Modern Fire-Resistant Fabrics—Requirements for Durability of Materials After Washing After a Fire

Abstract

1. Introduction

2. Method of Conducting the Literature Review

3. Characteristics of Fire-Resistant Fabrics

- -

- Fabrics made from inherently flame-retardant fibres;

- -

- Fabrics impregnated with flame retardants.

4. Flame Retardant Fabrics

- Formation of a charred layer (condensation effect);

- Release of non-combustible gases (gas phase effect);

- Thermal decomposition with the release of products that inhibit the chain reaction of combustion;

- Restriction of oxygen access to the fibre surface.

- −

- Phosphorus compounds—Phosphates, phosphonates, phosphorines, and their derivatives (e.g., THPC, TEPAP), which promote the formation of a charred layer and are commonly used for impregnating cellulose fabrics.

- −

- Nitrogen compounds—Often used in combination with phosphorus, increase thermal stability and synergistically support the carbonisation process.

- −

- Boron and silicon compounds—Act by forming a glassy protective layer that limits oxygen access.

- −

- Metal oxide nanoparticles (TiO2, SiO2, Al2O3, ZnO)—Used in modern multi-layer coatings, increase thermal resistance and improve the adhesion of the impregnating agent to the fibres [39]. Due to strong chemical bonds with the fibre surface, they exhibit increased resistance to leaching compared to traditional flame retardants. Promising results have also been obtained for aerogel fibres based on ultra-light aramid nanofibres.

5. Key Factors Affecting Fibre Durability After Fire and Washing

6. Methods for Assessing the Durability of Fabrics

- ISO 15797 [50]—Simulation of industrial washing processes to test resistance to aggressive chemicals and high temperatures;

- ISO 11612 [7] Test—Assessment of material resistance to convective heat and thermal radiation;

- Thermogravimetric Analysis (TGA)—Determining the thermal stability of a material;

- FTIR and SEM-EDS—Analytical techniques for assessing the presence of the impregnating agent and its changes after washing;

- ISO 13506 [54]—Testing of entire suits using an instrumental manikin to predict burn injuries.

7. The Impacts of Conventional and Advanced Cleaning Techniques on the Durability of Fire-Resistant Fabrics

- −

- It may cause the leaching of flame retardants from chemically modified fabrics;

- −

- It leads to fibre micro-cracking and loss of structural integrity in cotton fabrics;

- −

- The use of chlorine bleaches can significantly damage aramid fibres, lowering their strength.

8. Directions of Development and Research Perspectives

- −

- The availability of substrates;

- −

- The possibility of using waste to produce, for example, flame retardants, modifiers, and substances that reduce energy consumption;

- −

- Reductions in energy and water consumption;

- −

- Supporting a circular economy;

- −

- Reduction in waste.

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rabajczyk, A.; Wolański, R. Analysis of the Issue of Special Clothing in the Operation of Fire Protection Units. SFT 2023, 61, 64–84. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.; Khan, A.; Chandan, V.; Muller, M.; Valasek, P. Flammability and comfort properties of blended knit fabrics made from inherently fire-resistant fibers to use for fire fighters. Heliyon 2023, 9, e13127. [Google Scholar] [CrossRef]

- Taesan Ind Corporation. Flame Retardant Meta-Aramid Fiber Excellent in Anti-Static and Method of Manufacturing the Same. Patent KR20200012579A, 5 February 2020. [Google Scholar]

- Mazumder, N.S.; Islam, M.T. Flame Retardant Finish for Textile Fibers in Innovative and Emerging Technologies for Textile Dyeing and Finishing, 1st ed.; Rather, L.J., Haji, A., Shabbir, M., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 373–407. Available online: https://books.google.pl/books?id=YS8WEAAAQBAJ&printsec=frontcover&hl=pl#v=onepage&q&f=false (accessed on 3 November 2025).

- Qi, P.; Chen, F.; Li, Y.; Li, H.; Gu, X.; Sun, J.; Zhang, S. A Review of Durable Flame-Retardant Fabrics by Finishing: Fabrication Strategies and Challenges. Adv. Fiber Mater. 2023, 5, 731–763. [Google Scholar] [CrossRef]

- ISO 15025:2016; Protective Clothing—Protection Against Flame—Method of Test for Limited Flame Spread, Edition 2. International Organization for Standardization: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/61739.html (accessed on 3 November 2025).

- ISO 11612:2015; Protective Clothing—Clothing to Protect Against Heat and Flame—Minimum Performance Requirements, Edition 3. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/57457.html (accessed on 3 November 2025).

- EN 469:2020; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Firefighting Activities. The European Committee for Standardization: Brussels, Belgium, 2020.

- EN 531; European Standard for Protective Clothing in Industrial Environments. The European Committee for Standardization: Brussels, Belgium, 2023.

- NFPA 2112; Standard on Flame-Resistant Clothing for Protection of Industrial Personnel Against Short-Duration Thermal Exposures from Fire. NFPA: Quincy, MA, USA, 2023.

