Evaluation of Multiple Influences on the Unconfined Compressive Strength of Fibre-Reinforced Backfill Using a GWO–LGBM Model

Highlights

- A GWO–LGBM model is proposed for the high-accuracy prediction of UCS in fibre-reinforced CPB.

- Multi-factor analysis is applied to evaluate the coupled effects of mixture proportions, the tailings’ physical/chemical characteristics, and fibre properties on UCS.

- Cement content and curvature coefficient are identified as the primary factors affecting the UCS of CPB.

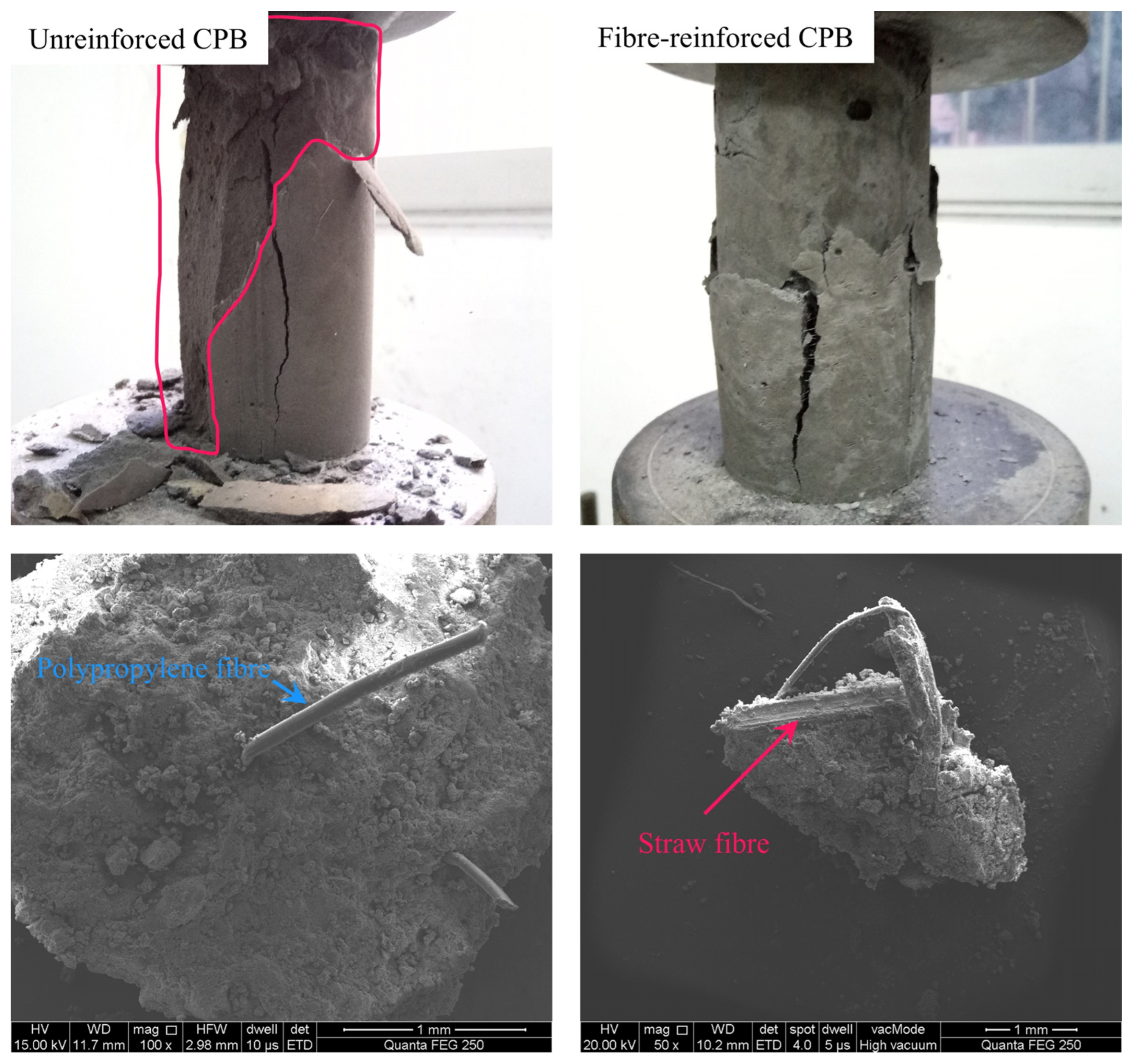

- Fibres are found to enhance structural bonding, whereas the chemical composition of tailings plays an inert role.

