Microstructure and Mechanical Properties of B4C-HfB2-SiC Ceramic Composites Prepared by In Situ Reaction

Abstract

1. Introduction

2. Experimental Procedures

3. Results and Discussion

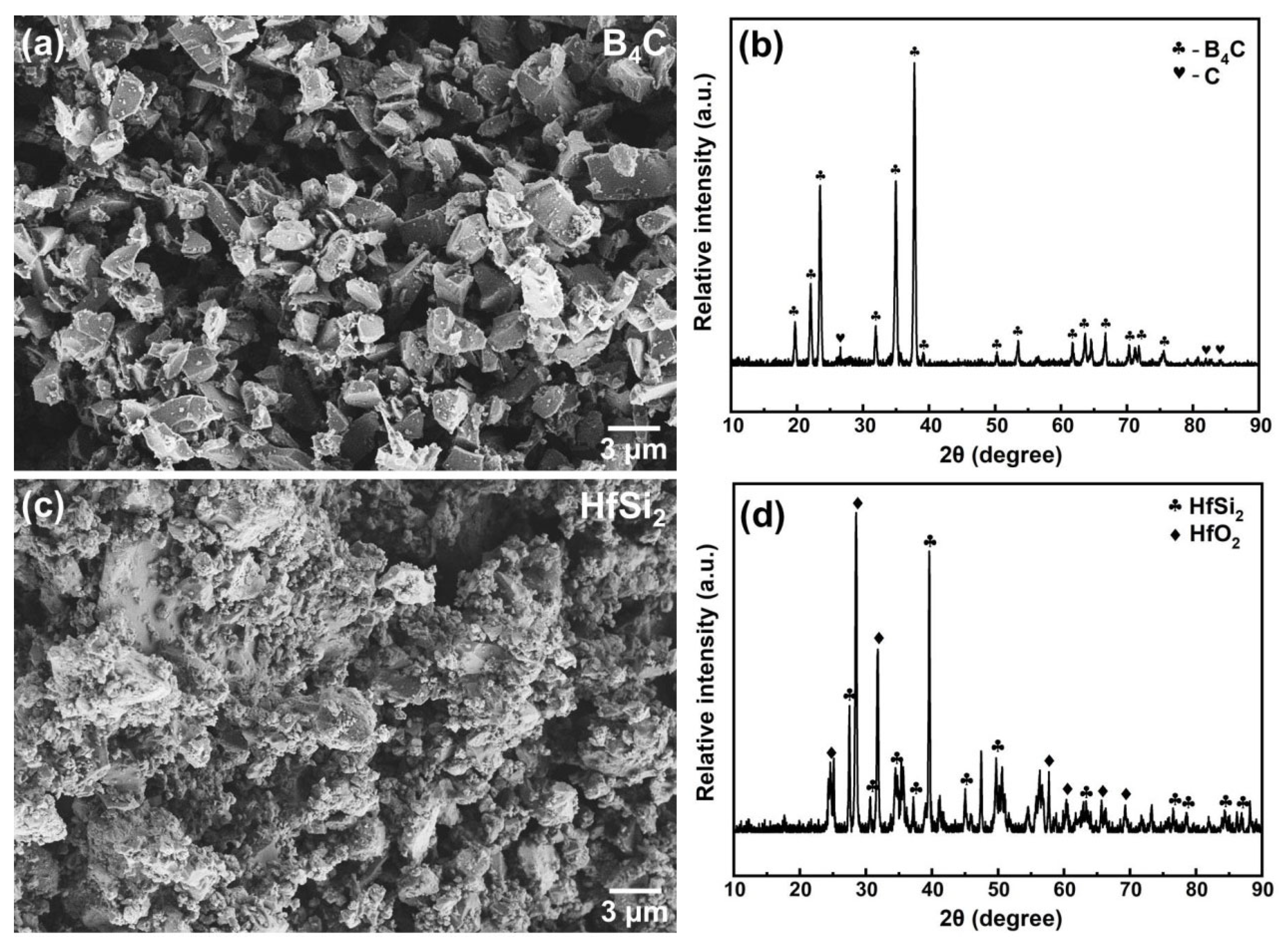

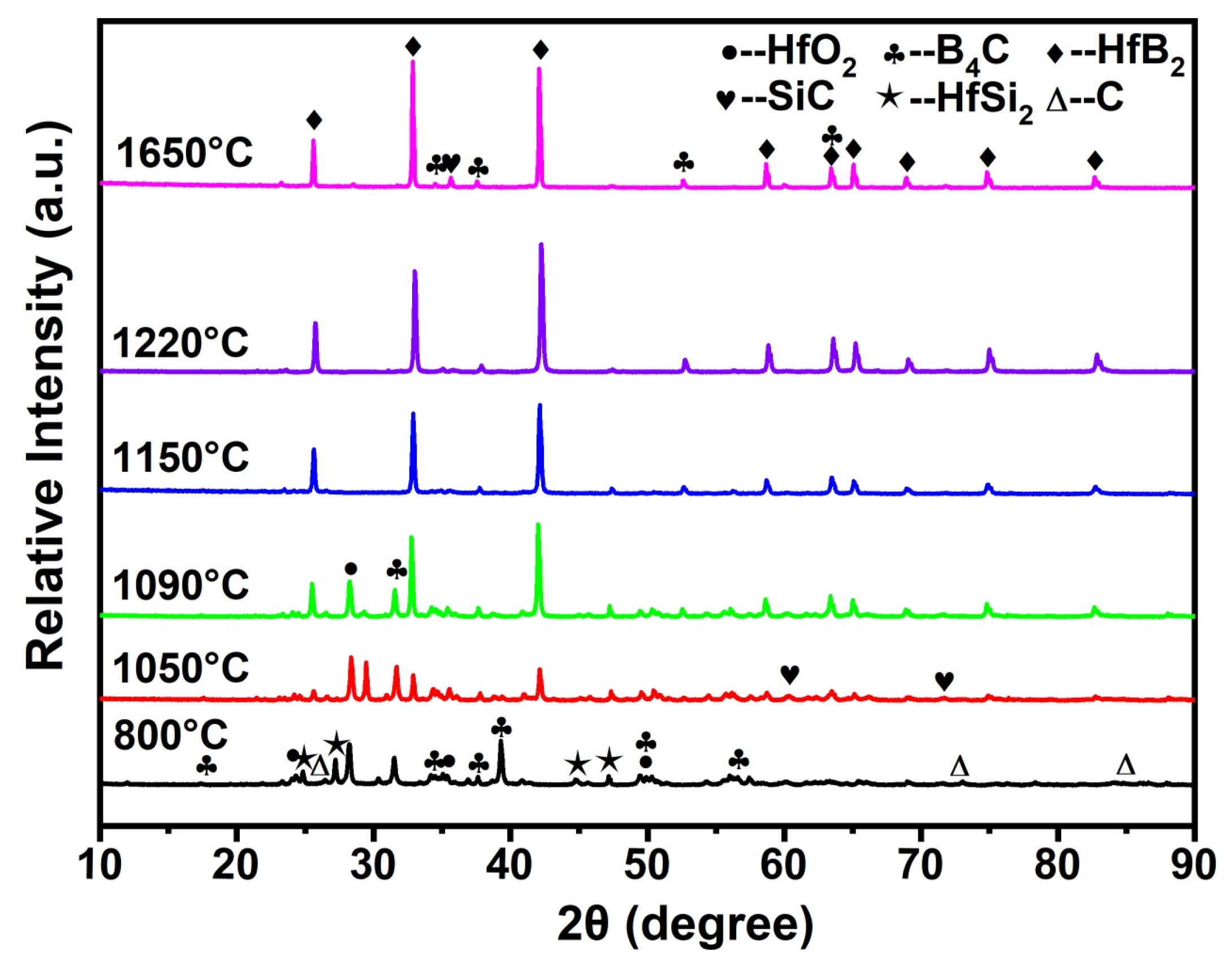

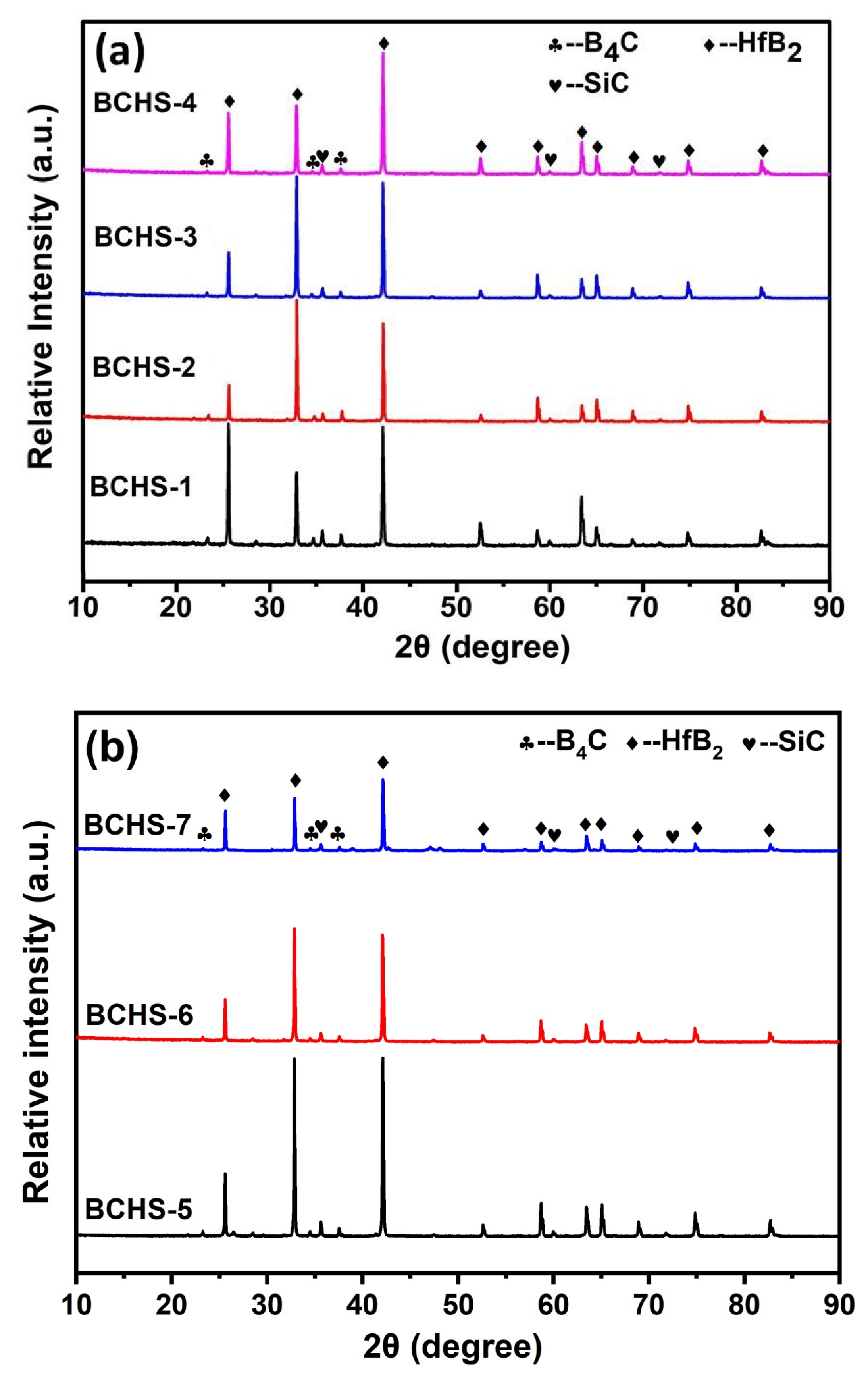

3.1. Phase Transition and Phase Identification

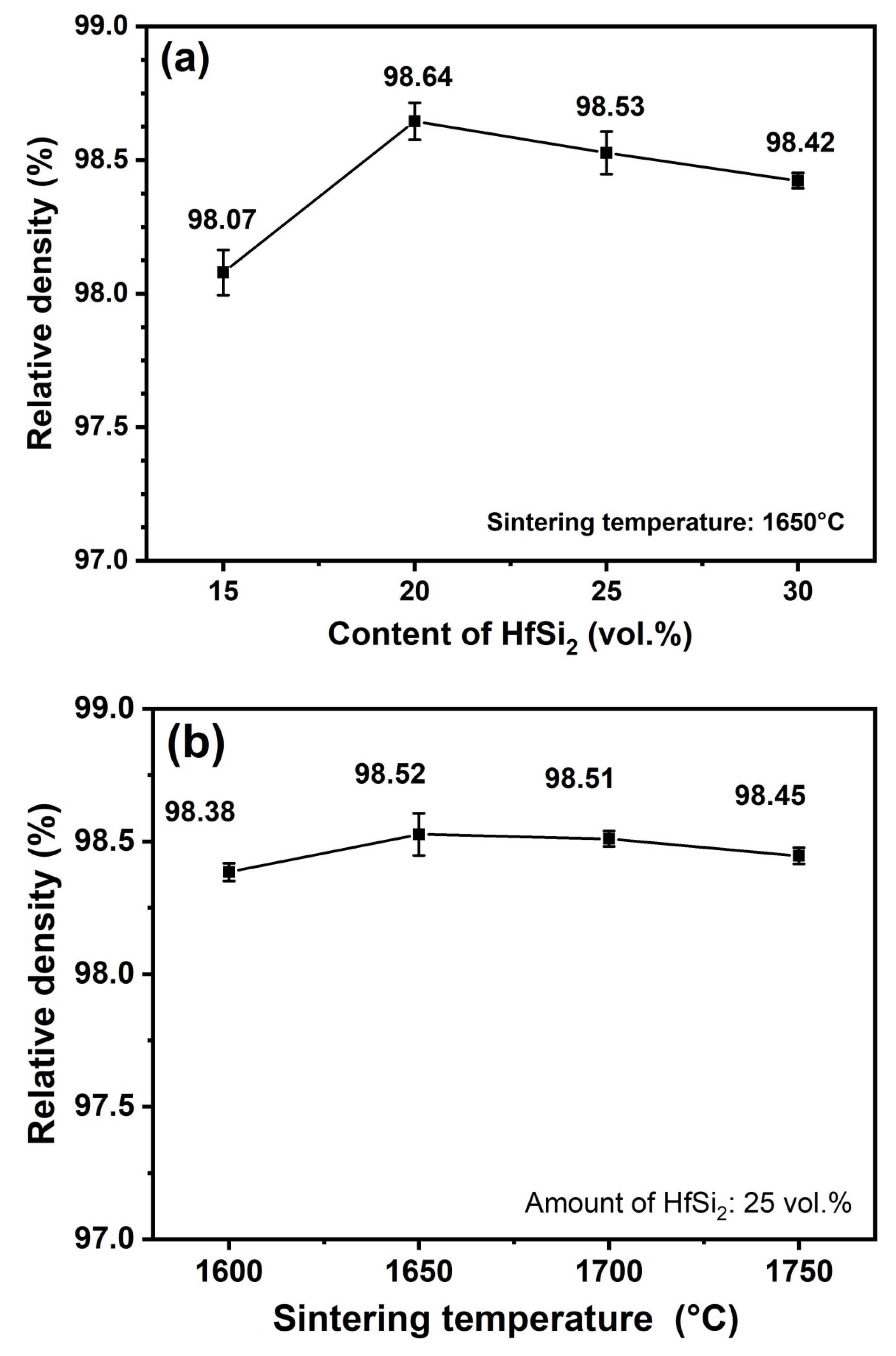

3.2. Relative Density

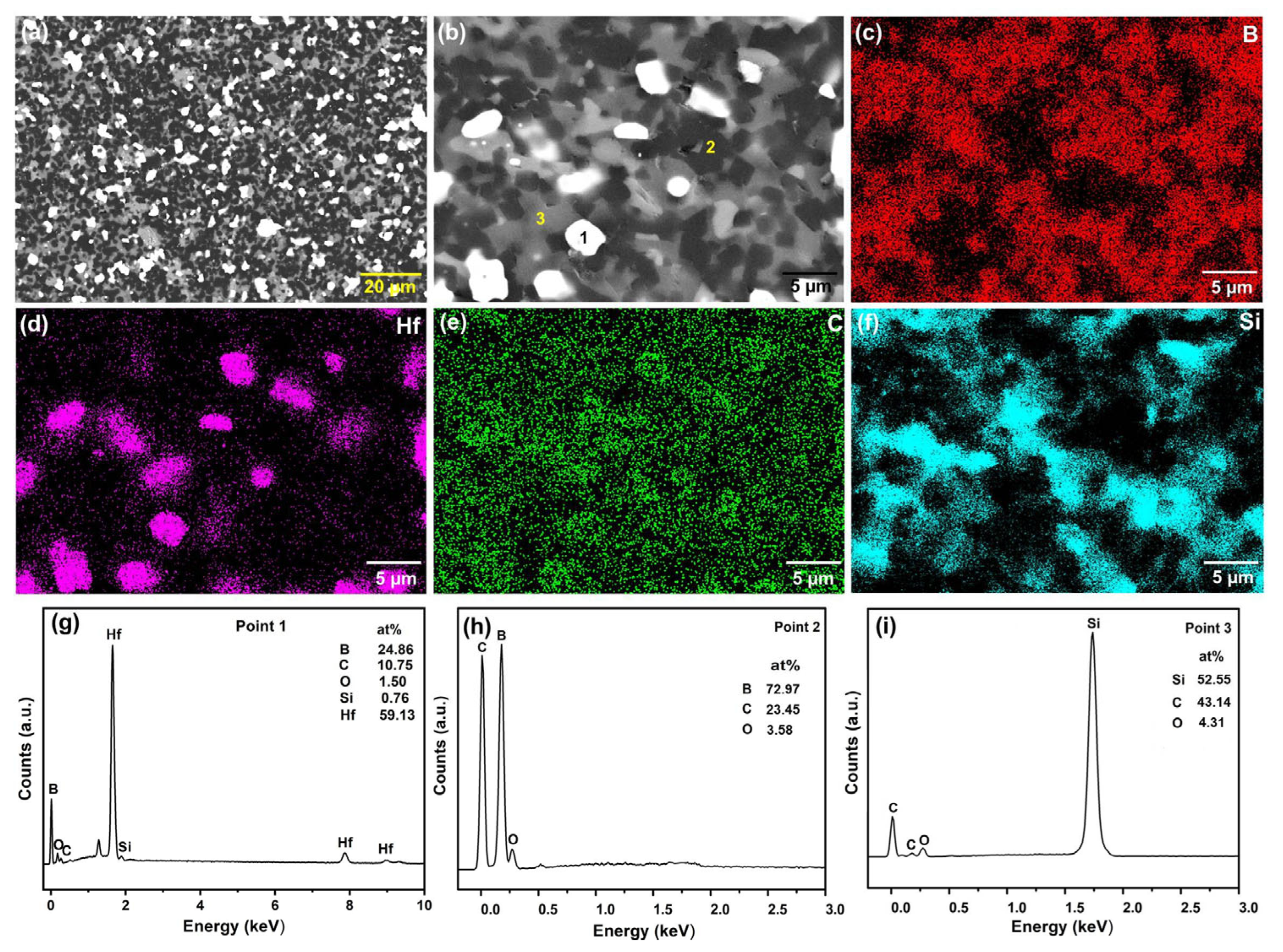

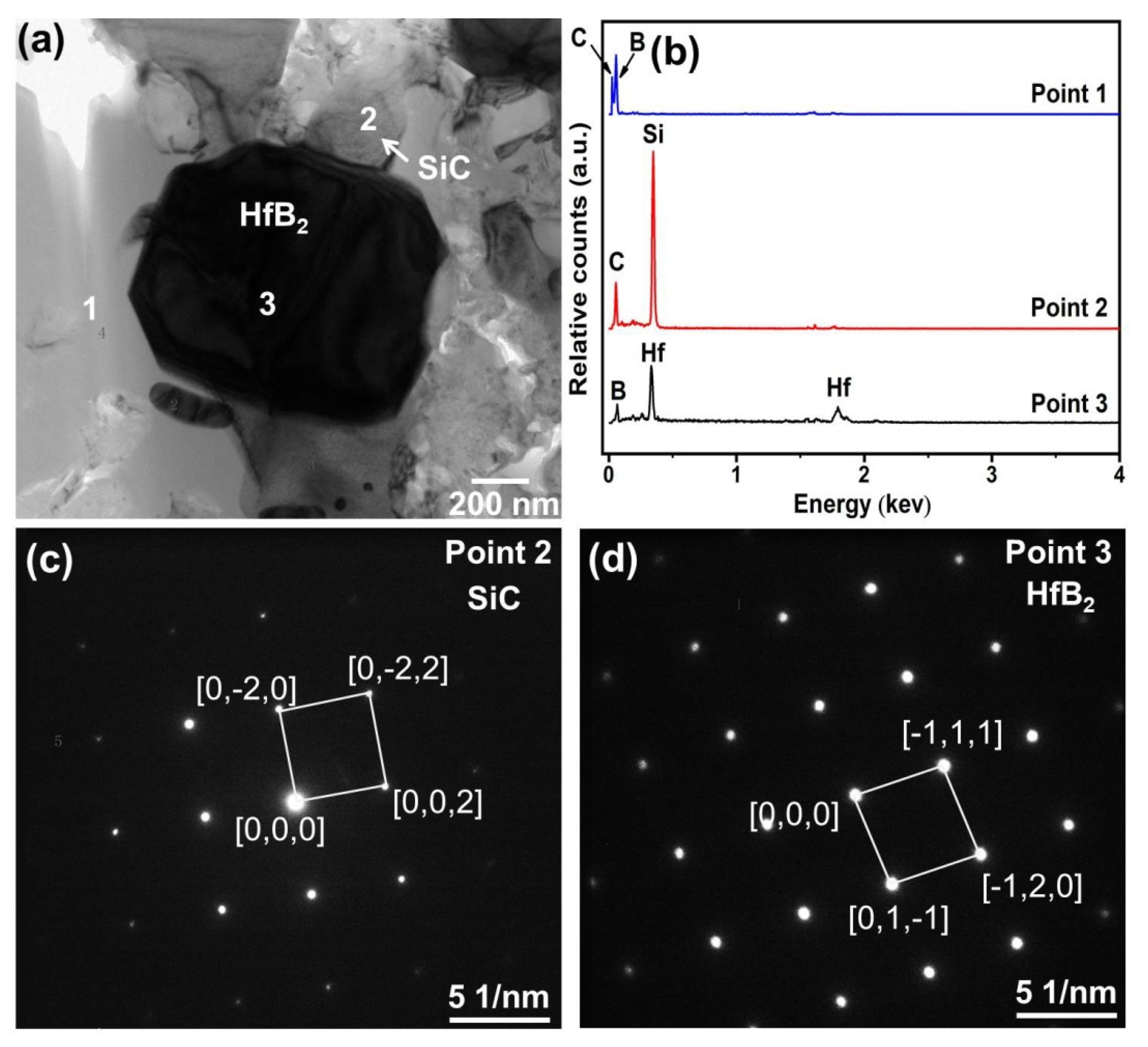