- Wolański, R.; Anna Rabajczyk, A. Selected Aspects of Transformation of Textile Elements of Firemen’s Personal Protection. SFT 2023, 61, 86–101. [Google Scholar] [CrossRef]

- Qi, L.; Qiu, S.; Xi, J.; Yu, B.; Hu, Y.; Xing, W. Construction of super-hydrophobic, highly effective flame retardant coating for cotton fabric with superior washability and abrasion resistance. J. Colloid Interface Sci. 2022, 607, 2019–2028. [Google Scholar] [CrossRef]

- Shakeriaski, F.; Ghodrat, M.; Maria Rashidi, M.; Samali, B. Smart coating in protective clothing for firefighters: An overview and recent improvements. J. Ind. Text. 2022, 51, 7428S–7454S. [Google Scholar] [CrossRef]

- McCann, J. 13—Identification of design requirements for smart clothes and wearable technology. In The Textile Institute Book Series. Smart Clothes and Wearable Technology, 2nd ed.; McCann, J., Bryson, D., Eds.; Woodhead Publishing: Cambridge, UK, 2023; pp. 327–369. [Google Scholar] [CrossRef]

- Shoaib, M.; Jamshaid, H.; Mishra, R.K.; Iqbal, K.; Müller, M.; Chandan, V.; Alexiou Ivanova, T. Flammability and Thermoregulation Performance of Multilayer Protective Clothing Incorporated with Phase Change Materials. Materials 2024, 17, 5826. [Google Scholar] [CrossRef] [PubMed]

- Eryuruk, S.H. Effect of Fabric Layers on Thermal Comfort Properties of Multilayered Thermal Protective Fabrics. Autex Res. J. 2019, 19, 271–278. [Google Scholar] [CrossRef]

- Kilinc, F.S. Handbook of Fire Resistant Textiles; Woodhead Publishing Ltd.: Cambridge UK, 2013; pp. 1–106. ISBN 978-0-85709-123-9. [Google Scholar]

- Gurusamy Pandian, P.G.; Ashifa, K.M. Analysis and design of fire resistance cloth in fire works industries. Mater. Today Proc. 2020, 33, 1032–1037. [Google Scholar] [CrossRef]

- SWAVELLE Group. Fire-Retardant vs. Fire-Resistant Fabrics. Available online: https://www.swavelle.com/in-the-news/fire-retardant-vs-fire-resistant-fabrics/ (accessed on 23 November 2025).

- Weil, E.D.; Levchik, S.V. Flame Retardants in Commercial Use or Development for Textiles. J. Fire Sci. 2008, 26, 243–281. [Google Scholar] [CrossRef]

- Khammatova, V.V.; Gainutdinov, R.F.; Khammatova, E.A.; Titova, L.V. Properties of high-strength aramid fiber textile materials for protective clothing. Fibre Chem. 2021, 53, 204–207. [Google Scholar] [CrossRef]

- Ni, Q.; Hou, B.; Cui, Q.; Chen, Z.; Fang, J.; Li, J. Preparation and performance of flame-retardant, superhydrophobic cotton fabric with enhanced wash durability and self-cleaning properties. Surf. Coat. Technol. 2025, 501, 131903. [Google Scholar] [CrossRef]

- Chin, J.J. Understanding Flame Retardant Fabrics: Classification, Standards and Applications. In Flame Retardant Fabric. Fire Safety Knowledge; BEGOODTEX: Shaoxing, China, 2025. Available online: https://begoodtex.com/understanding-flame-retardant-fabrics-classification-standards-and-applications/?srsltid=AfmBOoqTnABqHQH5iOwglfRpDjhHv5eicuJBZHPDb8xeOHCSECWIcueO (accessed on 23 November 2025).

- Latent Heat Solutions, LLC. Golden CO Thermal Management Materials Containing Phase Change Materials. Patent No. EP 3 253 583 B1, 29 November 2023. [Google Scholar]

- Jiangsu Textile Research Institute Inc. Classification of Flame Retardant Fabrics: Starting from Washability. 2024. Available online: https://www.cjti.com/news/classification-of-flame-retardant-fabrics-starting-from-washability (accessed on 23 November 2025).