Abstract

1. Introduction

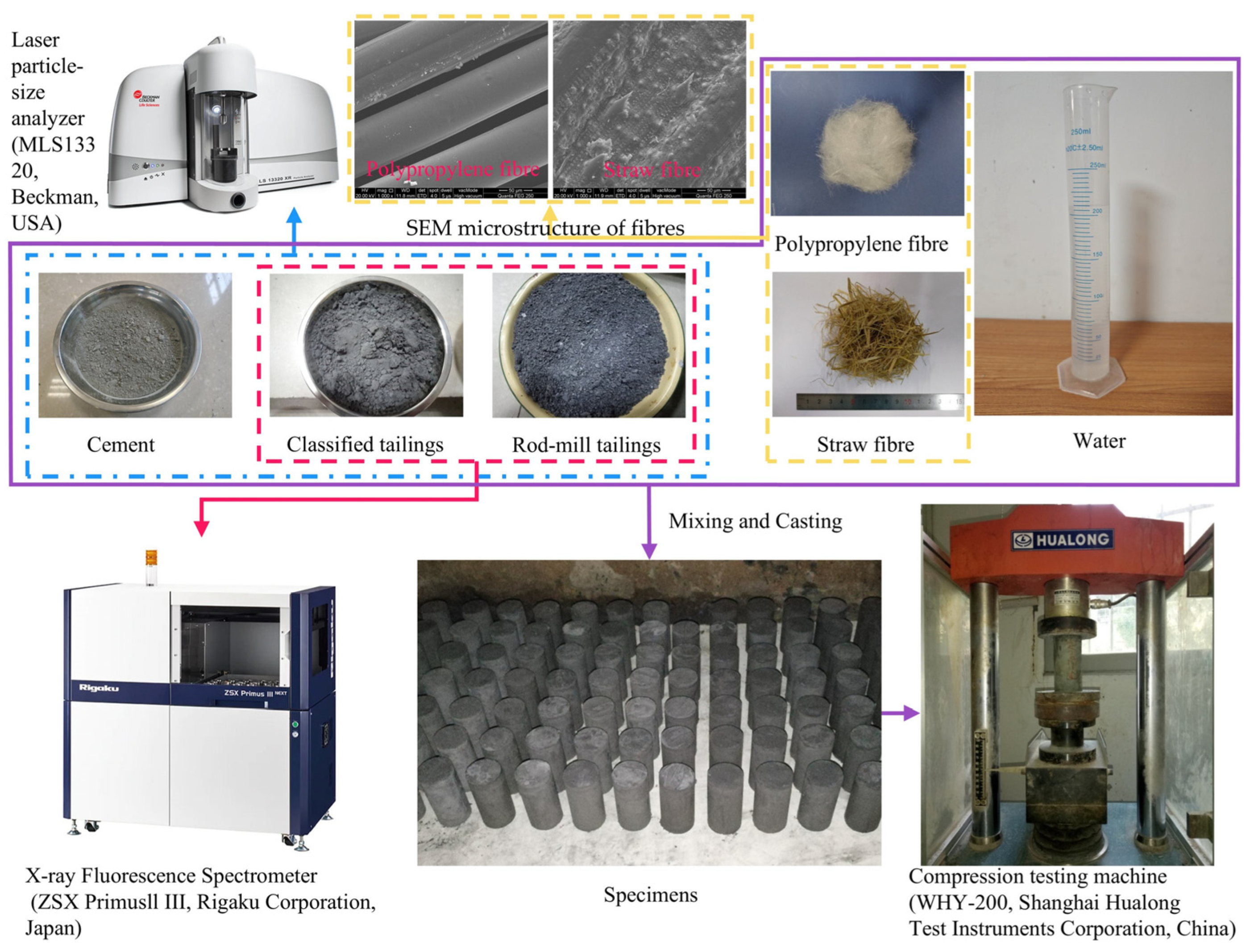

2. Materials and Mechanical Tests

2.1. Materials

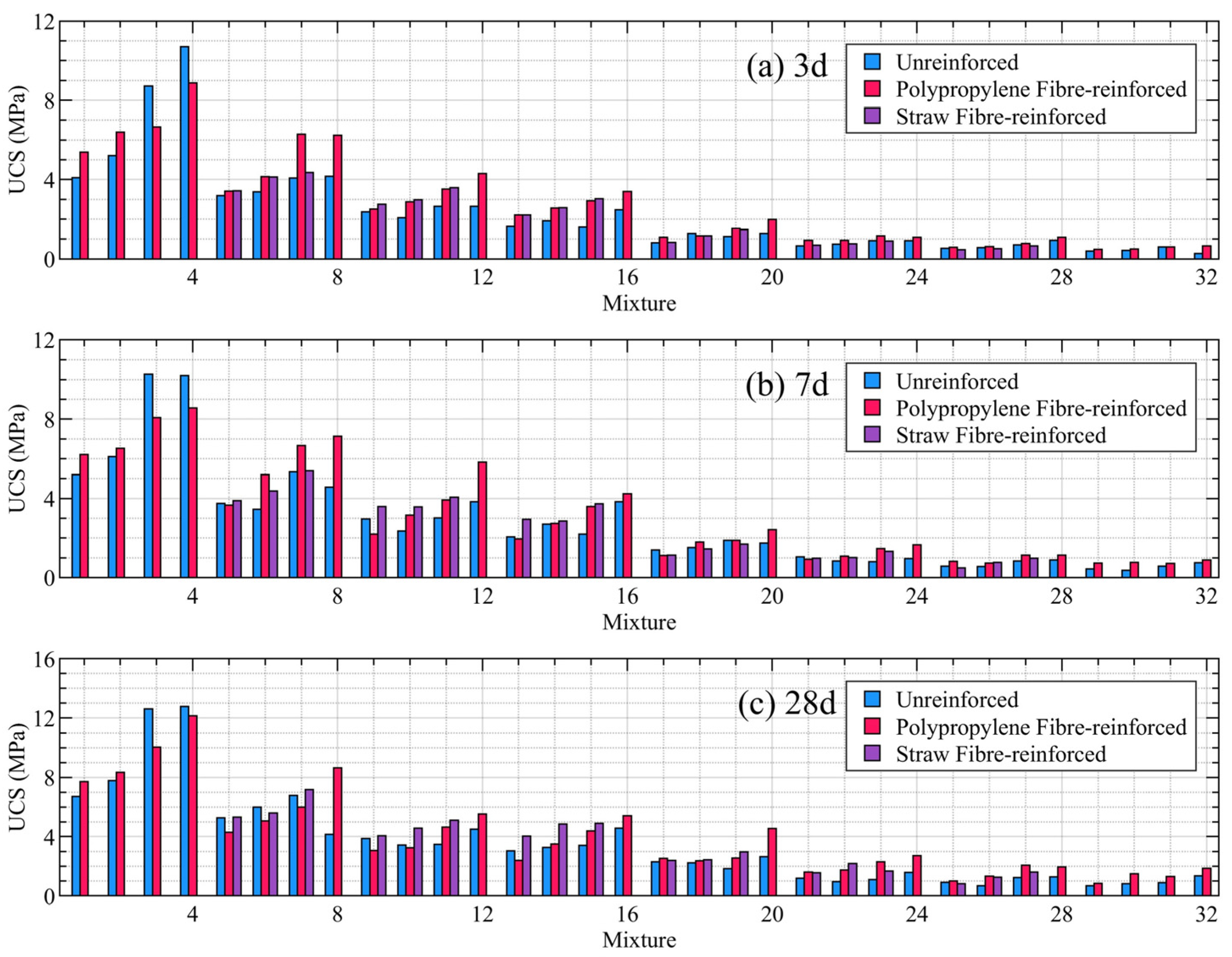

2.2. Mechanical Test

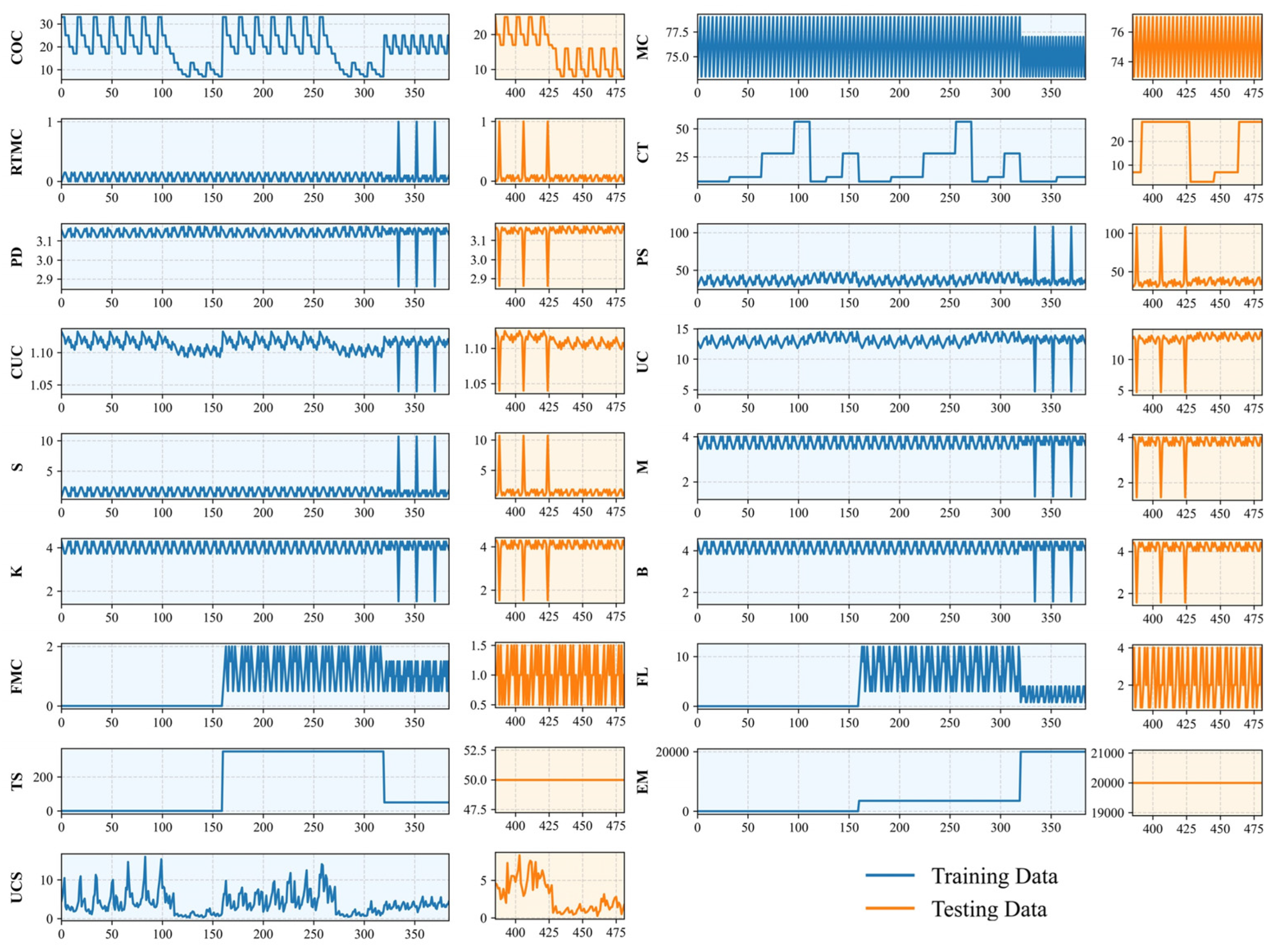

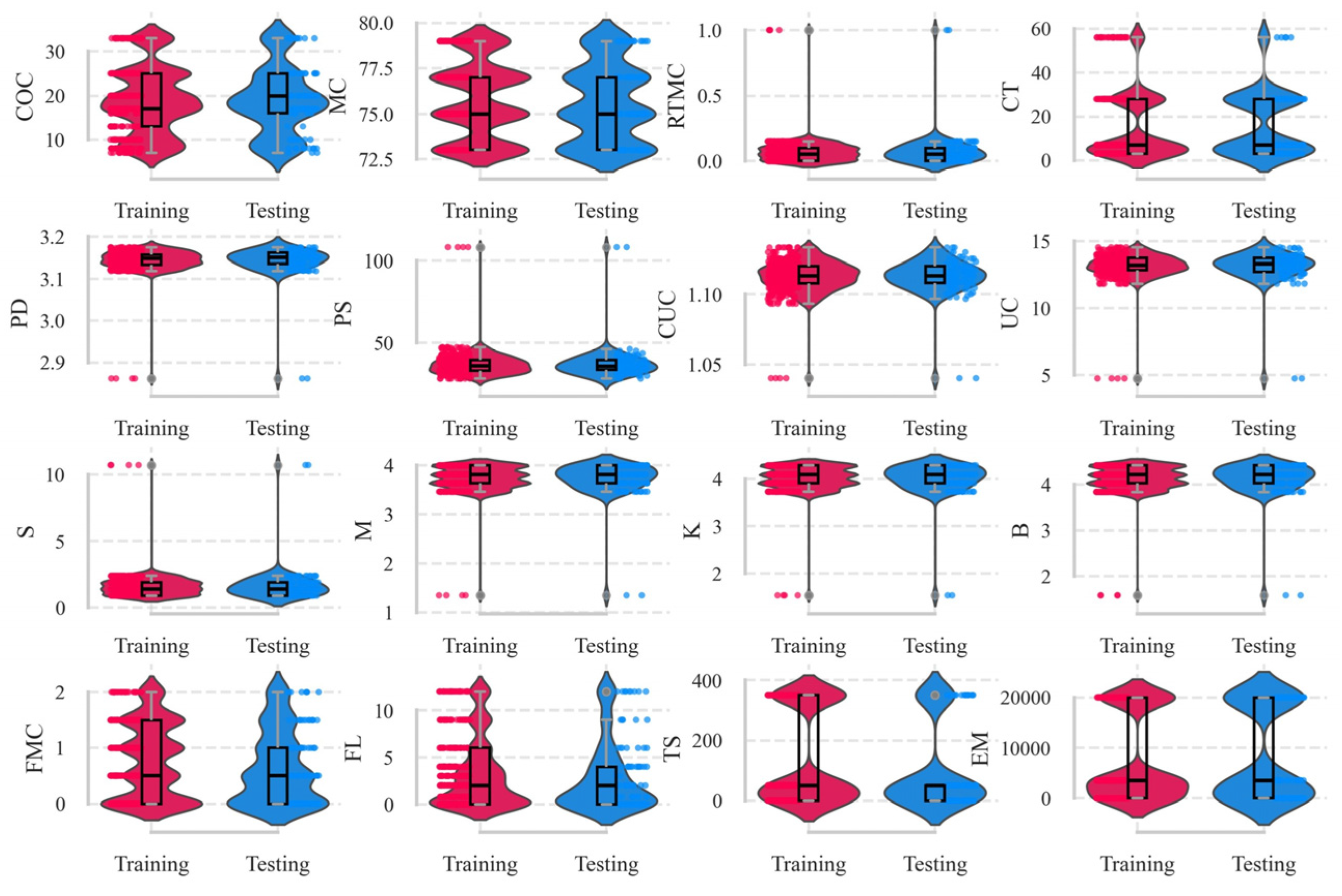

2.3. Data Description

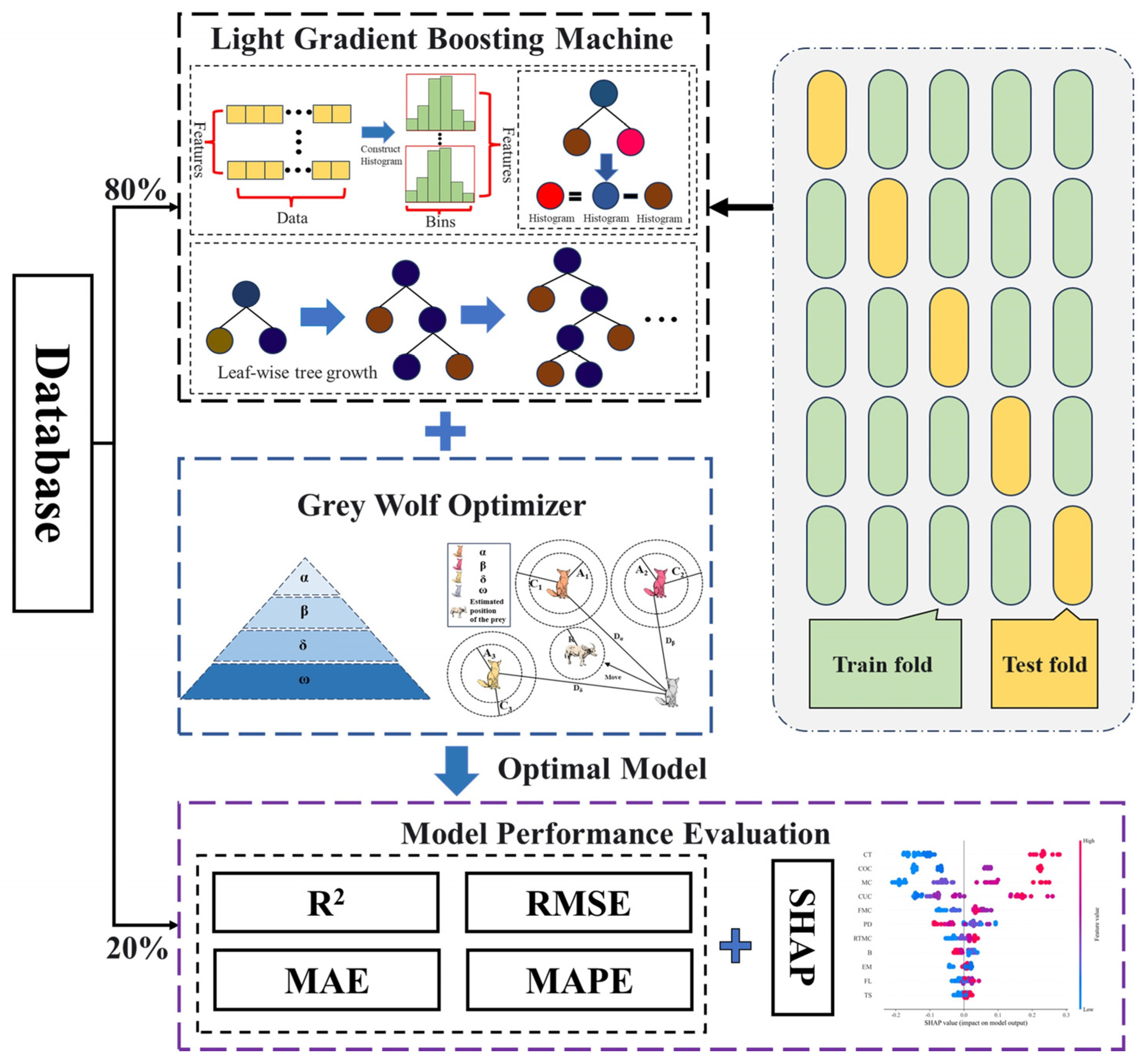

3. Methods

3.1. Machine-Learning Methods

3.1.1. Support Vector Regression (SVR)

3.1.2. Artificial Neural Networks (ANN)

3.1.3. Light Gradient Boosting Machine (LGBM)

3.1.4. Grey Wolf Optimizer (GWO)

3.1.5. GWO–LGBM

- Database Establishment. Construct a database for the UCS of fibre-reinforced CPB, containing 11 input variables and 1 output variable (UCS).