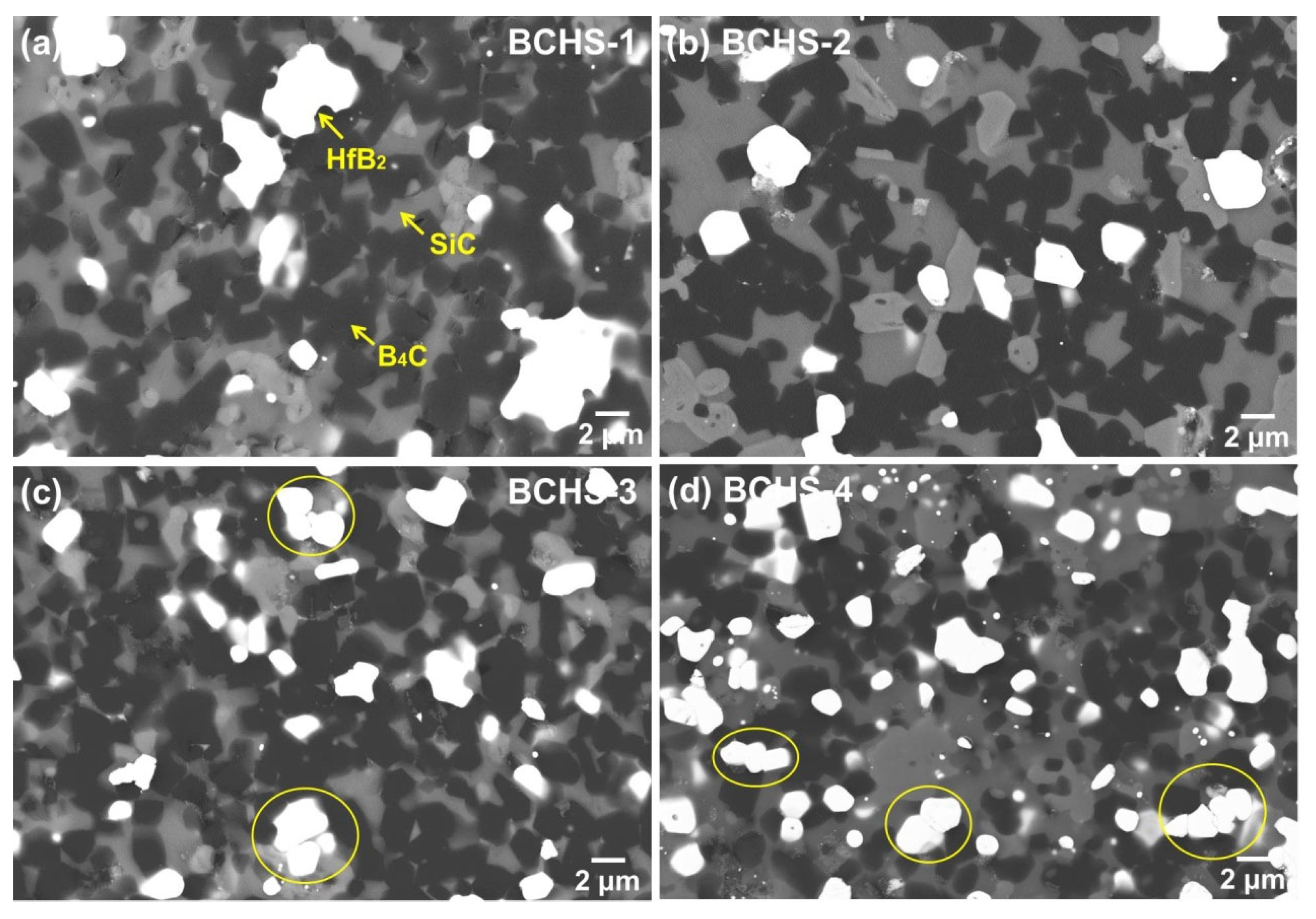

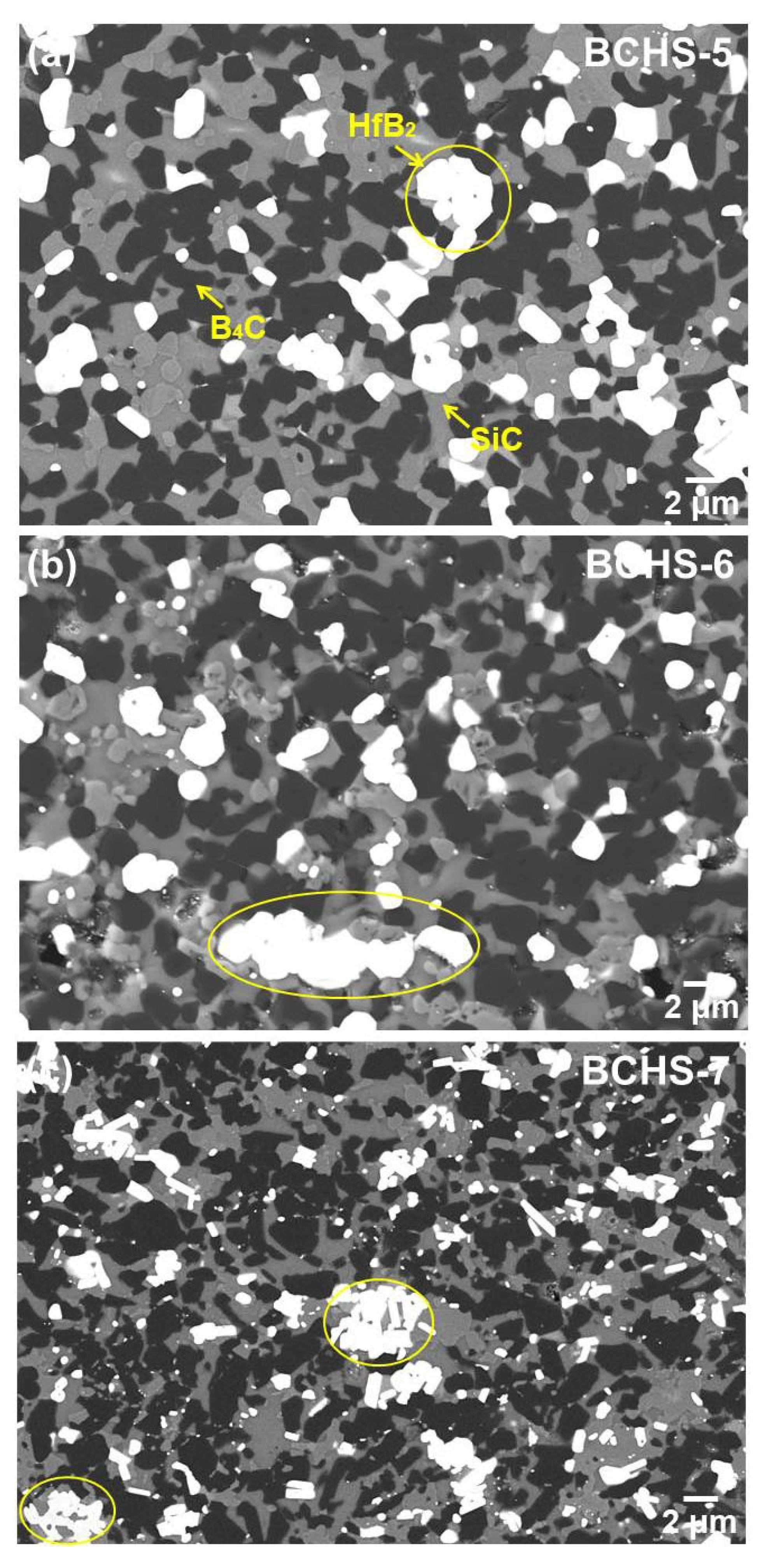

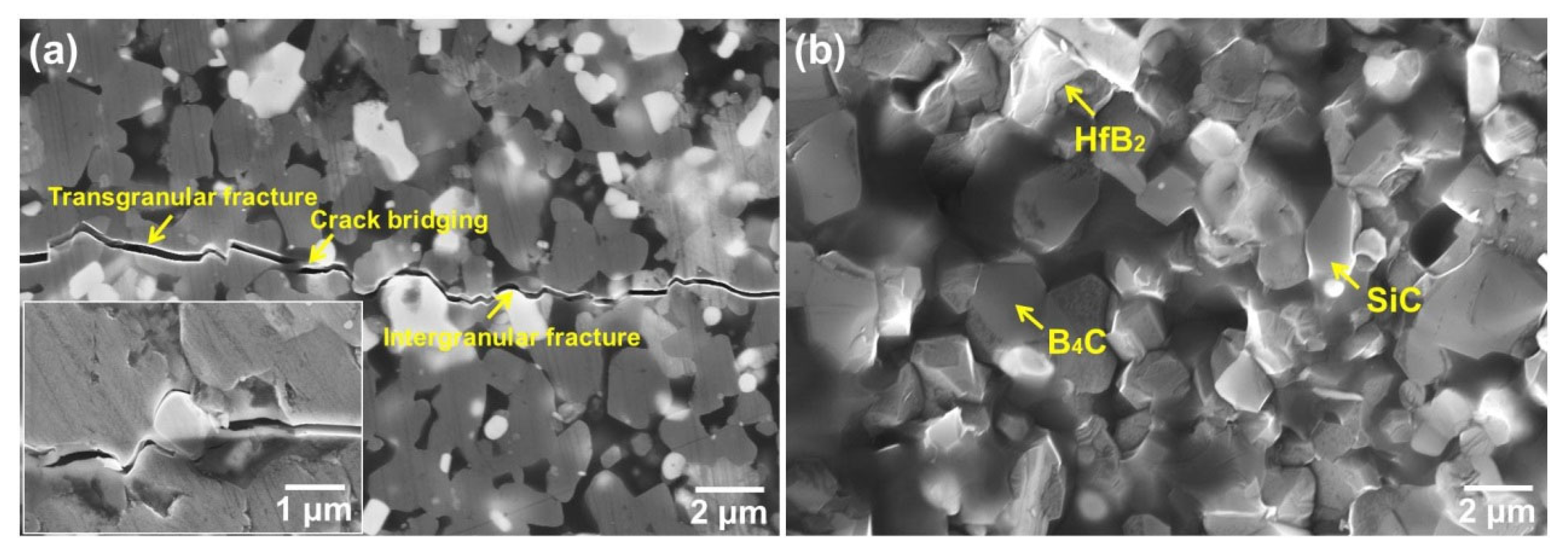

3.3. Microstructure

3.4. Mechanical Properties

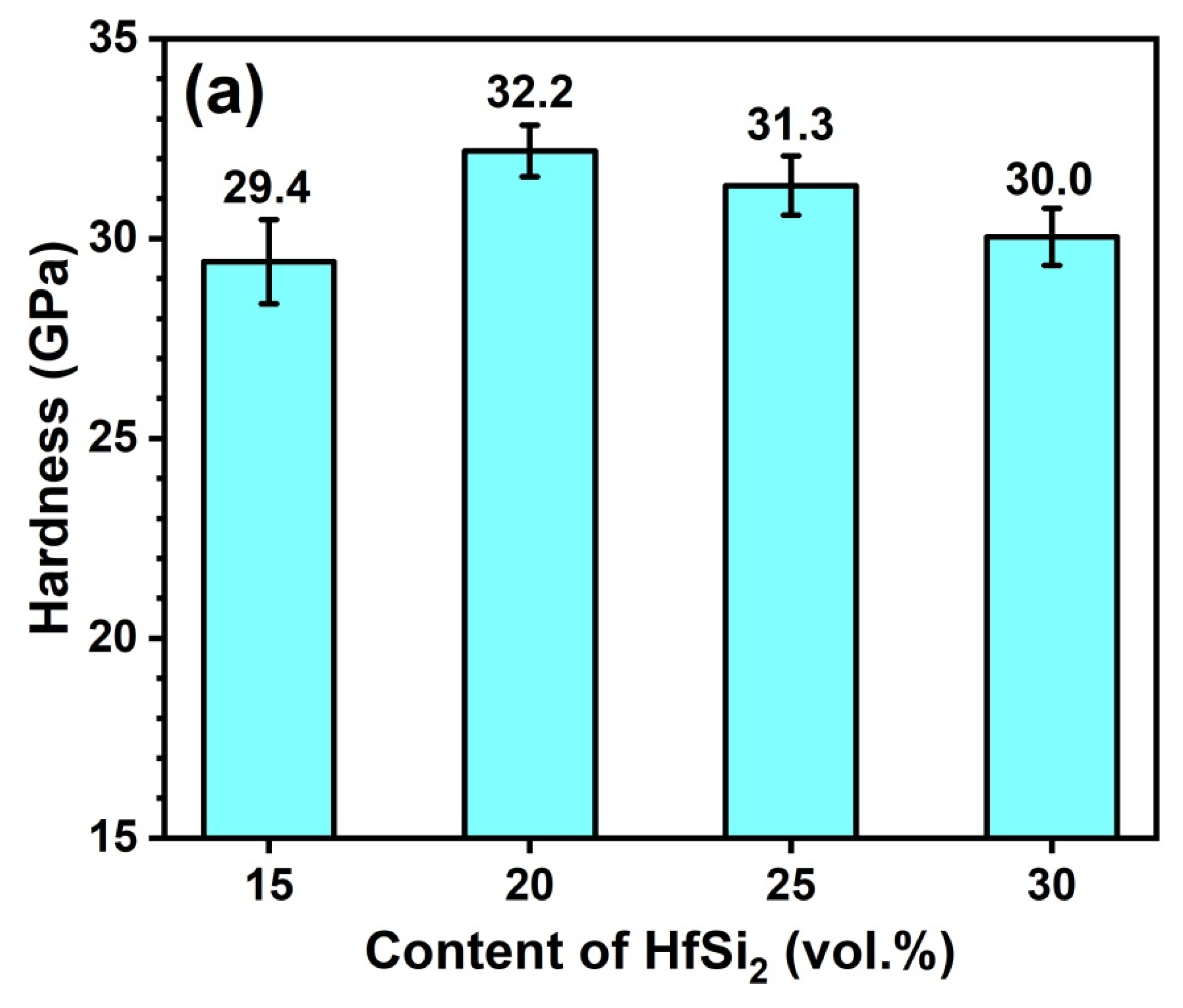

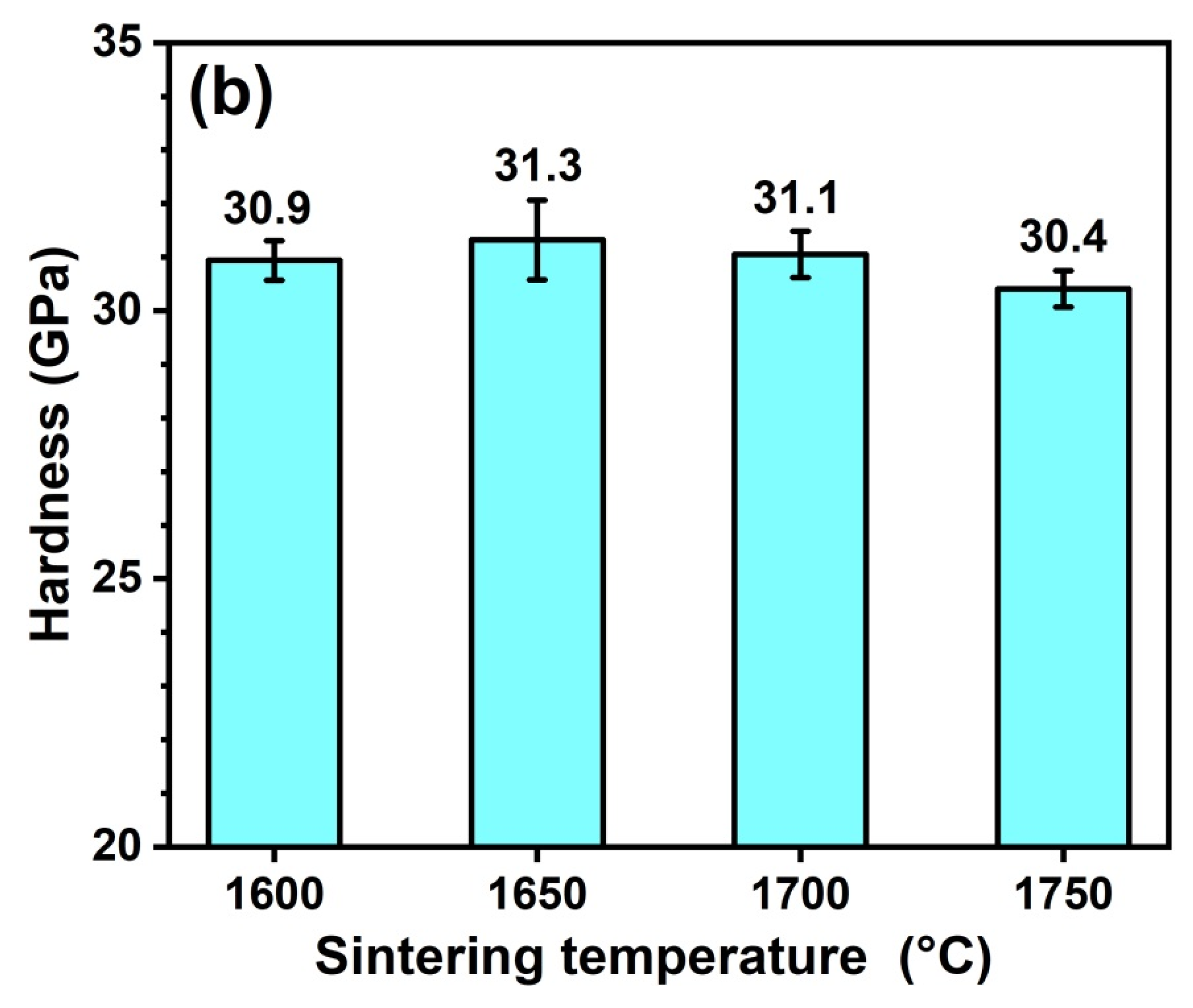

3.4.1. Hardness

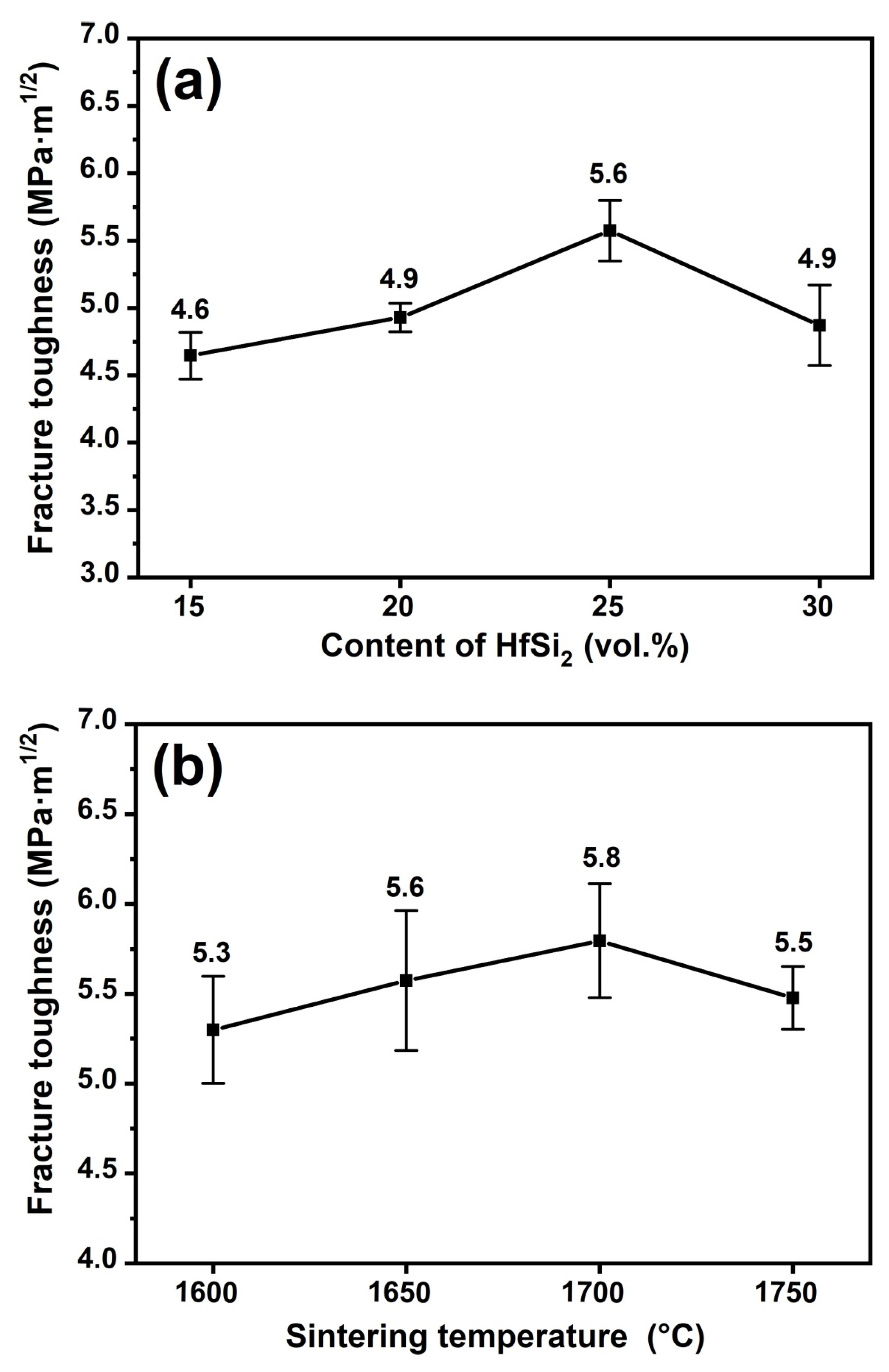

3.4.2. Fracture Toughness

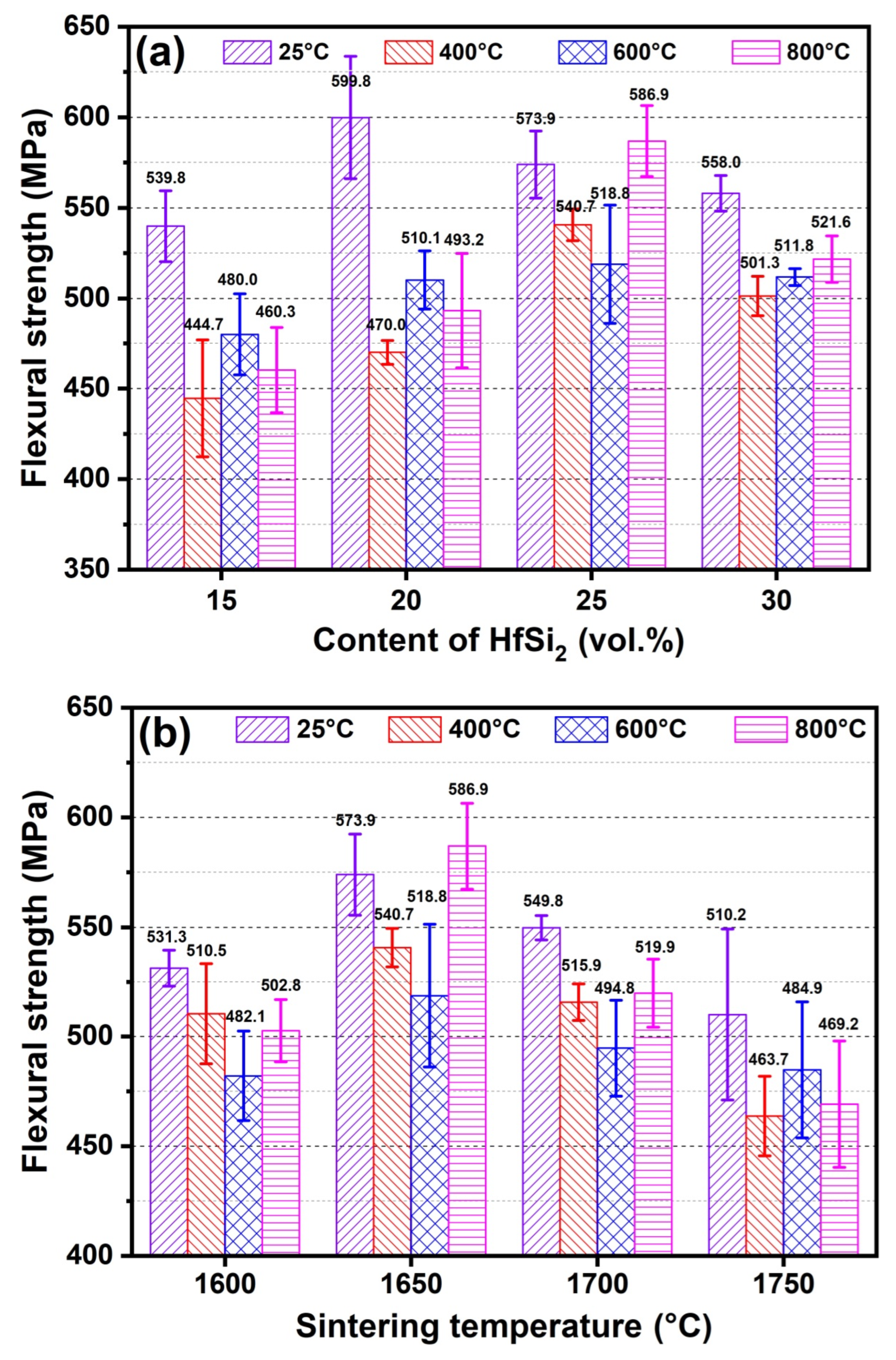

3.4.3. Flexural Strength

4. Conclusions

- (1)