- Ghosh, J.; Rupanty, N.S.; Noor, T.; Asif, T.R.; Islam, T.; Reukov, V. Functional coatings for textiles: Advancements in flame resistance, antimicrobial defense, and self-cleaning performance. RSC Adv. 2025, 15, 10984–11022. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Liu, L.; Wang, Y.; Li, H.; Jiang, Q.; Shi, Y.; Yang, G. Multifunctional coating with hydrophobicity, antibacterial and flame-retardant properties on cotton fabrics by layer-by-layer self-assembly curing of phytic acid and a tyrosine-derived hyperbranched benzoxazine. Int. J. Biol. Macromol. 2024, 279, 135151. [Google Scholar] [CrossRef] [PubMed]

- Ngo, H.-T.; Vu Thi Hong, K.; Nguyen, T.-B. Surface Modification by the DBD Plasma to Improve the Flame-Retardant Treatment for Dyed Polyester Fabric. Polymers 2021, 13, 3011. [Google Scholar] [CrossRef]

- Yang, G.; Peng, K.; Zhang, H.; Song, X.; Zhou, Y.; Shao, H. Structure and properties of flame-retardant Lyocell fibers prepared by blending method. Polym. Eng. Sci. 2022, 62, 3476–3486. [Google Scholar] [CrossRef]

- Ömeroğullari, Z.; Kut, D. Application of different types of flame retardant agents on cotton fabrics. In Proceedings of the 5th International Technical Textiles Congress, Izmir, Turkey, 7–9 November 2012; Available online: https://tekstil.deu.edu.tr/wp-content/uploads/2025/06/5ittcpdf.pdf (accessed on 18 November 2025).

- Zhou, S.; Huangfu, W.; You, F.; Li, D.; Fan, D. Flame Retardancy and Mechanism of Cotton Fabric Finished by Phosphorus Containing SiO2 Hybrid Sol. In Proceedings of the 2019 9th International Conference on Fire Science and Fire Protection Engineering (ICFSFPE), Chengdu, China, 18–20 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Patankar, K.C.; Maiti, S.; Singh, G.P.; Shahid, M.; More, S.; Adivarekar, R.V. Chemically modified wool waste keratin for flame retardant cotton finishing. Clean. Eng. Technol. 2021, 5, 100319. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, L.; Zuo, C.; Tan, W.; Ren, Y.; Liu, X. Eco-friendly, efficient and durable flame retardant lyocell fabrics prepared via a feasible grafting of taurine. Ind. Crops Prod. 2024, 218, 118925. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Q.; Peng, B.; Ren, Y.; Cheng, B.; Ding, C.; Su, X.; He, J.; Lin, S. Flame retardant cellulosic fabrics via layer-by-layer self-assembly double coating with egg white protein and phytic acid. J. Clean. Prod. 2020, 243, 118641. [Google Scholar] [CrossRef]

- Nguyen Thi, H.; Vu Thi Hong, K.; Ngo Ha, T.; Phan, D.-N. Application of Plasma Activation in Flame-Retardant Treatment for Cotton Fabric. Polymers 2020, 12, 1575. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Kandola, B.K.; Davies, P.J.; Zhang, S.; Padbury, S.A. Developments in flame retardant textiles—A review. Polym. Degrad. Stab. 2005, 88, 3–12. [Google Scholar] [CrossRef]

- Vodyashkin, A.A.; Makeev, M.O. Advanced post-processing techniques for hydrophobic and flame-retardant textiles. Polymers 2025, 17, 2744. [Google Scholar] [CrossRef]