- Data Pre-processing. Normalise the input and output variables by linearly scaling them to the range [−1, 1] to mitigate scale differences and enhance model training stability.

- Data Division. The dataset is randomly partitioned, allocating 80% for training and the remaining 20% for subsequent testing. The former subset supports parameter fitting, whereas the latter provides independent evidence of predictive performance.

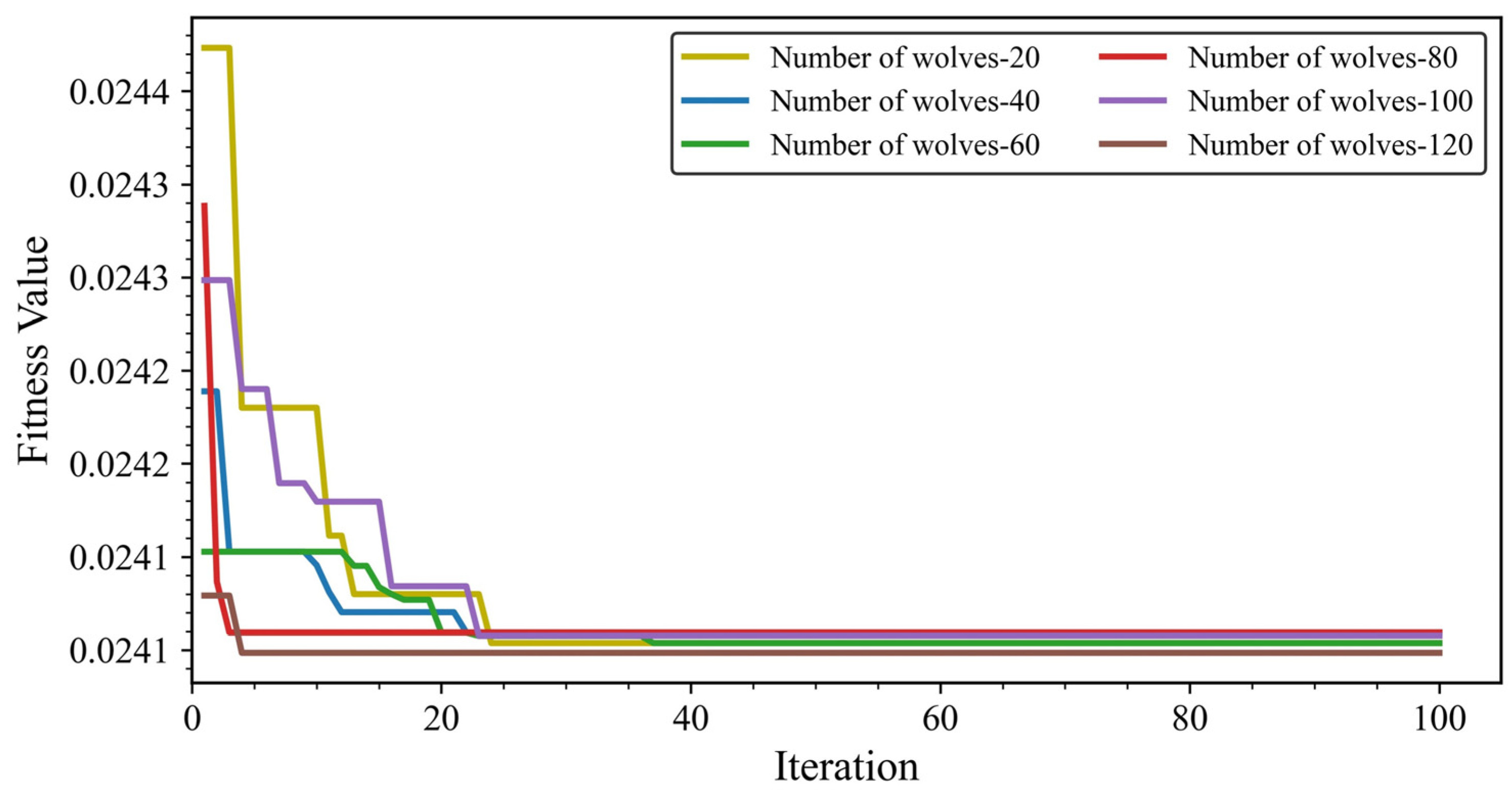

- Parameter Optimisation. Employ GWO to globally optimise the key hyperparameters of the LGBM model (such as learning rate, number of trees, and feature sampling rate) to obtain the optimal parameter combination.

- Model Training. Using the optimised parameter configuration, build the GWO–LGBM model with the training dataset to establish the mapping relationship between nonlinear features and UCS.

- Performance Evaluation. Validate the model using the testing dataset and assess prediction accuracy and generalisation capability through metrics such as the coefficient of determination (R2), root mean square error (RMSE), mean absolute error (MAE), and mean absolute percentage error (MAPE).

