3CoCrFeNi Complex Concentrated Alloy through Twinning Assisted B2 Precipitation. Acta Mater. 2021, 202, 448–462. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Lee, M.; Mantri, S.; Ren, Y.; Banerjee, R. Optimizing the Coupled Effects of Hall-Petch and Precipitation Strengthening in a Al0.3CoCrFeNi High Entropy Alloy. Mater. Des. 2017, 121, 254–260. [Google Scholar] [CrossRef]

- Yasuda, H.Y.; Miyamoto, H.; Cho, K.; Nagase, T. Formation of Ultrafine-Grained Microstructure in Al0.3CoCrFeNi High Entropy Alloys with Grain Boundary Precipitates. Mater. Lett. 2017, 199, 120–123. [Google Scholar] [CrossRef]

- Annasamy, M.; Haghdadi, N.; Taylor, A.; Hodgson, P.; Fabijanic, D. Static Recrystallization and Grain Growth Behaviour of Al0.3CoCrFeNi High Entropy Alloy. Mater. Sci. Eng. A 2019, 754, 282–294. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Wang, Z.; Ren, X. Excellent Tensile Property and Its Mechanism in Al0.3CoCrFeNi High-Entropy Alloy via Thermo-Mechanical Treatment. J. Alloys Compd. 2022, 897, 163218. [Google Scholar] [CrossRef]

- Mahata, C.; Kumar, K.N.; Bruder, E.; Gowtam, D.; Sadhasivam, M.; Durst, K.; Pradeep, K.G. Recovery of Metastable Solid Solution from a Severe Plastically Deformed Cu Alloyed FeMnCoCr High Entropy Alloy. J. Alloys Metall. Syst. 2025, 11, 100200. [Google Scholar] [CrossRef]

- Yoshida, S.; Park, N.; Shiotani, K.; Bai, Y.; Niiyama, T.; Shibata, A.; Shimokawa, T.; Tsuji, N. Ultra-Grain-Refinement of Face-Centered Cubic High/Medium-Entropy Alloys: Approaching the Limit of Grain Refinement through Severe Plastic Deformation and Recrystallization. Mater. Des. 2025, 258, 114622. [Google Scholar] [CrossRef]

- Ren, Q.; Li, T.; Xie, H.; Jia, Y.; Wan, M.; Huang, C.; Chen, C.; Li, J.; Lu, Y. Achieving Synergistic Strength-Ductility Enhancement in a Hierarchical Hetero-Lamellar AlCoCrFeNi2.1 Eutectic High-Entropy Alloy via Facile Hot-Rolling Strategy. Mater. Des. 2025, 259, 114734. [Google Scholar] [CrossRef]

- Kumar, P.; Jain, V.; Samal, S.; Ghosh, A. Effect of Hot Rolling and Annealing on Microstructure, Crystallographic Texture, and Mechanical Properties of Fe11.5 Co20.6 Ni40.7 Cr12.2 Al7.8 Ti7.2 High Entropy Alloy. Mater. Sci. Eng. A 2024, 915, 147228. [Google Scholar] [CrossRef]

- Liao, Y.; Song, Y.; Shu, N.; Niu, Y.; Zhang, H.; Sun, B.; Wang, Y.; Li, C.; Gu, J. Enhanced Strength-Ductility Synergy in Ferrous Medium-Entropy Alloys via Single-Step Hot Rolling. Mater. Sci. Eng. A 2025, 926, 147920. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, S.; Li, F.; Luo, Y.; Yao, Y.; Zhang, H.; Wang, Z.; Wang, L.; Wang, Z. Tailoring the Strength and Ductility of Al0.25CoCrFeNi High Entropy Alloy through Cryo-Rolling and Annealing. Mater. Sci. Eng. A 2021, 826, 141964. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, R.; Guo, Q.; Hou, H.; Zhao, Y. Predicting the Stacking Fault Energy in FCC High-Entropy Alloys Based on Data-Driven Machine Learning. J. Mater. Res. Technol. 2023, 26, 4813–4824. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, L.; Liang, Y.-J.; Xue, Y. Annealing Hardening in Cryo-Rolled High-Entropy Alloys by Belated Deformation Twinning. Mater. Sci. Eng. A 2021, 801, 140403. [Google Scholar] [CrossRef]