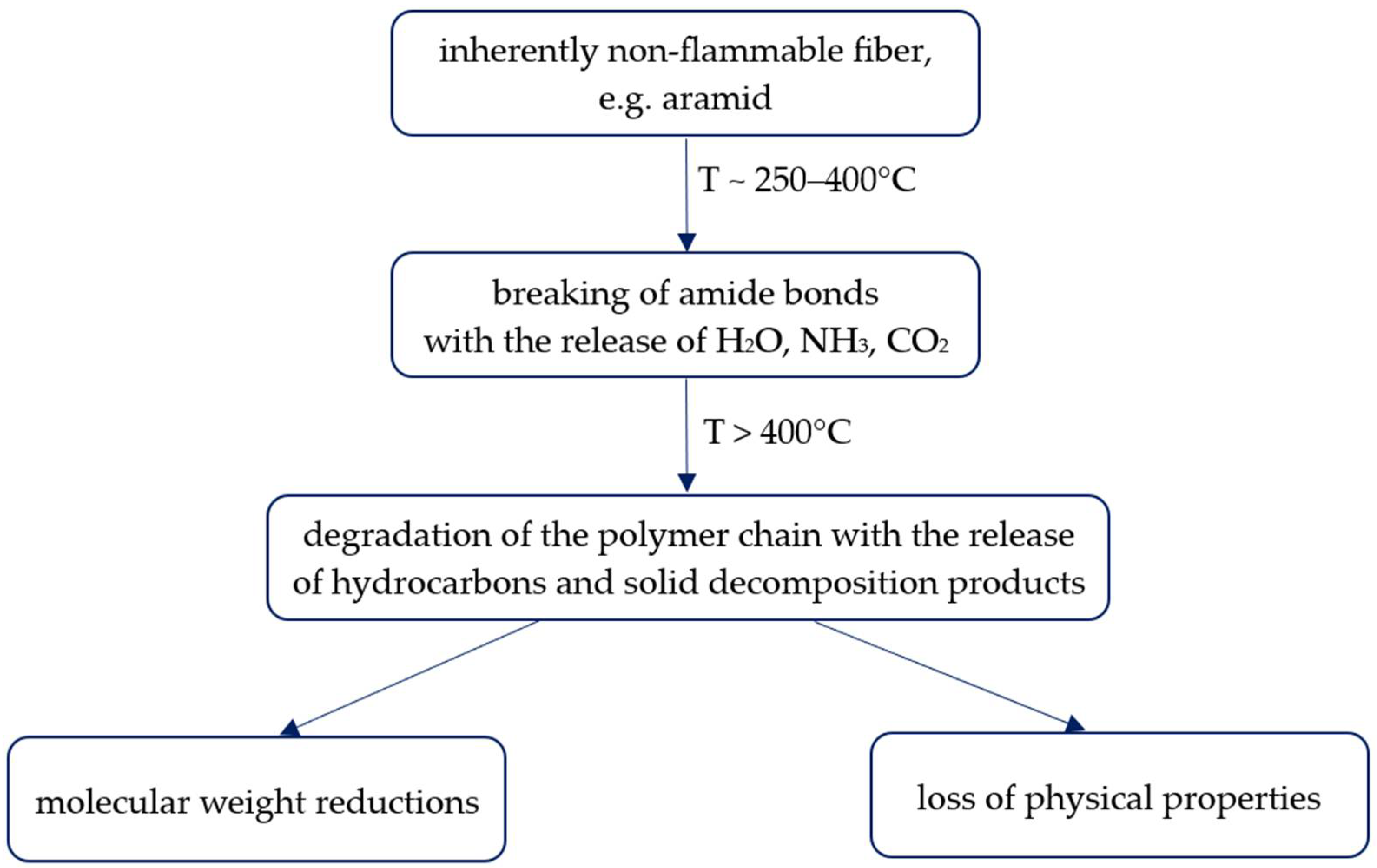

- Bourbigot, S.; Flambard, X. Heat Resistance and Flammability of High Performance Fibres: A Review. Fire Mater. 2002, 26, 155–168. [Google Scholar] [CrossRef]

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Arregui, F.J. Nanomaterials for Functional Textiles and Fibers. Nanoscale Res. Lett. 2015, 10, 501. [Google Scholar] [CrossRef]

- Trovato, V.; Sfameni, S.; Ben Debabis, R.; Rando, G.; Rosace, G.; Malucelli, G.; Plutino, M.R. How to address flame retardant technology on cotton fabrics by using functional inorganic sol–gel precursors and nanofillers: Flammability insights, research advances, and sustainability challenges. Inorganics 2023, 11, 306. [Google Scholar] [CrossRef]

- Li, M.; Chen, X.; Li, X.; Dong, J.; Zhao, X.; Zhang, Q. Controllable Strong and Ultralight Aramid Nanofiber-Based Aerogel Fibers for Thermal Insulation Applications. Adv. Fiber Mater. 2022, 4, 1267–1277. [Google Scholar] [CrossRef]

- Aspen Aerogels, Inc. Heat Resistant Aerogel Materials. Publication number: 20250289941, 18 September 2025. Available online: https://patents.justia.com/patent/20250289941 (accessed on 18 November 2025).

- He, A.; Xing, T.; Liang, Z.; Luo, Y.; Zhang, Y.; Wang, M.; Huang, Z.; Bai, J.; Wu, L.; Shi, Z.; et al. Advanced Aramid Fibrous Materials: Fundamentals, Advances, and Beyond. Adv. Fiber Mater. 2024, 6, 3–35. [Google Scholar] [CrossRef]

- Kerekes, Z.; Kopecsko, K.; Lubloy, E.; Szep, J. The effect of macrostructure and stability on the flammability of non-woven fabrics. J. Ind. Text. 2022, 51, 8472S–8489S. [Google Scholar] [CrossRef]

- Rathour, R.; Das, A.; Alagirusamy, R. Performance analysis of fire protective clothing: A review. Int. J. Occup. Saf. Ergon. 2024, 30, 1124–1142. [Google Scholar] [CrossRef]

- Horn, G.P.; Kesler, R.M.; Newman, H.; Stewart, J.W.; Smith, D.L.; Kerber, S.; Andrews, J.; Fent, K.W.; Smith, D.L. Impact of Repeated Exposure and Cleaning on Protective Properties of Structural Firefighting Turnout Gear. Fire Technol. 2021, 57, 791–813. [Google Scholar] [CrossRef] [PubMed]

- Girase, A.; Thompson, D.B.; Ormond, R.B. Impact of conventional and advanced cleaning techniques on the durability of firefighter turnout ensembles. Front. Mater. 2023, 10, 1138652. [Google Scholar] [CrossRef]

- AATCC TM61-2013e(2020)e2; Test Method for Colorfastness to Laundering: Accelerated. The American Association of Textile Chemists and Colorists: Durham, NC, USA, 2020. Available online: https://members.aatcc.org/store/tm61/495/ (accessed on 18 November 2025).