3.2. Performance Metrics

4. Result and Analysis

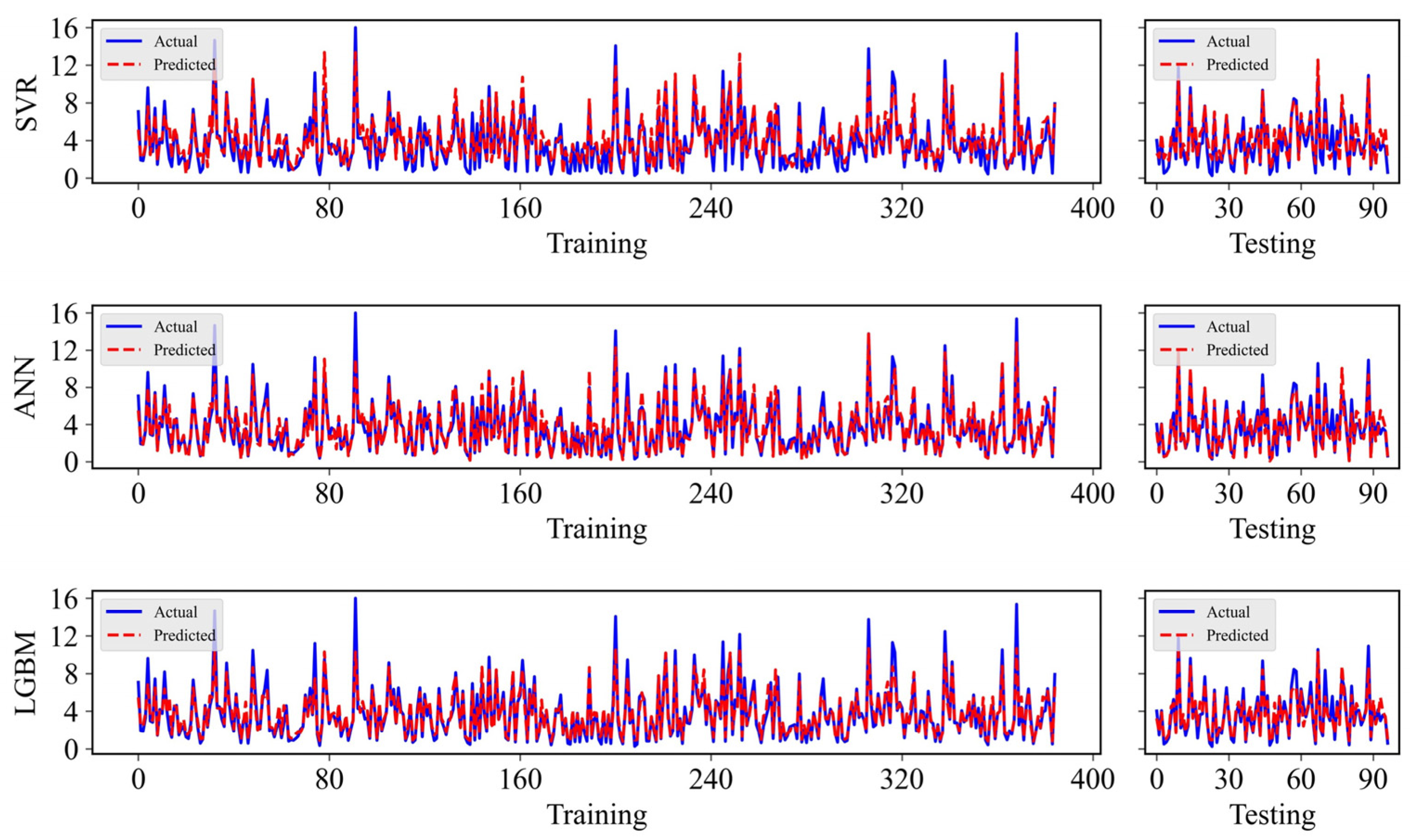

4.1. Result of SVR

4.2. Result of ANN

4.3. Result of LGBM

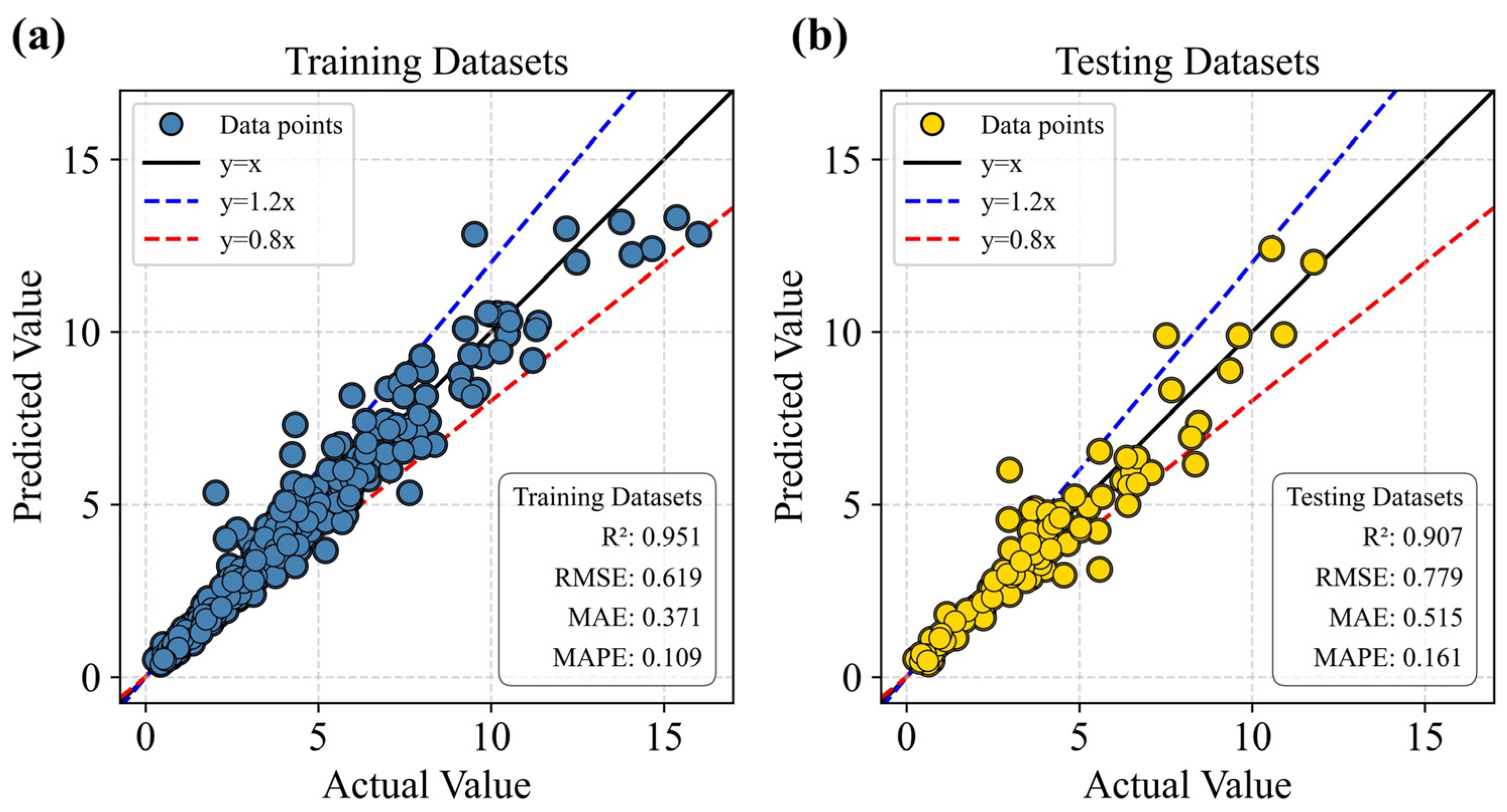

4.4. Result of GWO–LGBM

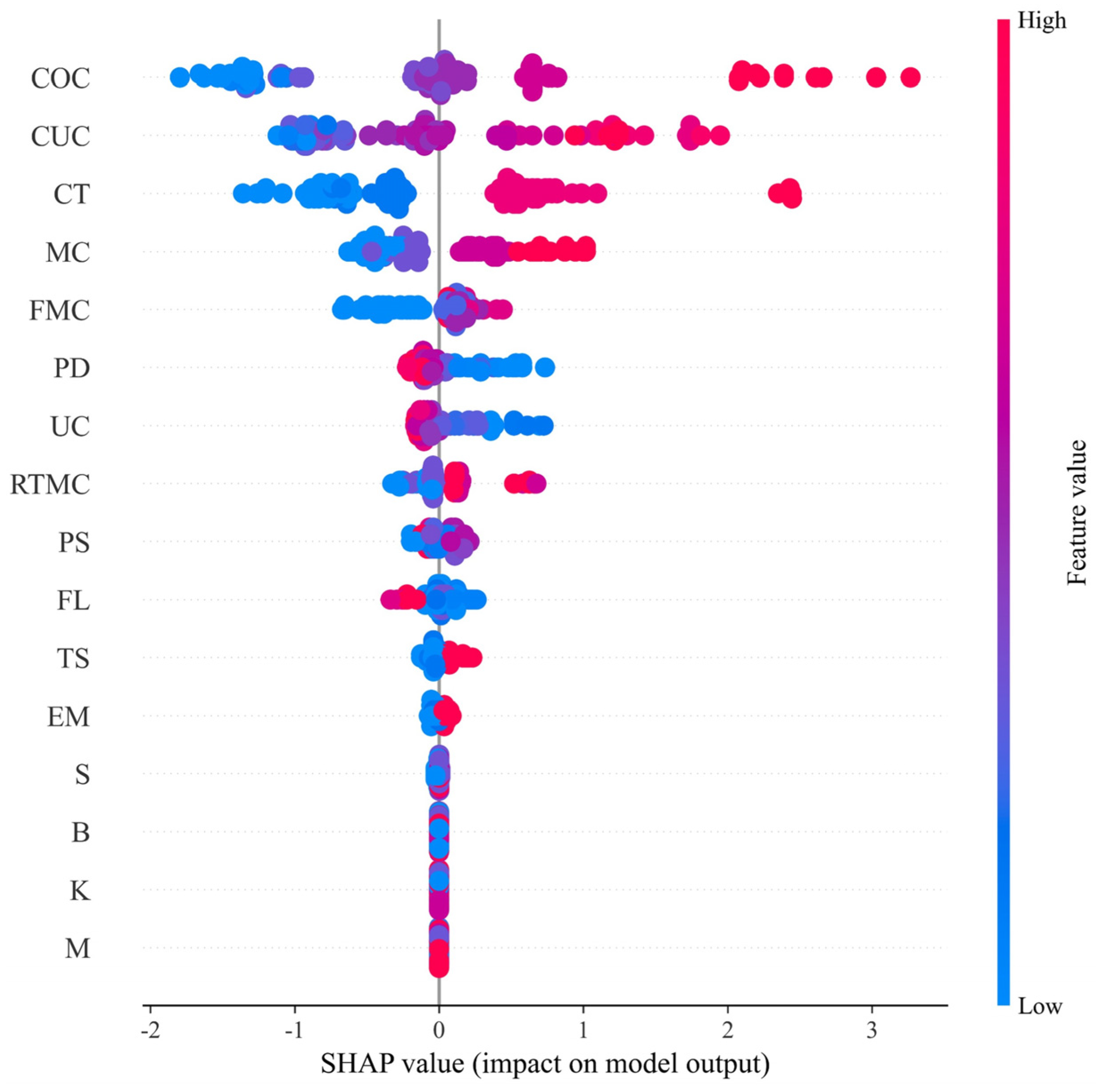

4.5. SHAP Feature Contribution Analysis

5. Discussion

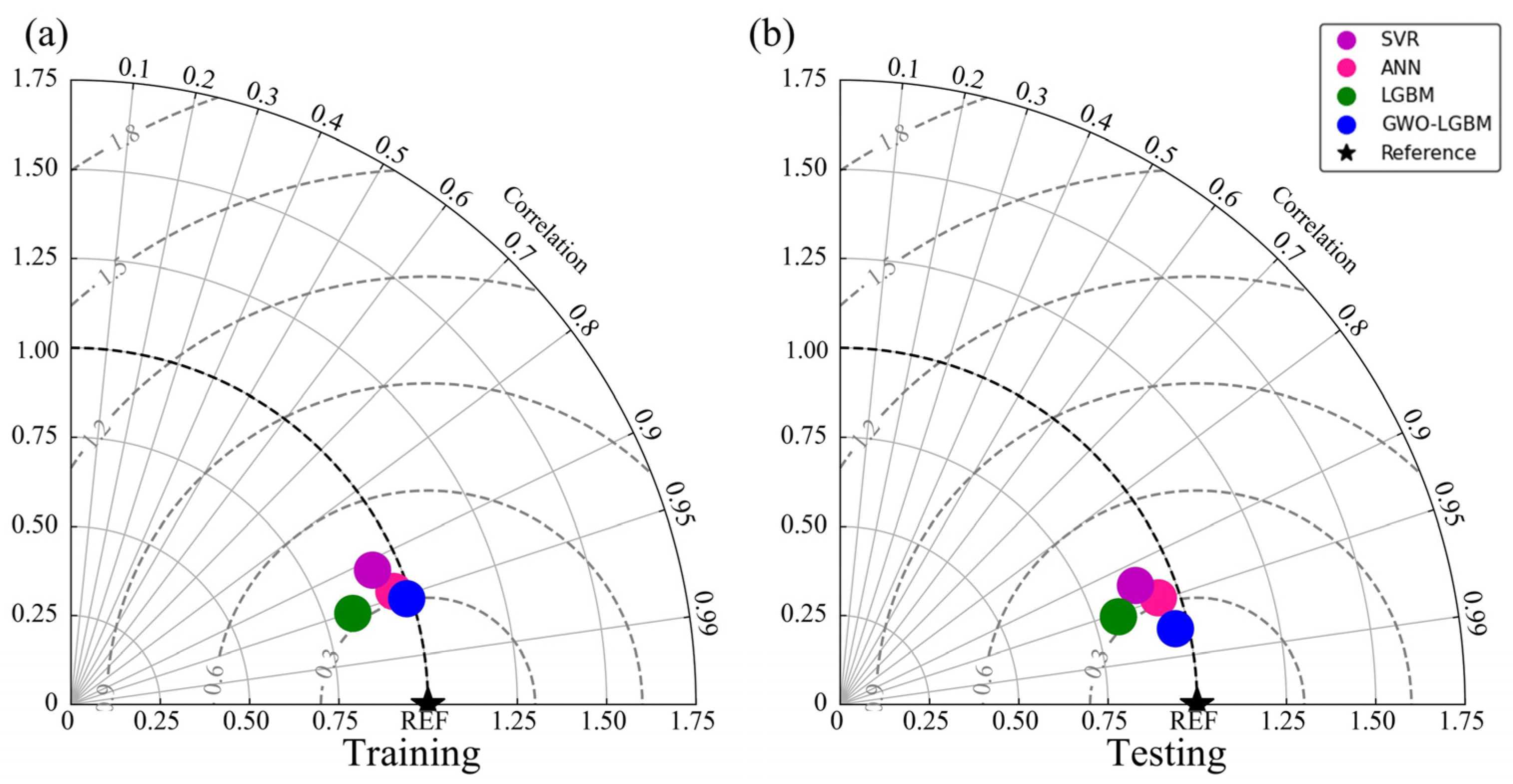

5.1. Performance Comparison

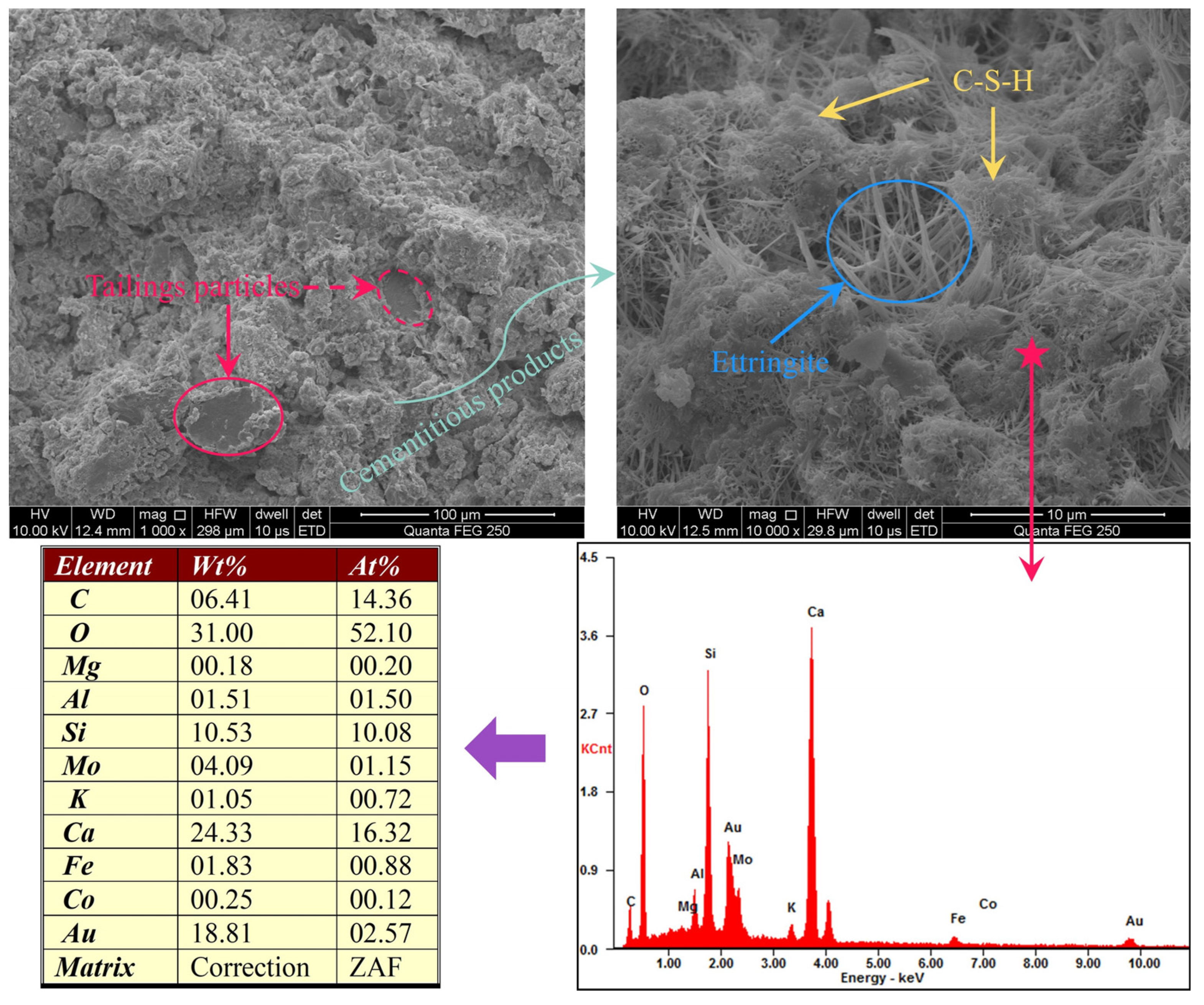

5.2. Macro and Micro Feature Verification

5.3. Research Significance and Limitations

6. Conclusions

- Adding both polypropylene and straw fibre can effectively improve the UCS of CPB. The addition of fibres effectively bridged the dispersed particles of the CPB, allowing the CPB to maintain relative integrity after failure and improving its residual strength.

- The GWO algorithm effectively optimised the key hyperparameters of the LGBM model, enhancing its stability and predictive accuracy. Compared with the SVR, ANN, and LGBM models, the GWO–LGBM model achieved a higher prediction accuracy for UCS (training set: R2 = 0.907, RMSE = 0.78, MAE = 0.515, MAPE = 0.157; testing set: R2 = 0.949, RMSE = 0.627, MAE = 0.38, MAPE = 0.115).

- Cement content, curvature coefficient, and curing time are the key factors controlling CPB strength, and all showed positive correlations with UCS. These variables jointly shaped the overall skeleton of the CPB.

- The alkalinity coefficient of the tailings exhibited a weak nonlinear relationship with UCS and the chemical composition of tailings acted largely as an inert contributor to the UCS of CPB, mainly providing aggregate support.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, A.; Wang, Y.; Wang, H.; Yin, S.; Miao, X. Coupled effects of cement type and water quality on the properties of cemented paste backfill. Int. J. Miner. Process. 2015, 143, 65–71. [Google Scholar] [CrossRef]

- Chen, Q.S.; Zhang, Q.L.; Fourie, A.; Chen, X.; Qi, C.C. Experimental investigation on the strength characteristics of cement paste backfill in a similar stope model and its mechanism. Constr. Build. Mater. 2017, 154, 34–43. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Strength evolution and deformation behaviour of cemented paste backfill at early ages: Effect of curing stress, filling strategy and drainage. Int. J. Min. Sci. Technol. 2016, 26, 809–817. [Google Scholar] [CrossRef]

- Abdulkadir, S.B.; Chen, Q.; Yilmaz, E.; Wang, D. Comparative and Meta-Analysis Evaluation of Non-Destructive Testing Methods for Strength Assessment of Cemented Paste Backfill: Implications for Sustainable Pavement and Concrete Materials. Materials 2025, 18, 2888. [Google Scholar] [CrossRef]