- Deng, Y.; Tasan, C.C.; Pradeep, K.G.; Springer, H.; Kostka, A.; Raabe, D. Design of a Twinning-Induced Plasticity High Entropy Alloy. Acta Mater. 2015, 94, 124–133. [Google Scholar] [CrossRef]

- Lilensten, L.; Couzinié, J.-P.; Bourgon, J.; Perrière, L.; Dirras, G.; Prima, F.; Guillot, I. Design and Tensile Properties of a Bcc Ti-Rich High-Entropy Alloy with Transformation-Induced Plasticity. Mater. Res. Lett. 2017, 5, 110–116. [Google Scholar] [CrossRef]

- Tirunilai, A.S.; Sas, J.; Weiss, K.-P.; Chen, H.; Szabó, D.V.; Schlabach, S.; Haas, S.; Geissler, D.; Freudenberger, J.; Heilmaier, M.; et al. Peculiarities of Deformation of CoCrFeMnNi at Cryogenic Temperatures. J. Mater. Res. 2018, 33, 3287–3300. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, H.; Li, W.; Ding, X.; Wang, Y.; Vitos, L. Generalized Stacking Fault Energy of Al-Doped CrMnFeCoNi High-Entropy Alloy. Nanomaterials 2020, 10, 59. [Google Scholar] [CrossRef]

- Liu, S.F.; Wu, Y.; Wang, H.T.; Lin, W.T.; Shang, Y.Y.; Liu, J.B.; An, K.; Liu, X.J.; Wang, H.; Lu, Z.P. Transformation-Reinforced High-Entropy Alloys with Superior Mechanical Properties via Tailoring Stacking Fault Energy. J. Alloys Compd. 2019, 792, 444–455. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Z.; Yan, K.; Le, W.; Naseem, S.; Zhang, H.; Yang, L. Investigation on Microstructure, Superior Tensile Property and Its Mechanism in Al0.3CoCrFeNi High-Entropy Alloy via Thermo-Mechanical Processing. Mater. Sci. Eng. A 2023, 866, 144690. [Google Scholar] [CrossRef]

- Liu, S.; Gao, H.; Wei, D.; Kong, C.; Kumara, L.S.R.; Fu, M.W.; Yu, H. Deformation Mechanism of a Metastable Medium Entropy Alloy Strengthened by the Synergy of Heterostructure Design and Cryo-Pre-Straining. Int. J. Plast. 2024, 183, 104162. [Google Scholar] [CrossRef]

- Xu, X.; Li, H.; Zhao, Y.; Zhang, X.; Pan, Y.; Liaw, P.K.; Hou, H. Enhancement of Strength-Ductility Trade-off in Al5Fe25Cr25Ni42.5Ti2.5 High Entropy Alloy through Annealing Twins. Mater. Sci. Eng. A 2025, 921, 147519. [Google Scholar] [CrossRef]

- Xu, X.; Song, Z.; Wang, K.; Li, H.; Pan, Y.; Hou, H.; Zhao, Y. Cryo-Rolling and Annealing-Mediated Phase Transformation in Al5Ti2.5Fe25Cr25Ni42.5 High-Entropy Alloy: Experimental, Phase-Field and CALPHAD Investigation. J. Mater. Sci. Technol. 2025, 219, 307–325. [Google Scholar] [CrossRef]

- Sang, P.; Liang, N.; Liu, Y.; Gu, L.; Zhang, Z.; Niu, K.; Wang, S.; Yang, X.-S.; Li, Y. Synergistic Improvement of Strength and Ductility by Nano-Lamellar L12 Precipitates in Co-Free NiFeCrAlTi Medium-Entropy Alloy. Mater. Sci. Eng. A 2025, 947, 149216. [Google Scholar] [CrossRef]