- ISO 6630:2021; Textiles—Domestic Washing and Drying Procedures for Textile Testing, Fourth Edition. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/13047.html (accessed on 18 November 2025).

- ISO 15797:2017; Textiles—Industrial Washing and Finishing Procedures for Testing of Workwear, Edition 2. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/65152.html (accessed on 18 November 2025).

- ASTM D6413/D6413M-22; Standard Test Method for Flame Resistance of Textiles (Vertical Test). ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://store.astm.org/d6413_d6413m-22.html (accessed on 18 November 2025).

- ISO 9151:2016; Protective Clothing Against Heat and Flame—Determination of Heat Transmission on Exposure to Flame, Edition 2. International Organization for Standardization: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/55326.html (accessed on 18 November 2025).

- ISO 6942:2022; Protective Clothing—Protection Against Heat and Fire—Method of Test: Evaluation of Materials and Material Assemblies When Exposed to a Source of Radiant Heat, Edition 4. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/76609.html (accessed on 18 November 2025).

- ISO 13506-1:2024; Protective Clothing Against Heat and Flame Part 1: Test Method for Complete Garments—Measurement of Transferred Energy Using an Instrumented Manikin, Edition 2. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/75863.html (accessed on 18 November 2025).

- ISO 13937-2:2020; Textiles—Tear Properties of Fabrics Part 2: Determination of Tear Force of Trouser-Shaped Test Specimens (Single Tear Method), Edition 1. International Organization for Standardization: Geneva, Switzerland, 2000. Available online: https://www.iso.org/standard/23370.html (accessed on 18 November 2025).

- ISO 13934-1:2013; Textiles—Tensile Properties of Fabrics Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method, Edition 2. International Organization for Standardization: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/60676.html (accessed on 18 November 2025).

- ISO 12947-1:1998; Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method Part Martindale Abrasion Testing Apparatus. International Organization for Standardization: Geneva, Switzerland, 1998. Available online: https://www.iso.org/standard/1931.html (accessed on 18 November 2025).

- ISO 12947-2:2016; Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method Part Determination of Specimen Breakdown. International Organization for Standardization: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/61058.html (accessed on 18 November 2025).

- ISO 12947-3:1998; Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method Part Determination of Mass Loss. International Organization for Standardization: Geneva, Switzerland, 1998. Available online: https://www.iso.org/standard/23620.html (accessed on 11 November 2025).

- ISO 12947-4:1998; Textiles—Determination of the Abrasion Resistance of Fabrics by the Martindale Method Part Assessment of Appearance Change. International Organization for Standardization: Geneva, Switzerland, 1998. Available online: https://www.iso.org/standard/23621.html (accessed on 11 November 2025).

- ASTM D3884-09(2017); Standard Guide for Abrasion Resistance of Textile Fabrics (Rotary Platform, Double-Head Method). ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://store.astm.org/d3884-09r17.html (accessed on 18 November 2025).

- Botta, V.; Magnusson, E. Deep Dive: Standards to Measure Textile Durability; ECOS—Environmental Coalition on Standards: Brussels, Belgium, 2022; Available online: https://ecostandard.org/wp-content/uploads/2023/01/ECOS-Report_Standards-to-measure-textile-durability_December-2023.pdf (accessed on 15 November 2025).

- ASTM D5587-15(2019); Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure. ASTM International: West Conshohocken, PA, USA, 2019. Available online: https://store.astm.org/d5587-15r19.html (accessed on 18 November 2025).

- ISO 13935-2:2014; Textiles—Seam Tensile Properties of Fabrics and Made-Up Textile Articles Part 2: Determination of Maximum Force to Seam Rupture Using the Grab Method. International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/60679.html (accessed on 11 November 2025).

- ISO 12945-1:2020; Textiles—Determination of Fabric Propensity to Surface Pilling, Fuzzing or Matting Part 1: Pilling Box Method. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75374.html (accessed on 11 November 2025).

- ISO 12945-2:2020; Textiles—Determination of Fabric Propensity to Surface Pilling, Fuzzing or Matting Part 2: Modified Martindale Method. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75375.html (accessed on 11 November 2025).

- ISO 12945-3:2020; Textiles—Determination of Fabric Propensity to Surface Pilling, Fuzzing or Matting Part 3: Random Tumble Pilling Method. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75376.html (accessed on 18 November 2025).

- ISO 12945-4:2020; Textiles—Determination of Fabric Propensity to Surface Pilling, Fuzzing or Matting Part 4: Assessment of pilling, Fuzzing and Matting by Visual Analysis. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75377.html (accessed on 18 November 2025).

- EN 16689:2017; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Technical Rescue. The European Committee for Standardization: Brussels, Belgium, 2017.

- ISO 12127-1:2015; Clothing for Protection Against Heat and Flame—Determination of Contact Heat Transmission Through Protective Clothing or Constituent Materials Part 1: Contact Heat Produced by Heating Cylinder. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/contents/data/standard/05/74/57456.html (accessed on 18 November 2025).