- Safari, A.; Taheri, A.; Karakus, M. Mechanical and Microstructural Behavior of Cemented Paste Backfill Under Cyclic Loading. Minerals 2025, 15, 123. [Google Scholar] [CrossRef]

- Cristelo, N.; Cunha, V.M.; Dias, M.; Gomes, A.T.; Miranda, T.; Araújo, N. Influence of discrete fibre reinforcement on the uniaxial compression response and seismic wave velocity of a cement-stabilised sandy-clay. Geotext. Geomembr. 2015, 43, 1–13. [Google Scholar] [CrossRef]

- Al-Osta, M.A. Exploitation of Ultrahigh-Performance Fibre-Reinforced Concrete for the Strengthening of Concrete Structural Members. Adv. Civ. Eng. 2018, 2018, 8678124. [Google Scholar] [CrossRef]

- Saeed, F.H.; Hejazi, F.A. Comprehensive Review of Retrofitted Reinforced Concrete Members Utilizing Ultra-High-Performance Fiber-Reinforced Concrete. Materials 2025, 18, 945. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Li, E.; Du, X. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Constr. Build. Mater. 2018, 190, 211–221. [Google Scholar] [CrossRef]

- Li, Q.; Sun, J.; Xie, X.; Dong, Q.; Wang, J.; Zhang, H.; Wen, T. Numerical Study on Impact Damage and Damage Evolution of Cemented Backfill. Crystals 2025, 15, 514. [Google Scholar] [CrossRef]

- Cai, X.; Wang, Y.; Zhao, Y.; Chen, L.; Yuan, J. Dynamic Fracture Strength Prediction of HPFRC Using a Feature-Weighted Linear Ensemble Approach. Materials 2025, 18, 4097. [Google Scholar] [CrossRef] [PubMed]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Wu, A.; Wang, Y.; Ruan, Z.E.; Xiao, B.; Wang, J.; Wang, L. Key theory and technology of cemented paste backfill for green mining of metal mines. Green Smart Min. Eng. 2024, 1, 27–39. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M. Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. Cem. Concr. Res. 2005, 35, 301–314. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 2010, 32, 819–828. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Du, X.; Chen, Q.; Qiu, X. Effect of overflow tailings properties on cemented paste backfill. J. Environ. Manag. 2019, 235, 133–144. [Google Scholar] [CrossRef]

- Kaviani, R. Rheological Properties of Cemented Paste Backfill with Iron Oxide and Aluminum Oxide Nanoparticles. Doctoral Dissertation, University of Ottawa, Ottawa, ON, Canada, 2005. [Google Scholar]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Hane, I.; Belem, T.; Benzaazoua, M.; Maqsoud, A. Laboratory characterization of cemented tailings paste containing crushed waste rocks for improved compressive strength development. Geotech. Geol. Eng. 2017, 35, 645–662. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhang, S.; Chen, H.; Zhou, J.; Yu, Z.; Huang, P. Fiber-reinforced cemented paste backfill: The effect of fiber on strength properties and estimation of strength using nonlinear models. Materials 2020, 13, 718. [Google Scholar] [CrossRef]