- Kočiško, R.; Petroušek, P.; Saksl, K.; Petryshynets, I.; Milkovič, O.; Csík, D. The Influence of Ti and Al on the Evolution of Microstructure and Mechanical Properties in Medium-Entropy and High-Entropy Alloys Based on AlxTixCrFe2Ni2. Materials 2025, 18, 1382. [Google Scholar] [CrossRef] [PubMed]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Hausermann, D. Two-Dimensional Detector Software: From Real Detector to Idealised Image or Two-Theta Scan. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- ISO 6892-1:2022; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test. International Organization for Standardization: Geneva, Switzerland, 2023.

- Tripathy, B.; Malladi, S.R.K.; Bhattacharjee, P.P. Development of Ultrafine Grained Cobalt-Free AlCrFe2Ni2 High Entropy Alloy with Superior Mechanical Properties by Thermo-Mechanical Processing. Mater. Sci. Eng. A 2022, 831, 142190. [Google Scholar] [CrossRef]

- Zhou, J.; Liao, H.; Chen, H.; Feng, D.; Zhu, W. Effect of Cold Rolling on Microstructure and Mechanical Behavior of Fe35Ni35Cr20Mn10 High-Entropy Alloy. Mater. Charact. 2024, 218, 114503. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, W.; Song, S.; Reddy, K.M.; Wang, X. Effect of Deformation Induced B2 Precipitates on the Microstructure and Mechanical Property of Al0.3CoCrFeNi High-Entropy Alloy. J. Alloys Compd. 2020, 821, 153445. [Google Scholar] [CrossRef]

- Liao, Y.C.; Chen, P.S.; Tsai, P.H.; Jang, J.S.C.; Hsieh, K.C.; Chang, H.W.; Chen, C.Y.; Huang, J.C.; Wu, H.J.; Lo, Y.C.; et al. Effect of Thermomechanical Treatment on the Microstructure Evolution and Mechanical Properties of Lightweight Ti65(AlCrNb)35 Medium-Entropy Alloy. Intermetallics 2022, 143, 107470. [Google Scholar] [CrossRef]

- Moemeni, S.; Dehghani, K. Exploring the Coupled Effect of Cold Rolling Level and Annealing Parameters on the Development of Microstructure, Mechanical Properties and Texture of Al0.3CoCrFeNi High Entropy Alloy. Mater. Today Commun. 2025, 46, 112687. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Zheng, Y.; Mishra, R.S.; Banerjee, R. Tensile Yield Strength of a Single Bulk Al0.3CoCrFeNi High Entropy Alloy Can Be Tuned from 160 MPa to 1800 MPa. Scr. Mater. 2019, 162, 18–23. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Asghari-Rad, P.; Park, J.M.; Moon, J.; Bae, J.W.; Zargaran, A.; Kim, H.S. Exceptional Cryogenic Strength-Ductility Synergy in Al0.3CoCrNi Medium-Entropy Alloy through Heterogeneous Grain Structure and Nano-Scale Precipitates. Mater. Sci. Eng. A 2019, 766, 138372. [Google Scholar] [CrossRef]

- Microstructure and Tensile Behaviors of FCC Al0.3CoCrFeNi High Entropy Alloy—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0925838808022780#fig2 (accessed on 19 December 2025).

- Duan, T.; Li, J.; Zou, G.; Chen, S.; Ye, L. Effect of Deformation-Induced Precipitation of B2 Phase on Superplasticity of Al0.5CoCrFeNiCu High-Entropy Alloy. Mater. Lett. 2025, 399, 139041. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Liu, C.; Zhao, J.; Wang, B.; Li, Z.; Luo, L.; Chen, R.; Su, Y.; Guo, J. Hall-Petch Strengthening by Grain Boundaries and Annealing Twin Boundaries in Non-Equiatomic Ni2FeCr Medium-Entropy Alloy. Metals 2023, 13, 134. [Google Scholar] [CrossRef]