- NFPA 1971:2018; Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting. National Fire Protection Association: Quincy, MA, USA, 2018. Available online: https://www.nfpa.org/codes-and-standards/nfpa-1971-standard-development/1971 (accessed on 18 November 2025).

- ISO 4892-1:2024; Plastics—Methods of Exposure to Laboratory Light Sources Part 1: General Guidance and Requirements. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/83801.html (accessed on 18 November 2025).

- ISO 4892-2:2013; Plastics—Methods of Exposure to Laboratory Light Sources Part 2: Xenon-Arc Lamps. International Organization for Standardization: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/55481.html (accessed on 18 November 2025).

- ISO 4892-3:2024; Plastics—Methods of Exposure to Laboratory Light Sources Part 3: Fluorescent UV Lamps. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/83802.html (accessed on 18 November 2025).

- ISO 1431-1:2024; Rubber, Vulcanized or Thermoplastic—Resistance to Ozone Cracking Part 1: Static and Dynamic Strain Testing. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/86601.html (accessed on 18 November 2025).

- ISO 1431-3:2017; Rubber, Vulcanized or Thermoplastic—Resistance to Ozone Cracking Part 3: Reference and Alternative Methods for Determining the Ozone Concentration in Laboratory Test Chambers. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/70223.html (accessed on 18 November 2025).

- ISO 105-B02:2014; Textiles—Tests for Colour Fastness Part B02: Colour Fastness to Artificial Light: Xenon Arc Fading Lamp Test. International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/65209.html (accessed on 15 November 2025).

- ISO 11092:2014; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance Under Steady-State Conditions (Sweating Guarded-Hotplate Test). International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/65962.html (accessed on 15 November 2025).

- ISO 9073-7:2024; Nonwovens—Test Methods Part 7: Determination of Bending Length. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/88393.html (accessed on 15 November 2025).

- Kaurin, T.; Pušić, T.; Dekanić, T.; Flinćec Grgac, S. Impact of Washing Parameters on Thermal Characteristics and Appearance of Proban®—Flame Retardant Material. Materials 2022, 15, 5373. [Google Scholar] [CrossRef]

- Hoque, M.S.; Dolez, P.I. Aging of high-performance fibers used in firefighters’ protective clothing: State of the knowledge and path forward. J. Appl. Polym. Sci. 2023, 140, e54255. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Gniazdowska, J.; Stojek, P.; Bąk, Ł. Sorption Processes of Selected PAHs on Selected Fire-Resistant Materials Used in Special Firefighter Clothing. Materials 2024, 17, 1741. [Google Scholar] [CrossRef] [PubMed]

- Krzemińska, S.M.; Szewczyńska, M.; Miśkiewicz, P.; Sygocki, W. Effects of Washing Conditions on PAH Removal Effectiveness in Firefighter Protective Clothing Materials. Materials 2025, 18, 4073. [Google Scholar] [CrossRef] [PubMed]

- Won, A.Y.; Yun, C. The Effects of Laundering on the Protective Performance of Firefighter Clothing. Fibers Polym. 2021, 22, 3232–3239. [Google Scholar] [CrossRef]

- Nayak, R.; Kanesalingam, S.; Houshyar, S.; Vijayan, A.; Wang, L.; Padhye, R. Effect of Repeated Laundering and Dry-cleaning on the Thermo-physiological Comfort Properties of Aramid Fabrics. Fibers Polym. 2016, 17, 954–962. [Google Scholar] [CrossRef]

- Nayak, R.; Houshyar, S.; Padhye, R. Recent trends and future scope in the protection and comfort of fire-fighters’ personal protective clothing. Fire Sci. Rev. 2014, 3, 4. Available online: http://www.firesciencereviews.com/content/3/1/4 (accessed on 15 November 2025). [CrossRef]

- Malucelli, G. Surface-Engineered Fire Protective Coatings for Fabrics through Sol-Gel and Layer-by-Layer Methods: An Overview. Coatings 2016, 6, 33. [Google Scholar] [CrossRef]

- Norouzi, M.; Zare, Y.; Kiany, P. Nanoparticles as Effective Flame Retardants for Natural and Synthetic Textile Polymers: Application, Mechanism, and Optimization. Polym. Rev. 2015, 55, 531–560. [Google Scholar] [CrossRef]