- Lu, S.; Koopialipoor, M.; Asteris, P.G.; Bahri, M.; Armaghani, D.J. A novel feature selection approach based on tree models for evaluating the punching shear capacity of steel fiber-reinforced concrete flat slabs. Materials 2020, 13, 3902. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.; Bui, X.N.; Tran, Q.H.; Le, T.Q.; Do, N.H.; Hoa, L.T.T. Evaluating and predicting blast-induced ground vibration in open-cast mine using ANN: A case study in Vietnam. SN Appl. Sci. 2019, 1, 125. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Yang, P.; He, X.; Pradhan, B.; Zhou, J.; Sheng, D. Toward precise long-term rockburst forecasting: A fusion of SVM and cutting-edge meta-heuristic algorithms. Nat. Resour. Res. 2024, 33, 2037–2062. [Google Scholar] [CrossRef]

- Ding, X.; Hasanipanah, M.; Rouhani, M.M.; Nguyen, T. Hybrid catboost models optimized with metaheuristics for predicting shear strength in rock joints. Bull. Eng. Geol. Environ. 2025, 84, 150. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q. Neural network and particle swarm optimization for predicting the unconfined compressive strength of cemented paste backfill. Constr. Build. Mater. 2018, 159, 473–478. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, X.; Chen, X.; Zhou, J.; Qi, C.; Chen, Q.; Rao, D. Artificial intelligence model for studying unconfined compressive performance of fiber-reinforced cemented paste backfill. Trans. Nonferrous Met. Soc. China 2021, 31, 1087–1102. [Google Scholar] [CrossRef]

- Arachchilage, C.B.; Fan, C.; Zhao, J.; Huang, G.; Liu, W.V. A machine learning model to predict unconfined compressive strength of alkali-activated slag-based cemented paste backfill. J. Rock Mech. Geotech. Eng. 2023, 15, 2803–2815. [Google Scholar] [CrossRef]

- Xi, B.; Li, E.; Fissha, Y.; Zhou, J.; Segarra, P. LGBM-based modeling scenarios to compressive strength of recycled aggregate concrete with SHAP analysis. Mech. Adv. Mater. Struct. 2024, 31, 5999–6014. [Google Scholar] [CrossRef]

- Shi, X.; Shi, Y.; Chen, X.; Wang, W. Effect of Polypropylene and Straw Fiber Materials on the Unconfined Compressive Strength of Tailings and Wasted Stone Mixed Backfill. Materials 2025, 18, 392. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standards Press of China: Beijing, China, 2021.