- Chen, P.-S.; Shiu, S.-J.; Tsai, P.-H.; Liao, Y.-C.; Jang, J.S.-C.; Wu, H.-J.; Chang, S.-Y.; Chen, C.-Y.; Tsao, I.-Y. Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions. Materials 2022, 15, 6324. [Google Scholar] [CrossRef]

- Gonçalves, C.N.; Paul, M.J.; Webster, R.F.; Kong, C.; Gludovatz, B.; Zepon, G.; Coury, F.G.; Mazzer, E.M. Impact of Rolling Temperature on the Deformation Structure and Mechanical Performance of a CrMnFeCoNi High-Entropy Alloy. J. Alloys Compd. 2024, 971, 172585. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, Y.; Zhang, J.; Lei, Y.; Song, P.; Ding, R.; Yao, X.; Chen, J. A Novel High Entropy Alloy with Outstanding Strength by Low Temperature Annealing after Severe Cold Rolling. J. Mater. Res. Technol. 2024, 28, 4358–4362. [Google Scholar] [CrossRef]

- Zhang, Z.; Cheng, Y.; Wang, X.; Song, S.; Ren, X. Investigation on Tensile Property and Mechanism of Partially Recrystallized Al0.1CoCrFeNi High-Entropy Alloy after Cold Rolling and Annealing Treatment. Mater. Sci. Eng. A 2025, 921, 147572. [Google Scholar] [CrossRef]

- Liu, X.X.; Ma, S.G.; Song, W.D.; Zhao, D.; Wang, Z.H. Microstructure Evolution and Mechanical Response of Co-Free Ni2CrFeAl0.3Tix High-Entropy Alloys. J. Alloys Compd. 2023, 931, 167523. [Google Scholar] [CrossRef]

- Fedoriková, A.; Petroušek, P.; Kvačkaj, T.; Kočiško, R.; Zemko, M. Development of Mechanical Properties of Stainless Steel 316LN-IG after Cryo-Plastic Deformation. Materials 2023, 16, 6473. [Google Scholar] [CrossRef]

- Stepanov, N.; Tikhonovsky, M.; Yurchenko, N.; Zyabkin, D.; Klimova, M.; Zherebtsov, S.; Efimov, A.; Salishchev, G. Effect of Cryo-Deformation on Structure and Properties of CoCrFeNiMn High-Entropy Alloy. Intermetallics 2015, 59, 8–17. [Google Scholar] [CrossRef]