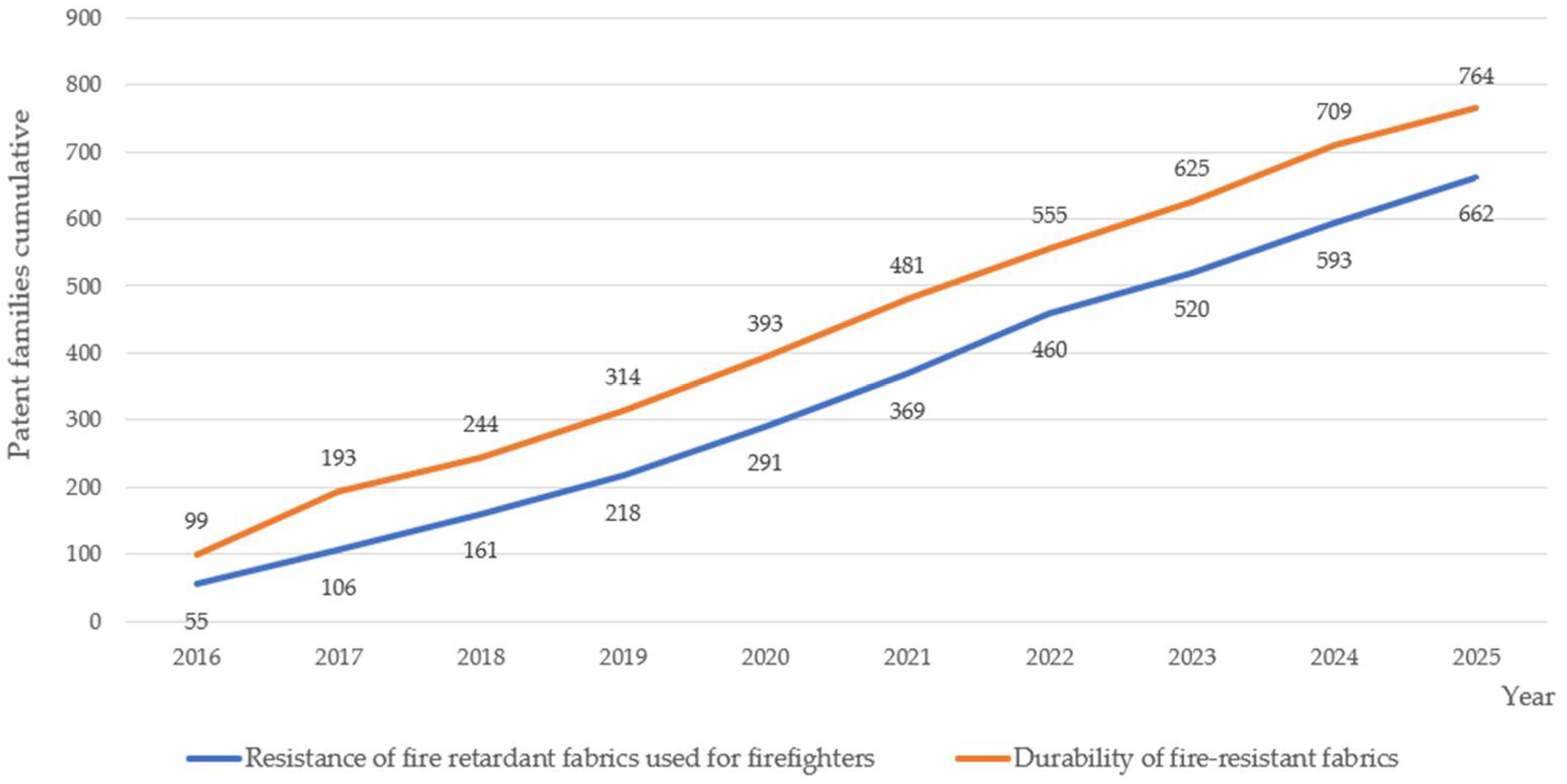

| Year | Durability of Fire-Resistant Fabrics | Resistance of Fire Retardant Fabrics Used by Firefighters | Citations |

|---|---|---|---|

| 2025 | 1 | 1 | 27 |

| 2024 | 2 | 2 | 56 |

| 2023 | 0 | 1 | 53 |

| 2022 | 1 | 2 | 60 |

| 2021 | 0 | 1 | 87 |

| 2022 | 0 | 0 | 51 |

| 2019 | 3 | 0 | 38 |

| 2018 | 1 | 0 | 10 |

| 2017 | 2 | 0 | 2 |

| 2016 | 3 | 0 | 0 |

| Modification Technique | Characteristics | Ref. |

|---|---|---|

| Fiber modification | The flame retardant is added during the mixing and/or spinning processes; e.g., melamine polyphosphate (MPP) and modified melamine cyanurate (MCA) were added to the cellulose solution to produce flame-retardant Lyocell fibres, Lyocell-MPP and Lyocell-MCA, respectively, by dry and wet spinning methods. | [29] |

| Yarn modification | Modification takes place during yarn formation, e.g., by mixing flame-retardant fibre with ordinary fibre or by applying a flame-retardant agent to the surface of the yarn; e.g., between 100% cotton fabrics with a warp and weft yarn thickness of 28.4 Ne and flame retardants with a density of 600 g/L; during testing the absorption coefficient increased by 90%. | [30] |