- HfSi2 reacted with B4C to form HfB2 and SiC in the temperature range of 1600 °C to 1750 °C for the ceramics with different amounts (15–30 vol.%) of HfSi2. HfB2, SiC, and B4C are distributed uniformly in the ceramics.

- (2)

- The formation of HfB2 and SiC improved the density and mechanical properties of B4C-HfB2-SiC composite ceramics. The relative density, Vickers hardness, fracture toughness, and flexural strength of ceramics sintered at 1650 °C with different content of HfSi2 increased first and then decreased with increasing the content of HfSi2. These properties for the ceramics containing 25 vol.% HfSi2 sintered at 1600–1750 °C also showed a similar trend.

- (3)

- The optimal comprehensive mechanical properties of the B4C-HfB2-SiC composite ceramics were sintered at 1650 °C with 25 vol.% HfSi2. The relative density, hardness, fracture toughness, and flexural strength of ceramic sintered at 1650 °C with HfSi2 content of 25 vol.% was 99.5%, 31.3 GPa, 5.6 MPa·m1/2, and 573.9 MPa, respectively, at RT. The flexural strength at 400–800 °C decreased slightly compared to that tested at RT.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shan, Q.; Tian, X.; Xue, Y.; Hu, J.; You, X.; Wu, B.; Qian, J.; Wang, Z. Initial damage behavior of Al2O3-modified SiCf/SiC-B4C composites after oxidation under wet atmosphere at 1200 °C. J. Am. Ceram. Soc. 2024, 107, 6032–6044. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, C.; Zhang, S.; Zhang, W. Mechanical properties and toughening mechanism of B4C-Al2O3 composite ceramics prepared by hot-press sintering. Ceram. Int. 2024, 50, 24499–24507. [Google Scholar] [CrossRef]

- Takano, M.; Nishi, T.; Shirasu, N. Characterization of solidified melt among materials of UO2 fuel and B4C control blade. J. Nucl. Sci. Technol. 2014, 51, 859–875. [Google Scholar] [CrossRef]

- Chakraborty, S.; Debnath, D.; Mallick, A.R.; Das, P.K. Mechanical, tribological, and thermal properties of hot-pressed ZrB2-B4C composite. Int. J. Appl. Ceram. Technol. 2015, 12, 568–576. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Wang, W.; Che, H.; Zhang, X.; Bai, Y.; Zhang, L.; Fu, Z. Densification behaviour and mechanical properties of B4C–SiC intergranular/intragranular nanocomposites fabricated through spark plasma sintering assisted by mechanochemistry. Ceram. Int. 2017, 43, 1904–1910. [Google Scholar] [CrossRef]

- Domnich, V.; Reynaud, S.; Haber, R.A.; Chhowalla, M. Boron carbide: Structure, properties, and stability under stress. J. Am. Ceram. Soc. 2011, 94, 3605–3628. [Google Scholar] [CrossRef]