| Region | Al | Cr | Fe | Ni |

|---|---|---|---|---|

| at. % | ||||

| Nominal | 7.1 | 18.52 | 37.04 | 37.04 |

| Actual | 8.99 | 17.11 | 36.25 | 37.65 |

| Dendrite | 8.84 | 17.98 | 36.99 | 36.19 |

| Inter-dendrite | 10.48 | 19.05 | 32.85 | 37.63 |

| State | YS [MPa] ± Dev | UTS [MPa] ± Dev | TE [%] ± Dev | RA [%] ± Dev |

|---|---|---|---|---|

| As-cast | 268 ± 8 | 474 ± 2 | 44.9 ± 5 | 54.4 ± 5 |

| HT | 191 ± 6.5 | 403 ± 1.7 | 48.5 ± 3.1 | 59.9 ± 3.1 |

| HR | 288 ± 2 | 645 ± 1 | 70.1 ± 2.3 | 69.1 ± 1.1 |

| AR20 | 738 ± 8.2 | 807 ± 6 | 21.0 ± 0.2 | 59.1 ± 0.4 |

| AR40 | 812 ± 10 | 941 ± 6.5 | 12.1 ± 0.4 | 45.7 ± 1.5 |

| AR60 | 839 ± 4.5 | 1045 ± 6 | 10.5 ± 0.3 | 41.3 ± 0.5 |

| CR20 | 795 ± 7.5 | 868 ± 6.5 | 13.4 ± 1.2 | 51.6 ± 4.7 |

| CR40 | 962 ± 9.9 | 1105 ± 5 | 9.4 ± 0.2 | 39.1 ± 0.5 |

| CR60 | 1040 ± 9.2 | 1235 ± 5.6 | 6.4 ± 0.5 | 30.2 ± 0.2 |

| Microstructure | Lattice Constant (Å) | |||

|---|---|---|---|---|

| Samples | AR60-600 | AR60-800 | CR60-600 | CR60-800 |

| FCC | 3.580 | 3.581 | 3.576 | 3.599 |

| BCC | 2.860 | 2.861 | 2.854 | 2.881 |

| Region | Al | Cr | Fe | Ni |

|---|---|---|---|---|

| at. % | ||||

| Matrix | 8.39 | 19.71 | 35.26 | 36.66 |

| Fine precipitates | 18.79 | 13.91 | 28.28 | 39.02 |

| Coarse precipitates | 27.63 | 8.55 | 18.01 | 45.82 |

| YS [MPa] | UTS [MPa] | ε [%] | RA [%] | |

|---|---|---|---|---|

| AR60 | 839 ± 5 | 1045 ± 6 | 10.5 ± 0.3 | 41.3 ± 0.5 |

| AR60-500 | 1110 ± 4.2 | 1253 ± 4.5 | 9.39 ± 1.5 | 21.8 ± 1.8 |

| AR60-600 | 1130 ± 6.7 | 1320 ± 6.7 | 12.8 ± 0.6 | 26.3 ± 2.1 |

| AR60-700 | 904 ± 8.3 | 1114 ± 7.5 | 16.8 ± 0.5 | 31.7 ± 1.5 |

| AR60-900 | 613 ± 8.5 | 872 ± 9.1 | 21.7 ± 1.1 | 23.2 ± 1.7 |

| CR60 | 1040 ± 10 | 1235 ± 5 | 6.4 ± 0.5 | 30.2 ± 0.2 |

| CR60-400 | 1370 ± 6.8 | 1447 ± 4.3 | 4.91 ± 0.8 | 43.7 ± 2.8 |

| CR60-500 | 1420 ± 5.5 | 1465 ± 5.1 | 5.5 ± 0.6 | 14.8 ± 1.3 |

| CR60-600 | 1271 ± 9.3 | 1411 ± 7.3 | 8.4 ± 0.3 | 16.1 ± 4 |

| CR60-700 | 911 ± 7.2 | 1024 ± 3.2 | 19.1 ± 0.9 | 19.0 ± 2.1 |

| CR60-900 | 577 ± 11.2 | 859 ± 8.3 | 27.8 ± 0.7 | 29.2 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Kočiško, R.; Petroušek, P.; Milkovič, O.; Diko, P.; Girman, V.; Sütőová, A.; Duchek, M.; Zemko, M. Tailoring the Mechanical Properties of Al0.4CrFe2Ni2 Medium-Entropy Alloy via Thermomechanical Processing. Materials 2026, 19, 502. https://doi.org/10.3390/ma19030502

Kočiško R, Petroušek P, Milkovič O, Diko P, Girman V, Sütőová A, Duchek M, Zemko M. Tailoring the Mechanical Properties of Al0.4CrFe2Ni2 Medium-Entropy Alloy via Thermomechanical Processing. Materials. 2026; 19(3):502. https://doi.org/10.3390/ma19030502

Chicago/Turabian StyleKočiško, Róbert, Patrik Petroušek, Ondrej Milkovič, Pavel Diko, Vladimír Girman, Andrea Sütőová, Michal Duchek, and Michal Zemko. 2026. "Tailoring the Mechanical Properties of Al0.4CrFe2Ni2 Medium-Entropy Alloy via Thermomechanical Processing" Materials 19, no. 3: 502. https://doi.org/10.3390/ma19030502

APA StyleKočiško, R., Petroušek, P., Milkovič, O., Diko, P., Girman, V., Sütőová, A., Duchek, M., & Zemko, M. (2026). Tailoring the Mechanical Properties of Al0.4CrFe2Ni2 Medium-Entropy Alloy via Thermomechanical Processing. Materials, 19(3), 502. https://doi.org/10.3390/ma19030502