- ASTM D7012-23; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens Under Varying States of Stress and Temperatures. ASTM International: West Conshohocken, PA, USA, 2023.

- Yang, K.; Zhao, X.; Wei, Z.; Zhang, J. Development overview of paste backfill technology in China’s coal mines: A review. Environ. Sci. Pollut. Res. 2021, 28, 67957–67969. [Google Scholar] [CrossRef]

- Nguyen, H. Support vector regression approach with different kernel functions for predicting blast-induced ground vibration: A case study in an open-pit coal mine of Vietnam. SN Appl. Sci. 2019, 1, 283. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Fallah, A.; Armaghani, D.J.; Azizi, A.; Mohamad, E.T. Three hybrid intelligent models in estimating flyrock distance resulting from blasting. Eng. Comput. 2019, 35, 243–256. [Google Scholar] [CrossRef]

- Yari, M.; He, B.; Armaghani, D.J.; Abbasi, P.; Mohamad, E.T. A novel ensemble machine learning model to predict mine blasting–induced rock fragmentation. Bull. Eng. Geol. Environ. 2023, 82, 187. [Google Scholar] [CrossRef]

- Asteris, P.G.; Tsavdaridis, K.D.; Lemonis, M.E.; Ferreira, F.P.V.; Le, T.T.; Gantes, C.J.; Formisano, A. AI-powered GUI for prediction of axial compression capacity in concrete-filled steel tube columns. Neural Comput. Appl. 2024, 36, 22429–22459. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Mahdevari, S.; Shahriar, K.; Yagiz, S.; Shirazi, M.A. A support vector regression model for predicting tunnel boring machine penetration rates. Int. J. Rock Mech. Min. Sci. 2014, 72, 214–229. [Google Scholar] [CrossRef]

- Liu, B.; Wang, R.; Guan, Z.; Li, J.; Xu, Z.; Guo, X.; Wang, Y. Improved support vector regression models for predicting rock mass parameters using tunnel boring machine driving data. Tunn. Undergr. Space Technol. 2019, 91, 102958. [Google Scholar] [CrossRef]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Noorian-Bidgoli, M.; Jahed Armaghani, D.; Khamesi, H. Feasibility of PSO-ANN model for predicting surface settlement caused by tunneling. Eng. Comput. 2016, 32, 705–715. [Google Scholar] [CrossRef]

- Asteris, P.G.; Roussis, P.C.; Douvika, M.G. Feed-forward neural network prediction of the mechanical properties of sandcrete materials. Sensors 2017, 17, 1344. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Koopialipoor, M.; Marto, A.; Yagiz, S. Application of several optimization techniques for estimating TBM advance rate in granitic rocks. J. Rock Mech. Geotech. Eng. 2019, 11, 779–789. [Google Scholar] [CrossRef]

- Ke, G.; Meng, Q.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Ye, Q.; Liu, T.Y. Lightgbm: A highly efficient gradient boosting decision tree. In Proceedings of the 31st Conference on Neural Information Processing Systems (NIPS 2017), Long Beach, CA, USA, 4–9 December 2017. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- de-Prado-Gil, J.; Palencia, C.; Silva-Monteiro, N.; Martínez-García, R. To predict the compressive strength of self compacting concrete with recycled aggregates utilizing ensemble machine learning models. Case Study Constr. Mater. 2022, 16, e01046. [Google Scholar] [CrossRef]

- Murthy, Y.I.; Meena, K.B.; Patel, N. Machine learning for predicting the half cell potential of cathodically protected reinforced cement concrete slabs subjected to chloride ingress. Eng. Appl. Artif. Intell. 2024, 137, 109090. [Google Scholar] [CrossRef]

- Sun, D.; Wang, J.; Wen, H.; Ding, Y.; Mi, C. Landslide susceptibility mapping (LSM) based on different boosting and hyperparameter optimization algorithms: A case of Wanzhou District, China. J. Rock Mech. Geotech. Eng. 2024, 16, 3221–3232. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. arXiv 2017, arXiv:1705.07874. [Google Scholar] [CrossRef]

- Sheshpari, M. A review on types of binder and hydration in cemented paste backfill (CPB). Electron. J. Geotech. Eng. 2025, 20, 5949–5963. [Google Scholar]

- Wang, J.; Xiao, B.; Liu, X.; Ruan, Z. Trends and applications of green binder materials for cemented paste backfill mining in China. Minerals 2025, 15, 97. [Google Scholar] [CrossRef]

- Wu, D.; Fall, M.; Cai, S.J. Coupling temperature, cement hydration and rheological behaviour of fresh cemented paste backfill. Miner. Eng. 2013, 42, 76–87. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, R.K.; Xie, C.W.; Liu, S. Effect of curing humidity on performance of cemented paste backfill. Int. J. Miner. Metall. Mater. 2020, 27, 1046–1053. [Google Scholar] [CrossRef]

| Chemical Composition | Al2O3 | SiO2 | MnO | Fe2O3 | MgO | CaO | K2O | TiO2 | P2O5 | S | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Classified tailings | 5.69 | 16.80 | 0.19 | 4.57 | 3.51 | 65.2 | 1.49 | 0.37 | 0.05 | 0.910 | 0.010 |

| Rod-mill tailings | 5.21 | 24.60 | 0.28 | 22.50 | 1.63 | 32.0 | 1.18 | 0.24 | 0.06 | 10.70 | 0.013 |

| Chemical Composition | Sr | Cr | Ni | Zn | Pb | Ba | Cl | F | Zr | As | Rb |

| Classified tailings | 0.032 | 0.098 | 0.008 | 0.732 | 0.228 | / | 0.018 | / | 0.008 | / | 0.006 |

| Rod-mill tailings | 0.022 | 0.076 | 0.009 | 0.448 | 0.47 | 0.061 | 0.019 | 0.337 | 0.007 | 0.084 | 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Chen, X.; Wang, Y.; Miao, S.; Zhang, S.; Yu, Z.; Du, L. Evaluation of Multiple Influences on the Unconfined Compressive Strength of Fibre-Reinforced Backfill Using a GWO–LGBM Model. Materials 2026, 19, 200. https://doi.org/10.3390/ma19010200

Chen X, Wang Y, Miao S, Zhang S, Yu Z, Du L. Evaluation of Multiple Influences on the Unconfined Compressive Strength of Fibre-Reinforced Backfill Using a GWO–LGBM Model. Materials. 2026; 19(1):200. https://doi.org/10.3390/ma19010200

Chicago/Turabian StyleChen, Xin, Yunmin Wang, Shengjun Miao, Shian Zhang, Zhi Yu, and Linfeng Du. 2026. "Evaluation of Multiple Influences on the Unconfined Compressive Strength of Fibre-Reinforced Backfill Using a GWO–LGBM Model" Materials 19, no. 1: 200. https://doi.org/10.3390/ma19010200

APA StyleChen, X., Wang, Y., Miao, S., Zhang, S., Yu, Z., & Du, L. (2026). Evaluation of Multiple Influences on the Unconfined Compressive Strength of Fibre-Reinforced Backfill Using a GWO–LGBM Model. Materials, 19(1), 200. https://doi.org/10.3390/ma19010200