- Balalan, Z.; Gulan, F. Microstructure and mechanical properties of Cu-B4C and CuAl-B4C composites produced by hot pressing. Rare Met. 2019, 38, 1169–1177. [Google Scholar] [CrossRef]

- Zou, J.; Huang, S.G.; Vanmeensel, K.; Zhang, G.; Vleugels, J.; Van der Biest, O. Spark plasma sintering of superhard B4C-ZrB2 ceramics by carbide boronizing. J. Am. Ceram. Soc. 2013, 96, 1055–1059. [Google Scholar] [CrossRef]

- Yamada, S.; Hirao, K.; Yamauchi, Y.; Kanzaki, S. Mechanical and electrical properties of B4C-CrB2 ceramics fabricated by liquid phase sintering. Ceram. Int. 2003, 29, 299–304. [Google Scholar] [CrossRef]

- Sousa, J.M.; Alves, A.C.; Toptan, F.; Ariza, E.; Guedes, A. Corrosion and Tribocorrosion Behavior of Ti-B4C Composites Joined with TiCuNi Brazing Alloy. J. Mater. Eng. Perform. 2019, 28, 4972–4982. [Google Scholar] [CrossRef]

- Huang, S.; Vanmeensel, K.; Vleugels, J. In-situ Synthesis and densification of B4C-(Zr,Ti)B2 composites by pulsed electric current sintering. J. Chin. Ceram. Soc. 2014, 2, 113–121. [Google Scholar]

- Yamada, S.; Hirao, K.; Yamauchi, Y.; Kanzaki, S. Densification behaviour and mechanical properties of pressureless-sintered B4C-CrB2 ceramics. J. Mater. Sci. 2002, 37, 5007–5012. [Google Scholar] [CrossRef]

- Demirskyi, D.; Sakka, Y. In situ fabrication of B4C-NbB2 eutectic composites by spark-plasma sintering. J. Am. Ceram. Soc. 2014, 97, 2376–2378. [Google Scholar] [CrossRef]

- Lin, X.; Ai, S.; Feng, Y.; Gao, D.; Guo, X.; Liu, Y.; Xie, B.; Gong, H.; Zhang, Y. Fabrication and properties of in-situ pressureless-sintered ZrB2/B4C composites. Ceram. Int. 2017, 43, 15593–15596. [Google Scholar] [CrossRef]

- Tang, J.; Ji, W.; Xie, J.; Shi, Y.; Zhu, Y.; He, Q.; Wang, W. Fine and High-performance B6.5C-TiB2-SiC-BN composite fabricated by reactive hot pressing via TiCN-B-Si Mixture. Ceram. Int. 2020, 46, 11013–11020. [Google Scholar] [CrossRef]

- Qu, Z.; He, R.; Cheng, X.; Fang, D. Fabrication and characterization of B4C-ZrB2-SiC ceramics with simultaneously improved high temperature strength and oxidation resistance up to 1600 °C. Ceram. Int. 2016, 42, 8000–8004. [Google Scholar] [CrossRef]

- Sun, W.; Tian, Y.; Xu, S.; Liu, L.; Lu, Y. Powder synthesis, densification, microstructure, and mechanical properties of HfB2-HfC ceramic Composites. Int. J. Appl. Ceram. Technol. 2023, 21, 195–206. [Google Scholar] [CrossRef]

- Chenari, P.; Balak, Z.; Shahedifar, V. Investigation of microstructure and mechanical properties of HfB2-HfC-TiC-B4C Composites. Mater. Chem. Phys. 2025, 341, 130927. [Google Scholar] [CrossRef]

- Ojalvo, C.; Guiberteau, F.; Ortiz, A.L. Fabricating toughened super-hard B4C composites at lower temperature by transient liquid-phase assisted spark plasma sintering with MoSi2 additives. J. Eur. Ceram. Soc. 2019, 39, 2862–2873. [Google Scholar] [CrossRef]

- He, Q.; Wang, A.; Liu, C.; Wang, W.; Wang, H.; Fu, Z. Microstructures and mechanical properties of B4C-TiB2-SiC composites fabricated by ball milling and hot Pressing. J. Eur. Ceram. Soc. 2018, 38, 2832–2840. [Google Scholar] [CrossRef]

- Wang, S.; Gao, S.; Xing, P.; Nie, D.; Yan, S.; Zhuang, Y. Pressureless liquid-phase sintering of B4C with MoSi2 as a sintering aid. Ceram. Int. 2019, 45, 13502–13508. [Google Scholar] [CrossRef]

- Feng, B.; Martin, H.-P.; Michaelis, A. Preparation and characterization of B4C-HfB2 composites as material for high-temperature thermocouples. Crystals 2022, 12, 621. [Google Scholar] [CrossRef]

- Sun, R.; Wei, X.; Hu, W.; Ying, P.; Wu, Y.; Wang, L.; Chen, S.; Zhang, X.; Ma, M.; Yu, D.; et al. Nanocrystalline cubic silicon carbide: A Route to Superhardness. Small 2022, 18, e2201212. [Google Scholar] [CrossRef] [PubMed]

- Leath, P.L. Cluster size and boundary distribution near percolation Threshold. Phys. Rev. B 1976, 14, 5046–5055. [Google Scholar] [CrossRef]

| Sample | B4C (vol.%) | HfSi2 (vol.%) | Sintering Temperature (°C) | Phase Fraction (vol.%) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|

| BCHS-1 | 85 | 15 | 1650 | B4C: 65.19; HfB2: 8.02; SiC: 26.79 | 3.2739 |

| BCHS-2 | 80 | 20 | 1650 | B4C: 58.24; HfB2: 11.01; SiC: 30.75 | 3.5559 |

| BCHS-3 | 75 | 25 | 1650 | B4C: 49.28; HfB2: 13.96; SiC: 36.76 | 3.8302 |

| BCHS-4 | 70 | 30 | 1650 | B4C:39.85; HfB2: 16.87; SiC: 43.28 | 4.0951 |

| BCHS-5 | 75 | 25 | 1600 | B4C: 50.51; HfB2: 14.14; SiC: 35.31 | 3.8253 |

| BCHS-6 | 75 | 25 | 1700 | B4C: 49.37; HfB2: 13.58; SiC: 37.05 | 3.8270 |

| BCHS-7 | 75 | 25 | 1750 | B4C: 47.83; HfB2: 14.05; SiC: 38.12 | 3.8246 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhong, L.; Liu, Q.; Chen, C.; Liang, S.; Zhong, Z. Microstructure and Mechanical Properties of B4C-HfB2-SiC Ceramic Composites Prepared by In Situ Reaction. Materials 2026, 19, 82. https://doi.org/10.3390/ma19010082

Zhong L, Liu Q, Chen C, Liang S, Zhong Z. Microstructure and Mechanical Properties of B4C-HfB2-SiC Ceramic Composites Prepared by In Situ Reaction. Materials. 2026; 19(1):82. https://doi.org/10.3390/ma19010082

Chicago/Turabian StyleZhong, Langxiang, Qiang Liu, Chengmin Chen, Shuibao Liang, and Zhihong Zhong. 2026. "Microstructure and Mechanical Properties of B4C-HfB2-SiC Ceramic Composites Prepared by In Situ Reaction" Materials 19, no. 1: 82. https://doi.org/10.3390/ma19010082

APA StyleZhong, L., Liu, Q., Chen, C., Liang, S., & Zhong, Z. (2026). Microstructure and Mechanical Properties of B4C-HfB2-SiC Ceramic Composites Prepared by In Situ Reaction. Materials, 19(1), 82. https://doi.org/10.3390/ma19010082