| Dip baking | A flame retardant is dissolved or dispersed in a solvent—the fabric is passed through the solvent, and the flame retardant is rapidly absorbed into the fabric via rollers, and is then fixed on the fibre surface by high-temperature calcination; e.g., ethanol (C2H5OH) as solvent and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO, flame retardant) resulted in a cotton fabric with a SiO2-KH570-DOPO hybrid solution. | [31] |

| Coating method/Spray method | The flame retardant is applied to one side of the fabric and then fixed by drying; e.g., modified keratin was applied to cotton fabric and then dried at 40 °C for 30 min, 80 °C for 1 h, and 110 °C for 3 min. | [32] |

| Chemical grafting | This involves bonding the flame retardant to the molecular chain of the fabric via a covalent bond; e.g., biomass-derived taurine was incorporated into Lyocell fabrics. | [33] |

| Layer-by-layer self-assembly | Flame retardants are deposited layer-by-layer on the substrate surface after alternating impregnation or spraying of the textile; e.g., cotton fabrics were treated successively with protein and phytic acid (PA). | [34] |

| Plasma method | The fabric surface is activated for more effective bonding with the flame retardant; e.g., cotton fabrics were exposed to atmospheric pressure dielectric discharge (APDBD) plasma and then treated with flame retardants (FR) using the pad–dry–cure method. | [35] |

| Parameter | Verification Method | Standards/Tests |

|---|---|---|

| Mechanical resistance of fabrics and seams | Abrasion resistance: tests to assess how well the material withstands prolonged contact with rough surfaces | [57,58,59,60,61] |

| Tensile strength: determines the maximum force a fabric can withstand before breaking | [56,62] | |

| Tear strength: tear tests assess how easily an existing cut will enlarge under a load | [55,63] | |

| Seam strength: seams must hold the layers together under a load and not come apart | [8,64] | |

| Resistance to pilling: assesses the tendency of the fabric surface to form balls (pills) when rubbed | [65,66,67,68] | |

| Resistance to puncture: although not always required by fire safety standards, it is sometimes tested as an additional factor—e.g., resistance to puncture by a sharp object (test using a spearhead and force measurement) | [69] | |

| Thermal resistance and heat protection | Resistance to flame (flammability test): the most basic test is a ‘small flame test’, which considers burning time after removal of the flame (afterflame time), glowing time (afterglow), length of charring/hole, occurrence of melting and dripping | [6,51] |

| Resistance to thermal radiation (method B, for fabrics) | [53] | |

| Resistance to convective heat | [52] | |

| Resistance to contact heat | [70] | |

| TPP (Thermal Protective Performance) RPP (Radiant Protective Performance) HTI, RHTI, time to second-degree burns Thermal resistance of materials (stability) | [71] | |

| Resistance to environmental and chemical factors | Resistance to UV rays and sunlight Resistance to rain, frost, and weather conditions | [71,72,73,74] |

| Resistance to chemicals typically found in firefighting operations Accelerated climatic ageing | [71] | |

| Impact of fire pollutants Resistance to washing and soaking | [8,72,73,74,75,76,77] | |

| Long-lasting comfort of use | Vapour permeability/water vapour resistance: measured, for example, as Ret (Resistance evaporative thermal) Thermal insulation (thermal resistance) | [78] |

| Stiffness, elasticity Weight and water absorption Ergonomics versus wear | [79] |

| Method | Advantages | Disadvantages | Impact on the Durability of Flame Resistance |

|---|---|---|---|

| Water cleaning | Widespread availability, low costs | Fiber degradation, leaching of flame retardants | Moderate/highly negative |

| Dry cleaning | Gentle on fibres, absence of swelling | Risk of damage with improper solvents | Low |

| Low-water technologies | Controlled pH, gentle process | Higher equipment costs | Low/moderate |

| Layer-by-layer (LbL) coatings | Very high wash durability | High cost | Very low |

| Nanotechnology | High stability of flame retardancy | Research phase | Very low |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Rabajczyk, A.; Zielecka, M.; Chmiel, M. Modern Fire-Resistant Fabrics—Requirements for Durability of Materials After Washing After a Fire. Materials 2026, 19, 44. https://doi.org/10.3390/ma19010044

Rabajczyk A, Zielecka M, Chmiel M. Modern Fire-Resistant Fabrics—Requirements for Durability of Materials After Washing After a Fire. Materials. 2026; 19(1):44. https://doi.org/10.3390/ma19010044

Chicago/Turabian StyleRabajczyk, Anna, Maria Zielecka, and Michał Chmiel. 2026. "Modern Fire-Resistant Fabrics—Requirements for Durability of Materials After Washing After a Fire" Materials 19, no. 1: 44. https://doi.org/10.3390/ma19010044

APA StyleRabajczyk, A., Zielecka, M., & Chmiel, M. (2026). Modern Fire-Resistant Fabrics—Requirements for Durability of Materials After Washing After a Fire. Materials, 19(1), 44. https://doi.org/10.3390/ma19010044